DriSteem RO-200 series, RO-201, RO-202, RO-203 Installation, Operation And Maintenance Manual

READ AND SAVE THESE INSTRUCTIONS

WATER TREATMENT

200 series

reverse-osmosis systems

Installation, Operation,

and Maintenance Manual

WARNINGS AND CAUTIONS

Warnings and cautions

WARNING CAUTION

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

mc_051508_1145

WARNING

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualifi ed

HVAC and electrical contractors and in compliance with local, state, federal, and governing codes. Improper installation

can cause property damage, severe personal injury, or death as a result of electric shock, burns, or fi re.

DriSteem Technical Support: 800-328-4447

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all

warnings and instructions could produce the hazardous situations described, resulting in property damage, personal

injury, or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause bacteria and mold

growth or dripping water into building spaces. Dripping water can cause property damage; bacteria and mold growth

can cause illness.

If the IOM is missing, go to www.dristeem.com to download a replacement.

Shut down the energy source

Before performing service or maintenance procedures on any part of the system, verify that all energy sources are off.

Failure to shut down the energy source could result in fi re, explosion, electrical shock, and other hazardous conditions.

These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury or death as a result of electrical

shock or fi re. Do not remove electrical panel cover/door or access panels until electrical power is disconnected.

Follow the shutdown procedure in th

the system.

e system IOM before performing service or maintenance procedures on any part of

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii

Warnings and cautions

WARNING

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any

part of the humidifi cation system. Failure to disconnect electrical power could result in fi re, electrical shock, and other

hazardous conditions. These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock

or fi re. Do not remove RO system electrical panel cover, heater terminal cover, or subpanel access panels until electrical

power is disconnected.

Follow the shutdown procedure in this manual before performing service or maintenance procedures on any part of the

system.

mc_052410_1510

Electric shock hazard

If the RO system starts up responding to a call for humidity during maintenance, severe bodily injury or death from

electric shock could occur. To prevent such start-up, follow the procedure below before performing service or maintenance

procedures on this RO system (after the tank has cooled down and drained):

1. Use Vapor-logic

2. Shut off all electrical power to the RO system using fi eld-installed fused disconnect, and lock all power disconnect

switches in OFF position.

3. Close fi eld-installed manual water supply shut-off valve.

mc_050808_1540

®

keypad/display to change control mode to Standby.

Fill in the following information for your records

Date of purchase

Customer's name

Model number

Serial number

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

Table of contents

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RO supply water requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Flow schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Initial system start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Normal operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start-up checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Test operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial system start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating do's and don't's . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Do . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Don't . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vapor-logic keypad/display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Changing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Controller display activity definitions . . . . . . . . . . . . . . . . . . . . . . . . 15

Test outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Status screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diagnostics and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Modbus, BACnet, LonTalk interoperability . . . . . . . . . . . . . . . . . . . . 18

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv

Table of contents

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

Maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

When to change sediment and carbon filters . . . . . . . . . . . . . . . . . . 20

Changing cartridge filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

When to clean or replace membranes . . . . . . . . . . . . . . . . . . . . . . .21

Replacing membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Membrane cleaning in the RO system . . . . . . . . . . . . . . . . . . . . . . . 22

How does it work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Scale cleaning cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Organic cleaning cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Membrane preservative cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Preserving procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Flushing out preservative/restart procedure . . . . . . . . . . . . . . . . 24

System monitoring and record keeping . . . . . . . . . . . . . . . . . . . . . . 25

System operating log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Water quality test strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Water Quality Test Strips Sample Pack . . . . . . . . . . . . . . . . . . . . . . 27

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RO system (Models 201, 202, and 203) . . . . . . . . . . . . . . . . . . . . . 28

Subpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ATTENTION INSTALLER

Read this manual before installing.

Leave manual with product owner.

