Page 1

READ AND SAVE THESE INSTRUCTIONS

®

STS

Steam-to-Steam Humidifier

Installation, Operation,

and Maintenance Manual

Page 2

WARNINGS AND CAUTIONS

Warnings and cautions

WARNING

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

CAUTION

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

WARNING

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualified

HVAC and electrical contractors and in compliance with local, state, federal, and governing codes. Improper installation

can cause property damage, severe personal injury, or death as a result of electric shock, burns, or fire.

DriSteem

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all

warnings and instructions could produce the hazardous situations described, resulting in property damage, personal injury,

or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause bacteria and mold

growth or dripping water into building spaces. Dripping water can cause property damage; bacteria and mold growth can

cause illness.

mc_011909_1215

®

technical support: 800-328-4447

Hot surfaces and hot water

This steam humidification system has extremely hot surfaces. Water in tank, steam pipes, and dispersion assemblies can

be as hot as 212 °F (100 °C). Discharged steam is not visible. Contact with hot surfaces, discharged hot water, or air

into which steam has been discharged can cause severe personal injury. To avoid severe burns, follow the cool-down

procedure in this manual before performing service or maintenance procedures on any part of the system.

mc_011909_1130

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii

Page 3

Warnings and cautions

WARNING

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any

part of the humidification system. Failure to disconnect electrical power could result in fire, electrical shock, and other

hazardous conditions. These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock

or fire. Do not open control cabinet door or remove subpanel access panels until electrical power is disconnected.

Follow the shutdown procedure below before performing service or maintenance procedures on any part of the system.

Shutdown procedure

To prevent serious injury, follow this shutdown procedure before performing service or maintenance procedures on this

humidifier, after the tank has cooled down and drained.

1. Follow the “Cool down humidifier” instructions on Page 50 (tap/softened water STS) or Page 53

(STS with RO/DI water option) to put the humidifier at a safe temperature for service.

2. Use the Vapor-logic

3. Place all power disconnects in OFF position and lock in OFF position.

4. Close the field-installed manual water supply shut-off valve.

5. Close the manual shut-off valve on the inlet steam supply.

®

keypad/display to change control mode to Standby.

CAUTION

Hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage the drain plumbing.

Humidifiers equipped with a water tempering device need fresh make-up water in order to function properly. Make sure the water

supply to the water tempering device remains open during draining.

If the humidifier is not equipped with a water tempering device, allow the tank to cool before opening the drain valve.

Excessive supply water pressure

Supply water pressure greater than 80 psi (550 kPa) can cause the humidifier to overflow.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

Page 4

Table of contents

1

WARNINGS AND CAUTIONS ...................................................ii

OVERVIEW.................................................................2

Product overview ........................................2

Tap/softened water ....................................2

RO/DI water option ...................................2

Water type conversion .................................2

Dimensions ............................................4

Capacities, electrical specifications, and weights ..................6

INSTALLATION ..............................................................7

Selecting a location ......................................7

Mounting methods .......................................8

Mounting the humidifier ...................................9

Support legs ........................................9

Wall brackets ........................................9

H-legs .............................................9

Trapeze hanger ......................................9

Weather cover .........................................10

Outdoor Enclosure ......................................12

Electrical specifications .................................13

Mounting ..........................................15

STS Outdoor Enclosure sequence of operation ................17

Alternate water seal and drain valve piping ..................18

Piping: ...............................................18

Drain ............................................18

Fill ...............................................20

Tap/softened water, one heat exchanger ...................22

Tap/softened water, two heat exchangers ...................23

RO/DI water option, one heat exchanger ...................24

RO/DI water option, two heat exchangers ..................25

Pressurized steam supply ...............................26

Humidification steam outlet .............................27

Wiring ..............................................28

Wiring diagram locations ..............................28

Electrical installation ..................................28

Wiring requirements ..................................28

Control wiring ......................................29

Grounding requirements ................................29

Sensor placement .......................................30

Dispersion: ............................................31

Selecting the dispersion assembly location ..................31

Interconnecting piping requirements .......................32

Drip tee installation ...................................34

Single tube and multiple tube ............................35

Rapid-sorb .........................................40

Ultra-sorb ..........................................46

Attention installer

Read this manual before installing.

Leave manual with product owner.

Where to find more information

Our web site:

The following documents are available on our

web site: www.dristeem.com

• Catalogs

– STS

– Ultra-sorb

• Installation, Operation, and Maintenance

manuals (IOM)

– Ultra-sorb Models LV and LH

– Ultra-sorb Model XV

– Vapor-logic controller (includes humidifier

operation and troubleshooting)

• DriSteem Humidification System Design

Guide (includes steam loss tables and

general humidification information)

DriCalc®:

DriCalc, our software for humidification system

sizing and selection, can be ordered at our

web site. Also in Dri-calc:

• Library of installation guides

• Dispersion and sensor placement in ducts

and air handlers

• Vertical airflows

Call us at 800-328-4447

Obtaining documents from our web site or

from DriCalc is the quickest way to view our

literature, or we will be happy to mail literature

to you.

®

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv

Page 5

Table of contents

OPERATION ..............................................................47

Start-up procedure ......................................47

Start-up checklist ........................................48

MAINTENANCE ........................................................... 49

Water quality .........................................49

Tap/softened water ......................................50

RO/DI water option .....................................53

Outdoor enclosure ......................................55

REPLACEMENT PARTS ...................................................... 56

Humidifier tank ........................................56

Control cabinet ........................................58

Outdoor enclosure ......................................59

WARRANTY .............................................................. 60

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

Page 6

OVERVIEW

Product overview

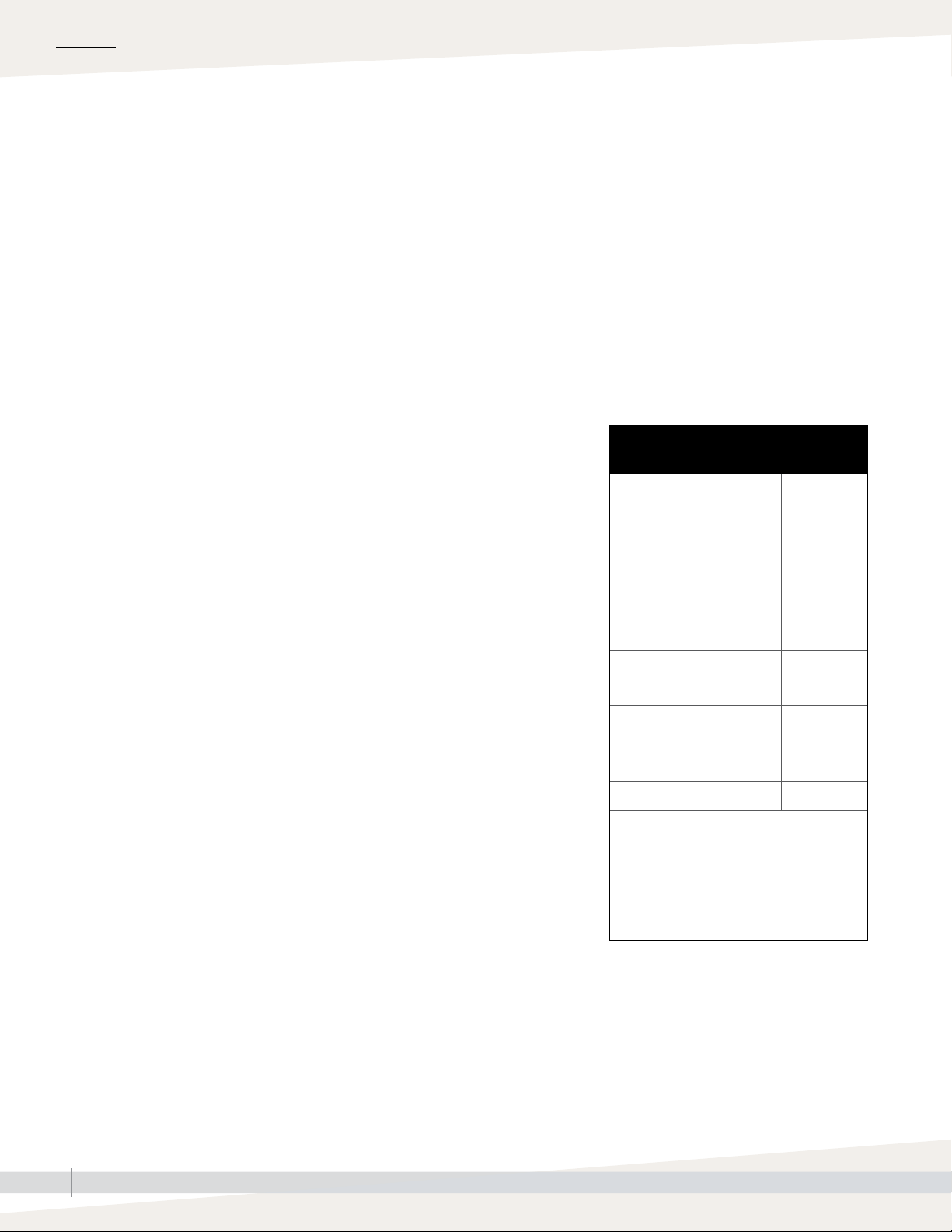

STS (steam-to-steam) humidifiers use pressurized boiler steam to heat clean fill

water into chemical-free steam for humidification. See Figure 3-1.

STS humidifiers are designed for use with tap/softened water and are

available with an option for RO/DI water (water that has been treated using

reverse osmosis, or deionized water).

TAP/SOFTENED WATER

A conductivity probe (Figure 3-2) monitors the water level in the tap/softened

water STS humidifier; therefore, water conductivity must be at least 30 µS/

cm for proper operation. A tap/softened water STS humidifier will not operate

with RO/DI water. For RO/DI water, use STS with the RO/DI water option.

RO/DI WATER OPTION

STS humidifiers with the RO/DI water option control water level with a float

valve (Figure 3-3). Float valves are compatible with RO/DI water only.

Humidifiers with the RO/DI water option are virtually maintenance free and

require little or no downtime.

WATER TYPE CONVERSION

STS tap/softened water humidifiers can be converted in the field for use with

RO/DI water, and STS RO/DI water humidifiers can be converted in the field

for use with tap/softened water. Contact your DriSteem representative or

distributor for parts and instructions.

Supply water guidelines

Supply water quality is an important component

of humidifier reliability and maintenance.

Examples:

• Corrosive water can decrease the service

life of the humidifier.

• Excessive water hardness can increase the

humidifier maintenance requirements.

To maximize humidifier service life and

minimize humidifier maintenance, DriSteem

has established guidelines for supply water

See Table 2-1.

mc_071912_1545

Table 2-1:

DriSteem supply water guidelines

Chlorides*

RO or DI water

Softened water

Tap water

* Damage caused by

chloride corrosion is

not covered by your

DriSteem warranty.

Total hardness

Tap water < 500 ppm

< 5 ppm

< 25 ppm

< 50 ppm

pH

RO, DI, or softened water

Tap water

Silica < 15 ppm

You may wish to take action to mitigate

potential negative effects to your

humidifier. Supply water outside of these

guidelines may void your DriSteem

warranty. Please contact your DriSteem

Representative or DriSteem Technical

Support if you need advice.

7 to 8

6.5 to 8.5

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

Page 7

Product overview

OVERVIEW

FIGURE 3-1: STS HUMIDIFIERS

Notes:

• Drain piping material must be suitable for 212 °F (100 °C) water.

• See the piping drawings on Pages 22 through 25.

Tap/softened water STS humidifier

Humidification steam outlet

Probe water level control

Automatic steam valve

Boiler steam

Steam trap

Condensate return

Water seal

Air gap

Open drain

Manual drain or optional

motorized drain valve

STS humidifier with the RO/DI water option

Humidification steam outlet

Float valve water level control

OM-938

Heat exchanger

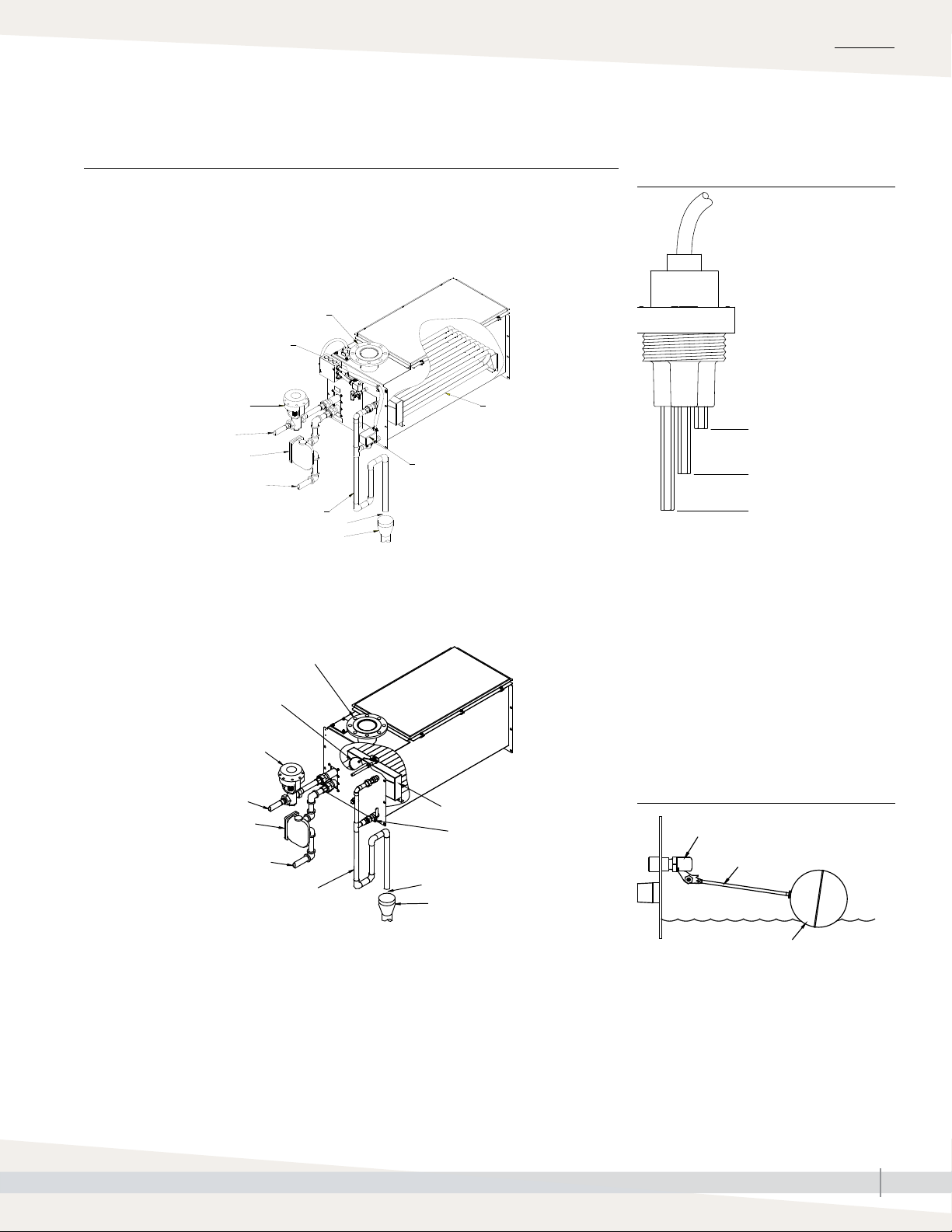

FIGURE 3-2: WATER LEVEL CONTROL

FOR TAP/SOFTENED WATER HUMIDIFIER

Fill valve closes when

water level rises to this

probe.

