Page 1

®

STS

Steam-to-Steam Humidifier,

DI Water

®

LTS

Liquid-to-Steam Humidifier,

DI Water

Service Kit Manual

WARNING

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

Read all warnings and instructions

This page provides important safety instructions; it is intended to supplement — not replace — the humidifier's Installation, Operation, and

Maintenance Manual (IOM). Read the IOM that was provided with the humidifier before performing service or maintenance procedures

on any part of the system. Failure to follow all warnings and instructions could produce the hazardous situations described here and in the

IOM, resulting in property damage, personal injury, or death.

If the IOM is missing, go to www.dristeem.com to download a replacement. mc_071608_0910

Hot surfaces and hot water

Steam humidification systems have extremely hot surfaces, and water in tanks, electrode cylinders, steam pipes, and dispersion assemblies

can be as hot as 212 °F (100 °C). To avoid severe burns, allow the entire humidification system to cool.

Follow the cool-down procedure in the humidifier's IOM before performing service or maintenance procedures on any part of the system.

mc_071608_0911

Electrical shock hazard

If the humidifier starts up at a call for humidity during maintenance, severe bodily injury or death from electrical shock could occur. To

prevent such start-up, follow the procedure below before performing service or maintenance procedures on this humidifier (after the tank

has cooled down and drained):

1. Use the Vapor-logic®3 controller keypad to change the control mode to Standby.

2. Shut off all electrical power to the humidifier using the field-installed fused disconnect, and lock all power disconnect switches in the

OFF position.

3. Close the field-installed manual water supply shut-off valve.

4. Close the manual inlet steam supply (on STS) or inlet hot liquid supply (on LTS) shut-off valve. mc_050808_1541

CAUTION

Indicates a hazardous situation that could result in damage to

or destruction of property if instructions are not followed.

WARNING

mc_051508_1145

Damage from hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage the drain plumbing.

If the humidifier is equipped with a water tempering device such as a DRI-STEEM Drane-kooler™, it needs fresh make-up water in order to function

properly. Make sure the water supply to the Drane-kooler remains open during draining.

If the humidifier is not equipped with a water tempering device, allow the tank to cool before opening the drain valve. mc_111308_1345

Parts in this service kit are for STS03 and/or LTS03 humidifiers (February 2003 to present). Parts are listed on page 2.

