Page 1

READ AND SAVE THESE INSTRUCTIONS

HYDROTRUE

™

Pre-treatment Systems

Installation, Operation,

and Maintenance Manual

Page 2

WARNINGS AND CAUTIONS

Warnings and cautions

WARNING CAUTION

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

mc_051508_1145

WARNING

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualified

HVAC and electrical contractors and in compliance with local, state, federal, and governing codes. Improper installation

can cause property damage, severe personal injury, or death as a result of electric shock, burns, or fire.

DriSteem Technical Support: 800-328-4447

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all

warnings and instructions could produce the hazardous situations described, resulting in property damage, personal

injury, or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause bacteria and mold

growth or dripping water into building spaces. Dripping water can cause property damage; bacteria and mold growth

can cause illness.

If the IOM is missing, go to www.dristeem.com to download a replacement.

Shut down the energy source

Before performing service or maintenance procedures on any part of the system, verify that all energy sources are off.

Failure to shut down the energy source could result in fire, explosion, electrical shock, and other hazardous conditions.

These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury or death as a result of electrical

shock or fire. Do not remove electrical panel cover/door or access panels until electrical power is disconnected.

Follow the shutdown procedure in the system IOM before performing service or maintenance procedures on any part of

the system.

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii

Page 3

Warnings and cautions

WARNING

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any part

of the system. Failure to disconnect electrical power could result in fire, electrical shock, and other hazardous conditions.

These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock

or fire.

Follow the shutdown procedure in this manual before performing service or maintenance procedures on any part of the

system.

Electric shock hazard

If the system starts up during maintenance, severe bodily injury or death from electric shock could occur. To prevent such

start-up, follow the procedure below before performing service or maintenance procedures on this system:

1. Shut off all electrical power to the system using field-installed fused disconnect, and lock all power disconnect switches

in OFF position.

2. Close field-installed manual water supply shut-off valve.

FILL IN THE FOLLOWING INFORMATION FOR YOUR RECORDS

Date of purchase

Customer's name

Model number

Serial number

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

Page 4

Table of contents

WARNINGS AND CAUTIONS ................................................ii

OVERVIEW..............................................................2

Dechlorinator specifications ...............................2

Single water softener specifications ..........................3

Duplex water softener specifications .........................4

Optional pretreatment skid mounting .........................6

Skidded single water softener and dechlorinator specifications .......7

Skidded duplex water softener and dechlorinator specifications ......8

Skidded duplex water softener specifications ...................9

INSTALLATION ......................................................... 10

Electrical installation ...................................10

Site requirements ......................................11

Start-up checklist ......................................13

System startup ........................................14

Plumbing and wiring for dual softener 21, 24, 30 inch models .....15

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv

Page 5

Table of contents

OPERATION ...........................................................

17

Softener and dechlorinator start-up .........................17

Loading the carbon media ...............................20

Loading the water softener media ..........................21

MAINTENANCE ........................................................ 22

Components .........................................22

Troubleshooting .......................................23

Water quality test strips .................................28

Water quality test log ..................................29

REPLACEMENT PARTS .................................................... 30

Water treatment system .................................30

WARRANTY ........................................................... 32

ATTENTION INSTALLER

Read this manual before installing.

Leave manual with product owner.

DriSteem

800-328-4447

WHERE TO FIND MORE INFORMATION

®

Technical Support

Our website:

The following documents is available on our

web site: www.dristeem.com

• Water Treatment Systems Catalog

• RO 200 series Installation, Operation,

and Maintenance Manual

• RO 400 series Installation, Operation,

and Maintenance Manual

DriCalc® sizing and selection software:

DriCalc, our software for system sizing and

selection, can be ordered at our web site.

Call us at 800-328-4447

Obtaining documents from our web site or

from DriCalc is the quickest way to view our

literature.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

Page 6

OVERVIEW

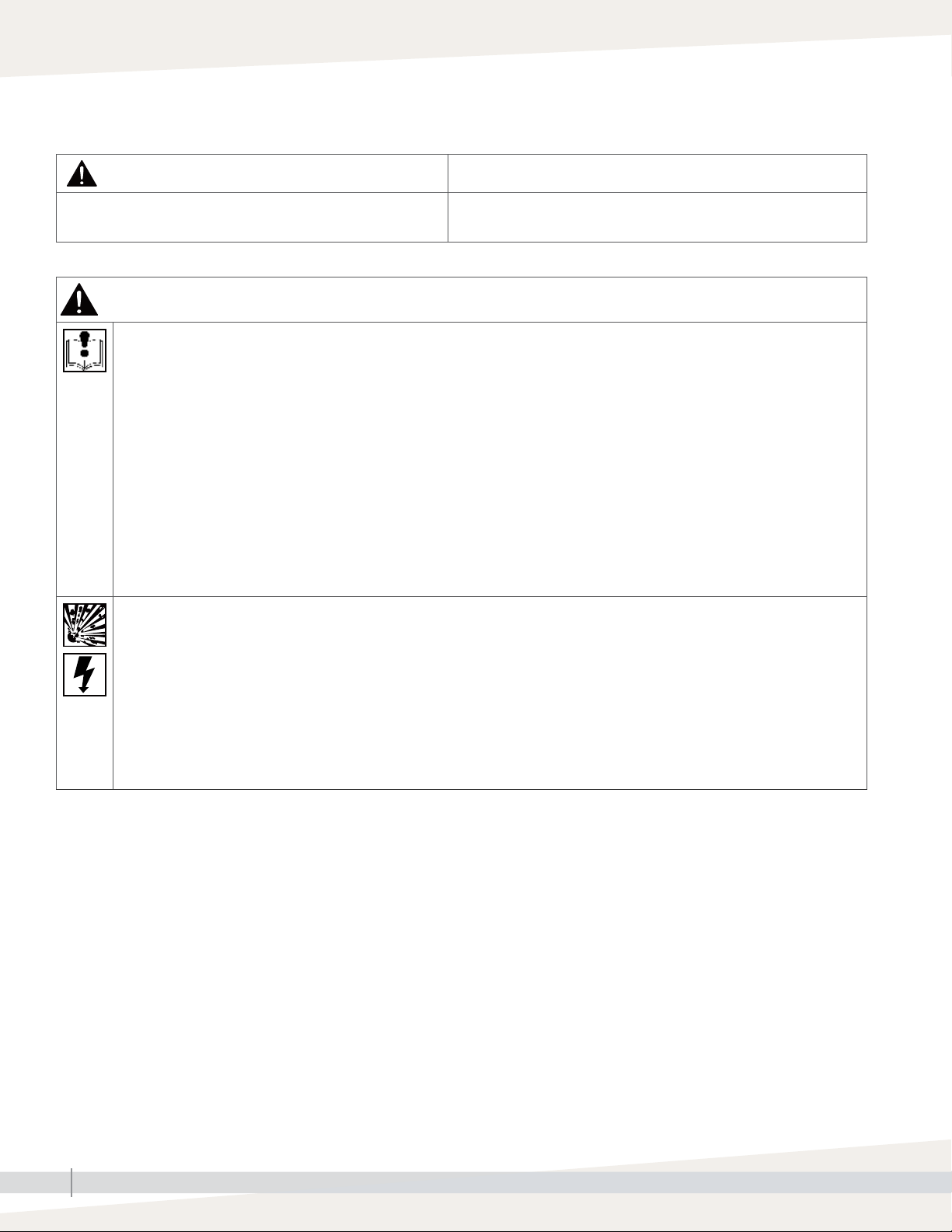

Dechlorinator specifications

DECHLORINATOR

The dechlorinator removes chlorine from the water that degrades the reverse

osmosis membranes.

120V, single-phase, 60 Hz, 5A electrical service is required for all

dechlorinator models, except for the DC-CB dechlorinator (requires no

electrical service).

FIGURE 2-2: WALL MOUNT DECHLORINATOR

Table 2-1:

Dechlorinator specifications

Dechlorinator model* Media volume

DC-CB Carbon black filter

3

DC-744

DC-844 0.75 ft

DC-948 1.00 ft

DC-1054 1.50 ft

DC-1252 2.00 ft3 (0.050 m3)

DC-1354 2.50 ft3 (0.071 m3)

DC-1465 3.00 ft3 (0.085 m3)

DC-1665 4.00 ft

DC-2162 6.00 ft3 (0.170 m3)

DC-2472 8.00 ft3 (0.227 m3)

DC-3072 12.50 ft3 (0.354 m3)

* DC-CB is wall mounted; all other models are floor mounted.

** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

*** DC-2162, DC-2472, and DC--3072 media shipped separate, but included in shipping weight total.

0.5 ft

(0.014 m3)

3

(0.021 m3)

3

(0.028 m3)

3

(0.042 m3)

3

(0.113 m3)

Dimensions,

diameter x height

4" × 20"

(102 x 508 mm)

7" × 44"

(178 x 1118 mm)

8" x 44"

(203 x 1118 mm)

9" × 48"

(229 x 1219 mm)

10" x 54"

(254 x 1372 mm)

12" x 52"

(305 x 1321 mm)

13" x 54"

(330 x 1372 mm)

14" x 65"

(356 x 1651 mm)

16" x 65"

(406 x 1651 mm)

21" x 62"

6(533 x 1575 mm)

24" x 72"

(610 x 1829 mm)

30" x 72"

(762 x 1829 mm)

Connections, in /out Backwash flow** Shipping weight***

1" — —

1" 2.7 gpm (10.2 L/m) 100 lbs (45.4 kg)

1" 3.2 gpm (12.1 L/m) 115 lbs (52.2 kg)

1" 4.2 gpm (15.9 L/m) 130 lbs (59.0 kg)

1" 5.3 gpm (20.1 L/m) 150 lbs (68.0 kg)

1" 7.5 gpm (28.4 L/m) 190 lbs (86.2 kg)

1" 10.0 gpm (37.9 L/m) 225 lbs (102.1 kg)

1" 12.0 gpm (45.4 L/m) 335 lbs (152.0 kg)

1" 15.0 gpm (56.8 L/m) 385 lbs (174.6 kg)

1.5" 25.0 gpm (94.6 L/m) 645 lbs (292.6 kg)

1.5" 33.0 gpm (124.9 L/m) 950 lbs (430.9 kg)

2" 50.0 gpm (189.3 L/m) 1535 lbs (696.3 kg)

