DriSteem RO-200 series, RO-201, RO-202, RO-203 Installation, Operation And Maintenance Manual

Page 1

READ AND SAVE THESE INSTRUCTIONS

WATER TREATMENT

200 series

reverse-osmosis systems

Installation, Operation,

and Maintenance Manual

Page 2

WARNINGS AND CAUTIONS

Warnings and cautions

WARNING CAUTION

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

mc_051508_1145

WARNING

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualifi ed

HVAC and electrical contractors and in compliance with local, state, federal, and governing codes. Improper installation

can cause property damage, severe personal injury, or death as a result of electric shock, burns, or fi re.

DriSteem Technical Support: 800-328-4447

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all

warnings and instructions could produce the hazardous situations described, resulting in property damage, personal

injury, or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause bacteria and mold

growth or dripping water into building spaces. Dripping water can cause property damage; bacteria and mold growth

can cause illness.

If the IOM is missing, go to www.dristeem.com to download a replacement.

Shut down the energy source

Before performing service or maintenance procedures on any part of the system, verify that all energy sources are off.

Failure to shut down the energy source could result in fi re, explosion, electrical shock, and other hazardous conditions.

These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury or death as a result of electrical

shock or fi re. Do not remove electrical panel cover/door or access panels until electrical power is disconnected.

Follow the shutdown procedure in th

the system.

e system IOM before performing service or maintenance procedures on any part of

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii

Page 3

Warnings and cautions

WARNING

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any

part of the humidifi cation system. Failure to disconnect electrical power could result in fi re, electrical shock, and other

hazardous conditions. These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock

or fi re. Do not remove RO system electrical panel cover, heater terminal cover, or subpanel access panels until electrical

power is disconnected.

Follow the shutdown procedure in this manual before performing service or maintenance procedures on any part of the

system.

mc_052410_1510

Electric shock hazard

If the RO system starts up responding to a call for humidity during maintenance, severe bodily injury or death from

electric shock could occur. To prevent such start-up, follow the procedure below before performing service or maintenance

procedures on this RO system (after the tank has cooled down and drained):

1. Use Vapor-logic

2. Shut off all electrical power to the RO system using fi eld-installed fused disconnect, and lock all power disconnect

switches in OFF position.

3. Close fi eld-installed manual water supply shut-off valve.

mc_050808_1540

®

keypad/display to change control mode to Standby.

Fill in the following information for your records

Date of purchase

Customer's name

Model number

Serial number

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

Page 4

Table of contents

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RO supply water requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Flow schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Initial system start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Normal operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start-up checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Test operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial system start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating do's and don't's . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Do . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Don't . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vapor-logic keypad/display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Changing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Controller display activity definitions . . . . . . . . . . . . . . . . . . . . . . . . 15

Test outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Status screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diagnostics and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Modbus, BACnet, LonTalk interoperability . . . . . . . . . . . . . . . . . . . . 18

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv

Page 5

Table of contents

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

Maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

When to change sediment and carbon filters . . . . . . . . . . . . . . . . . . 20

Changing cartridge filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

When to clean or replace membranes . . . . . . . . . . . . . . . . . . . . . . .21

Replacing membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Membrane cleaning in the RO system . . . . . . . . . . . . . . . . . . . . . . . 22

How does it work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Scale cleaning cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Organic cleaning cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Membrane preservative cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Preserving procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Flushing out preservative/restart procedure . . . . . . . . . . . . . . . . 24

System monitoring and record keeping . . . . . . . . . . . . . . . . . . . . . . 25

System operating log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Water quality test strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Water Quality Test Strips Sample Pack . . . . . . . . . . . . . . . . . . . . . . 27

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RO system (Models 201, 202, and 203) . . . . . . . . . . . . . . . . . . . . . 28

Subpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ATTENTION INSTALLER

Read this manual before installing.

Leave manual with product owner.

DriSteem® Technical Support

800-328-4447

Where to find more information

Our website:

The following documents are available on our

web site: www.dristeem.com

• Water Treatment Systems Catalog

• Vapor-logic Controller Installation and

Operation Manual

DriCalc® sizing and selection software:

DriCalc, our software for system sizing and

selection, can be ordered at our web site.

Call us at 800-328-4447

Obtaining documents from our web site or

from DriCalc is the quickest way to view our

literature, or we will be happy to mail literature

to you.

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Keypad/display and troubleshooting

The Vapor-logic Installation and Operation

Manual, which was shipped with your RO

system, is a comprehensive operation manual.

Refer to it for information about using the

keypad/display and Web interface, and for

troubleshooting information.

Download DriSteem literature

Most DriSteem product manuals are available

our website: www.dristeem.com

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

Page 6

OVERVIEW

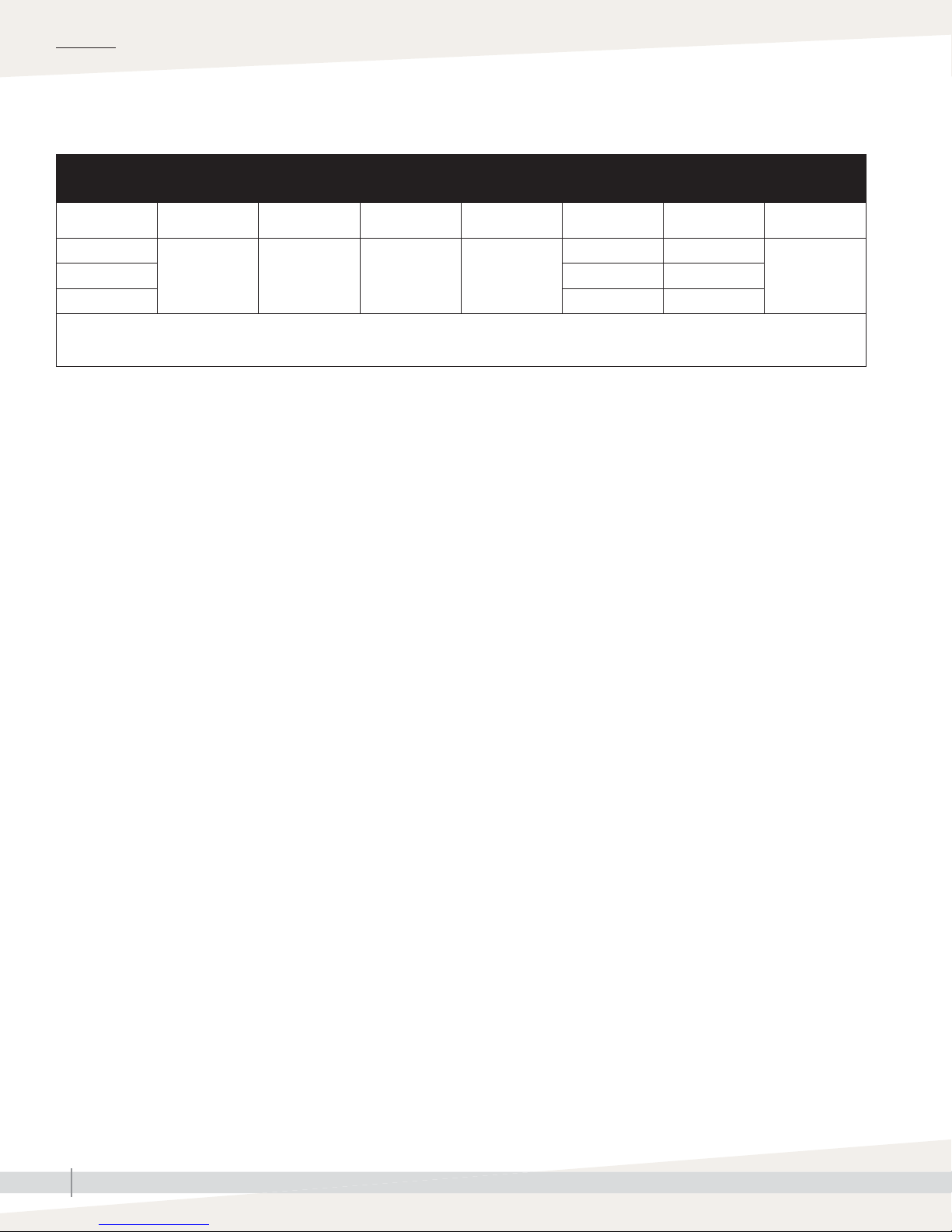

System specifi cations

Table 2-1:

RO station electrical specifications and weights

Model Hz Motor HP Volts*/Amps Phase/Frequency

201

202 124 lbs. (56 kg) 148 lbs. (67 kg)

203 130 lbs. (59 kg) 154 lbs. (70 kg)

* 115V or 230V must be ordered specifi cally

** Tank bladder pressure = 28 psi, tank full at 50 psi

*** Noise measurements taken 6.5' (2 m) in front of the RO-200 water treatment system.

60 1/3

110-120

VAC/5.5A

(208-240

VAC/2.8A)

1/60Hz

NOTES:

1. All systems rated at 50°F (10°C) using 1000 ppm sodium chloride (NaCl)

solution. System capacity decreases signifi cantly with decrease in feed

water temperature.

