Page 1

READ AND SAVE THESE INSTRUCTIONS

DRI-STEEM

®

®

MODEL STS and STS-DI

STEAM-TO-STEAM HUMIDIFIERS

Installation Instructions

and

Maintenance Operations

Manual

For Toll-Free Technical Support,

Call 1-800-328-4447

CUL LISTEDUL LISTED

Page 2

TABLE OF CONTENTS

TO THE PURCHASER AND THE INSTALLER

Thank you for purchasing DRI-STEEM STS® humidification equipment. We have designed and built this equipment to

give you total satisfaction and many years of trouble-free service. Proper installation and operating practices will

assure you of achieving that objective. We urge you to become familiar with the contents of this manual.

DRI-STEEM Humidifier Company

STS and STS-DI Humidifiers ....................................................................3

Capacities and Dimensions ......................................................................4

Mounting Methods ....................................................................................6

Piping ........................................................................................................8

Piping Diagrams: Steam, Water and Drain ..............................................11

Electrical.................................................................................................... 12

Steam Dispersion Installation ..................................................................13

RAPID-SORB

®

Assembly and Installation

• Horizontal Duct Installation ...............................................................15

• Vertical Duct Installation ...................................................................16

Start-Up and Operation

• Water Control with VAPOR-LOGIC2...................................................17

Recommended Maintenance ....................................................................18

STS-DI Start-up and Recommended Maintenance ..................................19

Trouble Shooting Guide ...........................................................................20

Replacement Parts ....................................................................................21

Two-Year Limited Warranty ......................................................................24

2

Page 3

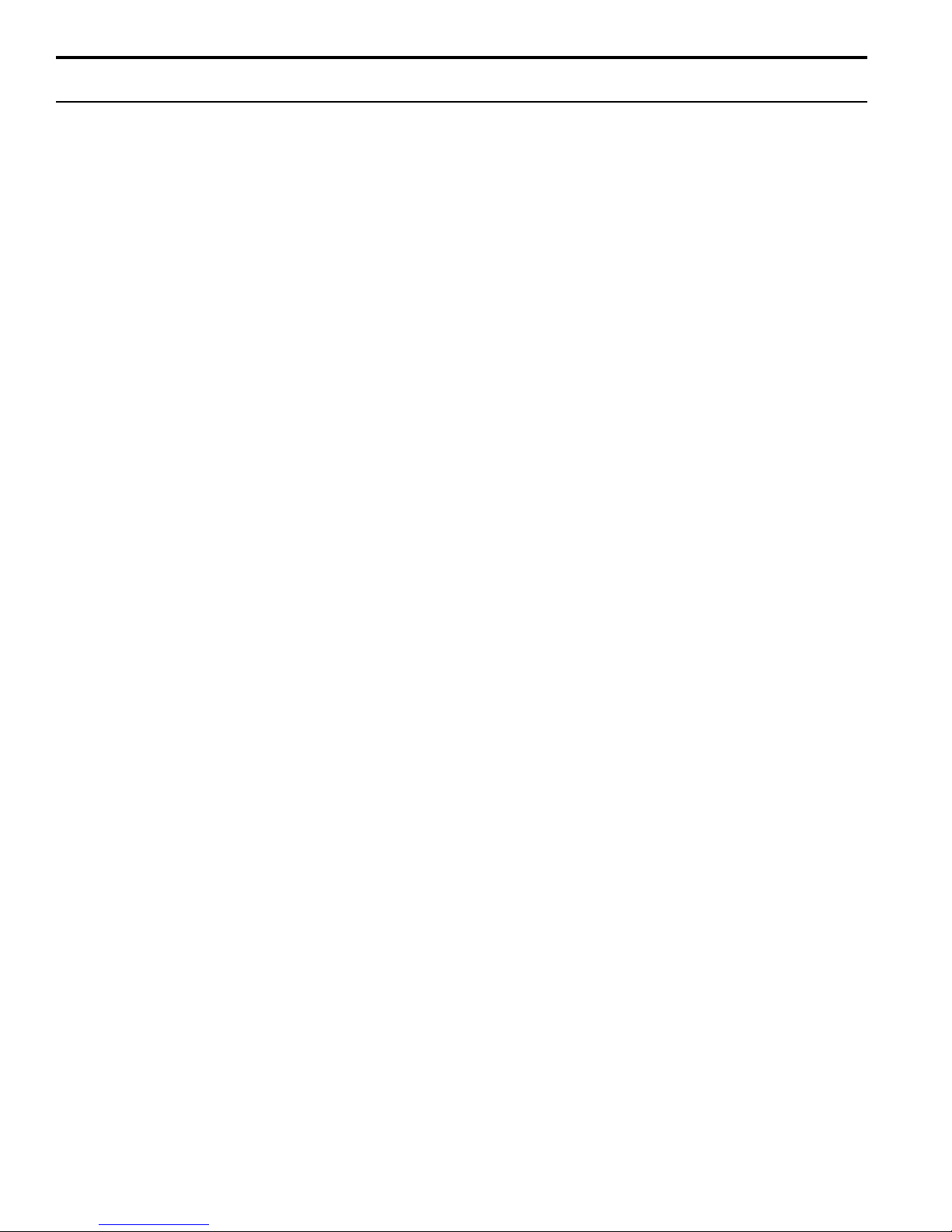

Water Supply Shut Off

Valve (not provided)

To Water Supply

Water Strainer

Automatic

Steam Valve

To Steam

Supply

Steam Trap

Condensate Return

Needle Valve

Water Seal

STS® AND STS®-DI HUMIDIFIERS

¼" NPT Fill

Make-Up Valve

Air Gap

Heat Exchanger

Skimmer Tube

Clean-Out Plate

Manual drain or Optional

Motorized Drain Valve

Open Drain

STS Humidifier

(For use with softened or

unsoftened water.)

This humidifier is designed for use

with either softened or unsoftened

water (preferably softened). The

probe-type level control system

requires water conductivity of 100

micromhos/cm (2 grains/gal) minimum

to function, and therefore will not

operate on water treated by reverse

osmosis or deionization. However,

STS humidifiers are available for use

with these water types. The standard

humidifier can be converted in the field

to a STS-DI model. See below.

¼" NPT Water

Supply Minimum

25 psi Water

Pressure

Automatic

Steam Valve

Steam Trap

Condensate Return

OM-471

STS-DI Humidifier

(For use with demineralized

or reverse osmosis water.)

For use with deionized or reverse

osmosis water. This unit produces

chemical-free steam and reliable,

accurate humidification control. It is

virtually maintenance-free, with no

wasted water, heat, or downtime.

Float Valve

Heat Exchanger

Manual Drain Valve

Water Seal

Air Gap

Note: Drain piping material must be suitable for 212°F (100°C) water.

