DriSteem STS Series, STS03, LTS Series, LTS03 Service Kit Manual

®

STS

Steam-to-Steam Humidifier,

DI Water

®

LTS

Liquid-to-Steam Humidifier,

DI Water

Service Kit Manual

WARNING

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

Read all warnings and instructions

This page provides important safety instructions; it is intended to supplement — not replace — the humidifier's Installation, Operation, and

Maintenance Manual (IOM). Read the IOM that was provided with the humidifier before performing service or maintenance procedures

on any part of the system. Failure to follow all warnings and instructions could produce the hazardous situations described here and in the

IOM, resulting in property damage, personal injury, or death.

If the IOM is missing, go to www.dristeem.com to download a replacement. mc_071608_0910

Hot surfaces and hot water

Steam humidification systems have extremely hot surfaces, and water in tanks, electrode cylinders, steam pipes, and dispersion assemblies

can be as hot as 212 °F (100 °C). To avoid severe burns, allow the entire humidification system to cool.

Follow the cool-down procedure in the humidifier's IOM before performing service or maintenance procedures on any part of the system.

mc_071608_0911

Electrical shock hazard

If the humidifier starts up at a call for humidity during maintenance, severe bodily injury or death from electrical shock could occur. To

prevent such start-up, follow the procedure below before performing service or maintenance procedures on this humidifier (after the tank

has cooled down and drained):

1. Use the Vapor-logic®3 controller keypad to change the control mode to Standby.

2. Shut off all electrical power to the humidifier using the field-installed fused disconnect, and lock all power disconnect switches in the

OFF position.

3. Close the field-installed manual water supply shut-off valve.

4. Close the manual inlet steam supply (on STS) or inlet hot liquid supply (on LTS) shut-off valve. mc_050808_1541

CAUTION

Indicates a hazardous situation that could result in damage to

or destruction of property if instructions are not followed.

WARNING

mc_051508_1145

Damage from hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage the drain plumbing.

If the humidifier is equipped with a water tempering device such as a DRI-STEEM Drane-kooler™, it needs fresh make-up water in order to function

properly. Make sure the water supply to the Drane-kooler remains open during draining.

If the humidifier is not equipped with a water tempering device, allow the tank to cool before opening the drain valve. mc_111308_1345

Parts in this service kit are for STS03 and/or LTS03 humidifiers (February 2003 to present). Parts are listed on page 2.