Fill valve opens when

water level is below this

probe.

Low-water cutoff.

Pressurized steam to

heat exchanger is cut if

water level drops below

this probe (if steam to

STS heat exchanger

is controlled by

Vapor-logic).

Humidifiers using tap or softened water control

water levels electronically using a three-rod

probe. The controller responds with the above

actions when the water level reaches each rod.

VLC-OM-030

Automatic steam valve

Boiler steam

Steam trap

Condensate return

Water seal

Heat exchanger

Manual drain valve

Air gap

Open drain

OM-939

FIGURE 3-3: WATER LEVEL CONTROL

FOR RO/DI-WATER OPTION HUMIDIFIER

Fill valve

Float rod

VLC-OM-026

Humidifiers using RO/DI water control water

level using a float valve. An optional low-water

cutoff switch is available as a remote water

indicator.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Float ball

3

Page 8

OVERVIEW

Dimensions

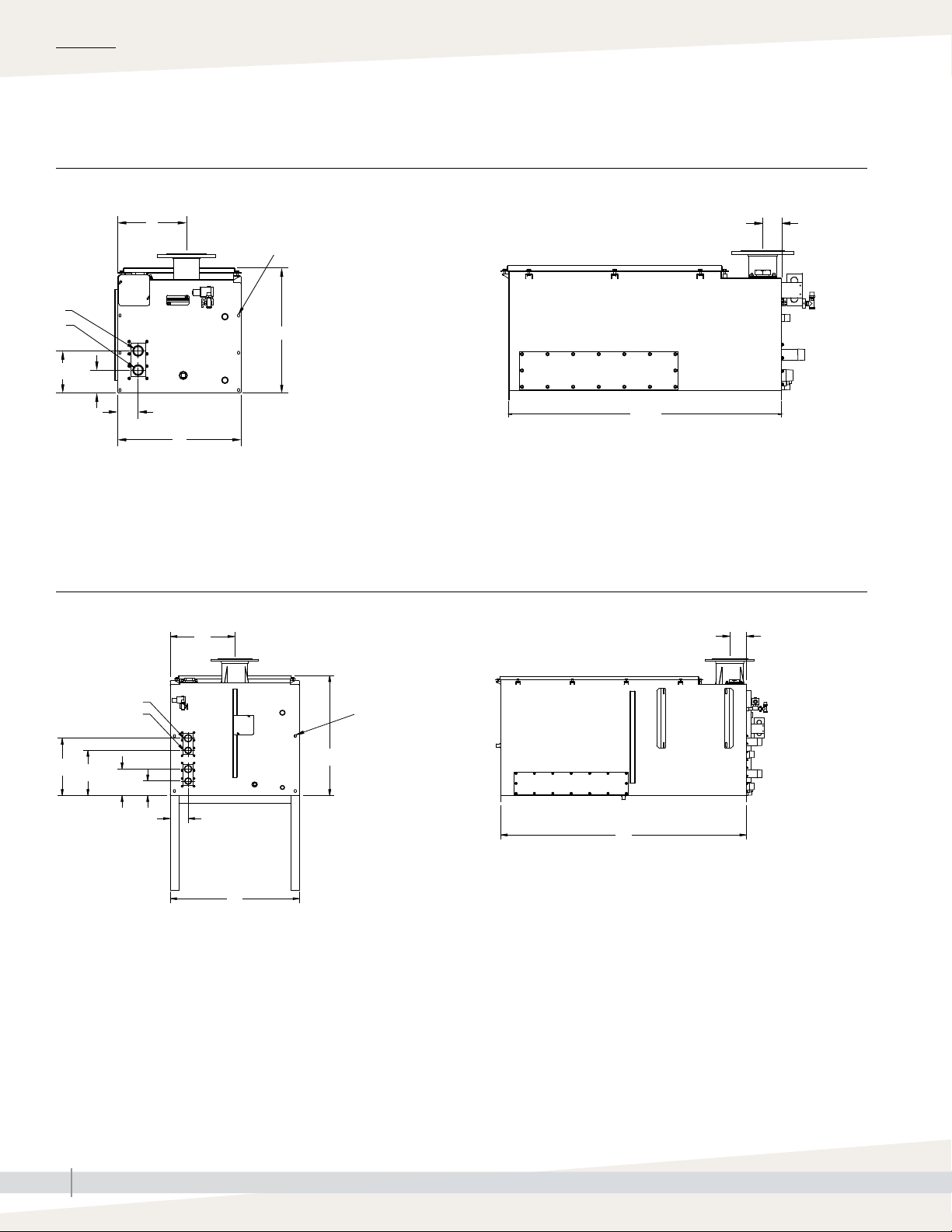

FIGURE 4-1: DIMENSIONS, STS MODELS 25, 50, 100, 200, AND 400 (WITH COPPER OR STAINLESS STEEL HEAT EXCHANGERS)

Front view Side view

L

J

K

D

E

Mounting holes:

Models 25–100: 5/16" (8 mm) slot

Models 200 & 400: 1/2" (12 mm) slot

A

M

H

B

Notes:

• Tap/softened water model shown

• See dimensions in Tables 5-1 and 5-2

FIGURE 4-2: DIMENSIONS, STS MODEL 800 (WITH COPPER OR STAINLESS STEEL HEAT EXCHANGERS)

Front view

J

K

F

G

D

E

OM-931

Side view

L

Mounting hole:

1/2" dia.

(12 mm) slot

A

H

C

C

OM-932

M

B

Notes:

• Tap/softened water model shown

• See dimensions in Tables 5-1 and 5-2

OM-936

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

Page 9

OVERVIEW

Dimensions

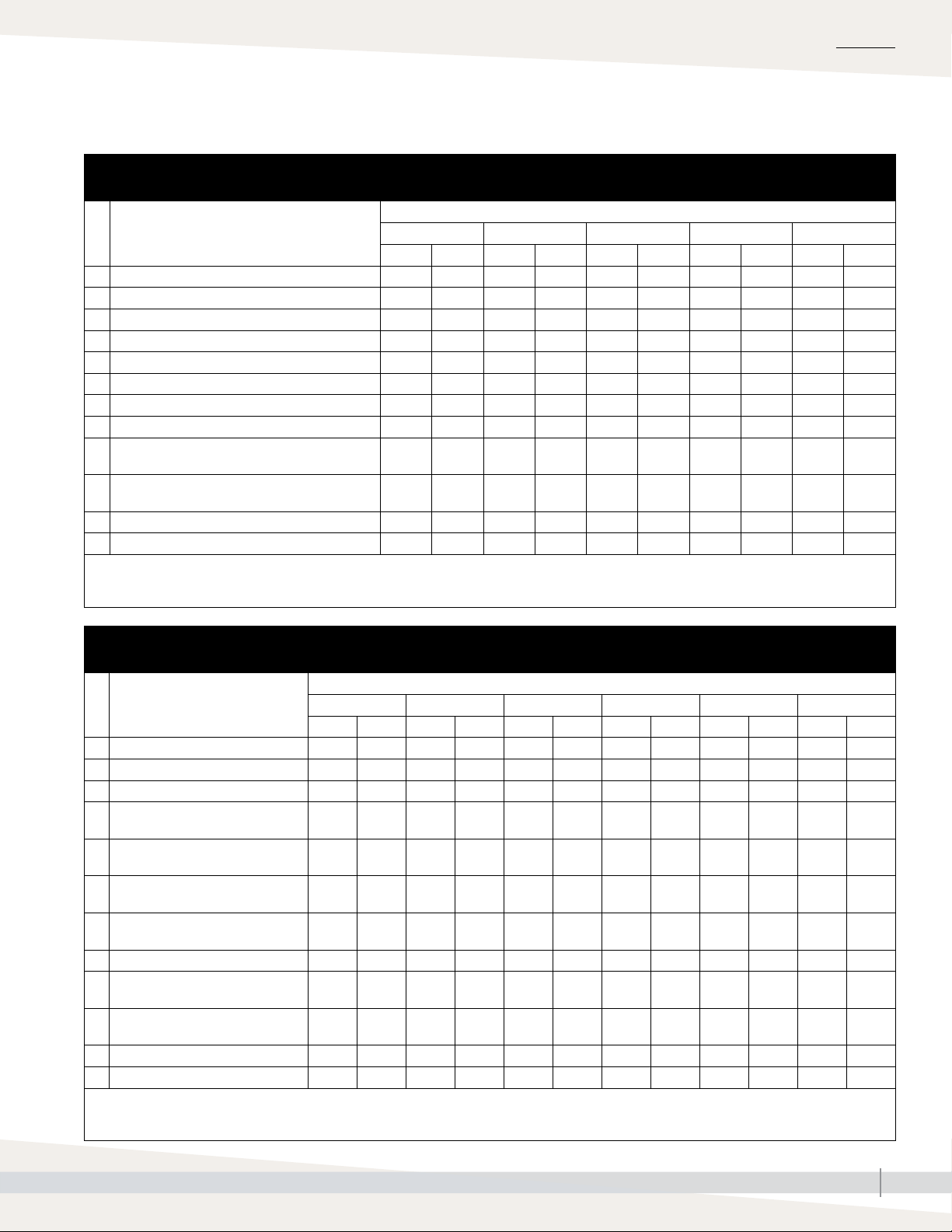

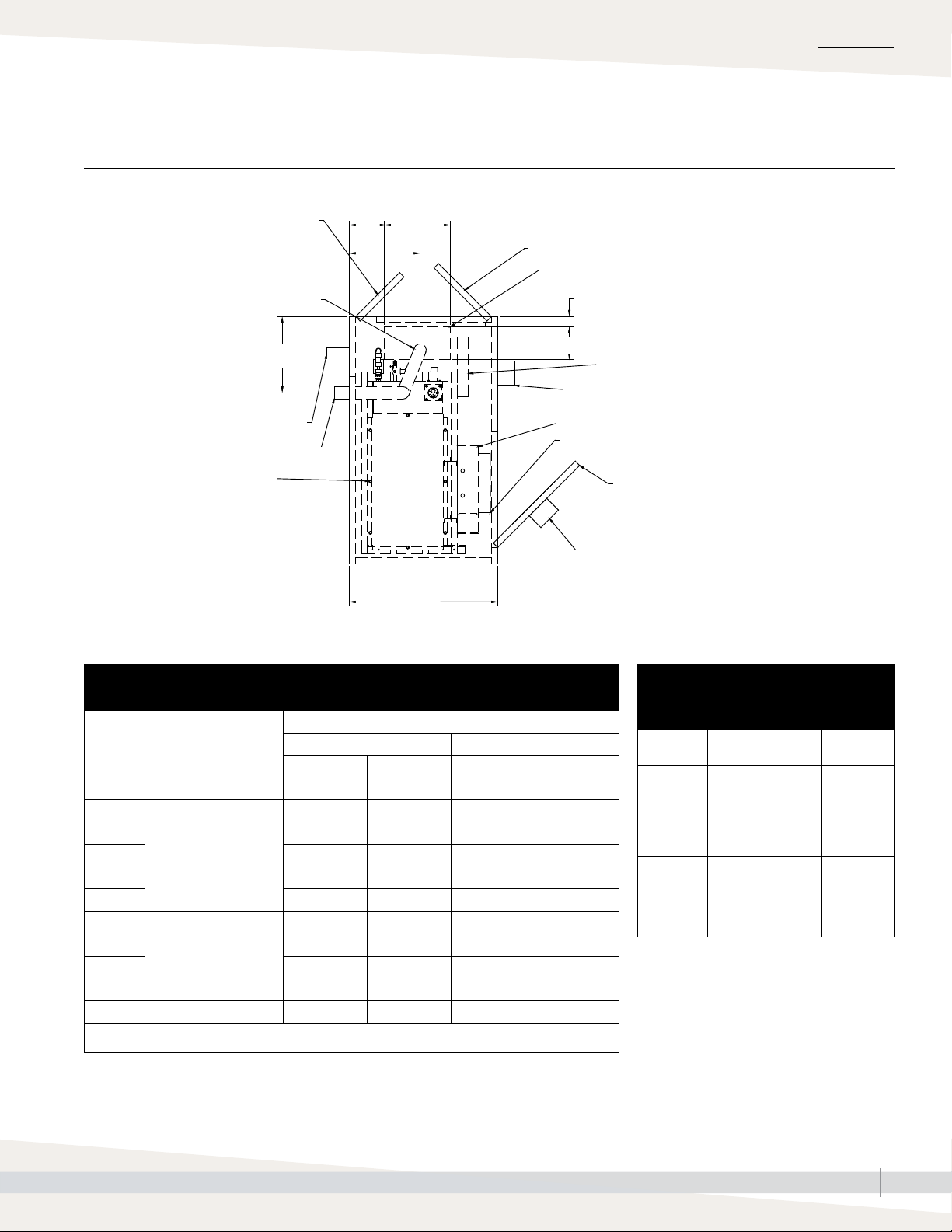

Table 5-1:

Dimensions, STS with copper heat exchangers

See drawings in Figures 4-1 and 4-2

Description

A Height** 19.50 495 19.50 495 19.50 495 19.50 495 29.75 756

B Width 14.75 375 14.75 375 19.25 489 30.25 768 30.25 768

C Length 23.65 600 39.65 1007 39.65 1007 55.15 1401 55.15 1401

D Bottom to supply inlet of first heat exchanger 6.63 168 6.63 168 6.63 168 6.63 168 6.63 168

E Bottom to return outlet of first heat exchanger 3.63 92 3.63 92 3.63 92 3.63 92 3.63 92

F Bottom to supply inlet of second heat exchanger — — — — — — — — 14.28 363

G Bottom to return outlet of second heat exchanger — — — — — — — — 11.24 285

H Side to heat exchanger 3.25 83 3.25 83 3.25 83 3.25 83 3.25 83

J Pressurized steam supply inlet

K Pressurized condensate return outlet

L Side to steam outlet 6.25 159 8.63 219 9.63 245 13.00 330 13.00 330

M Front to steam outlet 2.50 64 2.25 57 2.75 70 3.75 95 3.75 95

* C, S, and SNC in model numbers are explained in Table 6-1.