Open Drain

OM-487

3

Page 4

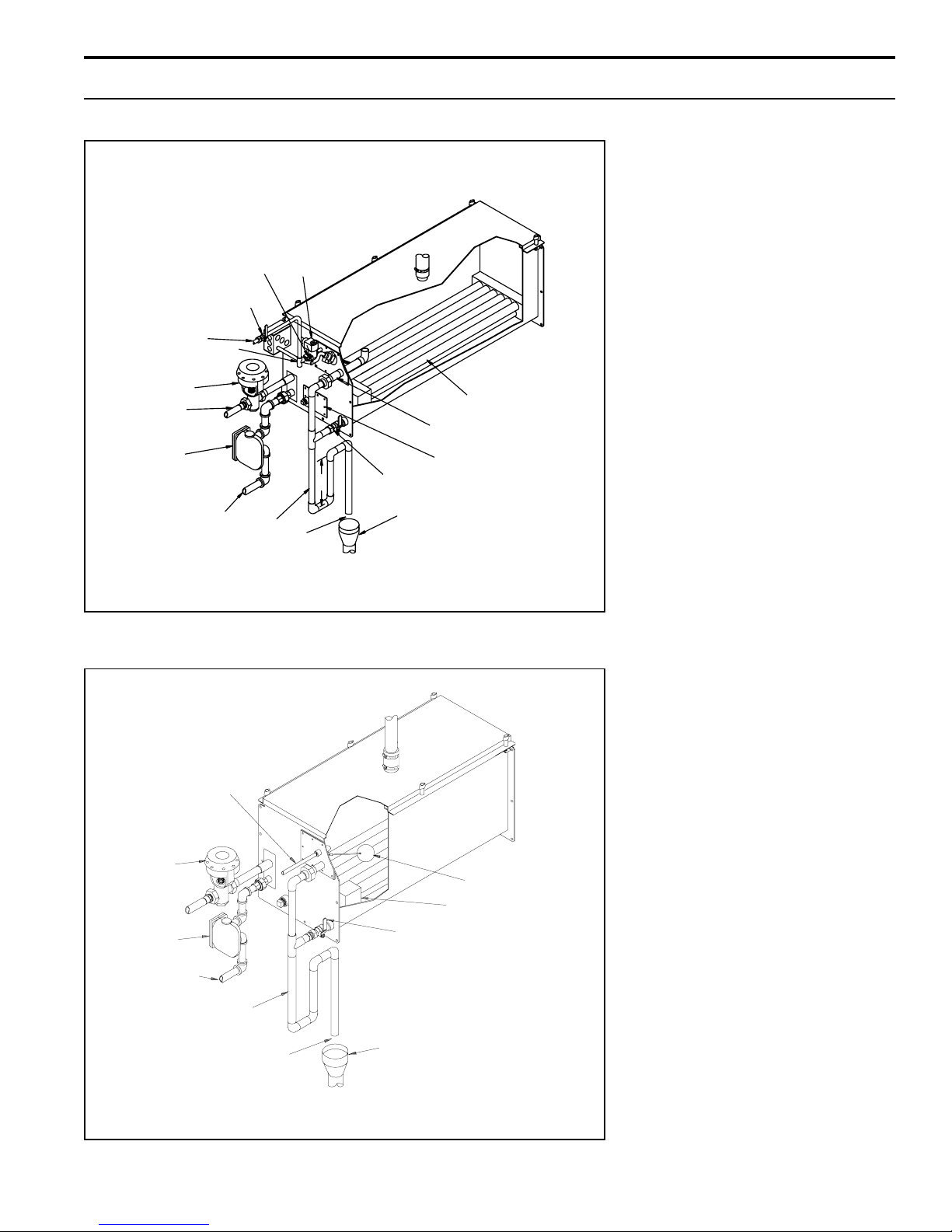

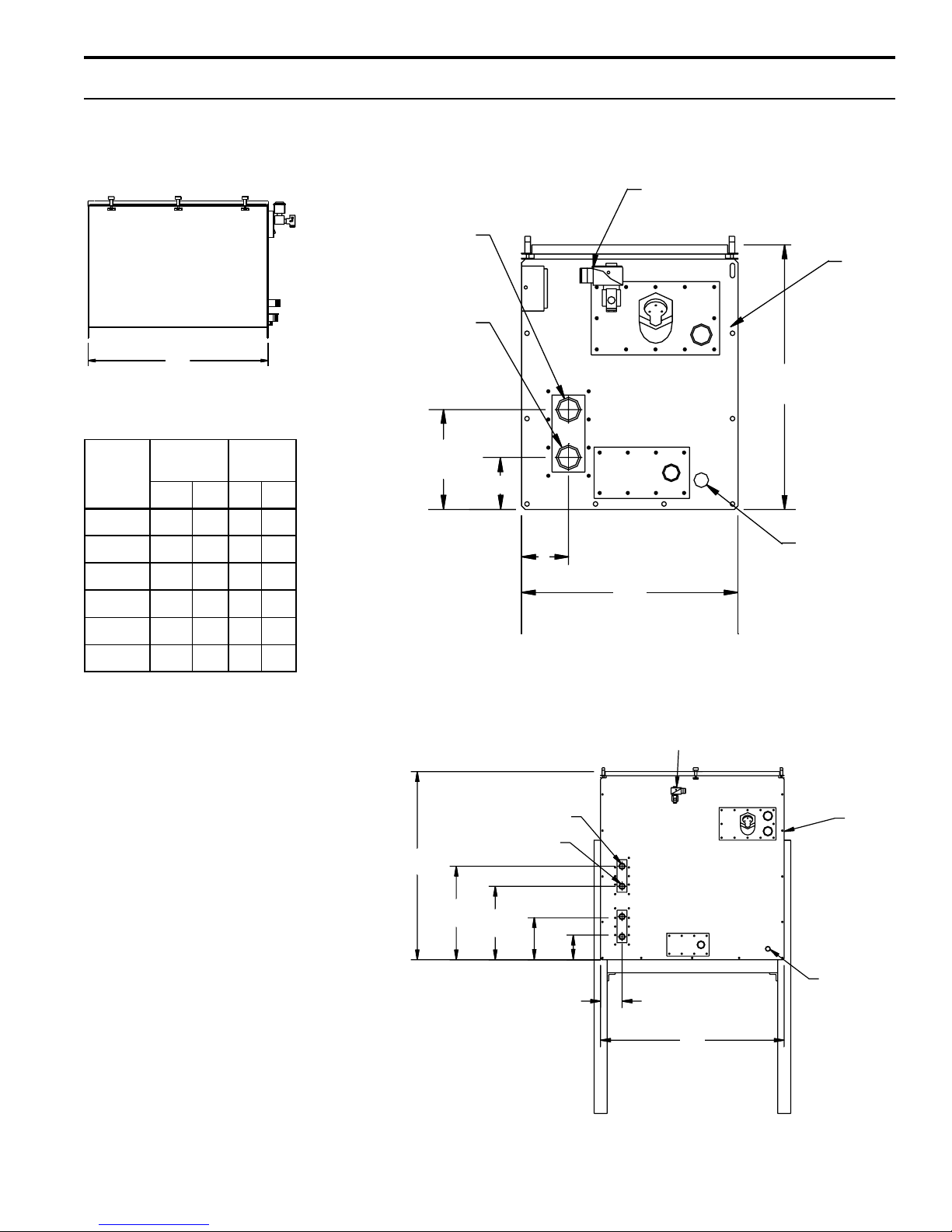

CAP ACITIES AND DIMENSIONS

Table 4-1: Mechanical dimensions for STS and STS-DI units with stainless steel heat exchanger(s)

noitpircseD

AthgiehllarevO 52.8156452.8156452.8156452.8156452.8156475.82527

BhtdiwecaF 57.4157357.4157352.9109452.8202752.8202752.82027

ChtgnelecaF 86.3200686.93010186.93010112.55004112.55004112.550041

DtelniylppusotmottobmorfecnatsiD 58.657158.657158.657158.657158.657158.6761

EteltuonruterotmottobmorfecnatsiD 53.35853.35853.35853.35853.35853.358

F

G

HregnahcxetaehotedismorfecnatsiD 52.33852.33852.33852.33852.33852.338

JtelniylppuS

KteltuonruteR

regnahcxetaehdnocesfo

regnahcxetaehdnocesfo

telniylppusotmottobmorfecnatsiD

teltuonruterotmottobmorfecnatsiD

Table 4-2: Mechanical dimensions for STS and STS-DI units with copper heat exchanger(s)

noitpircseD

AthgiehllarevO 52.8156452.8156452.8156452.8156475.82527

BhtdiwecaF 57.4157357.4157352.9109452.8202752.82027

ChtgnelecaF 86.3200686.93010186.93010112.55004112.550041

DtelniylppusotmottobmorfecnatsiD 36.607136.607136.607136.686136.6861

EteltuonruterotmottobmorfecnatsiD 95.30995.30995.30995.30995.309

F

G

HregnahcxetaehotedismorfecnatsiD 52.33852.33852.33852.33852.338

JtelniylppuS

KteltuonruteR

regnahcxetaehdnocesfo

regnahcxetaehdnocesfo

telniylppusotmottobmorfecnatsiD

teltuonruterotmottobmorfecnatsiD

S52-STSS05-STSS001-STSS002-STSCNS004-STSCNS008-STS

.nimm.nimm.nimm.nimm.nimm.nimm

--------------------05.41063

--------------------00.11582

TPN"

)02ND(

TPN"

)02ND(

.nimm.nimm.nimm.nimm.nimm

----------------82.41263

----------------42.11582

TPN"

)02ND(

TPN"

)02ND(

TPN"1

--

--

C52-STSC05-STSC001-STSC004-STSC008-STS

)52ND(

TPN"

)02ND(

--

--

TPN"

)02ND(

TPN"…1

)23ND(

TPN"1

--

--

--

--

--

)52ND(

TPN"

--

)02ND(

TPN"…1

)23ND(

TPN"…1

)23ND(

TPN"‰1

--

)04ND(

TPN"

--

)02ND(

rebmunledoM

--

--

TPN"…1

--

)23ND(

TPN"‰1

--

)04ND(

TPN"‰1

--

)04ND(

TPN"

--

)02ND(

TPN"…1

)23ND(

TPN"‰1

)04ND(

--

Table notes:

--

C= Copper

TPN"‰1

)04ND(

TPN"

)02ND(

Table notes:

S= Stainless steel

SNC= Stainless steel

without Teflon coating

--

For use with DI/RO

--

water only

Table 4-3: Capacities for units with

stainless steel heat exchangers

ledoM

rebmun

S52-STS

S05-STS

S001-STS

S002-STS

4

ISPaPkISPaPkISPaPkISPaPk

5430196310951301

01

5

52

11

hpp

h/gk

hpp

03

41

hpp

06

hpp

051

hpp

071

CNS004-STS**

hpp

212

CNS008-STS**

hpp

55

h/gk

hpp

72

011

h/gk

hpp

86

092

h/gk

hpp

77

293

h/gk

hpp

69

528

h/gk

hpp

03

h/gk

hpp

52

57

h/gk

hpp

05

041

h/gk

hpp

231

063

h/gk

hpp

871

255

h/gk

hpp

473

5901

h/gk

hpp

Table 4-4: Capacities for units with copper heat

exchangers

sregnahcxetaehleetssselniatshtiwseiticapactuptuO

)aPk(ISPerusserpmaetS*

41

53

h/gk

43

h/gk

46

h/gk

361

h/gk

052

h/gk

794

h/gk

61

hpp

h/gk

08

63

hpp

h/gk

051

86

hpp

h/gk

093

771

hpp

h/gk

736

982

hpp

h/gk

3221

555

hpp

Table 4-3 and 4-4 notes:

h/gk

* Steam pressure at connection to the STS steam valve (provided by DRI-STEEM)

ledoM

rebmun

ISPaPkISPaPkISPaPkISPaPk

5430196310951301

02

9

07

23

C52-STS

hpp

h/gk

hpp

05

32

C05-STS

hpp

001

C001-STS

hpp

003

C004-STS

hpp

056

C008-STS

hpp

051

h/gk

hpp

54

003

h/gk

hpp

631

085

h/gk

hpp

592

5721

h/gk

hpp

001

h/gk

hpp

86

002

h/gk

hpp

631

004

h/gk

hpp

362

027

h/gk

hpp

875

0051

h/gk

hpp

erusserpmaetS*

54

h/gk

19

h/gk

181

h/gk

723

h/gk

086

h/gk

** SNC = Stainless No (Teflon) Coating. For use with DI/RO water only.

sregnahcxetaehreppochtiwseiticapactuptuO

021

45

hpp

h/gk

042

901

hpp

h/gk

084

812

hpp

h/gk

097

853

hpp

h/gk

0061

627

hpp

h/gk

Page 5

CAP ACITIES AND DIMENSIONS

STS and STS-DI® all sizes STS and STS-DI (single heat exchanger) sizes 25S&C, 50S&C,

100S&C, 200S, 400C, and 400SNC

Side view

C

Table 5-1: Humidifier weights

Front view

¼" NPT water makeup valve

J

K

A

5/16" dia.

mounting

bolt holes

ledoM

rebmun

52-STS 571975934

05-STS 63325152175

001-STS 05395193136

002-STS* 058683542111

004-STS* 059134023541

008-STS* 0541856014681

Table 5-1 note:

*Suspending from overhead

construction is not recommended

due to operating weight of unit.

gnitarepO

thgiew

sblgksblgk

gnippihS

thgiew

D

E

¾" drain

H

B

STS and STS-DI (dual heat exchanger) size 800C and 800 SNC

Front view

¼"NPT water

make up valve

5

/16" dia

J

K

A

mounting bolt

holes

G

F

E

D

H

B

Note:

See Tables 4-1 and 4-2 (page 4) for dimensional data.

¾" drain

OM-336

5

Page 6

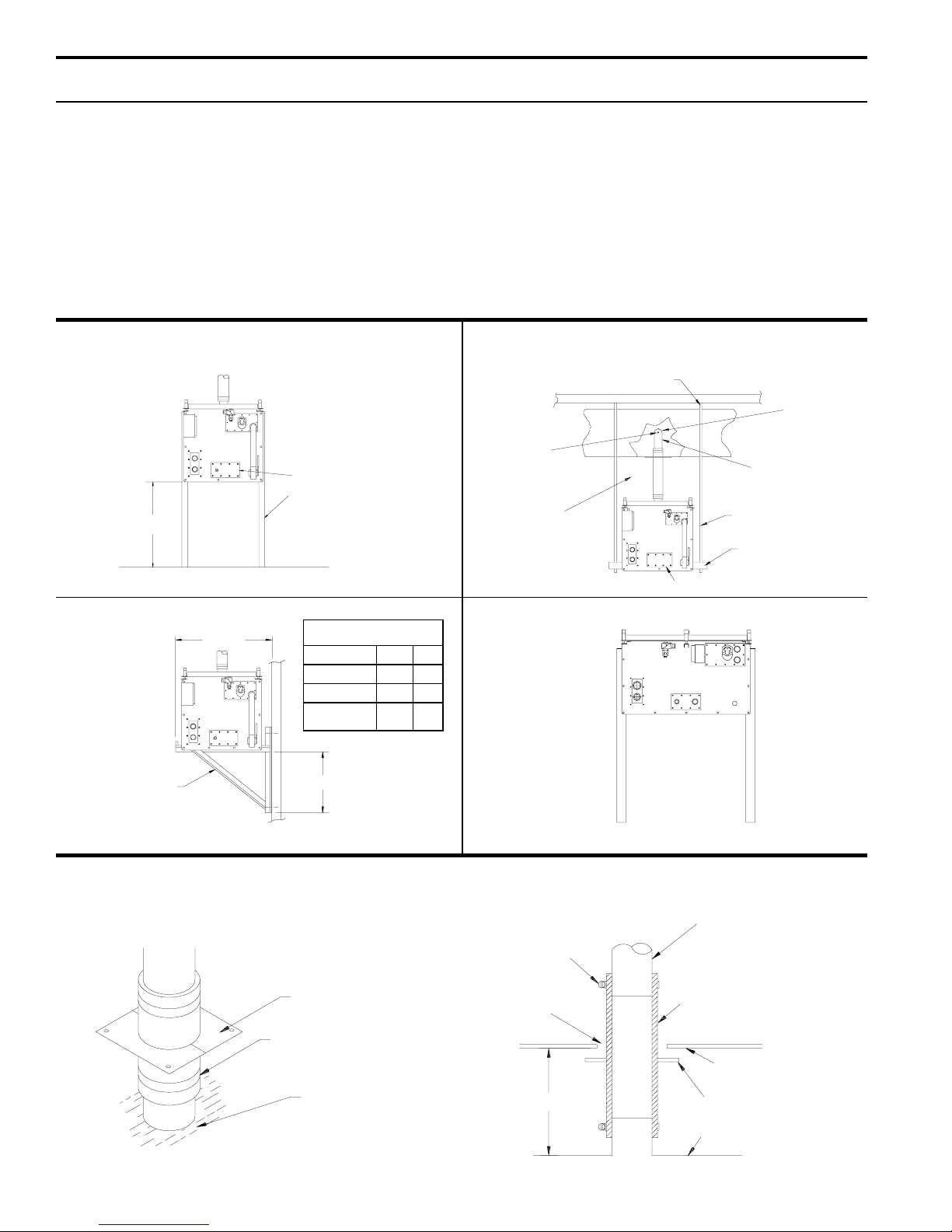

MOUNTING METHODS

Mounting Notes

1. For the electrode probe water level control and the

skimmer system to properly operate, the humidifier must

be mounted level in both directions.

2. Access (12" to 18" minimum) for periodic removal of the

top cover is recommended. In most cases, scale that

forms on the heat exchanger continuously flakes off as it

Figure 6-1: STS Mounting Options

1. Floor Stand

Clean-out

DRI-STEEM

*24"

*24" is standard, other lengths are optional.

support legs

(optional)

OM-504

forms and the loose scale settles to the bottom. A cleanout tray on the floor of the evaporator may be removed

periodically through the front clean-out opening.

3. Due to the size and weight of the STS

®

200, 400 and

800 units, the trapeze hanger and wall brackets are not

recommended.

2. Trapeze Hanger (see note 3 above)

Secure rods to overhead

construction suitable for the load

Inverted

U-tube

3/8"-16

Support Rod

Provide 12" to 18"

clearance under duct

for cover removal

OM-505

Clean-out

For best absorption

U-tube should be at

mid height of duct

Threaded rod of size

required

Angle or channel of

size required

3. Wall Brackets (see note 3 above)

A

Optional wall

brackets, two

required

snoisnemiD

tinUAB

05,52STS"¾51"62

001STS"¾02"23

,002STS

008,004

B

----

OM-517

4. Cradle

Models STS 200,

STS 400C and 800C

require cradle.

5. Mounting STS Unit on Underside of Duct

Mounting humidifier 12" to 18" below duct recommended to facilitate cover removal.