CAUTION

Page 2

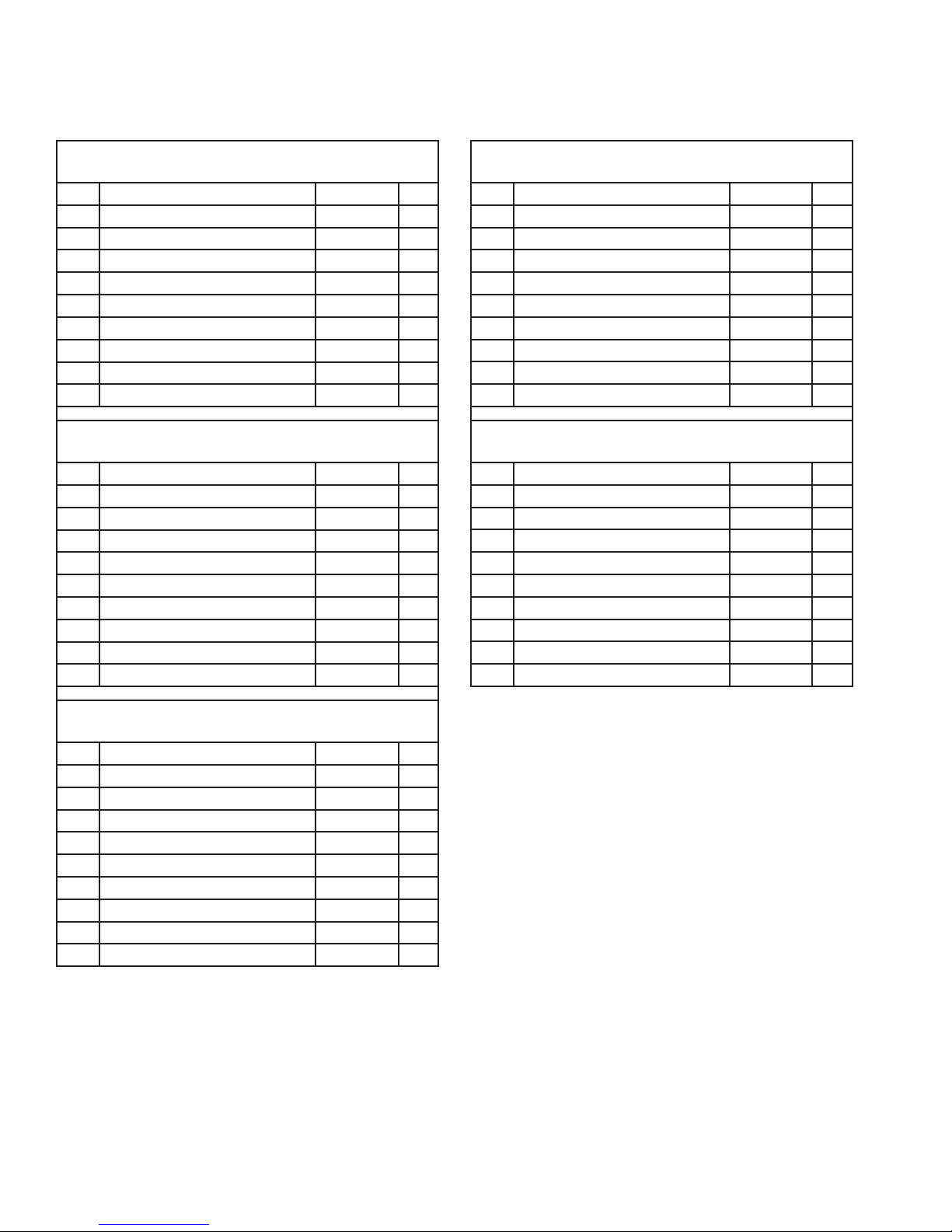

STS/LTS, DI water, service kit parts

STS03 / LTS03, DI water, 25

Service Kit No. 900100-701

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-001 1

5 Cover gasket 160692-001 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

STS03, DI water, 50

Service Kit No. 900100-702

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-002 1

5 Cover gasket 160692-002 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

STS03, DI water, 200/400

Service Kit No. 900100-704

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-003 1

5 Cover gasket 160692-004 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

STS03, DI water, 800 and LTS03, DI water, 400

Service Kit No. 900100-705

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-003 1

5 Cover gasket 160692-004 1

6 Heat exchanger gasket, front 308220 4

7 Washer, flat 10-32 700300-008 16

8 Nut, 10-32, w/Nylon insert 700252-003 16

9 Nut, 14-20, w/Nylon insert 700300-016 32

STS03 / LTS03, DI water, 100

Service Kit No. 900100-703

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-002 1

5 Cover gasket 160692-003 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

Page 2 • DRI-STEEM STS/LTS, DI Water, Service Kit Manual

Page 3

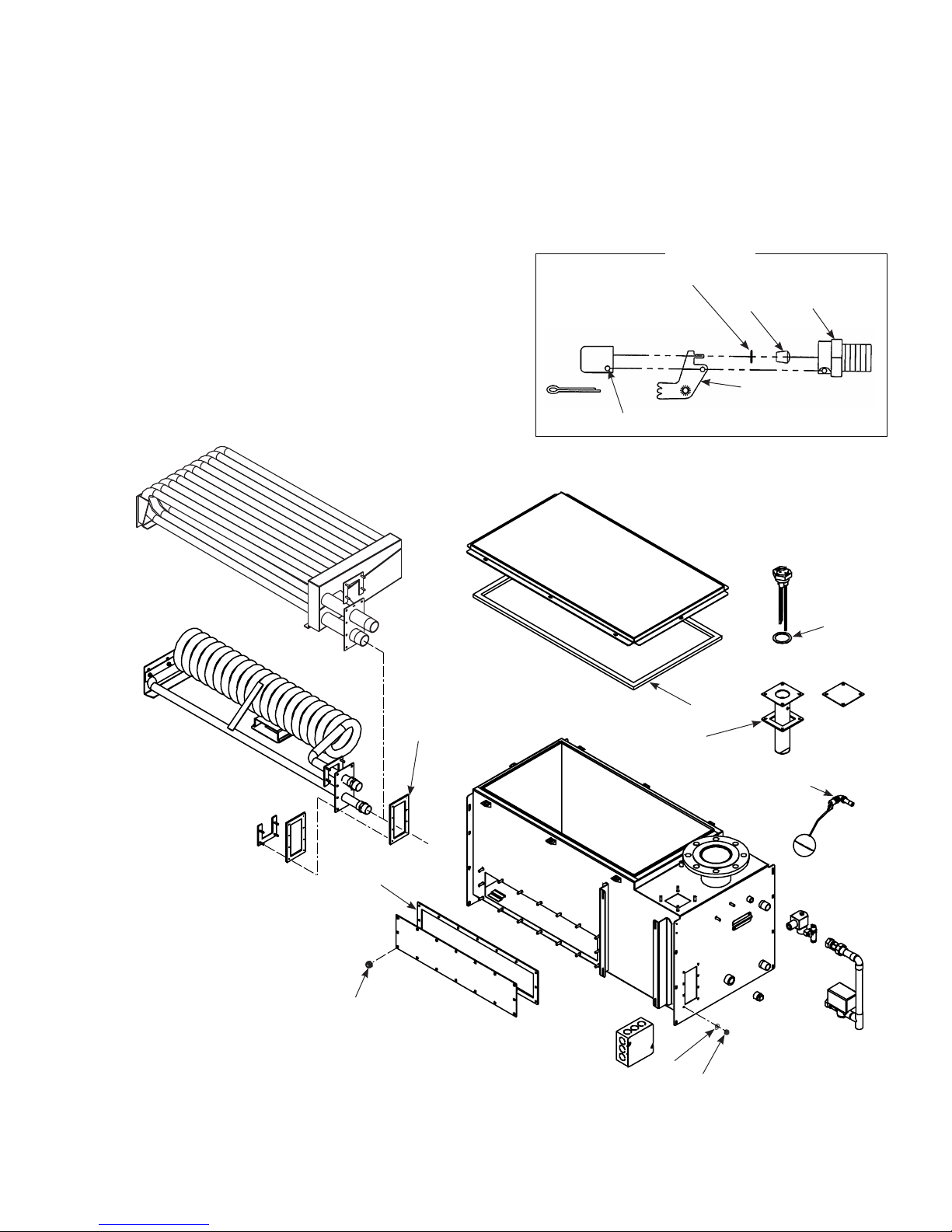

STS/LTS, DI water, service kit parts

This service kit contains the replacement parts called out in the

parts drawing to keep your DRI‑STEEM humidifier operating

at peak performance. This Service Kit Manual provides

important safety and service instructions; it is intended to

supplement — not replace — the humidifier's Installation,

Operation, and Maintenance Manual. Please see Read all

warnings and instructions on page 1.

While performing service and maintenance procedures,

replace existing parts with the new parts provided in the

service kit.

mc_052808_1400

STS heat exchanger

Float Valve

Put back-up washer on

arm first, then seat (2).

Insert cotter pin

2

Arm

Valve

OM-863-1

mc_051908_1410

LTS heat exchanger

Notes:

• Parts for both standard water and DI

water humidifiers are shown.

• Components may by oriented differently

than shown in drawing.

6

(small holes)

4

9

Torque to 25 to 35 in-lbs

(2.8 to 4.0 N-m).

Apply clear

silicone (1)

to both sides

of gasket.

5

3

See Float Valve inset.

7

8

DRI-STEEM STS/LTS, DI Water, Service Kit Manual • Page 3

LTS-OM-18X

OM-946X

mc_052108_1645

Page 4

STS/LTS, DI water, service instructions

Inspection and maintenance

Cool down humidifier

Before performing any maintenance, allow the tank to cool

down. Insulated and uninsulated tanks will have hot surfaces.

Note: Fresh make‑up water is used to speed up cooling. Do

not close the manual water supply before cooling down

the humidifier; otherwise the tank could stay hot for

several hours.

1. Close the manual shut‑off valve on the inlet steam supply

(STS humidifiers) or the inlet hot liquid supply (LTS

humidifiers).

2. Drain the tank:

Models with a standard drain valve:

a. Manually open the drain valve. The fill valve will open

after enough water has drained out of the tank.

b. Let the fill water run until the tank is cooled; then shut

off the field installed manual supply water shut‑off

valve.

c. Let the tank drain; then manually close the drain valve.

For models with end-of-season drain option (must have

Vapor‑logic3 controller), use the keypad to perform the

cool down procedure. Refer to the Vapor-logic3 Installation

and Operation Manual for more information:

a. Select Manual Drain in the control modes screen.

b Allow approximately half the water to drain out of the

tank.

c. Select Auto in the control modes screen; the fill valve

opens and the humidifier cools down.

d. When the fill valve closes, select Manual Drain in

the control modes screen and allow the tank to drain

completely dry. The humidifier should be cool enough

to work on.

mc_060308_0700

Annually (also recommended when maintenance is performed)

1. All safety devices in the control circuit should be cycled on

and off to verify they are functioning. These include:

• High limit switch

• Airflow proving switch

2. Inspect tank and gaskets for leaks.

3. Verify that the float valve is closing off. If the float valve

will not shut off, there may be particulate on the valve seat,

or the stopper may be worn and need replacing.

