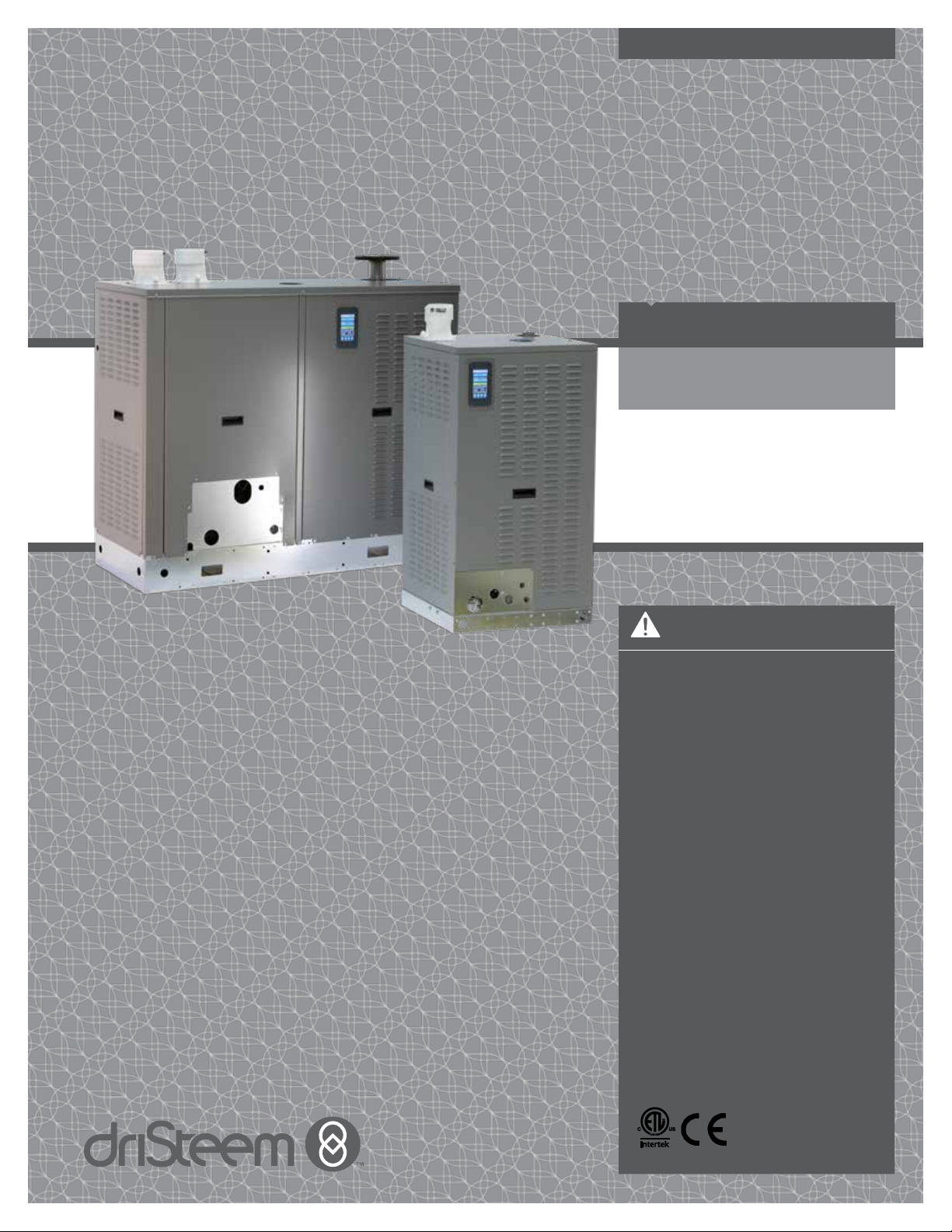

DriSteem GTS LX Series, GTS LX-50, GTS LX-75, GTS LX-100, GTS LX-200 Installation, Operation And Maintenance Manual

...Page 1

READ AND SAVE THESE INSTRUCTIONS

®

GTS

Gas-to-Steam Humidifier

LX Series

Installation, Operation,

and Maintenance Manual

WARNING

Fire or explosion hazard

If the information in this manual is not

followed exactly, a fire or explosion could

result, causing property damage, personal

injury, or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

If you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from an off-site phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed

by a qualified installer, service agency, or

the gas supplier.

For toll-free support call DriSteem Technical

Support: 1-800-328-4447

Page 2

Page 3

Warnings and cautions

WARNING

Indicates a hazardous situation that could result in death or

serious personal injury if instructions are not followed.

WARNING

Fire or explosion hazard

A. This appliance does not have a pilot. It is equipped with an ignition

device which automatically lights the burner.

Do NOT try to light the burner by hand.

B. Before operating, smell all around the appliance area for gas. Be sure

to smell next to the floor because gas can be heavier than air and settle

on the floor.

If you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from an off-site phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Do not use this appliance if any part has been under water.

Immediately call a qualified gas appliance service technician to inspect

the appliance and to replace any part of the control system and any

gas control that has been under water.

Attention installer

Read this manual before installing, and leave this manual with product

owner. This product must be installed by qualified HVAC and electrical

contractors. Installation must be code approved. Improper installation can

cause property damage, severe personal injury, or death as a result of

electric shock, burns, or fire.

DriSteem

North America: 800-328-4447

Europe: +3211823595

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on

any part of the system. Failure to follow all warnings and instructions could

produce the hazardous situations described, resulting in property damage,

personal injury, or death.

Failure to follow the instructions in this manual can cause moisture to

accumulate, which can cause bacteria and mold growth or dripping water

into building spaces. Dripping water can cause property damage; bacteria

and mold growth can cause illness.

®

Technical Support:

CAUTION

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

Continued

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

Page 4

Warnings and cautions

WARNING

Carbon monoxide, fire, explosion, and electrical shock hazards

Improper installation, adjustment, alteration, service, maintenance, or use can cause carbon monoxide poisoning, fire,

explosion, electrical shock, and other hazardous conditions. These hazardous conditions could cause personal injury,

property damage, or death. To prevent hazardous conditions, read all warnings; lock all power disconnect switches

in the OFF position before removing any access panels; and consult a qualified installer, service agency, local gas

supplier, or your distributor or branch for information or assistance. The qualified installer or agency must use only

factory authorized and listed kits or accessories when modifying this product.

• Inspect humidifier and accessories upon arrival for damaged, missing, or improper parts. If there is a problem, call

your local DriSteem Representative/Distributor.

• Application of this humidifier should have special attention given to vent sizing and material, gas input rate, and

unit sizing. Improper installation or misapplication of the humidifier can cause excessive servicing or permanent

component failure.

• When working on equipment, observe precautions in literature, tags, and labels attached to or shipped with the unit

and observe other safety precautions that may apply. Wear safety glasses and work gloves. Have a fire extinguisher

available during start-up, adjustment procedures, and service calls.

• Do not lift humidifier by gas controls, gas manifold, fire box, or shroud.

• Should overheating occur, or the gas supply fail to shut off, shut off the manual gas valve to the appliance before

shutting off the electrical supply.

• The evaporating chamber is designed as a nonpressurized vessel. DO NOT restrict piping where steam exits the

humidifier. Install drain piping and piping that connects the evaporating chamber to the dispersion assembly only as

described in this manual. DO NOT install a shut-off valve on the piping connecting the evaporating chamber to the

steam outlet.

• Check the humidifier name plate for the gas type indicated (natural gas or propane gas). Supply the humidifier only

with the gas type indicated, or burner failure will result. To convert the humidifier to a different gas type, contact

DriSteem Technical Support or your local DriSteem Representative/Distributor.

• Installation must conform to the requirements of the authority having jurisdiction or, in the absence of such

requirements, must conform to:

– In the United States: The National Fuel Gas Code, ANSI Z223.1 (latest edition).

– In Canada: Local plumbing or waste water codes and other applicable codes and with the current code CAN/

CGA-B149.1, “Installation Code for Natural Gas Burning Appliances and Equipment,” or CAN/CGA-B149.2,

“Installation Code for Propane Burning Appliances and Equipment.”

– In Europe: The National Gas Safety (Installation & Use) Regulations.

• Do not install in potentially explosive or flammable atmospheres laden with grain dust, sawdust, or similar airborne

materials.

• Installation of humidifier in high humidity or salt water atmospheres causes accelerated corrosion, reducing the

normal life-span of the unit.

• To prevent premature heat exchanger failure, do not locate any gas-fired unit in areas where chlorinated,

halogenated, or acid vapors are present in the atmosphere.

• Locate the humidifier in an area clear of combustible materials, gasoline, and other flammable vapors and liquids.

Continued

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

Page 5

Warnings and cautions

WARNING

Carbon monoxide, fire, explosion, and electrical shock hazards (continued)

• With the exception of sealed combustion units, do not locate units in tightly sealed rooms or small compartments

without provision for adequate combustion air and venting. Room air combustion must be supplied through a

minimum of two permanent openings in the wall, with at least one near the bottom. See "Combustion and ventilation

air" for additional information.

• Do not install the humidifier indoor directly on carpeting, tile, or other combustible material other than wood

flooring. Outdoor units may be installed directly on combustible flooring or, in the U.S., on wood flooring or Class

A, Class B or Class C roof covering materials.

• Remove all shipping brackets and materials before operating the humidifier.

• Do not locate humidifier in a negative pressure space. Combustion products could be suctioned from the venting.

See page 42.

• Humidifier flue gases must be vented to the outside atmosphere.

• Do not interfere, disable, or tamper with the devices monitoring the combustion gas discharge, including the flue

temperature and flue pressure sensors. Only authorized and trained technicians should perform any service on these

items.

• Do not interfere or tamper with any sealed components. Only authorized and trained technicians should perform

any service on these items.

• This humidifier is not intended for use by persons (including children) with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the humidifier.

• The GTS humidifier LX series must be vented and supplied with combustion and ventilation air as described in this

IOM. Ensure the vent and air piping and the combustion air supply comply with these instructions regarding vent,

system, air system, and combustion air quality. Inspect finished vent and air piping thoroughly to ensure all are

airtight and comply with the instructions provided and with all requirements of applicable codes. Failure to provide

a properly installed vent and air system will cause severe personal injury or death.

• This humidifier requires a special venting system. Use only approved stainless steel, PVC, CPVC, or polypropylene

pipe and fittings listed in this IOM. Failure to comply could result in severe personal injury, death, or substantial

property damage.

• Do not connect any other appliance to the vent pipe or multiple humidifiers to a common vent pipe. Failure to

comply could result in sever personal injury, death, or substantial property damage.

• The flue gas vent shall not pass through any air duct or plenum. Do not insulate plastic flue gas vent pipe.

• Do NOT mix components from different systems. The vent system could fail, causing leakage of flue products. Mixing

of venting materials will void the warranty.

• Power supply disconnect switch must be in the off position while making wiring connections to prevent electrical

shock and equipment damage. All units must be wired in strict accordance with the wiring diagrams furnished with

this unit.

• Turn off all gas while installing the gas piping and manual shutoff valve for the humidifier.

• The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures exceeding 0.5 psig (3.5 kPa).

Continued

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3

Page 6

Warnings and cautions

WARNING

Hot surfaces and hot water

This steam humidification system has extremely hot surfaces. Water in tank, steam tubing, and dispersion assemblies can

be as hot as 212 °F (100 °C). Discharged steam is not visible. Contact with hot surfaces, discharged hot water, or air

into which steam has been discharged can cause severe personal injury. To avoid severe burns, follow the cool-down

procedure in this manual before performing service or maintenance procedures on any part of the system.

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any

part of the humidification system. Failure to disconnect electrical power could result in fire, electrical shock, and other

hazardous conditions. These hazardous conditions could cause property damage, personal injury, or death.

Follow the shutdown procedure on Page 60 before performing service or maintenance procedures on any part of the

system.

Continued

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

Page 7

Warnings and cautions

CAUTION

Hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage some drain plumbing.

The humidifier is equipped with integrated water drain tempering that needs make-up water no greater than 90°F (32 °C) in order

to function properly. Make sure the water supply to the humidifier remains open during draining.

Excessive supply water pressure

Supply water pressure greater than 80 psi (550 kPa) can cause the humidifier to overflow.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

Page 8

Table of contents

PRODUCT OVERVIEW .........................................................8

Supply water guidelines .................................8

Universal water .......................................8

Water level control ....................................9

Models, capacities, electrical specifications, and weights ...........11

SPECIFICATIONS........................................................... 11

Indoor dimensions .......................................12

INSTALLATION ............................................................ 14

Location and clearance recommendations ......................14

Optional floor stand mount (Models 50, 75,100, and 150 only) ......16

Optional wall mount (Models 50, 75 and 100 only) ...............18

Outdoor enclosure .......................................19

Overview ..........................................19

Operation ..........................................20

Dimensions .........................................21

Location ...........................................22

Mounting ..........................................23

Freeze Protection Piping ................................25

Venting ............................................26

Wiring ...............................................27

Piping ...............................................28

Overview ..........................................29

Connection sizes .....................................30

Condensate return ....................................31

Supply water and drain overflow connections .................33

Supply water and drain ................................34

Flue gas condensate ..................................36

Gas ..............................................38

General venting ........................................42

Room air combustion ..................................42

Sealed combustion (combustion air from outside the building). . . . . . 46

Guidelines .........................................47

Vertical venting .........................................50

Sidewall venting ........................................52

Determine a location ..................................52

Sidewall installation ...................................54

Selecting a dispersion location ..............................55

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

Page 9

Table of contents

OPERATION ..............................................................

56

Start-up ..............................................56

Start-up checklist .....................................56

Start-up procedure ....................................57

Start-up commissioning checklist .............................58

MAINTENANCE ........................................................... 60

Inspection recommendations ................................60

Replacement parts ....................................61

Water quality and maintenance .............................62

Water quality recommendations ..........................62

Cool down procedure .................................63

Inspection and maintenance ................................64

Heat exchangers .....................................67

Combustion assemblies ...................................68

Removing the combustion assembly ........................68

Maintenance frequency ................................68

Burner maintenance instructions ...........................69

Ignitor and flame sense rod .............................69

REPLACEMENT PARTS ....................................................... 70

GTS humidifier (Models LX-50 through LX-150) ...................70

GTS humidifier (Models LX-200, LX-250, and LX-300) ..............72

GTS humidifier (Models LX-400 through LX-600) ..................74

Electrical parts .........................................76

Outdoor enclosure .......................................78

ATTENTION INSTALLER

Original Instructions

Read this manual before installing. Leave

manual with product owner.

DriSteem Technical Support

800-328-4447

Website:

Documents can be viewed, printed or ordered

from our website, www.dristeem.com.

DriCalc sizing and selection software:

DriCalc® is our humidification system sizing

and selection software, which can be accessed

from dristeem.com.