DriSteem® Technical Support

800-328-4447

Where to find more information

Our website:

The following documents are available on our

web site: www.dristeem.com

• Water Treatment Systems Catalog

• Vapor-logic Controller Installation and

Operation Manual

DriCalc® sizing and selection software:

DriCalc, our software for system sizing and

selection, can be ordered at our web site.

Call us at 800-328-4447

Obtaining documents from our web site or

from DriCalc is the quickest way to view our

literature, or we will be happy to mail literature

to you.

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Keypad/display and troubleshooting

The Vapor-logic Installation and Operation

Manual, which was shipped with your RO

system, is a comprehensive operation manual.

Refer to it for information about using the

keypad/display and Web interface, and for

troubleshooting information.

Download DriSteem literature

Most DriSteem product manuals are available

our website: www.dristeem.com

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

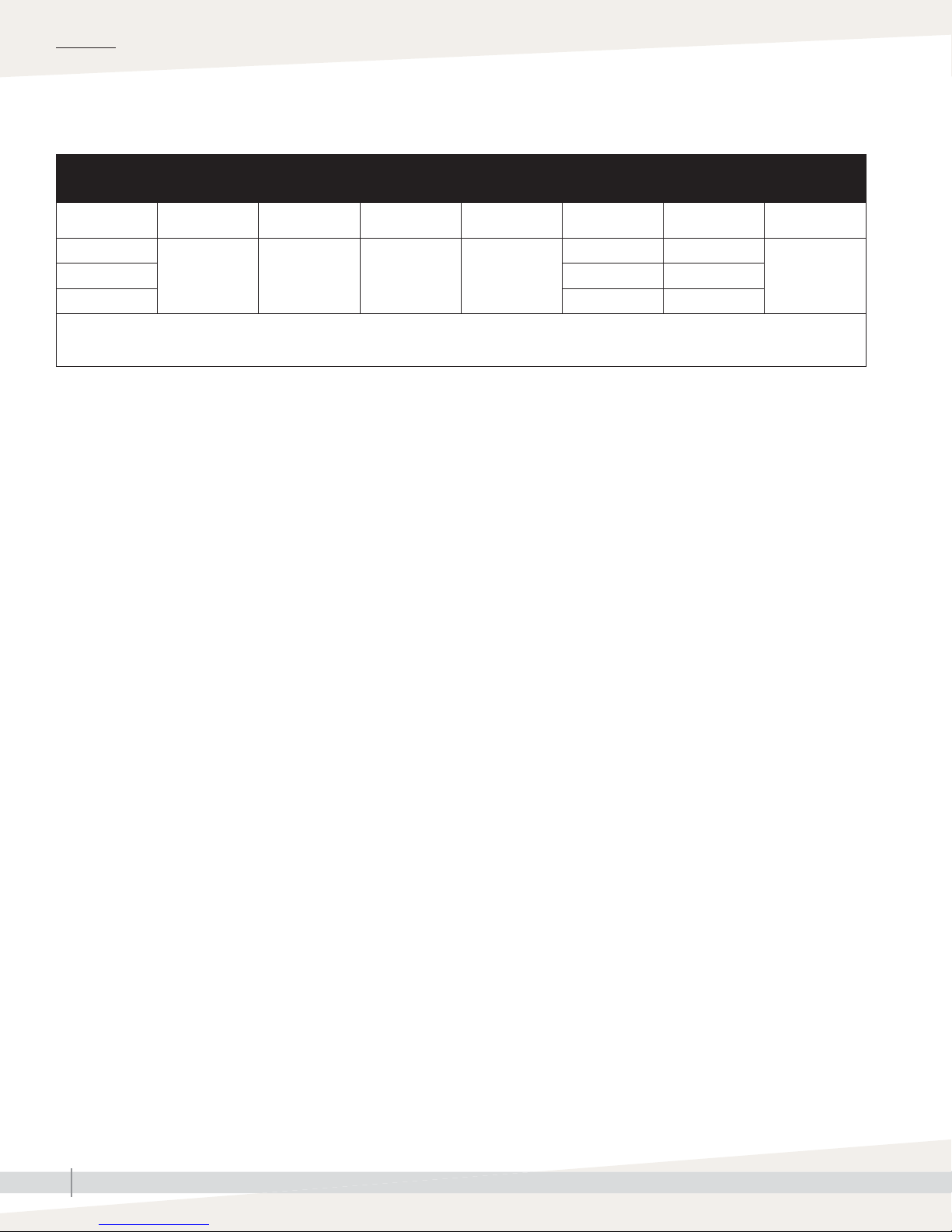

OVERVIEW

System specifi cations

Table 2-1:

RO station electrical specifications and weights

Model Hz Motor HP Volts*/Amps Phase/Frequency

201

202 124 lbs. (56 kg) 148 lbs. (67 kg)

203 130 lbs. (59 kg) 154 lbs. (70 kg)

* 115V or 230V must be ordered specifi cally

** Tank bladder pressure = 28 psi, tank full at 50 psi

*** Noise measurements taken 6.5' (2 m) in front of the RO-200 water treatment system.

60 1/3

110-120

VAC/5.5A

(208-240

VAC/2.8A)

1/60Hz

NOTES:

1. All systems rated at 50°F (10°C) using 1000 ppm sodium chloride (NaCl)