Approximate

shipping weight**

118 lbs. (54 kg) 142 lbs. (64 kg)

Operating

weight**

Noise***

49 dBA min.

58 dBa max.

2. Chlorine requirements for the feed water are:

a. Thin-Film (standard) 0 ppm

3. Feed water must be filtered to a turbidity of less than 1 NTU.

4. System recovery (permeate to concentrate ratio) must be maintained at

the recommended level. A higher than recommended recovery will lead

to a premature fouling of the membrane with a loss of permeate flow and

permeate quality.

5. Recommended minimum clearances if:

– 24" or greater (610 mm) above: 6" (152 mm) left, right and rear and

24" (610 mm) front

– less than 24" (610 mm) above: 6" (152 mm) left and right and 24"

(610 mm) front and rear

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

Page 7

System specifi cations

Table 3-1:

RO station capacities

Model 201 202 203

Rated capacity, permeate

Gallons/minute 0.2 0.4 0.6

Concentrate fl ow (reject)

Gallons/minute 0.6 - 1.1 0.7 - 1.2 0.5 - 1.0

Recirc fl ow (adjustable as needed)

Gallons/minute 0 - 0.5 0 - 0.5 0 - 0.5

System pressure, psi (pump pressure through membranes) 100 - 150 100 - 150 100 - 150

°F (°C) 50 (10) 50 (10) 50 (10)

Pre-fi lters

1

1, 2

OVERVIEW

Sediment cartridge - 5 micron 1 1 1

Carbon cartridge - 10 micron 2 2 2

Pressure sensor settings

Low pressure (for pump protection) 8 psi 8 psi 8 psi

1.

Reduce concentrate fl ow by the amount of recirc fl ow used to maintain the recommended maximum system level.

2.

Recirc fl ow usage will reduce water but may decrease membrane life.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3

Page 8

OVERVIEW

Product overview

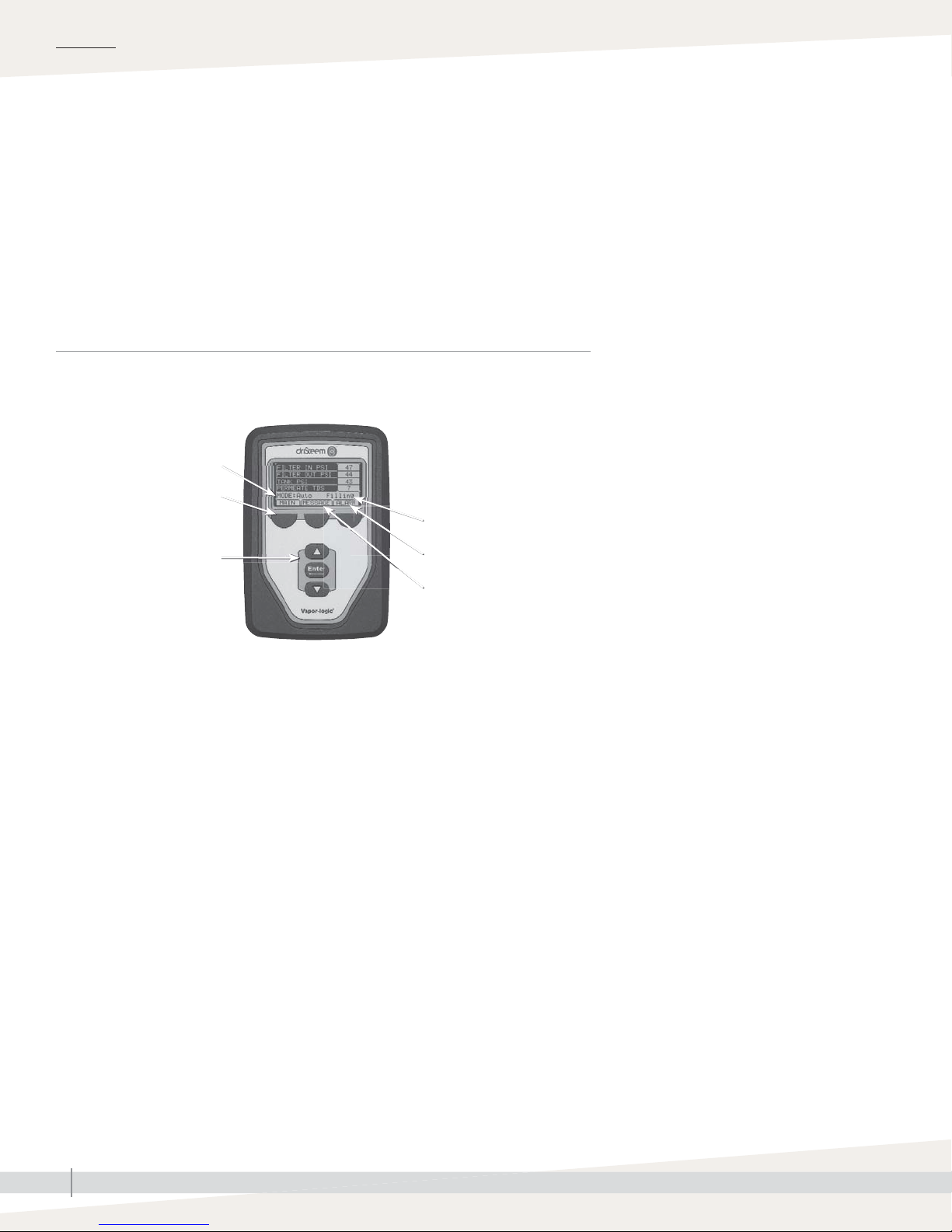

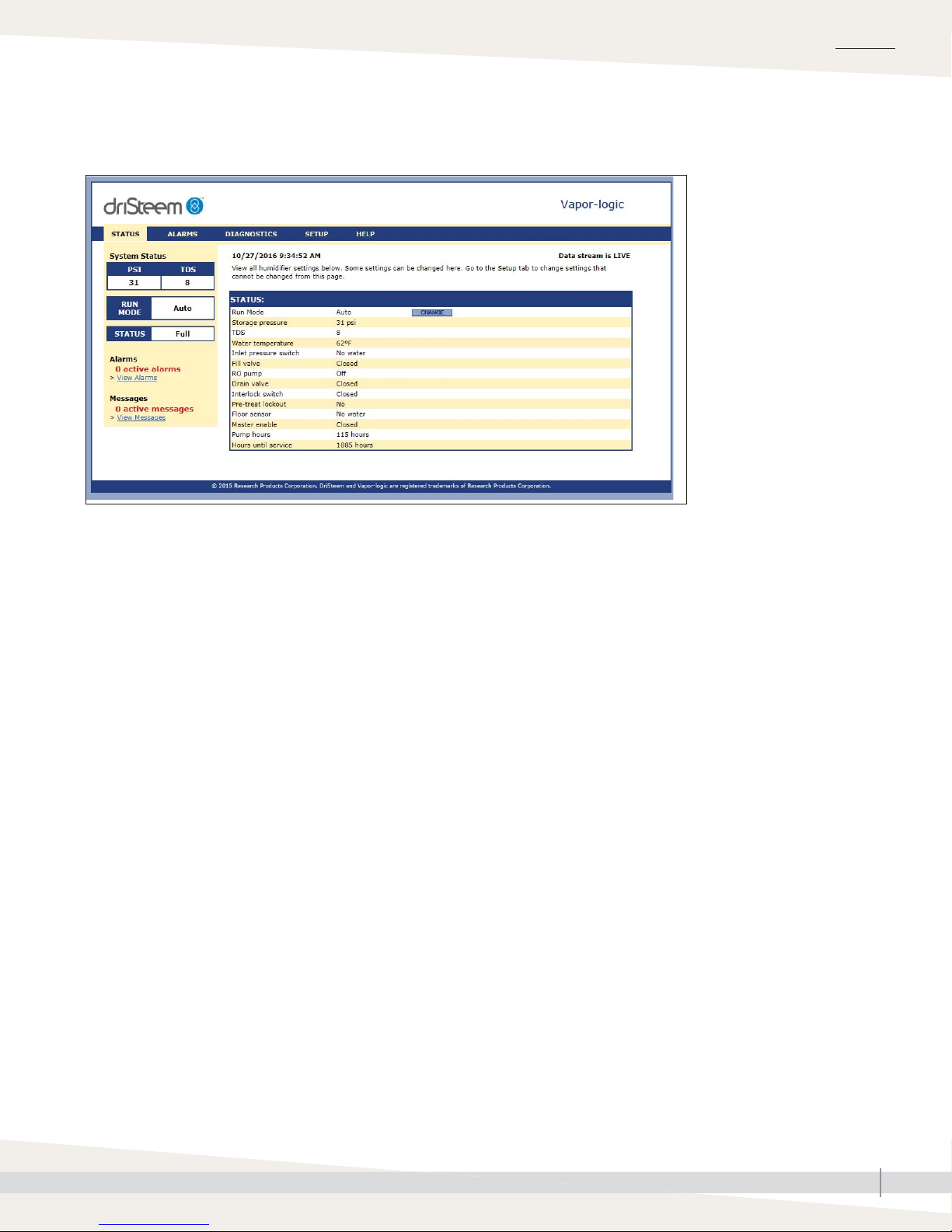

CONTROLLER

The Vapor-logic controller in the RO system provides menus for all RO system

functions, with a Web interface for Ethernet access (see Figure 4-1).

