Page 1

IMPORTANT: Read and save these instructions.

GTS

®

Gas -to -St eam Hum i di f ie r

In st all at io n, O peratio n,

an d M ainte na nc e Manu al

W A R N I N G !

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury, or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

W H A T T O D O

I F Y O U S M E L L G A S

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier

from an off-site phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed by a qualified installer, service

agency, or the gas supplier.

For toll-free technical support call:

1-800-328-4447

Page 2

ATTENTION INSTALLER

Read this manual before installing.

Leave manual with product owner.

DRI-STEEM technical support

800-328-4447

I m po r ta n t: Troubleshooting information for this humidifier is located

in the Vapor-logic4 Installation and Operation manual shipped with your

humidifier. If you do not have this manual, go to the literature section at

www.dristeem.com to download or order a copy.

Where to find more information

On our Web site:

The following related documents can be

viewed, printed or ordered from our web

site, www.dristeem.com

• Catalogs (include dispersion nonwetting

distance graphs):

– GTS

– Ultra-sorb

• Installation, Operation, and Maintenance

– Ultra-sorb

– Vapor-logic4® (includes sensor

placement recommendations and

troubleshooting information)

•

In Dri-calc:

Dri-calc® is our humidification system

sizing and selection software, which can be

ordered at www.dristeem.com.

Included in Dri-calc:

®

®

manuals:

DRI-STEEM Design Guide

loss tables and general humidification

information)

(includes steam

European models

The DRI-STEEM GTS Gas-to-Steam Humidifier has been certified

for compliance with harmonised European directives concerning

gas appliances, low voltage, and emission (Gas Appliance Directive

90/396/CEE). Testing was carried out by the Canadian Standards

Association; the notifying body is AFNOR in France, which is a

recognized authority by the European bodies and the DTI in the

United Kingdom.

Installation must conform to the requirements of the National Gas

Safety (Installation & Use) Regulations.

• A comprehensive library of installation

guide documents, including:

– Rapid-sorb installation instructions

for vertical airflows

– Recommended dispersion placement

within a duct or air handler

– Recommended sensor placement

Or call us at 800-328-4447

While obtaining documents from our web

site or from Dri-calc is the quickest way to

review our literature, we will also mail to

you any literature you need.

Page 3

Ta b l e o f c o n t e n t s

Overview

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications and capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation

Locating the humidifier, clearance recommendations . . . . . . 10

Outdoor enclosure mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring: Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Piping: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Piping: Supply water and drain overflow connections . . . . . . . 22

Piping: Water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Piping: Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Piping: Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Combustion and ventilation air . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Vertical and horizontal venting . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dispersion: General instructions . . . . . . . . . . . . . . . . . . . . . . . . . 35

Dispersion: Interconnecting piping requirements . . . . . . . . . . 36

Dispersion: Drip tee installation . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dispersion: Single tube and multiple tube . . . . . . . . . . . . . . . . . 39

Dispersion: Rapid-sorb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Dispersion: Area-type fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operation

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Safety systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Start-up commissioning checklist . . . . . . . . . . . . . . . . . . . . . . . . 56

Maintenance

For both GTS and GTS-DI models . . . . . . . . . . . . . . . . . . . . . . . 58

Maintenance: GTS standard water models . . . . . . . . . . . . . . . . . 60

Maintenance: GTS-DI models . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Troubleshooting

GTS troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacement parts

Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Electrical replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Outdoor enclosure electrical replacement parts . . . . . . . . . . . . 74

Information for European models only

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-77

Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back cover

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 1

Page 4

S a f e t y p r e c a u t i o n s

W A R N I N G !

The humidifier must be installed by

a qualified technician and meet the

requirements of all governing codes. Failure

to follow these instructions could cause

severe bodily injury or death.

W A R N I N G !

If you do not follow the instructions in this manual

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

For your safety, read this entire manual before

installing or operating the GTS humidifier.

A. This appliance does not have a pilot. It is equipped with an

ignition device which automatically lights the burner.

Do NOT try to light the burner by hand.

B. Before operating, smell all around the appliance area for

gas. Be sure to smell next to the floor because gas can be

heavier than air and settle on the floor.

FOR YOUR SAFETY: WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

C. Do not use this appliance if any part has been under water.

Immediately call a qualified gas appliance service technician

to inspect the appliance and to replace any part of the control

system and any gas control that has been under water.