As long as mineral‑free water is used in the humidifier, no

cleaning or flushing should be necessary.

Off-season maintenance

1. Perform a complete inspection of the following:

• Heat exchanger

• Float valve

• Humidifier tank and gaskets

2. After inspection, leave the humidifier empty until

humidification is required.

After the humidification season, DRI‑STEEM recommends a

complete inspection and cleaning of the heat exchanger and

water chamber. After cleaning, the unit should remain empty

until humidification is required.

On units with Teflon coated heat exchangers, do not use

a sharp object when cleaning. Cuts or scratches on the heat

exchanger will impair its ability to shed scale during operation

and could cause the Teflon to separate from the metal surface.

mc_060208_0708

mc_060208_0715

Shut down humidifier

Follow the procedure below before performing service or

maintenance procedures, (after the tank has cooled down and

drained):

1. Use the Vapor‑logic3 controller keypad to change the

control mode to Standby.

2. Shut off all electrical power to the humidifier using

the field‑installed fused disconnect, and lock all power

disconnect switches in the OFF position.

3. Close the field‑installed manual water supply shut‑off

valve.

4. Close the manual inlet steam supply (on STS) or inlet hot

liquid supply (on LTS) shut‑off valve.

Page 4 • DRI-STEEM STS/LTS, DI Water, Service Kit Manual

mc_060208_1440

Page 5

STS/LTS, DI water, service instructions

DI water requirements

• Verify regularly that water processing equipment

is operating correctly. The presence of chlorides in

improperly processed DI water eventually causes pitting

and failure of the heat exchanger tank and its components.

Your DRI‑STEEM warranty does not cover damage caused

by chloride corrosion.

• DI models do not require regular cleaning, although

regular inspections are advised.

• DI models do not require skimming or draining

and flushing to remove precipitated minerals. All

DI humidifiers should be drained at the end of a

humidification season either by manually opening

the drain valve or by programming the humidifier to

automatically drain at end‑of‑season (electric drain valve

and Vapor‑logic3 required).

Note: Although DI models do not require regular tank

cleaning, this service kit contains a new cleanout

plate gasket and nuts. If replacing the gasket, replace

the nuts also, and torque the nuts to 25 to 35 in‑lbs

(2.8 to 4.0 N‑m).

mc_060308_0720

mc_062608_1425

Start-up

Perform the Annual safety checks in the Inspection and

maintenance section on page 4.

If resuming operation after service, do not leave the humidifier

unattended; allow it to cycle through multiple fill cycles to

verify that all serviced parts are functioning properly. See the

humidifier's Installation, Operation, and Maintenance manual

for start‑up details.

mc_052908_1005

DRI-STEEM STS/LTS, DI Water, Service Kit Manual • Page 5

Page 6

Humidifier De-scaling Solution

Scale buildup on humidifier heat exchangers

acts as an insulator, reducing humidifier

performance while increasing energy

costs. To keep humidifiers operating as

efficiently as possible, remove scale with

DRI-STEEM's Humidifier De-scaling Solution,

available for purchase from your DRI-STEEM

representative or distributor.

The De-scaling Solution cleans without risk

of corroding humidifier tanks or welds. The

De-scaling Solution also cleans surfaces

unreachable by hand scraping.

DRI-STEEM's Humidifier De-scaling Solution

is the only approved cleaner/de-scaler for

use with DRI-STEEM humidifiers. Use of

other cleaners/de-scalers may void your

DRI-STEEM warranty.

mc_021908_1410-heatx

DRI-STEEM Corporation

An ISO 9001: 2000 certified corporation

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

European office:

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgium

+3211823595 (voice)

+3211817948 (fax)

E-mail: marc.briers@dristeem.com

Continuous product improvement is a

policy of DRI-STEEM Corporation; therefore,

product features and specifications are

subject to change without notice.

DRI-STEEM, LTS, STS, and Vapor-logic

are registered trademarks of DRI-STEEM

Corporation and are filed for trademark

registration in Canada and the European

community.

Drane-kooler is a trademark of DRI-STEEM

Corporation.

© 2013 DRI-STEEM Corporation

Form No. STS/LTS-DI-SKM-1013

Page 6 • DRI-STEEM STS/LTS, DI Water, Service Kit Manual

Part No. 891000-502 Rev D

DRI-STEEM products are warranted according to the terms and conditions of the standard

two-year Limited Warranty effective when the humidifier was purchased. See the literature

that was shipped with the humidifier for warranty information.

mc_081308_1405

Page 7

®

STS

Humidificateur vapeur-vapeur,

eau DI

®

LTS

Humidificateur liquide-vapeur,

eau DI

Manuel du nécessaire d'entretien

ATTENTION

Indique une situation dangereuse qui pourrait entraîner des blessures

graves voire la mort si les consignes ne sont pas respectées.

ATTENTION

Lire l'ensemble des mises en garde et des instructions

Cette page fournit des consignes de sécurité importantes ; elle est conçue pour compléter — non remplacer — le Manuel d'installation,

d'utilisation et de maintenance (IOM). Lire l'IOM qui a été fourni avec l'humidificateur avant d'effectuer des interventions d'entretien ou de

maintenance sur n'importe quelle pièce du système. Le non-respect de l'ensemble des mises en garde et des instructions pourrait engendrer les

situations dangereuses décrites dans ce document et dans l'IOM, et occasionner des dommages aux biens, des préjudices corporels voire la mort.

Si l'IOM est manquant, rendez-vous à www.dristeem.com pour télécharger un manuel de remplacement.

Surfaces et eau portées à température élevée

Les systèmes d'humidification à vapeur comportent des surfaces à température extrêmement élevée ; la température de l'eau présente

dans les cuves, les cylindres à électrode, les conduites de vapeur et les ensembles de dispersion peut atteindre 100 °C. Pour éviter tout

risque de brûlures graves, laisser refroidir tout le système d'humidification.

Suivre la procédure de refroidissement décrite dans l'IOM de l'humidificateur avant d'effectuer des interventions d'entretien ou de

maintenance sur n'importe quelle pièce du système.