EUROPEAN MODELS........................................................ 80

Authorized countries of destination ........................80

Appliance category ...................................80

WARRANTY .............................................................. 86

Two-year Limited Warranty ..............................86

Extended warranty ....................................86

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

7

Page 10

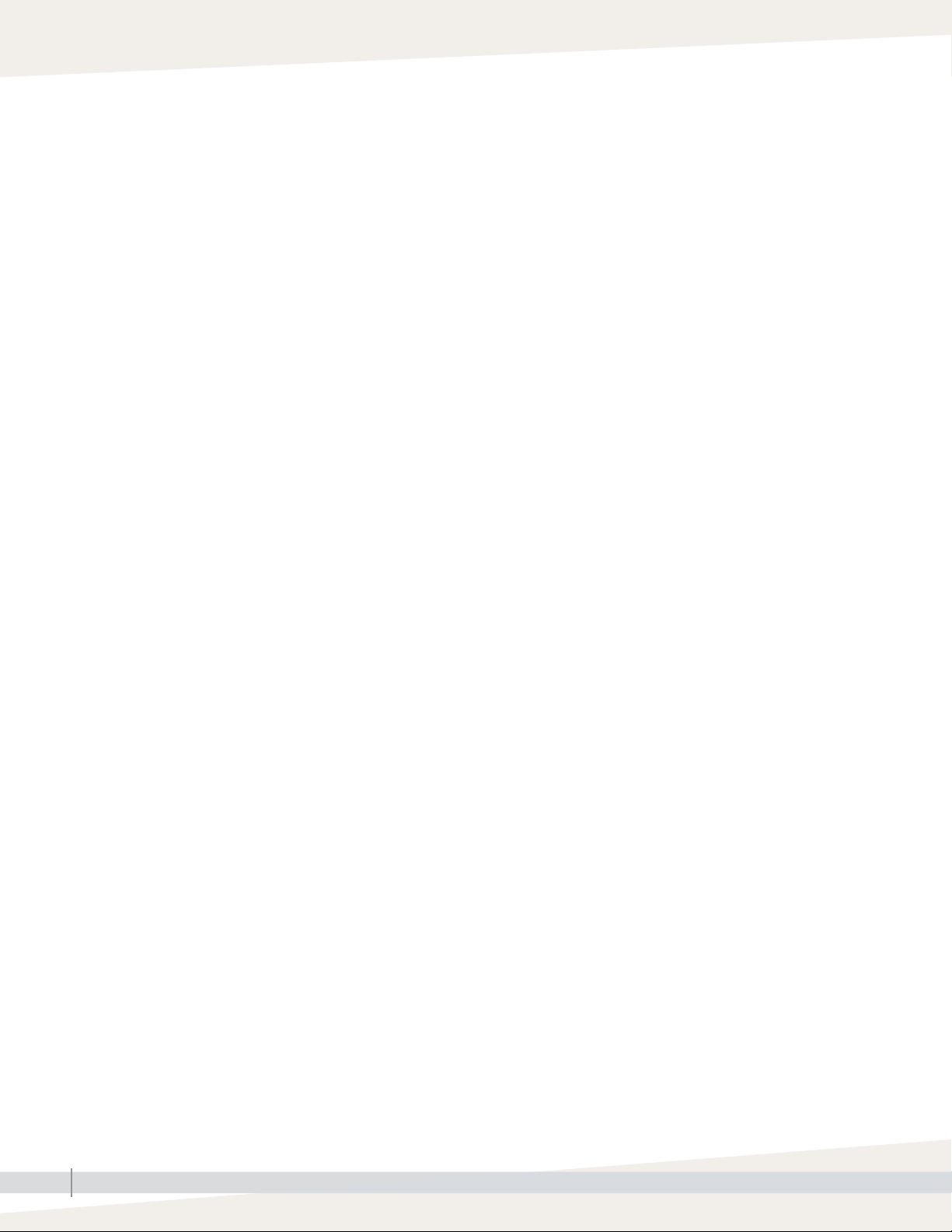

The GTS humidifier LX series burns either natural or propane gas to heat and

boil fill water into steam for humidification. The unit has either one or two

burners that fire into a heat exchanger submerged in a tank of water. When

there is a call for humidity, the burners fire and generate steam until the call for

humidity ends.

UNIVERSAL WATER

DriSteem's GTS humidifier LX series incorporates universal water control for use

with any water type (well, tap, softened, DI or RO water). There is no need to

change control configurations based on water type when ordering equipment

or retrofitting to fit new water sources in the field. The water level control

algorithm monitors water quality and any changes over time to assure the user

of accurate control no matter the type of water that is used.

PRODUCT OVERVIEW

Product overview

Supply water guidelines

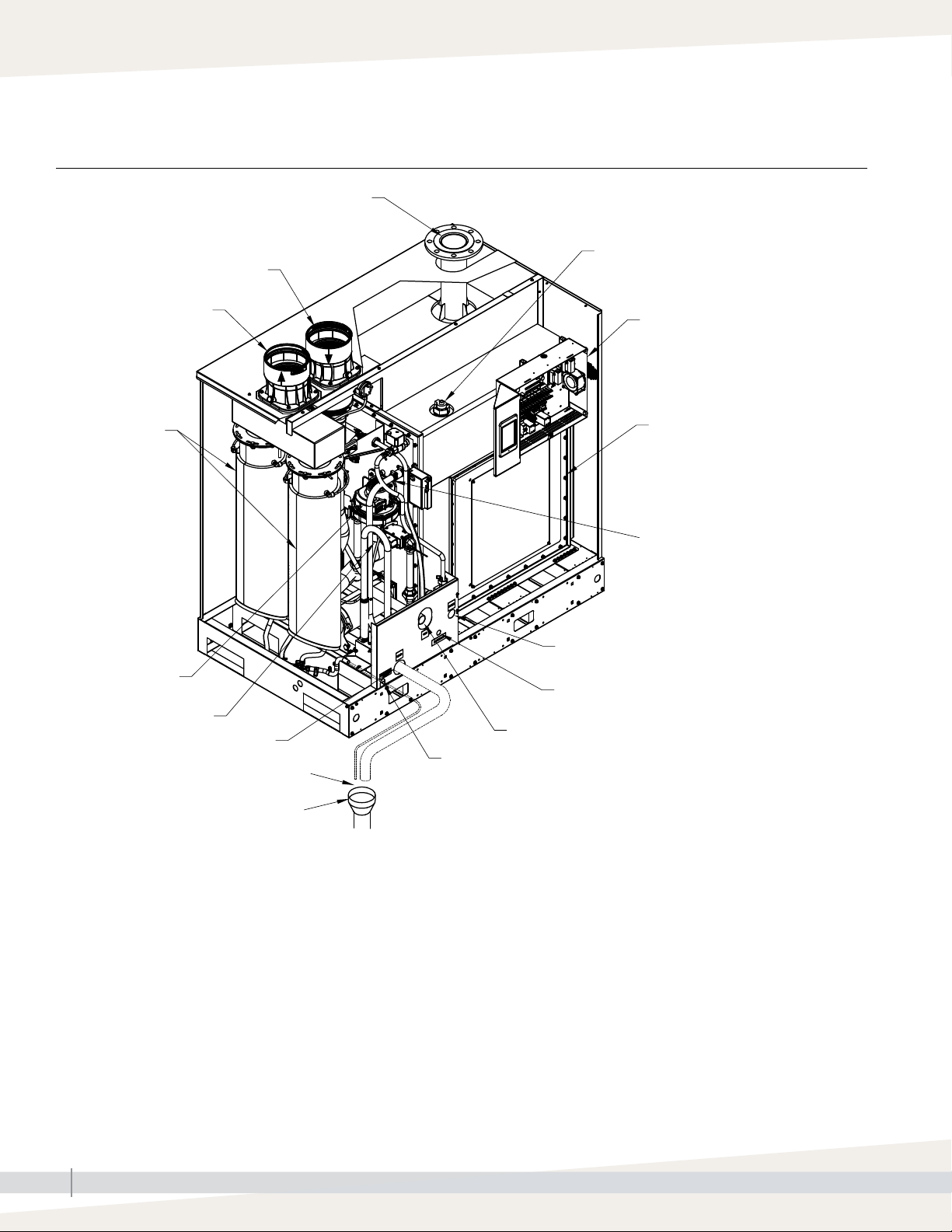

FIGURE 8-1: GTS HUMIDIFIER LX SERIES

Duct dispersion option shown: Ultra-sorb Model LV

Supply water guidelines

Supply water quality is an important component

of humidifier reliability and maintenance.

Examples:

• Corrosive water can decrease the service life

of the humidifier.

• Excessive water hardness can increase the

humidifier maintenance requirements.

To maximize humidifier service life and

minimize humidifier maintenance, DriSteem has

established guidelines for supply water. See

Table 8-1.

Table 8-1:

DriSteem supply water guidelines

Chlorides*

Tap water

RO/DI water

Softened water

* Damage caused by

chloride corrosion is

not covered by your

DriSteem warranty.

Total hardness

Tap water < 500 ppm

< 50 ppm

< 5 ppm

< 25 ppm

(29 gpg)

Steam outlet

Combustion air

intake

Flue gas

vent

Control components

Secondary

heat

exchanger

Blower

Gas valve

Supply

water

connection

Open drain

Drain

Air gap

Primary heat exchanger

Electrical field connection

Flue gas condensate

Gas connection

OM-7942

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8

pH

Tap water

RO/DI, softened water

6.5 to 8.5

7.0 to 8.0

Silica < 15 ppm

Supply water outside of the guidelines

may void your DriSteem warranty.

Please contact your DriSteem

Representative or DriSteem Technical

Support if you need advice.

Page 11

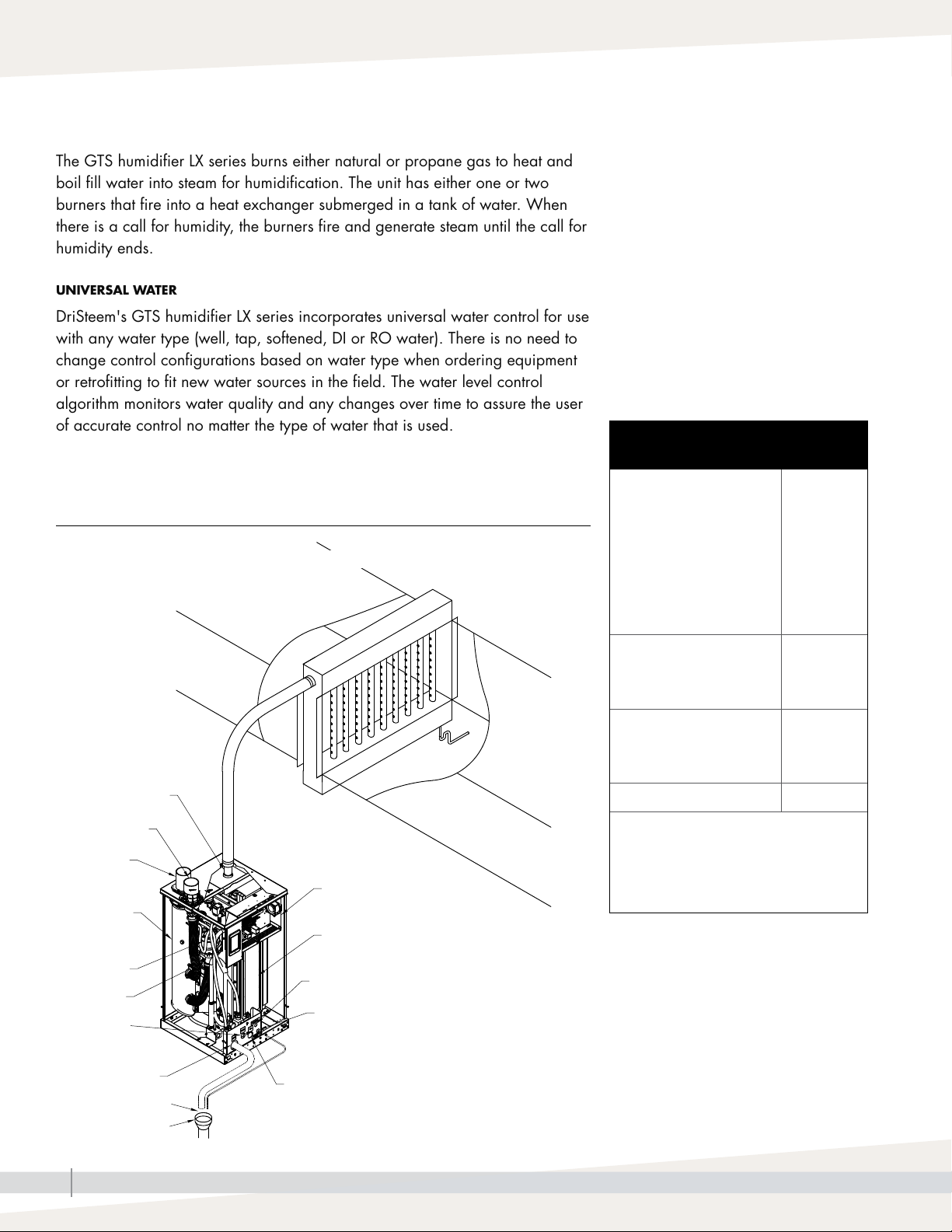

Product overview

WATER LEVEL CONTROL

The LX series of GTS humidifiers control water level using a three-rod probe

(see Figure 9-1). All water types and conductivities work with the universal

water system. The user does not need to select a new water type or change

hardware to change water types. Additional valves and Vapor-logic algorithms

measure and control the water level for optimum efficiency and low water

safety conditions. Vapor-logic automatically provides a steady output while

maintaining the water level between the bottom and middle probes.

FIGURE 9-2: GTS HUMIDIFIER LX SERIES (MODELS LX-50 THROUGH LX-150)

Steam outlet

Combustion air pipe

Flue gas vent

Secondary heat

exchanger

Water level sensing probe

Control

components

Overflow

outlet

FIGURE 9-1: WATER LEVEL CONTROL

Water level

is controlled

electronically using

three probes

Overflow/foam detection

Full

Low

VLC-OM-030

Blower

Gas valve

Supply water

connection

Drain

Air gap

Open drain

Note: Dashed lines indicate supplied by installer

Primary heat

exchanger

Electrical field

connection

Flue gas condensate

Gas connection

OM-7943

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

Page 12

Product overview

FIGURE 10-1: GTS HUMIDIFIER LX SERIES (MODELS LX-400 THROUGH LX-600)

Steam outlet

Flue gas vent

Secondary heat

exchanger

Blower

Combustion air pipe

Gas valve

Drain

Open drain

Air gap

Water level sensing probe

Control

components

Primary heat

exchanger

Overflow

outlet

Supply water

connection

Electrical field

connection

Gas connection

Flue gas condensate

OM-7996

Note: Dashed lines indicate supplied by installer

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

10

Page 13

SPECIFICATIONS

Models, capacities, electrical specifications, and weights

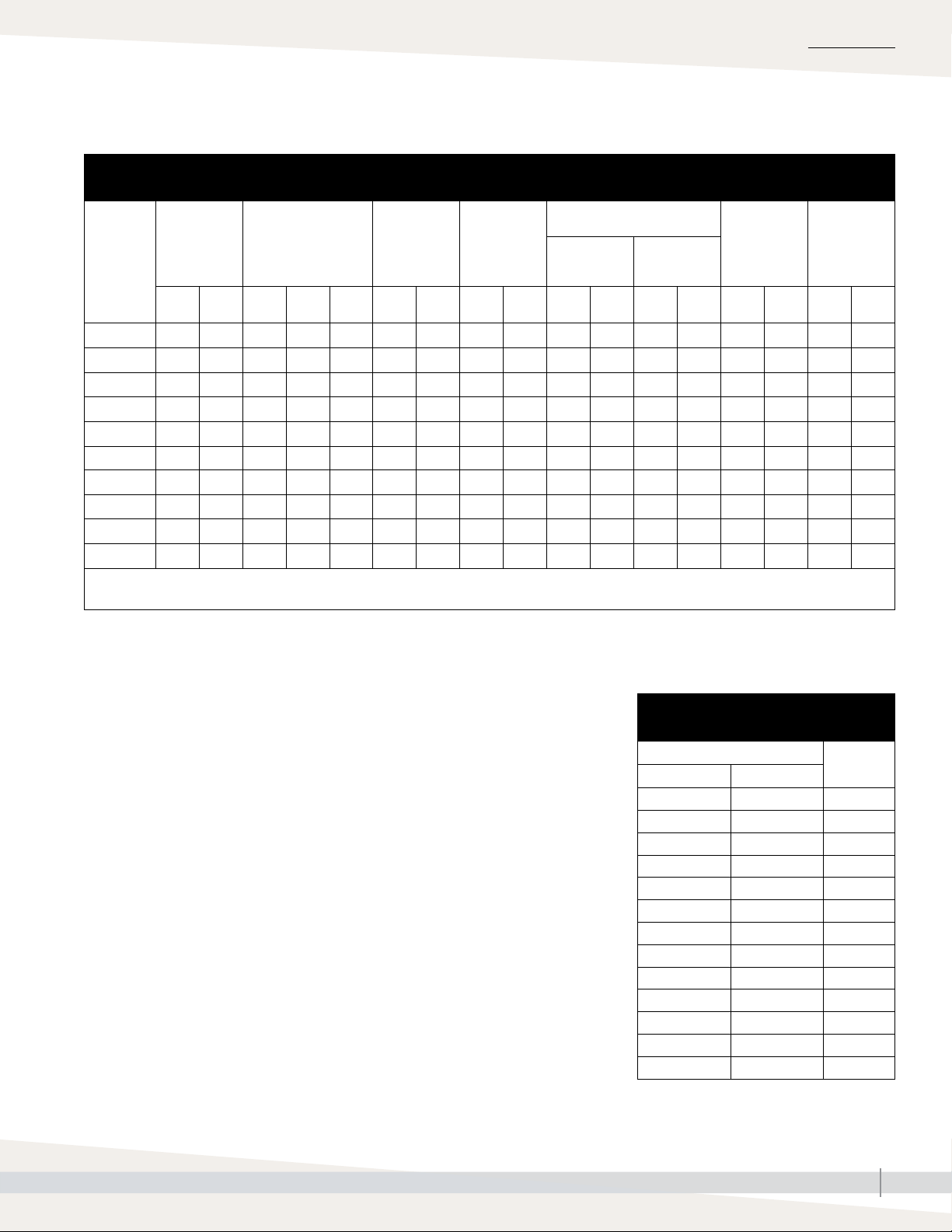

Table 11-1:

GTS models, capacities, electrical specifications, turndown, and weights

GTS humidifier

Maximum

GTS

model

LX-50 50 23 61 17.8 1.7 6 23 14 53 304 138 187 85 5:1 10 2.0 1.5

LX-75 75 34 91.5 26.8 2.5 9 34 14 53 304 138 187 85 6:1 12.5 2.0 1.5

LX-100 100 45 122 35.8 3.4 12 45 13 49 300 136 192 87 8:1 12.5 2.0 1.5

LX-150 150 68 183 53.6 5.1 18 68 25 95 450 204 242 110 6:1 25 2.5 2.0

LX-200 200 91 244 71.5 6.8 24 91 42 159 706 320 356 161 6.7:1 30 4.0 2.5

LX-250 250 113 305 89.4 8.5 30 114 42 159 706 320 356 161 8.3:1 30 4.0 2.5

LX-300 300 136 360 105.5 10 36 136 41 155 709 321 367 166 10:1 30 4.0 2.5

LX-400 400 181 488 143 13.5 48 182 80 303 1259 571 593 269 13.3:1 30 6.5 3.5

LX-500 500 227 610 178.8 16.9 60 227 80 303 1259 571 593 269 16.7:1 30 6.5 3.5

LX-600 600 272 720 211 20 72 273 78 295 1265 574 615 279 20:1 30 6.5 3.5

* For outdoor enclosures, see Table 26-1.

** Add approximately 60-90 lbs (27-41 kg) for packaging material.

steam

capacity

lbs/hr kg/h MBh kW m

Input

3

/h

Water usage

at maximum

capacity

gals/hrlitres/

hr

Tank

volume

gals litres lbs kg lbs kg ratio lbs/hr

LX series*

Operating

weight

Shipping

(empty)

weight**

Turndown

Full load

120V

60 Hz

amps*

230V

50 Hz

LP GAS

All models operate at rated input

HIGH ALTITUDE

The input shown6 in Table 11-2 is derate when operating units at a high

altitude. See the "Start-up procedure" on page 57 for adjusting oxygen

levels on the LX series gas valve.

Important: See Pages 80 and 81 for

additional European model specifications and

capacity notes.

Table 11-2:

High altitude derate

Altitude

feet meters

0–2000 0–610 0

2001–2500 610–765 2

2501–3000 765–915 4

3001–3500 915–1065 6

3501–4000 1065–1220 8

4001–4500 1220–1370 10

4501–5000 1370–1525 12

5001–5500 1525–1675 14

5501–6000 1675–1830 16

6001–6500 1830–1980 18

6501–7000 1980–2135 20

7001–7500 2135–2285 22

7501–8000 2285–2440 24

Input

derate %

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

Page 14

SPECIFICATIONS

Indoor dimensions

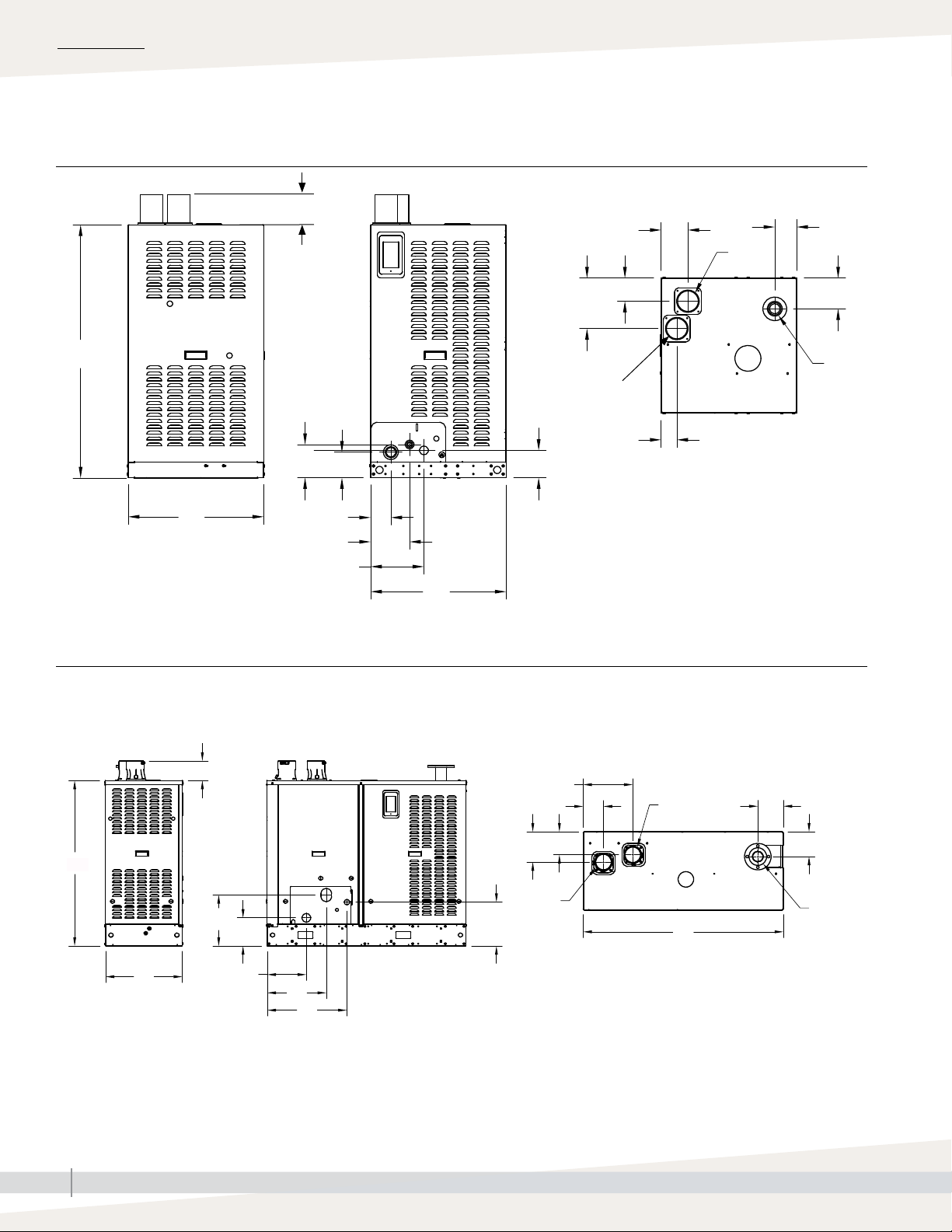

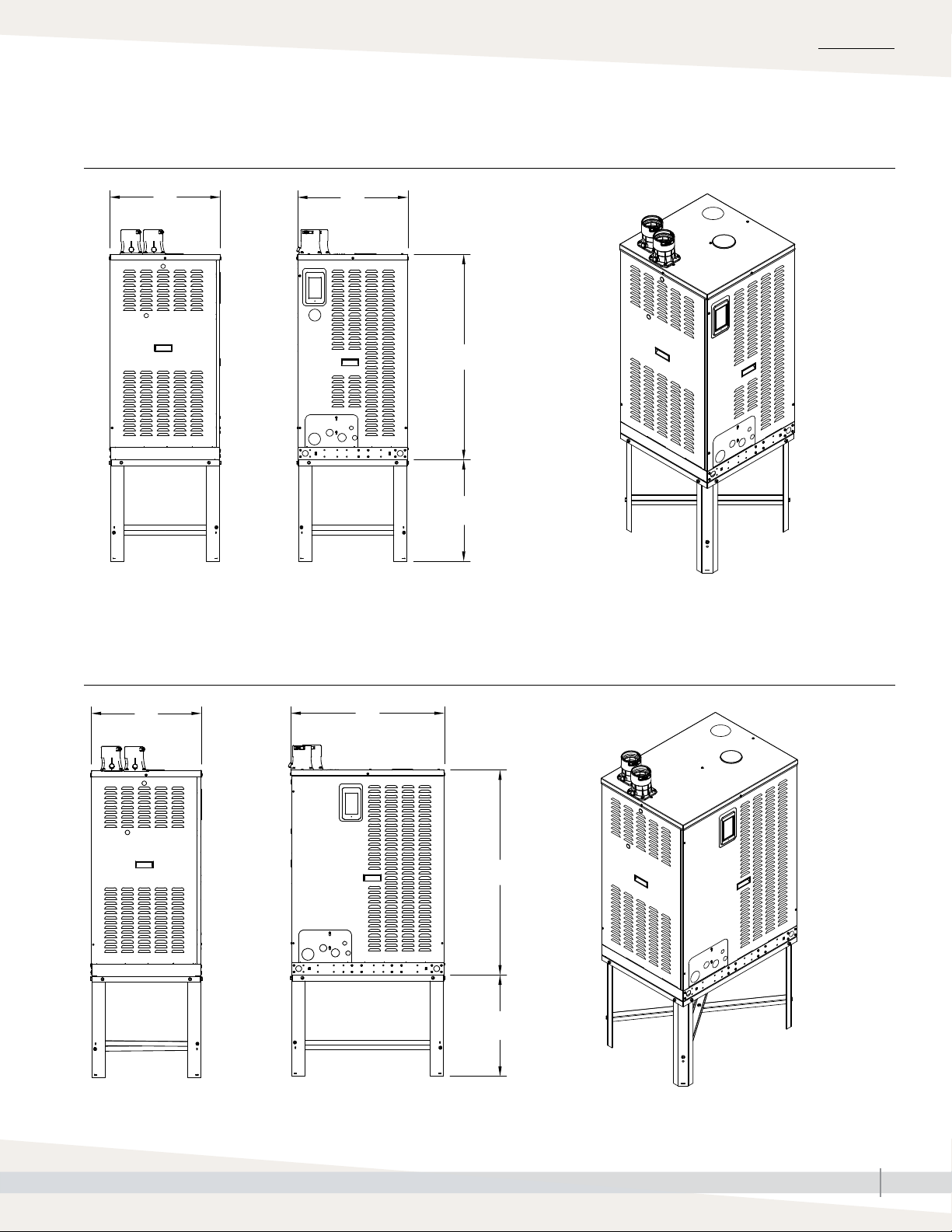

FIGURE 12-1: LX MODELS 50 - 150 INDOOR UNIT DIMENSIONS

Side view Front view Top view

C

B

See "Indoor unit dimensions" on page 13-1.

R

E

F

D

O

Q

P

T

L

N

M

S

K

A

J

G

H

J

OM-7946

FIGURE 12-2: LX MODELS 200 - 300 INDOOR UNIT DIMENSIONS

Side view Front view Top view

R

C

L

N

B

See "Indoor unit dimensions" on page 13-1.

M

T

K

S

P

E

O

D

F

Q

A

G

H

J

OM-8014

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12

Page 15

Indoor dimensions

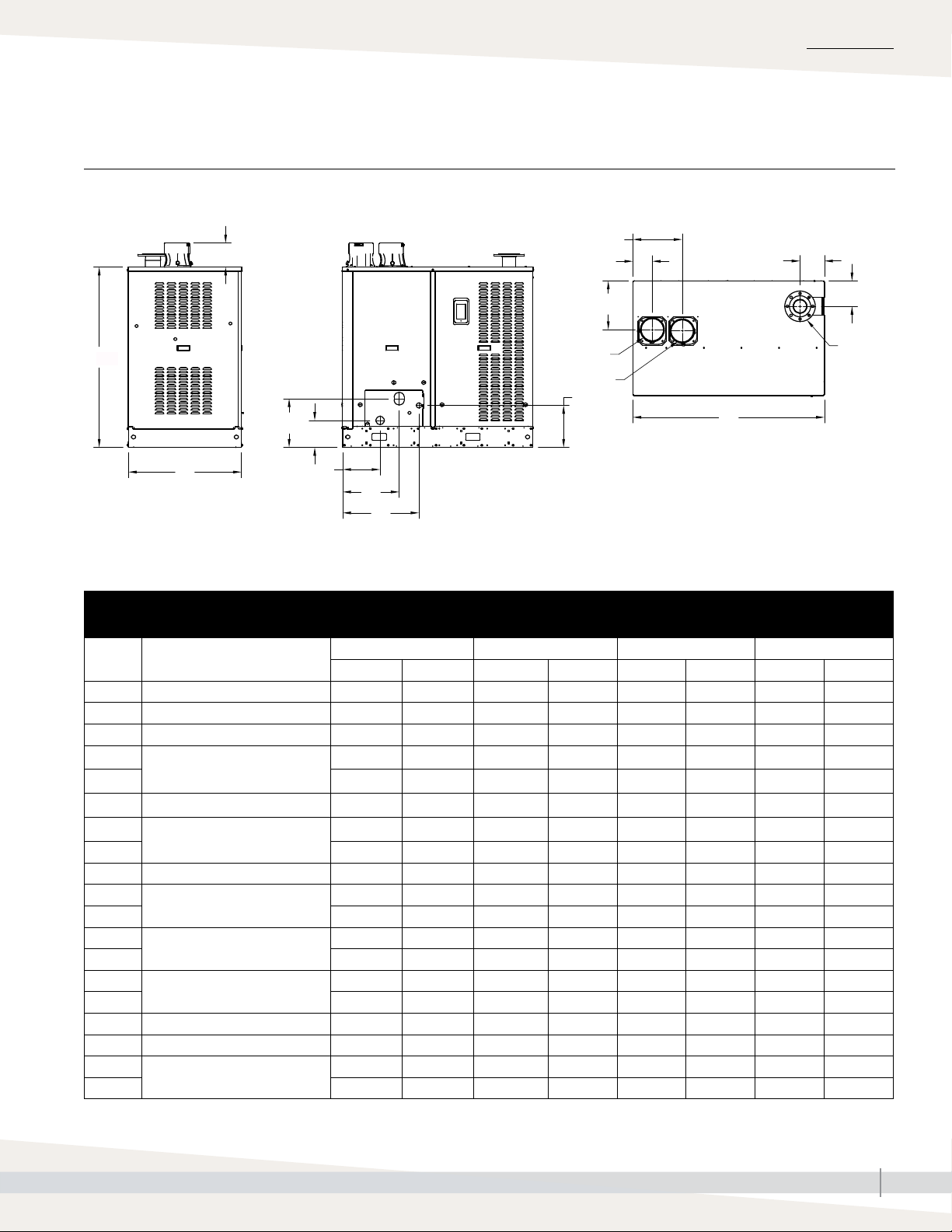

FIGURE 13-1: LX MODELS 400 - 600 INDOOR UNIT DIMENSIONS

Side view Front view Top view

R

SPECIFICATIONS

P

E

G

D

C

B

For outdoor dimensions see page 21.