The Vapor-logic Installation and Operation Manual ships with the RO system.

Refer to it for information on using the keypad/display and Web interface, and

for troubleshooting information.

FIGURE 4-1: VAPOR-LOGIC KEYPAD/DISPLAY AND WEB INTERFACE

KEYPAD/DISPLAY

Mode

Softkeys

for direct menu access

Navigation buttons

for item selection

Tank status

System alarms

System messages

Static IP addresses

See the Vapor-logic Controller Installation and

Operation Manual shipped with the RO system

for more information about confi guring IP

addresses.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

Page 9

Product overview

WEB INTERFACE

OVERVIEW

RO SUPPLY WATER REQUIREMENTS

Supply water quality is an important component

of DriSteem reverse osmosis system reliability and

maintenance.

Water hardness can increase the reverse osmosis system

maintenance requirements.

To maximize service life and minimize maintenance for

RO systems and downstream equipment, softened water is

required with all DriSteem RO systems.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

Page 10

OVERVIEW

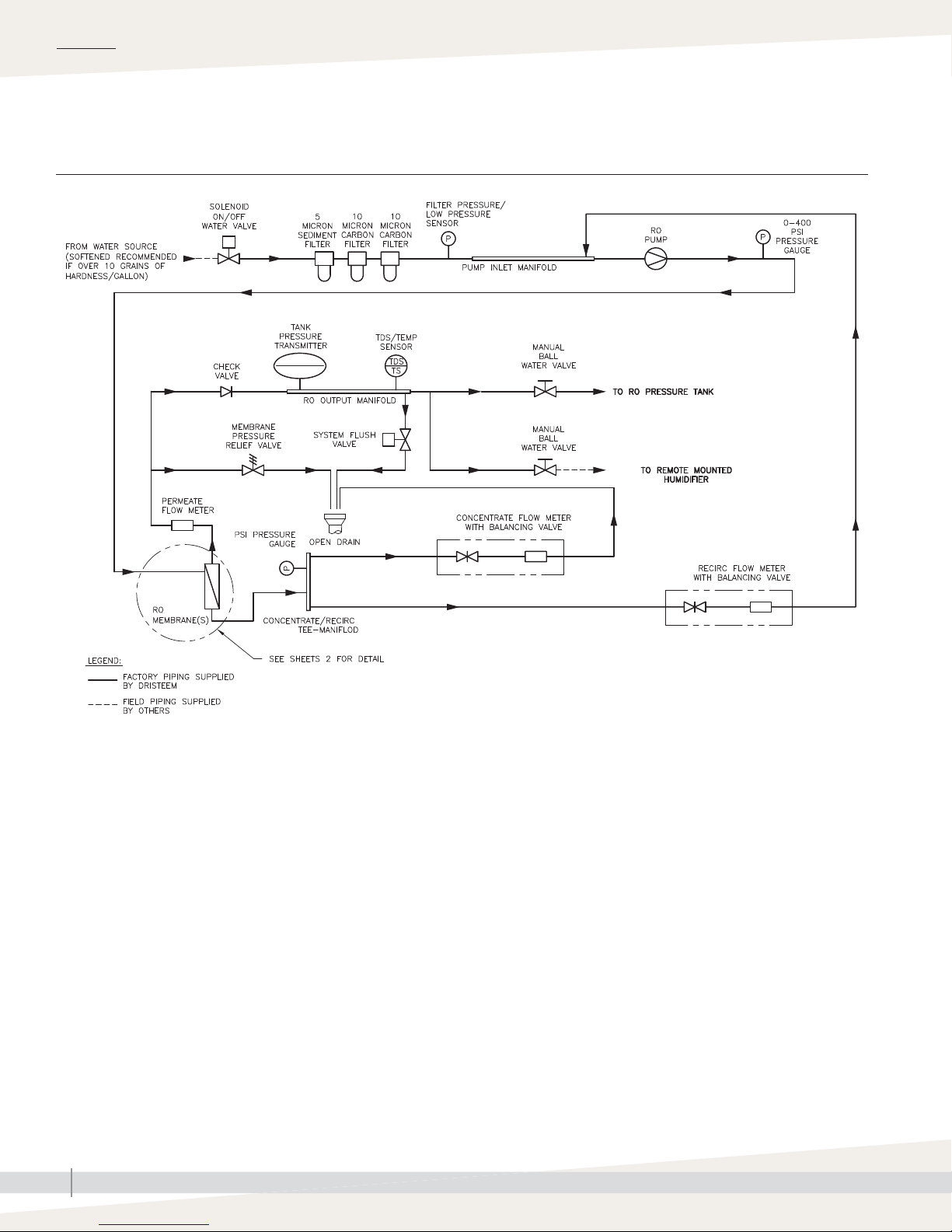

Flow schematic

FIGURE 6-1: FLOW SCHEMATIC

RO200-PIPING

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

Page 11

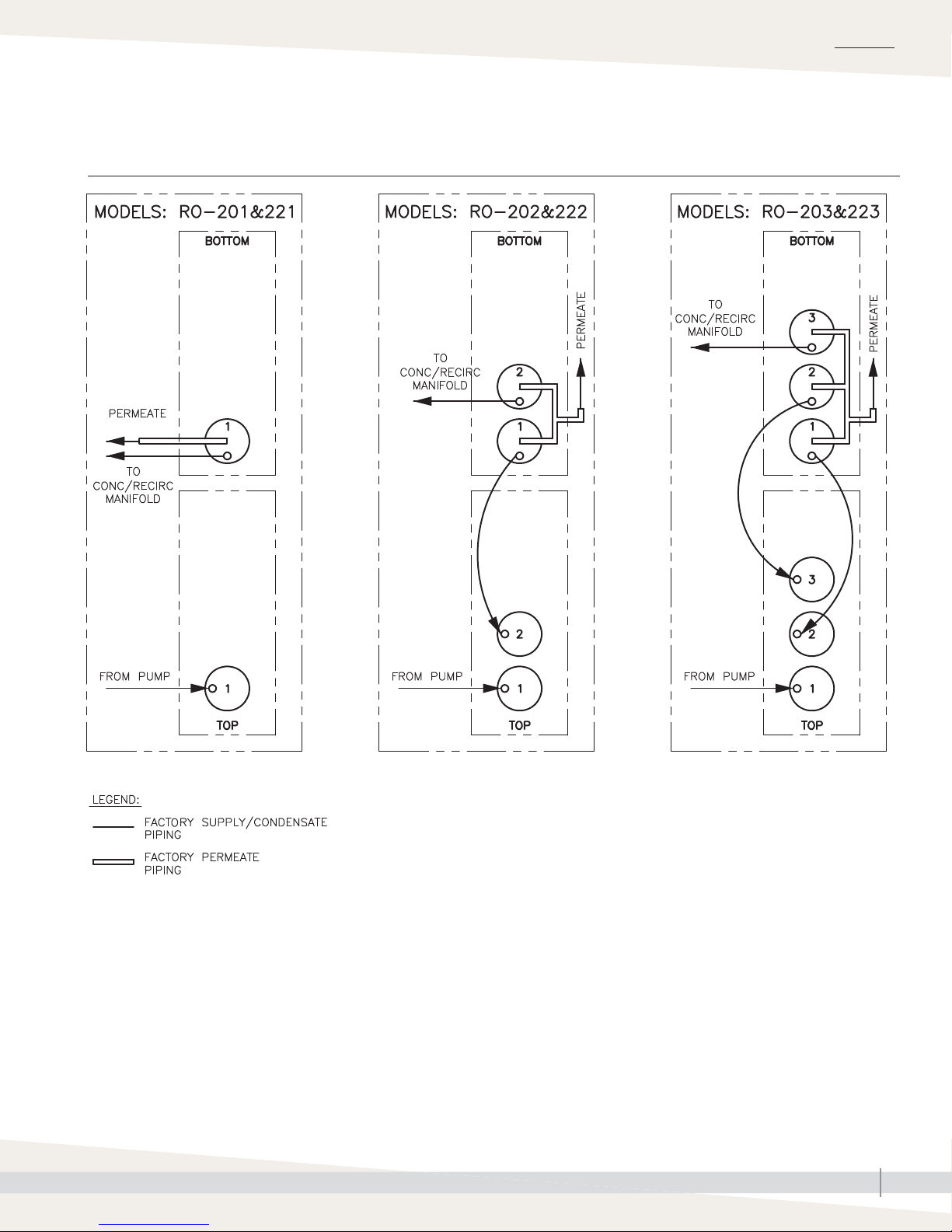

Flow schematic

FIGURE 7-1: FLOW SCHEMATIC

OVERVIEW

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

RO200-PIPING-1

7

Page 12

OVERVIEW

Component identifi cation

FIGURE 8-1: COMPONENT IDENTIFICATION

10

11

9

4

7

1

12

13

3

6

5

8

15

16

14

2

Table 8-1:

Component identification

Item Description

1 Vapor-logic keypad/display Power On/Off and status display

2 Inlet solenoid valve Normally closed. Opens when power is applied.

3 Filter pressure sensor

4 Sediment fi lter 5 micron sediment fi lter.

5 Carbon fi lter 10 micron extruded carbon cartridge to remove chlorine and reduce organics from the feed stream.

6 Low pressure sensor Shuts the system down if the inlet pressure is lower than 8 psi (adjustable).

7 High pressure pump and motor Rotary pump and motor to pressurize the incoming water.

8 Membrane modules RO membrane elements housed in stainless steel pressure tubes.

9 System pressure gauges Measure the system (feed) and concentrate (effl uent) pressure of the membrane modules.

10 Concentrate to drain control valve To adjust system pressure. Must not be completely closed when the system is in operation.

11 Concentrate recirc control valve To adjust and maintain adequate fl ow thru membranes

12 Permeate fl ow control valve Monitor permeate water fl ow.

13 TDS monitor Monitors the feed and permeate water quality.

14 Permeate check valve Prevents backfl ow into RO module.

15 Pipe drain Drain assembly. Run to a fl oor drain.

16 Vapor-logic control board The Vapor-logic control board is mounted inside the control cabinet.

Measure the feed and effl uent pressure of the cartridge fi lters. Pressure difference determines when

cartridge change out is required.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8

Page 13

Piping and instrumentation arrangement

FIGURE 9-1: FLOW SCHEMATIC WITH A CARTRIDGE DECHLORINATOR

INSTALLATION

OM-7905

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

Page 14

OPERATION

System operation

INITIAL SYSTEM START-UP

SYSTEM FLUSH

Direct permeate discharge to drain for fi rst 30 minutes of operation.

1. Connect the system to the appropriate electrical outlet, 110-120 VAC or

208-240 VAC 1 phase.

2. Ensure all plumbing connections are open to allow flow. Open the

concentrate valve (counterclockwise). Close the recirc valve (clockwise).

Ensure suffi cient pressure (40 psi recommended) is in feed line. If pressure

is less than 8 psi, the low pressure sensor will disallow start-up until

pressure is adequate.

3. Press the power button; the solenoid will open and the unit will start

operating.

4. After water is flowing from the concentrate line, adjust the concentrate

control valve to obtain designated flow for the specific model (see Table

3-2 on page 3).

5. If required, adjust recirc control valve to meet desired flow rates (see

Table 3-2 on page 3).

6. Allow the unit to run for 30 minutes to ensure proper flushing of system.

7. After the flush time is over, press the power button OFF.

8. Redirect the permeate line to the desired location.

NORMAL OPERATIONS

1. Turn the power back ON. After the pump starts, adjust the control valve to

the desired flow/pressure (not to exceed 150 psi).

FIGURE 10-1: CONTROL VALVES

CAUTION

To prevent concentrate from

precipitating and causing irreversible

fouling of the RO membrane, do not

operate the system with the control

valve completely closed.