Risque de choc électrique

Si l'humidificateur démarre en réponse à une demande d'humidification lors d'une intervention de maintenance, cela pourrait occasionner

des préjudices corporels graves voire la mort à la suite d'un choc électrique. Pour éviter un tel démarrage, suivre la procédure ci-dessous

avant toute intervention d'entretien ou de maintenance sur cet humidificateur (une fois que la cuve a été refroidie et vidangée) :

1. Utiliser le pavé numérique du dispositif de régulation Vapor-logic®3 pour basculer le mode de commande en Veille.

2. Couper toute l'alimentation électrique de l'humidificateur en utilisant le sectionneur à fusible installé sur site et verrouiller tous les

sectionneurs d'alimentation en position d'arrêt OFF.

3. Fermer le robinet de sectionnement d'alimentation manuelle en eau installé sur site.

4. Fermer le robinet de sectionnement manuel de l'alimentation en vapeur de l'entrée (sur STS) ou l'alimentation en liquide chaud de

l'entrée (sur LTS).

ATTENTION

Indique une situation dangereuse qui pourrait endommager ou détruire

des biens si les consignes ne sont pas respectées.

Dommages occasionnés par l'eau de refoulement à haute température

La température de l'eau de refoulement peut atteindre 100 °C et endommager la plomberie de vidange.

Si l'humidificateur est équipé d'un dispositif de tempérage de l'eau comme DRI-STEEM Drane-kooler™, il a besoin d'eau d'appoint fraîche pour

fonctionner correctement. S'assurer que l'alimentation en eau du Drane-kooler reste ouverte lors de la vidange.

Si l'humidificateur n'est pas équipé d'un dispositif de tempérage de l'eau, laisser la cuve refroidir avant d'ouvrir le robinet de vidange.

Les pièces citées dans ce nécessaire d'entretien sont prévues pour les humidificateurs STS03 et/ou LTS03 (février 2003 à ce jour).

ATTENTION

Les pièces sont répertoriées en page 2.

Page 8

STS/LTS, eau DI, pièces du nécessaire d'entretien

STS03 / LTS03, eau DI, 25

Nécessaire d'entretien n° 900100-701

N° Description de la pièce Référence. Qté.

1 Silicone, transparent (non représenté) 320000 1

2 Siège, éthylène propylène diène monomère

(EPDM) noir (voir l'encart Robinet à flotteur)

3 Joint d'étanchéité de la plaque de sonde 308416-001 1

4 Joint d'étanchéité de la plaque de nettoyage 308015-001 1

5 Joint d'étanchéité de protection 160692-001 1

6 Joint d'étanchéité de l'échangeur de chaleur,

avant

7 Rondelle, plate 10-32 700300-008 8

8 Écrou, 10/-32 avec bague de nylon 700252-003 8

9 Écrou, 14/-20 avec bague de nylon 700300-016 16

STS03, eau DI, 50

Nécessaire d'entretien n° 900100-702

N° Description de la pièce Référence. Qté.

1 Silicone, transparent (non représenté) 320000 1

2 Siège, éthylène propylène diène monomère

(EPDM) noir (voir l'encart Robinet à flotteur)

3 Joint d'étanchéité de la plaque de sonde 308416-001 1

4 Joint d'étanchéité de la plaque de nettoyage 308015-002 1

5 Joint d'étanchéité de protection 160692-002 1

6 Joint d'étanchéité de l'échangeur de chaleur,

avant

7 Rondelle, plate 10-32 700300-008 8

8 Écrou, 10/-32 avec bague de nylon 700252-003 8

9 Écrou, 14/-20 avec bague de nylon 700300-016 16

STS03 / LTS03, eau DI, 100

Nécessaire d'entretien n° 900100-703

N° Description de la pièce Référence. Qté.

1 Silicone, transparent (non représenté) 320000 1

2 Siège, éthylène propylène diène monomère

(EPDM) noir (voir l'encart Robinet à flotteur)

3 Joint d'étanchéité de la plaque de sonde 308416-001 1

4 Joint d'étanchéité de la plaque de nettoyage 308015-002 1

5 Joint d'étanchéité de protection 160692-003 1

6 Joint d'étanchéité de l'échangeur de chaleur,

avant

7 Rondelle, plate 10-32 700300-008 8

8 Écrou, 10/-32 avec bague de nylon 700252-003 8

9 Écrou, 14/-20 avec bague de nylon 700300-016 16

505210-003 1

308220 2

505210-003 1

308220 2

505210-003 1

308220 2

STS03, eau DI, 200/400

Nécessaire d'entretien n° 900100-704

N° Description de la pièce Référence. Qté.

1 Silicone, transparent (non représenté) 320000 1

2 Siège, éthylène propylène diène monomère

(EPDM) noir (voir l'encart Robinet à flotteur)

3 Joint d'étanchéité de la plaque de sonde 308416-001 1

4 Joint d'étanchéité de la plaque de nettoyage 308015-003 1

5 Joint d'étanchéité de protection 160692-004 1

6 Joint d'étanchéité de l'échangeur de chaleur,

avant

7 Rondelle, plate 10-32 700300-008 8

8 Écrou, 10/-32 avec bague de nylon 700252-003 8

9 Écrou, 14/-20 avec bague de nylon 700300-016 16

STS03, eau DI, 800 et LTS03, eau DI, 400

Nécessaire d'entretien n° 900100-705

N° Description de la pièce Référence. Qté.

1 Silicone, transparent (non représenté) 320000 1

2 Siège, éthylène propylène diène monomère

(EPDM) noir (voir l'encart Robinet à flotteur)

3 Joint d'étanchéité de la plaque de sonde 308416-001 1

4 Joint d'étanchéité de la plaque de nettoyage 308015-003 1

5 Joint d'étanchéité de protection 160692-004 1

6 Joint d'étanchéité de l'échangeur de chaleur,

avant

7 Rondelle, plate 10-32 700300-008 16

8 Écrou, 10/-32 avec bague de nylon 700252-003 16

9 Écrou, 14/-20 avec bague de nylon 700300-016 32

505210-003 1

308220 2

505210-003 1

308220 4

Page 8 • Humidificateurs STS/LTS DRI-STEEM, eau DI, Manuel du nécessaire d'entretien

Page 9

STS/LTS, eau DI, pièces du nécessaire d'entretien

Le nécessaire d'entretien contient les pièces de rechange

référencées dans le schéma des pièces qui permettent à votre

humidificateur DRI‑STEEM de continuer à fonctionner au

maximum de ses performances. Ce Manuel du nécessaire

d'entretien fournit des consignes de sécurité et d'entretien

importantes ; il est conçu pour compléter — non remplacer — le

Manuel d'installation, d'utilisation et de maintenance (IOM).

Lire l'ensemble des mises en garde et des instructions en page

1.

Lors des interventions d'entretien et de maintenance, remplacer

les pièces existantes par les pièces neuves fournies dans le

nécessaire d'entretien.

Échangeur de chaleur STS

Robinet à flotteur

Placer d'abord une rondelle

de soutien sur le bras, puis

asseoir l'ensemble (2).