L

N

M

K

S

F

Q

T

A

OM-7998

Table 13-1:

Indoor unit dimensions

Description

A Overall length 23.25 590 32.25 819 56 1422 56 1422

B Overall width 23.25 590 23.25 590 22 559 34 864

C Overall height 42.75 1085 42.75 1085 47 1194 53 1346

D

Flue position

E 4.4 112 4.4 112 5.61 143 5.6 142

F Flue diameter 3 76 3 76 4 102 6 152

G

Steam outlet position

H 5.3 135 5.3 135 6.9 175 7.4 188

J Steam outlet diameter 2 51 2 51 3 76 4 102

K

Gas inlet position

L 4.6 119 4.6 119 14.3 363 14.3 363

M

Drain position

N 4.5 114 4.5 114 8 203 8 203

O

Combustion air

P 2.7 69 2.7 69 14 363 14.5 368

Q Combustion air diameter 3 76 3 76 4 102 6 152

R Flue and combustion air height 5.5 140 5.5 140 5.6 142 7.1 180

S

Fill valve connection position

T 5.60 142 5.60 142 12.4 315 12.4 315

LX-50, LX-75, LX-100 LX-150 LX-200, LX-250, LX-300 LX-400, LX-500, LX-600

inches mm inches mm inches mm inches mm

4.3 109 4.3 109 8.7 221 14.5 368

3.8 97 3.8 97 7.1 180 7 178

9.2 234 9.2 234 16.6 4022 16.6 422

3.5 89 3.5 89 11 279 11 279

8.92 227 8.92 227 6.5 165 14.5 368

6.59 167 6.59 167 22.4 569 22.4 569

H

J

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

13

Page 16

INSTALLATION

Location and clearance recommendations

FINDING A LOCATION

• Provide a level, solid foundation for the humidifier.

• The GTS humidifier LX series vent and air piping can be installed through

the roof or through a sidewall. Use only vent/air piping methods described

in this IOM. Locate the humidifier as near as possible to an outside wall

or accessible roof space so that the flue pipe from the humidifier is short,

direct, and limited to wind exposure.

• Locate the unit so it and its electrical components are protected from water

during humidifier operation and service.

• Install the humidifier in a location away (and protected) from drafts. Follow

the instructions concerning combustion and ventilation air.

• Locate the humidifier in an area where leakage from the tank or its

connections will not result in damage to the adjacent structure or to lower

floors of the structure. When such locations cannot be avoided, install

a suitable drain pan (adequately drained) under the humidifier (field

supplied). The pan must not restrict combustion airflow.

WARNING

Installation requirements

The humidifier must be installed by

a qualified technician and meet the

requirements of all governing codes.

Failure to follow these instructions could

cause severe bodily injury or death.

• If located in an insulated space, keep the humidifier free and clear of

insulating materials. Insulating material can be combustible. Inspect the

humidifier area when the humidifier is installed or when insulation is

added.

• See the combustion air and flue gas venting section on page 42 for

pipe termination locations and instructions.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

14

Page 17

Location and clearance recommendations

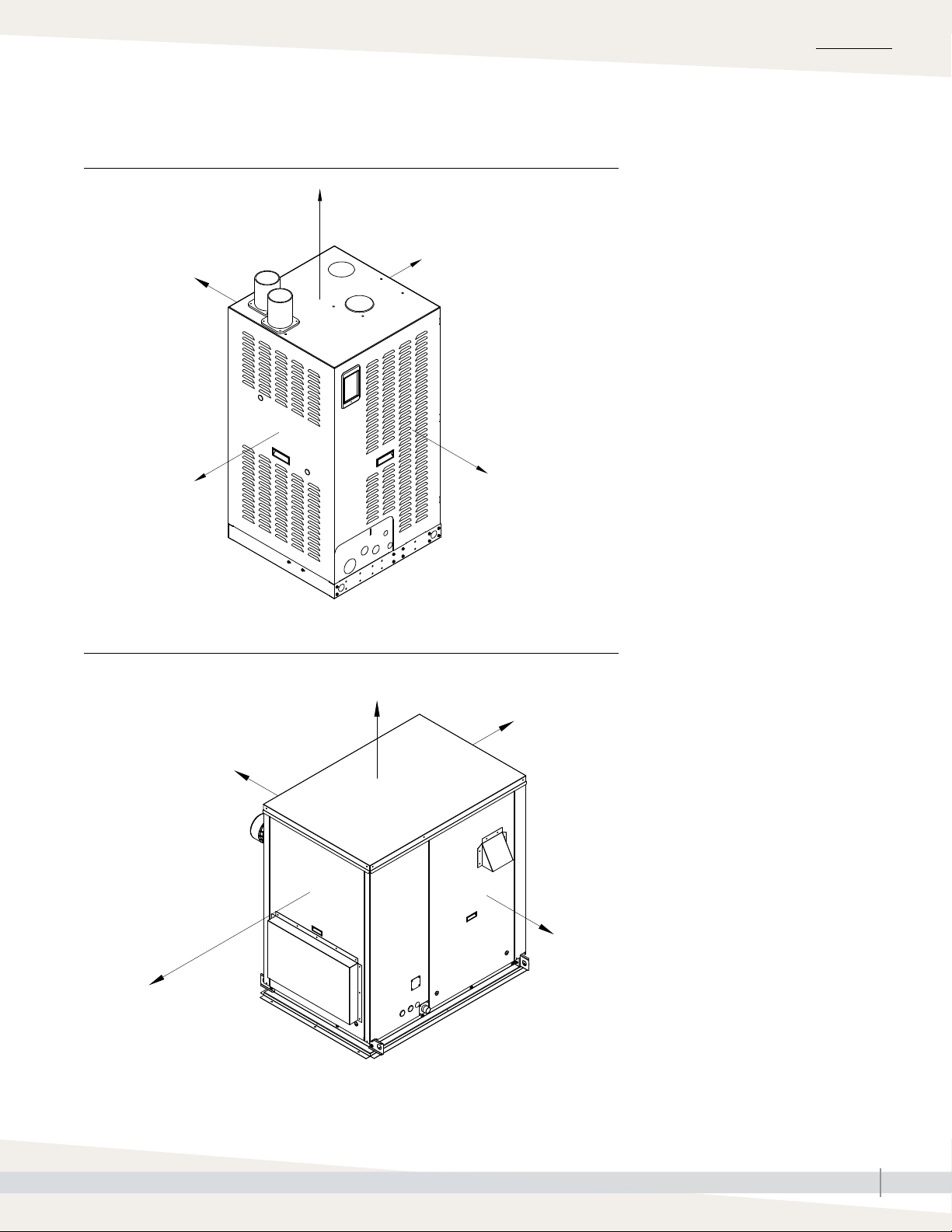

FIGURE 15-1: LX SERIES CLEARANCE RECOMMENDATIONS (INDOOR UNITS)

18" (457 mm)

Indoor Unit

INSTALLATION

1" (25 mm)

30" (762 mm) for

LX-50 through LX-150

54" (1372 mm) for

LX-200 through LX-600

FIGURE 15-2: LX SERIES CLEARANCE RECOMMENDATIONS (OUTDOOR UNITS)

Outdoor Unit

36" (914 mm)

1" (25 mm)

36" (914 mm)

OM-7947

36" (914 mm)

36" (914 mm) for

LX-50 through LX-150

54" (1372 mm) for

LX-200 through LX-600

36" (914 mm)

36" (914 mm)

OM-8012

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

15

Page 18

INSTALLATION

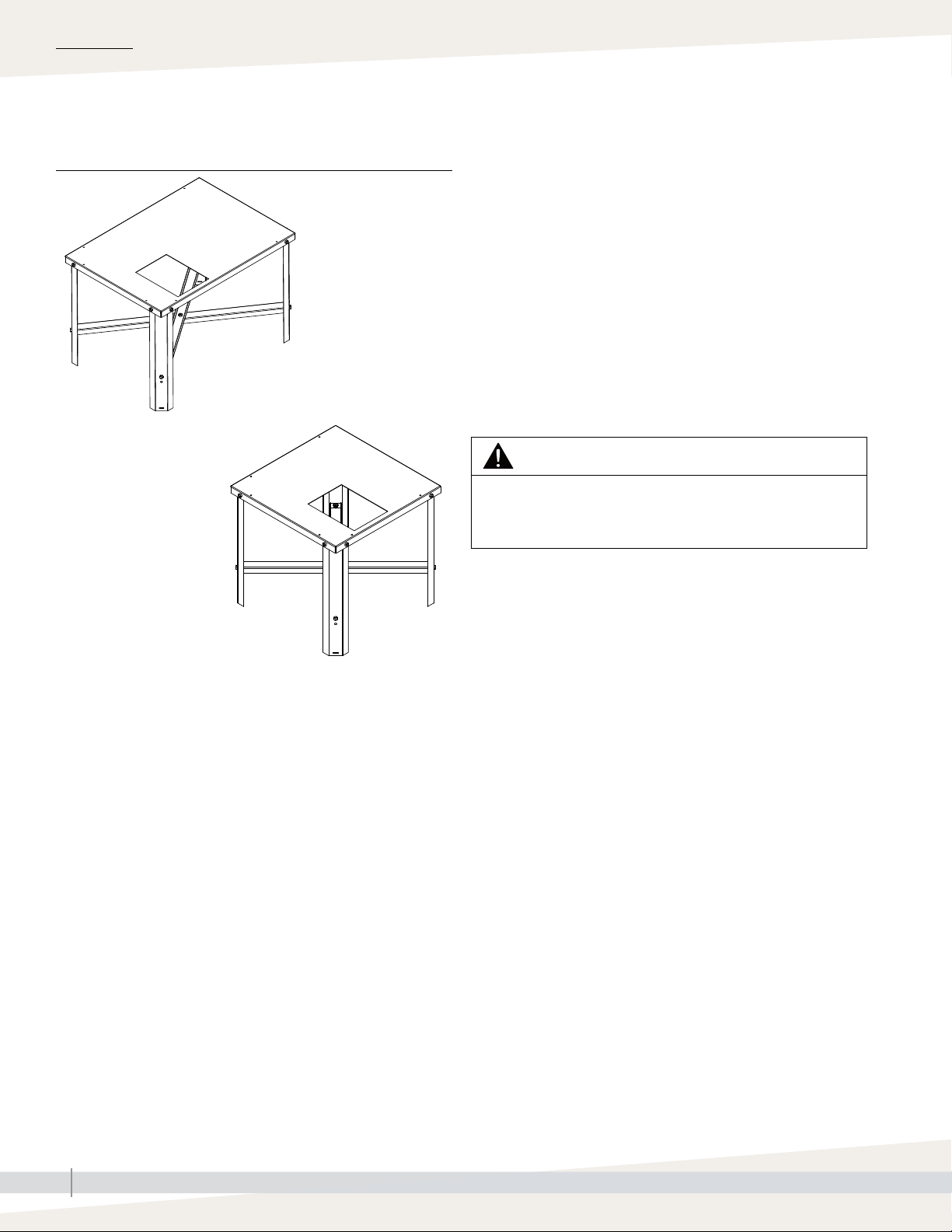

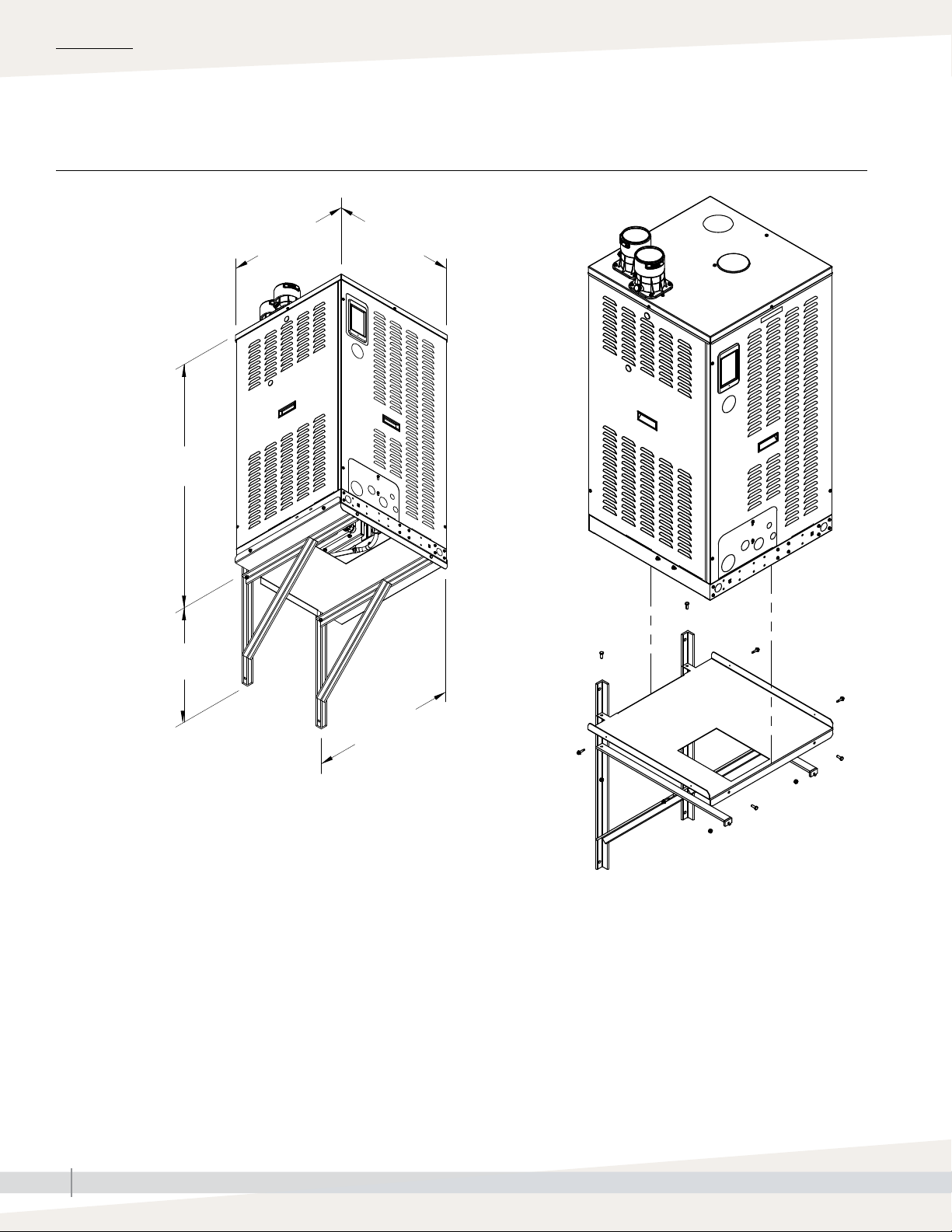

Optional floor stand mount (Models 50, 75,100, and 150 only)

FIGURE 16-1: LX SERIES FLOOR STAND MOUNT ASSEMBLY FLOOR STAND MOUNTING INSTRUCTIONS

Model LX-150

1. Refer to Figure 17-1 for assembly of the floor stand.

2. Use the hardware provided by DriSteem to assemble.

3. Arrange appropriate lifting mechanism and personnel

to mount the GTS humidifier LX series on the floor

stand. See Warning below.

