DriSteem GTS-DI Users/installation Instructions And Maintenance Operations Manual

READ AND SAVE THESE INSTRUCTIONS

This manual must be left with the owner and should be accessible for reference.

DRI-STEEM Models

®

®

GTS and GTS-DI

GAS-TO-STEAM HUMIDIFIERS

User's/Installation Instructions

and

Maintenance Operations Manual

WARNING: If the information in this manual

is not followed exactly, a fire or explosion

may result causing property damage,

personal injury, or loss of life.

• Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from an off-site

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

For Toll-Free Technical

Support, Call: 1-800-328-4447

TABLE OF CONTENTS

TO THE PURCHASER AND THE INSTALLER

Thank you for purchasing DRI-STEEM Model GTS® equipment. We have designed and built this equipment to give you

total satisfaction and many years of trouble-free service. Proper installation and operating practices will assure you of

achieving that objective. We therefore urge you to become familiar with the contents of this manual.

DRI-STEEM Humidifier Company

GTS Program Code Nomenclature ...................................... 3

Models GTS and GTS-DI Humidifiers .................................. 4

Safety Precautions ................................................................ 5

Installation

Precautions ................................................................ 6

Required Clearance ..................................................... 6

Locating the Humidifier .............................................. 7

Supply Water and Drain Overflow Connections ........ 7

Drain Piping and Material ........................................... 8

Make-up Water Piping and Material .......................... 8

Vapor Hose Piping ..................................................... 8

Gas Piping ................................................................. 9

Gas Leak Testing ....................................................... 9

Electrical .................................................................... 10

Combustion and Ventilation Air .................................. 10

Venting Guidelines (Stack Connection) ..................... 11

Specifications and Capacities ............................................. 13

Dimensions ........................................................................... 14

Piping Diagrams: Gas, Water, and Drain ........................... 15

Mounting the Humidifier ..................................................... 16

Steam Supply Connection Methods ................................... 17

Dispersion Tube Installation ............................................... 18

RAPID-SORB

®

Assembly and Installation

Horizontal Duct Installation .....................................19

Vertical Duct Installation .........................................20

ULTRA-SORB

®

Installation .................................................. 20

AREA-TYPE Application ...................................................... 21

Start-up and Operation ........................................................ 22

Maintenance

GTS (Standard Model Only) ...................................... 23

GTS-DI Model Only ................................................... 23

Both GTS and GTS-DI ............................................... 24

Air Shutter Adjustment Procedure ............................. 25

Replacement Parts ............................................................... 26

Wiring Diagrams ..................................................................28

Caution Labels ..................................................................... 32

Gas Control Valve ................................................................ 33

Maintenance Service Record .............................................. 34

Two-Year Limited Warranty ................................................ 36

2

GTS PROGRAM CODE NOMENCLATURE

GTS PROGRAM CODE NOMENCLATURE

1

How many tanks are in the system

(1-6)

What type of control does the unit have

S - Single staged

E - Externally staged

Z - Zone valve

T - TP

X – Slave

M – Master

Does the unit have VAV

V - Yes

O - No

Does the unit have temperature compensation

T - Yes

O - No

Humidity sensor type

C - 0-135 OHM humidistat Electric

D - 6-9 VDC humidistat

F - 1-10 VDC humidistat

E - 4-20 mA humidistat

X - 4-20 mA transmitter

S - Slave

N - None (On/Off)

P – 0-135 OHM humidstat Pneumatic

O

O

X

7

8A

(Example)

T

Burner size

5-50 MBH

7-75 MBH

1-100 MBH

6-67.5 MBH

Burner quantity

1 - One staged

2 - Two staged

4 - Four staged

5 - One modulating

6 - Two modulating

8 - Four modulating

Water level control

D - DI with manual drain

E - DI with auto drain (end of season)