Two-Piece Escutcheon Plate

fastens to bottom of duct

(duct omitted for clarity)

Vapor Hose

Cut hole in duct large

enough to allow passage

of hose clamp

Clamp

OM-755

Steam Dispersion

Tube

Vapor Hose

Bottom of Duct

Cover of STS Humidifier

OM-65

6

12" to 18"

Two-Piece Escutcheon Plate

Cover of STS Humidifier

OM-66

Page 7

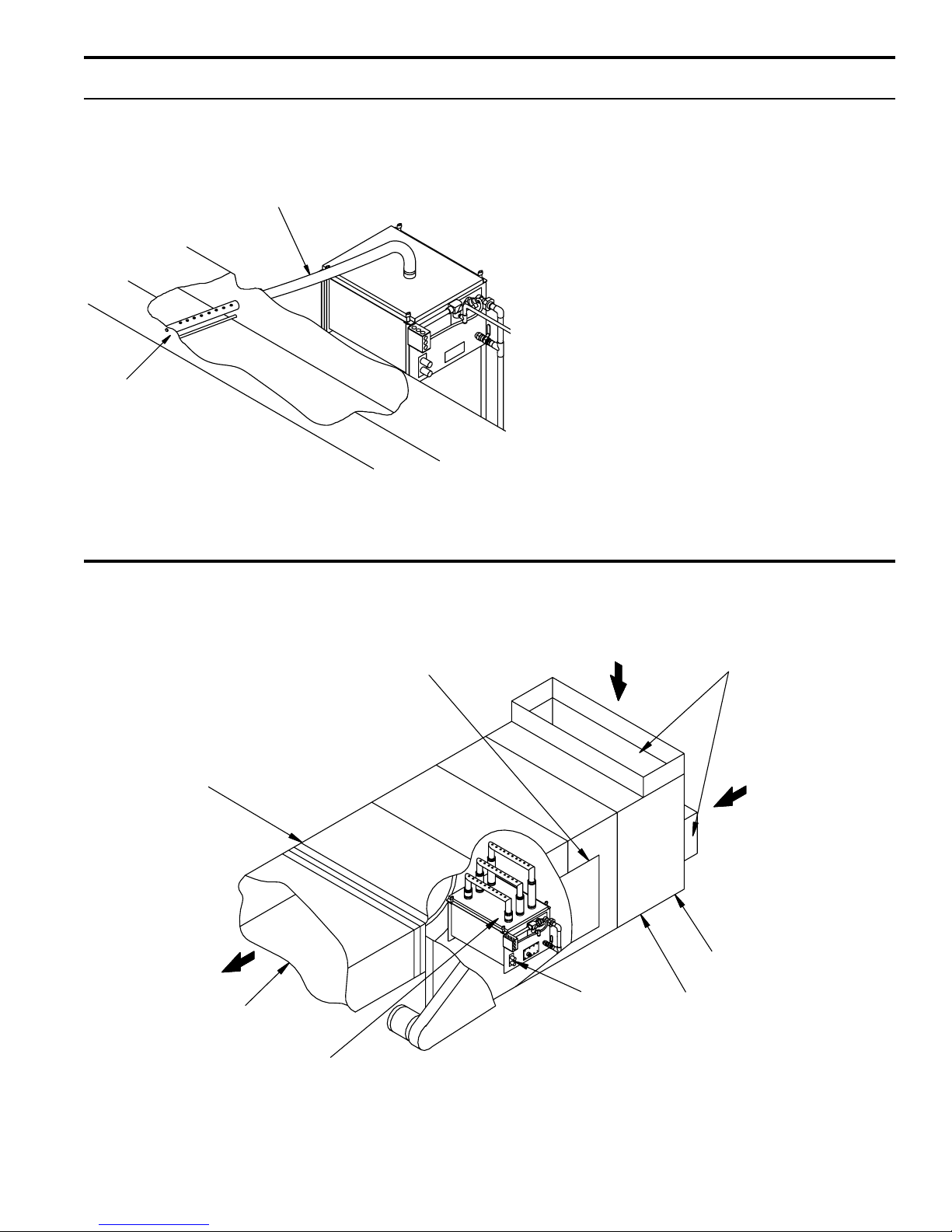

MOUNTING METHODS

6. Mounting STS Unit Away from Duct(s) Using Vapor Hose

Vapor hose. (Pitch back min. 2" per foot to humidifier with supports to

prevent pockets.) Maximum length 10'. Humidifier must be mounted level.

Stainless steel

dispersion tube in

middle of duct.

Maximum tube

length = 10'.

OM-50

7. Mounting STS in Air Handling Unit (with U-Tubes)

Gasketed Access Door

Air Handling Unit Casing

Airflow

Supply Air Duct

Set unit level. Locate unit so that steam

dispersion assembly is in the most active part

of the air stream.

Airflow

Humidifier

Centered in Air

Handling Unit

Outdoor and Return Airflow

into Air Handling Unit

Airflow

Filter and Mixing Box

Air Handling Unit Coil Section

OM-276

7

Page 8

PIPING

Steam Supply

The heat exchanger in the STS® standard humidifier is

designed for a maximum steam pressure of 15 psi. The

steam valve, trap and strainer are shipped loose for field

installation.

Make-up Water Piping

Either cold or hot water can be used for make-up. The

water pressure must be between 25 to 100 psi. If the

water pressure is above 60 psi and/or water hammer

would be objectionable, a pressure reducing valve or

shock arrester should be installed. Even though the STS

has an inner 1" air gap, some local codes may require a

vacuum breaker in the water supply pipe.

Make-up Water Considerations

When non-metallic water piping is used, it must be rated

to withstand 212°F or greater temperature. If not, the final

3 feet connected to the humidifier should be metallic and

should not be insulated.

As part of the fill valve assembly, a needle valve is

provided. It restricts the rush of cold water entering the

evaporating chamber during each fill cycle. The needle

valve adjusted to minimize output disruption and potential

"water hammer" (water pressure must be between 25 and

100 psi).

The STS Humidifier works with all water types - potable,

softened or demineralized make-up water.

Preferably this humidifier should be supplied with

softened water. The probe type level control system

requires water conductivity of 100 micromhos/cm

(2 gr/gal) minimum to function and will not operate

with water treated by reverse osmosis or deionizing

process. Specially designed STS DI humidifiers are

available for use with these water types.

Softened Water

There are two major advantages derived from using

softened water instead of potable water (assuming the

untreated supply water hardness is over 10 grains per

gallon): maintenance and accuracy of control.

Maintenance

The skimmer, in conjunction with softened water, is an

unbeatable combination for eliminating scale formation in

the evaporating chamber. Several seasons of operation

with no need for cleaning is normal, even with water

having up to 30 grains of dissolved minerals per gallon

prior to being softened.

Accuracy of Control

Reducing the higher skimmer quantity and eliminating the

drain/flush cycle (both of which are accomplished by the

use of softened water) improves controllability.

Softened Water Reduces Water Usage

The fewer number of make-ups per unit of time and the

lesser the amount of water per make-up, the more "on

time" or actual humidifying time will occur thus improving

control accuracy. This is especially true when modulating

control of the steam input to the humidifier is used.

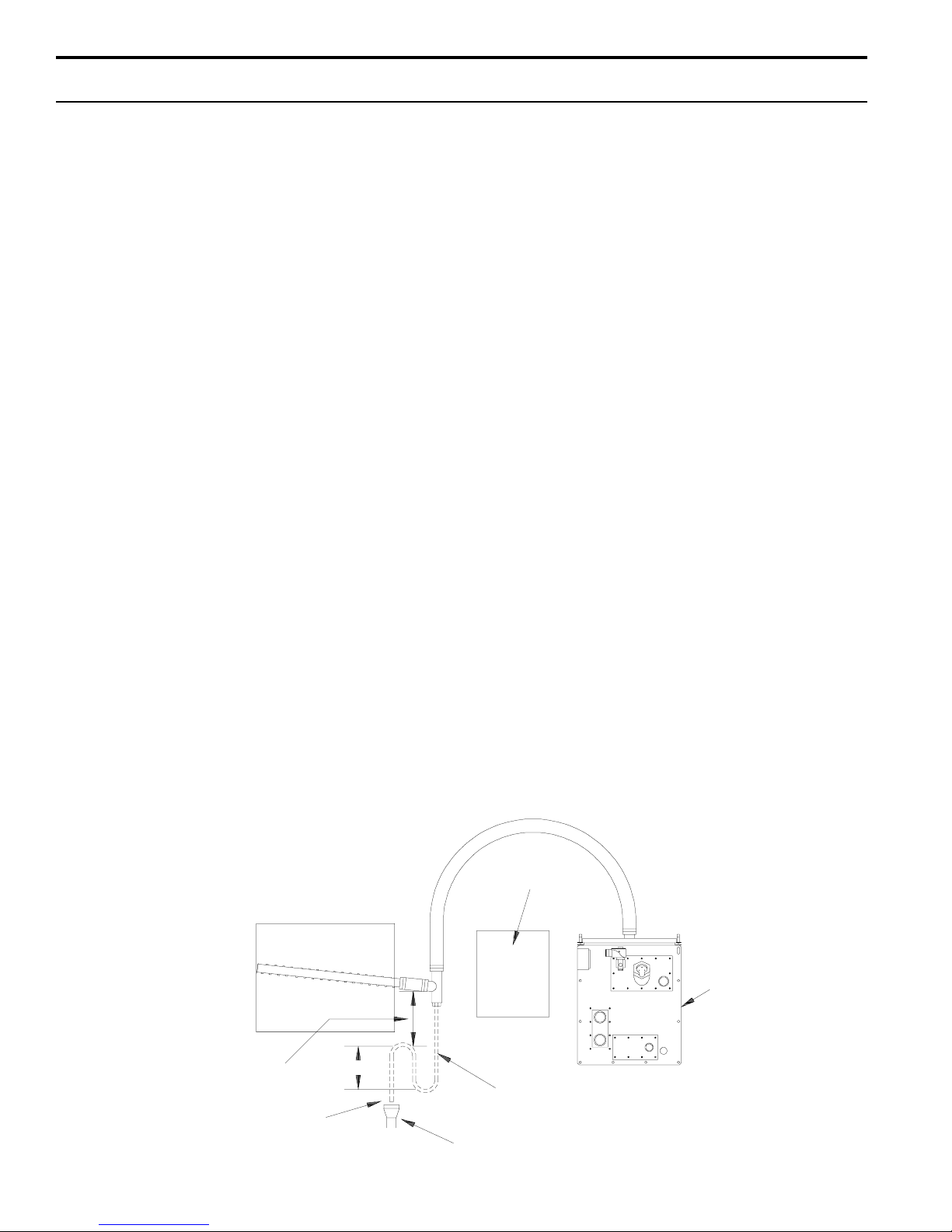

Figure 8-1:

This piping method is recommended when obstruction

prevents dispersion tube from being continuously pitched

back to the humidifier.