** Add 23.5" (597 mm) to overall height when STS is mounted on four support legs. Add 22.5" (572 mm) to overall height when STS is mounted

on two H-legs.

25C 50C 100C 400C 800C

inches mm inches mm inches mm inches mm inches mm

3/4" p ip e

thread

3/4" p ip e

thread

DN20

DN20

1¼" pipe

thread

3/4" p ip e

thread

DN32

DN20

STS model*

1¼" pipe

thread

1¼" pipe

thread

DN32

DN32

1½" pipe

thread

1¼" pipe

thread

DN40

DN32

1½" pipe

thread

1¼" pipe

thread

DN40

DN32

Table 5-2:

Dimensions, STS with stainless steel heat exchangers

See drawings in Figures 4-1 and

A Height** 19.50 495 19.50 495 19.50 495 19.50 495 19.50 495 29.75 756

B Width 14.75 375 14.75 375 19.25 489 30.25 768 30.25 768 30.25 768

C Length 23.65 600 39.65 1007 39.65 1007 55.15 1401 55.15 1401 55.15 1401

Bottom to supply inlet of first heat

D

exchanger

Bottom to return outlet of first heat

E

exchanger

Bottom to supply inlet of second

F

heat exchanger

Bottom to return outlet of second

G

heat exchanger

H Side to heat exchanger 3.25 83 3.25 83 3.25 83 3.25 83 3.25 83 3.25 83

J Pressurized steam supply inlet

K Pressurized condensate return outlet

L Side to steam outlet 6.25 159 8.63 219 9.63 245 13.00 330 13.00 330 13.00 330

M Front to steam outlet 2.50 64 2.25 57 2.75 70 3.75 95 3.75 95 3.75 95

* C, S, and SNC in model numbers are explained in Table 6-1.

** Add 23.5" (597 mm) to overall height when STS is mounted on four support legs. Add 22.5" (572 mm) to overall height when STS is mounted

on two H-legs.

Description

4-2

25S 50S 100S 200S 400SNC 800SNC

inches mm inches mm inches mm inches mm inches mm inches mm

6.85 174 6.85 174 6.85 174 6.85 174 6.85 174 6.85 174

3.35 85 3.35 85 3.35 85 3.35 85 3.35 85 3.35 85

— — — — — — — — — — 14.5 368

— — — — — — — — — — 11.0 279

3/4" pi pe

thread

3/4" pi pe

thread

DN20

DN20

1" pipe

thread

3/4" pi pe

thread

DN25

DN20

1" pipe

thread

3/4" pi pe

thread

STS model*

DN25

DN20

1½" pipe

thread

3/4" pi pe

thread

DN40

DN20

1½" pipe

thread

3/4" pi pe

thread

DN40

DN20

1½" pipe

thread

3/4" pi pe

thread

DN40

DN20

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

Page 10

OVERVIEW

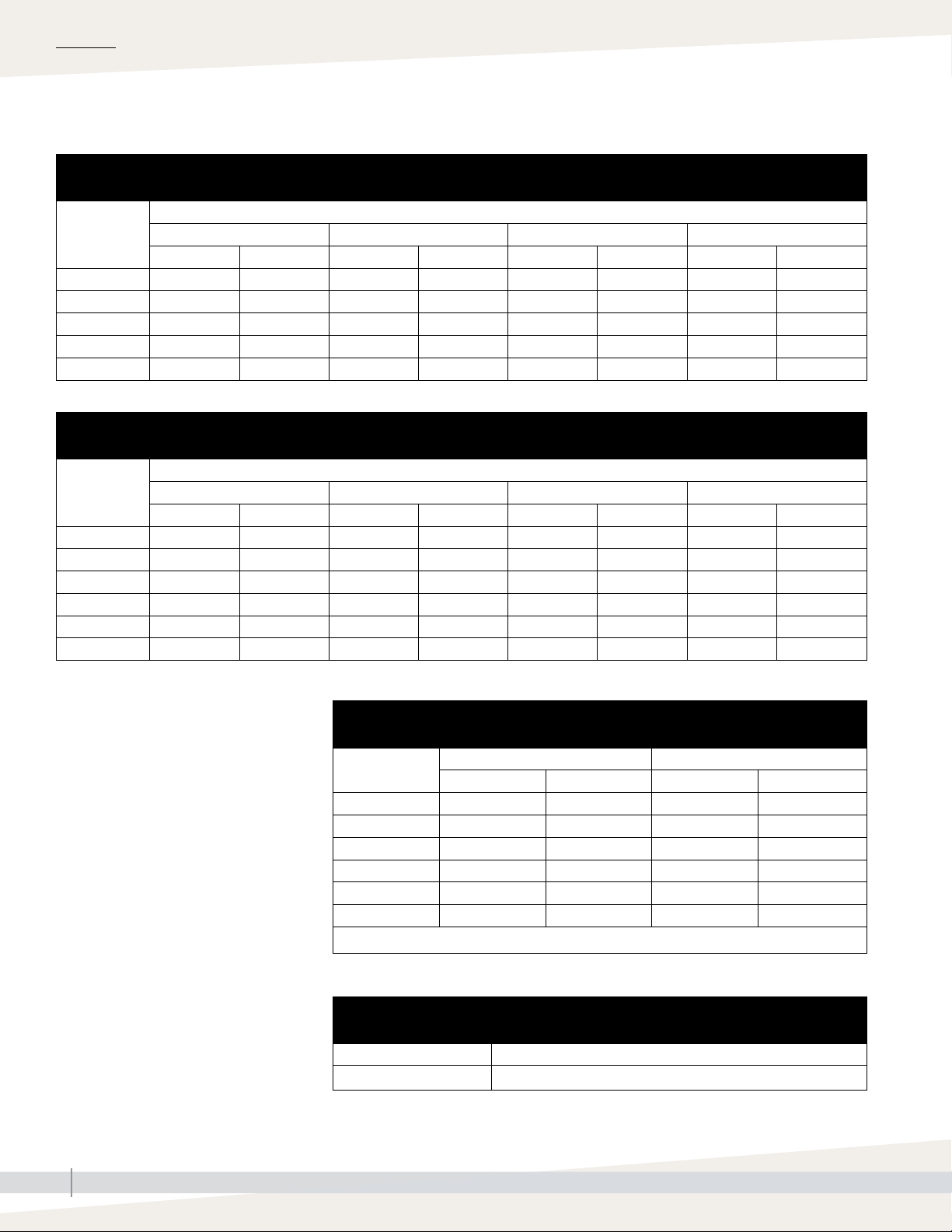

Capacities, electrical specifications, and weights

Table 6-1:

STS humidifier models and capacities with copper heat exchangers

Steam pressure at connection to STS steam valve (valve provided by DriSteem)

STS models

25C 20 9 70 32 100 45 120 54

50C 50 23 150 68 200 91 240 109

100C 100 45 300 136 400 181 480 218

400C 300 136 580 263 720 327 790 358

800C 650 295 1275 578 1500 680 1600 726

Table 6-2:

STS humidifier models and capacities with stainless steel heat exchangers

STS models

25S 10 5 25 11 30 14 35 16

50S 30 14 55 25 75 34 80 36

100S 60 27 110 50 140 64 150 68

200S 150 68 290 132 360 163 390 177

400SNC 170 77 392 178 552 250 637 289

800SNC 212 96 825 374 1095 497 1223 555

5 psi (34 kPa) 10 psi (69 kPa) 13 psi (90 kPa) 15 psi (103 kPa)

lbs/hr kg/h lbs/hr kg/h lbs/hr kg/h lbs/hr kg/h

Steam pressure at connection to STS steam valve (valve provided by DriSteem)

5 psi (34 kPa) 10 psi (69 kPa) 13 psi (90 kPa) 15 psi (103 kPa)

lbs/hr kg/h lbs/hr kg/h lbs/hr kg/h lbs/hr kg/h

For use with tap/softened or RO/DI water:

• STS models ending in C (copper heat

exchangers with a nickel coating)

• STS models ending in S (stainless steel heat

exchangers with a Teflon coating)

For use with RO/DI water option only:

STS models ending in SNC (stainless steel heat

exchangers with no coating)

Table 6-3:

STS humidifier weights

STS model

25 95 43 175 79

50 125 57 336 152

100 139 63 350 159

200 245 111 850 386

400 320 145 950 431

800 410 186 1450 658

* Operating weight does not include weight of interconnecting piping provided by installer.

Shipping weight Operating weight*

lbs kg lbs kg

Table 6-4:

STS humidifier electrical specifications

North America 120 V single phase max 3 amps

Europe 230 V single phase max 3 amps

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

Page 11

Selecting a location

When selecting the location of the humidifier, consider the following:

• Maximum ambient temperature for control cabinet is 104 °F (40 °C).

• Noises inherent to operation such as STS water fill cycles

• Easy access for maintenance

• Critical service and maintenance clearances around humidifier — primarily

top, left side, and front (see Figure 7-1).

• Convenient location to dispersion system for routing of steam hose or tubing

• Electrical connections — power, control, and safety circuits

• Steam supply piping connections — inlet steam piping, condensate piping,

and optional equipment (see Figure 26-1)

• Plumbing connections — supply water, drain piping, and condensate return

piping

• Water seal requirements

INSTALLATION

• Avoid locations above critical equipment or processes to avoid damage to

the equipment below in the event of a water leak.

• Avoid locations close to sources of electromagnetic emissions such as

power distribution transformers and high horsepower motors controlled by

variable frequency drives.

FIGURE 7-1: RECOMMENDED CLEARANCES

* Minimum access clearance of 18" (457 mm) recommended for periodic removal of top cover

for access to tank.

Left side:

36" (914 mm) with mounted control cabinet.

6"(152) without mounted control cabinet

Tap/softened water

model shown

Front: 36" (914 mm)

Top: 18" (457 mm)*

Rear: 6" (152 mm)

DC-1452

Right

side:

6" (152 mm)

Bottom:

24" (610 mm)

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

7

Page 12

INSTALLATION

Mounting methods

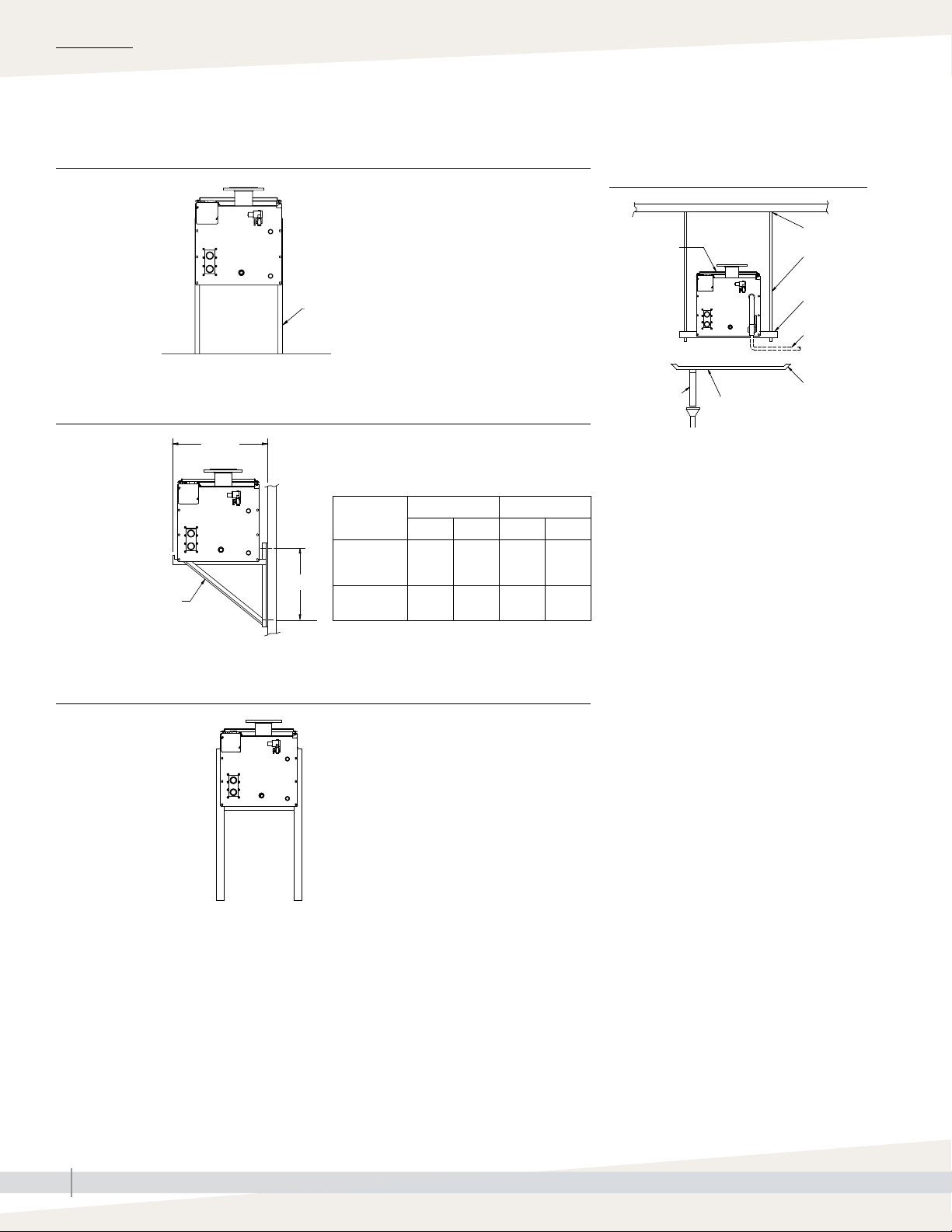

FIGURE 8-1: SUPPORT LEGS, STS MODELS 25, 50, AND 100 ONLY

Tap/softened water model shown

Optional set of four legs and hardware

OM-933

FIGURE 8-3: WALL BRACKETS, STS MODELS 25, 50, AND 100 ONLY

DC-1454

DriSteem optional wall

brackets (two required)

A

Tap/softened water model shown

STS model

25 and 50 15.5 394 24 610

B

100 21 533 30 762

A B

in. mm in. mm

FIGURE 8-2: TRAPEZE HANGER, STS

MODELS 25, 50, AND 100 ONLY

See Note 1

Provide 18"

(457 mm)

minimum

clearance

above cover

1¼" (DN32)

minimum

Tap/softened water model shown

Notes:

1. Secure rods to overhead construction.

2. 3/8" (M10) threaded rod of length required.