M - Probe with manual drain

A - Probe with auto drain

3

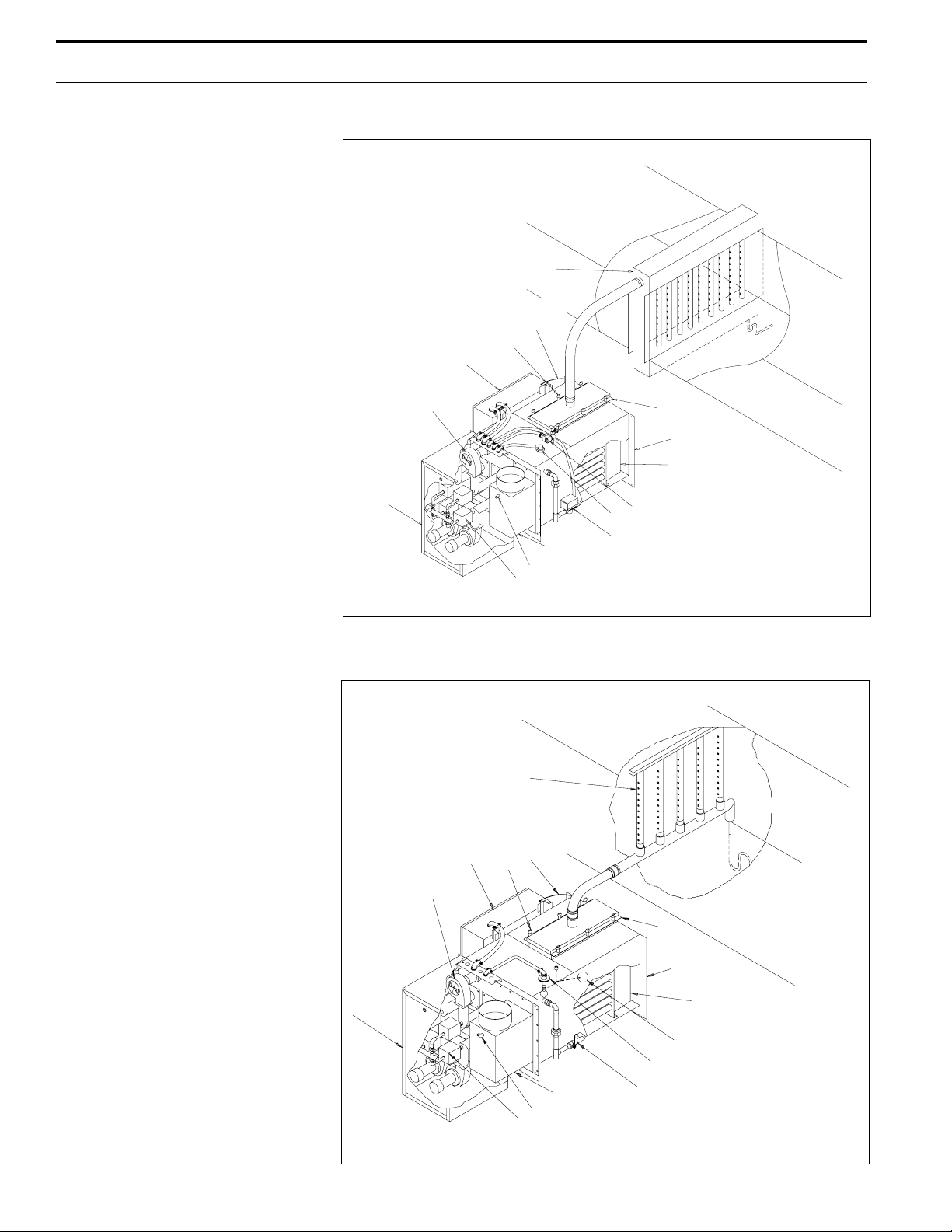

GTS Gas-to-Steam

Humidifier

This humidifier is designed to be

used with either softened or

unsoftened water. (Softening is

recommended to reduce need for

cleaning.) The probe-type level

control system requires water

conductivity of 100 micromhos/cm,

this translates to about 2 grains/gal

minimum to function, and therefore

will not operate on water treated by

reverse osmosis or deionization.

However, GTS humidifiers are

available for use with these water

types. The standard humidifier can

be converted in the field to a demineralized model. See below.

GTS® AND GTS-DI HUMIDIFIERS

®

Low-Water

Switch

Control Panel

Blower

ULTRA-SORB

Cover

Knob

Cover

Evaporating

Chamber

Heat Exchanger

GTS-DI Option

For use with deionized or reverse

osmosis water. This unit produces

chemical-free steam and reliable,

accurate humidification control. It

is virtually maintenance-free, with

no wasted water, heat, or downtime.

The DI unit uses a float valve to

control water levels.

Shroud

RAPID-SORB

Control Panel

Blower

Gas Valve

Cover

Knob

Flue Box

Blocked Vent Tap

®

Low-Water

Switch

Fill Valve

Probes

Manual or

Electric Drain Valve

Cover

Evaporating

Chamber

OM-730

Shroud

Flue Box Drain Valve

Blocked Vent Tap

Gas Valve

Heat Exchanger

Float Valve

Low-Water Cut-Out

OM-735

4

SAFETY PRECAUTIONS

WARNING:

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide

poisoning, an explosion, fire, electrical shock, or other

conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency,

local gas supplier, or your distributor or branch for

information or assistance. The qualified installer or

agency must use only factory authorized and listed kits

or accessories when modifying this product. A failure

to follow this warning can cause electrical shock, fire,

personal injury, or death.

• Inspect humidifier and accessories upon arrival for

damaged, missing, or improper parts. If there is a

problem, call DRI-STEEM.

• Application of this humidifier should have special

attention given to vent sizing and material, gas input

rate, and unit sizing. Improper installation or misapplication of the humidifier can require excessive servicing

or cause permanent component failure.

• When working on equipment, observe precautions in

this literature, tags, and labels attached to or shipped

with the unit and other safety precautions that may

apply. Wear safety glasses and work gloves. Have fire

extinguisher available during start-up, adjustment

procedures, and service calls.

• Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

• Do not lift humidifier by gas controls, gas manifold,

fire box, or control shroud.

• Should overheating occur, or the gas supply fail to

shut off, shut off the manual gas valve to the appliance

before shutting off the electrical supply.

5

INSTALLATION

Precautions

• The installation must conform to the requirements of

the authority having jurisdiction or, in the absence of

such requirements, to the National Fuel Gas Code,

ANSI Z223.1 (latest edition). In Canada, the installation

of this unit must comply with local plumbing or waste

water codes and other applicable codes and with the

current code CAN/CGS-B149.1 "Installation Code for

Natural Gas Burning Appliances and Equipment" or

CAN/CGA-B149.2, "Installation Code for Propane

Burning Applications and Equipment."

• Do not install in potentially explosive or flammable

atmospheres laden with grain dust, sawdust, or similar

airborne materials.

• Installation of humidifier in high humidity or salt water

atmospheres will cause accelerated corrosion, resulting

in a reduction of the normal life-span of the unit.

• To prevent premature heat exchanger failure, do not

locate ANY gas-fired unit in areas where chlorinated,

halogenated or acid vapors are present in the atmosphere.