solution. System capacity decreases signifi cantly with decrease in feed

water temperature.

Approximate

shipping weight**

118 lbs. (54 kg) 142 lbs. (64 kg)

Operating

weight**

Noise***

49 dBA min.

58 dBa max.

2. Chlorine requirements for the feed water are:

a. Thin-Film (standard) 0 ppm

3. Feed water must be filtered to a turbidity of less than 1 NTU.

4. System recovery (permeate to concentrate ratio) must be maintained at

the recommended level. A higher than recommended recovery will lead

to a premature fouling of the membrane with a loss of permeate flow and

permeate quality.

5. Recommended minimum clearances if:

– 24" or greater (610 mm) above: 6" (152 mm) left, right and rear and

24" (610 mm) front

– less than 24" (610 mm) above: 6" (152 mm) left and right and 24"

(610 mm) front and rear

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

System specifi cations

Table 3-1:

RO station capacities

Model 201 202 203

Rated capacity, permeate

Gallons/minute 0.2 0.4 0.6

Concentrate fl ow (reject)

Gallons/minute 0.6 - 1.1 0.7 - 1.2 0.5 - 1.0

Recirc fl ow (adjustable as needed)

Gallons/minute 0 - 0.5 0 - 0.5 0 - 0.5

System pressure, psi (pump pressure through membranes) 100 - 150 100 - 150 100 - 150

°F (°C) 50 (10) 50 (10) 50 (10)

Pre-fi lters

1

1, 2

OVERVIEW

Sediment cartridge - 5 micron 1 1 1

Carbon cartridge - 10 micron 2 2 2

Pressure sensor settings

Low pressure (for pump protection) 8 psi 8 psi 8 psi

1.

Reduce concentrate fl ow by the amount of recirc fl ow used to maintain the recommended maximum system level.

2.

Recirc fl ow usage will reduce water but may decrease membrane life.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3