3. Angle or channel sized to properly support

humidifier.

4. Humidifier drain to appropriate building

waste. Do not drain humidifier directly into

drip pan. Install water seal as shown on

Pages 22 through 25.

5. Drip pan (by installer) recommended in

overhead installations to prevent possible

water damage to equipment below.

DC-1453

See Note 5

See Note 2

See Note 3

See Note 4

25%

larger than

humidifier

FIGURE 8-4: H-LEGS, STS MODELS 200, 400, AND 800 ONLY

Tap/softened water model shown

Due to size and weight, STS models

200, 400, and 800 must be mounted

on H-legs.

OM-947

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8

Page 13

Mounting the humidifier

INSTALLATION

The STS humidifier tank must be level from side to side and front to back. For

all mounting methods, shim and adjust when mounting, and verify that tank is

level after it is filled and at operating weight.

SUPPORT LEGS

See Figure 8-1. Use the enclosed bolts, nuts, and washers to fasten the

legs to the tank.

WALL BRACKETS

See Figure 8-3. DriSteem does not recommend mounting STS model 200,

400, or 800 with wall brackets. DriSteem recommends using 3/8" (M10)

fasteners.

• Concrete or block wall: Use concrete anchors (expansion bolts) rated for the

operating weight of the STS humidifier. Position the wall brackets so they

are flush with the front and back flanges of the tank.

• Wood stud wall: Mount two horizontal 2 × 4 boards

(100 mm × 50 mm timbers) 16" (404 mm) on center:

– STS 25: Lag bolt (coach screw) the 2 × 4s to two studs.

– STS 50: Lag bolt the 2 x 4s to three studs.

– STS 100: Lag bolt the 2 x 4s to four studs.

Lag bolt the wall brackets to the horizontal 2 × 4s. Position the wall brackets

flush with front and back flanges of tank.

Important:

Installation must comply with local governing

codes.

These mounting methods are the only options

available to maintain compliance to the UL

998 standard. Alternate mounting methods will

compromise the humidifier’s CE, ETL, and C-ETL

approval.

Support legs, trapeze hanger, and wall

brackets are not available for STS models 200,

400, and 800.

Table 9-1:

STS mounting options

Mounting

method

Trapeze hanger standard —

H-legs — standard

Support legs optional —

Wall brackets optional —

25, 50, 100 200, 400, 800

STS model

• Metal stud wall: Follow the wood stud wall guidelines above, but provide

a second set of 2 × 4s (100 mm × 50 mm timbers) on the backside of the

wall. Run bolts with washers through the face 2 × 4, through each metal

stud, and through the backside 2 × 4. Fasten the bolts and the face and

backside 2 x 4s to the wall with washers and nuts.

H-LEGS

See Figure 8-4. With the STS tank securely held in place above the floor,

attach front and rear supports using the supplied 3/8" (M10) bolts, nuts, and

washers. Make sure the bottom of the tank is supported by the H -leg supports;

this can be accomplished by having the bolts slightly loose as the unit is

lowered to the floor, then tighten them after the unit is place.

TRAPEZE HANGER

See Figure 8-2. Secure the threaded rods to an overhead structure strong

enough to support the operating weight of the humidifier, field-installed piping,

and (if mounted on the humidifier) control cabinet.

For overhead installations, install a drip pan to prevent possible damage to

equipment below in the event of a water leak.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

Page 14

INSTALLATION

Weather cover

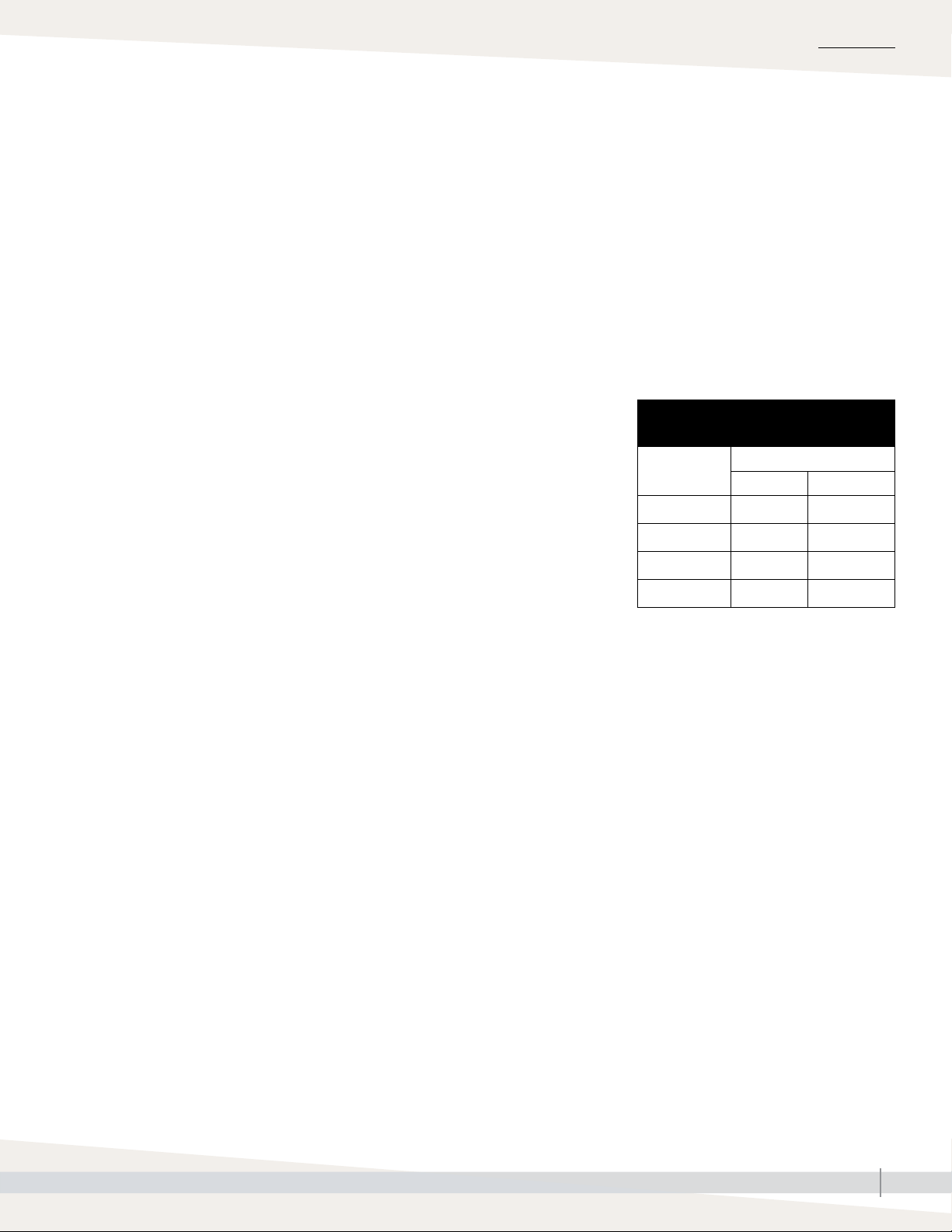

FIGURE 10-1: WEATHER COVER EXPLODED VIEW

Panel

Panel

Hinged door

FIGURE 10-2: WEATHER COVER DIMENSIONS

C

Panel

Panel

OM-7466

Hinged door

B

Table 10-1:

Weather cover weights

Weather cover size lbs kg

STS 25 to 100 425 193

STS 200 to 800 550 250

A

OM-7465

Table 10-2:

Weather cover dimensions

Letter Description

A Height 62 1575 66 1676

B Length 43.5 1105 53 1346

C Width 62 1575 78.25 1988

D Distance from bottom 22 559 22 559

STS 25 to 100 STS 200 to 800

inches mm inches mm

D

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

10

Page 15

Weather cover

The optional STS weather cover is water-resistant and designed to protect an

STS humidifier from rain and sun. This weather cover has been tested and

approved by ETL Testing Laboratories, Inc., and is listed to UL Standard 1995

and certified to CAN/CSA Standard C22.2 No. 236.

The weather cover is fully assembled at the DriSteem factory.

INSTALLATION NOTES

Open the hinged doors to make necessary connections to the humidifier. Refer

to the installation section of this manual for all electrical, supply water, and

drain connection requirements.

INSTALLATION ISSUES SPECIFIC TO WEATHER COVER APPLICATIONS

• Installation must comply with all governing codes.

• The bottom of the weather cover is open to accommodate piping and

electrical connections.

INSTALLATION

• Electrical connections must be made with approved, outdoor-rated,

watertight conduit.

• Freeze protection must be provided on all water piping.

• Steam supply must be insulated.

• Avoid using steam hose in outdoor applications — the effects of ultraviolet

rays will prematurely age the steam hose.

• Installer must drill a hole in weather cover for steam piping. Seal after

making steam connection to maintain weather protection.

• The steam outlet must be isolated with a union to allow easy disconnection

of the steam supply. This allows easy removal of the weather cover to

access the STS for service and maintenance.

ANNUAL WEATHER COVER MAINTENANCE REQUIREMENTS

• Check all fasteners and verify they are secure.

• Check for any sign of leakage — trace back to origin and repair.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

Page 16

INSTALLATION

Outdoor Enclosure

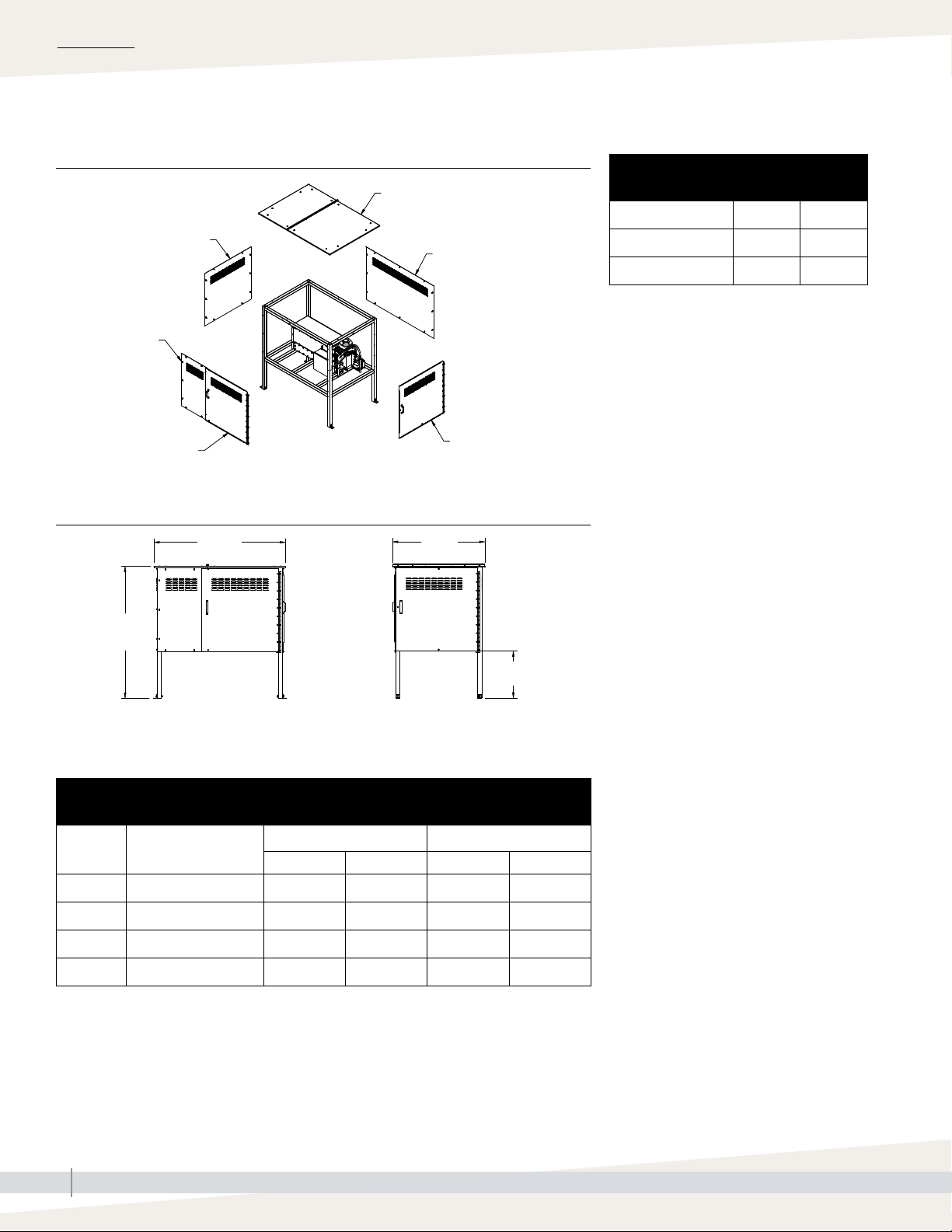

FIGURE 12-1: OUTDOOR ENCLOSURE WITH STANDARD OR OPTIONAL STEAM OUTLET, ELEVATION VIEW

Standard steam outlet

Ventilation fans

STS humidifier

Power block

See Note 2

Knockouts, 4" (102 mm) on center

Enclosure drain 1½" pipe thread

(DN40) with male nipple

L

Notes:

1. The Outdoor Enclosure has two available steam distribution configurations. The standard configuration has a steam outlet on the right side of the

Outdoor Enclosure for connecting to steam dispersion unit piping. The optional internal steam distribution configuration routes steam within the

Outdoor Enclosure and down through the enclosure pipe chase into a building.