CAUTION

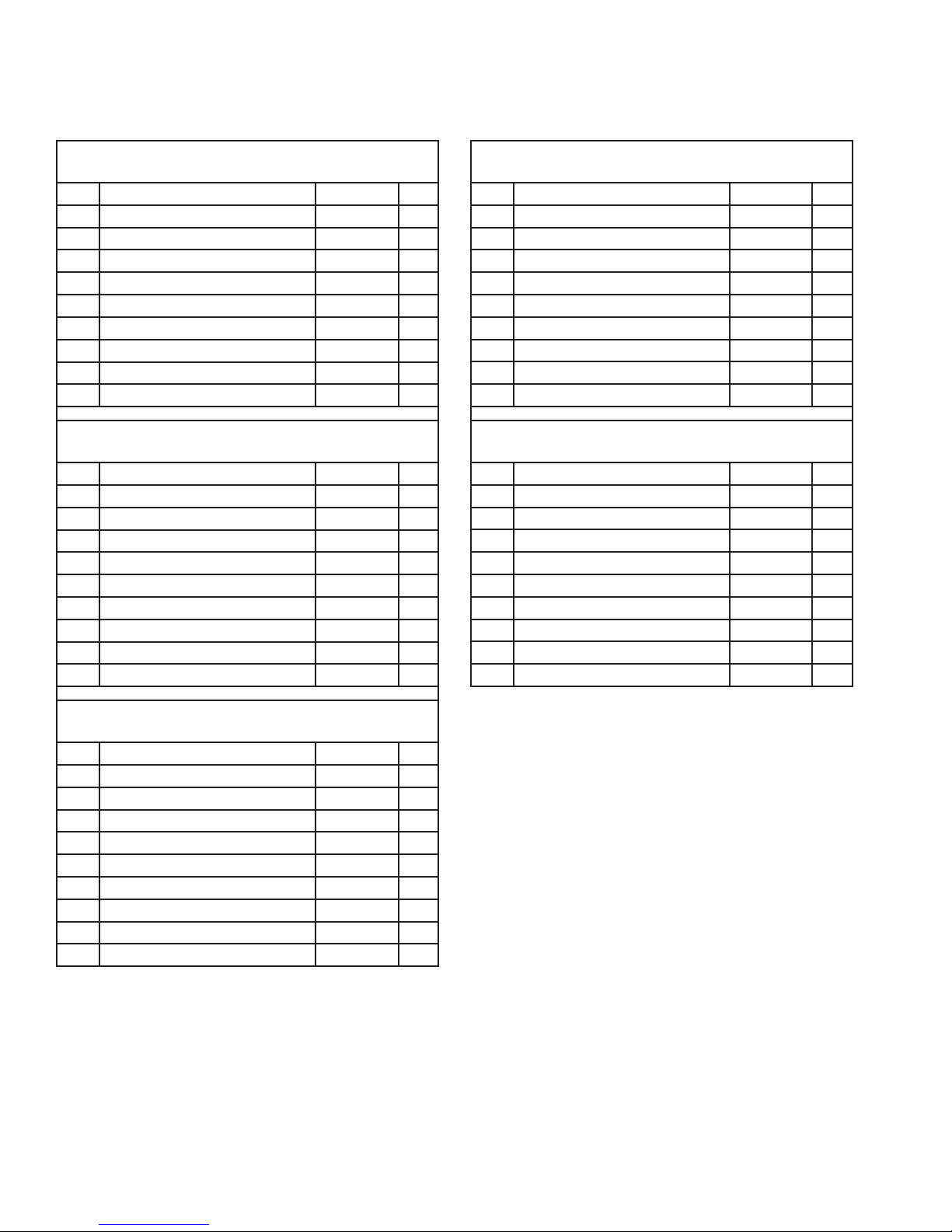

STS/LTS, DI water, service kit parts

STS03 / LTS03, DI water, 25

Service Kit No. 900100-701

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-001 1

5 Cover gasket 160692-001 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

STS03, DI water, 50

Service Kit No. 900100-702

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-002 1

5 Cover gasket 160692-002 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

STS03, DI water, 200/400

Service Kit No. 900100-704

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-003 1

5 Cover gasket 160692-004 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

STS03, DI water, 800 and LTS03, DI water, 400

Service Kit No. 900100-705

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-003 1

5 Cover gasket 160692-004 1

6 Heat exchanger gasket, front 308220 4

7 Washer, flat 10-32 700300-008 16

8 Nut, 10-32, w/Nylon insert 700252-003 16

9 Nut, 14-20, w/Nylon insert 700300-016 32

STS03 / LTS03, DI water, 100

Service Kit No. 900100-703

No. Part Description Part No. Qty.