Insérer la goupille fendue

2

Bras

Robinet

OM-863-1

Échangeur de chaleur LTS

Remarques :

• Les pièces correspondant aux

humidificateurs à eau standard et à eau

DI sont illustrées.

• Certains composants peuvent être

orientés différemment par rapport au

schéma.

6

(petits orifices)

4

9

Appliquer un couple de serrage

de 2,8 à 4,0 N-m

5

3

Voir l'encart Robinet à

flotteur.

7

8

Appliquer

du silicone

transparent

(1) aux deux

faces du joint

d'étanchéité.

LTS-OM-18X

OM-946X

Humidificateurs STS/LTS DRI-STEEM, eau DI, Manuel du nécessaire d'entretien • Page 9

Page 10

STS/LTS, eau DI, consignes d'entretien

Vapor‑logic3 pour basculer le mode de commande en

Refroidissement de l'humidificateur

Avant toute intervention de maintenance, laisser refroidir la

cuve. Certaines surfaces des cuves isolées et non isolées seront

portées à température élevée.

Remarque : De l'eau d'appoint fraîche est utilisée pour

accélérer le refroidissement. Ne pas fermer

l'alimentation manuelle en eau avant d'avoir

refroidi l'humidificateur ; autrement, la cuve

pourrait rester chaude pendant plusieurs heures.

1. Fermer le robinet de sectionnement manuel de

l'alimentation en vapeur de l'entrée (humidificateurs

STS) ou l'alimentation en liquide chaud de l'entrée

(humidificateurs LTS).

2. Vidange de la cuve :

Modèles ayant un robinet de vidange standard :

a. Ouvrir manuellement le robinet de vidange. Le robinet

de remplissage s'ouvrira dès qu'une quantité suffisante

d'eau aura été vidangée de la cuve.

b. Laisser couler l'eau de remplissage jusqu'à ce que

la cuve soit refroidie ; puis, fermer le robinet de

sectionnement de l'alimentation manuelle en eau

installé sur site.

c. Laisser la cuve se vidanger ; puis, fermer manuellement

le robinet de vidange.

Pour les modèles ayant l'option de vidange saisonnière

(doivent être équipés d'un dispositif de régulation

Vapor‑logic3), utiliser le pavé numérique pour effectuer la

procédure de refroidissement. Pour plus d'informations,

consulter le Manuel d'installation et d'utilisation

Vapor‑logic3 :

a. Sélectionner Manual Drain (vidange manuelle) à

l'écran Control Modes (modes de commande).

b Laisser environ la moitié de l'eau se vidanger hors de la

cuve.

c. Sélectionner Auto à l'écran Control Modes (modes

de commande) ; le robinet de remplissage s'ouvre et

l'humidificateur se refroidit.

d. Quand le robinet de remplissage se ferme, sélectionner

Manual Drain (vidange manuelle) à l'écran Control

Modes (modes de commande) et laisser la cuve se

vidanger complètement. L'humidificateur devrait avoir

suffisamment refroidi pour pouvoir effectuer la tâche.

Veille.

2. Couper toute l'alimentation électrique de l'humidificateur

en utilisant le sectionneur à fusible installé sur site et

verrouiller tous les sectionneurs d'alimentation en position

d'arrêt OFF.

3. Fermer le robinet de sectionnement d'alimentation

manuelle en eau installé sur site.

4. Fermer le robinet de sectionnement manuel de

l'alimentation en vapeur de l'entrée (sur STS) ou

l'alimentation en liquide chaud de l'entrée (sur LTS).

Inspection et maintenance

Annuellement (également recommandé lors de la

maintenance)

1. Tous les dispositifs de sécurité du circuit de commande

doivent être mis en marche, puis arrêtés, afin de vérifier

leur fonctionnement. Ces dispositifs comprennent

notamment :

• Commutateur de fin de course

• Commutateur de contrôle de débit d'air

2. Inspecter la cuve et les joints d'étanchéité pour déceler des

fuites éventuelles.

3. Vérifier que le robinet à flotteur se ferme. Si le robinet à

flotteur refuse de se fermer, il y a peut‑être des particules

sur le siège du robinet ou le bouchon est usé et doit être

remplacé.

Tant que de l'eau déminéralisée est utilisée dans

l'humidificateur, il ne doit pas être nécessaire de le nettoyer ou

de le rincer.

Maintenance de fin de saison

1. Effectuer une inspection complète des éléments suivants :

• Échangeur de chaleur

• Robinet à flotteur

• Cuve et joints d'étanchéité de l'humidificateur

2. Après l'inspection, laisser l'humidificateur à vide jusqu'à ce

qu'il y ait un besoin d'humidification.

En fin de saison d'humidification, DRI‑STEEM recommande

d'effectuer une inspection et un nettoyage complets de

l'échangeur de chaleur et de la chambre d'équilibre. Après le

nettoyage, l'appareil doit demeurer vide jusqu'à ce qu'il y ait

un besoin d'humidification.

Arrêt de l'humidificateur

Suivre la procédure ci‑dessous avant toute intervention

d'entretien ou de maintenance (une fois que la cuve a été

refroidie et vidangée) :

1. Utiliser le pavé numérique du dispositif de régulation

Page 10 • Humidificateurs STS/LTS DRI-STEEM, eau DI, Manuel du nécessaire d'entretien

Sur les appareils équipés d'échangeurs de chaleur à

revêtement en Téflon, ne pas utiliser d'objet tranchant lors

du nettoyage. Les entailles ou les griffes sur l'échangeur de

chaleur diminuent sa capacité à se défaire du tartre en cours

de fonctionnement et pourraient entraîner le décollement

duTéflon de la surface du métal.

Page 11

STS/LTS, eau DI, consignes d'entretien

Besoins en matière d'eau DI

• Vérifier régulièrement que l'installation de traitement de

l'eau fonctionne correctement. La présence de chlorures

dans une eau DI mal traitée finira par causer des piqûres

et entraîner la défaillance de la cuve de l'échangeur de

chaleur et de ses éléments. Les dommages causés par la

corrosion due au chlorure ne sont pas couverts par votre

garantie DRI‑STEEM.

• Les modèles DI n'ont pas besoin d'un nettoyage régulier,

même si des inspections ponctuelles sont conseillées.

• Les modèles DI ne requièrent ni écumage ni vidange et

rinçage pour éliminer les sels minéraux précipités. À la

fin d'une saison d'humidification, tous les humidificateurs

DI doivent être vidangés, soit en ouvrant manuellement le

robinet de vidange, soit en programmant l'humidificateur

de façon à ce qu'il effectue automatiquement une vidange à

la fin de la saison (robinet de vidange électrique et

Vapor‑logic3 requis).