2. There are four knockouts located on the right and left side of the enclosure. Knockout sizes are 1½" (hole dia. 50 mm) for STS models 25-100, and

2" (hole dia. 63.5 mm) for STS models 200-800. Run the electrical power into the enclosure at these knockouts.

3. All piping from the STS unit to the steam outlet is stainless steel pipe. Depending on the application, tubing or DriSteem steam hose is recommended

for interconnecting piping from steam outlet to dispersion assembly.

4. Install a riser trap in the branch line leading to the humidifier.

5. The preferred location for the STS steam control valve is inside the Outdoor Enclosure. If one of these valves must be located inside the building, it

must be located within 6' (1.8 m) of the humidifier to reduce pressure drop.

6. See the dimensions in Table 13-1.

K

Optional steam outlet

A

6.5"

DC-1476

Pipe chase

G

Table 12-1:

Outdoor Enclosure connection sizes

Description

Water makeup

(fill)

Drain 3/4” (DN20) 1” (DN25)

Condensate

return

Steam outlet See Table 27-1.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12

25 – 100 200 – 800

1/4” pipe thread (DN8) 1/4” pipe thread (DN8)

3/4” pipe thread (DN20) 3/4” pipe thread (DN20)

STS model

Table 12-2:

Outdoor Enclosure weights

Shipping weight* Operating weight*

STS model

lbs kg lbs kg

25 600 272 680 308

50 625 284 840 381

100 640 290 860 390

200 1050 476 1650 748

400 1125 510 1750 794

800 1225 556 2250 1021

* Includes humidifier

Page 17

Outdoor Enclosure

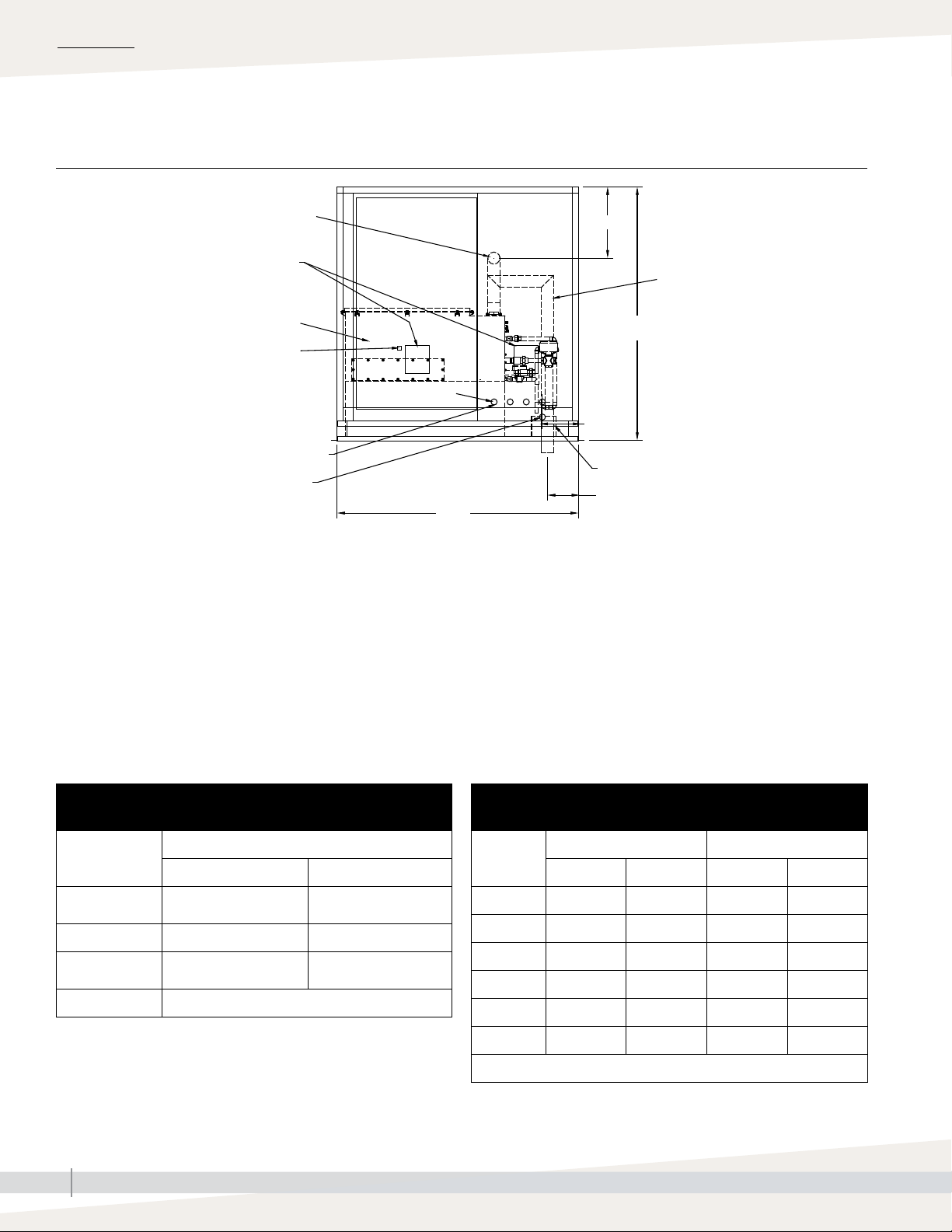

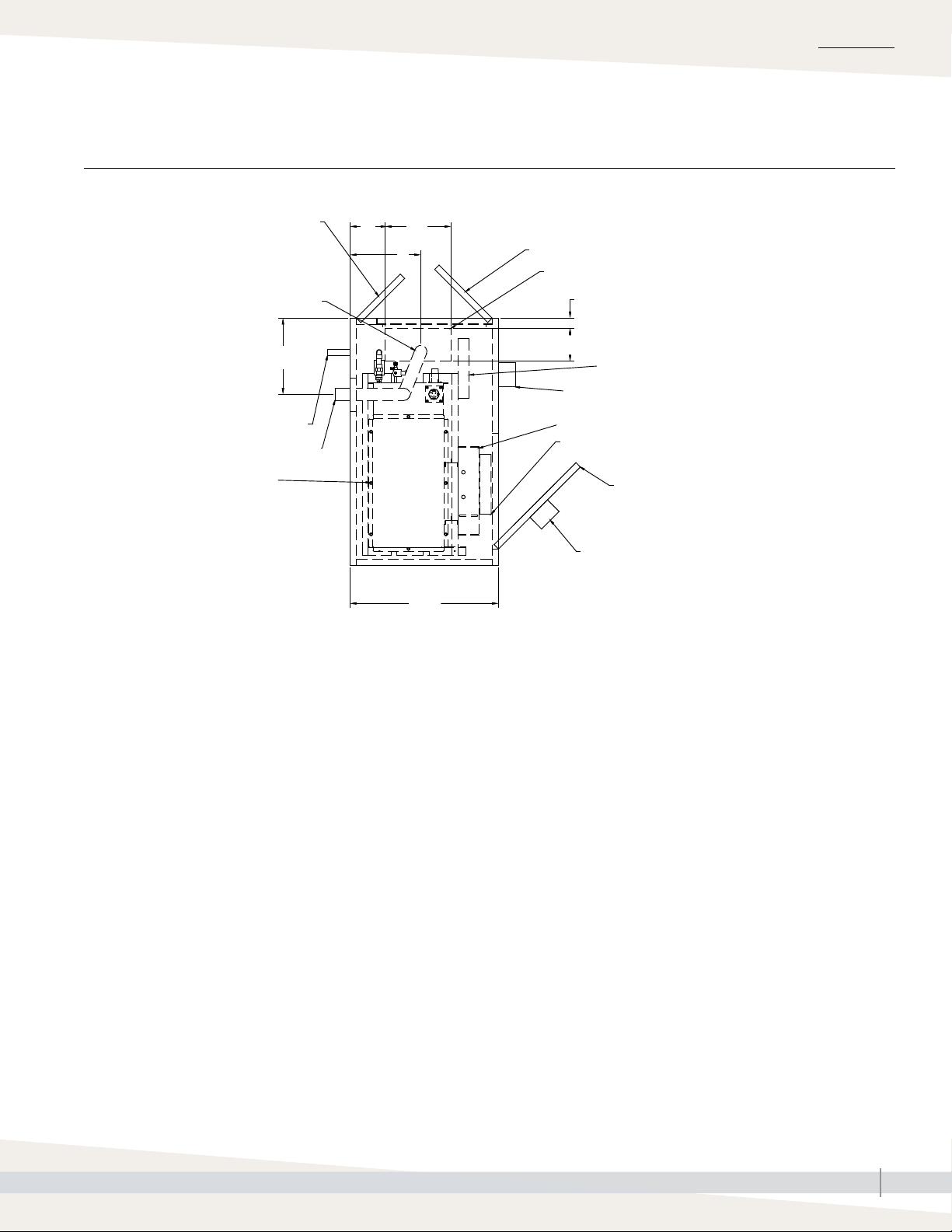

FIGURE 13-1: OUTDOOR ENCLOSURE, TOP VIEW

Valve access door:

• Models 25-100 have one access door

• Models 200-800 have two access doors

Optional steam outlet

(exits enclosure through pipe chase)

C

INSTALLATION

E

J

Valve access door

Pipe chase extending 1" (25 mm) above enclosure floor

D

H

Enclosure drain

Standard steam outlet (exits enclosure here)

STS humidifier

B

DC-1478

Table 13-1:

Outdoor Enclosure dimensions*

STS model

Item Description

A Enclosure height 56.00 1422 66.00 1676

B Enclosure width 36.00 914 46.00 1168

C

Pipe chase position

D 2.00 57 3.50 89

E

Pipe chase size

F 8.00 203 10.00 254

G

H 18.63 473 22.00 559

Steam pipe position

J 14.50 368 20.50 521

K 12.25 311 11.00 279

L Enclosure length 60.00 1524 78.00 1981

* See drawings in Figures 12-1 and 13-1.

25–100 200–800

inches mm inches mm

4.50 114 4.50 114

20.00 508 32.00 312

6.00 152 8.50 216

F

Valve section heater

Intake ventilation fan

Control panel

Control panel heater

Electrical and cleanout access door

Intake ventilation fan

Table 13-2:

STS Outdoor Enclosure electrical

specifications

Outdoor

Enclosure

without

heater

package

Outdoor

Enclosure

with heater

package

ELECTRICAL SPECIFICATIONS

Voltage Current

120 Vac,

50/60 Hz

120 Vac,

50/60 Hz

3.5 A 10 A

13.5 A 20 A

Maximum

disconnect

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

13

Page 18

INSTALLATION

Outdoor Enclosure

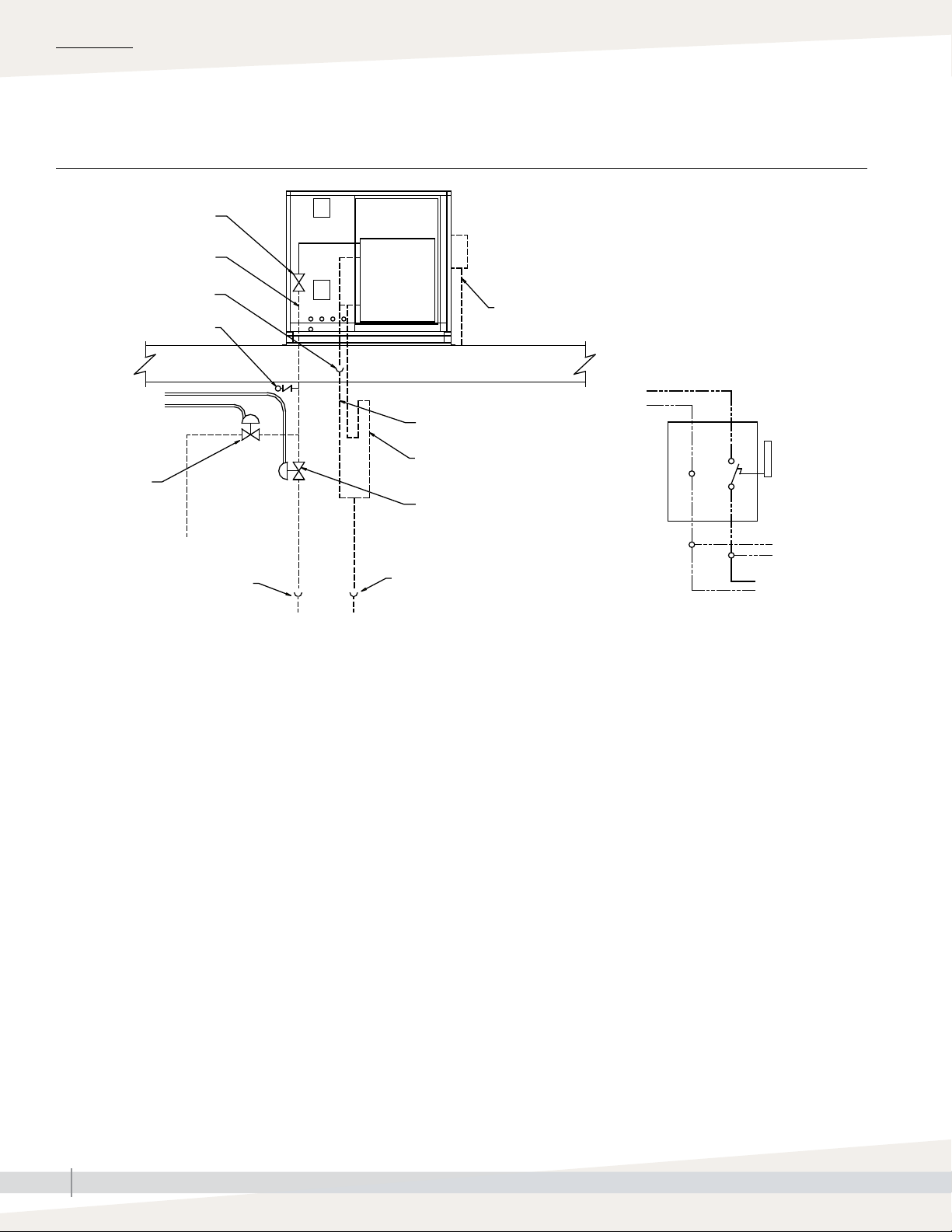

FIGURE 14-1: OUTDOOR ENCLOSURE INSTALLATION DETAIL

Normally closed fill

valve (by factory)

Make-up water supply

piping (by installer)

(See Note 2)

Open to drain

Vacuum breaker (by installer)

120 V from unit

disconnect or other

source (See Note 1)

Normally closed

(fail closed) min

3/8" electric

valve (by installer)

Domestic water, 80 psig

(582 kPa) maximum

Open drain

(See Note 4)

Notes:

1. Insulate supply water piping to avoid dripping from condensation. To ensure that water does not remain in the fill line and freeze if there is a loss

of power, DriSteem recommends field installing additional valves upstream of the fill valve in a conditioned space. Power these valves on the same

circuit that supplies the STS (as shown above); if the power goes off, water drains out of the fill line to prevent freezing.

