Page 1

Vapormist

Humidi-tech

Electric Humidifiers,

Standard Water

Service Kit Manual

®

, and CRUV

®

,

®

WARNING

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

Read all warnings and instructions

This page provides important safety instructions; it is intended to supplement — not replace — the humidifier's Installation, Operation, and

Maintenance Manual (IOM). Read the IOM that was provided with the humidifier before performing service or maintenance procedures

on any part of the system. Failure to follow all warnings and instructions could produce the hazardous situations described here and in the

IOM, resulting in property damage, personal injury, or death.

If the IOM is missing, go to http://www.dristeem.com/ds_lit.jsp to download a replacement. mc_071608_0910

Hot surfaces and hot water

Steam humidification systems have extremely hot surfaces, and water in tanks, electrode cylinders, steam pipes, and dispersion assemblies

can be as hot as 212 °F (100 °C). To avoid severe burns, allow the entire humidification system to cool.

Follow the cool-down procedure in the humidifier's IOM before performing service or maintenance procedures on any part of the system.

mc_071608_0911

Shut down the energy source

Before performing service or maintenance procedures on any part of the humidification system, verify that all energy sources are off.

Energy sources can be electricity, gas, steam, or hot liquid. Failure to shut down the energy source could result in carbon monoxide

poisoning, fire, explosion, electrical shock, and other hazardous conditions. These hazardous conditions could cause property damage,

personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury or death as a result of electrical shock or fire. Do not

remove the shroud/cover, electrical panel cover/door, access panels, or heater terminal cover until electrical power is disconnected.

Follow the shutdown procedure in the humidifier's IOM before performing service or maintenance procedures on any part of the system.

mc_050808_1551

CAUTION

Indicates a hazardous situation that could result in damage to

or destruction of property if instructions are not followed.

WARNING

mc_051508_1145

Electrical shock hazard

If the humidifier starts up at a call for humidity during maintenance, severe bodily injury or death from electrical shock could occur. To

prevent such start-up, follow the procedure below before performing service or maintenance procedures on this humidifier (after the tank

has cooled down and drained):

1. Use the Vapor-logic®3 or Vapor-logic4 keypad to change the control mode to Standby.

2. Shut off all electrical power to the humidifier using the field-installed fused disconnect, and lock all power disconnect switches in the

OFF position.

3. Close the field-installed manual water supply and gas shut-off valves. mc_050808_1530

Damage from hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage the drain plumbing.

If the humidifier is equipped with a water tempering device such as a DRI-STEEM Drane-kooler™, it needs fresh make-up water in order to function

properly. Make sure the water supply to the Drane-kooler remains open during draining.

If the humidifier is not equipped with a water tempering device, allow the tank to cool before opening the drain valve. mc_111308_1345

Parts in this service kit are for VM99, HT99, and CRUV99 humidifiers (August 1999 to present). Parts are listed on page 2.

CAUTION

Page 2

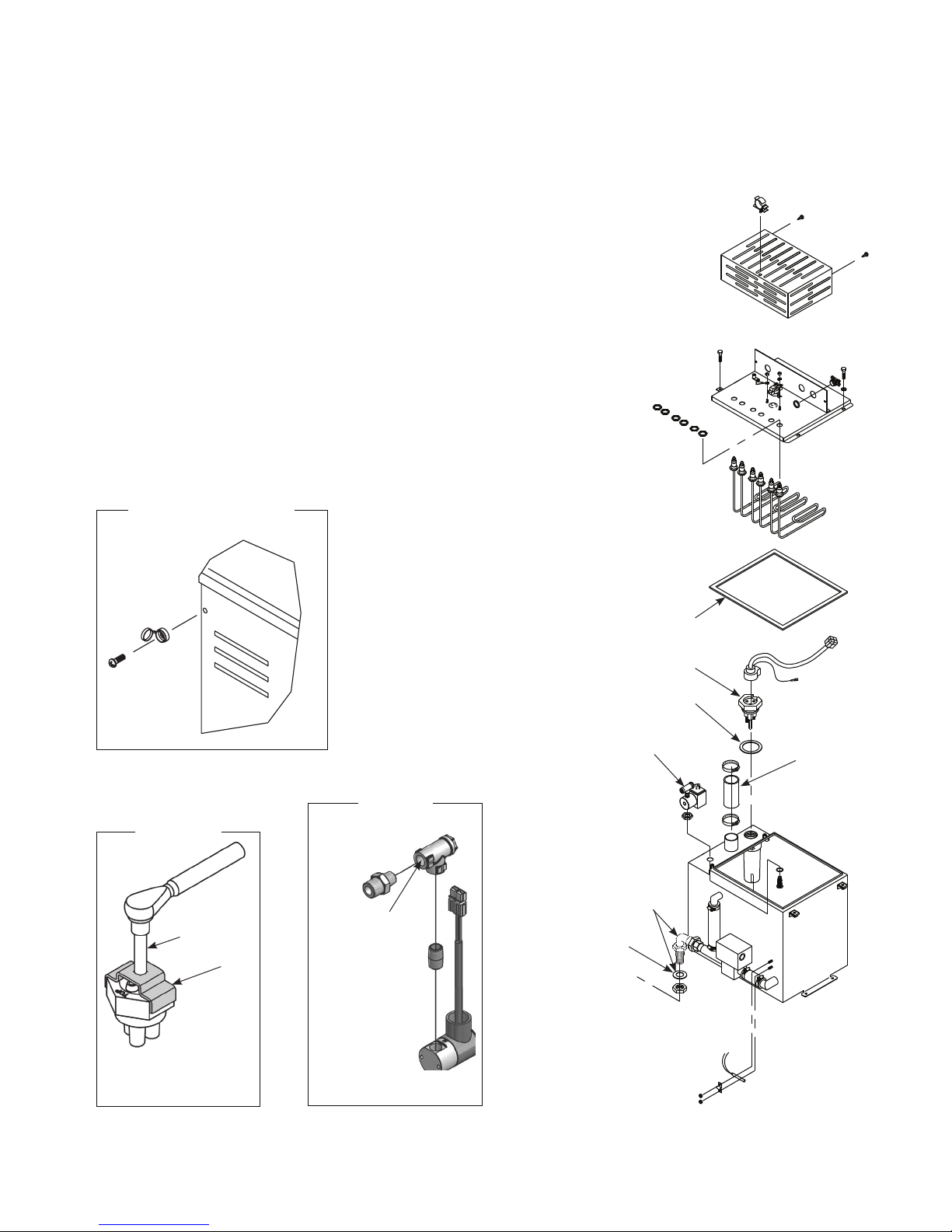

Vapormist/Humidi-tech/CRUV, standard water, service kit parts

VM99 / HT99 / CRUV99, standard water, 2 to 4 kW

Service Kit No. 900100-001

No. Part Description Part No. Qty.

1 Probe tool (see Probe Tool inset) 406201 1

2 Silicone, clear (not shown) 320000 1

3 Sediment screen (see Fill Valve inset) 300051 1

4 Cover gasket 160695-001 1

5 Probe gasket 309750-004 1

6 Bulkhead drain gasket (Vapormist/Humidi-tech only) 309750-005 1

7 Probe rod assembly 406303-005 1

8 Probe housing 308500 1

VM99 / HT99 / CRUV99, standard water, 6 to 34 kW

Service Kit No. 900100-002

No. Part Description Part No. Qty.

1 Probe tool (see Probe Tool inset) 406201 1

2 Silicone, clear (not shown) 320000 1

3 Sediment screen (see Fill Valve inset) 300051 1

4 Cover gasket (Vapormist/Humidi-tech only) 160695-002 1

5 Probe gasket 309750-004 1

6 Bulkhead drain gasket 309750-005 1

7 Probe rod assembly 406303-006 1

8 Probe housing 308500 1

Page 2 • DRI-STEEM Vapormist/Humidi-tech/CRUV, Standard Water, Service Kit Manual

Page 3

Vapormist/Humidi-tech/CRUV, standard water, service kit parts

This service kit contains the replacement parts called out in the

parts drawing to keep your DRI‑STEEM humidifier operating

at peak performance. This Service Kit Manual provides

important safety and service instructions; it is intended to

supplement — not replace — the humidifier's Installation,

Operation, and Maintenance Manual. Please see Read all

warnings and instructions on page 1.