More safety precautions are on the next page ▶

Pag e 2 • DRI - S TEE M G TS Hu m i difi e r Ins t a llat i on, O p e rat i o n, an d M aint e nanc e M anua l

Page 5

S a f e t y p r e c a u t i o n s ( c o n t i n u e d )

Safe operating instructions

1. STOP! Read the safety information on the previous page.

2. Set the humidistat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device that

automatically lights the burner. Do not try to light the burner

by hand.

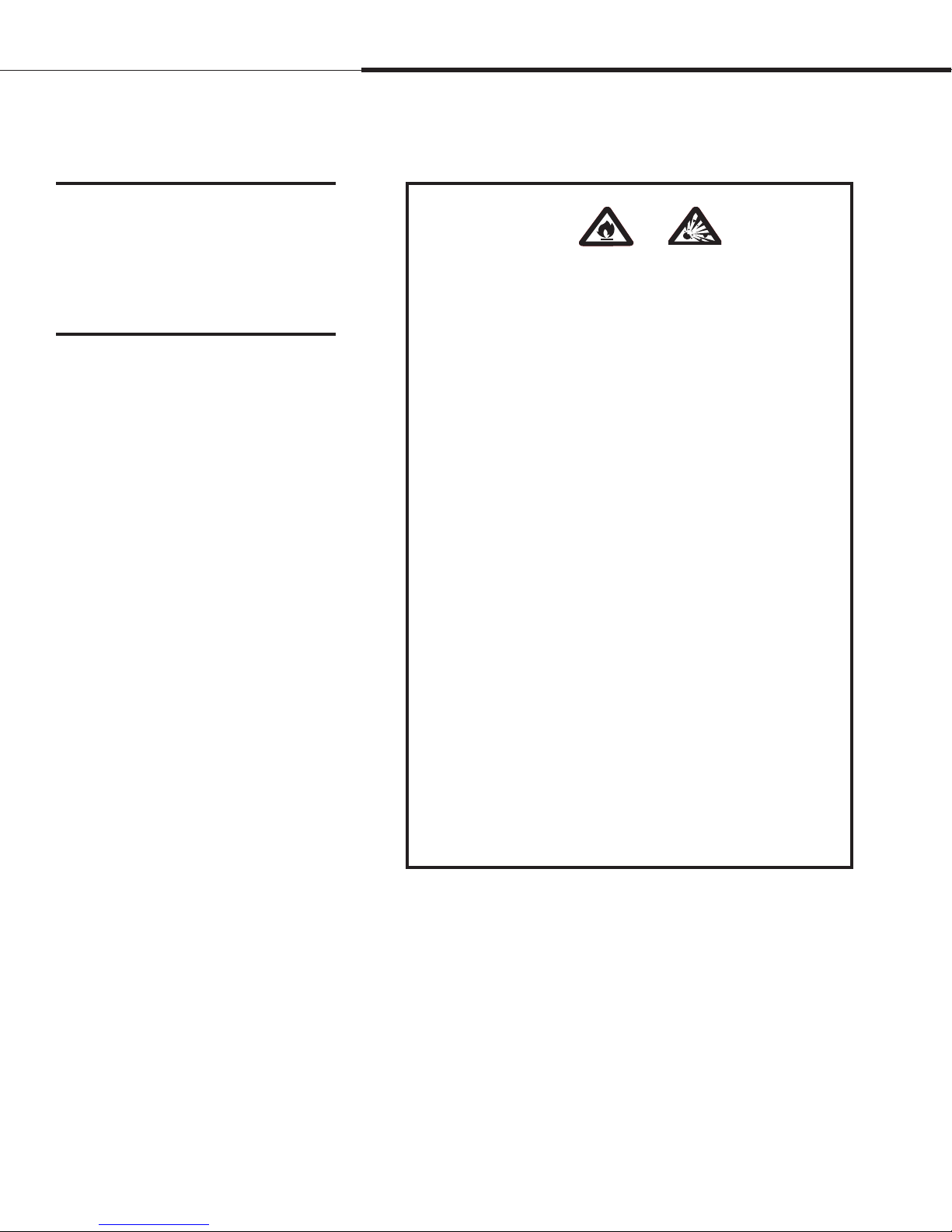

5. Remove control access panel.

6. Unplug the black power plug on the gas valve (see

Figure 3-1).

7. Wait five minutes to clear out any gas.

If you then smell gas, STOP! Follow “B” in the safety

information on the previous page.