2. Ensure that water lines are protected from freezing conditions.

• Install heat tracing and insulation on fill piping inside the Outdoor Enclosure.

• In extreme or critical applications in which the unlikely event of a water leak could cause severe damage, DriSteem recommends a thermostat

with a remote sensor on the fill line to cut power to the STS and safety valves to stop fill water to the STS and drain the fill piping when the

temperature is below freezing.

3. DriSteem recommends copper or iron drain piping for Outdoor Enclosures. On a loss of power the tank water will drain, but not be cooled by

the Drane-kooler because of the field supplied safety shut-off valves. If it is critical to keep the Drane-kooler functional in the case of a power loss,

disconnect the Drane-kooler and relocate it down inside the conditioned space of the building. Pipe the supply water for the Drane-kooler before the

safety shut-off valves.

4. If copper or iron piping is used for both the fill and drain piping, these drains may be tied together. Locate 1" air gap only in spaces with adequate

temperature and air movement to absorb flash steam; otherwise, condensation may form on nearby surfaces. Refer to governing codes for drain

pipe size and maximum discharge water temperature.

Humidifier

Roof decking

Drain line, min. 1½" electric

valve (See Note 3)

Optional water seal (P-trap)

drain line, min. 1½" (DN40)

(See Note 3)

Normally open (fail open) min

1/2" electric valve (by installer)

Open drain

(See Note 4)

Disconnect (by installer); see Detail A

120V supply.

Refer to Table 13-2 for electrical requirements.

OM-7558

Heated building interior

120 V

N

Disconnect

box

Detail A

To valves

(by installer)

(See Note 1)

To STS

humidifier

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

14

Page 19

Outdoor Enclosure

FIGURE 15-1: STS OUTDOOR ENCLOSURE, TOP VIEW

Valve access door:

• Models 25-100 have one access door

• Models 200-800 have two access doors

Optional steam outlet

(exits enclosure through pipe chase)

C

J

INSTALLATION

E

Valve access door

Pipe chase extending 1" (25 mm) above enclosure floor

D

H

Enclosure drain

Standard steam outlet (exits enclosure here)

STS humidifier

MOUNTING

B

DC-1478

F

Intake ventilation fan

Control panel

Control panel heater

Intake ventilation fan

• Outdoor Enclosure must be level and positioned with enough clearance to

open access doors.

• Verify that position of pad or curb properly supports Outdoor Enclosure,

and that support structure dimensions coincide with unit dimensions.

• Locate unit so air intakes are not close to exhaust fan outlets, gasoline

storage, or other contaminants that could potentially cause dangerous

situations. Using or storing gasoline or other flammable vapors and liquids

in open containers in vicinity of Outdoor Enclosure is hazardous.

Valve section heater

Electrical and cleanout access

door

Important note about STS Outdoor

Enclosure installation

• Install a riser trap in the branch line leading

to the humidifier.

• The preferred location for the STS steam

control valve is inside the Outdoor Enclosure.

If one of these valves must be located inside

the building, it must be located within 6'

(1.8 m) of the humidifier to reduce pressure

drop.

• When located on roof, Outdoor Enclosure air intakes must be a minimum

of 14" (356 mm) above roof to prevent intake of snow or splashed rain.

Position Outdoor Enclosure so prevailing winds do not blow into air intakes.

• Remove all shipping brackets and other packaging prior to installing the

unit.

• During transit, unloading, and setting of the unit, bolts and nuts may have

become loosened. Check that all nuts are tightened.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

15

Page 20

INSTALLATION

Outdoor Enclosure

MOUNTING (CONTINUED)

• There are four knockouts on the right and left side of the enclosure. It is

recommended that electrical power is run into enclosure at these knockouts.

• Outdoor Enclosure is designed for lifting by two methods:

– Preferred method of lifting is by forklift. This is only possible if the forks

extend across entire unit. Forks that do not extend across entire unit

could cause tipping, resulting in unsafe conditions or damage to the

unit.

– Alternative method of lifting is through unit’s channel base frame and/

or special lifting lug hooks installed on the unit. Use a load spreader of

sufficient width to ensure that lifting cables clear sides of unit. If such a

spreader is not available, insert wood strips between cables and unit

where necessary. All four lifting points must be used; they are marked

“lift here” on the unit.

In both cases it must be lifted from the bottom base and kept level, and

it must not tip, fall, or twist. If unit is severely twisted during handling,

permanent damage could occur. It is installer’s responsibility to verify

handling equipment’s capability to safely handle Outdoor Enclosure.

• Outdoor Enclosure has two available steam distribution configurations:

– Standard configuration is a steam outlet on one side of enclosure for

connecting to steam dispersion unit piping.

– Optional internal configuration routes steam within Outdoor Enclosure

and down through pipe chase into building.

See the drawings beginning on Page 12.

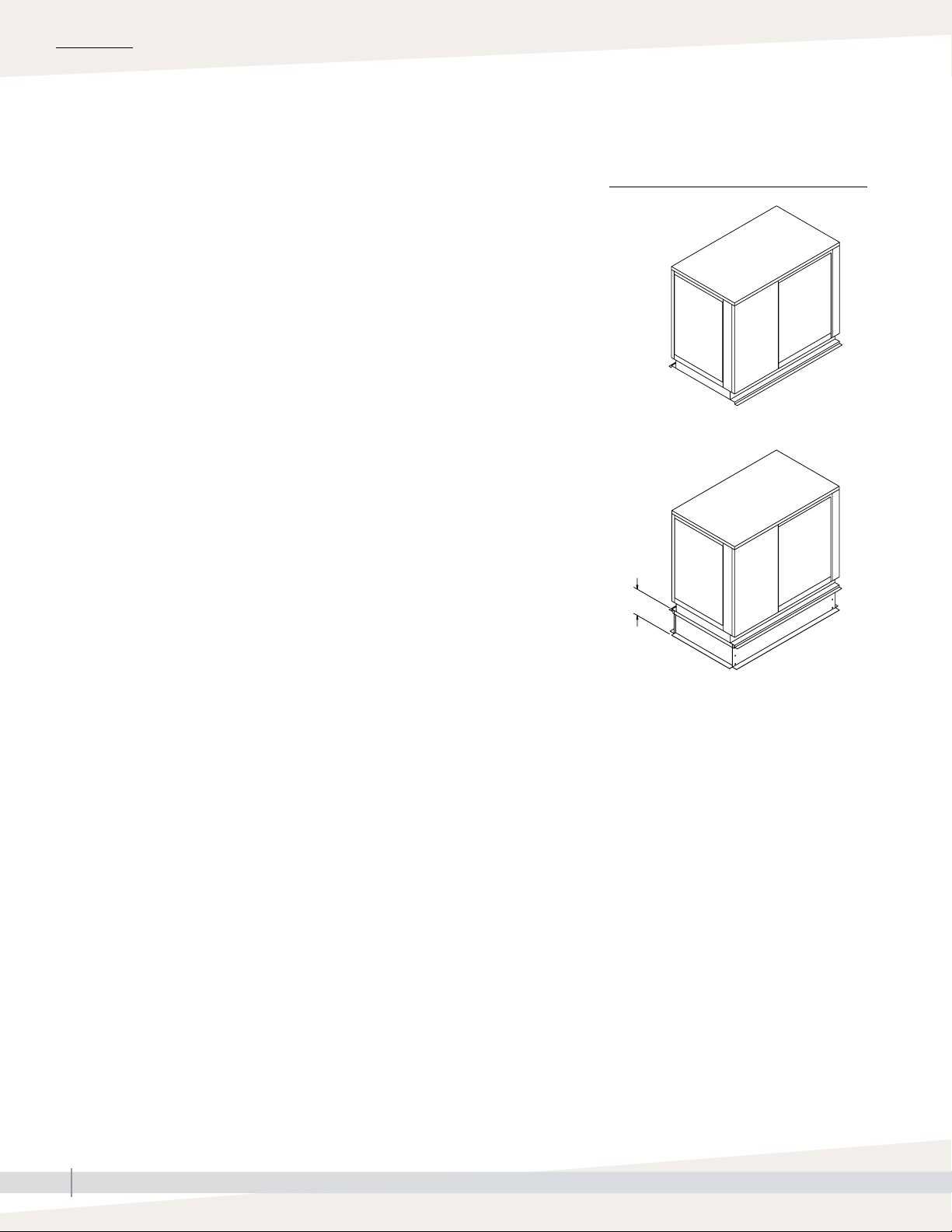

FIGURE 16-1: OUTDOOR ENCLOSURE

MOUNTING OPTIONS

Flush

DC-1110

Curb

OM-1095

14"

(356 mm)

• Pipe chase is inside enclosure. Cover for pipe chase is provided to maintain

proper pressure in enclosure if this opening is not utilized. However, it is

recommended that this pipe chase be used for both supply water piping

and drain piping, in which case pipe chase cover should be removed.

Install insulation rated for 212 °F (100 °C) to completely fill area around

pipes to maintain proper enclosure pressure.

• When enclosure is pad mounted or when pipe chase cannot be used,

supply water and drain piping can be run through the knockouts —

preferably on side opposite utility connections.

• When ordered with heater package, two thermostat-controlled strip heaters

are provided to keep enclosure at constant minimum temperature: one

heater is in control cabinet section, and one heater is in front section.

• Enclosure drain is provided. In case of water leak, water will drain from

enclosure through this drain.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

16

Page 21

Outdoor Enclosure

INSTALLATION

MOUNTING (CONTINUED)

• Keypad/display with standard 5' (1.5 m) cable ships mounted to subpanel

in Outdoor Enclosure. Keypad/display must not come in contact with strip

heaters or block intake ventilation hood.

• If constant monitoring of unit is desired, or if unit is located in a severe

climate, a remote-mount keypad/display should be installed. Additional

cable lengths up to 500 feet (152 m) are available as an option for this

mounting configuration.

• 16-gauge galvanized steel curbs (optional) are shipped unassembled for

ease of transporting to roof; they include all hardware for bolt-together

assembly, and all holes are matched before leaving factory. Curb must

be a minimum of 14" (356 mm) high. One 2" × 1/2" closed-cell curb

gasket with adhesive on one side is supplied with hardware. Gasket must

be installed between top of curb and base surface of Outdoor Enclosure

to prevent moisture from leaking into building from driving rain or melting

snow. Installation drawing is included.

• All piping from humidifier to steam outlet is stainless steel pipe. Depending

on the application, tubing or DriSteem steam hose is recommended for

interconnecting piping from steam outlet to dispersion assembly.

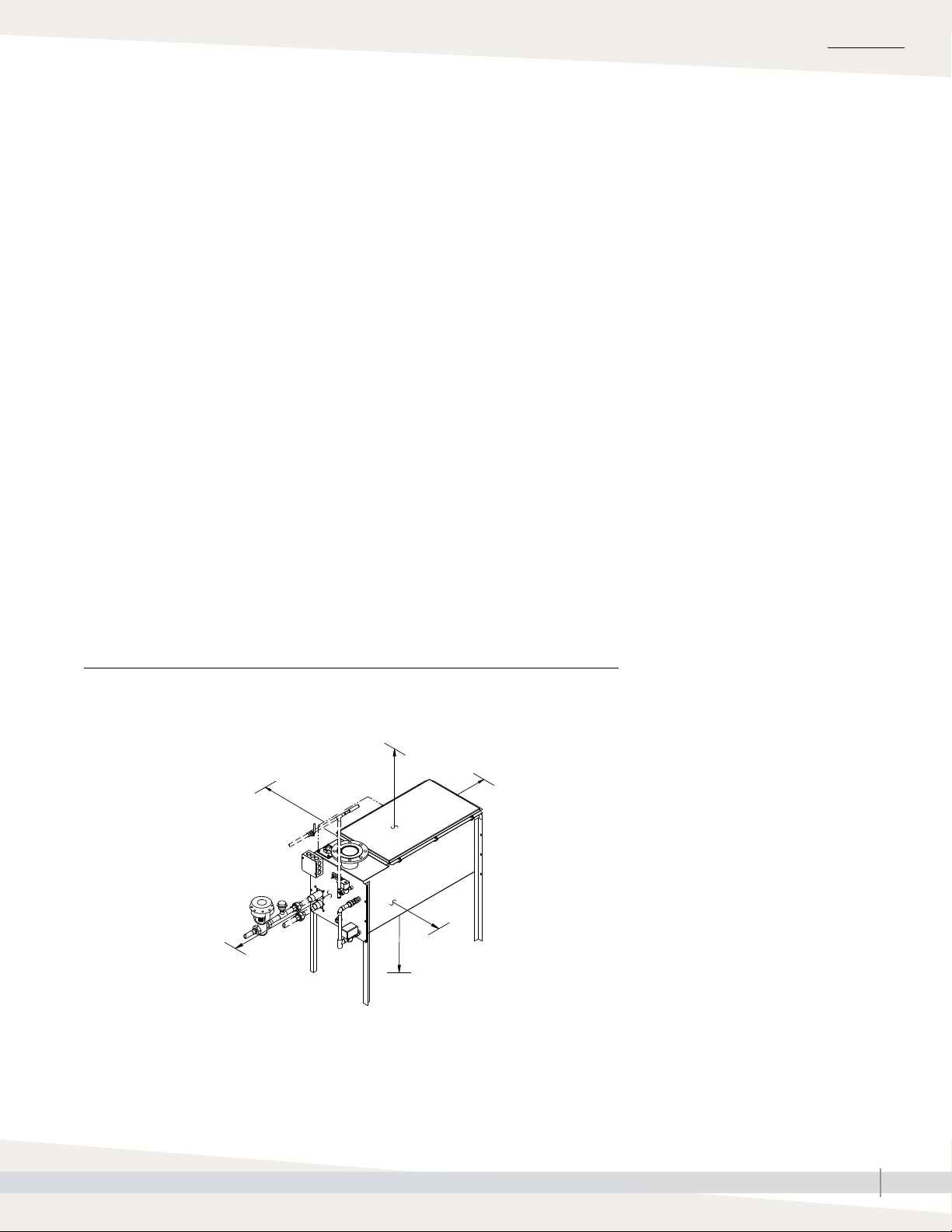

FIGURE 17-1: TYPICAL ROOFTOP INSTALLATION OVERVIEW

STS OUTDOOR ENCLOSURE SEQUENCE OF OPERATION

• Power is applied to Outdoor Enclosure:

• If ambient temperature in enclosure is below

50 °F (10 °C), the strip heaters power up.