While performing service and maintenance procedures,

replace existing parts with the new parts provided in the

service kit.

mc_052808_1400

Enclosure Screw Cap

(Vapormist/Humidi-tech)

Note: Components may by oriented

differently than shown in drawing.

OM-778-3

Probe Tool

Torque probe assembly

to 10 ft-lbs (13.6 N-m).

3/8" drive

1

OM-7395X

mc_051508_1320

Fill Valve

3

Sediment screen (3)

inside of Tee

TANKASM-VM2-4X

Apply clear silicone (2) to both sides of gasket.

See Fill Valve inset.

Vapormist/Humidi-tech only

6

4

7

5

8

OM-768X

DRI-STEEM Vapormist/Humidi-tech/CRUV, Standard Water, Service Kit Manual • Page 3

Page 4

Vapormist/Humidi-tech/CRUV, standard water, service instructions

Inspection and maintenance

Cool down humidifier

Before performing service or maintenance procedures, allow

the tank to cool down. Insulated and uninsulated tanks will

have hot surfaces

Note: Fresh make‑up water is used to speed up cooling. Do

not close the manual water supply before cooling down

the humidifier; otherwise the tank could stay hot for

several hours.

1. Verify that there is no call for humidity and that the

aquastat set point (adjusted using the keypad/display Setup

screens) is less than room temperature (default setting

is 40 °F [4 °C]) so that the heaters do not energize while

cooling down the tank.

2. Verify that the tank is in Auto mode so it will fill after

draining begins.

3. Drain the tank:

a. Manually open the drain valve by moving the valve

lever located on the back of the drain valve to the

manual open position. The fill valve will open after

enough water has drained out of the tank.

b. Let the fill water run until the tank is cooled; then shut

off the field‑installed manual supply water shut‑off

valve.

c. Let the tank drain; then manually close the drain valve.

mc_052708_1145

Shut down humidifier

Follow the procedure below before performing service or

maintenance procedures (after the tank has cooled down and

drained):

1. If the humidifier is equipped with a Vapor‑logic3 controller,

use the keypad to change the control mode to Standby.

2. Shut off all electrical power to the humidifier using

the field‑installed fused disconnect, and lock all power

disconnect switches in the OFF position.

3. Close the field‑installed manual water supply shut‑off valve.

mc_060208_0945

Annually (also recommended when maintenance is performed)

1. All safety devices in the control circuit should be cycled on

and off to verify they are functioning. These include:

• Highlimitswitch

• Airflowprovingswitch

• Lowwaterlevelprobe.Pulloutprobeplug;fillvalve

should energize.

2. Measure current draw of heaters and verify amp values per

stage by comparing to the wiring diagram located inside

the subpanel cover. This identifies any burned out heaters.

Only qualified electrical personnel should perform this

task.

3. Inspect tank and gaskets for leaks.

mc_060208_1005

Seasonally (or as required, depending on water quality)

Clean the evaporating chamber. See the facing page of this

Service Kit manual for Vapormist instructions; see the back

page for CRUV instructions.

Off-season maintenance

Perform complete inspection and cleaning of the following:

• Heaters

• Proberods

• Skimmerportandwaterseal

• Humidifiertank

After cleaning, the humidifier should remain empty until

humidification is required.

mc_052708_1210

Note: Steps 4 and 7 below apply only to Vapormist humidifiers.

Off-season shut-down procedure

1. If the tank is hot, cool it down first. See cool‑down

instructions at left.

2. Drain evaporating chamber.

3. Switch off electrical power.

4. Remove enclosure.

5. Shut off water supply to makeup valve.

6. Examine the evaporating chamber (see facing page of this

Service Kit manual), and clean if necessary.

7. Replace enclosure.

8. Leave chamber dry, power off, and the water shut‑off valve

closed until the next humidification season.

mc_060208_1030

Page 4 • DRI-STEEM Vapormist/Humidi-tech/CRUV, Standard Water, Service Kit Manual

Page 5

Vapormist/Humidi-tech/CRUV, standard water, service instructions

Vapormist service

1. Remove the evaporating chamber:

a. Remove the two fasteners on each side of the cover

enclosure (see Enclosure Screw Cap inset on page 3)

b. Remove the enclosure.

WARNING!

Do not remove the humidifier electrical panel cover or the

heater terminal cover until electrical power is disconnected.

Contact with energized circuits can cause property damage,

severe personal injury or death as a result of electrical shock.

c. If the Vapormist has an SDU mounted directly above it,

the SDU cover must be removed before removing the

humidifier cover.

d. If the tank is hot, cool it down first (see cool‑down

instructions on facing page).

e. Shut off the water supply.

f. Allow the tank to drain completely.

g. Shut off the electrical supply.

h. Disconnect the fill line at the supply side of the fill

valve.

i. Disconnect the electrical plugs between the tank

components and the back of the electrical panel

(includes: power plug, fill plug, drain plug, water level

control plug, tank temperature sensor plug and thermal

trip plug).

Important: Disconnect by pulling on plug

housing. Do not disconnect by pulling on cord or

wires.

j. Disconnect the drain union on the back left corner of

the frame.

k. Disconnect the steam supply hose from the top of the

tank.

l. Lift the tank foot above the frame flange and slide the

tank assembly forward to remove.

2. Loosen the four cover bolts and remove the cover assembly

from the tank.

3. Clean the tank interior using a putty knife or similar flat

instrument.

4. Clean the probes:

a. Unplug probe plug assembly. Leave ground wire

connected to tank.

b. Unscrew the probe rod assembly using the probe tool

connected to a 3/8" square drive.

c. Inspect the probe housing and clean, ensuring that all

the housing passageways are clear. Remove the housing

from the holding bracket by sliding the housing

horizontally toward the open end of the bracket.

• Thescaleshouldflakeoffeasilyfromtheprobe

assembly rods.

• Thebottom3/8"(10mm)ofeachrodisthesensing

portion; clean these areas with a wire brush,

abrasive pad, or steel wool.

d. Inspect the composite plastic probe rod assembly for

any signs of cracking, roughness, or deterioration. If

found, replace probe assembly.

e. Reassemble and install the probe and probe plug

assembly. Verify ground wire is solidly connected to

tank.

5. Secure the chamber cover, making sure the cover gasket is

seated and the chamber is sealed.

6. Re‑install the evaporating chamber:

a. Reconnect the fill line.

b. Reconnect the electrical plugs (plugs are color coded).

c. Reconnect the drain union.

d. Reconnect the vapor hose.

7. Verify electrical connections:

a. Verify that all DIN rail‑mounted components are

securely fastened to DIN rail.

b. Verify that all power terminal screws and lugs are tight

from power block to heaters. See the table below for

torque specifications.

Table 5-1:

Vapormist torque specifications

Screw or lug location

Power block 16 1.8

Contactor 16 1.8

Heater

nut

Heater

wire lug

8-32 (8.5 mm) nut 20 2.2

10-32 (9.5 mm) nut 25 2.8

6 gauge (10 mm2) wire 35 4.0

8 gauge (6 mm2) wire 25 2.8

10-14 gauge (<6 mm2) wire 20 2.2

Torque

inch - lbs N-m

c. Verify that all plugs located under the humidifier cover

are completely plugged in.

8. Move the drain valve lever back to the auto position.

9. Turn on the water supply.

10. Turn on the electrical power.

mc_060208_1055

DRI-STEEM Vapormist/Humidi-tech/CRUV, Standard Water, Service Kit Manual • Page 5

Page 6

Vapormist/Humidi-tech/CRUV, standard water, service instructions

Humidifier De-scaling Solution

Scale buildup on humidifier heaters

acts as an insulator, reducing humidifier

performance while increasing energy

costs. To keep humidifiers operating as

efficiently as possible, remove scale with

DRI-STEEM's Humidifier De-scaling Solution,

available for purchase from your DRI-STEEM

representative or distributor.