FIGURE 2-1: DECHLORINATOR

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

Page 7

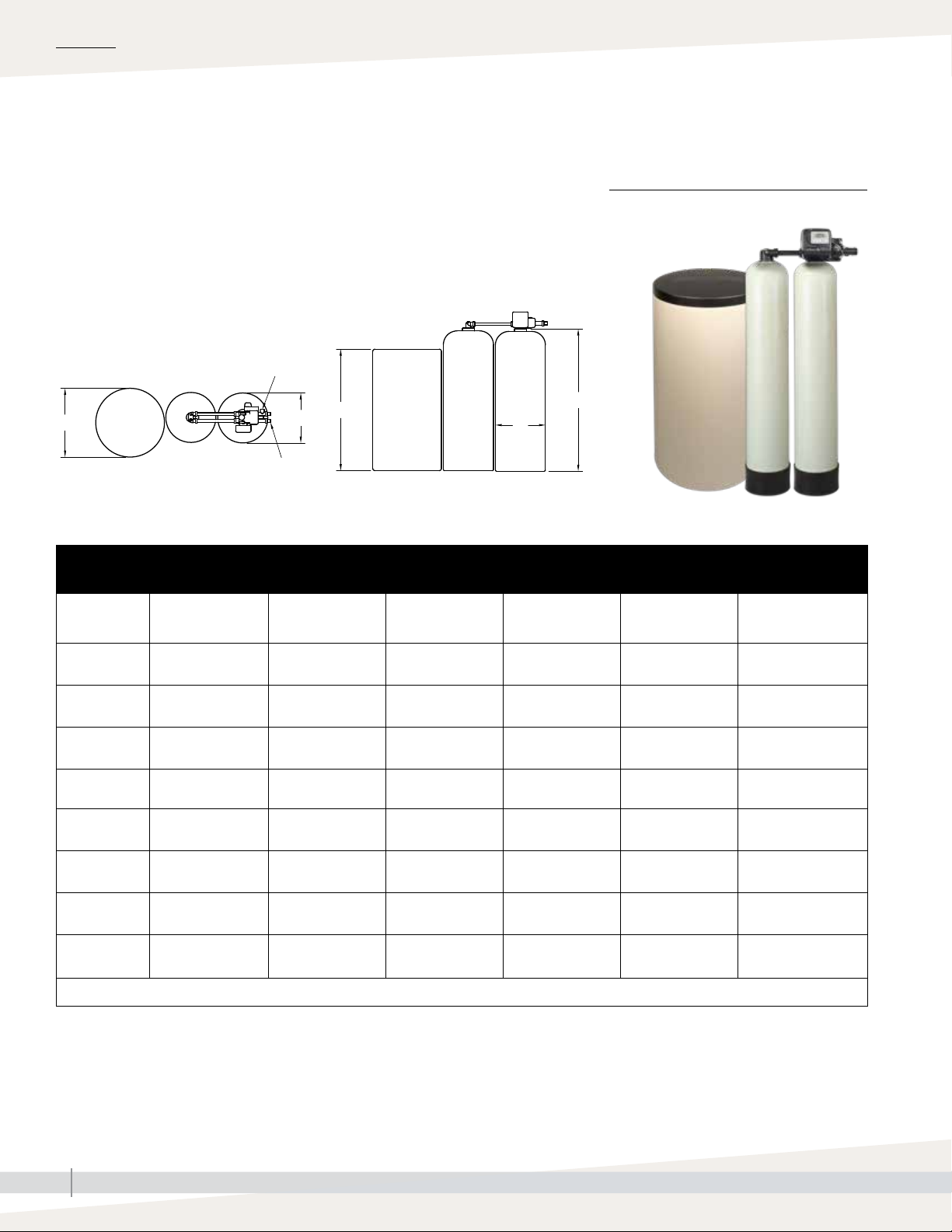

Single water softener specifications

OVERVIEW

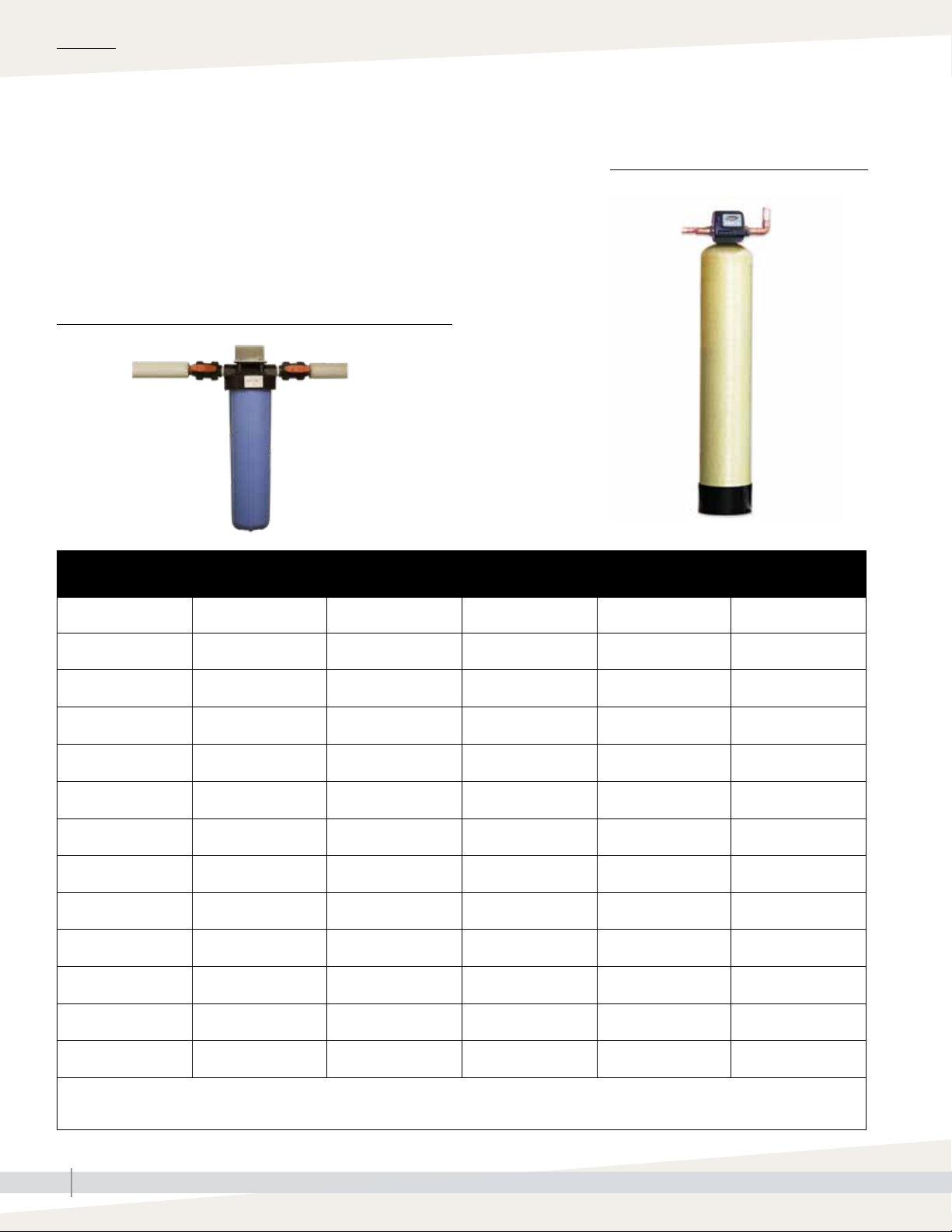

WATER SOFTENER AND BRINE TANK

The water softener and brine tank are floor-mounted and exchange water

FIGURE 3-1: SINGLE WATER SOFTENER

AND BRINE TANK

hardness for sodium.

120V, single-phase, 60 Hz, 5A electrical service is required for all water

softener models.

Water inlet

D

C

A

OM-7940

Water

outlet

B

A

Table 3-1:

Single softener and brine tank specifications

Softener model

WS-744

WS-844

WS-948

WS-1054

WS-1252

WS-1354

WS-1465

WS-1665

WS-2162

WS-2472

WS-3072

Media volume

per tank

3

0.5 ft

(0.014 m3)

3

0.75 ft

(0.021 m3)

3

1.00 ft

(0.028 m3)

3

1.50 ft

(0.042 m3)

3

2.00 ft

(0.050 m3)

3

2.50 ft

(0.071 m3)

3

3.00 ft

(0.085 m3)

3

4.00 ft

(0.113 m3)

6.00 ft3

(0.170 m3)

8.00 ft3

(0.227 m3)

12.50 ft3

(0.354 m3)

** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

*** WS-2162, WS-2472, and WS--3072 media shipped separate, but included in shipping weight total.

Resin tank

diameter (A) x

height (B) (per tank)

7" × 44"

(178 x 1118 mm)

8" x 44"

(203 x 1118 mm)

9" × 48"

(229 x 1219 mm)

10" x 54"

(254 x 1372 mm)

12" x 52"

(305 x 1321 mm)

13" x 54"

(330 x 1372 mm)

14" x 65"

(356 x 1651 mm)

16" x 65"

(406 x 1651 mm)

21" x 62"

(533 x 1575 mm)

24" x 72"

(610 x 1829 mm)

30" x 72"

(762 x 1829 mm)

Connections,

in/out

1"

1"

1"

1"

1"

1"

1"

1"

1.5"

1.5"

2"

Backwash flow**

1.35 gpm

(4.9 L/m)

1.70 gpm

(6.4 L/m)

2.2 gpm

(8.3 L/m)

2.7 gpm

(10.2 L/m)

3.2 gpm

(12.1 L/m)

4.2 gpm

(15.9 L/m)

5.3 gpm

(20.1 L/m)

6.5 gpm

(24.6 L/m)

12.0 gpm

(45.4 L/m)

15.0 gpm

(56.8 L/m)

25.0 gpm

(94.6 L/m)

Brine tank

diameter (C) x height

(D)

18" x 33"

(457 x 838 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

24" x 41"

(610 x 1041 mm)

24" x 41"

(610 x 1041 mm)

30" x 48"

(762 x 1219 mm)

39" x 48"

(991 x 1219 mm)

39" x 48"

(991 x 1219 mm)

Shipping weight***

110 lbs (49.9 kg)

125 lbs (56.7 kg)

140 lbs (63.5 kg)

160 lbs (72.6 kg)

200 lbs (90.7 kg)

235 lbs (106.6 kg)

345 lbs (156.5 kg)

395 lbs (179.2 kg)

655 lbs (297.1 kg)

960 lbs (435.4 kg)

