Page 1

Insulated Tube Option

INSTALLATION INSTRUCTIONS

ADDENDUM TO THE ULTRA-SORB MANUAL & RAPID-SORB INSTALLATION INSTRUCTIONS

Unpacking and installation

UNPACKING

• Remove the dispersion assembly from the shipping container; be careful

not to bump or scrape the PVDF insulating material on the dispersion

tubes.

• Some dispersion panels are shipped unassembled by customer request or

by shipping necessity. Do not lay loose insulated dispersion tubes across

or under anything that could compress or damage the insulating material.

Compressed insulating material has a reduced R-value.

• Avoid bumping or snagging the PVDF insulating material. Although PVDF

is robust, rough handling can cause tears, which could negatively impact

performance.

Water Treatment Systems

RAPID-SORB INSTALLATION

See the unpacking instructions above and the Rapid-sorb section of your

specific humidifier manual.

After installation and before start-up, remove the clear poly film by tearing it

along the perforation. Do not use a knife or sharp object to remove the poly

film.

ULTRA-SORB INSTALLATION

See the unpacking instructions above and the Ultra-sorb manual shipped

with your dispersion assembly.

After installation and before start-up, remove the clear poly film by tearing it

along the perforation. Do not use a knife or sharp object to remove the poly

film.

CAUTION

The insulated dispersion tubes are sleeved in clear poly film for

protection during processing, shipping, and installation.

To prevent dirty insulating material, leave the clear poly film on until

installation is complete.

Equally important, remove and discard the clear poly film before

start-up by tearing it along the perforations.

Ultra-sorb® steam

dispersion panel

Rapid-sorb® dispersion

tube system

Page 2

Retrofitting an existing Ultra-sorb

FIGURE 2-1: PVDF INSULATING

MATERIAL

The white PVDF

insulating material

stays on the tubes.

Do NOT remove it.

WARNING

Steam humidification systems have

extremely hot surfaces.

To avoid burns, allow humidifier, steam

pipes, and dispersion assembly to cool

before touching any part of the system.

Before you begin, shut off steam to the system, and let all hot surfaces cool.

See the Warning below.

Note: Replacement slip couplings with internal O-rings are shipped with

retrofit insulated tube orders. There are two types of slip couplings:

with shoulders and without. Slip couplings with shoulders must go on

the supply header end of the dispersion tube. See Figure 2-2.