The De-scaling Solution cleans without risk

of corroding humidifier tanks or welds. The

De-scaling Solution also cleans surfaces

unreachable by hand scraping.

DRI-STEEM's Humidifier De-scaling Solution

is the only approved cleaner/de-scaler for

use with DRI-STEEM humidifiers. Use of

other cleaners/de-scalers may void your

DRI-STEEM warranty.

mc_021908_1410-elec

DRI-STEEM Corporation

An ISO 9001: 2000 certified corporation

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

European office:

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgium

+3211823595 (voice)

+3211817948 (fax)

E-mail: marc.briers@dristeem.com

Continuous product improvement is a

policy of DRI-STEEM Corporation; therefore,

product features and specifications are

subject to change without notice.

DRI-STEEM, Vapormist, Humidi-tech, CRUV,

and Vapor-logic are registered trademarks

of DRI-STEEM Corporation and are filed for

trademark registration in Canada and the

European community.

Drane-kooler is a trademark of DRI-STEEM

Corporation.

CRUV Service

1. Drain the tank. See Step 3 on page 4.

2. Clean the probes. See Step 4 on page 5.

3. Remove the tank cover and wet vac minerals out of tank

(recommended).

4. To remove tank for cleaning, disconnect drain line union, fill valve

supply line, electrical connections to drain, (disconnecting field

wiring in conduit is NOT recommended,) thermal trip, heaters,

fill valve, and probe. Disconnect steam hose from top of tank and

remove mounting bracket fasteners.

5. Remove evaporating chamber and clean.

6. Install the probe and probe plug assembly. Verify that ground wire is

connected.

7. Replace tank cover, making sure tank is sealed tight.

8. Reconnect drain line union, fill valve supply line, electrical

connections to drain, thermal trip, heaters, fill valve, and probe.

Connect steam hose to top of tank.

9. Verify drain valve lever is in AUTO position.

The CRUV humidifier is again ready to humidify.

mc_060208_1100

Mineral precipitate

As evaporation takes place in the humidifier, some of the minerals

dissolved in the water precipitate out and float on the water surface. The

minerals not removed by the skimmer will settle to the bottom of the

evaporating chamber.

Cleaning the evaporating chamber

The heating element is self‑cleaning. The mineral buildup on the element

flakes off after reaching a thickness of about 1/16" (2 mm), and settles to

the bottom of the chamber.

Long heater element life can be expected when the operation of the

humidifier is observed for a few weeks following initial start‑up. By

observing the mineral build‑up rate, the frequency of both drain/flush

use and manual cleaning can be determined and adjustments made.

CAUTION

Before this mineral scale builds up on the underside of the heating

element, it must be removed. Failure to do so could result in premature

heater burnout.

The humidifier is designed for convenient cleaning and maintenance.

mc_052708_1130

Start-up

Perform the Annual safety checks in the Inspection and maintenance

section on page 4.

If resuming operation after service, do not leave the humidifier

unattended; allow it to cycle through multiple fill cycles to verify that all

serviced parts are functioning properly. See the humidifier's Installation,

Operation, and Maintenance manual for start‑up details.

mc_052908_1005

© 2011 DRI-STEEM Corporation

Form No. VM/CRUV-standard-SKM-0711

Page 6 • DRI-STEEM Vapormist/Humidi-tech/CRUV, Standard Water, Service Kit Manual

Part No. 891000-001 Rev C

DRI-STEEM products are warranted according to the terms and conditions of the standard

two-year Limited Warranty effective when the humidifier was purchased. See the literature

that was shipped with the humidifier for warranty information.

mc_081308_1405

Page 7

Humidi-tech

®

et CRUV

®

Humidificateurs électriques,

Eau standard

Manuel du nécessaire d'entretien

ATTENTION

Indique une situation dangereuse qui pourrait entraîner des blessures

graves voire la mort si les consignes ne sont pas respectées.

ATTENTION

Lire l'ensemble des mises en garde et des instructions

Cette page fournit des consignes de sécurité importantes ; elle est conçue pour compléter — non remplacer — le Manuel d'installation,

d'utilisation et de maintenance (IOM). Lire l'IOM qui a été fourni avec l'humidificateur avant d'effectuer des interventions d'entretien ou de

maintenance sur n'importe quelle pièce du système. Le non-respect de l'ensemble des mises en garde et des instructions pourrait engendrer les

situations dangereuses décrites dans ce document et dans l'IOM, et occasionner des dommages aux biens, des préjudices corporels voire la mort.

Si l'IOM est manquant, rendez-vous à http://www.dristeem.com/ds_lit.jsp pour télécharger un manuel de remplacement.

Surfaces et eau portées à température élevée

Les systèmes d'humidification à vapeur comportent des surfaces à température extrêmement élevée ; la température de l'eau présente

dans les cuves, les cylindres à électrode, les conduites de vapeur et les ensembles de dispersion peut atteindre 100 °C. Pour éviter tout

risque de brûlures graves, laisser refroidir tout le système d'humidification.

Suivre la procédure de refroidissement décrite dans l'IOM de l'humidificateur avant d'effectuer des interventions d'entretien ou de

maintenance sur n'importe quelle pièce du système.

Arrêt de la source d'énergie

Avant toute intervention d'entretien ou de maintenance sur n'importe quelle pièce du système d'humidification, vérifier que toutes les

sources d'énergie sont à l'arrêt. Les sources d'énergie peuvent être des sources d'électricité, de gaz, de vapeur ou de liquide à température

élevée. Le fait de ne pas arrêter la source d'énergie peut occasionner une intoxication au monoxyde de carbone, un incendie, une explosion

ou un choc électrique, et faire naître d'autres situations dangereuses. Ces situations dangereuses pourraient occasionner des dommages

aux biens, des préjudices corporels, voire la mort.

Tout contact avec des circuits alimentés peut occasionner des dommages aux biens, des préjudices corporels graves voire la mort à la suite

d'un choc électrique ou d'un incendie. Ne pas retirer l'enveloppe/la protection, la porte/la protection du panneau électrique, les panneaux

d'accès ou le couvre-bornes de l'élément chauffant avant d'avoir débranché l'alimentation électrique.

Suivre la procédure d'arrêt décrite dans l'IOM de l'humidificateur avant d'effectuer des interventions d'entretien ou de maintenance sur

n'importe quelle pièce du système.

Risque de choc électrique

Si l'humidificateur démarre en réponse à une demande d'humidification lors d'une intervention de maintenance, cela pourrait occasionner

des préjudices corporels graves voire la mort à la suite d'un choc électrique. Pour éviter un tel démarrage, suivre la procédure ci-dessous

avant toute intervention d'entretien ou de maintenance sur cet humidificateur (une fois que la cuve a été refroidie et vidangée) :

1. Utiliser le pavé numérique Vapor-logic®3 ou Vapor-logic4 pour basculer le mode de commande en veille.

2. Couper toute l'alimentation électrique de l'humidificateur en utilisant le sectionneur à fusible installé sur site et verrouiller tous les

sectionneurs d'alimentation en position d'arrêt OFF.

3. Fermer les robinets de sectionnement d'alimentation manuelle en eau et en gaz installés sur site.

ATTENTION

Indique une situation dangereuse qui pourrait endommager ou détruire

des biens si les consignes ne sont pas respectées.

Dommages occasionnés par l'eau de refoulement à haute température

La température de l'eau de refoulement peut atteindre 212 °F et endommager la plomberie de vidange.

Si l'humidificateur est équipé d'un dispositif de tempérage de l'eau comme DRI-STEEM Drane-kooler™, il a besoin d'eau d'appoint fraîche pour

fonctionner correctement. S'assurer que l'alimentation en eau du Drane-kooler reste ouverte lors de la vidange.