1 Silicone, clear (not shown) 320000 1

2 Seat, black EPDM (see Float Valve inset) 505210-003 1

3 Probe plate gasket 308416-001 1

4 Cleanout plate gasket 308015-002 1

5 Cover gasket 160692-003 1

6 Heat exchanger gasket, front 308220 2

7 Washer, flat 10-32 700300-008 8

8 Nut, 10-32, w/Nylon insert 700252-003 8

9 Nut, 14-20, w/Nylon insert 700300-016 16

Page 2 • DRI-STEEM STS/LTS, DI Water, Service Kit Manual

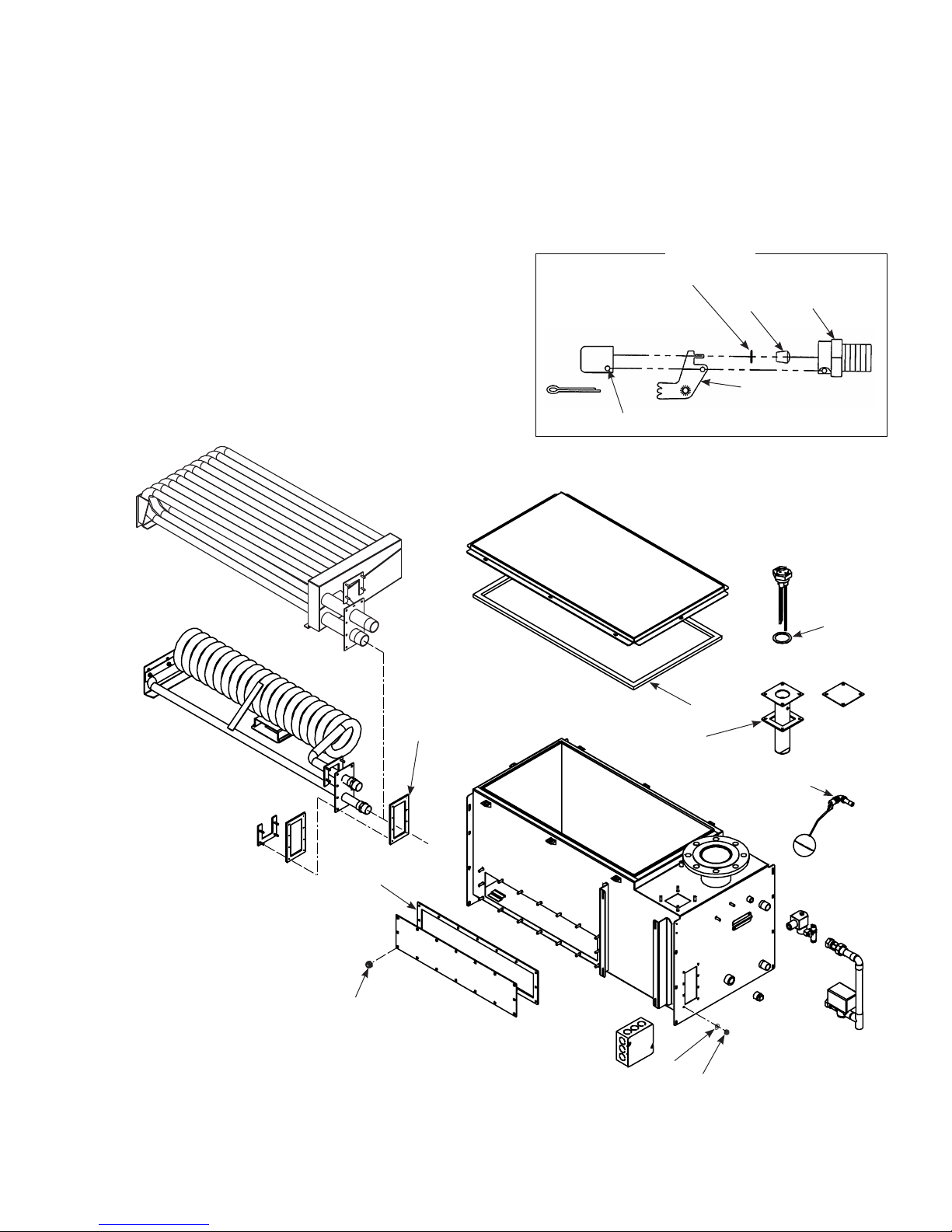

STS/LTS, DI water, service kit parts

This service kit contains the replacement parts called out in the

parts drawing to keep your DRI‑STEEM humidifier operating

at peak performance. This Service Kit Manual provides

important safety and service instructions; it is intended to

supplement — not replace — the humidifier's Installation,

Operation, and Maintenance Manual. Please see Read all

warnings and instructions on page 1.

While performing service and maintenance procedures,

replace existing parts with the new parts provided in the

service kit.

mc_052808_1400

STS heat exchanger

Float Valve

Put back-up washer on

arm first, then seat (2).

Insert cotter pin

2

Arm

Valve

OM-863-1

mc_051908_1410

LTS heat exchanger

Notes:

• Parts for both standard water and DI

water humidifiers are shown.

• Components may by oriented differently

than shown in drawing.

6

(small holes)

4

9

Torque to 25 to 35 in-lbs

(2.8 to 4.0 N-m).

Apply clear

silicone (1)

to both sides

of gasket.

5

3

See Float Valve inset.

7

8

DRI-STEEM STS/LTS, DI Water, Service Kit Manual • Page 3

LTS-OM-18X

OM-946X

mc_052108_1645

STS/LTS, DI water, service instructions

Inspection and maintenance

Cool down humidifier

Before performing any maintenance, allow the tank to cool

down. Insulated and uninsulated tanks will have hot surfaces.

Note: Fresh make‑up water is used to speed up cooling. Do

not close the manual water supply before cooling down

the humidifier; otherwise the tank could stay hot for

several hours.

1. Close the manual shut‑off valve on the inlet steam supply

(STS humidifiers) or the inlet hot liquid supply (LTS

humidifiers).

2. Drain the tank:

Models with a standard drain valve:

a. Manually open the drain valve. The fill valve will open

after enough water has drained out of the tank.

b. Let the fill water run until the tank is cooled; then shut

off the field installed manual supply water shut‑off

valve.

c. Let the tank drain; then manually close the drain valve.

For models with end-of-season drain option (must have

Vapor‑logic3 controller), use the keypad to perform the

cool down procedure. Refer to the Vapor-logic3 Installation

and Operation Manual for more information:

a. Select Manual Drain in the control modes screen.

b Allow approximately half the water to drain out of the

tank.

c. Select Auto in the control modes screen; the fill valve

opens and the humidifier cools down.

d. When the fill valve closes, select Manual Drain in

the control modes screen and allow the tank to drain

completely dry. The humidifier should be cool enough

to work on.

mc_060308_0700

Annually (also recommended when maintenance is performed)

1. All safety devices in the control circuit should be cycled on

and off to verify they are functioning. These include:

• High limit switch

• Airflow proving switch

2. Inspect tank and gaskets for leaks.

3. Verify that the float valve is closing off. If the float valve

will not shut off, there may be particulate on the valve seat,

or the stopper may be worn and need replacing.