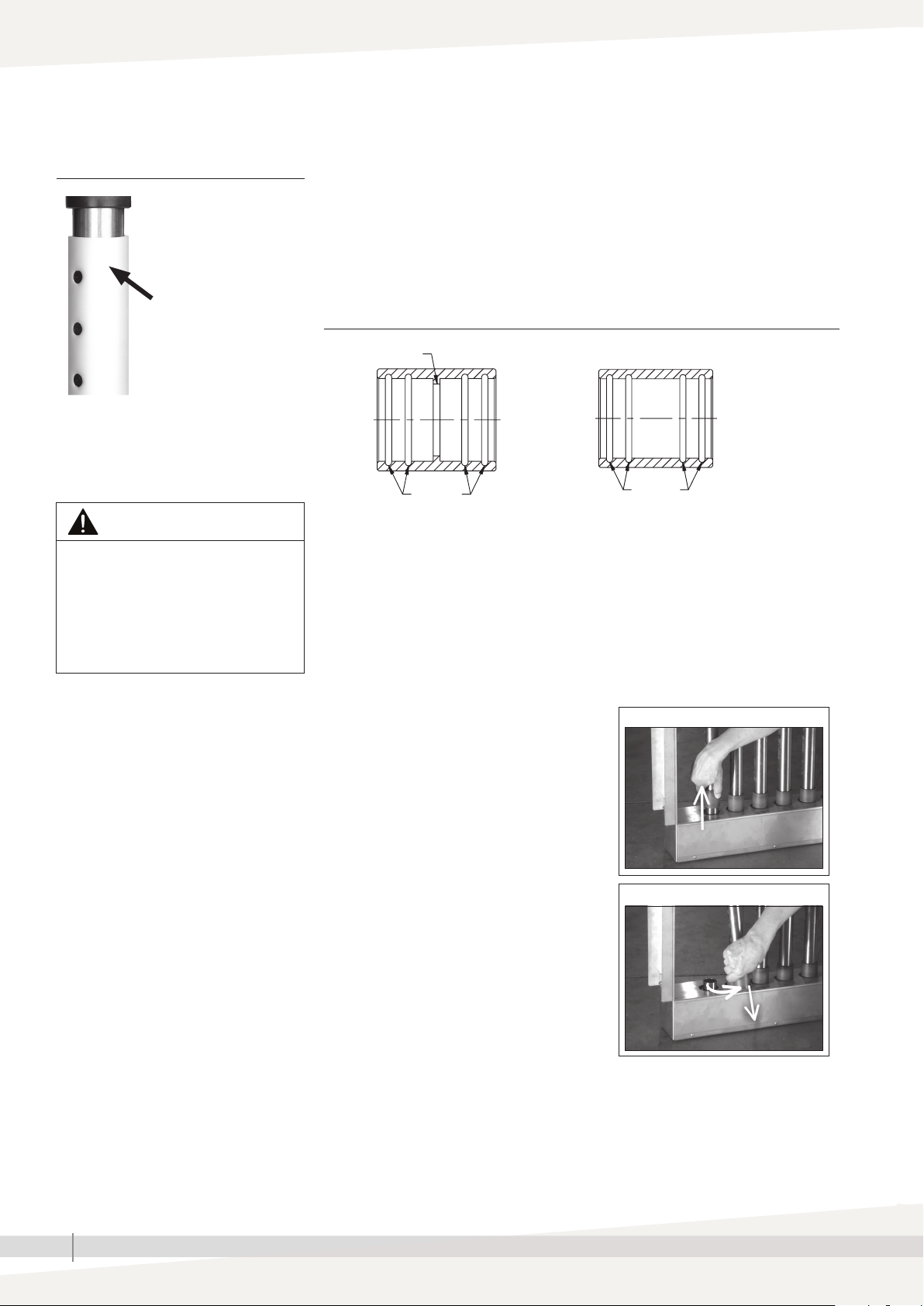

FIGURE 2-2: DISPERSION TUBE SLIP COUPLINGS

Shoulder

OM-238-6

O-rings

REMOVING UNINSULATED TUBES

O-rings

OM-238-7

Note: The photos below depict Ultra-sorb LV (vertical tubes). The supply

header is on the top, and the condensate header is on the bottom.

If retrofitting an Ultra-sorb LH (horizontal tubes), pay attention to the

location of the supply and condensate headers.

Perform the following steps for each uninsulated tube being removed:

1. With a pulling and twisting motion,

Step 1

slide the slip coupling off the

condensate header far enough to

reveal the end of the dispersion tube.

2. Swing the dispersion tube away

from the condensate header; pull the

Step 2

dispersion tube and slip coupling off

the supply header.

DRISTEEM INSULATED TUBE ADDENDUM

2

Page 3

Retrofitting an existing Ultra-sorb

3. Remove the dispersion tube. Make sure

Step 3

that nothing loose falls into the header.

INSTALLING INSULATED TUBES

Note: The photos below show the insulated dispersion tubes without the

clear poly film for demonstration purposes only. To prevent dirty

insulating material, install the insulated dispersion tubes before tearing

off the clear poly film.

Perform the following steps for each insulated

tube being installed:

Step 1

Slip coupling

with shoulder;

supply-headerend of tube

1. Slide the new slip couplings onto the

insulated dispersion tube as shown.

Slip coupling

without shoulder;

condensate-headerend of tube

For more information

Ultra-sorb dispersion assemblies are shipped

with a comprehensive manual. Refer to it for

assembly, parts, installation, troubleshooting,

piping, maintenance, performance, and

warranty information.

Rapid-sorb dispersion assemblies are shipped

with installation instructions. See the Rapidsorb section of the manual shipped with your

humidifier.

This addendum must be left with the owner

and should be accessible for reference.

2. Connect the dispersion tube to the supply

header with the shouldered slip coupling.

Push and twist the dispersion tube until

the shoulder bottoms out, then connect the

dispersion tube to the condensate header

with the other slip coupling.

3. Push the shoulder-less slip coupling against

the stop disk on the condensate header.

4. Rotate the dispersion tube to point the tubelets

across (perpendicular to) the airstream.

Step 2

Step 3

Step 4

DRISTEEM INSULATED TUBE ADDENDUM

3

Page 4

Caring for the insulating material

• If the insulating material gets torn, repair the tear with our Insulating

Material Repair Kit before dispersing steam or moving air through the air

handler to prevent further damage.

This available kit uses tested and proven PVDF as repair material; do not

use other adhesives or repair methods in place of the kit.

• If the insulating material gets dirty or smudged, gently clean it with

a damp cloth and a solution of soapy water or a diluted non-toxic,

biodegradable cleaner/degreaser.

• Do not clean the insulating material with a pressure washer. The direct

spray could cause damage.

• If using a torch in the vicinity of the dispersion panel, keep the flame

away from the insulating material to avoid damage

• PVDF is inherently resistant to UV light. Indirect, low-intensity UV-C light

from germicidal lamps will not cause the insulating material to degrade.

• Do not tighten mounting clamps or fasteners to any part of the dispersion

tube.

DRI-STEEM Corporation

a subsidiary of Research Products Corporation

DriSteem U.S. operations are 9001:2015 certified

www.dristeem.com

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

Continuous product improvement is a policy of DriSteem; therefore, product features

and specifications are subject to change without notice.

DriSteem, Rapid-sorb, and UItra-sorb are registered trademarks of Research

Products Corporation and are filed for trademark registration in Canada and the

European community.

Product and corporate names used in this document may be trademarks or

registered trademarks. They are used for explanation only without intent to infringe.

© 2016 Research Products Corporation

Form No. IT-IOM-Addendum-M-0316

Part No. 890000-155 Rev B

DRISTEEM INSULATED TUBE ADDENDUM

4

Loading...

Loading...