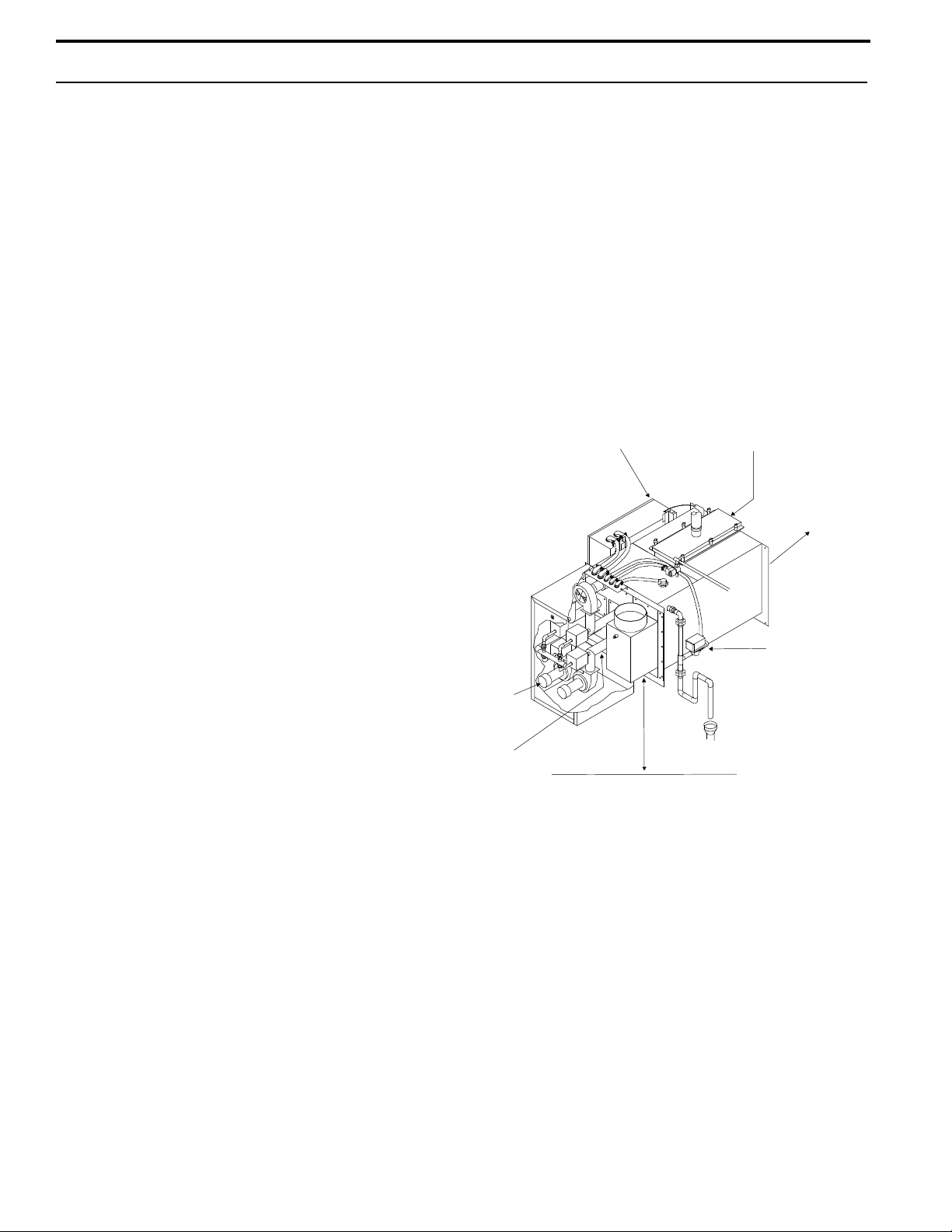

Required Clearance:

For recommended service and maintenance purposes the

following clearances should be maintained:

• Heat exchanger removal - front, 30"

• Burner shroud removal - front, 24"

• Control cabinet - left side, 36"

• Drain valve - right side, 12"

• Clean-out tray - rear, 30"

(not applicable with DI/RO systems)

• Cover removal - top, 18"

• Distance from vent box to combustible

floor - 30"

GTS clearance recommendations

Control cabinet, 36"

Cover, 18"

Cleanout tray, 30"

• Locate the humidifier in an area clear of combustible

materials, gasoline, and other flammable vapors and

liquids.

• Do not locate units in tightly sealed rooms or small

compartments without provision for adequate combustion

air and venting. Combustion air must be supplied to the

room through a minimum of two permanent openings in

the wall, at least one near the bottom. The openings

should provide one square inch of free area per 1000

BTUH input rating of the unit with a minimum of 100

square inches for each opening, whichever is greater.

See table 10-1 and information on pages 10 and 11 for

additional details.

Burner

shroud,

24"

Heat exchanger, 30"

Drain valve, 12"

30"

Floor

6

INSTALLATION

Important:

• Remove all shipping brackets and materials before

operating the humidifier.

• Humidifier flue gases must be vented to the outside

atmosphere.

• Power supply disconnect switch must be in the off

position while making wiring connections to prevent

electrical shock and equipment damage. All units must

be wired in strict accordance with wiring diagram furnished

with this unit.

• Turn off all gas while installing the run-out and manual

shut-off valve for the humidifier.

Locating the Humidifier

• Provide a level, solid foundation for the humidifier.

Locate the humidifier as near as possible to chimney or

outside wall so that the flue pipe from the humidifier is

short and direct. The location should also be such that

the gas ignition system components are protected from

water during humidifier operation and service.