4. Use the lifting hole on the base of humidifier to

carefully lift it off the ground. See Warning below.

OM-7972

Models LX-50 - LX-100

OM-7971

5. Slowly lower the humidifier on the floor stand.

6. Secure the base of the humidifier to the floor stand

using sheet metal screws.

WARNING

HEAVY OBJECT

To avoid muscle strain or back injury, use lifting aids and

proper lifting techniques when removing or replacing.

Notes:

• Weight of floor stand:

Models LX-50 - LX-100: 24 lbs (11 kg),

Model LX-150: 30 lbs (14 kg)

• Allows for condensate piping/pump

• Bottom supply water connection is located underneath the side

water connection. See fill valve connection position on page 13.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

16

Page 19

INSTALLATION

Optional floor stand mount (Models 50, 75,100, and 150 only)

FIGURE 17-1: LX SERIES WITH FLOOR STAND MOUNT (MODELS 50, 75, AND 100)

B

See "Indoor unit dimensions" on page 13-1.

A

C

21.125" (537mm)

OM-7970

OM-7962

FIGURE 17-2: LX SERIES WITH FLOOR STAND MOUNT (MODEL 150)

B

See "Indoor unit dimensions" on page 13-1.

A

C

21.125" (537mm)

OM-8021

OM-8022

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

17

Page 20

INSTALLATION

Optional wall mount (Models 50, 75 and 100 only)

FIGURE 18-1: LX SERIES WITH WALL MOUNT

42.75"

(1086 mm)

20.13"

(511 mm)

23.13" (587 mm)

22.88" (581 mm)

See "Indoor unit dimensions" on page 13-1.

24.63" (626 mm)

OM-7993

OM-7992

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

18

Page 21

INSTALLATION

Outdoor enclosure

GENERAL DESCRIPTION

Overview

• The outdoor GTS is CSA/ETL approved for installation outdoors. It uses an

optional heater and fans to properly operate in operating temperatures of

-40 ºF to 122 ºF (-40 ºC to 50 ºC). The unit is intended to be mounted on

a concrete pad or rooftop curb. Properly sized curbs are available from

DriSteem.

• The knockouts located on the front of the unit are used to run electrical

power and gas to the unit. There is a pipe chase located inside the

enclosure that is used for both the supply water and drain piping. Supply

water and drain piping will need to come through the knockouts at the front

of the unit if the chase cannot be used. Combustion air is drawn from within

the enclosure, and flue gas is vented out the back of the enclosure.

• An emergency drain is provided on the front of the unit. In case of a water

leak, water drains onto the roof through this emergency drain. The drain is

intended to have a field installed water seal.

• If constant monitoring of the unit is desired, or if the unit is located in a

severe climate, install a remote mount display. Additional cable lengths up

to 500’ (152 m) are available as an option.

• In cold climates, Freeze Protection Piping (see page 25), is an important

component to the proper operation of the outdoor humidifier.

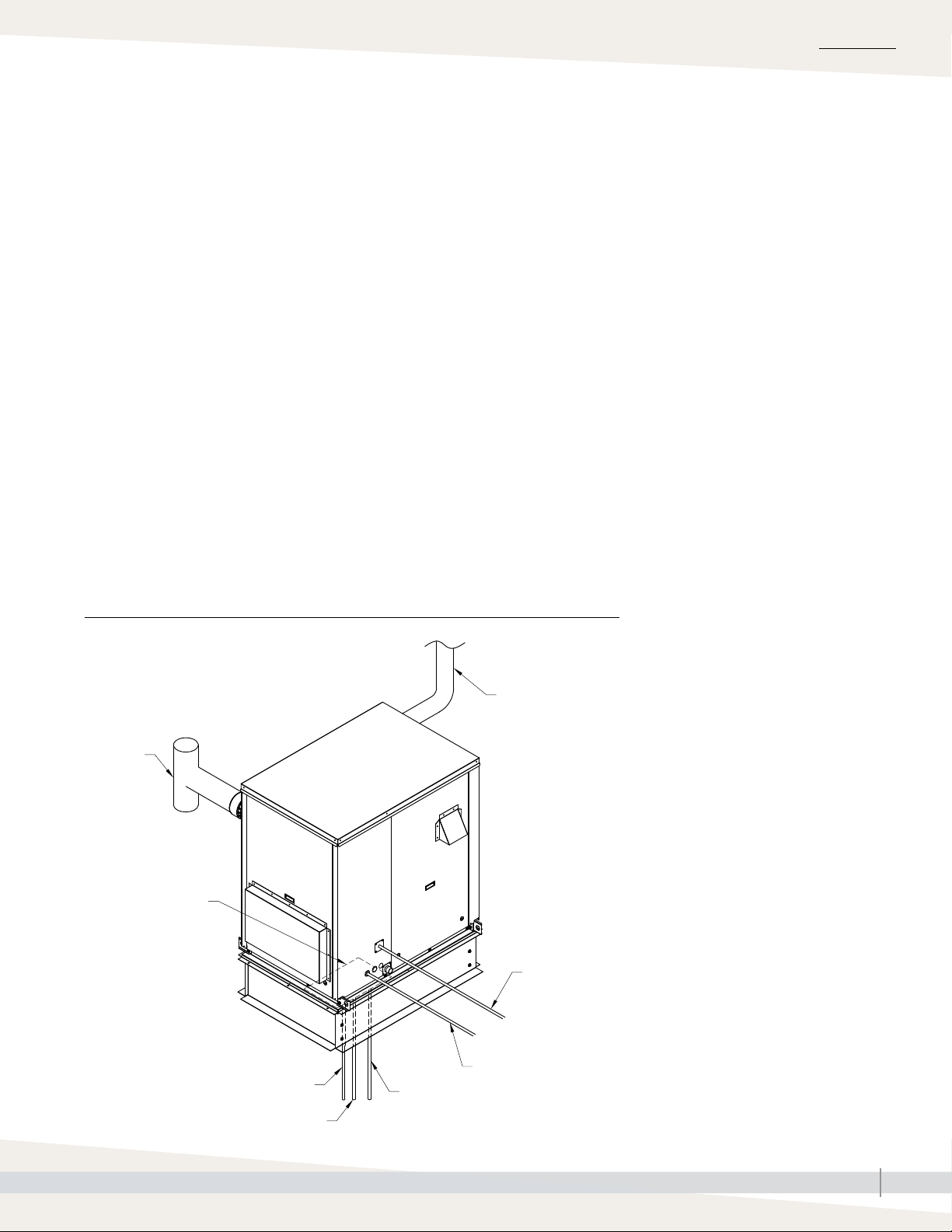

FIGURE 19-1: OUTDOOR ENCLOSURE TYPICAL INSTALLATION OVERVIEW

Steam outlet to

rooftop AHU

dispersion

Flue vent

Pipe chase

Gas piping

Flue condensate drain

Drain piping

Electrical

Fill

connections

OM-8004

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

19

Page 22

INSTALLATION

Outdoor enclosure: Operation

If the ambient temperature in the enclosure is below 50 ºF (10 ºC), the heater

is powered up. The heater remains powered up until the enclosure reaches

50 ºF (10 ºC). When there is no call for humidity, an aquastat maintains tank

temperature at the factory default of 50 ºF (10 ºC). This temperature can be

reset in the field to be from 50-180 ºF (10-82 ºC). If for any reason the tank

temperature falls below 40 ºF (4 ºC), the tank will drain to keep the unit from

freezing.

When the temperature of the enclosure reaches 85 ºF (29 ºC), the ventilation

fans turn on to cool the electronic components. If the enclosure temperature

reaches 150 ºF (66 ºC), the Vapor-logic controller will extinguish any

operating burners and allow the ventilation fans to cool the enclosure. When

the enclosure temperature falls below 150 ºF (66 ºC), the GTS humidifier

automatically resumes normal operation.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

20

Page 23

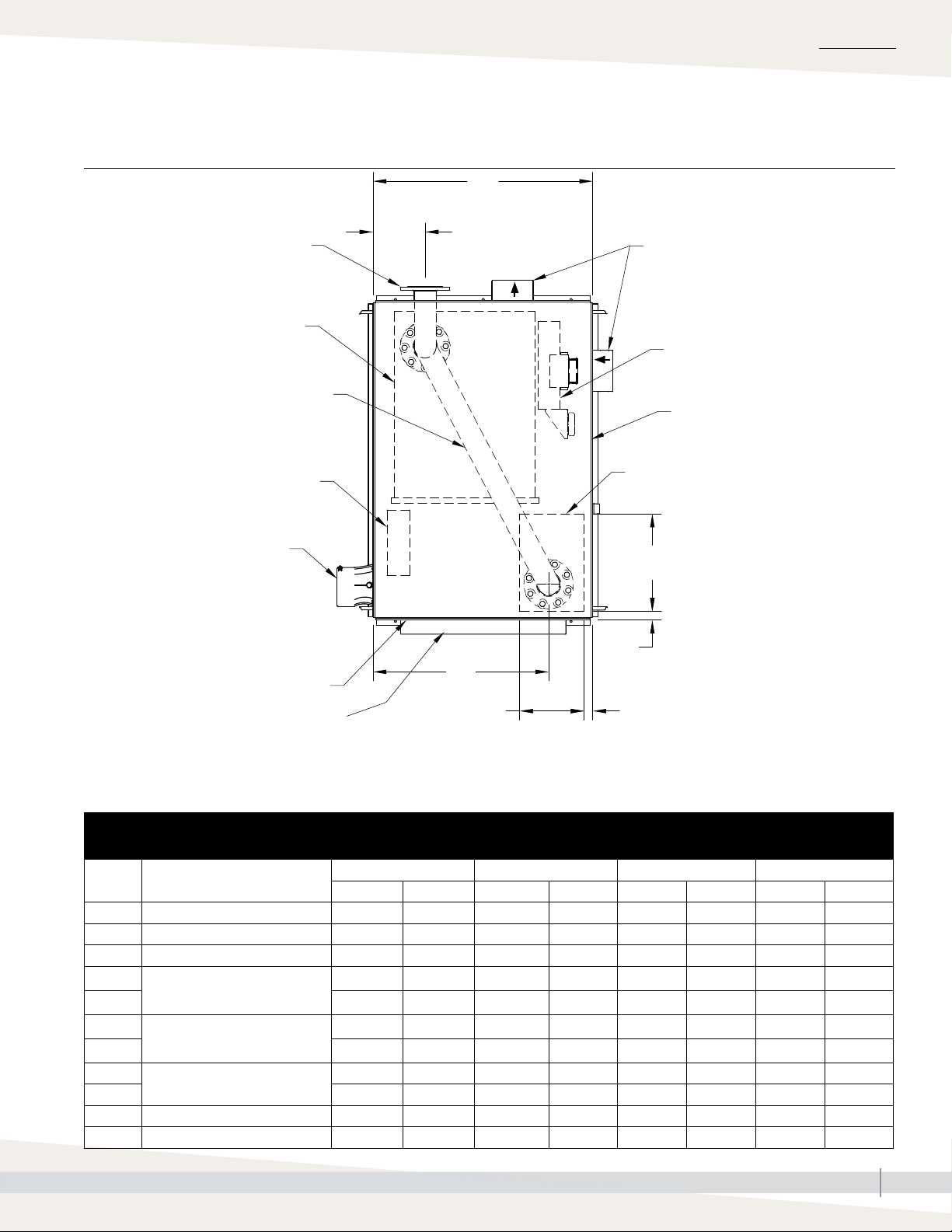

Outdoor enclosure: Dimensions

FIGURE 21-1: OUTDOOR ENCLOSURE TOP VIEW

INSTALLATION

B

Exit for standard steam outlet

GTS humidifier LX series

Exit for optional steam outlet

(through pipe chase)

Heater

Flue (by installer)

Access panel door

Air intake

H

J

F D

Ventilation fans

Control cabinet

Access panel door

Pipe chase

G

E

OM-8010

DIMENSIONS

• For outdoor unit weights, see Table 11-1.

• For clearances, see Figure 15-1.

Table 21-1:

Outdoor unit dimensions

Description

A Enclosure length 36 914.4 45 1143 57.35 1456.59 57.35 1456.59

B Enclosure width 27.35 694.7 27.35 694.7 27.35 694.69 39.10 993.04

C Enclosure height 57 1447.8 57 1447.8 62 1574.8 62 1574.8

D

Pipe chase position

E 6.51 165.28 6.51 165.3 2.048 52.02 2.05 52.04

F

Pipe chase size

G 11 279.4 11 279.4 16 406.4 16 406.4

H

Steam pipe position

J 22.61 574.2 21.33 541.76 22.16 562.84 31.48 799.36

K Curb height 14.0 - 36.0 356 - 914 14.0 - 36.0 356 - 914 14.0 - 36.0 356 - 914 14.0 - 36.0 356 - 914

L Height to bottom of flue outlet 47.0 1194 47.0 1194 45.0 1143 45.0 1143

LX-50, LX-75, LX-100 LX-150 LX-200, LX-250, LX-300 LX-400, LX-500, LX-600

inches mm inches mm inches mm inches mm

2.05 52.02 2.05 52.02 2.425 61.60 2.05 52.02

7 177.8 7 177.8 10 254 10 254

6.96 176.78 6.96 176.79 9.214 234.04 8.965 227.61

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

21

Page 24

INSTALLATION

Outdoor enclosure: Location

• The following information is not intended to supersede any requirements of

federal, state, or governing codes having jurisdiction; prior to locating the

unit, authorities having jurisdiction should be consulted.

• The GTS must be level and located so there is enough clearance for

opening the access panels (see recommended clearances on Page 15).

• Do not locate unit in areas where the surrounding air has high levels of

particulates, such as some industrial parks or areas near highways. In

situations such as these, you will need to filter the air inlets.

• The unit should be located so prevailing winds do not blow into the air

intakes.

• When located on the roof, the air intakes must be a minimum of 14”

(360mm) off the roof to prevent intake of snow or splashed rain.

• Locate unit so air intakes are not too close to other exhaust fan outlets,

gasoline storage, or other contaminants that could potentially cause

dangerous situations. Using and storing gasoline or other flammable vapors

and liquids in open containers near this appliance is hazardous.