1545 lbs (701.0 kg)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3

Page 8

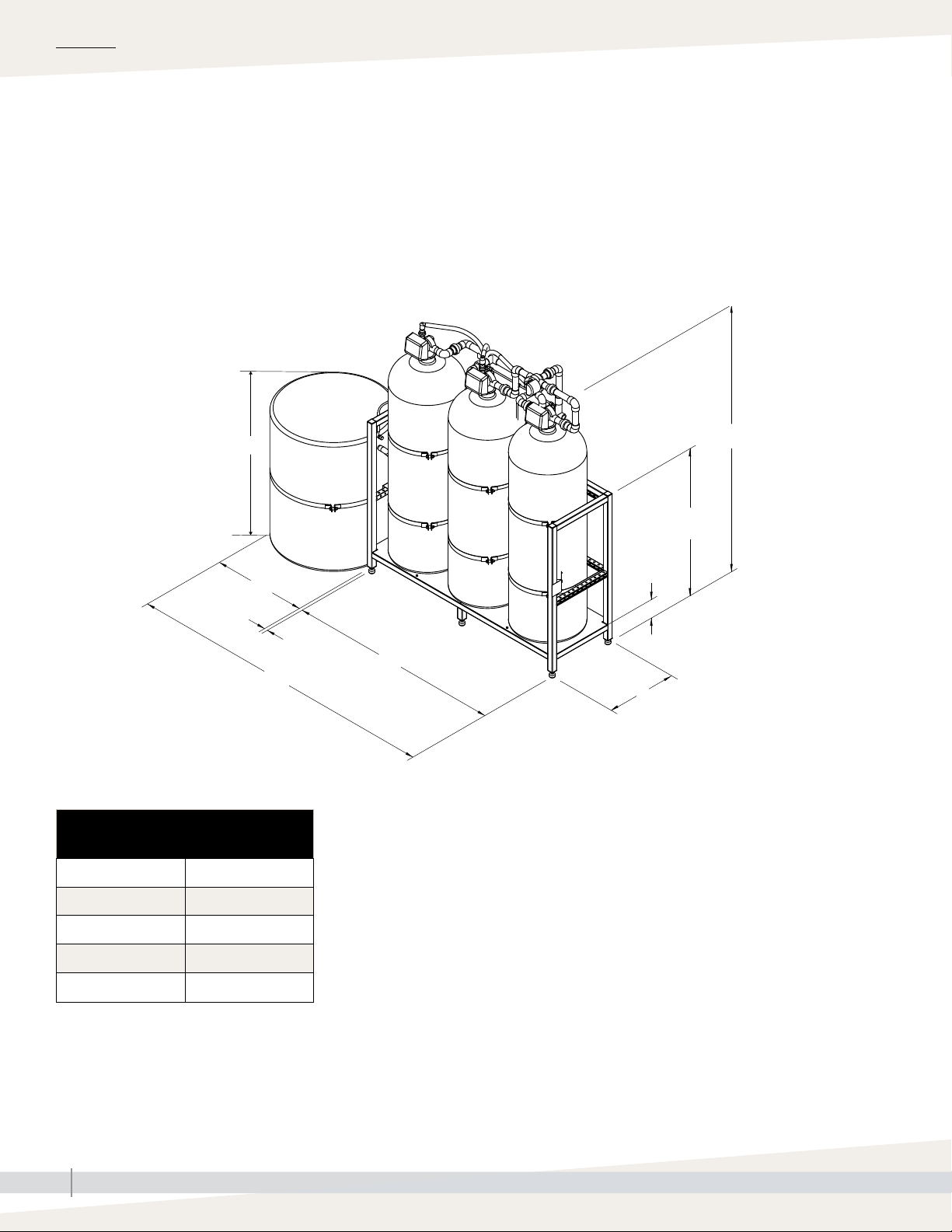

OVERVIEW

Duplex water softener specifications

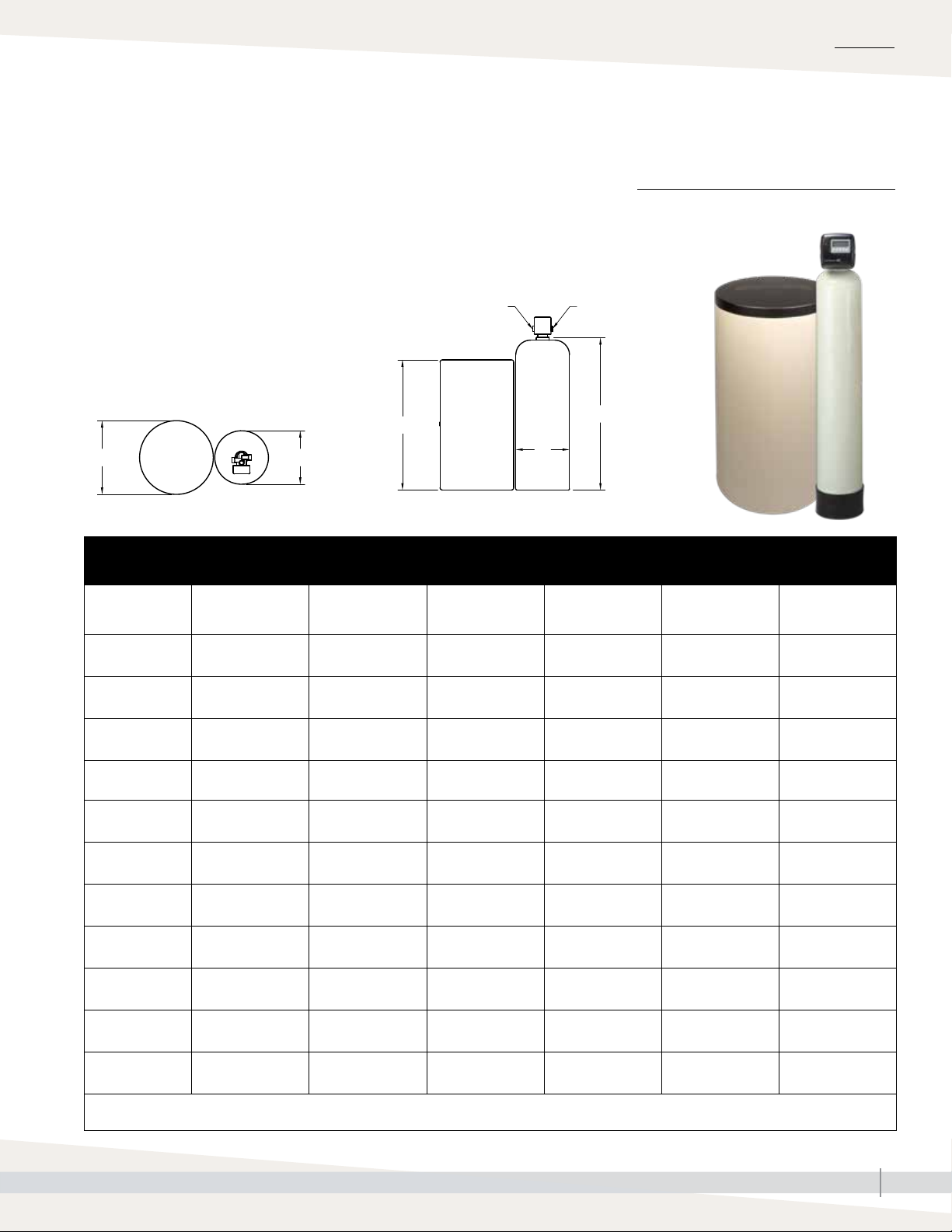

WATER SOFTENER AND BRINE TANK

The water softener and brine tank are floor-mounted and exchange water

hardness for sodium.

120V, single-phase, 60 Hz, 5A electrical service is required for all water

softener models.

NPT water inlet

D

C

A

A

Water outlet

OM-7941

Table 4-1:

Duplex softener and brine tank specifications

Softener model*

WD-744

WD-844

WD-948

WD-1054

WD-1252

WD-1354

WD-1465

WD-1665

Media volume

per tank

3

0.5 ft

(0.014 m3)

3

0.75 ft

(0.021 m3)

3

1.00 ft

(0.028 m3)

3

1.50 ft

(0.042 m3)

3

2.00 ft

(0.050 m3)

3

2.50 ft

(0.071 m3)

3

3.00 ft

(0.085 m3)

3

4.00 ft

(0.113 m3)

Resin tank

diameter (A) x

height (B) (per tank)

7" × 44"

(178 x 1118 mm)

8" x 44"

(203 x 1118 mm)

9" × 48"

(229 x 1219 mm)

10" x 54"

(254 x 1372 mm)

12" x 52"

(305 x 1321 mm)

13" x 54"

(330 x 1372 mm)

14" x 65"

(356 x 1651 mm)

16" x 65"

(406 x 1651 mm)

Connections,

in/out

1"

1"

1"

1"

1"

1"

1"

1"

Backwash flow**

1.35 gpm

(4.9 L/m)

1.7 gpm

(6.4 L/m)

2.2 gpm

(8.3 L/m)

2.7 gpm

(10.2 L/m)

3.2 gpm

(12.1 L/m)

4.2 gpm

(15.9 L/m)

5.3 gpm

(20.1 L/m)

6.5 gpm

(24.6 L/m)

FIGURE 4-1: DUPLEX WATER SOFTENER

AND BRINE TANK

B

Brine tank

diameter (C) x height

Shipping weight

(D)

100 lbs (45.4 kg) 210 lbs (95.3 kg)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

24" x 41"

(610 x 1041 mm)

24" x 41"

(610 x 1041 mm)

250 lbs (113.4kg)

270 lbs (122.5 kg)

310 lbs (140.6 kg)

390 lbs (176.9 kg)

460 lbs (208.7 kg)

680 lbs (308.4 kg)

778 lbs (352.9 kg)

** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

Page 9

Duplex water softener specifications

FIGURE 5-1: DUPLEX WATER SOFTENER

AND BRINE TANK

OVERVIEW

Table 5-1:

Duplex softener and brine tank specifications

Softener model*

WD-2162

WD-2472

WD-3072

** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

*** WD-2162, WD-2472, and WD--3072 media shipped separate, but included in shipping weight total.

Media volume

per tank

3

6.00 ft

(0.170 m3)

8.00 ft3

(0.227 m3)

12.50 ft3

(0.354 m3)

Resin tank

diameter (A) x

height (B) (per tank)

21" x 62"

(533 x 1575 mm)

24" x 72"

(610 x 1829 mm)

30" x 72"

(762 x 1829 mm)

Connections,

in/out

1.5"

1.5"

2"

Backwash flow**

12.0 gpm

(45.4 L/m)

15.0 gpm

(56.8 L/m)

25.0 gpm

(94.6 L/m)

diameter (C) x height

Brine tank

(D)

30" x 48"

(762 x 1219 mm)

39" x 48"

(991 x 1219 mm)

39" x 48"

(991 x 1219 mm)

Shipping weight***

1300 lbs (589.7 kg)

1910 lbs (866.4 kg)