Si l'humidificateur n'est pas équipé d'un dispositif de tempérage de l'eau, laisser la cuve refroidir avant d'ouvrir le robinet de vidange.

Les pièces citées dans ce nécessaire d'entretien sont prévues pour les humidificateurs HT99 et CRUV99 (août 1999 à ce jour).

ATTENTION

Les pièces sont répertoriées en page 2.

Page 8

Humidi-tech/CRUV, eau standard, pièces du nécessaire d'entretien

HT99 / CRUV99, eau standard, 2 à 4 kW

Nécessaire d'entretien n° 900100-001

N° Description de la pièce Référence. Qté.

1 Outil à sonde (voir l'encart Outil à sonde) 406201 1

2 Silicone, transparent (non représenté) 320000 1

3

Tamis à sédiments (voir l'encart Robinet de remplissage)

4 Joint d'étanchéité de protection 160695-001 1

5 Joint d'étanchéité de sonde 309750-004 1

6 Joint d'étanchéité de vidange Bulkhead (Humidi-tech

seulement)

7 Ensemble tige de sonde 406303-005 1

8 Carter de sonde 308500 1

HT99 / CRUV99, eau standard, 6 à 34 kW

Nécessaire d'entretien n° 900100-002

N° Description de la pièce Référence. Qté.

1 Outil à sonde (voir l'encart Outil à sonde) 406201 1

2 Silicone, transparent (non représenté) 320000 1

3

Tamis à sédiments (voir l'encart Robinet de remplissage)

4 Joint d'étanchéité de protection (Humidi-tech

seulement)

5 Joint d'étanchéité de sonde 309750-004 1

6 Joint d'étanchéité de drainage Bulkhead 309750-005 1

7 Ensemble tige de sonde 406303-006 1

8 Carter de sonde 308500 1

300051 1

309750-005 1

300051 1

160695-002 1

Page 8 • DRI-STEEM Humidi-tech/CRUV, eau standard, Manuel du nécessaire d'entretien

Page 9

Humidi-tech/CRUV, eau standard, pièces du nécessaire d'entretien

Le nécessaire d'entretien contient les pièces de rechange

référencées dans le schéma des pièces qui permettent à votre

humidificateur DRI‑STEEM de continuer à fonctionner au

maximum de ses performances. Ce Manuel du nécessaire

d'entretien fournit des consignes de sécurité et d'entretien

importantes ; il est conçu pour compléter — non remplacer — le

Manuel d'installation, d'utilisation et de maintenance (IOM).

Lire l'ensemble des mises en garde et des instructions en

page 1.

Lors des interventions d'entretien et de maintenance, remplacer

les pièces existantes par les pièces neuves fournies dans le

nécessaire d'entretien.

Capuchon vissé de

l'enceinte (Humidi-tech)

Remarque : Certains composants peuvent

être orientés différemment par

rapport au schéma.

OM-778-3

Outil à sonde

Embout mâle

de 3/8"

1

OM-7395X

Appliquer un couple de serrage de

13,6 N-m à la sonde.

Robinet de remplissage

3

Tamis à sédiments (3)

à l'intérieur du té

TANKASM-VM2-4X

4

7

Appliquer du silicone transparent

(2) aux deux faces du joint d'étanchéité.

Voir l'encart Robinet

de remplissage.

Humidi-tech seulement

5

6

8

OM-768X

DRI-STEEM Humidi-tech/CRUV, eau standard, Manuel du nécessaire d'entretien • Page 9

Page 10

Humidi-tech/CRUV, eau standard, consignes d'entretien

Inspection et maintenance

Refroidissement de l'humidificateur

Avant toute intervention d'entretien ou de maintenance, laisser

refroidir la cuve. Certaines surfaces des cuves isolées et non

isolées seront portées à température élevée

Remarque : De l'eau d'appoint fraîche est utilisée pour

accélérer le refroidissement. Ne pas fermer

l'alimentation manuelle en eau avant d'avoir

refroidi l'humidificateur ; autrement, la cuve

pourrait rester chaude pendant plusieurs heures.

1. Vérifier qu'il n'y a pas eu de demande d'humidification et

que le point de consigne de l'aquastat (réglé à l'aide du pavé

numérique ou des écrans de configuration de l'affichage) est

inférieur à la température ambiante (la valeur par défaut est

de 4 °C) afin que les éléments chauffants ne s'activent pas

lors du refroidissement de la cuve.

2. Vérifier que la cuve est en mode automatique de façon à ce

qu'elle se remplisse après le début de la vidange.

3. Vidange de la cuve :

a. Ouvrir manuellement le robinet de vidange en déplaçant

le levier situé à l'arrière du robinet de vidange en

position d'ouverture manuelle. Le robinet de remplissage

s'ouvrira dès qu'une quantité suffisante d'eau aura été

vidangée de la cuve.

b. Laisser couler l'eau de remplissage jusqu'à ce que la cuve

soit refroidie ; puis, fermer le robinet de sectionnement

de l'alimentation manuelle en eau installé sur site.

c. Laisser la cuve se vidanger ; puis, fermer manuellement

le robinet de vidange.

Arrêt de l'humidificateur

Suivre la procédure ci‑dessous avant toute intervention

d'entretien ou de maintenance (une fois que la cuve a été

refroidie et vidangée) :

1. Si l'humidificateur est équipé d'un dispositif de régulation

Vapor‑logic3, utiliser le pavé numérique pour basculer le

mode de commande en veille.

2. Couper toute l'alimentation électrique de l'humidificateur en

utilisant le sectionneur à fusible installé sur site et verrouiller

tous les sectionneurs d'alimentation en position d'arrêt OFF.

3. Fermer le robinet de sectionnement d'alimentation manuelle

en eau installé sur site.

Annuellement (également recommandé lors de la maintenance)

1.

Tous les dispositifs de sécurité du circuit de commande

doivent être mis en marche, puis arrêtés, afin de vérifier leur

fonctionnement. Ces dispositifs comprennent notamment :

• Commutateurdefindecourse

• Commutateurdecontrôlededébitd'air

• Sondedeniveaud'eaubas.Tirerlafichedelasonde;le

robinet de remplissage devrait s'activer.

2.

Mesurer le débit de courant des éléments chauffants et vérifier

les ampérages par étage par comparaison avec le schéma de

principe situé à l'intérieur de la protection du sous‑panneau.

Ceci permet d'identifier tous éléments chauffants grillés. Seul

le personnel qualifié en électricité peut effectuer cette tâche.

3. Inspecter la cuve et les joints d'étanchéité pour déceler des

fuites éventuelles.

À chaque saison (ou au besoin, selon la qualité de l'eau)

Nettoyer la chambre d'évaporation. Voir les instructions

relativesauHumidi-techsurlapageenregarddeceManuel

du nécessaire d'entretien ; voir les instructions relatives au

CRUV sur la page verso.

Maintenance de fin de saison

Effectuer une inspection et un nettoyage complets des

éléments suivants :

• Éléments chauffants

• Tiges de sonde

• Orifice de l'écumoire et siphon isolateur

• Cuve d'humidificateur

Après le nettoyage, l'humidificateur doit demeurer vide

jusqu'à ce qu'il y ait un besoin d'humidification.

Remarque : Les étapes 4 et 7 ci‑dessous s'appliquent

uniquementauxhumidificateursHumidi-tech.

Procédure d'arrêt hors saison

1. Si la température de la cuve est élevée, la refroidir au

préalable. Voir les instructions de refroidissement à gauche.

2. Vidanger la chambre d'évaporation.

3. Couper l'alimentation électrique.

4. Déposer l'enceinte.

5. Couper l'alimentation en eau au robinet d'appoint.

6.

Examiner la chambre d'évaporation (voir la page en regard de

ce Manuel du nécessaire d'entretien) et la nettoyer au besoin.

7. Remettre en place l'enceinte.

8. Laisser la chambre sèche, l'alimentation électrique coupée et

le robinet de sectionnement de l'alimentation en eau fermé

jusqu'à la prochaine saison d'humidification.