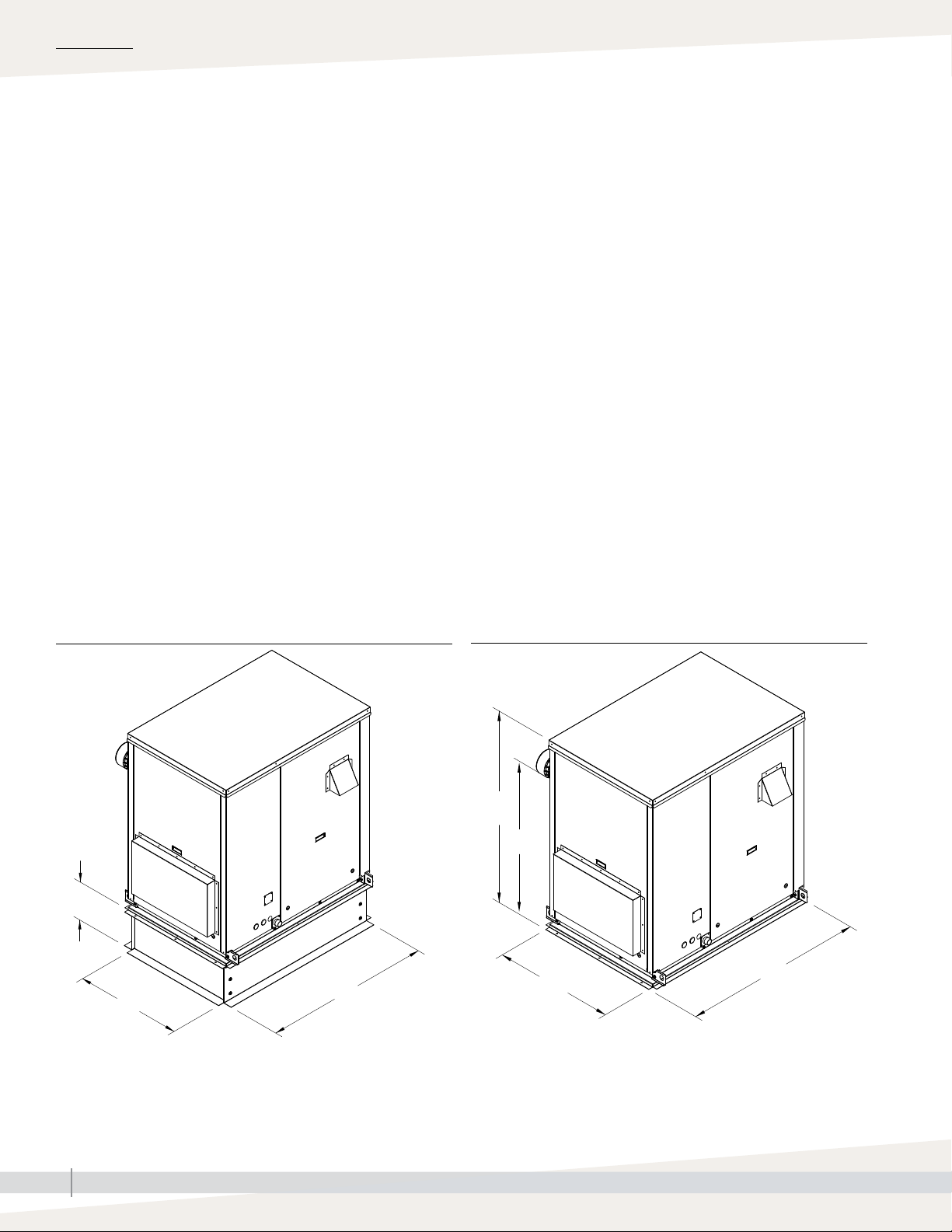

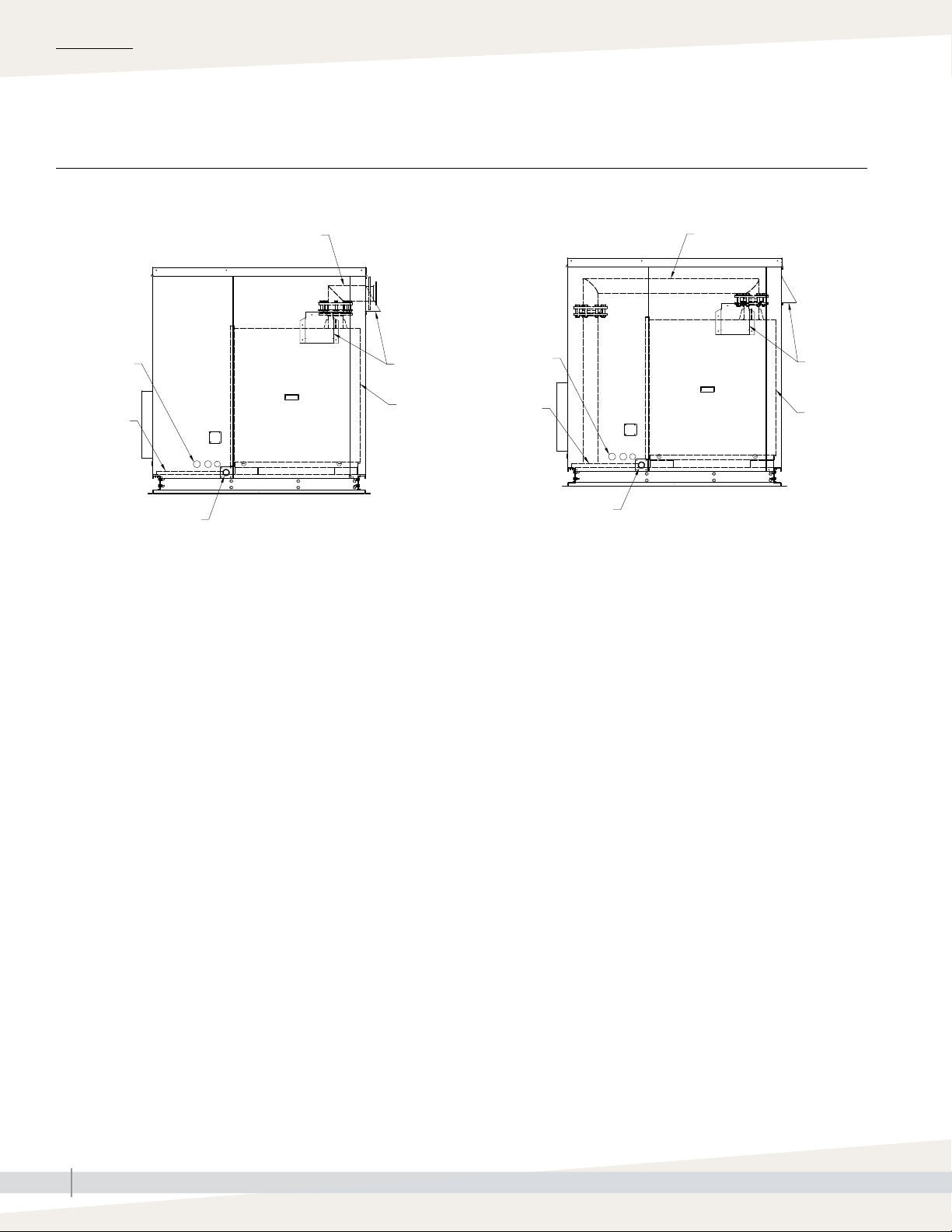

FIGURE 22-1: OUTDOOR ENCLOSURE MOUNTED ON A CURBBFIGURE 22-2: OUTDOOR ENCLOSURE MOUNTED FLUSH

C

L

K

A

B

A

OM-8008 OM-8009

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

22

Page 25

Outdoor enclosure: Mounting

• Verify that the position of the pad or curb properly supports the unit and

that support structure dimensions coincide with unit dimensions.

• DriSteem rooftop curbs are shipped knocked down for ease of transporting

to the roof. The curb is manufactured out of 14-gauge galvanized steel

and is shipped with all hardware for bolt-together assembly, a curb gasket

for sealing between the curb and the unit, and an installation drawing. All

holes are matched before leaving the factory.

• Roof curbs supplied by others must be at least 14” high, and there must

be a gasket between the top of the curb and the base surface of the unit to

prevent moisture from leaking into the building from either driving rain or

melting snow.

• Prior to installation, remove all of the unit packaging.

• The GTS outdoor enclosure must be lifted by the lift plates (See Figure

23-1) on the base of the unit. It must be lifted in a fashion that holds it

level and keeps it from tipping, falling, or twisting.

INSTALLATION

• If the unit is severely twisted during handling, permanent damage can

occur.

• It is the installer’s responsibility to verify the handling equipment’s

capability to safely handle the unit.

• All lifting operations must be accomplished with a load spreader of

sufficient width to ensure that the lifting cables clear the side of the unit.

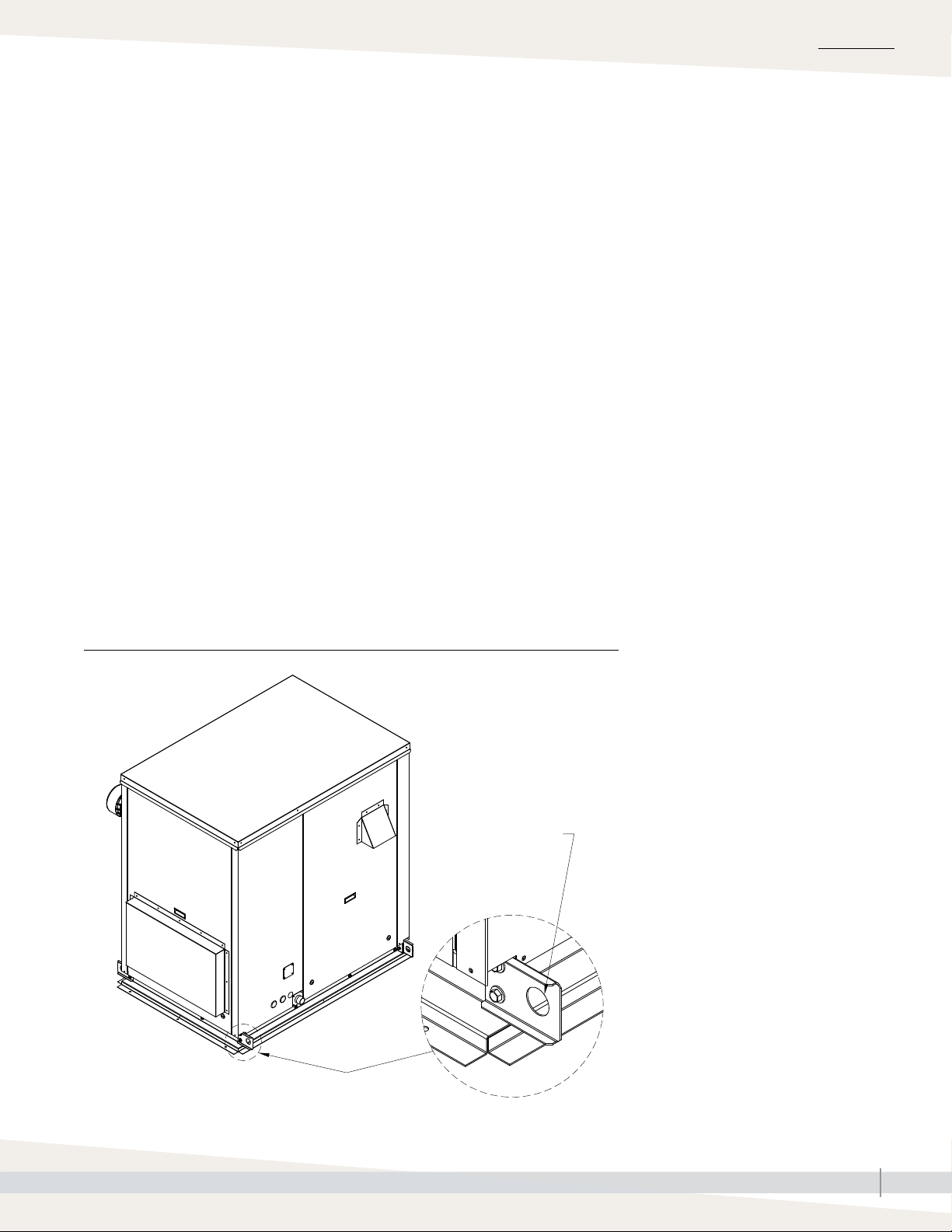

FIGURE 23-1: OUTDOOR ENCLOSURE MOUNTING WITH LIFT BRACKET

1-1½" dia 938 mm) hole

lifting bracket in each

corner (typical of 4)

OM-8011

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

23

Page 26

INSTALLATION

Outdoor enclosure: Piping

FIGURE 24-1: GTS OUTDOOR ENCLOSURE WITH STANDARD OR OPTIONAL STEAM OUTLET, ELEVATION VIEW

Standard steam outlet Optional steam outlet

Steam outlet

1½" (38 mm)

knockouts 4"

(102 mm) o.c.

Pipe chase

Emergency

drain

OM-8006

Ventilation

fans

GTS LX

humidifier

See Piping beginning on Page 28 for directions on

installing water, drain, flue gas condensate, and gas

on the GTS humidifier LX series. For Outdoor Enclosure

specific items, see below.

Steam outlet

1½" (38 mm)

knockouts 4"

(102 mm) o.c.

Pipe chase

Emergency drain

FLUE GAS CONDENSATE

Ventilation

fans

GTS LX

humidifier

OM-8007

For cold climates, do not drain condensate on roof. This

will cause the condensate to freeze and back up. Follow

local code requirements.

SUPPLY WATER AND DRAIN

• Using the pipe chase

Use insulation to completely fill the area around

the pipes in the chase to maintain proper enclosure

pressure and protect unit components from elevated

moisture levels within the building; insulation must

serve as an effective vapor barrier.

Use the provided pipe chase cover to seal off the pipe

chase. Cut necessary holes, and seal after installation.

• Using the knockouts on the front of the unit

Heat trace and insulate piping if freezing temperatures

is a concern.

• Insulate supply water piping inside the unit to avoid

dripping from condensation.

• For cold climates, see Freeze Protection Piping on Page

25.

STEAM

The humidifier has two available steam distribution

configurations. The standard configuration has a steam

outlet on the right side of the enclosure. The optional

internal steam distribution configuration routes steam

within the enclosure and down through the pipe chase into

a building.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

24

Page 27

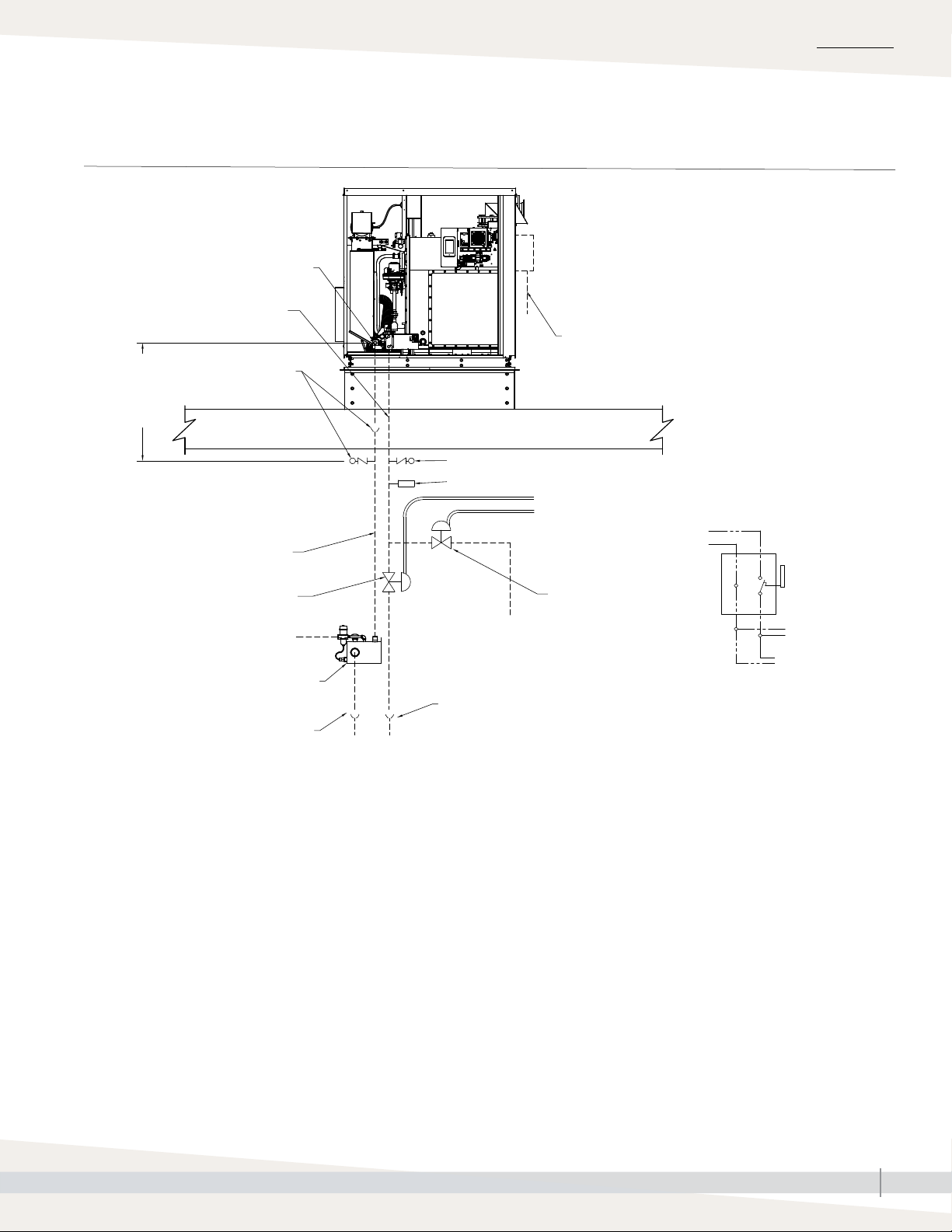

Outdoor enclosure: Freeze Protection Piping

FIGURE 25-1: OUTDOOR ENCLOSURE FREEZE PROTECTION PIPING

GTS humidifier in Outdoor Enclosure installed on rooftop

INSTALLATION

Drain connection

Supply water piping

(by installer)