3080 lbs (1397.1 kg)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

Page 10

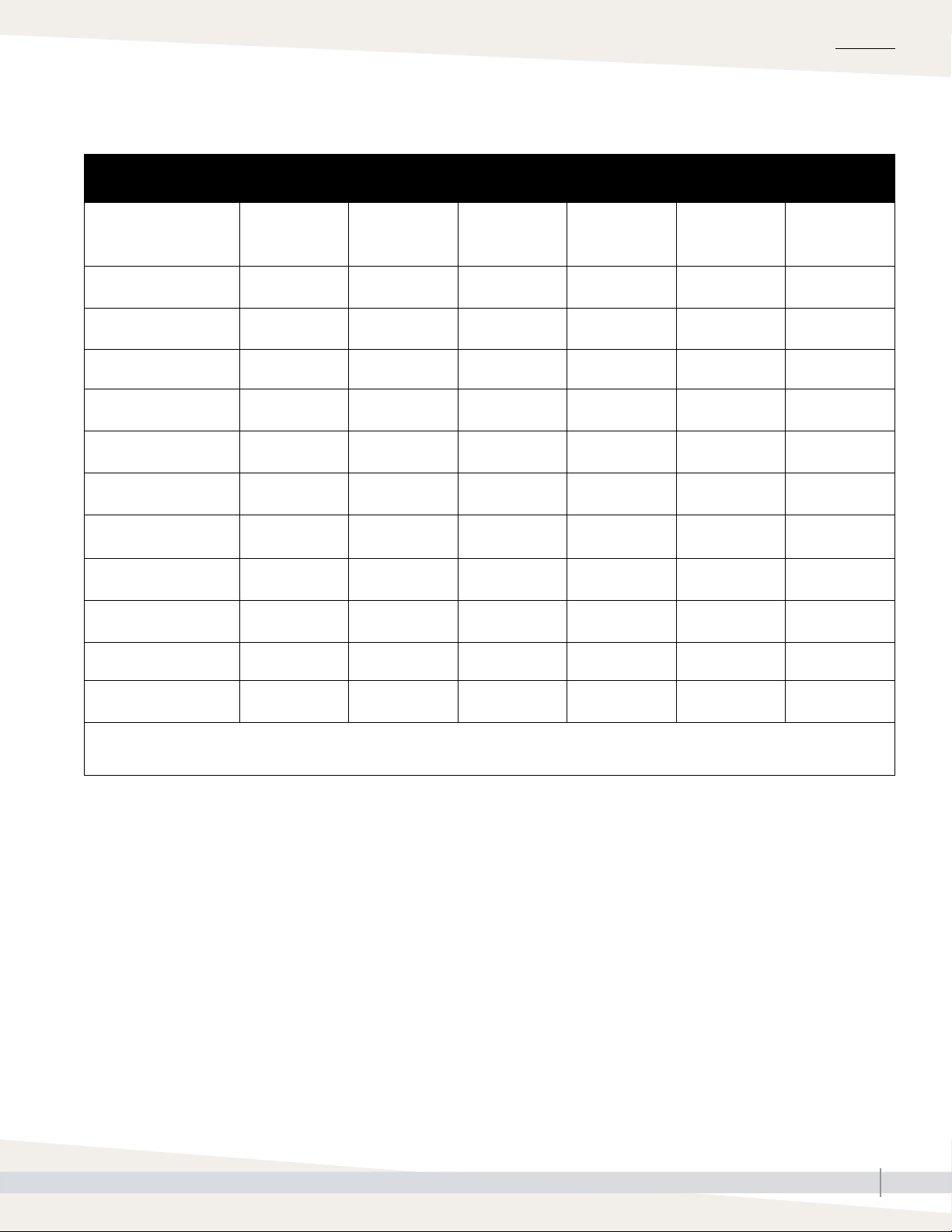

OVERVIEW

Optional pretreatment skid mounting

SELECT PRETREATMENT SKID MOUNTING FOR EASE OF INSTALLATION

Reduce installation cost and time by having pretreatment components come

pre-assembled. The DriSteem water softener(s), brine tank, and dechlorinator

have a single point water inlet, water outlet, and power for all components.

• Save time and cost on installation

• Maximize clearance

• Ensure proper installation and operation

Note: Duplex water softeners

for 21-inch diameter and

larger must have media

installed in the field.

Table 6-1:

Voltages

AC adapter U.S.

D

C

1" (25 mm)

L + C

B

54" (1372 mm)

6" (152 mm)

L

W

OM-7819a

Supply voltage 120 VAC

Supply frequency 60 Hz

Output voltage 12 VAC

Output current 500 mA

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

Page 11

Skidded single water softener and dechlorinator specifications

Table 7-1:

Skidded single water softener and dechlorinator

Skid size*

(outside dimensions)

L x W x H

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

Tank quantity on

skid

3

3

3

3

3

3

Media tank

diameter (A) x

height (B) (per

tank)

7" × 44"

(178 x 1118 mm)

8" x 44"

(203 x 1118 mm)

9" × 48"

(229 x 1016 mm)

10" x 54"

(254 x 1372 mm)

12" x 52"

(305 x 1321 mm)

13" x 54"

(330 x 1372 mm)

Connections,

in/out

1"

1"

1"

1"

1"

1"

Backwash flow***

1.35 gpm

(4.9 L/m)

1.70 gpm

(6.4 L/m)

2.2 gpm

(8.3 L/m)

2.7 gpm

(10.2 L/m)

3.2 gpm

(12.1 L/m)

4.2 gpm

(15.9 L/m)

Brine tank

diameter (C) x

height (D)

18" x 33"

(457 x 838 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

OVERVIEW

Shipping weight

370 lbs

(167.8 kg)

400 lbs

(181.4 kg)

420 lbs

(190.5 kg)

470 lbs

(213.2 kg)

530 lbs

(240.4 kg)

620 lbs

(281.2 kg)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

100"x 34" x 54"

(2540 x 864 x 1372 mm)

66"x 28" x 54" **

(1676 x 711 x 1372 mm)

82"x 28" x 54" **

(2083 x 711 x 1372 mm)

* Non-skidded pre-treatment dimensions are 4" (102 mm) less.

** Skid does not include brine tank. The brine tank is floor mounted.

*** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

3

3

3

2

2

14" x 65"

(356 x 1651 mm)

16" x 65"

(406 x 1651 mm)

21" x 62"

(533 x 1575 mm)

24" x 72"

(610 x 1829 mm)

30" x 72"

(762 x 1829 mm)

1"

1"

1.5"

1.5"

2"

5.3 gpm

(20.1 L/m)

6.5 gpm

(24.6 L/m)

12.0 gpm

(45.4 L/m)

15.0 gpm

(56.8 L/m)

25.0 gpm

(94.6 L/m)

24" x 41"

(610 x 1041 mm)

24" x 41"

(610 x 1041 mm)

30" x 48"

(762 x 1219 mm)

39" x 48"

(991 x 1219 mm)

39" x 48"

(991 x 1219 mm)

860 lbs

(390.1 kg)

910 lbs

(412.8 kg)

1540 lbs

(698.5 kg)

2090 lbs

(948.0 kg)

3280 lbs

(1487.8 kg)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

7

Page 12

OVERVIEW

Skidded duplex water softener and dechlorinator specifications

Table 8-1:

Skidded duplex water softener and dechlorinator

Skid size

(outside dimensions)

L x W x H

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

Tank quantity

on skid

4

4

4

4

4

4

Media tank

diameter (A) x

height (B) (per tank)

7" × 44"

(178 x 1118 mm)

8" x 44"

(203 x 1118 mm)

9" × 48"

(229 x 1016 mm)

10" x 54"

(254 x 1372 mm)

12" x 52"

(305 x 1321 mm)

13" x 54"

(330 x 1372 mm)

Connections,

in/out

1"

1"

1"

1"

1"

1"

Backwash flow***

1.35 gpm

(4.9 L/m)

1.7 gpm

(6.4 L/m)

2.2 gpm

(8.3 L/m)

2.7 gpm

(10.2 L/m)

3.2 gpm

(12.1 L/m)

4.2 gpm

(15.9 L/m)

Brine tank

diameter (C) x height (D)

18" x 33"

(457 x 838 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

Shipping weight

490 lbs

(222.3 kg)

545 lbs

(247.2 kg)

575 lbs

(260.8 kg)

640 lbs

(290.3 kg)

760 lbs

(344.7 kg)

865 lbs

(392.4 kg)

82"x 28" x 54"

(2083 x 711 x 1372 mm)

82"x 28" x 54"

(2083 x 711 x 1372 mm)

82"x 28" x 54" **

(2083 x 711 x 1372 mm)

82"x 28" x 54" **

(2083 x 711 x 1372 mm)

100"x 34" x 54" **

(2540 x 864 x 1372 mm)

* Non-skidded pre-treatment dimensions are 4" (102 mm) less.

** Skid does not include brine tank. The brine tank is floor mounted.

*** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

4

4

3

3

3

14" x 65"

(356 x 1651 mm)

16" x 65"

(406 x 1651 mm)

21" x 62"

(533 x 1575 mm)

24" x 72"

(610 x 1829 mm)

30" x 72"

(762 x 1829 mm)

1"

1"

1.5"

1.5"

2"

5.3 gpm

(20.1 L/m)

6.5 gpm

(24.6 L/m)

12.0 gpm

(45.4 L/m)

15.0 gpm

(56.8 L/m)

25.0 gpm

(94.6 L/m)

24" x 41"

(610 x 1041 mm)

24" x 41"

(610 x 1041 mm)

30" x 48"

(762 x 1219 mm)

39" x 48"

(991 x 1219 mm)

39" x 48"

(991 x 1219 mm)

1215 lbs

(551.1 kg)

1363 lbs

(618.2 kg)

2145 lbs

(972.9 kg)

3060 lbs

(1387.9 kg)

4855 lbs

(2202.2 kg)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8

Page 13

Skidded duplex water softener specifications

Table 9-1:

Skidded duplex water softener

Skid size

(outside dimensions)

L x W x H

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

52"x 26" x 54"

(1321 x 660 x 1372 mm)

Tank quantity on

skid

3

3

3

3

3

3

Media tank

diameter (A) x

height (B) (per

tank)

7" × 44"

(178 x 1118 mm)

8" x 44"

(203 x 1118 mm)

9" × 48"

(229 x 1016 mm)

10" x 54"

(254 x 1372 mm)

12" x 52"

(305 x 1321 mm)

13" x 54"

(330 x 1372 mm)

Connections,

in/out

1"

1"

1"

1"

1"

1"

Backwash flow***

1.35 gpm

(4.9 L/m)

1.7 gpm

(6.4 L/m)

2.2 gpm

(8.3 L/m)

2.7 gpm

(10.2 L/m)

3.2 gpm

(12.1 L/m)

4.2 gpm

(15.9 L/m)

Brine tank

diameter (C) x

height (D)

18" x 33"

(457 x 838 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

18" x 40"

(457 x 1016 mm)

OVERVIEW

Shipping weight

370 lbs

(167.8 kg)

410 lbs

(185.9 kg)

430 lbs

(195.0 kg)

470 lbs

(213.2 kg)

550 lbs

(249.5 kg)

620 lbs

(281.2 kg)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

66"x 28" x 54"

(1676 x 711 x 1372 mm)

100"x 34" x 54"

(2540 x 864 x 1372 mm)

66"x 28" x 54" **

(1676 x 711 x 1372 mm)

82"x 28" x 54" **

(2083 x 711 x 1372 mm)

* Non-skidded pre-treatment dimensions are 4" (102 mm) less.

** Skid does not include brine tank. The brine tank is floor mounted.

*** Based on 60 to 90 psi (415 to 620 kPa) inlet pressure.

3

3

3

2

2

14" x 65"

(356 x 1651 mm)

16" x 65"

(406 x 1651 mm)

21" x 62"

(533 x 1575 mm)

24" x 72"

(610 x 1829 mm)

30" x 72"

(762 x 1829 mm)

1"

1"

1.5"

1.5"

2"

5.3 gpm

(20.1 L/m)

6.5 gpm

(24.6 L/m)

12.0 gpm

(45.4 L/m)

15.0 gpm

(56.8 L/m)

25.0 gpm

(94.6 L/m)

24" x 41"

(610 x 1041 mm)

24" x 41"

(610 x 1041 mm)

30" x 48"

(762 x 1219 mm)

39" x 48"

(991 x 1219 mm)

39" x 48"

(991 x 1219 mm)

860 lbs

(390.1 kg)

958 lbs

(434.5 kg)

1540 lbs

(698.5 kg)

2090 lbs

(948.0 kg)

3280 lbs

(1487.8 kg)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

Page 14

INSTALLATION

Electrical installation

The control valve and fittings are not designed to support the weight of the

system or the plumbing.

• Teflon tape is recommended to be used on all threads. Do not use pipe

dope, as it may break down the plastics in the control valve.