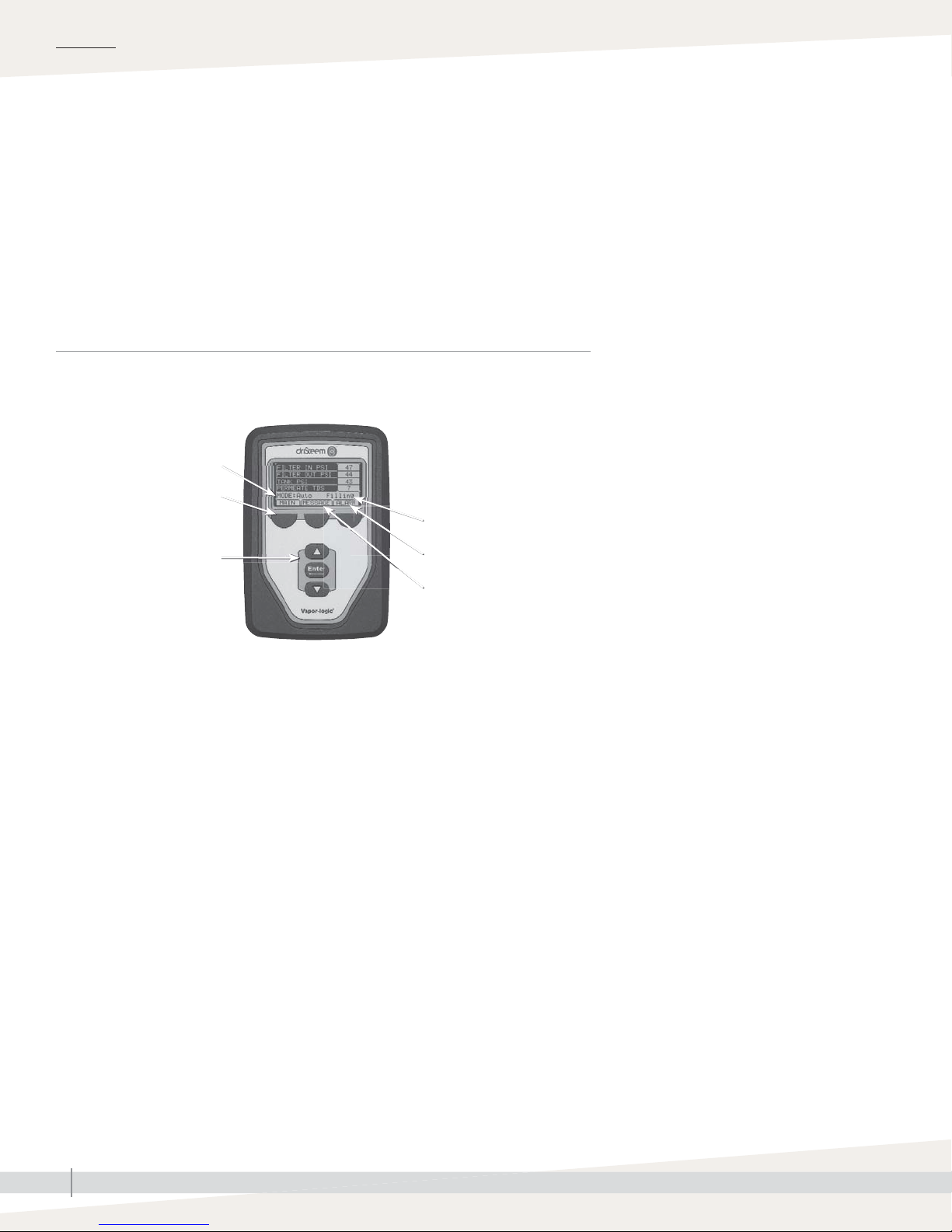

OVERVIEW

Product overview

CONTROLLER

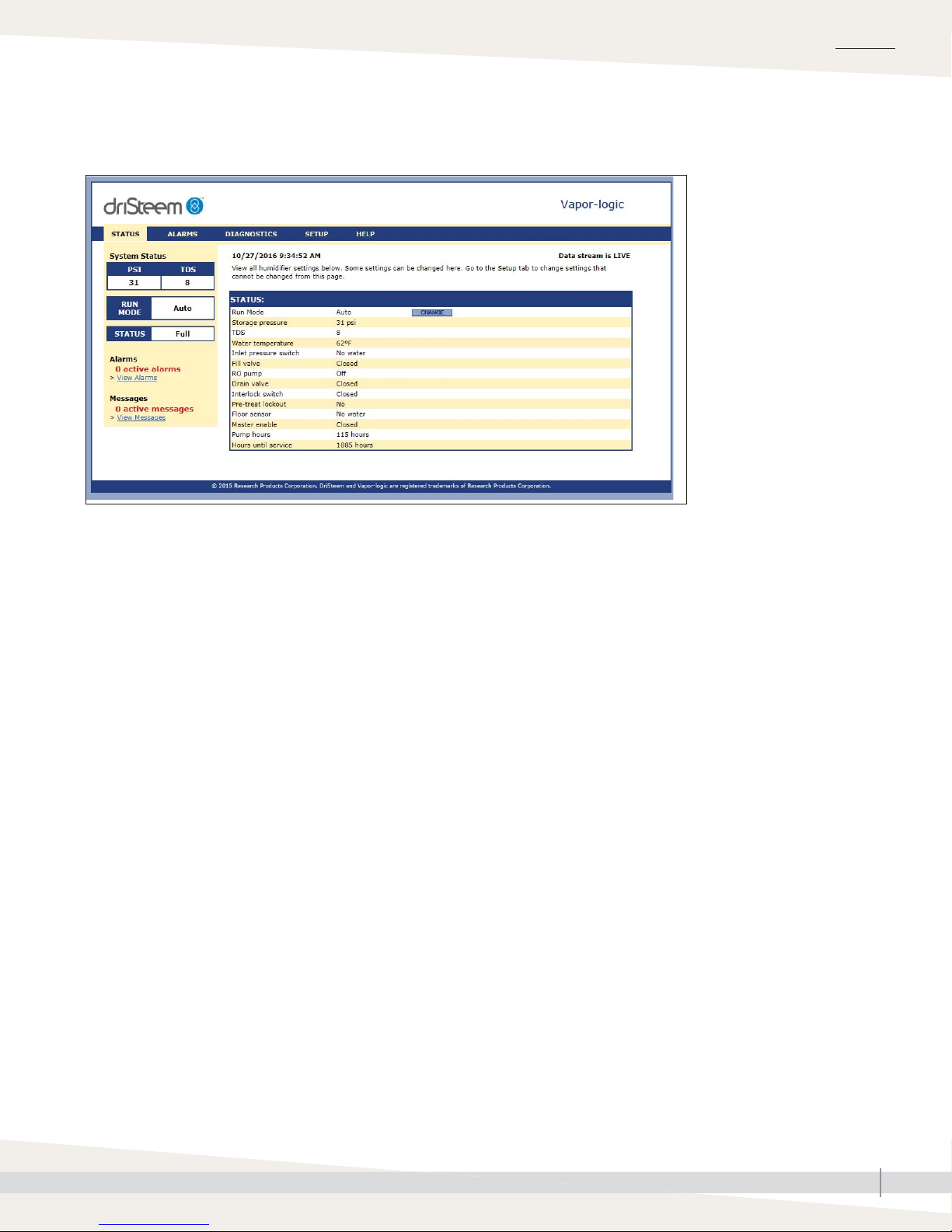

The Vapor-logic controller in the RO system provides menus for all RO system

functions, with a Web interface for Ethernet access (see Figure 4-1).

The Vapor-logic Installation and Operation Manual ships with the RO system.

Refer to it for information on using the keypad/display and Web interface, and

for troubleshooting information.

FIGURE 4-1: VAPOR-LOGIC KEYPAD/DISPLAY AND WEB INTERFACE

KEYPAD/DISPLAY

Mode

Softkeys

for direct menu access

Navigation buttons

for item selection

Tank status

System alarms

System messages

Static IP addresses

See the Vapor-logic Controller Installation and

Operation Manual shipped with the RO system

for more information about confi guring IP

addresses.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

Product overview

WEB INTERFACE

OVERVIEW

RO SUPPLY WATER REQUIREMENTS

Supply water quality is an important component

of DriSteem reverse osmosis system reliability and

maintenance.

Water hardness can increase the reverse osmosis system

maintenance requirements.

To maximize service life and minimize maintenance for

RO systems and downstream equipment, softened water is

required with all DriSteem RO systems.