Install open

drain or vacuum

breaker within

12" (305 mm)

vertical

Open drain or

vacuum breaker

(by installer)

Heated building interior

Typical drain line, min. 1½"

Normally open (fail open) minimum

8 gpm electric valve (by installer)

Domestic water, 20-80 psig

(582 kPa) maximum

Optional Drane-kooler water

tempering device

Open drain (See Note 4)

Disconnect (by installer); see Detail A

120 V supply (230 V in Europe)

Roof decking

Vacuum breaker (by installer)

Water hammer arrestor (by installer)

120 V (230 V in

Europe) from unit

disconnect or other

source (See Note 2)

Normally closed

(fail closed)

minimum

Domestic water,

20-80 psig (582

kPa) maximum

Open drain

(See Note 4)

8 gpm electric valve

(by installer)

Detail A

120 V

(230 V in

Europe)

N

Disconnect

box

To supply and drain

valves (by installer)

(See Note 2)

To GTS LX humidifier

OM-8005

Piping notes:

1. Insulate supply water piping to avoid dripping from condensation.

2. To ensure that water does not remain in the fill line and freeze if there is a loss of power, use field installed additional valves upstream of the fill

valve in a conditioned space. Power these valves on the same circuit as the GTS; if the power goes off, water drains out of the fill line to prevent

freezing (see above).

3. In extreme or critical applications in which the unlikely event of a water leak could cause severe damage, use a thermostat with a remote sensor

on the fill line to cut power to the Model LX and safety valves to stop fill water to the Model LX and drain the fill piping when the temperature is

below freezing.

4. Locate 1" air gap only in spaces with adequate temperature and air movement to absorb flash steam; otherwise, condensation may form on

nearby surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

5. If drain water tempering is required in the case of a power outage, install a Drane-kooler water tempering device. Pipe the cold water supplying

the Drane-kooler ahead of the field-installed additional valves mentioned in Note 2.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

25

Page 28

INSTALLATION

Outdoor enclosure: Venting

See General Venting beginning on Page 42 for directions on venting. For

Outdoor Enclosure specific items, see below.

• Flue gas venting should include a 90 degree elbow and end with a tee to

the back of the unit to minimize effects of wind and prevent condensate

from dripping on to the unit. Governing codes prevail.

• Combustion air is drawn from within the DriSteem outdoor enclosure which

is sufficiently vented.

Table 26-1:

Outdoor unit amps and weights

Full Load Amps

Model

LX-50 7.0 4.5 3.0 2.5 479 217 362 164

LX-75 7.0 4.5 3.0 2.5 479 217 362 164

LX-100 7.0 4.5 3.0 2.5 475 216 367 166

LX-150 7.5 5.0 3.5 3.0 629 285 421 191

LX-200 9.0 5.5 5.0 3.5 914 415 564 256

LX-250 9.0 5.5 5.0 3.5 914 415 564 256

LX-300 9.0 5.5 5.0 3.5 916 415 574 260

LX-400 16.5 8.5 7.5 4.5 1606 729 940 426

LX-500 16.5 8.5 7.5 4.5 1606 729 940 426

LX-600 16.5 8.5 7.5 4.5 1612 731 962 436

** Add approximately 60-90 lbs (27-41 kg) for packaging material.

(Heater Package)

120V 60 Hz 230V 50Hz 120V 60Hz 230V 50Hz lbs kg lbs kg

Full Load Amps

(No Heater Package)

Operating weight Shipping (empty) weight*

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

26

Page 29

Wiring

INSTALLATION

WARNING

Grounding

Installation must meet the requirements of governing codes or, in the absence of

governing codes, in accordance with the National Electrical Code, ANSI/NFPA

70, or Canadian Electrical Code, CSA C22.1, or IEE wiring regulations (BS7671).

The electrical subpanel must have an uninterrupted or unbroken ground to minimize

personal injury if an electrical fault should occur. This ground can consist of electrical

wire or conduit approved for electrical ground when installed in accordance with

existing electrical codes. Do not use gas piping as an electrical ground.

• GTS humidifiers must be supplied with 120 Vac, 60 Hz (North American

models) or 230 Vac, 50 Hz (European models) separately fused electrical

service. The GTS humidifier is equipped with transformers to step down the

voltage to 24 Vac control voltage.

• When installed, the GTS humidifier must be electrically grounded in

accordance with governing codes or, in the absence of governing codes,

in accordance with the National Electrical Code, ANSI/NFPA 70; or

Canadian Electrical Code, CSA C22.1; or IEE wiring regulations (BS7671).

• In North America, the electrical conductors shall be Type MTW (105 °C)

AWG #14 (2.5 mm2) wire for 120 V line voltage , with BLACK WIRE

for HOT, WHITE WIRE for NEUTRAL, GREEN AND YELLOW WIRE for

GROUND. Units with Outdoor Enclosure must use AWG #12 (4 mm2) for

120 V line voltage. Use #18 gauge (1 mm2) for control wiring.

WARNING

Fire hazard

Do not connect aluminum wire between

disconnect switch and humidifier. Use

only copper wire. Failure to follow

these instructions could cause a fire,

resulting in severe bodily injury, death,

or significant property damage.

• In Europe, the electrical conductors shall be Type MTW (105 °C) 2.5 mm2

wire for line voltage (230V), with BLACK WIRE for LINE, BLUE WIRE for

NEUTRAL, GREEN AND YELLOW WIRE for GROUND, and 2.5 mm2 wire

for control wiring.

• All electrical components and wiring must be protected from mechanical

damage and water. The control system requires an earth ground for proper

operation.

• The GTS humidifier is adjusted for correct performance at the factory. Only

a qualified gas appliance technician may alter throttle setting.

• Check the electric current characteristics and capacity requirements against

the nameplate. All wiring must be in accordance with all governing codes

and with the GTS wiring diagrams located inside the control cabinet. See

the electrical specifications in Table 11-1 (North America) and Table

81-1 (Europe).

• Refer to the Vapor-logic Installation and Operation Manual for additional

information on the controller furnished with this GTS humidifier.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

27

Page 30

INSTALLATION

Piping

FIGURE 28-1: LX SERIES FIELD PIPING OVERVIEW - MODELS LX-50 THROUGH LX-150

Shock arrester recommended to reduce

water hammer (by installer)

Steam hose or tubing

Steam outlet

Flue gas vent

Combustion air intake

7/8" (22mm) electrical field connection

Install level

Offset humidifier from floor drain to prevent

flash steam from rising into the humidifier

1" NPT (DN25) drain piping must be rated

for 212 °F (100 °C) (by installer)

1" (25 mm) air gap or

vacuum breaker

Open drain required. See first note below.

Supply water line; water pressure range

25 to 80 PSI (172 to 582 kPa); water

Install level

OM-7952

Gas inlet connection

Flue gas condensate

(see page 36)

Notes:

• Locate air gap only in spaces with adequate temperature and air

movement to absorb flash steam; otherwise, condensation may form

on nearby surfaces. Refer to governing codes for drain pipe size and

maximum discharge water temperature.

• Dashed lines indicate provided by installer.

• Humidifier flue gases must be vented to the outside atmosphere.

• Supply water inlet is more than 2" (51 mm) above skim/overflow port,

eliminating the possibility of backflow or siphoning from tank. No

additional backflow prevention is required; however, governing codes

prevail.

• For additional backflow prevention installation, install at a minimum of

40' (12 m) from the humidifier.

• Damage caused by chloride corrosion is not covered by your DriSteem

warranty.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

28

Page 31

INSTALLATION

Piping:

FIGURE 29-1: LX SERIES FIELD PIPING OVERVIEW - MODELS LX-200 THROUGH LX-600

Overview

Steam hose or tubing

Steam outlet

Install level

Combustion air intake

Flue gas vent

7/8" (22mm) electrical

field connection

Shock arrester recommended to reduce

water hammer (by installer)

Supply water line; water

pressure range 25 to 80 PSI

(172 to 582 kPa); water

Install level

Flue gas condensate

(see page 36)

1" (25 mm) air gap or vacuum breaker

Open drain required. See first note below.

Notes:

• Locate air gap only in spaces with adequate temperature and air

movement to absorb flash steam; otherwise, condensation may form

on nearby surfaces. Refer to governing codes for drain pipe size and

maximum discharge water temperature.

• Dashed lines indicate provided by installer.

• Humidifier flue gases must be vented to the outside atmosphere.

• Supply water inlet is more than 2" (51 mm) above skim/overflow port,

eliminating the possibility of backflow or siphoning from tank. No

additional backflow prevention is required; however, governing codes

prevail.

• For additional backflow prevention installation, install at a minimum of

40' (12 m) from the humidifier.

• Damage caused by chloride corrosion is not covered by your DriSteem

warranty.

Gas inlet connection

Offset humidifier from floor drain to prevent

flash steam from rising into the humidifier

1½" NPT (DN40) drain piping must be

rated for 212 °F (100 °C) (by installer)

OM-7997

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

29

Page 32

INSTALLATION

Connection sizesPiping:

Table 30-1:

Connection sizes

Description

Gas supply 1/2 (pipe thread) 15 1/2 (pipe thread) 15 3/4 (pipe thread) 20 1 ¼ (pipe thread) 32

LX-50, LX-75, LX-100 LX-150 LX-200, LX-250, LX-300 LX-400, LX-600

inches DN inches DN inches DN inches DN

Sealed

combustion piping

Flue vent 3 80 3 80 4 100 6 150

Supply water

Drain 1 (drain block) 25 1 (drain block) 25 1 (drain block) 25 1 (drain block) 25

Steam outlet*

Flue gas

condensate

Condensate return

(recommended)

Notes:

For pipe thread steam outlet options, see DriCalc, DriSteem’s free sizing and selection software, available at www.dristeem.com.

*

STEAM PIPING SUPPORT

3/8 (pipe thread - side)

1/2 (pipe thread - bottom)1015

(all steam: hose/pipe

3 80 3 80 4 100 6 150

3/8 (pipe thread - side)

1/2 (pipe thread - bottom)1015

2

50

(all steam: hose/pipe

thread)

5/8 (OD) 18 5/8 (OD) 18 5/8 (OD) 18 5/8 (OD) 18

3/4 (pipe thread) 20 3/4 (pipe thread) 20 3/4 (pipe thread) 20 3/4 (pipe thread) 20

2

thread)

3/8 (pipe thread - side)

1/2 (pipe thread - bottom)1015

503 (all steam: flange/pipe

thread)

3/8 (pipe thread - side)

1/2 (pipe thread - bottom)1015

804 (all steam: flange/pipe

thread)

100

Support interconnecting piping between the humidifier steam outlet and the

dispersion system with pipe hangers. Failure to properly support the entire

steam piping weight can cause damage to the humidifier tank and void the

warranty.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

30

Page 33

INSTALLATION

Piping:

FIGURE 31-1: LX SERIES CONDENSATE RETURN FIELD PIPING - MODELS LX-50 THROUGH LX-150

Air vent tube

6" (150 mm) minimum

Condensate return

Optional condensate return piping from dispersion unit, ¾" pipe thread

(DN20) fitting at humidifier

vent height

Condensate return

H

Use union for cleanout plate removal

Access by others

OM-8001

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

31

Page 34

INSTALLATION

Piping:

FIGURE 32-1: LX SERIES CONDENSATE RETURN FIELD PIPING - MODELS LX-200 THROUGH LX-600

Condensate return

Air vent tube

6" (150 mm) minimum

vent height

Optional condensate return piping from dispersion

unit, ¾" pipe thread (DN20) fitting at humidifier

Access by others

H

Condensate return

Manual drain valve (if required)

OM-8000

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

32

Page 35

Supply water and drain overflow connectionsPiping:

AUTOMATIC DRAIN WATER TEMPERING

The GTS humidifier LX series is shipped with drain water tempering enabled.

This feature can be disabled in the Vapor-logic controller. When drain water

tempering is enabled, the following steps will take place to ensure drain water

is less than 140°F (60 °C):

1. Water greater than 140°F (60 °C) is detected in the drain assembly with a

temperature sensor.

2. Fill valves open, directing cool water to the drain port within the tank.

3. Hot and cold water mix in the tank near the drain port.

4. Drain port valve opens and sends tempered water to the drain manifold.

5. The Vapor-logic controller controls the drain and fill valves using input

from the drain temperature sensor to enable closed-loop control of drain

water temperature, thus ensuring it does not exceed 140°F (60°C) while

minimizing water usage.

INSTALLATION

SUPPLY WATER CONNECTIONS

Regardless of the type of water used, the following general instructions MUST

be followed:

• There is one water connection to the humidifier. Water is connected in the

field to the fill water manifold. The fill water manifold provides water to the

humidifier tank and to the secondary heat exchanger. The water provided

to the tank is also used for tempering drain water.

• Make union connections at the humidifier on the make-up water supply and

drain/overflow lines.

• Provide a shutoff valve in the supply water line to isolate the humidifier from

the water system while servicing.

• A shock arrester, provided by installer, is required to reduce water hammer.

• A 2" (51 mm) air gap is provided in the humidifier tank to accommodate

skim and/or overflow protection and prevent water backflow.

• Note: Follow governing code requirements regarding size of drain pipe.

• Use insulating unions or bushings to make connections between copper and

other dissimilar metal fittings, such as galvanized steel. These insulating

fittings are required to minimize electrolytic corrosion, which results from the

direct connection of dissimilar metals in a water system.

• Before beginning ignition sequence of the humidifier at a new installation,

make sure the humidifier tank is full of water and the water is free to flow

into the tank.

• Do not use heated supply water. Using supply water over 90°F (32 °C) will

adversely effect the performance of the GTS humidifier LX series.

• Water inlet and outlet must be permanent pipe connections shown in Table

30-1. Do not connect with hose-sets or other non-permanent methods.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

33

Page 36

INSTALLATION

Supply water and drainPiping:

SUPPLY WATER PIPING

• The GTS humidifier has a 2" (51 mm) internal air gap to prevent back

siphoning into a potable water system. However, some governing codes

may require additional protection such as a vacuum breaker or backflow

preventer.

• The supply water pressure range must be 25 psi to 80 psi (172 kPa to 552

kPa).

• The supply water assembly has both a 3/8" (DN10) pipe thread (side) and

1/2" (DN 15) pipe thread (bottom) connection.

• During an integral drain tempering event, cold water in the internal drop

tube may cause a low rolling sound.