Supply Water and Drain Overflow

Connections

IMPORTANT: The humidifier is shipped with the automatic drain valve locked in the manual open position.

This position reduces the possibility of damaging the

valve seat from the heat of sweating the drain connection

during installation. After the drain connection has been

completed the "manual open" lever position must be reset

to the auto position. Failure to close the drain valve will

not allow the tank to fill.

Regardless of the type of water used, the following

general instructions must be followed:

• Union connections must be made at the humidifier on

the cold water supply and drain/overflow lines.

• A shut-off valve should be provided in the supply water

line to isolate the humidifier from the water system while

servicing.

• If the water pressure is above 60 psi and/or water

hammer would be objectionable, a pressure reducing

valve or shock arrester should be installed.

• The humidifier should be installed in a location away

from drafts and properly protected. If installed in a

separate room, follow the instructions concerning

combustion and ventilation air.

• The humidifier should be located in an area where

leakage from the tank or its connections will not result

in damage to the adjacent structure or to lower floors of

the structure. When such locations cannot be avoided,

it is recommended that a suitable drain pan, adequately

drained, be installed under the humidifier. The pan must

not restrict combustion air flow.

• The humidifier must not be installed on carpeting, tile,

or other combustible material other than wood flooring

(indoor application only).

• Install humidifier so electrical components are protected from water.

• The appliance must be kept free and clear of insulating materials when located in an insulated space.

Insulating material may be combustible. Inspection of

the appliance area must be performed when the appliance is installed, or when insulation is added.

• A 3/4” opening is provided in the humidifier tank to

accommodate skim and/or overflow protection. A water

seal is required on the drain/overflow connection and a 1”

air gap should be provided prior to a building drain. (Note:

Follow local code requirements regarding size of drain

pipe.) The water seal must be piped to hold steam in the

humidifier and also provide a pressure relief if the steam

outlet becomes clogged. (See diagram on page 15)

• Insulating unions or bushings must be used to make

connections between copper and other dissimilar metal

fittings, such as galvanized steel. These insulating

fittings are required to minimize electrolytic corrosion,

which results from the direct connection of dissimilar

metals in a water system.

• Before beginning ignition sequence of the humidifier at a

new installation, be sure the humidifier tank is full of water

and the water is free to flow into the tank.

7

INSTALLATION

Drain Piping and Material

Drain piping diagrams are provided on page 15. If nonmetallic pipe or hose is used, it must be capable of

withstanding temperatures up to 212°F.

To prevent steam from escaping out the drain line, a

water seal must be provided in the drain line of sufficient

height to contain the pressure developed within the

humidifier and steam dispersion system. To determine

the proper height of the water seal, see table 15-1 on

page 15.

Make-up Water Piping and Material

Make-up water piping diagrams are provided on page 15.

Minimum make-up water pressure must be 25 psig.

When non-metallic water piping is used, it must be rated

to withstand 212°F or greater temperature. If not, the

final 3 feet connected to the humidifier should be metallic

and should not be insulated.

As part of the fill valve assembly, the needle valve

restricts the rush of cold water entering the evaporating

chamber during the fill cycle. Adjusting the supply water

flow with the needle valve will reduce fill cycle noise

from the collapsing steam head in the humidifier. Adjusting the needle valve will also reduce the drop in

output during a fill cycle. Care must be taken to not

reduce the fill rate below the humidifier's capacity, this it

will cause a low-water shutdown.