Remarque : Bien que les modèles à eau DI ne nécessitent pas

de nettoyage régulier de la cuve, ce nécessaire

d'entretien contient des écrous et un joint

d'étanchéité pour une plaque de nettoyage neuve.

En cas de remplacement du joint d'étanchéité,

remplacer également les écrous et appliquer un

couple de serrage de 2,8 à 4,0 N‑m aux écrous.

Démarrage

Effectuer les contrôles de sécurité Annuels prévus à la section

Inspection et maintenance en page 4.

En cas de reprise du fonctionnement après un entretien,

ne pas laisser l'humidificateur sans surveillance ; le laisser

accomplir plusieurs cycles de remplissage afin de vérifier

que toutes les pièces entretenues fonctionnent correctement.

Voir les détails du démarrage dans le Manuel d'installation,

d'utilisation et de maintenance de l'humidificateur.

Humidificateurs STS/LTS DRI-STEEM, eau DI, Manuel du nécessaire d'entretien • Page 11

Page 12

DRI-STEEM Corporation

ISO 9001 : 2000 société certifiée

Bureau européen :

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgique

+3211823595 (téléphone)

+3211817948 (télécopie)

E-mail : marc.briers@dristeem.com

Siège social aux États-Unis :

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 ou 952-949-2415

952-229-3200 (télécopie)

DRI-STEEM Corporation poursuit une politique

d'amélioration continue de ses produits. Par conséquent,

les caractéristiques et les spécifications des produits

peuvent changer sans préavis.

DRI-STEEM, LTS, STS et Vapor-logic sont des marques

déposées de DRI-STEEM Corporation et ont fait l'objet

d'une demande de dépôt de marque au Canada et dans la

Communauté Européenne.

Drane-kooler est une marque déposée de DRI-STEEM

Corporation.

© 2013 DRI-STEEM Corporation

Formulaire n° STS/LTS-DI-SKM-F-1013

Référence. 891000-502 Rev D

Page 12 • Humidificateurs STS/LTS DRI-STEEM, eau DI, Manuel du nécessaire d'entretien

Les produits DRI-STEEM sont garantis selon les modalités de la garantie limitée de deux ans

standard prenant effet à la date d'achat de l'humidificateur. Voir la documentation fournie avec

l'humidificateur pour plus d'informations sur la garantie.

Page 13

®

STS

Dampf-/Dampf-Befeuchter,

entsalztes Wasser

®

LTS

Fluid-/Dampf-Befeuchter,

entsalztes Wasser

Anleitung für Wartungssatz

VORSICHT

Weist auf einen Betriebszustand hin, der zu schweren Verletzungen

oder Tod führen kann, falls die Anweisungen mißachtet werden.

Alle Warnhinweise und Arbeitsanweisungen lesen

Diese Seite enthält wichtige Sicherheitshinweise; sie ist als Zusatz zu verstehen und NICHT als Ersatz für die Installations- und

Bedienungsanleitung. Daher zuerst die Installations- und Bedienungsanleitung des Befeuchters lesen, welche mit dem Befeuchter geliefert

wurde, bevor jegliche Wartungsarbeiten am System durchgeführt werden. Nichteinhaltung dieser Warnhinweise kann zu den hier und in

der Befeuchter-Bedienungsanleitung beschriebenen gefährlichen Betriebszuständen führen, welche Sachschäden, Verletzungen oder Tod

zur Folge haben können.

Fehlt die Befeuchter-Bedienungsanleitung, diese von www.dristeem.com herunterladen.

Heiße Oberflächen und heißes Wasser

Dampf-Befeuchtungssysteme weisen sehr heiße Oberflächen auf und das Wasser in den Tanks, Elektrozylindern, Dampfrohren und

Verteilmodulen kann bis zu 100 °C heiß sein. Daher das gesamte Befeuchtersystem zuerst abkühlen um Verbrühungen zu vermeiden.

Das Abkühlverfahren in der Befeuchter-Bedienungsanleitung befolgen, bevor jegliche Wartungsarbeiten an Teilen des Systems erfolgen.

Gefahr durch Stromschlag

Falls der Befeuchter während der Wartung einschaltet kann dies zu schweren Verletzungen oder Tod durch Stromschlag führen. Um

ein automatisches Einschalten zu verhindern, die nachfolgenden Anweisungen beachten, bevor jegliche Wartungsarbeiten an diesem

Befeuchter erfolgen (nachdem der Tank abgekühlt und entwässert wurde):

1. Mit Hilfe des Vapor-logic®3 Steuergeräts in den Steuermodus Standby schalten.

2. Die Stromversorgung am bauseitigen gesicherten Hauptschalter abschalten und alle Schalter in Position AUS sperren.

3. Das bauseitige manuelle Wasserzufuhrventil schließen.

4. Das manuelle Absperrventil der Dampfzufuhr (am STS) oder der Fluidzufuhr (am LTS) schließen.

ACHTUNG

Weist auf einen Betriebszustand hin, der zu Sachschäden führen kann,

falls die Anweisungen mißachtet werden.

VORSICHT

Schäden aufgrund heißem Abwasser

Abwasser kann bis zu 100 °C heiß sein und die Ablaufverrohrung beschädigen.

Ist der Befeuchter mit einem Abwasserkühlgerät wie z.B. dem DRI-STEEM Drane-kooler™ ausgerüstet muss ein Kaltwasseranschluss vorhanden sein,

damit das Gerät ordnungsgemäß funktioniert. Daher sicherstellen, die Wasserzufuhr zum Drane-kooler-Kühlgerät ist während des Abkühlvorgangs

geöffnet.

Weist der Befeuchter kein Abwasserkühlgerät auf, den Tank zuerst abkühlen lassen, bevor das Ablaufventil geöffnet wird.

Teile für diesen Wartungssatz passen zu Befeuchtern STS03 bzw. LTS03 (Februar 2003 bis heute). Für Teileliste siehe Seite 2.