4" Minimum

Air Gap

OM-702

8

Obstruction

STS Humidifier

H

¾" Tubing

Funnel or Floor

Drain*

* Note: Refer to governing codes

for drain pipe size requirements.

Page 9

PIPING

Potable Water

For water less than 10 grains per gallon hardness the

skimmer system alone, without softening, usually provides a full season or more of humidification without a

need for cleaning the evaporator.

For water hardness above 10 grains per gallon and where

softened water is not available the timer operated drain/

flush feature is available. The humidifier control module

contains an integral adjustable timer which accumulates

the "on" or actual humidifying time of the unit. When this

accumulated time reaches the amount previously pre-set

in the control module, the drain/flush cycle is activated.

Drain Piping

A drain line should be extended from the skimmer/drain

connection to a sanitary waste. A water seal should be

provided in the drain line of sufficient height to contain

the pressure developed within the humidifier. Without this,

steam will be forced through the drain line which would be

objectionable. The depth of the water seal must be

sufficient to overcome the static pressure of the air

handling system plus the pressure developed by the

humidifier itself. (Refer to table 11-1 on page 11.)

Figure 9-1: This piping method is recommended when

humidifier must be mounted higher than the duct.

STS

Humidifier

1½" S.S. Tubing Tee

(supplied by others)

H

Air Gap

Funnel or Floor

Drain*

OM-703

* Note: Refer to governing codes

for drain pipe size requirements.

9

Page 10

PIPING

Figure 10-1 - Piping of STS® from an overhead steam

supply main with condensate returned to a vented gravity

flow return system. Note the steam trap installed at the

bottom of the branch rise feeding the steam valve of the

STS. Failure to install this trap will cause water hammer,

which could damage the STS heat exchanger.

Figure 10-1 Figure 10-2

Steam Main

Alternate Vacuum

Breaker Position

Figure 10-2 - Depicts the same supply configuration,

however the condensate return main is above the STS

and the condensate must be "lifted". Lifts in excess of six

inches per PSI steam inlet pressure should not be

attempted. Check valves down stream of both steam

traps are necessary to avoid hammer and associated

problems.

In both instances, Figure 10-1 and 10-2, vacuum breakers

are necessary to ensure condensate can drain from the

heat exchanger when the steam valve closes.

Steam Main

Alternate Vacuum

Breaker Position

12"

End of

Branch Trap

(by others)

Trap "A"

12"

Vacuum Breaker

(by others)

Swing

Check

Valves

(by

others)

Gravity Condensate Return

OM-586

12"

12"

Vacuum Breaker

(by others)

Swing Check Valves (by others)

To Elevated

Condensate Return

OM-586

10

Page 11

PIPING DIAGRAMS: STEAM, WATER AND DRAIN

Figure 11-1: Standard STS

Water Supply Shut Off

Valve (not provided)

To Water Supply

Automatic Steam Valve

To Steam Supply

Steam Trap

Condensate Return

®

Needle Valve

Water Strainer

Water Seal

¼" NPT FillMake-Up Valve

H

Air Gap

Heat Exchanger

Skimmer Tube

Clean-Out Plate

Manual drain or Optional

Motorized Drain Valve

Open Drain

OM-471

Note: Refer to governing codes on

drain pipe sizing requirements.

Table 11-1: Water Seal Height Recommendations

Water S e a l H e ig ht (H )

Unit Output

(pounds per hour)H(inches)

5-138 12

139-183 15

184 and higher 18

Figure 11-2: STS-DI

¼" NPT Water

Supply Minimum

25 psi Water

Pressure

Automatic

Steam Valve

Steam Trap

Condensate Return

Water Seal

Air Gap

Note: Drain piping material must be suitable for 212°F (100°C) water.

Manual Drain Valve

H

Open Drain

Float Valve

Heat Exchanger

OM-487

11

Page 12

PIPING DIAGRAMS: STEAM, WATER AND DRAIN

Figure 12-1: Alternate Water Seal and Valve Piping

Used when water seal must be elevated above flow line of

drain connection (Humidifier near floor). Water seal height

recommendations refer to table 11-1.

Water Seal Flow

Line Cannot Be

Above Skimmer

Skimmer

Drain Connection

H

Air Gap

ELECTRICAL

The electrical supply is 120 volt, single phase. The

control cabinet should be mounted in a location for

service. All wiring must be in accordance with all governing codes and the STS® wiring diagram. A wiring diagram

is inside the control cabinet. The wiring between the

control cabinet and the humidifier must be 105°C rated

wire.

Manual Or Optional

Motorized Drain Valve

Note: Flow Line At

This Point Must Not

Be Above Flow Line

Open Drain

At Drain Connection

OM-489

Please refer to the VAPOR-LOGIC2 O&M for electrical

connection information on the controller.

Caution: Only qualified electrical personnel should

perform installation and start-up procedures.

12

Page 13

STEAM DISPERSION INSTALLATION

STS Dispersion Tube Installation with Condensate Drain

Vapor Hose

• Vapor hose should be supported

to prevent sags or low spots and

to maintain a minimum pitch of 2"

per foot back to the humidifier.

• When mounting the humidifier

above the level of dispersion tube,

see page 9.

Failure to follow the above recommendation may result in excessive

back pressures being imposed on

the humidifier. This in turn may lead

to dispersion tube(s) spitting, lost

water seals or leaking gaskets.

When distance between humidifier

and the dispersion tube(s) exceeds

10 feet, consult factory for special

recommendations.

Hard Piping

• Hard piping should have a

minimum I.D. of 1½".

• A minimum pitch of 2" per foot

back to the humidifier should be

maintained.

• 90° elbows are not recommended,

use two 45° elbows one foot apart

instead.

• Thin wall tubing will heat up faster

and cause less start up loss than

heavywall pipe.

• Insulating the hard piping will

reduce the loss in output caused

by condensation.

Tube Mounting

• Mount dispersion tube level.

• Best vapor absorption occurs

when dispersion tube discharges

against the air flow.

**Return line piping material

must be suitable for 212° F

(100°C) water.

Minimum Condensate Drain Line

Sizing

• One or two tubes: 3/4" I.D.

• Three or more tubes - 1" I.D.

Figure 13-1: Single Tube

2.5"

Movable Escutcheon Plate (Plate

can be mounted within limits of 2.5".)

1.5"

2.5"

OM-351

3.25"

3.25"

3.25"

3.25"

3.25"

3.25"

¼" NPT

End

Figure 13-2: Multiple Tube with

Condensate Wasted

to Floor Drain

Dispersion Tube

1-½" Dia. Vapor

Hose or Hard

Tubing

STS® Humidifier

OM-1020

Water Seal

(5" approx.)

Insertion Length

Pre-molded High Temperature

Resin Steam Inserts

½" O.D.Copper

Tubing (condensate drain)

Dispersion

Tube

Duct

6" Min.

½" O.D. Condensate

Drain Tube

Condensate Drain Tube by

Others** (3/4" minimum)

Floor Drain*

* Note: Refer to governing codes

for drain pipe size requirements.

Figure 13-3: Multiple Tube with Condensate Return to Humidifier

Dispersion Tube

Duct

Dispersion Tube

1-½" Dia. Vapor

Hose or Hard

Tubing

STS Humidifier

½" Air Vent

6" Min.

Water Seal

(5"

approx.)

½" O. D. Condensate

Drain Tube

Refer to Water Seal Height

table 17-1, page 17

Mounting

Bracket

Mounting

Bracket

Air Flow

Air Flow

OM-1021

¾" Condensate Return

Connection (on face plate)

Condensate Drain

Tube by Others ** (3/4" minimum)

* Note: Refer to governing codes

for drain pipe size requirements.

13

Page 14

STEAM DISPERSION INSTALLATION

Selecting the Location:

A. It is very important that the dispersion method be

located where the water vapor being discharged will

be carried off with the airstream and will not cause

condensation or dripping from the duct.