Vapor Hose Piping

When a vapor hose and stainless steel dispersion

tubes are used, they should be pitched back to the

humidifier. A minimum slope of 2" per foot (with no “low

spots”) is recommended. When this is not possible due

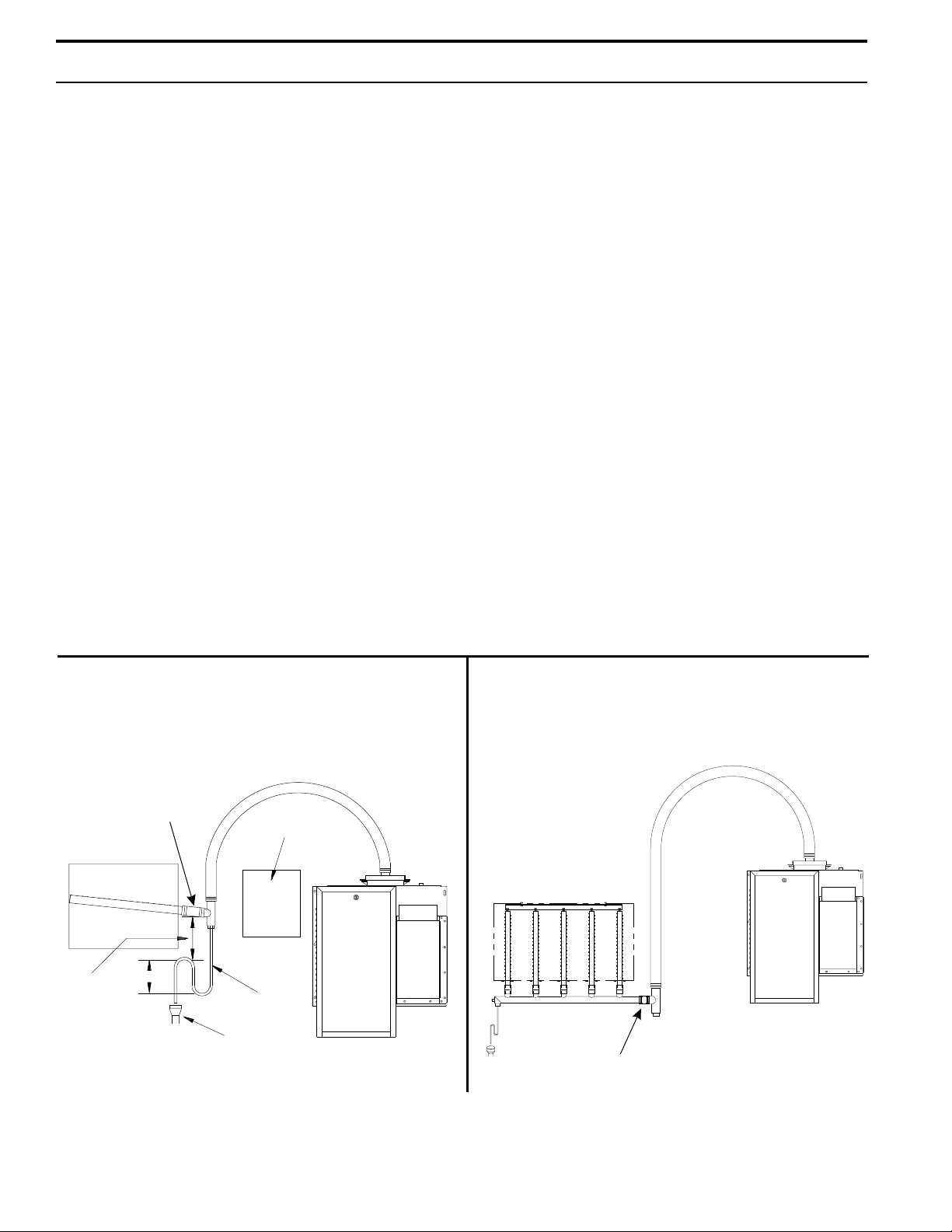

to duct elevation or an obstruction, alternate arrangements may be used as shown in figures 8-1 and 8-2

below.

Any condensate that forms in the vapor hose must be

removed. Preferably, it should be returned to an open

drain with a water seal of sufficient height to contain the

duct static pressure, as shown in figure 8-1.

Figure 8-1: Piping method recommended when

obstruction prevents dispersion tube from being

continuously pitched back to humidifier

Inline Tee

(1½" Dia. - Part # 162710)

(2" Dia. - Part # 162712)

Duct

5" Min.

4" Min.

Funnel or

OM-749

Notes:

• The GTS typically requires multiple dispersion tubes.

* Refer to local codes for drain pipe size requirements.

Floor Drain*

Obstruction

GTS

¾" Tubing

Figure 8-2: Piping method recommended when

humidifier must be mounted higher than the duct

Duct

GTS

Inline Tee

(1½" Dia. - Part # 162710)

(2" Dia. - Part # 162712)

OM-750

8

INSTALLATION

Gas Piping

(See "Gas Piping" diagram on page 15.)

CAUTION:

Gas pressure to humidifier controls must never

exceed 14” W.C. (1/2 psi). A 1/8" inch NPT plugged

tapping, accessible for test gauge connection, must

be installed immediately upstream of the gas supply

connection to the appliance.

• Piping installation must be in accordance with local

codes, and ANSI Z233.1, “National Fuel Gas Code,” or

CAN/CGA-B149 in Canada. Do not use flexible connectors.

• Piping to units should conform with local and national

requirements for type and volume and gas handled, and

pressure drop allowed in the line. Refer to table 9-1 and

9-2 to determine the cubic feet per hour (cfh) for the

type of gas and size of unit to be installed. Using this

value and the length of pipe necessary, determine the

pipe diameter. Where several units are served by the

same main, the total capacity, gas flow (cfh), and length

of main must be considered. Avoid pipe sizes smaller

than 1/2”. Table 9-1 allows for the usual number of

fittings with a 0.3” W.C. pressure drop.

• After threading and reaming the ends, inspect piping

and remove loose dirt and chips.

• Support piping so that no strains are imposed on unit

or controls.

• Use two wrenches when connecting piping to unit

controls.

• Provide a drip pocket before each unit and in the line

where low spots cannot be avoided.

• Take-off to unit should come from top or

side of main to avoid trapping condensate.

• Piping subject to wide temperature

variations should be insulated.

• Pitch piping up toward unit at least

1/4” per 15’ of horizontal run.

• Compounds used on threaded joints of

gas piping must be resistant to the

harmful action of liquefied petroleum

gases.

• Purge air before lighting unit by

disconnecting piping at gas control. In

no case should line be purged into

heat exchanger.

• After installation, check field piping

and humidifier gas train for gas leaks.