• Allow one foot of clearance to service WS1.5 valves and two feet of

clearance to service WS2 and WS2QC valves.

• The valve will withstand transportation and storage temperatures of -13 °F

(-25 °C) to 131 °F (55 °C) and for short periods up to 158 °F (70 °C). If

valve has been exposed to freezing conditions let valve warm up to room

temperature before running water through it. The valve has been packaged

to prevent damage from the effects of normal humidity, vibration and

shock.

SINGLE SOFTENER LOCKOUT SWITCH

Single softeners have a RO lockout switch if it is desired to lockout the RO

system to prevent any hard water passing to the RO system when the softeners

are in backwash. See Figure 10-1 for connections to the RO system lockout

terminals.

FIGURE 10-1: SINGLE SOFTENER LOCKOUT SWITCH WIRING

CAUTION

Do not use Vaseline, oils, other

hydrocarbon lubricants or spray

silicone anywhere. A silicone lubricant

may be used on black o-rings but is

not necessary.

CAUTION

Hydrocarbons such as kerosene,

benzene, gasoline, etc., may damage

products that contain o-rings or

plastic components. Exposure to such

hydrocarbons may cause the products

to leak. Do not use the products(s)

contained in this document on water

supplies that contain hydrocarbons

such as kerosene, benzene, gasoline,

etc.

WMS_Lockout_wiring

CAUTION

DriSteem water meters should not

be used as the primary monitoring

device for critical or health effect

applications.

To lockout terminals on RO system

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

10

Page 15

Site requirements

SITE REQUIREMENTS

1. The plug in Power Adapter is for dry locations only, and should be

connected to an uninterrupted outlet installed within 15 feet (4.57 meters)

of the water conditioner. If the Power Adapter cord has not yet been

connected to the control valve, remove the control valve cover and the

drive bracket, and thread the Power Adapter cord through the hole in the

back plate. Reinstall the drive bracket. Weave the cord through the hooks

on the right hand side of the drive bracket and connect the end to the

four-prong connector on the printed circuit board. Replace the cover, and

plug the Power Adapter into an uninterrupted outlet.

2. The tanks should be on a firm, level surface.

3. All plumbing should be done in accordance with local codes.

4. Do not locate unit where it or its connections (including the drain and

overflow lines) will ever be subjected to room temperatures below 40° F

(4° C).

INSTALLATION

5. INLET/OUTLET PLUMBING: Connect to a supply line downstream of

outdoor spigots. Install an inlet shutoff valve and plumb to the unit’s inlet.

Installation of a bypass valve is recommended. If using plastic fittings,

ground the water conditioner per local electrical codes. Do not install

any water conditioner with less than 10 feet of piping between its outlet

and the inlet of a water heater. If a water meter is used, install the water

meter on the outlet side of the control valve. The turbine assembly may

be oriented in any direction, but is usually oriented pointing up to reduce

drainage out of the pipe during service.

6. Locate the water conditioner so the distance between the drain and the

water conditioner is as short as possible. All units are shipped without a

drain line flow control washer. Correctly size the drain line and install an

appropriately sized drain line flow control. 1.5” valves are shipped with

a ¾” fitting that can be used with the drain line flow controls up to 10

gpm, or an optional 1” fitting can be purchases to be used with drain line

flow controls up to 25 gpm. For higher backwash rates, the adapter can

be removed and the 1 ¼” NPT threaded drain outlet can be used. For 2”

valves the drain outlet is 1.5” NPT threads. Solder joints near the drain

must be done prior to connecting the drain line flow control fitting. Leave

at least 6” (152.4mm) between the drain line flow control fitting and

the solder joints to prevent heat from damaging the flow control. Avoid

elevating the drain line above the control valve where possible. Discharge

the drain line through an air gap to a receptacle in accordance with local

plumbing codes.

IMPORTANT: Never insert a drain line directly into a drain, sewer line or trap.

Always allow and air gap between the drain line and the receptacle to prevent

back siphonage.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

Page 16

INSTALLATION

Site requirements

7. Regenerant tanks should be accessible for easy refilling. If the control

valve is to be used to regenerate the water conditioner with brine

(saturated salt solution) or other regenerants, use a polyethylene tube to

connect the brine valve contained in the regenerant tank to the regenerant

port on the control valve. It is recommended the brine valve contain a

safety float. The 1.5” control valve’s regenerant port has a ½” fitting.

Note: ½” tubing that runs longer than 6 feet may restrict draw rates with

G and H injectors. A 5/8” fitting is also available.

The 2” control valve regenerant port has a 1” threaded connection. To

ensure acceptable operation of the injectors, use 1” pipe to connect to the

brine tank.

An overflow drain line from the regenerant tank that discharges into

an acceptable drain is recommended, as a regenerant overflow could

damage furnishings or the building structure. Connect a line to the

overflow fitting on the regenerant tank. If an overflow fitting is not already

installed on the regenerant tank, install one. Do not elevate the overflow

drain line. Discharge the overflow drain line through an air gap to a

receptacle in accordance with local plumbing codes.

FIGURE 12-1: WATER SOFTENER CLEARANCE

Softener tanks

Minimum 4" (102 mm)

clearance

DechlorinatorBrine tank

OM-7906a

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12

Page 17

INSTALLATION

Start-up checklist

If an item in the Start-up checklist below does not apply to your system, skip to the next item and continue the process.

☐ Read this manual and all other information that was provided with your system.

☐ Verify that all field wiring is done according to the instructions in this manual and in the unit wiring diagram.

☐ Confirm that proper grounding and an approved earth ground are provided.

☐ Slowly turn on the water supply and confirm there are no leaks.

☐ Add water to the brine tank. 1/3 water (12-inches) water and 2/3 salt.

☐ Systems with tank-style carbon filter with control valve: Ensure that elastomeric Drain Line Flow Control restrictor

washer is installed correctly in drain outlet plumbing assembly. This is required to prevent overflow and potential

carry-over of carbon to the drain system.

See “Dechlorinator” on Page 22 of this manual.

☐ Inspect to insure that no flexible plumbing lines have been kinked or damaged during installation.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

13

Page 18

INSTALLATION

System startup

1. After installation is completed, turn on the supply water to check for leaks.

2. Fully open a cold water faucet downstream of the system.

3. Allow water to run until clear.

4. Close the cold water faucet.

5. Turn off the supply water.

6. The system is now ready for startup.

SYSTEM STARTUP

7. Initiate manual regeneration of the control valve to regenerate: press the

REGEN button for three seconds.

8. Ensure drain line flow remains steady for 10 minutes or until clear. Step

through the different regeneration cycles by pressing the REGEN button

again.

9. Observe regeneration effluent and continue to regenerate until discharge

is clear. Steps 7 and 8 may need to be repeated as necessary.

10. Observe that the brine tank is filling during brine tank refill cycle.

11. Install brine tank overflow line. Attach plastic tubing to the fittings from

the brine tank and run to an open drain. This drain line will not be under

pressure. Do not tie into the backwash drain line. This line should be

higher than the normal drain line, and must be a separate line from fitting

to drain. It is a safety overflow drain and will not be in use during normal

operation.

12. Observe that the valve advances through the different regeneration cycles

and ends in service. Step through the different regeneration cycles by

pressing REGEN.

13. Fill brine tank with salt. Salt may be sodium chloride (NaCl) or potassium

chloride (KCI). Fill tank to only 2/3 full. Note: The brine tank holds a

large quantity of salt, so you will not need to refill at frequent intervals.

Refilling the brine tank with salt should be performed after your system

is successfully installed and has been operating trouble-free. Brine tank

should be refilled with salt at least two hours before the next generation is

performed.

14. Review Tables 17-1 and 18-1 to ensure settings are properly

programmed before placing the softener in service.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

14

Page 19

Plumbing and wiring for dual softener 21, 24, 30 inch models

Note:

• All plumbing is to be done in accordance with state and local codes.

• The control valve, fittings and/or bypass are designed to accommodate minor plumbing

misalignments but are not designed to support the weight of a system or the plumbing.

• Connect to a supply line downstream of outdoor spigots. Install an inlet shutoff valve and plumb

them to the unit’s inlet. Installation of a bypass valve is recommended. If using plastic fittings,

ground the water conditioner per local electrical codes.

• Do not use pipe dope or other sealant on threads. Use teflon tape on threaded inlet, outlet and

drain fittings.

1. Plumb the Motorized Alternating Valve (MAV) according to Figure 15-1. Note: Ensure that

the valve labeled “Alt A” is connected to the “A” port on the MAV, and the valve labeled “Alt

B” is connected to the “B” port.

2. Install connecting piping between raw water source and input pipe on control valve.

3. Install drain line from control valve to a free flowing drain. Solder joints near the drain must

be done prior to connecting the drain line flow control fitting. Leave at least 6” (152.4mm)

between the drain line flow control fitting and the solder joints to prevent heat from damaging

the flow control. Avoid elevating the drain line above the control valve where possible.

Discharge the drain line through an air gap to a receptacle in accordance with local plumbing

codes.

INSTALLATION

Important: Never insert a drain line directly into a drain, sewer line or trap. Always allow an air

gap between the drain line and the receptacle to prevent back siphonage.

FIGURE 15-1: PLUMBING THE MOTORIZED ALTERNATING VALVE

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

15

Page 20

INSTALLATION

Plumbing and wiring for dual softener 21, 24, 30 inch models

4. Install the water meter on the outlet side of the control valve. The meter may be threaded

directly into the valve or may be plumbed separately downstream of the unit. Ensure the arrow

on the meter body is going the same direction as the water flow. The turbine assembly may

be oriented in any direction, but is usually oriented pointing up to reduce drainage out of the

pipe during service. Meter can be installed horizontally or vertically.

5. Install piping between meter output and point of use.

6. Use a tee to install Brine/Refill line between brine tank and regenerant line.

7. Install an overflow drain line from the regenerant tank. Connect a line to the 1” overflow fitting

on the regenerant tank. Do not elevate the overflow drain line. Discharge the overflow drain

line through an air gap to a recaptacle in accordance with local plumbing codes.

VALVE WIRING

1. Connect MAV Motor Wire & Interconnect cable to valve head Alt A:

• On the backside of the valve, remove the strain relief cover with a screwdriver.

• Remove the cover of the valve by pulling out on the release tabs located on each side of

the cover.

• Feed the MAV motor wire and interconnect (communication) cable through the hole in the

back of the valve.

• Connect the MAV motor wire to the two pin connector labeled “DRIVE” on the PC Board.

• Connect the interconnect (communication) cable to the three pin connector labelled

“INTERCONNECT CABLE” on the PC Board.

• After connecting the cables, weave the wires through the strain relief on the backside of the

valve, and replace the strain relief cover and screw. Replace the valve cover.

2. Connect MAV Cables to valve head Alt B:

• On the backside of the valve, remove the strain relief cover with a screwdriver.

• Remove the cover of the valve by pulling out on the release tabs located on each side of

the cover.

• Feed the other end of the interconnect (communication) cable & the meter cable through the

hole in the back of the valve.

• Connect the interconnect cable to the three pin connector labelled “INTERCONNECT

CABLE” on the PC Board.