B. In general, the dispersion method is best placed

where the air can most readily absorb the moisture

being added without causing condensation at or after

the unit. This will normally be after the heating coil or

where the air temperature is highest.

C. Do not place the dispersion method too close to the

intake of a high efficiency filter. The filter may

remove the visible moisture and become waterlogged.*

D. Do not place dispersion method where water vapor

will impinge on a metal surface.

E. Do not place the dispersion method too close to a

split in the duct. The unit may put more moisture in

one branch then the other.

Installation Above Valuable Equipment

Water piping and humidifiers should not be installed

above expensive apparatus or equipment. The risk of a

broken water pipe, leaking valve gland, condensation or

other water leaks may occur causing serious damage

and costly repairs to the equipment below.

Where this type of installation cannot be avoided install a

drip tray constructed of galvanized sheet under the

humidifier, valve, etc. to catch any possible water drip.

It is advisable to terminate the drain above an open floor

drain. The overflow from the STS

®

should be piped

separately to a floor drain rather than the drip pan.

Figure 14-1: Installation Above Valuable Equipment

This length of duct should have sealed seams.

Humidifier2'

Air Flow

STS Humidifier

Drip Pan

Refer to governing codes regarding drip pan

depth and drain pipe size requirements.

* The distance steam will travel within a given airstream is predictable and can be determined using the STS catalog.

If this has already been done, the travel distance should be specified; if not, consult the STS catalog or contact you

DRI-STEEM representative or the DRI-STEEM factory.

*

Vapor Absorption Area

Allow 12"-18" space for cover

removal during maintenance.

Ceiling Line

OM-59

14

Page 15

RAPID-SORB® ASSEMBLY AND INSTALLATION

Horizontal Duct Installation

1. Unpack Shipment and verify receipt of all

RAPID-SORB components with packing list. Report

any shortages at once to the DRI-STEEM factory.

2. Provide necessary access around and into duct work.

3. Locate 1" x 1½" stainless steel channel inside duct

centered between duct side walls. Hang channel from top

of duct with the two mounting holes provided.

4. Locate dispersion tubes and slide hose cuffs over end

of each tube, include a pair of hose clamps.

5. Note direction of air flow within duct then arrange each

dispersion tube so steam will blow perpendicular to the air

flow. Use the hex bolts provided to attach tubes to

overhead 1" x 1½" channel. Do not secure. On units with

the header mounted outside the duct, punch-out necessary clearance holes in base of duct to slide dispersion

tubes up from bottom (see figure 15-2).

6. For a Header Inside the Duct (See figure 15-1.):

Punch or cut out necessary clearance holes for

RAPID-SORB header. Slide header into the duct, position

header and slide the dispersion tube hose cuffs or slip

couplings over the header dispersion tube nipples.

Position the header so vertical dispersion tubes are

perpendicular to duct and pitch the header toward condensate drain. Secure header to the mounting bracket. Use

escutcheon plates to secure header where it enters the

duct.

7. Connect a condensate drain to header, provide the

water trap as shown and run to open drain, sized per

governing codes.

8. Attach the header swivel hose connector to main

header using the hose cuff and clamps provided, do not

secure.

9. Route the necessary number of vapor hoses or pipes

from the humidifier tank, position connector to accept the

hoses or pipes and secure.

Note: Refer to page 10 for vapor hose information on

routing and for alternate vapor hose installation methods.

Figure 15-1: RAPID-SORB Unit

Header Inside Duct

S.S. Dispersion

Tube

Orificed

Tubelets

Hose Cuff

Pitch 1/8" per foot (minimum)

Header

Optional companion

flange connection

1" x 1-1/2" 304 S.S. Channel

Condensate

Drain, 3/4" NPT

3/4" Copper Min.

Air Gap

Open Drain

Duct

Support Bolt

(By Installer)

6"

Min.

5" Min.

Check that the dispersion tubes release steam perpendicular to the air flow. Secure tubes to the overhead

channel. Secure the channel to the duct, and secure hose

cuffs or slip couplings over tube and header tube nipples.

For a Header Outside the Duct (see figure 15-2.):

Position header under dispersion tubes, then slide hose

cuffs or slip couplings over header dispersion tube

nipples.

Position the header so dispersion tubes are perpendicular

to duct and pitch the header to condensate drain. Secure

dispersion tubes in place with the tube escutcheon plates

provided.

Check the position of the tubes for steam release perpendicular to the air flow. Secure tubes to the overhead

channel, and secure channel to the duct. With header

pitched to condensate drain, slip hose cuffs or slip

couplings over tube nipples and secure.

Figure 15-2: RAPID-SORB Unit

Header Under Duct

Duct

Bolt

Support

Bracket

Orificed Inserts

View A-A

Hose Cuff

Hose

Clamps

STS

S.S. Dispersion

Tube

Pitch 1/8"/foot (min.)

Header

Connection

A

A

Condensate

Drain, ¾" NPT

¾" Copper Min.

Open Drain

1" x 1½" 304S.S.

Duct

Escutcheon

Plate

Mounting

Bracket

6" Min.

5" Min.

Air Gap

15

Page 16

RAPID-SORB® ASSEMBLY AND INSTALLATION

Vertical Duct Installation

Install the RAPID-SORB® with dispersion tubes and

header pitched to condensate drain as shown in figures

16-1,16-2, and 16-3.

Figure 16-1: Plan View

1/8" per foot

pitch minimum

Steam

Supply

Figure 16-3: Elevation View

Tube with Drain

3/4" NPT Coupling

6" Min.

5" Min.

5" Min.

Airflow

Recommended 1/4"

per foot pitch

1/4" NPT

Drain

Condensate

Drain

Figure 16-2: Elevation View

Tube without Drain

Airflow

Recommended 2" per

foot pitch

6" Min.

5" Min.

Table 16-1*: Maximum Steam Carrying Capacity in

Lbs/Hr and Kg/Hr

Vapor Hose

Hose I.D.

1

1

/2" (38 mm) 150 lbs/hr 68 kg 11/2" (38 mm) 150 lbs/hr 68 kg/h

2" (50 mm) 250 lbs/hr 115 kg 2" (50 mm) 220 lbs/hr 100 kg/h

Developed Length

of 10’ (3.0 Meters)* *

Copper or Stainless Steel Tubing and

Schedule 40 Steel Pipe

Tube or

Pipe Size

3" (75 mm) 450 lbs/hr 205 kg/h

4" (100 mm) 750 lbs/hr 340 kg/h

5" (125 mm) 1400 lbs/hr 635 kg/h

6" (150 mm) 2300 l bs/hr 1043 kg/h

Base on Developed

Length of 20’ (6 Meters)**

Open Drain

- - - - Dashed line indicates field piping.

16

* Based on total pressure drop in piping/hose of 5" (12.65 mm) W.C.

** For developed length add 50% to measured length for pipe fittings.

Note: To minimize lossof humidifier capacity and efficiency, it is recommended

that tubing/piping be installed.

Page 17

START-UP AND OPERATION

Figure 17-1: Reliable Electronic Probe Control

Maintains Water Level

Probe

Housing

Probe Rod

Water Levels

Probe

OM-270

A- Fill Valve Closes

B - Fill Valve Opens

C - Low Water Indication

A simple three-probe conductivity sensor cycles a

solenoid-operated water fill valve to maintain the proper

water levels.

The STS® humidifier is provided with a standard

VAPOR-LOGIC

®

microprocessor control system, see the

2

VAPOR-LOGIC2 Installation and Operations Manual for

more information. Then continue reading this manual

beginning at the maintenance section on page 20.

Water Control with VAPOR-LOGIC

2

When the power is activated the solenoid-operated water

fill valve will open, filling the evaporating chamber. Filling

will continue until water reaches level A, at which time the

fill valve will close. To ensure that the water seal is filled

with water, disconnect probe plug and cable from probe

rod assembly (located on face plate), allowing the fill

valve to re-energize and overfill humidifier tank. This

process will take only seconds; probe plug and cable

must then be reconnected.

Water Refill

During operation, the water line will drop to level B. At this

level the fill valve opens, and remains open until the water

line returns to level A.

Adjustable Surface Skimmer

Each time the evaporating chamber refills, the upper

¼" of water is immediately drained off through the skimmer. This carries away the mineral residue formed during

the previous evaporating cycle. This skimming action

effectively removes most of the mineral concentration in

much the same way as the surface blowdown does in a

steam boiler. This simple device greatly reduces the

frequency of cleaning the evaporating chamber.

Note: Preferably this humidifier should be supplied

with softened water. However, the probe type level

control system requires water conductivity of 100

micromhos/cm (2 grains/gal) minimum to function

and may not operate in water treated by the reverse

osmosis or deionizing process. Specially designed

STS Model DI humidifiers are available for use with

these water types.