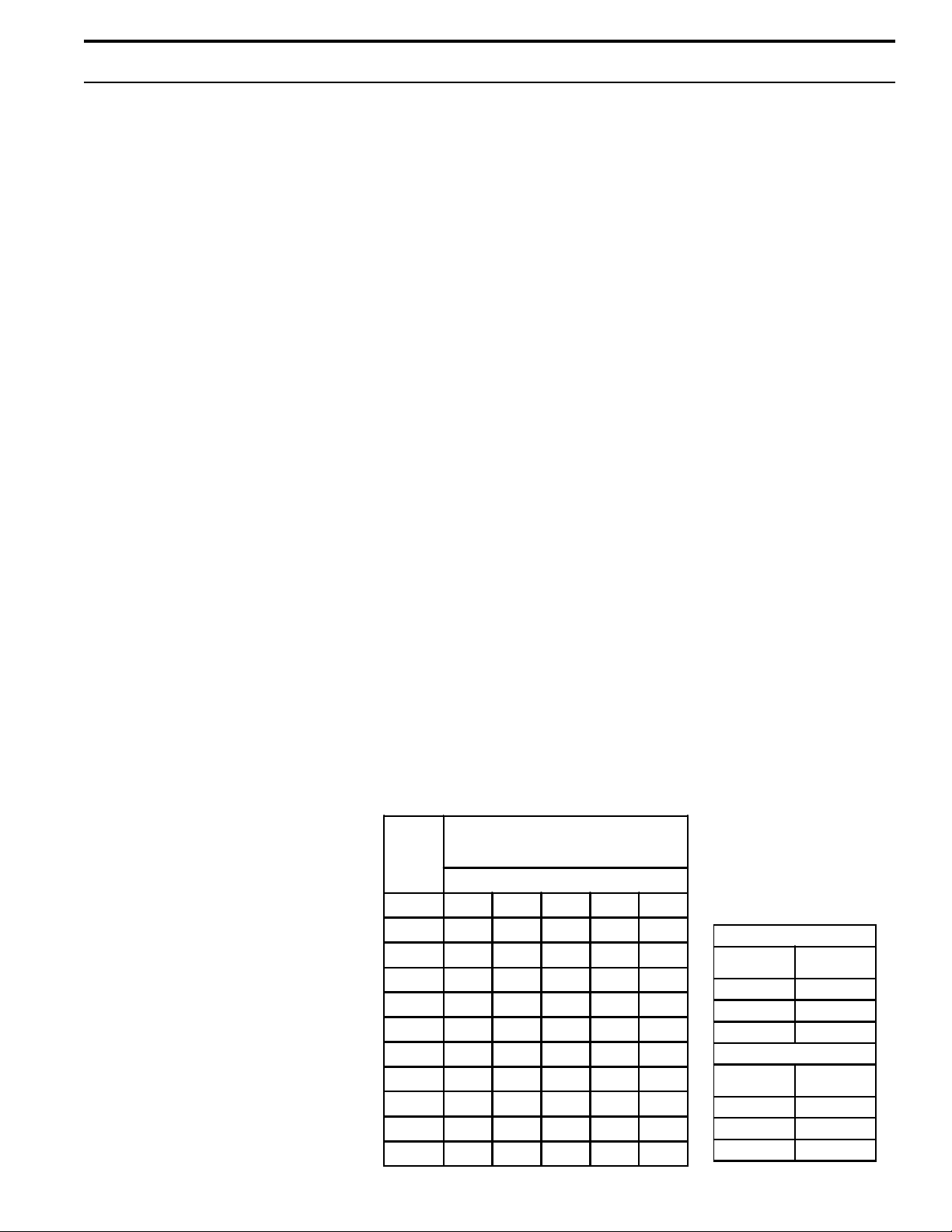

Table 9-1: Gas Pipe Capacities for Gas

Pressures of .5 PSIG or Less

Length

of Pipe

Feet

1/2 3/4 1 1-1/4 1-1/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

• Do not use soap solution, or open flame on humidifier

gas train. A gas leak detector is recommended.

• Install a ground joint union and a manual shut-off valve

immediately upstream of the unit including a 1/8” NPT

plugged tapping accessible for test gauge connection.

Plugged tappings for test gauges are located on all gas

valves.

• Allow at least 5 feet of piping between any high

pressure regulator and unit pipe connection.

Gas Leak Testing

• When leak testing the gas supply piping system, the

humidifier and its gas shut-off valve must be disconnected

during any pressure testing in excess of 14” W.C. (½ psi).

The humidifier must be isolated from the gas supply piping

system by closing its field-installed manual shut-off valve

during any pressure testing equal to or greater than 14"

W.C. (½ psi).

• Check gas supply pressure with all burners running at

inlet pressure tap of combination gas control. (See page

33) The recommended supply pressure should be 7"

W.C. on natural gas or 11" W.C. on LP gas. Purging of

gas piping should be performed as described in ANSI

Z223.1 (latest edition) or, in Canada, in CAN/CGA-B149

codes.

• Minimum supply pressure. Natural - 4½" W.C.

LP - 10" W.C.

• Single stage gas valves GTS™-300, 150, and 75 outlet

pressure (manifold) should be factory set at 3 1/2" w.c. for

natural, 9" w.c. for L.P. This pressure can be checked on

the combination gas valve at the out pressure tap (see

page 33).

Table 9-2: Specific

Gas Flow in Piping (Cu. Ft. per Hr.)

(At pressure drop of 0.3 in. water.

Specific gravity = 0.60)

Iron Pipe Size (NPT) Inches

Gravity Conversion

Factors

Multiplying factor to be used

with table 9-1 when the

specific gravity of gas is other

than 0.60.

Natural Gas

Specific

Gravity

0.55 1.04

0.60 1.00

0.65 0.962

Propane Gas

Specific

Gravity

1.50 0.633

1.53 0.626

1.60 0.612

Factor

Factor

9

INSTALLATION

• Two stage gas valves (used on GTS® 400, 200 and 100)

have a 10 second high fire stage and then drop to a

normal fire stage. Factory settings for natural gas are 5"

w.c. high, 3 1/2" w.c. normal. Factory settings for L.P. gas

are 8" w.c. high, 6" w.c. low. These pressures can be

checked on the combination gas valve at the out pressure

tap (see page 33).

Electrical

CAUTION:

Do not connect aluminum wire between disconnect

switch and humidifier. Use only copper wire.

WARNING:

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code, ANSI/NFPA

70 and Canadian Electrical Code, CSA C22.1, or local

codes to minimize personal injury if an electrical fault

should occur. This may consist of electrical wire or

conduit approved for electrical ground when installed in

accordance with existing electrical codes. Do not use gas

piping as an electrical ground.