• After connecting the cables, weave the wires through the strain relief on the backside of the

valve, and replace the strain relief cover and screw. Replace the valve cover.

• Ensure meter cable is connected to the meter assembly.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

16

Page 21

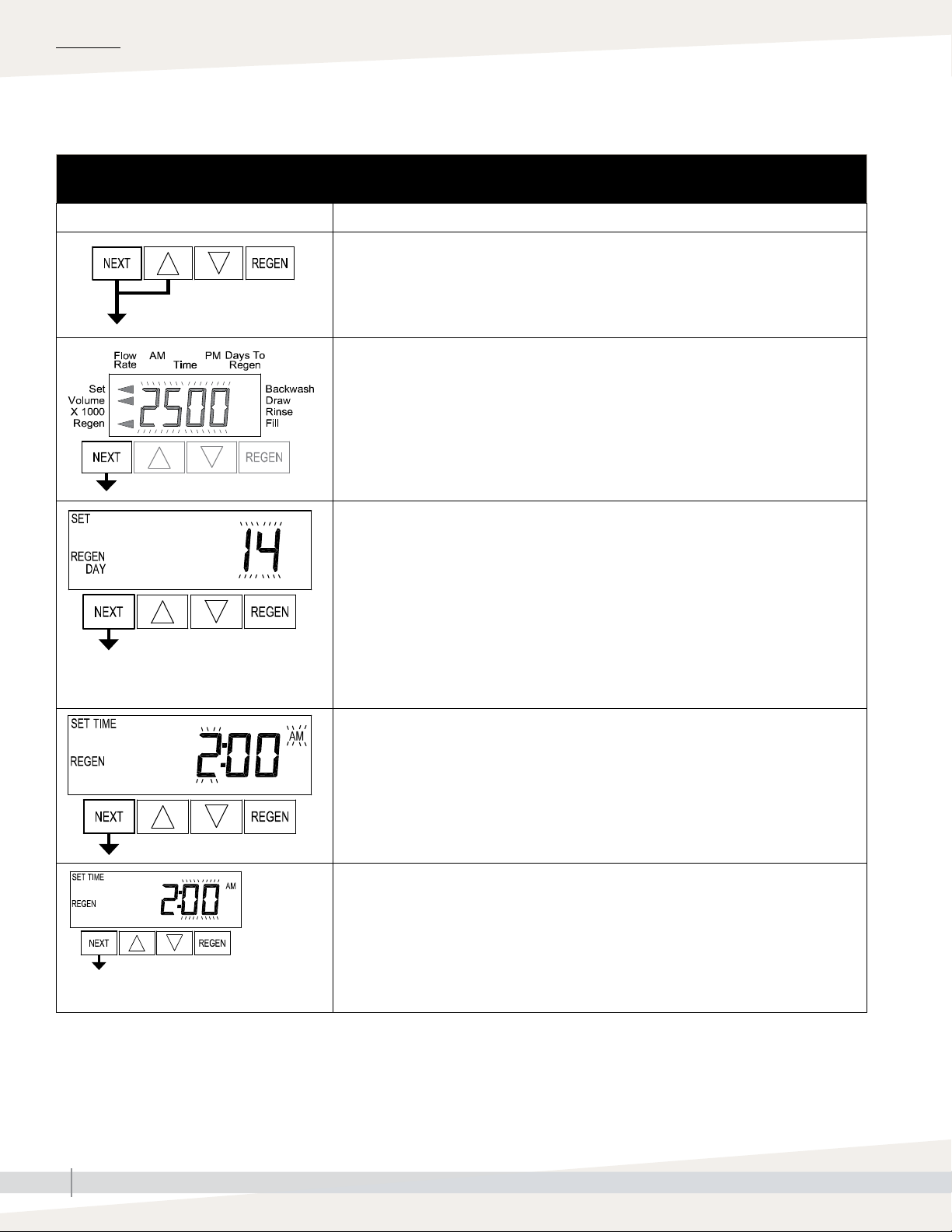

Softener and dechlorinator start-up

Table 17-1:

Set time of day

Buttons Description

1. Press NEXT until the time of day screen is displayed.

2. Press and hold the or until the SET indicator is displayed and the hour flashes.

3. Press the or until the correct hour is displayed.

4. Press NEXT. The minutes will flash.

5. Press or until the correct minute is displayed.

6. Press NEXT to return to the display screen.

Note: In the event of a prolonged power outage, time of day flashes, indicating that it needs to

be reset. All other information will be stored in memory no matter how long the power outage.

Complete the steps above to reset the time of day.

OPERATION

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

17

Page 22

OPERATION

SETTINGS

Softener start-up

Table 18-1:

Softener start-up

Buttons Description

To enter Installer Display press NEXT and simultaneously for about 5 seconds and release.

Press or to enter the volumetric capacity in gallons. See Table 19-1. Press NEXT to go to

the Day Override screen. Press REGEN to return to previous step.

Day Override: When volume capacity is set to “oFF”, sets the number of days between

regenerations. When volume capacity is set to AUTO or to a volume, sets the maximum number

of days between regenerations. If value set to “oFF”, regeneration initiation is triggered solely by

volume used.

If value is set in days (allowable range from 1 to 28) regeneration initiation will be called for on

that day regardless of actual water usage. Set Day Override using or :

• number of days between regeneration (1 to 28); or

• “oFF”.

Press NEXT. Press REGEN to return to previous step.

Next Regeneration Time (hour): Set the hour of day for regeneration using or . The default

time is 2:00. This display will show “REGEN on 0 GAL” if “on 0” is selected in Set Regeneration

Time

Press NEXT. Press REGEN to return to previous step.

Next Regeneration Time (minutes): Set the minutes of day for regeneration using or .

Press NEXT to exit Installer Display Settings. Press REGEN to return to previous step.

EXIT INSTALLER DISPLAY

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

18

Page 23

Softener start-up

OPERATION

SALT USAGE AND GRAINS CAPACITY SETTINGS

The softener can be set to use different amounts of salt per regeneration. The

higher the quantity of salt used, the higher the resin's hardness removing

capacity will be. DriSteem recommends using 10lbs/cu. ft. Alternatively,

higher salt usage may be set in order to maximize resin capacity between

regenerations, or a lower salt usage settings can be used to reduce salt

consumption, but this will result in more frequent regeneration.

• To find volume capacity:

• Find the model and desired salt setting from Table 19-1. DriSteem

recommends using 10lbs/cu. ft. to find the total grains capacity for the

tank model.

• Divide the grains capacity by the number of grains per gallon of

hardness present in the feed water. (Example: If feed water is 10

grains per gallon hardness, the WS-744 [with 10cu. ft. salt setting]

has 14,500 grains capacity. 14,500 ÷ 10 = 1,450 gallon capacity).

• To find brine fill time:

• Use number from Brine fill time column for the model number in the

appropriate salt settings column.

Water softener salt quantity estimate

Total brine tank volume (cubic inches)= π r2 h

• r = radius of the brine tank in inches

• h = height of the brine tank in inches

Pounds of salt needed =

2/3 x (Brine Tank Volume / 1728) x 28

Example

For a WS-1465 softener, the pounds of salt

needed = 2/3 x (π x 242 x 41 / 1728) x 28

= 200 lbs

Table 19-1:

Capacity (per tank) at various pounds of salt per regeneration settings

Grains

10 lbs/cu. ft.

(Recommended)

Salt used

per regen

Brine

fill time

(minutes)

Grains

capacity

7.5 lbs/cu. ft. 5 lbs/cu. ft.

Salt used

per regen

Brine

fill time

(minutes)

Grains

capacity

Salt used

per regen

Brine

fill time

(minutes)

15 lbs/cu. ft.

Model

WS-744 15,000 7.5 5.0 14,500 5.0 3.3 12,850 3.8 2.5 10,000 2.5 1.7

WS-844 18,000 9.0 6.0 17,400 6.0 4.0 15,420 4.5 3.0 12,000 3.0 2.0

WS-948 22,500 11.3 7.5 21,750 7.5 5.0 19,275 5.6 3.8 15,000 3.8 2.5

WS-1054 37,500 18.8 12.5 36,250 12.5 8.3 32,125 9.4 6.3 25,000 6.3 4.1

WS-1252 52,500 26.3 17.5 50,750 17.5 11.6 44,975 13.1 8.8 35,000 8.8 5.8

WS-1354 60,000 30.0 20.0 58,000 20.0 13.2 51,400 15.0 10.0 40,000 10.0 6.6

WS-1465 90,000 45.0 30.0 87,000 30.0 19.8 77,100 22.5 15.0 60,000 15.0 9.9

WS-1665 105,000 52.5 35.0 101,500 35.0 23.1 89,950 26.3 17.5 70,000 17.5 11.6

WS-2162 198,000 90.0 60.0 174,000 60.0 40.0 152,400 45.0 30.0 120,000 30.0 20.0

WS-2472 264,000 120.0 80.0 232,000 80.0 53.3 203,200 60.0 40.0 160,000 40 26.7

WS-3072 412,500 188.0 28.5 362,500 125.0 18.9 317,000 94.0 14.2 250,000 63.0 9.5

Grains

capacity

Salt used

per regen

(pounds)

Brine

fill time

(minutes)

capacity

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

19

Page 24

OPERATION

Loading the carbon media

LOADING THE CARBON MEDIA

FIGURE 20-1: LOADING THE MEDIA

1. Place tank on a level, solid surface in the correct position for installation.

Lift the riser tube from the tank, keeping the attached hub within the

opening of the tank. Within the tank, assemble the laterals onto the

hub, twisting each lateral into the hub to lock securely. Gently lower the

assembly to the bottom of the tank. The top of the riser tube should be

about level with the top of the tank. (See Figure 20-1).

2. The “riser tube” inside the media/resin tank delivers treated water to your

control valve. It will need to be temporarily covered with tape on the top

end to prevent anything from falling down inside the tube during loading.

3. Step back and look at the tank to make sure it is standing straight,

and not tilted. The black base on the bottom of the tank should also be

straightened before filling the tank. If your tank is tilted, simply pick up the

tank 2-3 inches off the floor and drop it gently (but firmly) down, favoring

the side of the base that needs to be adjusted.

4. Before loading the media, fill the tank with 2-3 feet of water (or 1/3 full,

depending on the tank size), to soften the fall of the rocks and prevent

damage to the distributor. To load the media, use a funnel in the top of the media tank with the riser tube still

inside. Make sure the riser tube is covered with tape to keep media out.

5. Scoop the media into the funnel, slowly letting it fall down inside the media tank around the riser tube. Fill the

tank with the media provided, pouring the media in the following order (1st will end up on the bottom of the tank,

last will end up at the top of the tank, etc.). Note: The tank will be approximately ½ - 2/3 full after loading is

complete.

I. Gravel – YMGRVL11618 – 1 CF (100 lbs.) per bag

II. Gravel ¼” × 1/8” – YMGRVL1418 – 0.5 CF (50 lbs) per bag (not used in DC-2162)

III. YMC1240RCOAL – 1 CF (27.5 lbs.) per bag

6. Remove the funnel from the top of the tank, and the tape from the end of the riser tube. Brush any loose media or

resin off the top opening of the tank.