Page 10 • DRI-STEEM Humidi-tech/CRUV, eau standard, Manuel du nécessaire d'entretien

Page 11

Humidi-tech/CRUV, eau standard, consignes d'entretien

Entretien Humidi-tech

1. Déposer la chambre d'évaporation :

a. Retirerlesdeuxattachesdechaquecôtédel'enceintede

protection (voir l'encart Capuchon vissé de l'enceinte en

page 3)

b. Déposer l'enceinte.

ATTENTION

Ne pas retirer la protection du panneau électrique de l'humidificateur

ou le couvre-bornes de l'élément chauffant avant d'avoir débranché

l'alimentation électrique. Tout contact avec des circuits alimentés peut

occasionner des dommages aux biens, des préjudices corporels graves

voire la mort à la suite d'un choc électrique ou d'un incendie.

c. SileHumidi-techcomporteuneunitédedistribution

de l'espace (SDU) montée directement à l'aplomb, il

faut retirer la protection de la SDU avant de déposer la

protection de l'humidificateur.

d. Si la température de la cuve est élevée, la laisser refroidir

au préalable (voir les consignes de refroidissement sur la

page en regard).

e. Couper l'alimentation en eau.

f. Laisser la cuve se vidanger totalement.

g. Couper l'alimentation électrique.

h. Débrancherlaconduitederemplissageducôté

d'alimentation du robinet de remplissage.

i.

Débrancher les fiches électriques entre les éléments de la

cuve et l'arrière du panneau électrique (comprenant : fiche

d'alimentation, fiche de remplissage, fiche de vidange,

fiche de commande du niveau d'eau, fiche du capteur de

température de la cuve et fiche du déclencheur thermique).

Important: Débrancher en tirant sur le boîtier de la

fiche. Ne pas débrancher en tirant sur le cordon ou les fils.

j. Débrancher le raccord de vidange dans le coin arrière

gauche du châssis.

k. Débrancher le tuyau d'alimentation en vapeur du haut

de la cuve.

l.

Soulever le pied de la cuve au‑dessus de la bride du châssis

et faire coulisser la cuve vers l'avant pour déposer.

2. Desserrer les quatre boulons de la protection et déposer la

protection de la cuve.

3. Nettoyer l'intérieur de la cuve à l'aide d'un couteau à

mastiquer ou d'un instrument plat similaire.

4. Nettoyer les sondes :

a. Débrancher la fiche de la sonde. Laisser le fil de terre

connecté à la cuve.

b. Dévisser la tige de la sonde à l'aide de l'outil à sonde

connecté à une douille à embout mâle de 3/8".

c.

Inspecter le carter de la sonde et le nettoyer, en s'assurant

que toutes ses voies de passage sont dégagées. Retirer le

carter du support de maintien en faisant coulisser le carter

horizontalement vers l'extrémité ouverte du support.

•

Le tartre devrait se détacher aisément des tiges de sonde.

•

Les 10 mm du bas de chaque tige sont la partie

détectrice ; nettoyer cette partie à l'aide d'une brosse

métallique, d'un tampon abrasif ou de laine d'acier.

d. Inspecter la tige de sonde en plastique composite pour

déceler toute fissure, rugosité ou détérioration. Dans ce

cas, remplacer la sonde.

e.

Remonter et installer la sonde et la fiche de la sonde.

Vérifier que le fil de terre est solidement connecté à la cuve.

5. Fixer la protection de la chambre, en s'assurant que le joint

d'étanchéité de la protection est bien en place et la chambre

est fermée de façon étanche.

6. Réinstaller la chambre d'évaporation :

a. Reconnecter la conduite de remplissage.

b. Reconnecter les fiches électriques (les fiches sont

repérées par un code de couleur).

c. Reconnecter le raccord de vidange.

b. Reconnecter le tuyau à vapeur.

7. Vérifier les branchements électriques :

a. Vérifier que tous les composants montés sur guide DIN

sont solidement fixés au guide DIN.

b. Vérifier que toutes les vis et les cosses des bornes

d'alimentation sont serrées entre le bloc d'alimentation

et les éléments chauffants. Voir les spécifications de

couple de serrage dans le tableau ci‑dessous.

Tableau 11-1 :

Spécifications de couple de serrage

Humidi-tech

Emplacement de vis ou de

cosse

Bloc d'alimentation 1,8

Contacteur 1,8

Écrou

d'élément

chauffant

Cosse de fil

d'élément

chauffant

8,5 mm Écrou 2,2

9,5 mm Écrou 2,8

2

Fil 10 mm

2

Fil 6 mm

Fil < 6 mm

2

Couple de serrage

N-m

4,0

2,8

2,2

c. Vérifier que toutes les fiches situées sous la protection de

l'humidificateur sont enfoncées à fond.

8. Ramener le levier du robinet de vidange en position

automatique.

9. Ouvrir l'alimentation en eau.

10. Allumer l'alimentation électrique.

DRI-STEEM Humidi-tech/CRUV, eau standard, Manuel du nécessaire d'entretien • Page 11

Page 12

Humidi-tech/CRUV, eau standard, consignes d'entretien

Entretien CRUV

1. Vidanger la cuve. Voir l'étape 3 en page 4.

2. Nettoyer les sondes. Voir l'étape 4 en page 5.

3. Déposer la protection de la cuve et éliminer à l'aspirateur industriel

eaux et poussières les sels minéraux présents dans la cuve

(recommandé).

4. Pour déposer la cuve en vue du nettoyage, déconnecter le raccord

de la conduite de vidange, la conduite d'alimentation du robinet de

remplissage, les branchements électriques sur la vidange (il n'est PAS

recommandé de déconnecter le câblage sur site dans le conduit),

le déclencheur thermique, les éléments chauffants, le robinet de

remplissage et la sonde. Déconnecter le tuyau de vapeur au sommet

de la cuve et rétirer les attaches du support de montage.

5. Déposer la chambre d'évaporation et la nettoyer.

6. Installer la sonde et la fiche de la sonde. Vérifier que le fil de terre est

connecté.

7. Remettre en place la protection de la cuve, en s'assurant que la cuve

est fermée de façon étanche.

8. Reconnecter le raccord de la conduite de vidange, la conduite

d'alimentation du robinet de remplissage, les branchements

électriques sur la vidange, le déclencheur thermique, les éléments

chauffants, le robinet de remplissage et la sonde. Connecter le tuyau

de vapeur au sommet de la cuve.

9. Vérifier que le levier du robinet de vidange est en position AUTO.

DRI-STEEM Corporation

ISO 9001 : 2000 société certifiée

Bureau européen :

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgique

+3211823595 (téléphone)

+3211817948 (télécopie)

E-mail : marc.briers@dristeem.com

Siège social aux États-Unis :

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 ou 952-949-2415

952-229-3200 (télécopie)

DRI-STEEM Corporation poursuit une politique

d'amélioration continue de ses produits. Par conséquent,

les caractéristiques et les spécifications des produits

peuvent changer sans préavis.

DRI-STEEM, Humidi-tech, CRUV et Vapor-logic sont des

marques déposées de DRI-STEEM Corporation et ont fait

l'objet d'une demande de dépôt de marque au Canada et

dans la Communauté Européenne.

Drane-kooler est une marque déposée de

DRI-STEEM Corporation.

© 2011 DRI-STEEM Corporation

L'humidificateur CRUV est prêt pour un nouveau cycle d'humidification.

Précipités minéraux

Au fur et à mesure qu'intervient l'évaporation dans l'humidificateur,

certains des sels minéraux dissous dans l'eau précipitent et flottent à la

surface de l'eau. Les sels minéraux qui ne sont pas éliminés par l'écumoire

se déposent au fond de la chambre d'évaporation.

Nettoyage de la chambre d'évaporation

L'élément chauffant se nettoie automatiquement. Les sels minéraux

accumulés sur l'élément se détachent après avoir atteint une épaisseur

d'environ 2 mm et se déposent au fond de la chambre.