Strip heaters remain on until enclosure

reaches 50 °F (10 °C) to ensure that

enclosure temperature does not drop below

the freezing point.

• When there is no call for humidity, an

aquastat maintains tank temperature at

the factory default of 70 °F (21 °C). This

temperature can be reset in the field to be

from 40 to 180 °F (4 to 82 °C).

• When the ambient temperature in the

enclosure reaches 85 °F (29 °C), two

ventilation fans turn on to cool the electronic

components. A high limit is also provided

to power down the STS if the enclosure

temperature reaches 150 °F (66 °C). In

a high limit situation, the ventilation fans

continue to run and once the enclosure

temperature falls below 130 °F (54 °C), the

STS automatically resumes normal operation.

• A normally open drain valve is provided on

the STS Outdoor Enclosure to drain the tank

in the event of a power loss.

Humidifier in Outdoor Enclosure

Electrical connections

Remote Vapor-logic keypad

Drain piping

Water piping

Curb

Steam piping

Roof surface

OM-7464

FIGURE 17-2:

OUTDOOR ENCLOSURE CLEARANCES

Left side:

36"

(914 mm)

Front:

36"

(914 mm)

Top:

Keep open

Back:

12"

(305 mm)

OM-955

mc_012611_1546

Right side:

24"

(610 mm)

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

17

Page 22

INSTALLATION

ALTERNATE WATER SEAL AND DRAIN VALVE PIPING

Piping:

Drain

The drain line piped from the humidifier must be run to an approved sanitary

waste or suitable drain. If nonmetallic pipe or steam hose is used, it must be

rated for 212 °F (100 °C) minimum continuous operating temperature.

Minimum drain pipe sizes:

STS models 25 through 100: 3/4" (DN20) outside diameter.

STS models 200 through 800: 1" (DN25) outside diameter.

If the length of the drain piping exceeds 10' (3 m), increase the pipe size.

If combining multiple drain lines, ensure that proper common pipe sizing

practices are used.

Do not locate the humidifier directly above a floor drain — skim and drain

water dumped into the floor drain will cause flash steam. This steam will rise

and saturate electrical components, adversely affecting component life and

performance.

TEMPERING DRAIN WATER

Governing codes may require that the 212 °F (100 °C) drain and skim water

from the humidifier be tempered before it is discharged into the building drain

piping. The Drane-kooler® option will temper 6 gpm (22.7 L/m) of 212 °F

(100 °C) water to 140 °F (60 °C).

See the detailed piping drawings on Pages 22

through 25.

WATER SEAL

To allow normal operation and prevent steam from escaping through the drain

line, the installer must provide a water seal of a sufficient height to contain the

pressure developed in the humidifier system. See Table 27-1 for water seal

heights.

Drain piping after the water seal must be pitched a minimum of 1/8"/ft (1%)

toward the drain. Governing codes may require more pitch.

CONDENSATE PUMP

If the proximity of a drain requires the humidifier drain and skim water to be

lifted by a pump, DriSteem offers a condensate pump option. A check valve

is required on the discharge of the pump. Electrical power for the pump is

independent of the humidifier. Plug the pump into a wall outlet; an integral float

switch turns the pump on and off.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

18

Page 23

INSTALLATION

Piping:

Drain

STS with RO/DI water option and manual drain has a pipe thread fitting on the

drain valve and on the skim/overflow fitting. Prior to dumping into a drain, the

installer needs to connect the drain and skim/overflow, provide a water seal of

height H1 (see Table 22-1), and pipe.

DRAIN CONNECTION

Note: This section applies to all tap/softened water STS models and all STS

models with the RO/DI and auto drain options.

The installer should install a water seal of height H1 (see Table 22-1).

The drain connection provided is a ProBite™ quick connection. Connect as

follows:

1. See Warning and Caution at right.

2. Cut drain line to length for insertion depth shown below for your ProBite

connector size. Cut must be clean and smooth.

3. Ream and de-burr drain line before connecting to ProBite connection.

Make sure drain line is clean, round, and free from damage.

4. Mark insertion depth on drain line according to table below for your

ProBite connection size.

5. Push drain line into ProBite connection to insertion depth marked in Step 4.

WARNING

Do not insert fingers or any body part

into ProBite connection openings

Insert only piping into ProBite

connection. Inserting fingers or any

body part could require emergency

medical attention for removal.

CAUTION

ProBite installation precautions

To avoid damage to the ProBite

connection:

• In addition to DriSteem drain

piping material requirements on

the facing page, ProBite fittings are

compatible only with copper, PEX,

CPVC or stainless steel.

• Do not solder within 10" (250 mm)

of the ProBite connection.

• Do not use heat or glue when

installing the ProBite connection.

FIGURE 19-1: DRAIN CONNECTION (ALL MODELS EXCEPT STS WITH RO/DI

WATER OPTION AND MANUAL DRAIN)

ProBite fitting

Connector

size

D

OM-7644

Drain line

D

3/4" 1

Insertion depth (D)

in. mm

1

/1627 mm

1" 1 5/1633 mm

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

19

Page 24

INSTALLATION

Piping:

WATER SUPPLY PIPING

All STS humidifier models have a 1" (25 mm) internal air gap to prevent back

siphoning into a potable water system. However, some governing codes may

require additional protection such as a vacuum breaker or backflow preventer.

The supply water pressure range must be 25 to 80 psi (172 to 552 kPa).

TAP/SOFTENED WATER STS

Water supply assembly includes a strainer, needle valve, and fill solenoid —

1/4" pipe thread (DN8) connection. European models are provided with a

3/8" pipe thread (DN10) connection. Since the primary component of the

water supply assembly is a solenoid valve, there may be noise issues that

surface during a fill cycle.

During a fill cycle, the supply water drops the water temperature in the tank

and may collapse the steam, which can cause a low rolling sound. To diminish

this, adjust the needle valve to decrease the water fill rate and/or use hot

supply water.

In cases where water hammer occurs when the fill solenoid closes, a shock

arrester is recommended. Reducing the supply water pressure (minimum

25 psi [172 kPa]) or using flexible tubing (rated 212 °F [100 °C], minimum

continuous operating temperature) may diminish the noise, but installing a

shock arrester is the best solution.

Fill

The minimum water conductivity for the probe-type water level control system to

work is 30 µS/cm.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

20

Page 25

INSTALLATION

Piping:

STS WITH RO/DI WATER OPTION

A float valve controls the water supply — 1/4" pipe thread (DN8) connection.

European models are provided with a 3/8" pipe thread (DN10) connection.

For the end-of-season drain option, a solenoid valve is added on the inlet of the

float valve. This option shuts off the fill water supply and drains the tank when

there is no demand for humidity for 72 hours. (This is a default setting, which is

adjustable. To modify this value, see the Vapor-logic Installation and Operation

Manual.)

When using nonmetallic tubing for supply water, it must be rated for 212 °F

(100 °C) minimum continuous operating temperature. DriSteem recommends

installing a three-foot (914 mm) piece of noninsulated stainless steel pipe

directly off the humidifier prior to connecting to the nonmetallic tubing. When

using nonmetallic tubing, DriSteem recommends the installer place a 2"

(50 mm) water seal/loop in the supply line to isolate steam during RO/DI

water system maintenance.

DriSteem recommends installing a strainer in the water supply line to prevent

clogging of the float valve orifice. A strainer is highly recommended when

the humidifier has the end-of-season drain option. The strainer will prevent

particulate from collecting at the solenoid valve seat.

Fill

If an STS humidifier with the RO/DI water option is supplied with tap water, the

float valve assembly will become clogged and run without water.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

21

Page 26

INSTALLATION

Piping:

FIGURE 22-1: FIELD PIPING OVERVIEW FOR TAP/SOFTENED WATER STS MODELS 25, 50, 100, 200, AND 400

3/4" pipe thread (DN20) dispersion unit condensate return inlet*

Water supply line (see Table 23-1); water pressure range

25 to 80 psi (172 to 582 kPa); water conductivity

30 µS/cm minimum

Optional condensate return

piping from evaporative

dispersion unit*

* Condensate return piping is

not needed for Ultra-sorb

Model XV dispersion unit, which

returns pressurized condensate

to the boiler. See the Ultra-sorb

Model XV Installation Guide for

condensate piping requirements.

Tap/softened water, one heat exchanger

Water supply shut-off valve (by installer)

If water piping to humidifier is nonmetallic, we

recommend a 2" (50 mm) metallic water seal or loop

in the supply line to isolate steam during maintenance

Unions (by installer)

Vacuum breaker

(by installer)

Air vent tube

H2 (see

Table 22-1)

6"

(152 mm)

minimum

®

3/4" (DN20) minimum condensate

drain piping rated for 212 °F (100 °C)*

Strainer

From

steam

source

Condensate return to

nonpressurized system,

by gravity only

Trap

Shock arrester recommended to reduce water hammer

(by installer)

12"

(305

mm)

minimum

drop to

trap

Drain, skim, overflow

piping rated for 212 °F

(100 °C) (see sizes in

Table 23-1)

Pitch 1/8"/ft

(1%) toward drain

H1 (see

Table

22-1)

Steam outlet

Install level

Install level

Electric drain valve

Overflow line

DC-1451

If run is over 10' (3 m),

increase pipe to 1¼" (DN32)

1" (25 mm) air gap

Open floor drain.

See first note below.

Water seal line

MUST be below

drain valve to ensure

humidifier drains

correctly

Notes:

• Offset humidifier from floor drain to prevent flash steam from rising into the humidifier.

• Locate air gap only in spaces with adequate temperature and air movement to absorb flash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

• Water supply inlet is more than 1" (25 mm) above skim/overflow port, eliminating the possibility of backflow or siphoning from tank. No additional

backflow prevention is required; however, governing codes prevail.

• Damage caused by chloride corrosion is not covered by your DriSteem warranty.

• Dashed lines indicate provided by installer.

Table 22-1:

Heights required to overcome humidifier internal pressure (H1, H2)

Water seal height (H1) Air vent height (H2)

Unit output

lbs/hr kg/h inches mm inches mm inches mm

≤ 138 ≤ 62 12 305 27 686 — —

139-183 63–83 15 381 30 762 — —

> 183 > 83 18 457 33 838 42.25 1073

All STS models

25, 50, 100, 200, 400 800

STS models

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

22

Page 27

INSTALLATION

Piping:

FIGURE 23-1: FIELD PIPING OVERVIEW FOR TAP/SOFTENED WATER STS MODEL 800

3/4" pipe thread (DN20) dispersion unit condensate return inlet*

Shock arrestor (by installer) recommended to eliminate water hammer

Water supply line (see Table 23-1); water pressure range

25 to 80 psi (172 to 582 kPa); water conductivity

30 µS/cm minimum

6" (152 mm) minimum

* Condensate return piping is

not needed for Ultra-sorb

Model XV dispersion unit, which

returns pressurized condensate

to the boiler. See the Ultra-sorb

Model XV Installation Guide for

condensate piping requirements.

Tap/softened water, two heat exchangers

Water supply shut-off valve (by installer)

Unions (by installer)

Optional condensate return

piping from evaporative

dispersion unit*

Air vent tube

®

Vacuum breaker

(by installer)

Strainers

From

steam

source

H2 (see

Table 22-1)

Condensate return to

nonpressurized system,

by gravity only

3/4" (DN20) minimum condensate

drain piping rated for 212 °F (100 °C)*

Traps

12"

(305

mm)

minimum

drop to

trap

H1 (see

Table

22-1)

Drain, skim, overflow

piping rated for

212 °F (100 °C)

(see sizes in Table

23-1)

Pitch 1/8"/ft

(1%) toward drain

Steam outlet

Overflow

line

Install level

DC-1467

Install level

Electric drain valve

If run is over 10' (3 m),

increase pipe to 1¼" (DN32)

Water seal line MUST be

below drain valve to ensure

humidifier drains correctly

1" (25 mm) air gap

Open floor drain.

See first note below.

Notes:

• Offset humidifier from floor drain to prevent flash steam from rising into the humidifier.

• Locate air gap only in spaces with adequate temperature and air movement to absorb flash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

• Water supply inlet is more than 1" (25 mm) above skim/overflow port, eliminating the possibility of backflow or siphoning from tank. No additional

backflow prevention is required; however, governing codes prevail.

• Damage caused by chloride corrosion is not covered by your DriSteem warranty.

• Dashed lines indicate provided by installer.

Table 23-1:

STS connection sizes

Description Connection size

Water makeup (fill) 1/4" pipe thread (DN8), all STS models

Drain

Steam outlet Varies with capacity and dispersion type; see Table 27-1

Condensate return 3/4" pipe thread (DN20)

Pressurized steam supply inlet and

return outlet

3/4" (DN20) for STS models 25 through 100

1" (DN25) for STS models 200 through 800

See sizes in Tables 5-1 and 5-2.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

23

Page 28

INSTALLATION

Piping:

FIGURE 24-1: FIELD PIPING OVERVIEW FOR STS MODELS 25, 50, 100, 200, AND 400 WITH RO/DI WATER OPTION

Water supply line (see Table 25-1); water pressure range

25 to 80 psi (172 to 582 kPa); first 3' (1 m) of supply line

must be rated for 212 °F (100 °C)

If water piping to humidifier is nonmetallic, we recommend

a 2" (50 mm) metallic water seal or loop in the supply line

to isolate steam during maintenance

Optional condensate return

piping from evaporative

dispersion unit*

Air vent tube

* Condensate return piping is

not needed for Ultra-sorb

Model XV dispersion unit,

which returns pressurized

condensate to the boiler.

See the Ultra-sorb Model

XV Installation Guide

for condensate piping

requirements.