17

Page 18

RECOMMENDED MAINTENANCE

Caution: Allow unit to cool before performing any mainte-

nance. Manually open the drain valve and the fill valve

will be energized. Let the fill water run until the tank is

cooled then shut off the contractor/field installed supply

water valve.

STS® is designed to deal with dissolved minerals in one

of two ways depending on the degree of hardness. For

light to moderate hardness (up to 10 grains per gallon)

the surface skimmer action plus periodic cleaning is

usually adequate. For high mineral content water (above

10 grains per gallon) a periodic drain and flush along with

periodic cleaning may be helpful.

The frequency of cleaning will be dictated by water

condition and evaporation load.

Caution: When performing maintenance on the STS

always turn off electric power to control panel. Close steam

supply and water make-up valves.

Seasonally or as Required

1. Cleaning Tank

Remove loose scale in humidifier tank before the build-up

reaches the underside of the heat exchanger(s).

Summer Maintenance

After the humidification season, a complete inspection and

cleaning of the heat exchanger, probe control, skimmer,

and water chamber is recommended. After cleaning, the

unit should remain empty until humidification is required.

On units with TEFLON® coated heat exchangers, do

not use a sharp object when cleaning. Cuts or

scratches on the heat exchanger will impair its ability to

shed scale during operation, and could cause the TEFLON

to separate from the metal surface.

Adjusting the Surface Skim Bleed-Off Quantity

The skim time determines the quantity of water skimmed

with each fill cycle. The skim time is field adjustable

using the VAPOR-LOGIC2 keypad.

Model STS®-DI Only

The humidifier should be inspected for leaks at least

annually. All safety devices in the control cabinet should

be cycled on and off to verify that they are functioning.

Cleaning the Evaporating Chamber

As long as mineral-free water is used in the STS-DI

humidifier, no cleaning or flushing of the evaporating

chamber should be necessary.

2. Cleaning Probes

Remove cap assembly and unscrew the probe holder from

the STS unit. The scale will easily flake off from the

sensing probes. The sensing portion (bottom 3/8") of the

probe should be brushed clean with stainless steel wool.

Re-install the probe holder with arrows up and “top”

marking at the top.

3. Cleaning Skimmer Tube

Remove the elbow section of the skimmer and rotate

tube so that loosened material will drop out. Loosen

deposits with a long tool such as a screwdriver or

section of small diameter pipe and reassemble elbow.

Skimmer drainage should be verified by visual inspection once per week. Water should drain from skimmer

drain pipe after each fill cycle. (For cleaning piping,

disconnect and flush out. If mineral deposits have

restricted the flow, replace piping.)

4. Inspect Gaskets

Replacement procedures are provided with new

gaskets.

18

Page 19

STS-DI START-UP AND RECOMMENDED MAINTENANCE

Introduction

After the system has been properly installed and

connected to both electrical and water supplies, it may

then be started.

Mounting

Check mounting to see that unit is level and securely

supported before filling with water.

Piping

Verify that all piping connections have been completed

as recommended and that steam and water pressures

are available.

Electrical

Verify that all wiring connections have been made in

accordance with the STS® wiring diagram.

Control System

For VAPOR-LOGIC

to the Installation and Operations Manual enclosed with

the product shipment.

®

microprocessor control system, refer

2

Control Circuits

a) Adjust humidistat to “call” setting.

b) Open shut-off valve on water supply line.

Water should flow through float valve.

c) Turn electric power on to control cabinet.

d) Fill the water seal in drain line by manually

opening drain valve for a few seconds.

e) Open steam stop valve. Steam should be heard

passing through the automatic steam valve into the

humidifier heat exchanger.

f) Check out function of field installed air flow

switch, high limit duct humidistat, and controlling

humidistat to ensure that they are in control of

steam valve.

Recommended Maintenance-STS-DI System

(deionized water)

The STS-DI humidifier does not require regular maintenance. A periodic visual inspection is recommended to

identify gasket or piping leaks. Control circuit and

safety switches should be checked to verify they

properly control the steam valve.

Caution: Overtightening cover will cause leaks.

All cover knobs are turned down at the factory until

the bottom of the knob makes contact with the

flange, then one half turn further. If more compression is required, turn all knobs a half turn more. Do

not turn knobs more than a half turn before identifying that a leak still exists.

19

Page 20

TROUBLE SHOOTING GUIDE

Symptom Possible Cause Recommended Action

Humidifier Will Not Heat No control transformer output.

Humidistat is not calling.

Saftey controls open (high limit,

air proving, etc...)

Faulty control board.

Probe corrosion.

Steam stop valve closed.

Steam trap plugged.

Low or no steam.

Steam strainer plugged.

Humidifier Will Not Fill No water pressure.

Faulty water fill valve.

Plugged water strai ner.

Plugged valve.

Faulty control board.

Humidifier Does Not Stop Filling Lack of tank-to-probes continuity.

Water conductivity less than 100

micromhos/cm minimum (2 grains

per gallon)

Verify control voltage. Set humidistat to

"call". Inspect for faulty humidistat.

Check safety controls.

Verify control voltage and probe. Wires

are connected correctly.

Replace probes*.

Verify val ve is opened.

Clean trap body.

Verify steam is present.

Clean strainer.

Verify manual water supply valve is

open.

Verify action of fill solenoid valve, verify

contol voltage present at coil. Audible

click should be heard as solenoid

operates.

Open strainer.

Clean valve.

Verify control voltage.

Jumper terminals 1 & 3 if water sops,

verify tank ground to term 3; check

water supply conducti vi ty; then consult

factory .

20

Manual drain is not fully closed.

Fill valve is stuck open.

Fill valve installed backwards.

Low Output Automatic drain valve not seating.

Manual drain is not fully closed.

Excessive skimming amount.

Fill valve is stuck open.

Low supply steam pressure.

Steam valve inoperable.

Steam trap blocked.

Scale coated heat exchanger.

Make up Water Va lv e Sh ort C irc uits El ectrode probes may be

incorrectly wired.

Probes are scale coated.

*Although the three stainless steel electrode probes will eventually erode due to corrosion they are usually functional for up to approximately 5000

hours of operation.

Close manual ball valve.

Check valve for foreign matter.

Check for correct water flow, through

valve, note arrow.

Clean ball and seat of valve.

Close manual ball valve.

Red uce ski mme r o r skim time.

Check valve for foreign matter.

Check steam supply pressure.

Not opening fully.

Not passing condensate.

Clean heat exchanger.

Confirm that wi ring agrees with

diagram.

Clean probes.

Page 21

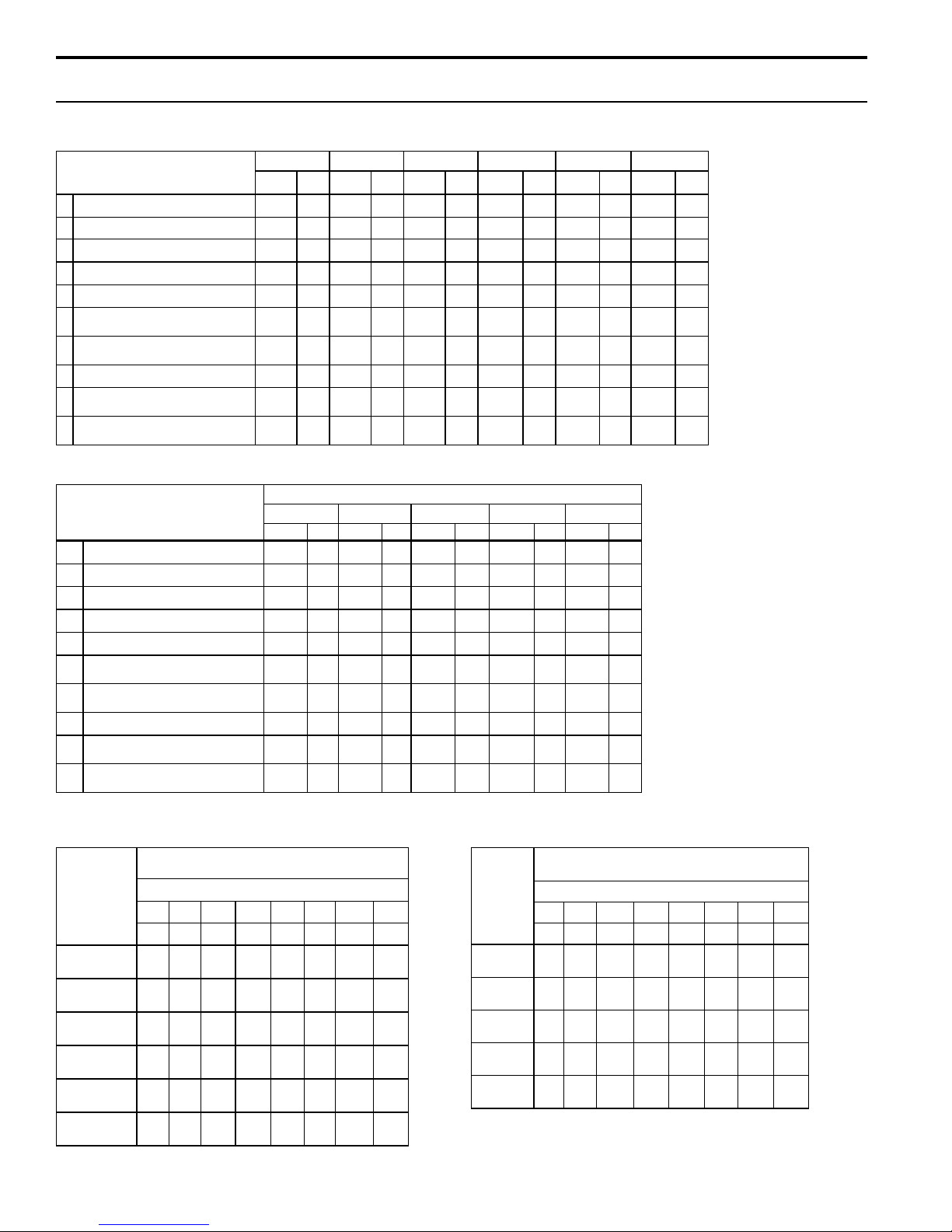

Figure 21-1: STS® Humidifier

REPLACEMENT P ARTS

Table 21-1: STS Humidifier Table 21-1: continued

No. Description Part No.