• In cases where water hammer occurs when the fill solenoid closes, a shock

arrester is recommended. Reducing the supply water pressure (minimum

25 psi [172 kPa]) or using flexible tubing (rated for 212 °F [100 °C]

minimum continuous operating temperature) may diminish the noise, but

installing a shock arrester is the best solution.

• The end-of-season feature drains the tank when there is no demand for

humidity for 72 hours. (This length of time is a default setting and is

user-adjustable. See the Vapor-logic Installation and Operation Manual for

more information.)

• Supply water tubing must be rated for at least 80 psi (552 kPa) at 140°F

(60 °C) continuous service.

DRAIN

The drain line piped from the humidifier must be run to an approved sanitary

waste or suitable drain that accommodates a 12 gpm flow rate. Although

the GTS humidifier is equipped with integral water tempering, if nonmetallic

drain pipe or hose is used, it should be rated for 212 °F (100 °C) minimum

continuous operating temperature.

If vertical drop of drain exceeds 12” (305 mm) a vacuum breaker or open

drain with air gap must be installed within 12 vertical inches (305 mm) of unit.

Failure to do so will create a siphon during drain events, disrupting normal

drain operation and allowing steam to enter the drain through the overflow

p-trap outlet (see Figure 35-2).

Important: Damage caused by chloride

corrosion is not covered by your DriSteem

warranty. See “Supply water guidelines” on

Page 8.

Table 34-1:

Supply water guidelines

Supply water

pressure

Supply water

flow rate

Supply water

temperature

25-80 psi

at 6.0 gpm

flow rate

6.0 gpm 21 l/min

34°F to 90°F 1°C to 32°C

172-552 kPa

Table 34-2:

Water tempering specifications

for optional Drain-kooler water

tempering device

Maximum

Water type

Hot water

inflow

Cold water

inflow*

Tempered

water outflow

* Cold water inflow pressure must be between

25 psi and 80 psi (172 kPa and 552 kPa).

Flow rate

U.S.

gpm

L/m °F °C

6 22.7 212 100

6 22.7 90 32

12 45.4 140 60

Maximum

temperature

Ensure the drain piping configuration (diameter, length, slopes, elbows,

hangers, etc.) supports a 12 gpm flow rate for proper drain operation and to

prevent overflow and spillage from an open drain with air gap.

Do not reduce the size of the drain piping. If the length of the drain piping

exceeds 10' (3 m), increase the pipe size. If combining multiple drain lines

together, ensure proper common pipe sizing practices are used.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

34

Page 37

INSTALLATION

Supply water and drainPiping:

Do not locate the humidifier directly above a floor drain — skim and drain

water dumped into the drain will cause flash steam. This steam will rise

and saturate electrical components, adversely affecting component life and

performance.

An open drain or vacuum breaker with a 1" (25 mm) air gap between the

drain piping and the drain is required. Locate air gap only in spaces with

adequate temperature and air movement to absorb flash steam; otherwise,

condensing on nearby surfaces may occur.

Drain piping after the water seal must be pitched a minimum of 1/8"/ft (1%)

toward the drain. Governing codes may require more pitch.

If the proximity of a drain requires the humidifier drain and skim water to be

lifted, use a water pump with capacity of at least 12 gallons per minute (gpm)

or 45.4 litres per minute (L/m). A check valve is required on the discharge of

the pump (see Figure 35-1). Electrical power for the pump is independent of

the humidifier.

The GTS humidifier has an auxiliary 3/4" (20 DN) drain outlet located on or

near the cleanout plate. This drain outlet can be hard-piped during installation

to enable rapid tank draining before maintenance. This outlet can also provide

access for removing scale from the tank bottom. If this connection is used,

install a union to facilitate removal of the cleanout plate.

Drain water tempering

Governing codes may require that the 212 °F

(100 °C) drain and skim/overflow water

from the humidifier be tempered before it is

discharged into the building drain piping. The

GTS humidifier has closed loop integral drain

tempering.

Integral tempering sequence:

1. Water greater than 140 °F (60 °C) is

detected in the drain manifold with a

temperature sensor.

2. Tank fill valve opens and directs cold

water through the tank and toward the

drain.

3. Drain valve opens and sends tempered

water to the drain manifold.

4. Feedback from the drain manifold

temperature sensor will open/close the

drain valve/fill valves to maintain a

maximum of 140 °F (60 °C) in the drain

manifold.

FIGURE 35-1: LIFTING DRAIN WATER FIGURE 35-2: VERTICAL DRAIN

Inlet drain water piping, by installer

Water pump

Note: Size water pump to handle a minimum of 12 gpm (45.4 L/m).

Discharge piping, by installer

Check valve

DC-1117

Install open drain or

vacuum breaker within

12" (305 mm)

Greater than

12" (305 mm)

OM-8023

Open

drain or

vacuum

breaker

(by

installer)

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

35

Page 38

INSTALLATION

Flue gas condensatePiping:

FLUE CONDENSATE PIPING GUIDELINES

• Follow local code requirements for discharge of condensate. The flue gas

condensate will have a 2-4 pH range and may need to be treated prior to

discharge.

• Minimum drain pipe size is 5/8" inside diameter.

• If treatment is needed, DriSteem offers a condensate neutralizer kit.

The neutralizer should be installed per manufacturer instructions below

condensate p-trap level. Avoid obstructions as condensate could be

damaging to surrounding surfaces and articles.

• Prime the condensate p-trap at the base of the secondary heat exchanger.

FIGURE 36-1: GTS SEALED COMBUSTION CONNECTION

- MODELS LX-50 THROUGH LX-150

Combustion air intakeFlue gas vent to outside

24" (607 mm)

6" - 8"

(152 - 203 mm)

Flue gas condensate

½" (13 mm)

Notes:

1. Use flexible tubing that is rated for acidic condensate.

2. All tubing must allow flow away for humidifier to condensate

neutralizer (if equipped).

3. Condensate neutralizer should be installed per manufacturer

instructions below the condensate p-trap level.

4. If floor drain is greater than 5' (1.5 m) from humidifier, use a

5/8" PVC pipe instead of a hose.

5/8" secondary

heat exchanger

condensate

Optional

condensate

neutralizer

5/8" (16 mm)

Open

drain

OM-7967

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

36

Page 39

Flue gas condensatePiping:

FIGURE 37-1: GTS SEALED COMBUSTION CONNECTION - MODELS LX-200 THROUGH LX-600

Combustion air intake

Flue gas vent to outside

INSTALLATION

Optional

condensate

neutralizer

5/8" (16 mm) secondary

heat exchanger condensate

Notes:

1. Use flexible tubing that is rated for acidic condensate.

2. All tubing must allow flow away for humidifier to condensate

neutralizer (if equipped).

3. Condensate neutralizer should be installed per manufacturer

instructions below the condensate p-trap level.

4. If floor drain is greater than 5' (1.5 m) from humidifier, use a ½"

PVC pipe instead of a hose.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5/8" (16 mm)

Open

drain

OM-7995

37

Page 40

INSTALLATION

Piping:

GAS PIPING GUIDELINES

Gas

• After threading and reaming the ends of the pipes, inspect piping and

remove loose dirt and chips.

• Support piping so there are no strains imposed on unit or controls.

• Use two wrenches when tightening piping to unit or controls.

• Provide a drip pocket before each unit and in the line where low spots

cannot be avoided.

• Takeoff to unit should come from top or side of main to avoid trapping

condensate.

• Piping that is subject to wide temperature variations should be insulated.

• Pitch piping up toward unit at least 1/4" (6 mm) per 15' (4.5 m) of

horizontal run.

• Compounds used on threaded joints of gas piping must be resistant to the

harmful action of liquefied petroleum gases.

WARNING

Fire or explosion hazard

Purge air before lighting unit by disconnecting piping at gas control. In no case should

line be purged into heat exchanger. Failure to follow these instructions could cause a

fire or explosion, resulting in bodily injury, death, or significant property damage.

WARNING

Fire hazard

Supply the humidifier only with the

gas type (natural gas or LP gas) listed

on the humidifier name plate. Failure

to supply the humidifier with the listed

gas type could result in burner failure

or a fire, causing property damage,

personal injury, or death.

To convert the humidifier to natural

gas or LP gas, contact DriSteem

Technical Support or your DriSteem

Representative/Distributor.

Important: For North American models,

the recommended supply pressure is 7" wc

(1.75 kPa) for natural gas or 11" wc (1.83

kPa) for LP gas.

For European models, the required supply

pressure is 20 or 25 mbar for natural gas and

30, 37, or 50 mbar for propane gas.

• After installation, check field piping and humidifier gas train for gas leaks.

• Do not use soap solution or open flame on humidifier gas train. A gas leak

detector is recommended.

• Install a ground joint union and a manual shutoff valve immediately

upstream of the unit. Install a plugged tapping upstream of the shut-off

valve, accessible for test gauge connection (see Caution).

• Allow at least 5' (1.5 m) of piping between any high pressure regulator

and unit pipe connection.

• Piping installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, must conform to:

• In the United States: The National Fuel Gas Code, ANSI Z223.1

(latest edition).

• In Canada: Local plumbing or waste water codes and other applicable

codes and with the current code CAN/CGS-B149.1, “Installation

Code for Natural Gas Burning Appliances and Equipment,” or CAN/

CGA-B149.2, “Installation Code for Propane Burning Appliances and

Equipment.”

• In Europe: The National Gas Safety (Installation & Use) Regulations.

CAUTION

Install connection for gas pressure test

gauge

Gas pressure to the humidifier controls

must never exceed 24" wc (6 kPa, 60

mbar), or the gas valve will become

damaged and require replacement.

The gas pressure diagnostic port on

the gas valve can be used to check

pressure. Loosen the screw and push

a 5/16" ID hose over the fitting

connected to a gauge. Remove the

hose and tighten the screw when

finished.

Install a 1/8" pipe thread (DN6)

plugged tapping, accessible for

test gauge connection, immediately

upstream of the gas supply connection

to the appliance.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

38

Page 41

INSTALLATION

Gas (continued)Piping:

• Piping to units should conform with local and national requirements for

type, volume, and gas handled and for pressure drop allowed in the line.

Refer to the tables on this page to determine the gas flow in ft3/hr or m3/hr

for the type of gas and size of unit to install. Using this value and the length

of pipe necessary, determine the pipe diameter. Where several units are

served by the same main, the total capacity, gas flow, and length of main

must be considered. Avoid pipe sizes smaller than 1/2" (DN15). Table

39-2 allows for the usual number of fittings with a 0.3" wc (0.07 kPa)

pressure drop.

• When the specific gravity of the gas is other than 0.60 for natural gas or

1.53 for propane, use Table 39-1.

Table 39-2:

Gas pipe capacities for gas pressures of 0.5 psig (3.45 kPa) or less

3

/hr and m3/hr at pressure drop of 0.3" wc (0.07 kPa)

Specific gravity = 0.60

Nominal iron pipe diameter in inches (DN)

Length of

pipe

ft m ft

Gas flow in piping in ft

1/2" (DN15) 3/4" (DN20) 1" (DN25) 1¼" (DN32) 1½" (DN40)

3

/hr m3/hr ft3/hr m3/hr ft3/hr m3/hr ft3/hr m3/hr ft3/hr m3/hr

Table 39-1:

Specific gravity conversion factors

Natural gas

Specific gravity Factor

0.55 1.04

0.60 1.00

0.65 0.962

Propane gas

Specific gravity Factor

1.50 0.633

1.53 0.626

1.60 0.612

Note:

Use the above multiplying factor with Table:

39-2 when the specific gravity of gas

is other than 0.60 (natural gas) or 1.53

(propane).

10 3 132 3.7 278 7.9 520 14.7 1050 29.7 1600 45.3

20 6 92 2.6 190 5.4 350 9.9 730 20.7 1100 31.1

30 9 73 2.1 152 4.3 285 8.1 590 16.7 890 25.2

40 12 63 1.8 130 3.7 245 6.9 500 14.2 760 21.5

50 15 56 1.6 115 3.3 215 6.1 440 12.5 670 19.0

60 18 50 1.4 105 3.0 195 5.5 400 11.3 610 17.3

70 21 46 1.3 96 2.7 180 5.1 370 10.5 560 15.9

80 24 43 1.2 90 2.5 170 4.8 350 9.9 530 15.0

90 27 40 1.1 84 2.4 160 4.5 320 9.1 490 13.9

100 30 38 1.1 79 2.2 150 4.2 305 8.6 460 13.0

See example on page 40

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

39

Page 42

INSTALLATION

Gas (continued)Piping:

EXAMPLE

For this example, refer to the tables on Page 39.

To determine gas piping size, begin by calculating the cubic feet/hour (ft3/hr)

or m3/hr using the following formula:

• Btuh (kW) input / calorific value of gas

Calorific values are:

• Natural gas: 1025 Btu/ft3 (10.6 kW-hr/m3)

• Propane: 2500 Btu/ft3 (25.9 kW-hr/m3)

For example, if you have a LX-150 operating on natural gas, calculate the ft3/

hr or m3/hr as follows:

• 183,000 Btuh / 1025 Btu/ft3 = 390 ft3 per hour

• 117.2 kW / 10.6 kW-hr/m3 = 11.1 m3 per hour above your calculated

ft3/hr or m3/hr. In this example, you are looking for the next highest

value above 390 ft3/hr (11.05 m3/hr), which is 400 ft3/hr (11.3 m3/hr)

and indicates the use of a 1¼" (DN32) pipe for this application.

Using the same example, if the specific gravity of your natural gas was 0.55

(instead of the 0.60 standard), see Table 39-2 for an adjustment factor.

In this case, the factor would be 1.04, which you multiply by the 390 ft3/hr

(11.05 m3/hr) value. This gives you a new value of 406 ft3/hr (11.49 m3/hr).

Referring again to Table 39-2, you see that for the same 60 ft (18 m) length,

you now need to use 1½" (DN40) pipe due to the change in the specific

gravity of the gas.

Gas leak testing

• When leak-testing the gas supply piping

system, disconnect the humidifier and its gas

shutoff valve during any pressure in excess

of 24" wc (6 kPa). Isolate the humidifier from

the gas supply piping system by closing its

field-installed manual shutoff valve during

any pressure not equal to 24" wc (6 kPa).

• With the burner running at full capacity,

check gas supply pressure at the inlet

pressure tap of the combination gas control

valve.

For North American models, the

recommended supply pressure is 7" wc

(1.75 kPa) for natural gas or 11" wc (1.83

kPa) for LP gas. Perform gas piping purging

as described in ANSI Z223.1 (latest edition)

or in Canada, CAN/CGA-B149 codes. The

minimum supply pressure is 6" wc (1 kPa) for

natural gas or LP gas.

For European models, the required supply

pressure is 20 or 25 mbar for natural gas

and 30, 37, or 50 mbar for propane gas.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

40

Page 43

Gas (continued)Piping:

FIGURE 41-1: GTS GAS PIPING

All Models

INSTALLATION

See page 30 for connection sizes

OM-7953

Drip pocket

Manual gas shutoff valve

Plugged test gauge connection

3” (76 mm) min.

GTS HUMIDIFIER LX SERIES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

41

Page 44

INSTALLATION

General venting

The GTS humidifier is pre-plumbed to support both room air and sealed

combustion. See Warning. Requirements and recommendations for each

follow.

ROOM AIR COMBUSTION

• All fuel burning equipment must be supplied with air for combustion of

the fuel. Sufficient air must be provided to ensure there is not a negative

pressure in the equipment room or space.

• Provide adequate combustion and ventilation air in accordance with

Section 5.3, Air for Combustion and Ventilation, of the National Fuel

Gas Code, ANSI Z223.1 or applicable provisions of governing codes.

Canadian installations must be installed in accordance with sections 7.2,

7.3, and 7.4 of the CAN/CGA.B149 Installation Codes and all authorities

having jurisdiction.