2. The recirculation valve may now be adjusted to achieve desired

recirculation flow rate, ensuring concentrate flow rate is as specified.

SHUTDOWN

1. Press the power button to shut unit OFF. Close the isolation valve if it is

installed on the feed line.

CAUTION

Do not exceed recommended

maximum recovery.

2. If the unit is to be shut down for more than one week, a membrane

preservative should be used. To accomplish this, perform 30 second flush

using cartridge filter insert (see page 24 for more information). After

30 seconds, press the power button OFF, and close the concentrate valve.

This will hold the preservative in the pressure vessel.

3. When the system is restarted after an extended shutdown, follow initial

system start-up procedures.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

10

Page 15

OPERATION

Start-up checklist

If an item in the Start-up checklist below does not apply to your system, skip to the next item and continue the process.

☐ Read this manual and all other information that was provided with your system.

☐ Verify that all fi eld wiring is done according to the instructions in this manual and in the unit wiring diagram.

☐ Confi rm that proper grounding and an approved earth ground are provided.

☐ Confi rm that the keypad/display is mounted with its modular cable routed away from high-voltage circuits and

connected to the Display connector on the Vapor-logic board.

☐ Install cartridge fi lter and check for leaks.

☐ Precharge pressurized RO storage tank to 28 psi (195 kPa).

Note: This precharge pressure is for pressurized RO storage tank cut-in and cut-out switch points at 30 and 50 psi

(210 and 345 kPa) respectively.

☐ Turn on the water supply, and confi rm there are no leaks.

☐ Turn on power to the unit, and confi rm the Main menu is displayed on the keypad/display. The display may take

several seconds to appear as the controller powers up.

☐ Confi rm in the Main Menu that the mode is “Auto” and that status is “Idle.”

☐ When “Idle” appears in main menu, confi rm that the inlet pressure is at least 40 psi (276 kPa) on the display.

☐ With suffi cient water available, the system in Auto mode, and the storage tank pressure less than 30 psi (210 kPa),

verify that the pump is activated.

☐ Set perm fl ow and recirc fl ow meter to desired setting.

☐ If you experience diffi culties, have the keypad/display information available along with the serial number and unit

Model, and call DriSteem Technical Support at 800-328-4447.

Note: Instructions on how to properly care for the freeze protect chemical that is shipped with the system is available

on the SDS sheet at www.dristeem.com.

☐ Inspect to insure that no fl exible plumbing lines have been kinked or damaged during installation.

WARNING

Tipping hazard

Before installing the 200 series

reverse-osmosis system, use

supplied leg brackets or lag points

to permanently fi x the system to

the fl oor and/or adjacent building

structure. Failure to install according

to instructions can result in serious

injury or death. See page 10 for

instructions.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

Page 16

OPERATION

Start-up

START-UP PROCEDURE

Check component installation per the layout shown in Figure 6-1

(depending on your model). After all components are installed and connected

properly:

1. Perform all applicable “Start-up checklist” items on Page 11.

2. Read and follow instructions in the “Operation” section of Vapor-logic

Installation and Operation Manual.

Note: During start-up, do not leave the system unattended.

TEST OPERATION

Using the keypad/display or web interface, place pump station in Auto mode.

Perform the following procedure:

1. If the system has a full RO holding tank, create a call for water by draining

water from the tank until the pressure falls below 30 psi (210 kPa).

2. Monitor system performance, and watch for leaks.

3. If a leak is found:

a. Remove demand signal, and put the system in Standby mode.

b. Tighten any loose connections.

c. Return system to Auto mode.

d. If a leak persists, replace tubing or fi tting that is leaking.

Important

If the system is not in operation within six

months of shipment, it is strongly recommended

to use an organic cleaning cartridge prior

to performing the start-up checklist to ensure

proper operation. See page 11 for

information and part number.

CAUTION

If the pump chatters loudly, it is

starving for water (cavitating). Turn the

unit OFF immediately to prevent pump

damage. Correct the low pressure

condition before proceeding.

FIGURE 12-1: SOLENOID VALVE INLET

4. Leave system in Auto mode. It will automatically refill the RO holding tank

when pressure falls below 30 psi (210 kPa).