ACHTUNG

Page 14

STS/LTS, entsalztes Wasser, Wartungssatz-Teile

STS03 / LTS03, entsalztes Wasser, 25

Wartungssatz-Nr. 900100-701

Nr. Benennung Teile-Nr. Menge

1 Silikon, klar (nicht dargestellt) 320000 1

2 Sitz, schwarz EPDM (siehe Einzelheit

Füllventil)

3 Dichtung, Abdeckung Sonde 308416-001 1

4 Dichtung Abdeckung Reinigungsöffnung 308015-001 1

5 Dichtung Abdeckung 160692-001 1

6 Dichtung Wärmetauscher, vorne 308220 2

7 Scheibe, flach 10-32 700300-008 8

8 Mutter, 10-32, mit Nyloneinsatz 700252-003 8

9 Mutter, 14-20, mit Nyloneinsatz 700300-016 16

STS03, entsalztes Wasser, 50

Wartungssatz-Nr. 900100-702

Nr. Benennung Teile-Nr. Menge

1 Silikon, klar (nicht dargestellt) 320000 1

2 Sitz, schwarz EPDM (siehe Einzelheit

Füllventil)

3 Dichtung, Abdeckung Sonde 308416-001 1

4 Dichtung Abdeckung Reinigungsöffnung 308015-002 1

5 Dichtung Abdeckung 160692-002 1

6 Dichtung Wärmetauscher, vorne 308220 2

7 Scheibe, flach 10-32 700300-008 8

8 Mutter, 10-32, mit Nyloneinsatz 700252-003 8

9 Mutter, 14-20, mit Nyloneinsatz 700300-016 16

505210-003 1

505210-003 1

STS03, entsalztes Wasser, 200/400

Wartungssatz-Nr. 900100-704

Nr. Benennung Teile-Nr. Menge

1 Silikon, klar (nicht dargestellt) 320000 1

2 Sitz, schwarz EPDM (siehe Einzelheit

Füllventil)

3 Dichtung, Abdeckung Sonde 308416-001 1

4 Dichtung Abdeckung Reinigungsöffnung 308015-003 1

5 Dichtung Abdeckung 160692-004 1

6 Dichtung Wärmetauscher, vorne 308220 2

7 Scheibe, flach 10-32 700300-008 8

8 Mutter, 10-32, mit Nyloneinsatz 700252-003 8

9 Mutter, 14-20, mit Nyloneinsatz 700300-016 16

STS03, entsalztes Wasser, 800 und LTS03, entsalztes Wasser, 400

Wartungssatz-Nr. 900100-705

Nr. Benennung Teile-Nr. Menge

1 Silikon, klar (nicht dargestellt) 320000 1

2 Sitz, schwarz EPDM (siehe Einzelheit

Füllventil)

3 Dichtung, Abdeckung Sonde 308416-001 1

4 Dichtung Abdeckung Reinigungsöffnung 308015-003 1

5 Dichtung Abdeckung 160692-004 1

6 Dichtung Wärmetauscher, vorne 308220 4

7 Scheibe, flach 10-32 700300-008 16

8 Mutter, 10-32, mit Nyloneinsatz 700252-003 16

9 Mutter, 14-20, mit Nyloneinsatz 700300-016 32

505210-003 1

505210-003 1

STS03 / LTS03, entsalztes Wasser, 100

Wartungssatz-Nr. 900100-703

Nr. Benennung Teile-Nr. Menge

1 Silikon, klar (nicht dargestellt) 320000 1

2 Sitz, schwarz EPDM (siehe Einzelheit

Füllventil)

3 Dichtung, Abdeckung Sonde 308416-001 1

4 Dichtung Abdeckung Reinigungsöffnung 308015-002 1

5 Dichtung Abdeckung 160692-003 1

6 Dichtung Wärmetauscher, vorne 308220 2

7 Scheibe, flach 10-32 700300-008 8

8 Mutter, 10-32, mit Nyloneinsatz 700252-003 8

9 Mutter, 14-20, mit Nyloneinsatz 700300-016 16

Seite 14 • DRI-STEEM STS/LTS, entsalztes Wasser, Anleitung für Wartungssatz

505210-003 1

Page 15

STS/LTS, entsalztes Wasser, Wartungssatz-Teile

Dieser Wartungssatz enthält Ersatzteile gemäß den Angaben

der Teilezeichnung für einen optimalen Betrieb Ihres

DRI‑STEEM Befeuchters. Die vorliegende Anleitung enthält

wichtige Sicherheits‑ und Wartungsanweisungen und ist kein

Ersatz für die mit dem Befeuchter gelieferte Installations‑ und

Bedienungsanleitung. Bitte lesen Sie alle Warnhinweise und

Arbeitsanweisungen auf Seite 1.

Bei der Durchführung von Wartungsarbeiten die alten Teile mit

den neuen Teilen aus diesem Wartungssatz ersetzen.

STS-Wärmetauscher

Schwimmerventil

Stützscheibe zuerst auf

Hebel montieren und

dann Sitz (2).

Splint einfügen

2

Hebel

Ventil

OM-863-1

LTS-Wärmetauscher

Anmerkungen:

• Es werden Befeuchter-Teile für

Normalwasser und entsalztes WasserModelle dargestellt.

• Komponenten können eine

unterschiedliche Ausrichtung erfordern,

wie dargestellt in der Zeichnung.

6

(kleine Löcher)

4

9

Anziehmoment 2,8 bis 4,0 Nm.

Klares

Silikon (1)

auf beiden

Seiten der

Dichtung

auftragen.

5

3

Siehe Einzelheit

Schwimmerventil.

7

8

LTS-OM-18X

OM-946X

DRI-STEEM STS/LTS, entsalztes Wasser, Anleitung für Wartungssatz • Seite 15

Page 16

STS/LTS, entsalztes Wasser, Wartungsanweisungen

3. Das bauseitig installierte manuelle Absperrventil in der

Befeuchter abkühlen

Bevor jeglichen Wartungsarbeiten zuerst den Tank abkühlen

lassen. Wärmegedämmte und nicht gedämmte Tanks weisen

heiße Oberflächen auf.

Anmerkung: Zur Abkühlung ist frisches Zusatzwasser

erforderlich. Daher den Wasserzulauf erst

sperren, nachdem der Befeuchter abgekühlt

wurde. Andernfalls bleibt der Tank noch für

mehrere Stunden heiß.

1. Das manuelle Absperrventil der Dampfzufuhr (STS‑

Befeuchter) bzw. der Fluidzufuhr (LTS‑Befeuchter)

schließen.

2. Den Tank entwässern:

Modelle mit Standard-Ablaufventil:

a. Das Ablaufventil von Hand öffnen. Das Füllventil öffnet

nachdem eine gewisse Menge Wasser aus dem Tank

abgelaufen ist.

b. Die Wasserzulaufleitung offen lassen, bis sich der

Tank ausreichend abgekühlt hat. Dann das bauseitig

installierte manuelle Absperrventil in der Zulaufleitung

schließen.

c. Den Tank entwässern lassen und danach das

Ablaufventil von Hand schließen.

Für Modelle mit der Option Entwässern am Ende der

Saison (muss ein Vapor‑logic3 Steuergerät aufweisen), mit

Hilfe des Steuergeräts den Abkühlprozess durchführen.