As long as mineral‑free water is used in the humidifier, no

cleaning or flushing should be necessary.

Off-season maintenance

1. Perform a complete inspection of the following:

• Heat exchanger

• Float valve

• Humidifier tank and gaskets

2. After inspection, leave the humidifier empty until

humidification is required.

After the humidification season, DRI‑STEEM recommends a

complete inspection and cleaning of the heat exchanger and

water chamber. After cleaning, the unit should remain empty

until humidification is required.

On units with Teflon coated heat exchangers, do not use

a sharp object when cleaning. Cuts or scratches on the heat

exchanger will impair its ability to shed scale during operation

and could cause the Teflon to separate from the metal surface.

mc_060208_0708

mc_060208_0715

Shut down humidifier

Follow the procedure below before performing service or

maintenance procedures, (after the tank has cooled down and

drained):

1. Use the Vapor‑logic3 controller keypad to change the

control mode to Standby.

2. Shut off all electrical power to the humidifier using

the field‑installed fused disconnect, and lock all power

disconnect switches in the OFF position.

3. Close the field‑installed manual water supply shut‑off

valve.

4. Close the manual inlet steam supply (on STS) or inlet hot

liquid supply (on LTS) shut‑off valve.

Page 4 • DRI-STEEM STS/LTS, DI Water, Service Kit Manual

mc_060208_1440

STS/LTS, DI water, service instructions

DI water requirements

• Verify regularly that water processing equipment

is operating correctly. The presence of chlorides in

improperly processed DI water eventually causes pitting

and failure of the heat exchanger tank and its components.

Your DRI‑STEEM warranty does not cover damage caused

by chloride corrosion.

• DI models do not require regular cleaning, although

regular inspections are advised.

• DI models do not require skimming or draining

and flushing to remove precipitated minerals. All

DI humidifiers should be drained at the end of a

humidification season either by manually opening

the drain valve or by programming the humidifier to

automatically drain at end‑of‑season (electric drain valve

and Vapor‑logic3 required).

Note: Although DI models do not require regular tank

cleaning, this service kit contains a new cleanout

plate gasket and nuts. If replacing the gasket, replace

the nuts also, and torque the nuts to 25 to 35 in‑lbs

(2.8 to 4.0 N‑m).

mc_060308_0720

mc_062608_1425

Start-up

Perform the Annual safety checks in the Inspection and

maintenance section on page 4.

If resuming operation after service, do not leave the humidifier

unattended; allow it to cycle through multiple fill cycles to

verify that all serviced parts are functioning properly. See the

humidifier's Installation, Operation, and Maintenance manual

for start‑up details.

mc_052908_1005

DRI-STEEM STS/LTS, DI Water, Service Kit Manual • Page 5

Humidifier De-scaling Solution

Scale buildup on humidifier heat exchangers

acts as an insulator, reducing humidifier

performance while increasing energy

costs. To keep humidifiers operating as

efficiently as possible, remove scale with

DRI-STEEM's Humidifier De-scaling Solution,

available for purchase from your DRI-STEEM

representative or distributor.

The De-scaling Solution cleans without risk

of corroding humidifier tanks or welds. The

De-scaling Solution also cleans surfaces

unreachable by hand scraping.

DRI-STEEM's Humidifier De-scaling Solution

is the only approved cleaner/de-scaler for

use with DRI-STEEM humidifiers. Use of

other cleaners/de-scalers may void your

DRI-STEEM warranty.

mc_021908_1410-heatx

DRI-STEEM Corporation

An ISO 9001: 2000 certified corporation

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

European office:

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgium

+3211823595 (voice)

+3211817948 (fax)

E-mail: marc.briers@dristeem.com

Continuous product improvement is a

policy of DRI-STEEM Corporation; therefore,

product features and specifications are

subject to change without notice.

DRI-STEEM, LTS, STS, and Vapor-logic

are registered trademarks of DRI-STEEM

Corporation and are filed for trademark

registration in Canada and the European

community.

Drane-kooler is a trademark of DRI-STEEM

Corporation.

© 2013 DRI-STEEM Corporation

Form No. STS/LTS-DI-SKM-1013

Page 6 • DRI-STEEM STS/LTS, DI Water, Service Kit Manual

Part No. 891000-502 Rev D

DRI-STEEM products are warranted according to the terms and conditions of the standard

two-year Limited Warranty effective when the humidifier was purchased. See the literature

that was shipped with the humidifier for warranty information.

mc_081308_1405

Loading...

Loading...