7. The bottom of the control valve has an opening with O-rings inside; lubricate the O-ring with a non-petroleum

based lubricant. Position the valve over the top of the media tank, making sure the top of the riser tube inserts

inside the opening in the bottom of the valve.

8. Screw the valve down into the media tank. Another person should hold the tank as the valve is being snugly

tightened onto the tank. Do not over-tighten. Tighten until snug, tighten a bit more, then Stop. The large o-ring will

seal itself.

Table 20-1:

Carbon media quantity per model

Carbon model I. Gravel 1/16 x 1/8 II. Gravel 1/4 x 1/8 III. Carbon

DC-2162 1 CF (100 lbs) N/A (0) 6 CF (165 lbs)

DC-2472 1 CF (100 lbs) 1 CF (100 lbs) 8 CF (220 lbs)

DC-3072 2 CF (200 lbs) 2 CF (200 lbs) 12.5 CF (344 lbs)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

20

Page 25

OPERATION

Loading the water softener media

LOADING THE WATER SOFTENER MEDIA

1. Place each resin tank on a level, solid surface in the correct position for installation, taking note of correct ALT A

and ALT B tank positions. Lift the riser tube from the tank, keeping the attached hub within the opening of the tank.

Within the tank, assemble the laterals onto the hub, twisting each lateral into the hub to lock securely. Gently lower

the assembly to the bottom of the tank. The top of the riser tube should be about level with the top of the tank. (See

Figure 20-1).

2. The “riser tube” inside the media/resin tank delivers treated water to your control valve. It will need to be

temporarily covered with tape on the top end to prevent anything from falling down inside the tube during loading.

3. Step back and look at the tank to make sure it is standing straight, and not tilted. The black base on the bottom of

the tank should also be straightened before filling the tank. If your tank is tilted, simply pick up the tank 2-3 inches

off the floor and drop it gently (but firmly) down, favoring the side of the base that needs to be adjusted.

4. Before loading the media, fill the tank with 2-3 feet of water (or 1/3 full, depending on the tank size), to soften

the fall of the rocks and prevent damage to the distributor. To load the media, use a funnel in the top of the media

tank with the riser tube still inside. Make sure the riser tube is covered with tape to keep media out.

5. Scoop the media into the funnel, slowly letting it fall down inside the media tank around the riser tube. Fill the

tank with the media provided, pouring the media in the following order (1st will end up on the bottom of the tank,

last will end up at the top of the tank, etc.). Note: The tank will be approximately ½ - 2/3 full after loading is

complete. Refer to Table 21-1 for the proper quantities of each media.

I. Gravel – YMGRVL11618 – 1 CF (100 lbs.) per bag

II. Gravel ¼” × 1/8” – YMGRVL1418 – 0.5 CF (50 lbs) per bag (not used in DC-2162)

III. Resin - CGS - 1CF (50 lbs) per bag

6. Remove the funnel from the top of the tank, and the tape from the end of the riser tube. Brush any loose media or

resin off the top opening of the tank.

7. The bottom of the control valve has an opening with O-rings inside; lubricate the O-ring with a non-petroleum

based lubricant. Position the valve over the top of the media tank, making sure the top of the riser tube inserts

inside the opening in the bottom of the valve.

8. Screw the valve down into the media tank. Another person should hold the tank as the valve is being snugly

tightened onto the tank. Do not over-tighten. Tighten until snug, tighten a bit more, then Stop. The large o-ring will

seal itself.

Table 21-1:

Water softener resin and media quantity per model

Water softener model I. Gravel 1/16 x 1/8 II. Gravel 1/4 x 1/8 III. Softening resin (per tank)

WS-2162 1 CF (100 lbs) N/A (0) 6 CF (300 lbs)

WS-2472 1 CF (100 lbs) 1 CF (100 lbs) 8 CF (400 lbs)

WS-3072 2 CF (200 lbs) 2 CF (200 lbs) 12.5 CF (638 lbs)

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

21

Page 26

MAINTENANCE

Components

DECHLORINATOR

1. Visually inspect components for leaks or breakage.

2. Monthly, have a water sample taken after dechlorinator to check for

chlorine. If 2 ppm or greater, replace carbon media.

WATER SOFTENER

1. Check brine tank salt level at least weekly. Maintain salt level above the

half-full mark at all times.

Note: DriSteem recommends using pulverized salt because it dissolves

easily.

2. Visually inspect all components for leaks or breakage.

3. Annually, have a water sample taken downstream from water softener to

check for hardness. If water hardness is 15 ppm or greater, make sure

there is salt in brine tank. If there is salt, and water hardness if 15 ppm or

greater, contact DriSteem for water softener resin replacement.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

22

Page 27

Troubleshooting

Table 23-1:

Troubleshooting

Issue Possible Cause Solution

1. No display. No power at electric outlet. Repair outlet or use working outlet.

MAINTENANCE

2. Does not display correct time

of day.

3. Display does not indicate that

water is flowing. Refer to user

instructions for how the display

indicates water is flowing.

Control valve power adapter not plugged into outlet

or power cord end not connected to PC board

connection.

Improper power supply. Verify proper voltage is being delivered to PC board.

Poor connection between POD connector and PC

board.

Defective power adapter. Replace power adapter.

Defective PC board. Replace PC board.

Power Adapter plugged into electric outlet controlled

by light switch.

Tripped breaker switch and/or tripped GFI. Reset breaker switch and/ or GFI switch.

Power outage. Reset time of day.

Defective PC board. Replace PC board.

Bypass/ isolation valve in bypass position. Turn bypass/ isolation handles to place in service position.

Meter is not connected to meter connection on PC

board.

Restricted/ stalled meter turbine. Remove meter and check for rotation or foreign material.

Meter wire not installed securely into three pin

connector.

Defective meter. Replace meter

Plug power adapter into outlet or connect power cord end

to PC board connection.

Check connector on POD, possible broken wire or terminal

pin not inserted properly in connector. Clean pins on PC

board by plugging & unplugging the POD connector a few

times to remove excess protective coating.

Use uninterrupted outlet.

Connect meter to three pin connection labeled FLOW on

PC board.

Verify meter cable wires are installed securely into three pin

connector labeled FLOW.

Defective PC board. Replace PC board.

4. Control valve regenerates at

wrong time of day.

5. Time of day flashes on and off. Power outage. Reset time of day.

6. Control valve does not

regenerate automatically when

the REGEN button is depressed

and held.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

Power outage. Reset time of day.

Time of day not set correctly. Reset to correct time of day.

Time of regeneration set incorrectly. Reset regeneration time.

Control valve set at “on 0” (immediate regeneration). Check programming setting and reset to dEL (for a delayed

regen time)

Broken drive gear or drive cap assembly. Replace drive gear or drive cap assembly. Contact

Dristeem technical support.

Defective PC board. Replace PC board.

For the case of systems, another unit in regen would

not allow another unit to go into regeneration.

Wait for unit in regeneration to finish.

23

Page 28

MAINTENANCE

Troubleshooting

Table 24-1:

Troubleshooting

Issue Possible Cause Solution

7. Control valve does not

regenerate automatically but

does when the REGEN button is

depressed and held.

Bypass/ isolation valves in bypass position. Turn bypass/ isolation valves handles to place in service

position.

Meter is not connected to meter connection on PC

board.

Restricted/ stalled meter turbine. Remove meter and check for rotation or foreign material.

Incorrect programming. Check for programming error.

Connect meter to three pin connection labeled FLOW on

PC board.

8. Hard or untreated water is

being delivered.

9. Control valve uses too much

regenerant.

10. Residual regenerant being

delivered to service.

Meter wire not installed securely into three pin

connector.

Defective meter. Replace meter.

Defective PC board. Replace PC board.

Check water quality directly at unit outlet.

Water quality is good

• Bypass/ isolation valves are open or faulty

Water quality is poor

• Damaged seal/stack assembly

• Faulty riser tube or seal

• Control valve body type and piston type mix

matched

Media is exhausted, water quality is poor

• Higher than anticipated water usage

• Meter not registering

• No regenerant or low level of regenerant in

regenerant tank

• Control fails to draw in regenerant

• Water quality fluctuation

• Fouled media bed

Improper refill setting or refill fill flow control is not

sized properly

Improper program settings Check program setting to make sure they are specific to the

Control valve regenerates frequently Check for leaking fixtures that may be exhausting capacity

Low water pressure Check incoming water pressure – water pressure must

Plugged, fouled, or incorrect injector size Inspect and clean or replace injector, or replace injector

Restricted drain line Check drain line for restrictions or debris and clean.

Verify meter cable wires are installed securely into three pin

connector labeled FLOW.

External bypass leak

• Fully close bypass/ isolation valves or replace

Internal bypass leak

• Replace seal/stack assembly

• Verify seal placement & engagement with riser

• Verify proper control valve body type and piston type

match

No internal leaks

• Check program settings or diagnostics for abnormal

water usage

• See Troubleshooting Guide #3

• Check refill setting in programming. Check refill flow

control for restrictions or debris and clean or replace,

check refill flow control rate for proper fill time.

• Refer to Troubleshooting Guide # 12

• Test water and adjust program values accordingly

• Replace media bed

Check refill setting and check refill flow control for proper

refill rate.

water quality and application needs.

or system is undersized.

remain at minimum of 25 psi.

with correct size for the application.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

24

Page 29

Troubleshooting

Table 25-1:

Troubleshooting

Issue Possible Cause Solution

11. Excessive water in

regenerant tank

Tank is being overfilled

• Improper program settings

• Missing refill flow controller

Previous regenerant is not being drawn out See Troubleshooting Guide #12

Excess from fill cycle

• Verify program settings

• Visual inspection / measure volume output into container

MAINTENANCE

12. Control valve fails to draw in

regenerant

13. Water running to drain Power outage during regeneration or unit is currently

14. Err – 1001 = Control unable

to sense motor movement

Injector is plugged Remove injector and clean or replace

Faulty regenerant piston Replace regenerant piston

Regenerant line connection leak Inspect regenerant line for air leak

Drain line restriction or debris cause excess back

pressure

Drain line too long or too high Shorten length and/or height

Low water pressure Check incoming water pressure – water pressure must

Damaged seal/ stack assembly Inspect seal stack assembly for damage and replace

in regeneration

Damaged seal/ stack assembly Replace seal/ stack assembly

Piston assembly failure Replace piston assembly

Drive cap assembly not tightened properly Re-tighten the drive cap assembly

Motor not inserted fully to engage pinion, motor wires

broken or disconnected

PC Board not properly snapped into drive bracket Properly snap PC Board into drive bracket and then

Missing reduction gears Replace missing gears

Inspect drain line and clean to correct restriction

remain at minimum of 25 psi

Upon power being restored control will finish the remaining

regeneration time. Reset time of day.

Disconnect power, make sure motor is fully engaged, check

for broken wires, make sure two pin connector on motor

is connected to the two pin connection on the PC Board

labeled REGEN. Press NEXT and REGEN buttons for about

3 seconds to resynchronize software with piston position.

Press NEXT and REGEN buttons for about 3 seconds to

resynchronize software with piston position.