Siehe Vapor-logic3 Installations- und Bedienungsanleitung für

weitere Informationen:

a. Am Steuergerät Steuermodus und Manuell Ablassen

wählen.

b Warten bis der Tank ungefähr zur Hälfte leer ist.

c. Dann am Steuergerät Steuermodus Auto wählen. Nun

öffnet das Füllventil und der Befeuchter kühlt ab.

d. Wenn das Füllventil schließt im Steuermodus wieder

Manuell Ablassen wählen und den Tank komplett

entwässern. Der Befeuchter sollte nun ausreichend

abgekühlt sein um daran zu arbeiten.

Befeuchter abschalten

Die nachfolgenden Anweisungen beachten bevor jegliche

Wartungsarbeiten ausgeführt werden (Nachdem der Tank

abgekühlt hat und entwässert ist):

1. Mit Hilfe des Vapor‑logic3 Steuergeräts den Befeuchter in

Modus Standby schalten.

2. Die komplette Stromzufuhr zum Befeuchter mit Hilfe des

bauseitigen Sicherungs‑Trennschalter sperren und alle

Stromtrennschalter in Position AUS sperren.

Wasser‑Zulaufleitung schließen.

4. Das manuelle Absperrventil der Dampfzufuhr (STS‑

Befeuchter) bzw. der Fluidzufuhr (LTS‑Befeuchter)

schließen.

Inspektion und Wartung

Jährlich (sowie nach Wartungsarbeiten)

1. Alle Sicherheitsgeräte im Steuerkreis sollten Ein/Aus

getaktet werden um deren ordnungsgemäße Funktion zu

prüfen. Diese umfassen:

• Maximal‑Grenzwertschalter

• Luftströmungsschalter

2. Tank und Dichtungen auf Undichtheiten überprüfen.

3. Sicherstellen das Schwimmerventil schließt. Ist dies nicht

der Fall können die Ursache Verunreinigungen im Ventilsitz

oder ein abgenutzter Stopfen sein, der ausgetauscht werden

muss.

Solange entsalztes Wasser mit dem Befeuchter zum Einsatz

kommt ist keine Reinigung oder Spülung erforderlich.

Wartung außerhalb der Saison

1. Eine komplette Inspektion und Reinigung folgender Teile

durchführen:

• Wärmetauscher

• Schwimmerventil

• Befeuchtertank und Dichtungen

2. Nach erfolgter Inspektion sollte der Befeuchter leer bleiben,

bis eine Befeuchtung erforderlich wird.

Nach der Befeuchtungssaison empfiehlt DRI‑STEEM eine

komplette Inspektion und Reinigung des Wärmetauschers und

Wasserkammer. Nach erfolgter Reinigung sollte der Befeuchter

leer bleiben, bis eine Befeuchtung erforderlich wird.

Bei Befeuchtern, welche teflonbeschichtete Wärmetauscher

aufweisen, keine scharfen Werkzeuge zur Reinigung

verwenden. Schnitte oder Beschädigungen an der Schichtung

verhindern ein Abblättern des Kesselsteins während dem

Betrieb und das Teflon kann sich aufgrund von Beschädigungen

von der Metalloberfläche lösen.

Seite 16 • DRI-STEEM STS/LTS, entsalztes Wasser, Anleitung für Wartungssatz

Page 17

STS/LTS, entsalztes Wasser, Wartungsanweisungen

Anforderungen für entsalztes Wasser

• Regelmäßig die ordnungsgemäße Funktion des

Wasseraufbereitungssystems prüfen. Chlor in unsachgemäß

aufbereitetem Wasser führt zur Korrosionsschäden und

einem Versagen des Befeuchtertanks. Schäden aufgrund

von Chloridkorrosion werden nicht von der DRI‑STEEM

Gewährleistung abgedeckt.

• DI‑Modelle erfordern keine regelmäßige Reinigung sollten

aber regelmäßig auf einen ordnungsgemäßen Betrieb

überprüft werden.

• DI‑Modelle erfordern keinen Überlauf oder regelmäßiges

Entwässern oder Spülen um Salzablagerungen zu

entfernen. Alle DI‑Befeuchter sollten am Ende der Saison

entwässert werden, entweder durch manuelles Öffnen des

Ablaufventils oder durch Programmierung des Befeuchters

eine automatische Entwässerung am Ende der Saison

durchzuführen (erfordert ein elektrisches Ablaufventil und

Vapor‑logic3 Steuergerät).

Anmerkung: Obwohl die DI‑Modelle keine regelmäßige

Tankreinigung erfordern umfasst der

Wartungssatz eine Dichtung für die

Reinigungsöffnung und Muttern. Wird die

Dichtung ausgetauscht auch die Muttern

ersetzen und mit einem Anziehmoment von

2,8 bis 4,0 Nm festziehen.

Inbetriebnahme

Zuerst die jährlichen Sicherheitsprüfungen in Abschnitt

Inspektion und Wartung auf Seite 4 durchführen.

Nach erfolgter Wartung muss der Befeuchter über mehrere

Fülltakte überwacht werden, um sicherzustellen, alle

gewarteten Teile funktionieren ordnungsgemäß. Siehe auch

Abschnitt Inbetriebnahme in der Befeuchter‑Installations‑ und

Bedienungsanleitung.

DRI-STEEM STS/LTS, entsalztes Wasser, Anleitung für Wartungssatz • Seite 17

Page 18

DRI-STEEM Corporation

Zertifiziert gemäß ISO 9001: 2000

Europaniederlassung:

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgien

+3211823595 (voice)

+3211817948 (fax)

E-mail: marc.briers@dristeem.com

US-Hauptsitz:

14949 Technology Drive

Eden Prairie, MN 55344

+1 800-328-4447 oder +1 952-949-2415

+1 952-229-3200 (Fax)

DRI-STEEM Corporation praktiziert eine fortwährende

Produktentwicklung; deshalb behalten wir uns

Produktänderungen ohne Vorankündigung vor.

DRI-STEEM, LTS, STS, und Vapor-logic sind

eingetragene Warenzeichen von DRI-STEEM

Corporation und als eingetragene Warenzeichen in

Kanada und der EU beantragt.

Drane-kooler ist ein Warenzeichen von DRI-STEEM

Corporation.

© 2013 DRI-STEEM Corporation

Form-Nr. STS/LTS-DI-SKM-G-1013

Teile-Nr. 891000-502 Rev D

Seite 18 • DRI-STEEM STS/LTS, entsalztes Wasser, Anleitung für Wartungssatz

DRI-STEEM Produkte sind garantiert für einen Zeitraum von zwei Jahren ab dem Kaufdatum

entsprechend den Konditionen der zweijährigen begrenzten Gewährleistung. Siehe mit dem

Befeuchter gelieferte Literatur für Einzelheiten zur Gewährleistung.

Loading...

Loading...