On peut s'attendre à ce que l'élément chauffant ait une durée de vie

importante quand le fonctionnement de l'humidificateur est surveillé

pendant les quelques semaines qui suivent le démarrage initial. Surveiller

la vitesse d'accumulation des sels minéraux permet de déterminer à la fois

la fréquence des vidanges et rinçages et du nettoyage manuel et d'apporter

des ajustements.

ATTENTION

Le tartre doit être éliminé avant de commencer à s'accumuler au‑dessous

de l'élément chauffant. Le non‑respect de cette consigne pourrait

entraîner le grillage prématuré de l'élément chauffant.

L'humidificateur est conçu pour faciliter le nettoyage et la maintenance.

Démarrage

EffectuerlescontrôlesdesécuritéAnnuels prévus à la section Inspection

et maintenance en page 4.

En cas de reprise du fonctionnement après un entretien, ne pas laisser

l'humidificateur sans surveillance ; le laisser accomplir plusieurs cycles de

remplissage afin de vérifier que toutes les pièces entretenues fonctionnent

correctement. Voir les détails du démarrage dans le Manuel d'installation,

d'utilisation et de maintenance de l'humidificateur.

Formulaire n° VM/CRUV-standard-SKM-F-0711

Référence 891000-001 Rev C

Page 12 • DRI-STEEM Humidi-tech/CRUV, eau standard, Manuel du nécessaire d'entretien

Les produits DRI-STEEM sont garantis selon les modalités de la garantie limitée de deux ans

standard prenant effet à la date d'achat de l'humidificateur. Voir la documentation fournie avec

l'humidificateur pour plus d'informations sur la garantie.

Page 13

Humidi-tech

®

, and CRUV

®

Elektro-Befeuchter,

Normalwasser

Anleitung für Wartungskit

VORSICHT

Weist auf einen Betriebszustand hin, der zu schweren Verletzungen

oder Tod führen kann, falls die Anweisungen mißachtet werden.

Alle Warnhinweise und Arbeitsanweisungen lesen

Diese Seite enthält wichtige Sicherheitshinweise; sie ist als Zusatz zu verstehen und NICHT als Ersatz für die Installations- und

Bedienungsanleitung. Daher zuerst die Installations- und Bedienungsanleitung des Befeuchters lesen, welche mit dem Befeuchter geliefert

wurde, bevor jegliche Wartungsarbeiten am System durchgeführt werden. Nichteinhaltung dieser Warnhinweise kann zu den hier und in

der Befeuchter-Bedienungsanleitung beschriebenen gefährlichen Betriebszuständen führen, welche Sachschäden, Verletzungen oder Tod

zur Folge haben können.

Fehlt die Befeuchter-Bedienungsanleitung, diese von http://www.dristeem.com/ds_lit.jsp herunterladen.

Heiße Oberflächen und heißes Wasser

Dampf-Befeuchtungssysteme weisen sehr heiße Oberflächen auf und das Wasser in den Tanks, Elektrozylindern, Dampfrohren und

Verteilmodulen kann bis zu 100 °C heiß sein. Daher das gesamte Befeuchtersystem zuerst abkühlen um Verbrühungen zu vermeiden.

Das Abkühlverfahren in der Befeuchter-Bedienungsanleitung befolgen, bevor jegliche Wartungsarbeiten an Teilen des Systems erfolgen.

Die Energiezufuhr abschalten

Bevor jeglicher Wartung an Teilen des Befeuchtungssystems, sicherstellen, die gesamte Energiezufuhr ist abgeschaltet. Die

Energiequellen können, Strom, Gas, Dampf oder heißes Fluid sein. Nichteinhaltung dieser Anweisung kann zu Kohlenmonoxidvergiftung,

Feuer, Explosion, Stromschlag und anderen gefährlichen Betriebszuständen führen. Diese gefährlichen Betriebszustände können zu

Sachschäden, Verletzungen oder Tod führen.

Kontakt mit stromführenden Schaltkreisen kann zu Sachschäden, schweren Verletzungen oder Tod führen. Daher zuerst die Stromzufuhr

abschalten und aussperren, bevor jegliche Abdeckungen oder Schaltkästen geöffnet bzw. Arbeiten an Klemmen oder Elektrik

durchgeführt werden.

Die Anweisungen zur korrekten Abschaltung in der Befeuchter-Bedienungsanleitung befolgen, bevor jegliche Wartungsarbeiten an Teilen

des Systems erfolgen.

ACHTUNG

Weist auf einen Betriebszustand hin, der zu Sachschäden führen kann,

falls die Anweisungen mißachtet werden.

VORSICHT

Gefahr durch Stromschlag

Falls der Befeuchter während der Wartung einschaltet kann dies zu schweren Verletzungen oder Tod durch Stromschlag führen. Um

ein automatisches Einschalten zu verhindern, die nachfolgenden Anweisungen beachten, bevor jegliche Wartungsarbeiten an diesem

Befeuchter erfolgen (nachdem der Tank abgekühlt und entwässert wurde):

1. Mit Hilfe des Vapor-logic®3 oder Vapor-logic4 Steuergeräts in den Steuermodus Standby schalten.

2. Die Stromversorgung am bauseitigen gesicherten Hauptschalter abschalten und alle Schalter in Position AUS sperren.

3. Die bauseitigen manuellen Wasser- und Gaszufuhrventile schließen.

Schäden aufgrund heißem Abwasser

Abwasser kann bis zu 100 °C heiß sein und die Ablaufverrohrung beschädigen.

Ist der Befeuchter mit einem Abwasserkühlgerät wie z.B. dem DRI-STEEM Drane-kooler™ ausgerüstet muss ein Kaltwasseranschluss vorhanden sein,

damit das Gerät ordnungsgemäß funktioniert. Daher sicherstellen, die Wasserzufuhr zum Drane-kooler-Kühlgerät ist während des Abkühlvorgangs

geöffnet.

Weist der Befeuchter kein Abwasserkühlgerät auf, den Tank zuerst abkühlen lassen, bevor das Ablaufventil geöffnet wird.

Teile für diesen Wartungssatz passen zu Befeuchter, HT99 und CRUV99 (ab August 1999 bis heute). Für Teileliste siehe Seite 2.

ACHTUNG

Page 14

Humidi-tech/CRUV, Normalwasser, Wartungssatz-Teile

HT99 / CRUV99, Normalwasser, 2 bis 4 kW

Wartungssatz-Nr. 900100-001

Nr. Benennung Teile-Nr. Menge

1 Sondenwerkzeug (siehe Abbildung Sondenwerkzeug) 406201 1

2 Silikon, klar (nicht dargestellt) 320000 1

3 Filtereinsatz (siehe Abbildung Füllventil) 300051 1

4 Dichtung Abdeckung 160695-001 1

5 Dichtung Sonde 309750-004 1

6 Dichtung Trennwand-Ablauf (Nur Humidi-tech) 309750-005 1

7 Sondenbaugruppe 406303-005 1

8 Sondengehäuse 308500 1

HT99 / CRUV99, Normalwasser, 6 bis 34 kW

Wartungssatz-Nr. 900100-002

Nr. Benennung Teile-Nr. Menge

1 Sondenwerkzeug (siehe Abbildung Sondenwerkzeug) 406201 1

2 Silikon, klar (nicht dargestellt) 320000 1

3 Filtereinsatz (siehe Abbildung Füllventil) 300051 1

4 Dichtung Abdeckung (Nur Humidi-tech) 160695-002 1

5 Dichtung Sonde 309750-004 1

6 Dichtung Trennwand-Ablauf 309750-005 1

7 Sondenbaugruppe 406303-006 1

8 Sondengehäuse 308500 1

Seite 14 • DRI-STEEM Humidi-tech/CRUV, Normalwasser, Anleitung für Wartungssatz

Page 15

Humidi-tech/CRUV, Normalwasser, Wartungssatz-Teile

Dieser Wartungssatz enthält Ersatzteile gemäß den Angaben

der Teilezeichnung für einen optimalen Betrieb Ihres

DRI‑STEEM Befeuchters. Die vorliegende Anleitung enthält

wichtige Sicherheits‑ und Wartungsanweisungen und ist kein

Ersatz für die mit dem Befeuchter gelieferte Installations‑ und

Bedienungsanleitung. Bitte lesen Sie alle Warnhinweise und

Arbeitsanweisungen auf Seite 1.