Damaged or dirty reduction gear reflectors Clean or replace reduction gear

Faulty or dirty optics on back of PC board Clean or replace PC board

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

25

Page 30

MAINTENANCE

Troubleshooting

Table 26-1:

Troubleshooting

Issue Possible Cause Solution

15. Err – 1002 = Control valve

motor ran too short and was

unable to find the next cycle

position and stalled

16. E4, Err – 1004, Err – 104 =

Control valve motor ran too long

and timed out trying to reach

home position

17. Err -1006, Err – 106,

Err - 116 = MAV/ SEPS/ NHBP/

AUX MAV valve motor ran too

long and unable to find the

proper park position.

Motorized Alternating Valve =

MAV

Separate Source = SEPS

No Hard Water Bypass = NHBP

Auxiliary MAV = AUX MAV

18. Err – 1007, Err – 107,

Err - 117 = MAV/ SEPS/ NHBP/

AUX MAV valve motor ran too

short (stalled) while looking for

proper park position

Motorized Alternating Valve =

MAV

Separate Source = SEPS

No Hard Water Bypass = NHBP

Auxiliary MAV = AUX MAV

Foreign material is lodged in control valve Open up control valve and pull out piston assembly and

seal/ stack assembly for inspection. Press NEXT and

REGEN buttons for about 3 seconds to resynchronize

software with piston position.

Mechanical binding Check piston and seal/ stack assembly, check reduction

gears, check drive bracket and main drive gear interface.

Press NEXT and REGEN buttons for about 3 seconds to

resynchronize software with piston position. Check that

pinion is not pressed up tight against motor

Main drive gear too tight Loosen main drive gear. Press NEXT and REGEN buttons

for about 3 seconds to resynchronize software with piston

position. Verify free motion by rotating main drive gear by

hand, driving piston in and out

Improper voltage being delivered to PC board Verify that proper voltage is being supplied. Press NEXT

and REGEN buttons for about 3 seconds to resynchronize

software with piston position.

Drive bracket not snapped in properly and out enough

that reduction gears and drive gear do not interface

Control valve programmed for ALT A or b, nHbP, SEPS,

or AUX MAV with out having a MAV or NHBP valve

attached to operate that function

MAV/ NHBP motor wire not connected to PC Board Connect MAV/ NHBP motor to PC Board two pin

MAV/ NHBP motor not fully engaged with reduction

gears

Foreign matter built up on piston and stack assemblies

creating friction and drag enough to time out motor

Foreign material is lodged in MAV/ NHBP valve Open up MAV/ NHBP valve and check piston and seal/

Mechanical binding Check piston and seal/ stack assembly, check reduction

Snap drive bracket in properly then Press NEXT and

REGEN buttons for 3 seconds to resynchronize software

with piston position or disconnect power supply from PC

Board for 5 seconds and then reconnect.

Press NEXT and REGEN buttons for 3 seconds to

resynchronize software with piston position or disconnect

power supply from PC Board for 5 seconds and then

reconnect. Then re-program valve to proper setting

connection labeled DRIVE. Press NEXT and REGEN buttons

for 3 seconds to resynchronize software with piston

position or disconnect power supply from PC Board for 5

seconds and then reconnect.

Properly insert motor into casing, do not force into

casing Press NEXT and REGEN buttons for 3 seconds to

resynchronize software with piston position or disconnect

power supply from PC Board for 5 seconds and then

reconnect.

Replace piston and stack assemblies. Press NEXT and

REGEN buttons for 3 seconds to resynchronize software

with piston position or disconnect power supply from PC

Board for 5 seconds and then reconnect.

stack assembly for foreign material. Press NEXT and

REGEN buttons for 3 seconds to resynchronize software

with piston position or disconnect power supply from PC

Board for 5 seconds and then reconnect.

gears, drive gear interface, and check MAV/ NHBP

black drive pinion on motor for being jammed into motor

body. Press NEXT and REGEN buttons for 3 seconds to

resynchronize software with piston position or disconnect

power supply from PC Board for 5 seconds and then

reconnect.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

26

Page 31

System operating log

Table 27-1:

System operating log

Date

Time

Chlorine

Cartridge in psi

Cartridge out psi

Water temperature

TDS in

TDS out

System psi

MAINTENANCE

Concentrate psi

Cartridge filter change

Membrane change

Recorded by

Notes

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

27

Page 32

MAINTENANCE

Water quality test strips

Carbon filters in the system should be changed regularly to maintain proper

pressure and flow and water quality.

The carbon filter removes chlorine. Change the carbon filter when chlorine

from supply water starts to pass through. Check regularly for chlorine pass

through.

To check for chlorine, obtain a water sample from the concentrate drain line

and test the water. If chlorine is present, change the carbon filter and record

the interval to estimate the next carbon filter change.

For best results, test water chlorine every two weeks.

To order more Water Quality Test Strips, contact your local

DriSteem rep, or call 1-800-328-4447.

Total Chlorine ppm - end pad

0 0.5 1.0 2.0 4.0 10.0

Free Chlorine ppm

0 0.5 1.0 2.0 4.0 10.0

Total Hardness (CaCo3) grains per gallon

0 1.5 3 7 15 25

0 25 50 120 250 425

Total Alkalinity ppm (CaCo3)

0 40 80 120 180 240

pH - pad nearest handle

6.2 6.8 7.2 7.8 8.4

ppm

DIRECTIONS:

1. Dip entire strip into water for 1 second (or

pass under water stream), remove. Do not

shake excess water from the test strip. Hold

the strip for 30 seconds.

2. Compare TOTAL HARDNESS, TOTAL

ALKALINITY and pH pads to color chart to the

left.

3. Dip strip into the water again and move back

and forth for 30 seconds (or hold two chlorine

pads under water stream for 10 seconds).

4. Compare CHLORINE pads to color chart to

the left.

5. Track results in the chart.

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

28

Page 33

Water quality test log

MAINTENANCE

Date tested

Week 1 _________

Week 3 _________

Week 5 _________

Week 7 _________

Week 9 _________

Week 11 _________

Week 13 _________

Week 15 _________

Total Chlorine

ppm

Free Chlorine

ppm

Total Hardness Total Alkalinity pH

Week 17 _________

Week 19 _________

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

29

Page 34

REPLACEMENT PARTS

Water treatment system

FIGURE 30-1: REPLACEMENT PARTS

Softener &

dechlorinator

control valve

dechlorinator_head

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

30

Page 35

Water treatment system

Table 31-1:

Water softener replacements parts

Description Qty. Part No.

Single tank water softener

Softener single control valve 1" inlet (7" - 16" tank) 1 550134-001

Softener single control valve 1.5" inlet (21" - 24" tank) 1 550134-002

Softener single control valve 2" inlet (30" tank) 1 550134-003

Dual tank water softener

Dual softener control valve 1" inlet (7" - 16" tank) 1 550134-021

Dual softener control valve 1.5" inlet (21" - 24" tank) 1 550134-022

Dual softener control valve 2" inlet (30" tank) 1 550134-023

REPLACEMENT PARTS

Table 31-2:

Dechlorinator replacements parts

Description Qty. Part No.

Housing filter wall mount accessory 20" with valves (filter not included) 1 550028-001

Carbon filter, 4x20" 1 550027-002

Dechlorinator single control valve 1" inlet (7" -16" tank) 1 550134-011

Dechlorinator single control valve 1.5" inlet (21" - 24" tank) 1 550134-012

Dechlorinator single control valve 2" inlet (30" tank) 1 550134-013

DRISTEEM PRE-TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

31

Page 36

WARRANTY

Expect quality from the industry leader

Since 1965, DriSteem has led the industry

with innovative methods for humidifying and

cooling air with precise control. Our focus on

ease of ownership is evident in the design of

our Water Treatment Systems, which feature

low maintenance and comprehensive control.

DriSteem also leads the industry with a Twoyear Limited Warranty and optional extended

warranty.

For more information

www.dristeem.com

sales@dristeem.com

For the most recent product information

visit our Web site: www.dristeem.com

TWO-YEAR LIMITED WARRANTY

DRI-STEEM Corporation (“DriSteem”) warrants to the original user that its products will be free from

defects in materials and workmanship for a period of two (2) years after installation or twentyseven (27) months from the date DriSteem ships such product, whichever date is the earlier.

If any DriSteem product is found to be defective in material or workmanship during the applicable

warranty period, DriSteem’s entire liability, and the purchaser’s sole and exclusive remedy, shall

be the repair or replacement of the defective product, or the refund of the purchase price, at

DriSteem’s election. DriSteem shall not be liable for any costs or expenses, whether direct or

indirect, associated with the installation, removal or reinstallation of any defective product. The

Limited Warranty does not include cylinder replacement for electrode steam humidifiers or media

replacement for Wetted Media Systems.

DriSteem’s Limited Warranty shall not be effective or actionable unless there is compliance with

all installation and operating instructions furnished by DriSteem, or if the products have been

modified or altered without the written consent of DriSteem, or if such products have been subject

to accident, misuse, mishandling, tampering, negligence or improper maintenance. Any warranty

claim must be submitted to DriSteem in writing within the stated warranty period. Defective

parts may be required to be returned to DriSteem. Excluded from the Limited Warranty are all

consumable and wear and tear items such as cylinders, membranes, filters, or media replacements.

These items are subject to usual wear and tear during usage.

DriSteem’s Limited Warranty is made in lieu of, and DriSteem disclaims all other warranties,

whether express or implied, including but not limited to any IMPLIED WARRANTY OF

MERCHANTABILITY, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, any

implied warranty arising out of a course of dealing or of performance, custom or usage of trade.

DriSteem SHALL NOT, UNDER ANY CIRCUMSTANCES BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, LOSS OF PROFITS, REVENUE OR BUSINESS) OR DAMAGE OR INJURY TO PERSONS OR

PROPERTY IN ANY WAY RELATED TO THE MANUFACTURE OR THE USE OF ITS PRODUCTS. The

exclusion applies regardless of whether such damages are sought based on breach of warranty,

breach of contract, negligence, strict liability in tort, or any other legal theory, even if DriSteem has

notice of the possibility of such damages.

DRI-STEEM Corporation

a subsidiary of Research Products Corporation

DriSteem U.S. operations are ISO

9001:2015 certified

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

European office:

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgium

+3211823595 (voice)

E-mail: dristeem-europe@dristeem.com

Continuous product improvement is a policy of

DriSteem; therefore, product features and

specifications are subject to change without

notice.

DriSteem and Vapor-logic are registered

trademarks of Research Products Corporation

and are filed for trademark registration in

Canada and the European community.

Product and corporate names used in this

document may be trademarks or registered

trademarks. They are used for explanation only

without intent to infringe.

© 2019 Research Products Corporation

By purchasing DriSteem’s products, the purchaser agrees to the terms and conditions of this Limited

Warranty.

EXTENDED WARRANTY

The original user may extend the term of the DriSteem Limited Warranty for a limited number of

months past the initial applicable warranty period and term provided in the first paragraph of this

Limited Warranty. All the terms and conditions of the Limited Warranty during the initial applicable

warranty period and term shall apply during any extended term. An extended warranty term of

an additional twelve (12) months or twenty four (24) months of coverage may be purchased. The

extended warranty term may be purchased until eighteen (18) months after the product is shipped,

after which time no extended warranties are available. When a DriSteem humidifier is purchased