INITIAL SYSTEM START-UP

1. Close the manual valves to both the RO holding tank and all downstream

equipment. Open the manual valve leading to the drain.

2. Open the feed water supply valve.

3. Open the concentrate control valve fully counterclockwise. Close the

recirculation valve.

4. Put the system into 'Auto' mode. Note inlet water pressure must be at least

40 psi (276 kPa).

5. If incoming pressure is too high, an inlet pressure regulator (not included)

may be installed. This should be set at 40 psi (276 kPa).

6. Some fittings may have loosened during shipment. Check for leaks at all

tube fittings and threaded joints.

7. Allow the unit to run for at least 30 minutes to flush the preservative

solution from the system.

CAUTION

Pump and system performance will be

adversely affected if the feed/suction

line is restricted.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12

Page 17

Start-up

OPERATION

1. Once the preservative solution has been flushed from the system, shut

down the system by putting the system into 'Standby' mode on the Vaporlogic keypad and close the manual valve going to the drain. Open the

manual valves to both the RO storage tank and downstream equipment.

2. Run a ¾" MNPT from the stand pipe drain to an open drain.

3. Put the system back into 'Auto' mode.

4. Adjust the throttle valve to get the specified permeate flow (if applicable).

5. Adjust the concentrate valve and recirculation valve until the specified

permeate flow and recirculation flow are obtained. It may be necessary to

readjust the throttle valve. See Table 3-1.

6. Test the operation of a low pressure sensor by slowly closing the inlet

water supply valve. The unit should shut off after a short 5 second time

delay.

7. Once all the desired flows are set, allow the system to run for

approximately 30 minutes. Then record the performance information using

the system operation data log on page 26. The values recorded at

startup will be important for determining system performance at a later

date.

OPERATING DO'S AND DON'T'S

CAUTION

Do not operate the system with the

control valve closed.

Important:

By setting the feed pressure as low as possible

to meet the application requirement, the

service life of the pump and RO elements

will be optimized. The system should be run

continuously when possible, rather than go

through frequent start/stop cycles.

CAUTION

Damage to pump

Do not close the valve. Do not operate

the pump below minimum combined

fl ow rate (permeate + concentrate +

recirculating).

DO

1. Change the cartridge filters regularly

2. Monitor the system and keep a log daily

3. Run the system, as much as possible, on a continuous basis.

4. Adjust the system recovery to the recommended value

DON'T

1. Permit chlorine in the feed water.

2. Shut down the system for extended periods. If system will be down for

more than one week, treat the system with a membrane preservative. See

page 20 for instructions.

3. Close the throttle valve completely.

4. Operate the system with insufficient feed flow.

CAUTION

Confi rm all lines are connected before

plugging in unit power.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

13

Page 18

OPERATION

Vapor-logic keypad/display

FIGURE 14-1: USING THE VAPOR-LOGIC KEYPAD/DISPLAY

Typical Home screen

Tank pressure/status

Change Mode from the Home

screen by pressing the Up or

Down arrow keys until Mode

is highlighted, press Enter,

press Up or Down arrow keys

to change, press Enter to

confi rm

Total dissolved solids (TDS)

Status

Press Main softkey for

Main menu; other softkey

functions vary by screen

Press Up or Down

arrow to move through

menus and screens

Alarm

label flashes

when there is a

system alarm

Message

label fl ashes

when there is a

system message

Press

Enter

to select or

confi rm

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

14

Page 19

Keypad/display Home screens,Test outputs, Test run

OPERATION

Vapor-logic returns to the Home screen on the keypad/display after a userdefi ned period of idleness. The Home screen displays the items most frequently

viewed.

CHANGING MODE

Mode can be changed from the Home screen. Press the Up or Down arrow

key until the Mode is highlighted, press Enter, press Up or Down arrow key to

change value, press Enter to confi rm. All other parameters shown on the Home

screen are for viewing only and cannot be changed. Go to the Setup menu to

change these items.

CONTROLLER DISPLAY ACTIVITY DEFINITIONS

(Figure 15-1)

RO fl ush: System is performing an RO fl ush.

Idle: No demand, or an active alarm is preventing operation.

Filling: System is supplying high-pressure water to meet demand.

Full: Storage tank is full, system not running.

TEST OUTPUTS

When completing an installation or repair, cycle all outputs, to verify

operation. Go to the test outputs section of the Diagnostics menu and scroll

through each connected output to verify operation. During testing, the unit

mode changes to Standby and the tank status changes to Test.

FIGURE 15-1: RO STATION KEYPAD/

DISPLAY HOME SCREEN

TEST RUN

Vapor-logic has a test run capability to confi rm system functionality. This

capability allows a technician to simulate a demand when there isn’t one (such

as when performing routine maintenance). To confi rm functionality, go to the

test run section of the Diagnostics menu. Set system demand percent and set

test run time duration. During testing, the unit mode changes to Standby and

the tank status changes to Test.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

15

Page 20

OPERATION

Status screen

Table 16-1:

Status screen

Note: Your system might not have all of the items listed in this table.

Menu

item

Run mode Standby -- -- --

TDS -- 0 9999 ppm

TDS set point 50 0 100 ppm

Water temperature

Safety interlock Closed Open Closed --

Inlet pressure sensor -- No water Water --

Storage pressure -- 0 100 psi Storage tank pressure.

Pump hours -- 0 100,000 Hours

Default

value

Minimum

value

-- -50 250 °F Sensor range

-- -46 121 °C Sensor range

Maximum

value

Units Notes

Operating mode of unit. Choose from Auto, Standby, or Drain.

• In Auto mode, the unit operates normally. All unit components are

monitored and controlled. If there is a call for cooling/humidifi cation, the

system reacts.

• In Standby mode, the unit is offl ine. All control inputs appear but are

not acted upon; however, if the water temperature falls below the freeze

protect set point, the drain valve opens.

• In Drain mode, the RO Flush valve opens, the RO tank drains, and the RO

system begins making RO water. All unit operation is suspended, and the

RO Flush valve remains open until the model specifi c RO fl ush time is met

the unit is taken out of RO fl ush mode, or the RO tank is drained.

• See the Diagnostics section for information about Test outputs and Test run

modes.

Table 16-2:

Setup screen

Note: Your system might not have all of the items listed in this table.

Menu

item

Membrane fl ush 300 0 300 seconds

System fl ush 72 1 336 hours

Default

value

Minimum

value

Maximum

value

Units Notes

Table 16-3:

TDS setting

Note: Your system might not have all of the items listed in this table.

Menu

item

High TDS causes Alarm Message Alarm --

TDS setpoint 50 25 100 --

Default

value

Minimum

value

Maximum

value

Units Notes

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

16

Page 21

OPERATION

Diagnostics and Alarms

Table 17-1:

Diagnostics menu

Note: Your system might not have all of the items listed in this table.

Message Description Auto-clear?

Pretreat lockout Softener or other pretreatment is preventing the RO station from operation. Yes

No master enable Master enable for the system is open. Yes

Excessive TDS

Service unit Regularly scheduled unit servicing is due. No

I-lock open Interlock safety switch is open. Yes

Notes:

• The Messages Log displays message name, date and time of occurrence, plus “Active,” “Cleared” or “Auto-cleared.”

• Active messages display fi rst in the Messages Log, followed by cleared messages (auto-cleared and/or manually-cleared) listed in order of

occurrence.

• The Messages Log displays a maximum of 10 messages. Cleared messages leave the log fi rst.

• If a message event occurs and is not manually or auto cleared during unit operation, the message will stay there until there is demand and the

unit is running.

TDS measurement during RO production exceeds the TDS set point.

The system will continue to operate but the membranes may need to be replaced.

Yes

Table 17-2:

Alarm menu

Alarm level Description Auto-clear?

Temp sensor fault Water temperature/TDS sensor reading is out of range. Yes

Low inlet pressure* Water pressure at RO inlet is less than 10 psi. Yes

High storage

pressure

Floor sensor active Optional fl ooded fl oor pan circuit is active. No

Storage pressure

sensor

Excessive TDS

Notes:

• See the "troubleshooting" section in the Vapor-logic Installation and Operation Manual for alarm possible causes and recommended actions.

• The Alarms Log displays alarm name, date, and time of occurrence, plus "Active," "Cleared," or "Auto-cleared."

• Active alarms display fi rst in the Alarms Log, followed by cleared alarms (auto-cleared and/or manually-cleared) listed in order of occurrence.

• The Alarms Log displays maximum 30 alarms. Cleared alarms leave the log fi rst.

• If an alarm event occurs and is not manually cleared or auto-cleared during unit operation, the alarm will remain until there is demand and the

unit is running.