Bei der Durchführung von Wartungsarbeiten die alten Teile mit

den neuen Teilen aus diesem Wartungssatz ersetzen.

Kappe Gehäuseschraube

(Humidi-tech)

Anmerkung: Bauteile können eine

unterschiedliche Ausrichtung

erfordern als hier dargestellt.

OM-778-3

Sondenwerkzeug

3/8" Einsatz

Anziehmoment für Sonden-

Baugruppe 13.6 Nm.

1

OM-7395X

Füllventil

3

Filtereinsatz (3)

im -T-Stück

TANKASM-VM2-4X

Klares Silikon (2) auf beiden Seiten der Dichtung

auftragen.

Siehe Einzelheit Füllventil.

Nur Humidi-tech

6

4

7

5

8

OM-768X

DRI-STEEM Humidi-tech/CRUV, Normalwasser, Anleitung für Wartungssatz • Seite 15

Page 16

Humidi-tech/CRUV, Normalwasser, Wartungsanweisungen

Inspektion und Wartung

Befeuchter abkühlen

Bevor jeglichen Wartungsarbeiten zuerst den Tank abkühlen

lassen. Wärmegedämmte und nicht gedämmte Tanks weisen

heiße Oberflächen auf.

Anmerkung: Zur Abkühlung ist frisches Zusatzwasser

erforderlich. Daher den Wasserzulauf erst sperren

nachdem der Befeuchter abgekühlt wurde.

Andernfalls bleibt der Tank noch für mehrere

Stunden heiß.

1. Sicherstellen, es wird keine Befeuchtung gefordert und der

Wasserthermostat‑Einstellwert liegt unter der aktuellen

Raumtemperatur(EinstellungmitHilfedesSteuergeräts

in Anzeige Setup, Vorgabeeinstellung ist 4 °C) damit die

HeizgerätenichteinschaltenwährendderTankabkühlt.

2. Sicherstellen der Tank ist in Modus Auto damit sich der

Tank wieder füllt, wenn die Entwässerung beginnt.

3. Den Tank entwässern:

a. Am Ablaufventil den Ventilhebel, der sich auf der

RückseitedesVentilsbefindet,vonHandindiePosition

'Manuell öffnen' schieben. Das Füllventil öffnet nachdem

eine gewisse Menge Wasser aus dem Tank ausgelaufen

ist.

b. Die Wasserzulaufleitung offen lassen, bis sich der

Tank ausreichend abgekühlt hat. Dann das bauseitig

installierte manuelle Absperrventil in der Zulaufleitung

schließen.

c. Den Tank entwässern lassen und danach das

AblaufventilvonHandschließen.

Befeuchter abschalten

Die nachfolgenden Anweisungen beachten bevor jegliche

Wartungsarbeiten ausgeführt werden (Nachdem der Tank

abgekühlt hat und entwässert ist):

1. Ist der Befeuchter mit einer Vapor‑logic3 Steuerung

ausgerüstet,mitHilfedesSteuergerätsdenBefeuchterin

Modus Standby schalten.

2. DiekompletteStromzufuhrzumBefeuchtermitHilfedes

bauseitigen Sicherungs‑Trennschalter sperren und alle

Stromtrennschalter in Position AUS sperren.

3. Das bauseitig installierte manuelle Absperrventil in der

Wasser‑Zulaufleitung schließen.

Jährlich (sowie nach Wartungsarbeiten)

1. Alle Sicherheitsgeräte im Steuerkreis sollten Ein/Aus

getaktet werden um deren ordnungsgemäße Funktion zu

prüfen. Diese umfassen:

• Maximal-Grenzwertschalter

• Luftströmungsschalter

• Wassermangel-Pegelsonde.DazudenSteckerander

Sonde abziehen; Das Füllventil sollte nun schalten.

2. DieStromaufnahmederHeizgerätemessenunddie

gemessenen Werte pro Stufe mit den Werten im Schaltplan,

der sich auf der Innenseite der Abdeckung befindet,

vergleichen.DamitlassensichausgebrannteHeizgeräte

erkennen. Diese Arbeit darf nur von einem qualifizierten

Elektriker durchgeführt werden.

3. Tank und Dichtungen auf Undichtheiten überprüfen.

Saisonal (oder wie erforderlich, abhängig von der

Wasserqualität)

Die Verdampfungskammer reinigen. Siehe

gegenüberliegendeSeiteindieserAnleitungfürHumidi-

tech Anweisungen; siehe Rückseite für CRUV Anweisungen.

Wartung außerhalb der Saison

Eine komplette Inspektion und Reinigung folgender Teile

durchführen:

• Heizgeräte

• Sondenstäbe

• SkimmeranschlussundWasserdichtung

• Befeuchtertank

Nach erfolgter Reinigung sollte der Befeuchter leer bleiben,

bis eine Befeuchtung erforderlich wird.

Anmerkung: Die nachfolgenden Schritte 4 und 7 gelten nur für

Humidi-techBefeuchter.

Stilllegung außerhalb der Saison

1. Ist der Tank noch heiß, die Anweisungen unter Befeuchter

Abkühlen in der linken Spalte beachten.

2. Die Verdampfungskammer entwässern.

3. Die Stromzufuhr abschalten.

4. Gehäuseabnehmen.

5. Wasserzulauf zum Zusatzwasserventil schließen.

6. Verdampfungskammer inspizieren (siehe gegenüberliegende

Seite dieser Anleitung), und falls erforderlich reinigen.

7. Gehäusewiedermontieren.

8. Bis zur nächsten Saison die Kammer trocken, den Strom

abgeschaltet und das Wasserabsperrventil geschlossen

lassen.

Seite 16 • DRI-STEEM Humidi-tech/CRUV, Normalwasser, Anleitung für Wartungssatz

Page 17

Humidi-tech/CRUV, Normalwasser, Wartungsanweisungen

Humidi-tech Wartung

1. Die Verdampfungskammer ausbauen:

a. Die zwei Schrauben auf jeder Seite der

Gehäuseabdeckunglösen(sieheEinzelheitKappe

GehäuseschraubenaufSeite3)

b. DasGehäuseabnehmen.

VORSICHT!

Die Abdeckungen der Schaltplatine und HeizgeräteKlemmenleiste am Befeuchter erst öffnen, nachdem die

Stromzufuhr ausgesperrt ist. Der Kontakt mit Schaltkreisen

kann zu Sachschäden, schweren Verletzungen oder Tod durch

Stromschlag führen.

c. IstdirektüberdemHumidi-tech-BefeuchtereinSDU-

Modul montiert, muss die SDU‑Abdeckung zuerst

abgenommen werden, bevor die Befeuchter‑Abdeckung

abgenommen werden kann.

d. Ist der Tank noch heiß, diesen zuerst abkühlen

(siehe Anweisungen zum Abkühlen auf der

gegenüberliegenden Seite).

e. Die Wasserzufuhr absperren.

f. Den Tank komplett entwässern.

g. Die Stromzufuhr aussperren.

h. Die Zulaufleitung auf der Zufuhrseite des Füllventils

trennen.

i. Die Elektrostecker zwischen den Tankkomponenten

und Rückseite der Platine abziehen (einschließlich:

Stromstecker, Füllstecker, Ablaufstecker,

Wasserstandregel‑Stecker, Tanktemperatursensor‑Stecker

und Thermoauslöser‑Stecker).