• GTS Humidifiers should be supplied with 120-volt AC,

60-Hz, 15-amp separately fused electrical service. The

GTS humidifier is equipped with a transformer to step

down the voltage to 24 VAC control voltage.

• When installed, the GTS humidifier must be electrically

grounded in accordance with local codes or, in the absence of local codes, with the National Electrical Code

ANSI/NFPA No. 70-1987. The electrical conductors shall

be Type MTW (105°C) AWG #14 wire for line voltage

(120V), with BLACK WIRE for HOT; WHITE WIRE for

NEUTRAL, GREEN WIRE for GROUND; and #18 gauge

for control wiring. All electrical components and wiring

must be protected from mechanical damage and water.

The control system requires an earth ground for proper

operation.

• The humidifier is adjusted for correct performance. Do

not alter fan or operate motors at reduced speed.

Combustion and Ventilation Air

CAUTION:

Air for combustion must not be contaminated by

halogen compounds, which include fluoride, chloride,

bromide and iodide. These elements are found in

aerosol sprays, detergents, bleaches, cleaning solvents, salts, air fresheners, and other household

products.

CAUTION:

The operation of exhaust fans, kitchen ventilation

fans, clothes dryers, or fireplaces could create a

negative pressure condition at the humidifier. Makeup air must be provided for the ventilation devices, in

addition to that required by the humidifier.

• All fuel burning equipment must be supplied with air for

combustion of the fuel. Sufficient air MUST be provided

to ensure there will not be a negative pressure in the

equipment room or space.

• Provisions for adequate combustion and ventilation air

must be provided in accordance with Section 5.3, Air for

Combustion and Ventilation, of the National Fuel Gas

Code, ANSI Z223.1-1988, or applicable provisions of the

local building codes. Canadian installations must be

installed in accordance with sections 7.2, 7.3, and 7.4 of

the CAN/CGA.B149 Installation Codes, and all authorities

having jurisdiction.

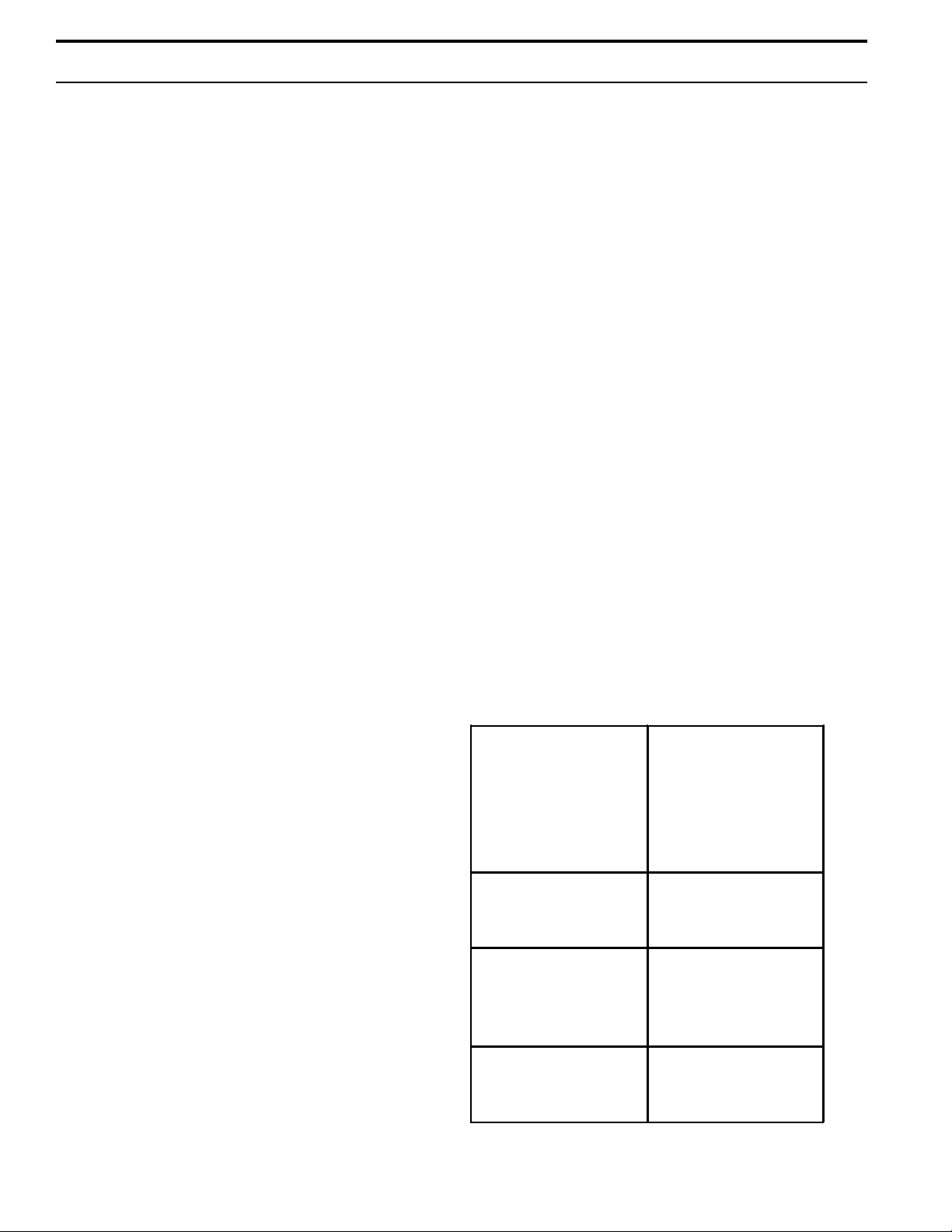

Table 10-1: Location of Humidifier and Required Air

Openings to Confined Space

Confined Space - All air

from inside the building;

conventional frame.