* Pressure alarm will occur if inlet pressure falls below 5 psi. Alarm will self-clear when RO system supply pressure is above 10 psi for at least 10

consecutive seconds. A pressure fault can be manually cleared at any time. System will try to operate every 10 consecutive seconds per hour up to

72 hours while in low pressure alarm condition.

Tank storage pressure has exceeded 60 psi. Yes

Pressure sensor reading is out of range. Yes

TDS measurement during RO production exceeds the TDS set point.

The system will continue to operate but the membranes may need to be replaced.

No

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

17

Page 22

OPERATION

Modbus, BACnet, LonTalk interoperability

Table 18-1:

Interoperability vaiable and object names

Variable name and

BACnet object name

Read-only analog variables

Storage_pressure RO IR-1 AI-1 nvoStoragePress Storage pressure psi bar 0 100

Pump_1_hour RO IR-2 AI-2 nvoPumpHours Hours of operation hours hours 0 100000

Water_temp RO IR-3 AI-3 nvoWaterTemp

TDS RO IR-4 AI-4 nvoTDS TDS — — 0 9999

Set Variables

Run_mode

TDS_setpoint RW HR-2 AV-1 nviTDS_SP TDS set point — — 0 75

Read-only digital I/O

Safety_interlock RO DI-1 BI-01 nvol-LockSW

Pretreat_lockout_sw RO DI-2 BI-02 nvoPreTreatSW

Floor_water_sw RO DI-3 BI-03 nvoFloorSW

Inlet_pressure_sw RO DI-4 BI-04 nvoInletPressSW

Master_enable_sw RO DI-5 BI-05 nvoMasterEnabSW

Supply_valve RO DI-6 BO-01 nvoSupplyValve

Drain_valve RO DI-7 BO-02 nvoDrainValve

RO_pump RO DI-8 BO-03 nvoROpump 0=Off; 1=On ————

Notes:

1. Modbus Input Registers (IR1-IR4) 16 bit read only

Modbus Holding Registers (HR1-HR2) 16 bit read/write

Modbus Discrete Input Registers (DI1-DI8) single bit read only

Modbus Coil Registers (DV1-DV8) single bit read/write

2. nvi LonTalk SNVTs are write-only; nvo are read-only

Read Only

(RO) or

Read Write

(RW)

Write HR-1 MSV-01 nviRunMode

Read HR-1 MSV-01 nvoRunMode

Modbus

register

number*

BACnet

Object

Type and

Instance

LonTalk variable

names**

Description Units Range

I-P units SI units I-P units SI units

Temperature of RO

water

Mode of the unit

or system. The

defi ned options

are:

1=Auto;

2=Local standby;

3=System standby;

4=Manual drain;

5=Test outputs;

6=Test run

Mode of the unit

or system. The

defi ned options

are:

1=Auto;

2=Local standby;

3=System standby;

4=Manual drain;

5=Test outputs;

6=Test run

0=Open;

1=Closed

0=Open;

1=Closed

0=Water;

1=No Water

0=No Water;

1=Water

0=Open;

1=Closed

0=Open;

1=Closed

0=Open;

1=Closed

F C -50 to 250 -46 to 121

— — 1 to 4 1 to 4

1 to 6 1 to 6

————

————

————

————

————

————

————

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

18

Page 23

OPERATION

Modbus, BACnet, LonTalk interoperability

Table 18-1:

Interoperability vaiable and object names

Variable name and

BACnet object name

Faults and Alarms

ProgOutput1_status RW DV--01 BV-01 nvoDryConStat1 NO or NC output — — — —

ProgOutput2_status RW DV-02 BV-02 nvoDryConStat2 No or NC output — — — —

Active_manually_

cleared_alarm_exists

Clear_all_faults RW DV-04 BV-04 nviClrAllFault

Alarm_temp_sensor_

failed

Alarm_low_inlet_

pressure

Alarm_excessive_

storage_pressure

Alarm_fl oor_water_

sensor_activated

Alarm_pressure_sensor_

out_of_range

Alarm_excessive_TDS_

during_fi ll

Message_pretreat_

lockout_active

Message_excessive_

TDS_during_fi ll

Message_service_unit RW DV-13 BV-13 nvoMsgSrviceUnt

Message_interlock_open RW DV-14 BV-14 nvoMsgllockOpen

Message_master_

enable_open

Notes:

1. Modbus Input Registers (IR1-IR11) 16 bit read only

Modbus Holding Registers (HR1-HR10) 16 bit read/write

Modbus Discrete Input Registers (DI1-DI9) single bit read only

Modbus Coil Registers (DV1-DV15) single bit read/write

2. nvi LonTalk SNVTs are write-only; nvo are read-only

Read Only

(RO) or

Read Write

(RW)

RW DV-03 BV-03 nvoAlarmManCl

RW DV-05 BV-05 nvoAlmTempSense

RW DV-06 BV-06 nvoAlmInPress

RW DV-07 BV-07 nvoAlmOutPress

RW DV-08 BV-08 nvoAlmFloorWet

RW DV-09 BV-09 nvoAlmPrSensOOR

RW DV-10 BV-10 nvoAlmExcessTDS

RW DV-11 BV-11 nvoMsgPretreatL

RW DV-12 BV-12 nvoMsgExcessTDS

RW DV-15 BV-15 nvoMsgNoMastEnb

Modbus

register

number*

BACnet

Object

Type and

Instance

LonTalk variable

names**

Description Units Range

I-P units SI units I-P units SI units

Flags all manually

cleared alarms

When set will clear

all active faults

See Table 17-2:

Alarm menu

See Table 17-2:

Alarm menu

See Table 17-2:

Alarm menu

See Table 17-2:

Alarm menu

See Table 17-2:

Alarm menu

See Table 17-2:

Alarm menu

See Table 17-1:

Diagnostics menu

See Table 17-1:

Diagnostics menu

See Table 17-1:

Diagnostics menu

See Table 17-1:

Diagnostics menu

See Table 17-1:

Diagnostics menu

——— —

——— —

——— —

——— —

——— —

——— —

——— —

——— —

——— —

——— —

——— —

——— —

——— —

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

19

Page 24

MAINTENANCE

Maintenance information

MAINTENANCE TIPS

Maintain proper operating conditions:

• Do not exceed 90 psi (620 kPa) on the fi lter inlet pressure reading.

• Do not over use recirculation fl ow. This can cause premature scaling of the

membrane. A proper concentrate fl ow is required for a long membrane life.

See page 3 for maximum recirculation fl ow.

• To ensure no chlorine reaches the RO membranes, test the water from your

dechlorinator periodically for chlorine break through.

WHEN TO CHANGE SEDIMENT AND CARBON FILTERS

Sediment and carbon fi lters should be changed regularly to maintain proper

pressure and fl ow and water quality.

Change the carbon fi lter when chlorine from supply water starts to pass

through. The carbon fi lter removes chlorine. Check regularly for chlorine pass

through. To check for chlorine, obtain a water sample from the concentrate

drain line and test the water. If chlorine is present, change the carbon fi lter and

record the interval to estimate the next carbon fi lter change.

Change the sediment fi lter when the difference between fi lter inlet pressure and

fi lter outlet pressure increases by 10 psi over the initial pressure difference.

For example, if initial readings are 60 psi in and 58 psi out, the difference is

2 psi. Therefore, when that difference reaches 12 psi, it is time to replace the

sediment and carbon cartridges.

FIGURE 20-1: SEDIMENT FILTER

DriSteem replacement part

• 2.5" x 10" - (part number: 550030-002)

FIGURE 20-2: CARBON FILTER

CHANGING CARTRIDGE FILTERS

1. Put the system into 'Standby' mode and shut down the RO system.

2. Close inlet supply valve.

3. Un-assemble the filter housing (twist the sump counter-clockwise).

4. Remove and inspect the cartridge. Replace as needed.

5. Before replacing housing, insure that O-ring seal is lubed and placed in

groove of housing. Inspect seal and replace as needed.

6. Assemble housing (turn the sump clockwise into the cap until tight).

Important: Verify regularly that water processing equipment is operating

correctly. The presence of chlorides in improperly process deionized water will

eventually cause pitting and failure of the equipment the RO system is servicing

and its components. Damage cause by chloride corrosion is not covered by

your DriSteem warranty. The RO system has an automatic drain sequence

(ADS) set based on default supply concentration of 20 ppm. Adjust ADS to

actual supply water connection.

DriSteem replacement part

• 2.5" x 10" - (part number: 550030-003)

CAUTION

Chlorine can damage the membrane.