Wichtig: Den Stecker beim Abziehen am

Steckergehäuse halten und nicht am Kabel ziehen.

j. Die Ablaufverrohrung an der hinteren linken Ecke des

Rahmens lösen.

k. Den Dampfzufuhrschlauch von der Tankoberseite lösen.

l. Den Tankfuß über dem Rahmenflansch heben und

die Tank‑Baugruppe nach vorne ziehen um diese

herauszunehmen.

2. Die vier Schrauben der Abdeckung lösen und die

Abdeckung vom Tank abnehmen.

3. Die Tankinnenseite mit einem Kittmesser oder ähnlich

flachem Werkzeug reinigen.

4. Die Sonden reinigen:

a. Die Sondenstecker‑Baugruppe abziehen. Den

Erdungsdraht dabei nicht vom Tank lösen.

b. DieSondenstab-BaugruppemitHilfedesSonden-

werkzeugs und einer 3/8" Einatz‑Verlängerung lösen.

c. Das Sondengehäuse inspizieren und reinigen, dabei

darauf achten, dass alle Durchgänge frei sind. Das

GehäusehorizontalRichtungoffeneSeitederHalterung

ziehen und herausnehmen.

• DerKesselsteinsolltesichleichtvonden

Sondenstäben lösen.

• Dieunteren10mmjedenStabssindderSensorteil;

diesen Bereich jeweils mit einer Stahlbürste,

Scheuerpad oder Stahlwolle reinigen.

d. Den Verbundkunststoffteil der Sondenstäbe auf Risse,

raue Oberflächen oder Verwitterung prüfen und wenn

vorhanden, Sondenbaugruppe ersetzen.

e. Die Sonde und Sondenstecker‑Baugruppe wieder

montieren. Sicherstellen der Erdungsdraht ist fest mit

dem Tank verbunden.

5. Die Kammerabdeckung montieren und dabei sicherstellen,

die Dichtung der Abdeckung sitzt ordnungsgemäß und die

Kammer ist dicht.

6. Die Verdampfungskammer wieder einbauen:

a. Zulaufleitung wieder anschließen.

b. Elektrostecker wieder einstecken (Stecker sind

farbkodiert).

c. Ablaufverschraubung wieder anschließen.

d. Dampfschlauch wieder anschließen.

7. Alle Elektroanschlüsse überprüfen:

a. Sicherstellen alle Komponenten auf der DIN‑Schiene

sind sicher befestigt.

b. Sicherstellen die Klemmenschrauben der Klemmleiste

zudenHeizgerätensindfestgezogen.Siehenachstehende

Tabelle für korrekte Anziehmomente.

Tabelle 17-1:

Humidi-tech Anziehmomente

Schrauben oder Klemmenpunkt

Stromleiste 1,8

Schütz 1,8

Heiz-

gerät

Mutter

Heizgerät

Drahtklemme

8.5 mm Mutter 2,2

9.5 mm Mutter 2,8

10 mm2 Draht 4,0

6 mm2 Draht 2,8

<6 mm2 Draht 2,2

Anziehmoment

Nm

c. Sicherstellen, alle Stecker unter der Befeuchterabdeckung

sind komplett eingesteckt.

8. DenHebelamAblaufventilzurückaufPositionAutostellen.

9. Die Wasserzufuhr öffnen.

10. Die Stromversorgung einschalten.

DRI-STEEM Humidi-tech/CRUV, Normalwasser, Anleitung für Wartungssatz • Seite 17

Page 18

Humidi-tech/CRUV, Normalwasser, Wartungsanweisungen

CRUV Wartung

1. Tank entwässern. Siehe Schritt 3 auf Seite 4.

2. Die Sonden reinigen. Siehe Schritt 4 auf Seite 5.

3. Die Tankabdeckung abnehmen und die Mineralien mit einem geeigneten

Staubsauger aus dem Tank entfernen (empfohlen).

4. Um den Tank zur Reinigung auszubauen, die Ablaufrohrverschraubung,

Füllventil‑Zulaufleitung, Elektroverbindungen zum Ablauf, (lösen der

bauseitigenVerdrahtungimKanalistNICHTempfohlen)Thermoauslöser,

Heizgeräte,FüllventilundSondelösen.DenDampfschlauchvonder

TankoberseitelösenundBefestigungenderHalterungausbauen.

5. Verdampfungskammer herausnehmen und reinigen.

6. Die Sonden‑ und Sondenstecker‑Baugruppe montieren. Sicherstellen der

Erdungsdraht ist angeschlossen.

7. Tankabdeckung montieren und sicherstellen der Tank ist dicht.

8. Die Ablaufverrohrung, Füllventil‑Zulaufleitung, Elektroverbindungen

zumAblauf,Thermoauslöser,Heizgeräte,FüllventilundSondewieder

montieren. Den Dampfschlauch zur Tankoberseite verbinden.

9. Sicherstellen,derHebelamAblaufventilstehtaufPositionAUTO.

Der CRUV‑Befeuchter ist wieder einsatzbereit.

DRI-STEEM Corporation

Zertifiziert gemäß ISO 9001: 2000

Europaniederlassung:

Marc Briers

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgien

+3211823595 (Tel)

+3211817948 (Fax)

E-mail: marc.briers@dristeem.com

US-Hauptsitz:

14949 Technology Drive

Eden Prairie, MN 55344

+1 800-328-4447 oder +1 952-949-2415

+1 952-229-3200 (Fax)

DRI-STEEM Corporation praktiziert eine

fortwährende Produktentwicklung; deshalb behalten

wir uns Produktänderungen ohne Vorankündigung

vor.

DRI-STEEM, Humidi-tech, CRUV und Vapor-logic

sind eingetragene Warenzeichen von DRI-STEEM

Corporation und als eingetragene Warenzeichen in

Kanada und der EU beantragt.

Drane-kooler ist ein Warenzeichen von

DRI-STEEM Corporation.

Salzablagerungen

Bei der Verdampfung im Befeuchter lösen sich eine gewisse Menge Salze, die

dann auf der Wasseroberfläche schwimmen. Salze welche nicht abgeschöpft

werden sinken zum Boden der Verdampfungskammer.

Reinigung der Verdampfungskammer

DasHeizelementistselbstreinigend.DieKesselsteinablagerungenbröckelnab,

wenn sie eine Dicke von 2 mm erreichen und setzen sich am Kammerboden ab.

UmdieStandzeitdesHeizelementeszuverlängernsolltederBefeuchterbetrieb

nach der ersten Inbetriebnahme über einige Wochen beobachtet werden.

Durch die Beobachtung der Kesselstein‑Ablagerungsrate kann die Frequenz

der Entwässerungs‑/ Spültakte und die manuelle Reinigung bestimmt und

optimiert werden.

ACHTUNG

BevorKesselsteinablagerungenaufdieUnterseitedesHeizelementes

heranreichen, müssen diese entfernt werden. Nichteinhaltung dieser Anweisung

kannzueinemvorzeitigenVersagenderHeizelementeführen.

Der Befeuchter ist für eine einfache Reinigung und Wartung ausgelegt.

Inbetriebnahme

Zuerst die jährlichen Sicherheitsprüfungen in Abschnitt Inspektion und

Wartung auf Seite 4 durchführen.

Nach erfolgter Wartung muss der Befeuchter über mehrere Fülltakte

überwacht werden, um sicherzustellen, alle gewarteten Teile funktionieren

ordnungsgemäß. Siehe auch Abschnitt Inbetriebnahme in der Befeuchter‑

Installations‑ und Bedienungsanleitung.

© 2011 DRI-STEEM Corporation

Form Nr. VM/CRUV-standard-SKM-G-0711

Teile-Nr. 891000-001 Rev C

Seite 18 • DRI-STEEM Humidi-tech/CRUV, Normalwasser, Anleitung für Wartungssatz

DRI-STEEM Produkte sind garantiert für einen Zeitraum von zwei Jahren ab dem Kaufdatum

entsprechend den Konditionen der zweijährigen begrenzten Gewährleistung. Siehe mit dem Befeuchter

gelieferte Literatur für Einzelheiten zur Gewährleistung.

Loading...

Loading...