1 Tank, STS-25 164404-025 *

1 Tank, STS-50 164404-050 *

1 Tank, STS-100 164404-100 *

1 Tank, STS-200/400 164404-400 *

1 Tank, STS 800 164404-800 *

2 C ov er, STS-25 165359 *

2 C ov er, STS-50 165360 *

2 C ov er, STS-100 165365 *

2 C ov er, STS-200/400/800 165369 *

3 Gasket, Cover, STS-25 160690-224 *

3 Gasket, Cover, STS-50 160690-240 *

3 Gasket, Cover, STS-100 160690-340 *

3 Gasket, Cover, STS 200/400/800 1606 90-200 *

4 Knob, T-Handled Utility 700725

5 Heat Exchanger, STS-25S 164420-101 *

5 Heat Exchanger, STS-50S 164420-102 *

5 Heat Exchanger, STS-100S 164420-103 *

5 Heat Exchanger, STS-200S 164420-104 *

* Specify humidifier model and serial numbers when ordering.

No. Description Part No.

6 Heat Exchanger, STS-25C 1 64 43 6-1 01 *

6 Heat Exchanger, STS-50C 1 64 43 6-1 02 *

6 Heat Exchanger, STS-100C 164436-103 *

6 Heat Exchanger, STS-400/800C 164436-104 *

7 Support, Heat Exchanger Mtg Plate 124437

8 Cl ean Out Plate 165470

9 Gasket, Clean Out and Mtg Plate 308220

10 Valve, ¾" Ball (Manual Drain) 505011

11 Gasket, Probe/Float Pl ate 308220 -001

12 Probe Plate, STS-25/50/100 164411

12 Probe Plate, STS-200/400/800 164411-002

13 Baffle, Probe Plate 124443

14 Probe Plug 406050-002

15 Probe Assembly 406060

16 Valve, ¾" Electric (Auto D rain) 505400-001

17 F ill Valve, ¼" Solenoid, .125, STS-25, 50, 100 505084

17 F ill Valve, ¼" Solenoid, .281, STS -400, 800 505085

18 Strainer, ¼" Sediment 300050

19 Valve, Needl e ¼" 505070-001

* Specify humidifier model and serial numbers when ordering.

OM-518

21

Page 22

Figure 22-1: STS®-DI Humidifier

REPLACEMENT PARTS

OM-519

Table 22-1: STS-DI Humidifier Table 22-1: continued

No. Description Part No.

1 Tank, STS-25 164404-025 *

1 Tank, STS-50 164404-050 *

1 Tank, STS-100 164404-100 *

1 Tank, STS-200/400 164404-400 *

1 Tank, STS 800 164404-800 *

2 Cover, STS-25 165359 *

2 Cover, STS-50 165360 *

2 Cover, STS-100 165365 *

2 Cover, STS-200/400/800 165369 *

3 Gasket, Cover, STS-25 160690-224 *

3 Gasket, Cover, STS-50 160690-240 *

3 Gasket, Cover, STS-100 160690-340 *

3 Gasket, Cover, STS 200/400/800 160690-200 *

4 Knob, T-Handled Util ity 700725

No. Description Part No.

6 Heat Exchanger, STS-25C 164436-101 *

6 Heat Exchanger, STS-50C 164436-102 *

6 Heat Exchanger, STS-100C 164436 -103 *

6 Heat Exchanger, STS-400/800C 164436-104 *

7 Support, Heat Exchanger Mtg Plate 124437

8 Clean Out Plate 165470

9 Gasket, Cl e an Out and Mtg Pl ate 3 08 22 0

10 Valve, ¾" Ba l l (Manual Drai n) 505011

11 Gasket, Probe/Float Pl ate 308220-001

12 Float Plate, STS-25/50/100 164410

12 Float Plate, STS-200/400/800 164410-002

13 Baffle, Probe Plate 124442

14 Float Valve Assembly STS 25-400 505210

14 Float Valve Assembly STS 25-800 505300

5 Heat Exchanger, STS-25S 164420-101 *

5 Heat Exchanger, STS-50S 164420-102 *

5 Heat Exchanger, STS-100S 164420-103 *

5 Heat Exchanger, STS-200S 164420-104 *

* Specify humidifier model and serial numbers when ordering.

22

* Specify humidifier model and serial numbers when ordering.

Page 23

REPLACEMENT PARTS

Figure 23-1: STS® Control Cabinet with VAPOR-LOGIC

®

Controls

2

Table 23-1: VAPOR-LOGIC

No. Description Part No.

1 Power Block 408300-001

2 Transformer 408960

3 Ground Lug 40925 0-017

4 LW430, Microprocessor Board 408641

5 LW440, Display Board 408651

®

Controls

2

OM-1044

23

Page 24

TWO-YEAR LIMITED WARRANTY

DRI-STEEM Humidifier Company (“DRI-STEEM”) warrants to the original user that its products will be free from

defects in materials and workmanship for a period of two (2) years after installation or twenty-seven (27)

months from the date DRI-STEEM ships such product, whichever date is the earlier.

If any DRI-STEEM product is found to be defective in material or workmanship during the applicable

warranty period, DRI-STEEM’s entire liability, and the purchaser’s sole and exclusive remedy, shall be

the repair or replacement of the defective product, or the refund of the purchase price, at DRI-STEEM’s

election. DRI-STEEM shall not be liable for any costs or expenses, whether direct or indirect, associated with

the installation, removal or re-installation of any defective product.

DRI-STEEM’s limited warranty shall not be effective or actionable unless there is compliance with all installation and operating instructions furnished by DRI-STEEM, or if the products have been modified or altered

without the written consent of DRI-STEEM, or if such products have been subject to accident, misuse, mishandling, tampering, negligence or improper maintenance. Any warranty claim must be submitted to DRI-STEEM in

writing within the stated warranty period.

DRI-STEEM’s limited warranty is made in lieu of, and DRI-STEEM disclaims all other warranties, whether

express or implied, including but not limited to any IMPLIED WARRANTY OF MERCHANTABILITY, ANY

IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, any implied warranty arising out of a

course of dealing or of performance, custom or usage of trade.

DRI-STEEM SHALL NOT, UNDER ANY CIRCUMSTANCES BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOSS OF

PROFITS, REVENUE OR BUSINESS) OR DAMAGE OR INJURY TO PERSONS OR PROPERTY IN ANY

WAY RELATED TO THE MANUFACTURE OR THE USE OF ITS PRODUCTS. The exclusion applies regardless of whether such damages are sought based on breach of warranty, breach of contract, negligence, strict

liability in tort, or any other legal theory, even if DRI-STEEM has notice of the possibility of such damages.

By purchasing DRI-STEEM’s products, the purchaser agrees to the terms and conditions of this limited

warranty.

14949 Technology Drive • Eden Prairie, MN 55344

Phone: (952) 949-2415 • Fax: (952) 949-2933

E-Mail: sales@dristeem.com • Web: www.dristeem.com

International Office:

Bell Place, Bell Lane • Syresham, Brackley • NN13 5HP, U.K.

Phone: +44 1280 850122

Fax: +44 1280 850124

E-Mail: 106277.1443@compuserve.com

Continuous product improvement is a policy of DRI-STEEM Humidifier Company therefore,

product features and specifications are subject to change without notice.

DRI-STEEM, RAPID-SORB, STS, VAPOR-LOGIC and VAPOR-LOGIC2 are Registered Trademarks of the DRI-STEEM Humidifier Company.

Form No. STSOM-0200 Copyright © 2000 DRI-STEEM Humidifier Company, Inc. Printed in the U.S.A.

24

TEFLON is a Registered Trademark of Dupont.

Loading...

Loading...