A carbon pre-fi lter is installed to

remove chlorine from fee water. Care

must be taken to change this carbon

fi lter as needed to accomplish effective

chlorine removal. Excessive chlorine

in feed stream may require additional

pre-fi ltration. The feed stream should

be tested for chlorine at least once

a week. Always follow proper

maintenance procedures.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

20

Page 25

Maintenance continued

MAINTENANCE

WHEN TO CLEAN OR REPLACE MEMBRANES

In normal operation, the membrane in reverse osmosis elements can become

fouled by mineral scale, biological matter, and grime. These deposits build

up during operation until it causes loss in water output or loss of salt rejection,

or both. Elements should be cleaned or replaced whenever the water output

rate drops by 10 percent from its initial fl ow rate (the fl ow rate established

during the fi rst 24 to 48 hours of operation) or when TDS in the product water

(permeate) rises above 50. This is indicated through a message on the Vaporlogic controller (above 75 will alarm).

It should be noted that the water output rate will drop if feed water temperature

decreases (about 1.5% per °F). This is normal and does not indicate membrane

fouling. A malfunction in the pretreatment, pressure control or pump can cause

a drop in feed water delivery pressure, feed water fl ow, product water output,

or an increase in salt passage. If such adjustments are needed, the element

may not require cleaning.

REPLACING MEMBRANES

TOOLS

• Rubber mallet

• Flat blade screwdriver

• Open end wrench, ⅞ inch

• Safety glasses

FIGURE 21-1: PRE-FILTER

1

1. Sediment filter:

Removes sediments and particles down

to 5 micron size.

2. Carbon filter:

Primarily to remove chlorine; also

removes organics and sediments down

to 10 microns.

2

2

PROCEDURE

1. Turn OFF the RO system.

2. Relieve pressure on the membrane by opening the supply valve.

3. Remove all lines from the top of the pressure vessel(s). Make sure the

fittings are marked so the fittings go back to the correct locations after

replacing.

Note: Membranes on RO system are removed and inserted from the top.

4. Remove end plugs by pulling carefully. See Figure 21-2.

FIGURE 21-2: DRISTEEM REVERSE

OSMOSIS MEMBRANES

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

21

Page 26

MAINTENANCE

Maintenance continued

MEMBRANE CLEANING IN THE RO SYSTEM

Membrane cleaning cartridges:

• Clean membranes without having to remove them from the RO system

• Reduce downtime

• Maintain the system performance at a higher level

• Prolong membrane life by regular use of cleaning cartridges

HOW DOES IT WORK?

NOTE: Clean monthly to obtain optimum results.

1. Exchange the system's sediment filter with a cleaning cartridge.

2. Follow the instructions.

3. Restart the system.

4. Repeat the process if required.

SCALE CLEANING CARTRIDGE

The scale cleaning cartridge is for removal of mineral scale and build-up.

CLEANING PROCEDURE

1. Put the system into 'Standby' mode and shutdown the RO system.

2. Disconnect permeate line and divert to drain before any cleaning

cartridge is installed.

3. Remove the sediment filter from the pre-filter housing.

FIGURE 22-1: 10 INCH SCALE CLEANING

CARTRIDGE

DriSteem replacement part

• 2.5" x 10" - (part number: 550045-401)

CAUTION

Handle all chemicals with care. Wear

protective clothing and eye protection.

4. Replace the sediment filter with the cleaning cartridge and assemble into

the filter housing.

5. Turn the system ON and put into 'Auto' mode. After 30-40 seconds, shut

down the system.

OPTIONAL: Instead of time, use one of the following criteria:

a. Run the system until the pH of the concentrate is almost the same as the

cleaning solution (pH=3)

b. Permeate rate for the system drops to a very low value.

6. Let the membrane(s) soak in the cleaning solution overnight.

7. Remove the empty cleaning cartridge and replace it with the original filter.

8. Restart the system. Direct the permeate to drain for five minutes.

9. Go back to normal operations.

CAUTION

The system must be fl ushed thoroughly

between acid and alkaline cleaning.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

22

Page 27

Maintenance continued

MAINTENANCE

ORGANIC CLEANING CARTRIDGE

The organic cleaning cartridge is for removal of organics/fouling.

CLEANING PROCEDURE

1. Put the system into 'Standby' mode and shutdown the RO system.

2. Disconnect permeate line and divert permeate to drain during cleaning.

3. Remove the sediment filter from the filter housing.

4. Replace the sediment filter with the cleaning cartridge and assemble into

the filter housing.

5. Turn the system ON. After 30-40 seconds, shut down the RO system.

OPTIONAL: Instead of time, use one of the following criteria:

a. Run the system until the pH of the concentrate is almost the same as the

cleaning solution (pH=10-12)

b. Permeate rate for the system drops to a very low value.

6. Let the membrane(s) soak in the cleaning solution overnight.

7. Remove the empty cleaning cartridge and replace it with the original filter.

8. Restart the system. Direct the permeate to drain for five minutes.

9. Go back to normal operations.

FIGURE 23-1: 10 INCH ORGANIC

CLEANING CARTRIDGE

DriSteem replacement part

• 2.5" x 10" - (part number: 550045-501)

CAUTION

Handle all chemicals with care. Wear

protective clothing and eye protection.

CAUTION

The system must be fl ushed thoroughly

between acid and alkaline cleaning.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

23

Page 28

MAINTENANCE

Storage

To prevent bacterial growth and help maintain fl ux, it is recommended that

elements be immersed in a preservative solution if the system will be OFF for

more than one week.

MEMBRANE PRESERVATIVE CARTRIDGE

PRESERVING PROCEDURE

1. Shut down the RO system.

2. Disconnect the permeate line and direct permeate to drain during

cleaning/preserving.

3. Remove the 5M filter cartridge from the pre-filter housing.

4. Replace the filter cartridge with the preservative cartridge and assemble

into the filter housing.

5. Turn the system ON. After 30-40 seconds, shut down the system.

6. Drain the system of the permeate solution as much as possible by opening

a valve/fitting at a low point in the system.

7. Close OFF the inlet and outlet to the membrane/system.

FLUSHING OUT PRESERVATIVE/RESTART PROCEDURE

8. Open valves and put the system back in the position it was before

preserving.

FIGURE 24-1: 10 INCH BIG BLUE

CLEANING CARTRIDGE

DriSteem replacement part

• 2.5" x 10" - (part number: 550045-802)

9. Remove the empty preservative cartridge and replace it with a new

cartridge filter.

10. Restart the system. Direct permeate to drain for 15-30 minutes.

11. Go back to normal operation.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

24

Page 29

System monitoring and record keeping

The system should be monitored and all pertinent data recorded on a daily

basis. This includes cartridge fi lter pressure in/out, system pressure in/out,

fl ow and water quality (TDS) in/out. Data is needed to determine operating

effi ciency and for performing system maintenance. The latter includes cleaning

of the membranes, adjusting the operating conditions as well as replacement

of cartridge fi lters and RO membranes.

Table 25-1:

Troubleshooting

Issue Possible Cause Solution

Inlet pressure low* Low supply pressure Correct incoming supply pressure

MAINTENANCE

Cartridge fi lters plugged Change fi lters

Solenoid valve malfunction Replace solenoid valve and/or coil

Permeate fl ow low Low water temperature Adjust water temperature

Low system pressure Adjust concentrate control valve

Membranes fouled Clean membranes

Pump noisy Low inlet fl ow See "Inlet pressure low"

Permeate quality poor Low inlet fl ow Adjust concentrate control valve

Low system pressure See "Inlet pressure low"

Recovery too high Reduce recirculation control valve

Membranes fouled Clean membranes

Membranes damaged Replace membranes

* Pressure alarm will occur if inlet pressure falls below 5 psi. Alarm will self-clear when RO system supply pressure is above 10 psi for at least 10

consecutive seconds. A pressure fault can be manually cleared at any time. System will try to operate every 10 consecutive seconds per hour up to

72 hours while in low pressure alarm condition.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

25

Page 30

MAINTENANCE

System operating log

Table 26-1:

System operating log

Date

Time

Chlorine

Cartridge in psi

Cartridge out psi

Water temperature

TDS in

TDS out

System psi

Concentrate psi

Cartridge fi lter change

Membrane change

Recorded by

Notes

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

26

Page 31

MAINTENANCE

Water quality test strips

WATER QUALITY TEST STRIPS SAMPLE PACK

• Carbon fi lters in the RO-200 water treatment system should be changed regularly to maintain proper pressure and

fl ow and water quality.

• The carbon fi lter removes chlorine. Change the carbon fi lter when chlorine from supply water starts to pass through.

Check regularly for chlorine pass through.

• To check for chlorine, obtain a water sample from the concentrate drain line and test the water. If chlorine is

present, change the carbon fi lter and record the interval to estimate the next carbon fi lter change.