Brick or stone

construction with normal

infiltration. (Can only be

rarely used with larger

input units.)

Two openings, 1 square

inch per opening per

1000 BTU/hr. input.*

The minimum free area

of opening is 100 square

inches.

• The current characteristics, and capacity requirements

should be checked against the nameplates. All wiring

must be in accordance with all governing codes, and with

GTS wiring diagram located inside the control cabinet.

See table 13-1 for information on the various models.

• See page 14 for recommended knockout locations for

the electrical power supply and control wiring connections

on the control cabinet.

• See separate publication for the specific controller

furnished with this specific GTS humidifier.

10

Confined Space - All air

from outside the building

through air ducts.

Confined Space - All air

from outside the

building, through wall

openings only (no

ducts.)

Unconfined Space - All

air from outside the

building.

Two openings, 2 ducts, 1

square inch per opening

per 2000 BTU/hr. input.*

Two openings, 1 square

inch per opening per

4000 BTU/hr. input.*

Same as confined

space, all air from

outside the building.*

*Note the minimum dimension of any opening is three

inches.

INSTALLATION

• For proper and safe operation this appliance needs air

for combustion and ventilation. DO NOT block or

obstruct air openings on the appliance, spaces around the

appliance, or air openings communicating with the appliance area.

• DO NOT block the flow of combustion and ventilation

air. To provide for necessary oxygen for proper combustion, opening must be provided to allow outside air to enter

the space in which the heater is located. Enclosed

spaces, such as equipment rooms, must be vented at the

blower for combustion air. The size of air openings must

be based on all gas-burning equipment installed in the

space involved. Four types of locations, and the requirements of each, are outlined in table 10-1, on page 10.

Vertical and Horizontal Venting Guidelines

(Stack Connection)

• The GTS® is a fan assisted category 1 appliance.

• The purpose of venting the gas humidifier is to completely remove all products of combustion and ventilation

gases to the outside air, without condensation in the

stack.

• When connecting the humidifier to a gas vent or chimney, the installation shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1, or Section 7, Venting Systems and Air

Supply Appliances, of the CAN/CGA B149 Installation

Codes, the local building codes, and the vent

manufacturer's instructions.

• Do not reduce the vent diameter, and avoid short turns

in the vent piping. Use the same size stack as the vent

furnished with the humidifier. Maintain a minimum

upward slope of 1/4-inch-per-linear foot on all horizontal

runs. Maintain proper support of vent connections and

joints. Observe clearances (in accordance with applicable codes) from all combustible materials, and obtain

an approved cap for the stack outlet. The bottom of the

cap must be one stack diameter above the top of the

stack.

• Inspect for proper and tight construction. Any restrictions or obstructions must be removed. An existing

chimney may require cleaning.

• Chimney or vent must extend at least 3 feet above its

passage through a roof and at least 2 feet above any ridge

within 10 feet of the chimney. (Local codes apply.)

• Minimum clearance from the vent connector to combustible material is 6 inches unless the combustible materials

are protected in accordance with applicable codes. The

recommended vent system for the GTS-400, 200 and

100 humidifiers is constructed of Type C single wall vent

pipe (UL or CUL listed). Type C vent requires varying

levels of insulation when penetrating a combustible wall

depending on vent temperatures.

• This humidifier must not be connected to a chimney flue

servicing a separate appliance designed to burn solid

fuel.

• Never connect this humidifier to a chimney serving a

fireplace, unless the fireplace opening is permanently

sealed off.

• The recommended vent system for the GTS-300, 150,

and 75 humidifier is constructed of Type B double-wall

vent pipe (UL or CUL listed). Type B vent is rated for

400°F plus ambient temperature. A minimum 1-inch

clearance is required between Type B vent and combustible materials. Field expertise has shown that venting

through a properly sized Type B vent significantly

reduces the occurrence of vent condensation.

• It may be necessary to add insulation to Type B doublewall vent and to single-wall vent connector, if allowed by

local codes, in some applications. When insulation is

required, it must be at least 1-inch thick fiberglass with foil

backing. Using permanent foil tape, attach insulation to

vent pipe. Both the foil tape and fiberglass insulation

must be suitable for temperatures up to 450°F.

• Insulation must be added to any vent connector which

will be exposed to ambient temperatures of 30°F or less,

especially any application using single-wall vent pipe as a

connector.

• Do not insulate vent pipe exposed to outdoor weather

conditions (i.e. above roof lines).

• Venting into an unlined masonry or concrete chimney is

prohibited by code.

• If this humidifier is connected to a lined, masonry

chimney, the chimney must be sized and installed according to the provisions of the National Fuel Gas Code, or

Canadian CAN/CGA.B149 requirements. Vent connectors

from the humidifier to the chimney should be made with

insulated Type C single-wall vent pipe or Type B vent

pipe for GTS-300, 150, and 75. The GTS-400, 200 and

100 is approved for single wall vent only.

• Installation of the vent pipe should be as directly as

possible, with a minimum number of turns or elbows.

• Rigidly support the vent pipe every 5 feet or less with

hangers or straps to ensure that there will be no movement after installation. The humidifier vent box should not

be supporting the weight of the vent piping.

11

Loading...

Loading...