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

OVERVIEW

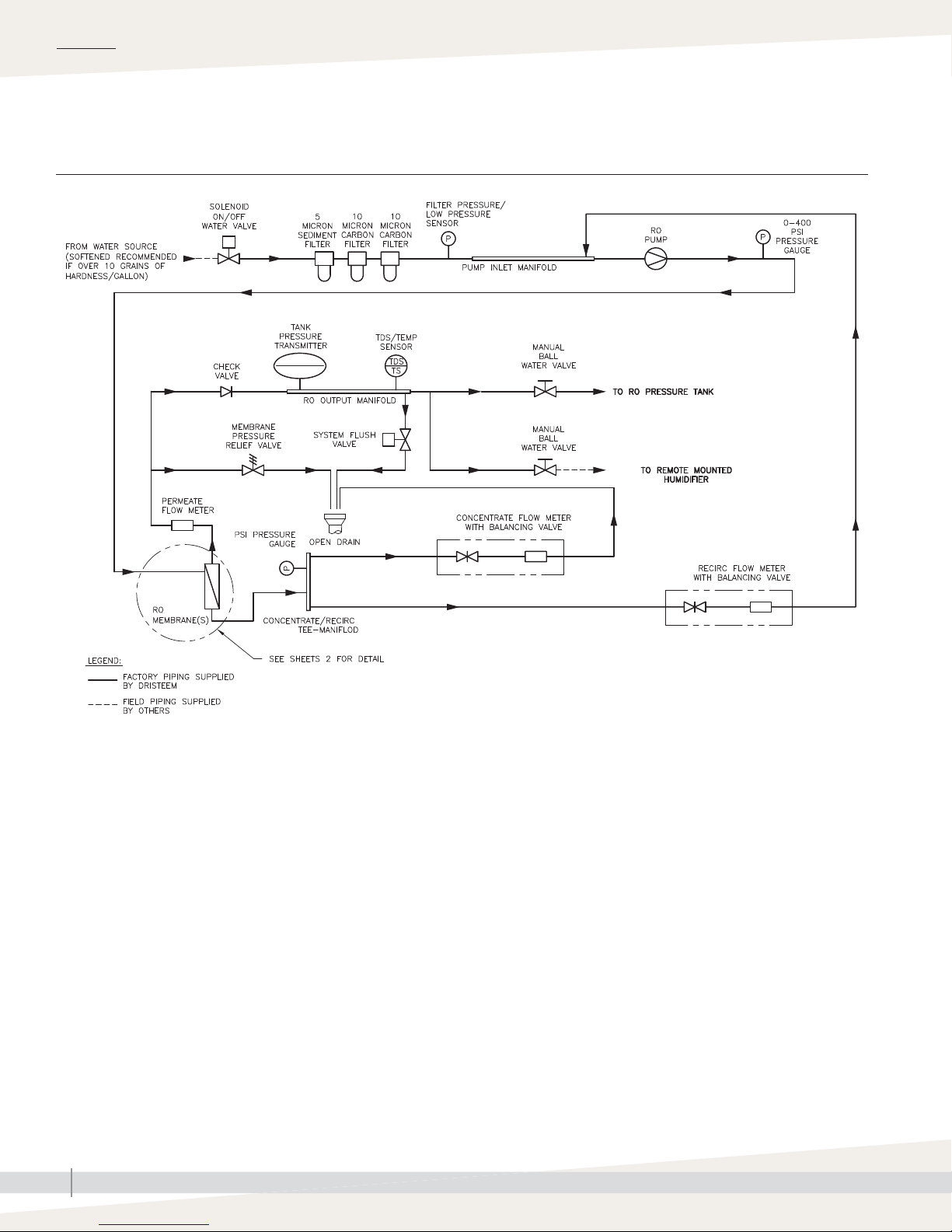

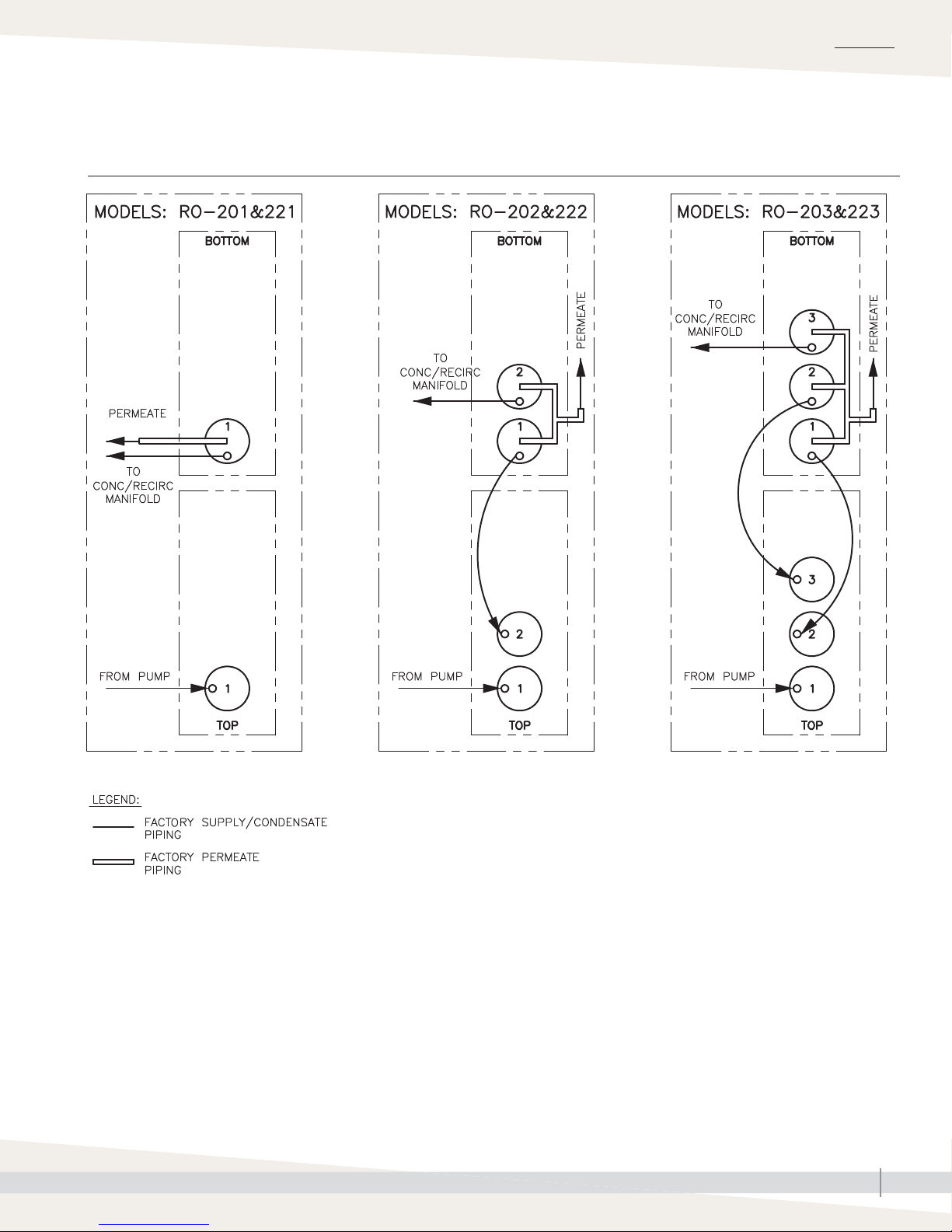

Flow schematic

FIGURE 6-1: FLOW SCHEMATIC

RO200-PIPING

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

Flow schematic

FIGURE 7-1: FLOW SCHEMATIC

OVERVIEW

DRISTEEM RO 200 SYSTEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

RO200-PIPING-1

7

Loading...

Loading...