• For best results, test water chlorine every two weeks.

• To order more Water Quality Test Strips, contact your local

DriSteem rep, or call 1-800-328-4447.

Total Chlorine ppm - end pad

0 0.5 1.0 2.0 4.0 10.0

Free Chlorine ppm

0 0.5 1.0 2.0 4.0 10.0

Total Hardness (CaCo3) grains per gallon

0 1.5 3 7 15 25

0 25 50 120 250 425

ppm

Total Alkalinity ppm (CaCo3)

0 40 80 120 180 240

pH - pad nearest handle

6.2 6.8 7.2 7.8 8.4

DIRECTIONS:

1. Dip entire strip into water for 1 second (or

pass under water stream), remove. Do not

shake excess water from the test strip. Hold

the strip for 30 seconds.

2. Compare TOTAL HARDNESS, TOTAL

ALKALINITY and pH pads to color chart to the

left.

3. Dip strip into the water again and move back

and forth for 30 seconds (or hold two chlorine

pads under water stream for 10 seconds).

4. Compare CHLORINE pads to color chart to

the left.

5. Track results in the chart below.

6. Change the carbon cartridge filter once

chlorine is detected in the concentrate water

of the RO 200 water treatment system (see

page 20).

Table 27-1:

Water quality test log

Date tested Total chlorine ppm Free chlorine ppm Total hardness Total alkalinity pH

Week 1 _________

Week 3 _________

Week 5 _________

Week 7 _________

Week 9 _________

Week 11 _________

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

27

Page 32

REPLACEMENT PARTS

RO system (Models 201, 202, and 203)

FIGURE 28-1: RO 200 SYSTEM REPLACEMENT PARTS

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

28

OM-7871

Exploded view of the each unique

replacement part for the RO 200

system.

Page 33

RO system (Models 201, 202, and 203)

Table 29-1:

RO system replacements parts

No. Description Qty. Part No.

1 PUMP MOTOR 1/3 HP 100-120/200-240V 1 400292-001

REPLACEMENT PARTS

2

3 GAUGE LIQUID FILLED 400 PSI PNL MNT KIT 2 260004-400

4 METER 2GPM FLOW W/NEEDLE VALVE 1/4" FNPT 2 501907-402

5 METER 2GPM FLOW 1/4" FNPT 1 501907-302

6 SEDIMENT FILTER 2.5" X 10" 5 MICRON 1 550030-002

7 CARBON FILTER 2.5" X 10" 10 MICRON 2 550030-003

8 HOUSING FILTER 2.5" X 10" 3 550030-001

9 MANIFOLD ASSY OUTPUT RO-200 STAND ALONE 1 187714-002

10 MEMBRANE RO 2.5" X 21" EXTRA LOW ENERGY VARIES 550035-025

11 MEMBRANE VESSEL ASSY 2.5" X 23-5/16" VARIES 550038-025

12 TANK WATER PRESSURIZED 4.4 GAL 1 550029-004

13 DRAIN ASSY RO-200 1 165103-011

14 VALVE 1/2" SOLENOID TWO-WAY N.C. 3.35 CV 1 505107-050

* Specify RO system model and serial numbers when ordering.

PUMP ROTARY VANE BRASS 90 GPH 1 400294-001

PUMP ROTARY VANE BRASS 105 GPH 1 400294-002

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

29

Page 34

REPLACEMENT PARTS

Subpanel

FIGURE 30-1: CONTROL CABINET ASSY RO-200

OM-7939

Table 30-1:

Control cabinet assy RO-200

No. Description Qty. Part No. No. Description Qty. Part No.

1 Main controller VL6 1 408496-006 9 Terminal DIN rail 20A center 1 408252-001

Module LON protocol

2

(LON option only)

3 Resistor 1.2K OHM through hole 1 408995-008 11 Contactor 35A SIEMENS 1 407010-001

4 Bushing 7/8" shutter HEYCO 1 407129 12 Display VL w/o back Vapor-logic 1 408495-002

5 Lug medium 1 409250-027 13 Case rear display Vapor-logic 1 408495-003

6 Terminal block 3 pole pressure contact 1 408300-002 14 Wire data cable 27" RJ-12 1 408490-014

Transformer 120/208/240/480V TO

7

24VAC 75V

8 Terminal DIN rail end cap 1 408252-005 16 Plug 3 circuit vertical euro molex 1 406246-003

1 408642 10 Terminal DIN rail end 1 408252-006

1 408965-001 15 Mount wallplate wallphone SST 1 408490-021

17 Plug 4 circuit vertical euro molex 1 406246-004

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

30

Page 35

Notes

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

31

Page 36

W

ARRANTY

Expect quality from the industry leader

Since 1965, DriSteem has led the industry

with innovative methods for humidifying and

cooling air with precise control. Our focus on

ease of ownership is evident in the design of

our Water Treatment Systems, which feature

low maintenance and comprehensive control.

DriSteem also leads the industry with a Twoyear Limited Warranty and optional extended

warranty.

For more information

www.dristeem.com

sales@dristeem.com

For the most recent product information

visit our Web site: www.dristeem.com

Two-year Limited Warranty

DRI-STEEM Corporation (“DriSteem”) warrants to the original user that its products will be free from

defects in materials and workmanship for a period of two (2) years after installation or twentyseven (27) months from the date DriSteem ships such product, whichever date is the earlier.

If any DriSteem product is found to be defective in material or workmanship during the applicable

warranty period, DriSteem’s entire liability, and the purchaser’s sole and exclusive remedy,

shall be the repair or replacement of the defective product, or the refund of the purchase price,

at DriSteem’s election. DriSteem shall not be liable for any costs or expenses, whether direct

or indirect, associated with the installation, removal or reinstallation of any defective product.

Excluded from the Limited Warranty are all consumable and wear and tear items such as cylinders,

membranes, fi lters, or media replacements. These items are subject to usual wear and tear during

usage.

DriSteem’s Limited Warranty shall not be effective or actionable unless there is compliance with

all installation and operating instructions furnished by DriSteem, or if the products have been

modifi ed or altered without the written consent of DriSteem, or if such products have been subject

to accident, misuse, mishandling, tampering, negligence or improper maintenance. Any warranty

claim must be submitted to DriSteem in writing within the stated warranty period. Defective parts

may be required to be returned to DriSteem.

DriSteem’s Limited Warranty is made in lieu of, and DriSteem disclaims all other warranties,

whether express or implied, including but not limited to any IMPLIED WARRANTY OF

MERCHANTABILITY, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, any

implied warranty arising out of a course of dealing or of performance, custom or usage of trade.

DriSteem SHALL NOT, UNDER ANY CIRCUMSTANCES BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, LOSS OF PROFITS, REVENUE OR BUSINESS) OR DAMAGE OR INJURY TO PERSONS OR

PROPERTY IN ANY WAY RELATED TO THE MANUFACTURE OR THE USE OF ITS PRODUCTS. The

exclusion applies regardless of whether such damages are sought based on breach of warranty,

breach of contract, negligence, strict liability in tort, or any other legal theory, even if DriSteem has

notice of the possibility of such damages.

By purchasing DriSteem’s products, the purchaser agrees to the terms and conditions of this Limited

Warranty.

DRI-STEEM Corporation

a subsidiary of Research Products Corporation

DriSteem U.S. Headquarters is an ISO

9001:2008 certifi ed company

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

European offi ce:

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgium

+3211823595 (voice)

E-mail: dristeem-europe@dristeem.com

Continuous product improvement is a policy of

DriSteem; therefore, product features and

specifi cations are subject to change without

notice.

DriSteem and Vapor-logic are registered

trademarks of Research Products Corporation

and are fi led for trademark registration in

Canada and the European community.

Product and corporate names used in this

document may be trademarks or registered

trademarks. They are used for explanation only

without intent to infringe.

© 2018 Research Products Corporation

Extended warranty

The original user may extend the term of the DriSteem Limited Warranty for a limited number of

months past the initial applicable warranty period and term provided in the fi rst paragraph of this

Limited Warranty. All the terms and conditions of the Limited Warranty during the initial applicable

warranty period and term shall apply during any extended term. An extended warranty term of

an additional twelve (12) months or twenty four (24) months of coverage may be purchased. The

extended warranty term may be purchased until eighteen (18) months after the product is shipped,

after which time no extended warranties are available. When a Dristeem humidifi er is purchased

with a DriSteem RO system, an extended twenty-four (24) month coverage is included.

Any extension of the Limited Warranty under this program must be in writing, signed by DriSteem,

and paid for in full by the purchaser.

Form No. RO-200-IOM-EN-0618

Part No. 890000-876 Rev B

Loading...

Loading...