RO/DI water option, one heat exchanger

Steam outlet

3/4" pipe thread (DN20)

dispersion unit condensate return inlet*

Unions (by installer)

Vacuum breaker

6"

(152 mm)

minimum

®

(by installer)

Strainer

H2 (see Table

24-1)

3/4" (DN20) minimum

condensate drain piping

rated for 212 °F (100 °C)*

From

steam

source

Condensate return to

nonpressurized system,

by gravity only

Trap

12"

(305

mm)

minimum

drop to

trap

H1 (see

Table

24-1)

Drain, skim, overflow piping

rated for 212 °F (100 °C)

(see sizes in Table 25-1)

Install level

Overflow line

Pitch 1/8"/ft

(1%) toward drain

Install level

DC-1459

Manual SST drain valve (electric drain valve

available for end-of-season drain option)

If run is over 10' (3 m),

increase pipe to 1¼" (DN32)

Water seal line MUST

be below drain valve to

ensure humidifier drains

correctly

1" (25 mm) air gap

Open floor drain.

See first note below.

Notes:

• Offset humidifier from floor drain to prevent flash steam from rising into the humidifier.

• Locate air gap only in spaces with adequate temperature and air movement to absorb flash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

• Water supply inlet is more than 1" (25 mm) above skim/overflow port, eliminating the possibility of backflow or siphoning from tank. No additional

backflow prevention is required; however, governing codes prevail.

• Damage caused by chloride corrosion is not covered by your DriSteem warranty.

• Dashed lines indicate provided by installer.

Table 24-1:

Heights required to overcome humidifier internal pressure (H1, H2)

Water seal height (H1) Air vent height (H2)

Unit output

lbs/hr kg/h inches mm inches mm inches mm

≤ 138 ≤ 62 12 305 27 686 — —

139-183 63–83 15 381 30 762 — —

> 183 > 83 18 457 33 838 42.25 1073

All STS models

25, 50, 100, 200, 400 800

STS models

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

24

Page 29

INSTALLATION

Piping:

FIGURE 25-1: FIELD PIPING OVERVIEW FOR STS MODEL 800 WITH RO/DI WATER OPTION

If water piping to humidifier is nonmetallic, we recommend a

2" (50 mm) metallic water seal or loop in the supply line to

isolate steam during maintenance

Optional condensate

return piping from

dispersion unit*

* Condensate return

piping is not needed for

Ultra-sorb® Model XV

dispersion unit, which

returns pressurized

condensate to the boiler.

See the Ultra-sorb Model

XV Installation Guide

for condensate piping

requirements.

RO/DI water option, two heat exchangers

Water supply line (see Table 25-1); water

pressure range 25 to 80 psi (172 to 582 kPa)

Air vent tube

Strainer (by installer)

Vacuum breakers (by installer)

6"

(152 mm)

minimum

H2 (see Table

24-1)

3/4" (DN20)

minimum condensate drain piping

rated for 212 °F (100 °C)*

Unions (by installer)

Strainers

(by installer)

From

steam

source

Traps

Condensate return

to nonpressurized

system, by gravity

only

12"

(305 mm)

minimum

drop to

traps

Steam outlet

Pitch 1/8"/ft

(1%) toward drain

H1 (see

Table

24-1)

Drain, skim,

overflow piping

rated for 212 °F

(100 °C)

(see sizes in

Table 25-1)

Install level

Overflow

line

Install level

DC-1468

3/4" pipe thread (DN20)

dispersion unit condensate

return inlet*

Manual SST drain valve (electric drain valve

available for end-of-season drain option)

If run is over 10' (3 m), increase pipe to

1¼" (DN32)

Water seal line MUST be below

drain valve to ensure humidifier

drains correctly

1" (25 mm) air gap

Open floor drain.

See first note below

Notes:

• Offset humidifier from floor drain to prevent flash steam from rising into the humidifier.

• Locate air gap only in spaces with adequate temperature and air movement to absorb flash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

• Water supply inlet is more than 1" (25 mm) above skim/overflow port, eliminating the possibility of backflow or siphoning from tank. No additional

backflow prevention is required; however, governing codes prevail.

• Damage caused by chloride corrosion is not covered by your DriSteem warranty.

• Dashed lines indicate provided by installer.

Table 25-1:

STS connection sizes

Description Connection size

Water makeup (fill) 1/4" pipe thread (DN8), all STS models

Drain

Steam outlet Varies with capacity and dispersion type; see Table 27-1

Condensate return 3/4" pipe thread (DN20)

Pressurized steam supply inlet

and return outlet

3/4" (DN20) for STS models 25 through 100

1" (DN25) for STS models 200 through 800

See sizes in Tables 5-1 and 5-2

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

25

Page 30

INSTALLATION

Piping:

Pressurized steam supply

The heat exchanger in the STS humidifier is designed for a maximum steam

pressure of 15 psi (105 kPa). The steam valve, trap, and strainer are shipped

loose for field installation.

Figure 26-1 shows piping from an overhead steam supply main with

condensate returned to a vented gravity flow return system. Note the steam

trap installed at the bottom of the branch feeding the steam valve of the STS.

Failure to install this trap will cause water hammer, which could damage the

STS heat exchanger.

Vacuum breakers are necessary to ensure that condensate can drain from the

heat exchanger when the steam valve closes.

Lifting condensate with pressurized steam is not recommended. Premature heat

exchanger failure and erratic control can occur when using pressurized steam

to lift condensate. A steam condensate pump is recommended when lifting

condensate in a pressurized system.

FIGURE 26-1: STEAM SUPPLY PIPING TO STS HUMIDIFIER

Note:

For STS 800 models, to guarantee steam output

capacities, a dedicated steam valve and steam

trap is required for each heat exchanger.

End of branch trap

(by installer)

Steam main

12"

Steam trap, required for proper

operation (by DriSteem)

Alternate vacuum

breaker position

12"

Vacuum breaker

(by installer)

Swing check valves

(by installer)

OM-941

Gravity condensate return

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

26

Page 31

INSTALLATION

Piping:

Humidification steam outlet

Table 27-1:

STS steam outlet sizes and types

STS model

25 X

50 X X

100 X X X

200 X X X X

400 X X X X

800 X X X

Note: For pipe thread steam outlet options, see DriCalc, DriSteem’s free sizing and selection

software, available at www. dristeem.com.

FIGURE 27-3: FLANGE CONNECTION

Support member

Hose size Flange size

2" (DN50) 3" (DN80) 4" (DN100) 5" (DN125) 6" (DN150)

Support tubing from above to prevent

excessive weight on humidifier outlet.

Allow for thermal expansion.

FIGURE 27-1: HOSE CONNECTION

Steam hose

Hose clamp

Steam outlet

connection

(tubing)

DC-1455

Note: Tap/softened water model shown.

FIGURE 27-2: TUBING CONNECTION

USING HOSE CUFF WITH CLAMPS

Tubing

Hose

clamps

6" (152 mm)

long hose cuff

Steam outlet

connection

(tubing)

DC-1458

Steam outlet connection (flange)

Notes:

• Dashed lines indicate provided by installer.

• Tap/softened water model shown.

DC-1456

Notes:

• Dashed lines indicate provided by installer.

• Tap/softened water model shown.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

27

Page 32

INSTALLATION

Wiring

WIRING DIAGRAM LOCATIONS

• Ladder style wiring diagrams (located inside control cabinet door)

show power, control, and humidifier-to-control-cabinet interconnection

requirements.

• External connections diagrams (located inside control cabinet door) show

connection points to the microprocessor-based controller and wire terminals

for the following external safety and control devices: airflow proving

switches, high limits, transmitters, or humidistats.

All wiring must be in accordance with all governing codes and with STS wiring

diagrams.

ELECTRICAL INSTALLATION

Wiring and branch circuit protection is provided by the installer per the

National Electrical Code (NEC) or in Europe, IEC 60364. For power supply

and machine ground connections, size the wire using the 75 °C wiring table,

per the NEC (or IEC 60364). Then use copper conductors rated for a 105 °C

environment. The wiring from the control cabinet to the humidifier must be

rated for 105 °C.

All STS humidifiers have a 120V, single phase electrical supply for North

America or 230V, single phase electrical supply for Europe. Verify current

characteristics and capacity requirements against those listed on the name

plate.

WIRING REQUIREMENTS

WARNING

Electric shock hazard

Only qualified electrical personnel

should perform field wiring installation

procedures. Improper wiring or contact

with energized circuits can cause

property damage, severe personal

injury, or death as a result of electric

shock and/or fire.

Do not open control cabinet until

electrical power is disconnected.

CAUTION

Damage from debris

When drilling penetrations in the

control cabinet, protect all internal

components from debris, and vacuum

out the control cabinet when finished.

Failure to comply with this directive

can damage sensitive electronic

components, cause erratic operation

or failure, and void your DriSteem

warranty.

The length of wire from the control cabinet to the humidifier must not exceed

50' (15 m). Run control wiring in dedicated, earthed, metal conduit or cable

trays or trunking that is separated from the building’s power wiring.

FIGURE 28-1: WATER LEVEL CONTROL WIRING FOR VAPOR-LOGIC

Brown or black, top probe rod (full water condition)

Orange or white, middle probe rod (refill water condition)

Violet or red, bottom probe rod: Low water condition,

tap/softened water

TOP

MID

LOW

Notes:

• See Outdoor Enclosure electrical

specifications in Table 13-2.

• Damage caused by chloride corrosion is not

covered by your DriSteem warranty.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

28

Page 33

Wiring

INSTALLATION

The control cabinet should be mounted in a location convenient for service with

a minimum of 36" (914 mm) clearance in front of the door.

The installer is responsible for making electrical connections at the power

terminals.

CONTROL WIRING

The following wiring methods for external low-voltage control wiring should

minimize electrical noise problems:

• Humidistat, RH transmitter, and temperature transmitter wiring must be

minimum 18-gauge (1 mm2) plenum rated, shielded (screened), twisted pair

wire with a bare drain wire for grounding.

2

• Airflow proving switch wiring must be minimum 18-gauge (1 mm

) stranded

wire run in conduit. The airflow proving switch can be wired using minimum

18-gauge (1 mm2) plenum rated, shielded (screened), twisted pair wire with

a bare drain wire for grounding.

• The shield (screen) wire should be connected to the shield (screen) ground

terminal/lug with a length less than 2" (51 mm). Do not ground the shield

(screen) wire on the humidistat or transmitter end.

• Water level control device, fill valve, and drain valve wiring must be

minimum 18-gauge stranded wire run in a separate conduit from power

wires. DO NOT USE SHIELDED (SCREENED) CABLE FOR WATER LEVEL

CONTROL DEVICES.

Important:

procedures can result in erratic operation or

failure.

This product has been tested at the factory for

proper operation. Product failures resulting from

faulty handling, incorrect wiring, or shorting of

wires together on external components are not

covered under your DriSteem warranty. Review

information and diagrams before proceeding.

Failure to follow these wiring

• The tank temperature sensor can be run with 18-gauge (1 mm2) stranded

wire if the control cabinet is located within 10' ( 3 m) of the humidifier. For

wire lengths of 10' to 50' (3 m to 15 m), use 18-gauge (1 mm2) plenum

rated, shielded (screened), twisted pair wire with a bare drain wire for

grounding.

GROUNDING REQUIREMENTS

The approved earth ground must be made with solid metal-to-metal connections

and must be a good conductor of radio frequency interference (RFI) to earth

(multistranded conductors).

Ground wire should be the same AWG (mm2) size as the power wiring or

sized per NEC requirements (in Europe, IEC 60364 requirements).

When the control cabinet is mounted remotely from the humidifier, a ground

wire is necessary from the machine ground lug on the humidifier to the

machine ground lug in the control cabinet. The bonding machine ground wire

should be no less than 14-gauge AWG (mm2) or sized per NEC or IEC 60364

requirements.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

29

Page 34

INSTALLATION

Sensor placement

SENSOR LOCATION IS CRITICAL

Sensor location has a significant impact on humidifier performance. See the

recommendations below and Figure 30-1.

Note: DriSteem recommends that you do not interchange room and duct

humidity devices. Room humidity devices are calibrated with zero or

little airflow, whereas duct humidity devices require air passing across

them.

Recommended humidity control (transmitter/humidistat) locations:

A Ideal. Ensures the best uniform mix of dry and moist air with stable

temperature control.

B Acceptable, but room environment can affect controllability, such as when

sensor is too close to air grilles, registers, or heat radiation from room

lighting.

C Acceptable. Provides uniform mixture of dry and moist air. If extended time

lag exists between humidity generation and sensing, extend sampling time.

D Acceptable (behind wall or partition) for sampling entire room if sensor is

near an air exhaust return outlet. Typical placement for sampling a critical

area.

E Not acceptable. These locations might not represent actual overall

conditions in the space.

Other factors affecting humidity control

Humidity control involves more than the

controller’s ability to control the system. Other

factors that play an important role in overall

system control are:

• Size of humidification system relative to load

• Overall system dynamics associated with

moisture migration time lags

• Accuracy of humidistats and humidity

transmitters and their location

• Dry bulb temperature accuracy in space or

duct

• Velocities and airflow patterns in ducts and

space environments

• Electrical noise or interference

F Not acceptable. Do not place sensors near windows, door passageways,

or areas of stagnant airflow.

Recommended safety (airflow and high limit) sensor location:

G Best sensing location for high limit humidistat or humidity sensor and airflow

proving switch.

FIGURE 30-1: RECOMMENDED SENSOR LOCATIONS

Outside air

Relief air

Damper control

Return air

A

DC-1084M

8' to 12'

(2.4 m to 3.7 m)

min.

Air handling

C

E

F

Doorway

Window

unit

E

D

B

Wall or

partition

F

F

Window

High limit humidistat or high limit transmitter

(set at 90% RH maximum) for VAV applications

Airflow switch or differential pressure switch

(sail type recommended for VAV applications)

G

Vapor absorption has taken place

Point of vapor absorption

Humidifier dispersion assembly

Turning vanes

Temperature compensation option: Place a temperature compensation

sensor on the lower corner of the inside surface of double-pane window

glass on north- or northeast-facing window.

STS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

30

Page 35

INSTALLATION

Dispersion:

Selecting the dispersion assembly location

DriSteem humidifiers operate with several types of dispersion assemblies for

open spaces and for ducts and air handling units.

Dispersion assemblies in ducts and air handling units must be positioned where

the water vapor being discharged is carried off with the airstream and is