If you don’t smell gas, go to the next step.

8. Plug the black power plug back into the gas valve.

9. Replace control access panel.

10. Turn on all electric power to the appliance.

To turn off gas to appliance

1. Set the humidistat to lowest setting.

2. Turn off all electric power to the

appliance if service is to be performed.

3. Remove control access panel.

4. Unplug the black power plug on the gas

valve.

5. Replace control access panel.

11. Set humidistat to desired setting.

12. If the appliance will not operate, follow the instructions on this

page titled, “To turn off gas to appliance,” and call your service

technician or gas supplier.

More safety precautions are on the next page ▶

Figure 3-1:

Detail of gas valve

Top view

Gas

valve

Gas valve

power

plug

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 3

Page 6

S a f e t y p r e c a u t i o n s ( c o n t i n u e d )

W A R N I N G !

Improper installation, adjustment, alteration, service, maintenance, or

use can cause carbon monoxide poisoning, explosion, fire, electrical

shock, or other conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency, local gas supplier,

or your distributor or branch for information or assistance. The qualified

installer or agency must use only factory authorized and listed kits

or accessories when modifying this product. A failure to follow this

warning can cause electrical shock, fire, personal injury, or death.

• Inspect humidifier and accessories upon arrival for damaged, missing,

or improper parts. If there is a problem, call DRI-STEEM.

• Application of this humidifier should have special attention given to

vent sizing and material, gas input rate, and unit sizing. Improper

installation or misapplication of the humidifier can cause excessive

servicing or permanent component failure.

• When working on equipment, observe precautions in literature, tags,

and labels attached to or shipped with the unit and observe other

safety precautions that may apply. Wear safety glasses and work

gloves. Have a fire extinguisher available during start-up, adjustment

procedures, and service calls.

• Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and any gas

control that has been under water.

• Do not lift humidifier by gas controls, gas manifold, fire box, or

shroud.

• Should overheating occur, or the gas supply fail to shut off, shut

off the manual gas valve to the appliance before shutting off the

electrical supply.

• The evaporating chamber is designed as a non-pressurized vessel.

DO NOT restrict piping where steam exits the humidifier.

Install drain piping and piping that connects the evaporating

chamber to the dispersion assembly only as described in this manual.

DO NOT install a shut-off valve on the piping connecting the

evaporating chamber to the steam outlet.

Pag e 4 • DRI - S TEE M G TS Hu m i difi e r Ins t a llat i on, O p e rat i o n, an d M aint e nanc e M anua l

More safety precautions are on the next page ▶

Page 7

S a f e t y p r e c a u t i o n s ( c o n t i n u e d )

W A R N I N G !

• Installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, must conform to:

In the United States: The National Fuel Gas Code, ANSI Z223.1

(latest edition).

In Canada: Local plumbing or waste water codes and other

applicable codes and with the current code CAN/CGA-B149.1,

“Installation Code for Natural Gas Burning Appliances and

Equipment,” or CAN/CGA-B149.2, “Installation Code for Propane

Burning Appliances and Equipment.”

In Europe: The National Gas Safety (Installation & Use) Regulations.

• Do not install in potentially explosive or flammable atmospheres

laden with grain dust, sawdust, or similar airborne materials.

• Installation of humidifier in high humidity or salt water atmospheres

causes accelerated corrosion, reducing the normal life-span of the

unit.

• To prevent premature heat exchanger failure, do not locate any gasfired unit in areas where chlorinated, halogenated, or acid vapors are

present in the atmosphere.

• Locate the humidifier in an area clear of combustible materials,

gasoline, and other flammable vapors and liquids.

• With the exception of sealed combustion units, do not locate units

in tightly sealed rooms or small compartments without provision for

adequate combustion air and venting. Room air combustion must be

supplied through a minimum of two permanent openings in the wall,

with at least one near the bottom. See the table and information on

Page 30 for additional information.

• Remove all shipping brackets and materials before operating the

humidifier.

• Do not locate humidifier in a negative pressure space. Combustion

products could be suctioned from the venting.

• Humidifier flue gases must be vented to the outside atmosphere.

• Power supply disconnect switch must be in the off position while

making wiring connections to prevent electrical shock and equipment

damage. All units must be wired in strict accordance with the wiring

diagrams furnished with this unit.

• Turn off all gas while installing the gas piping and manual shutoff

valve for the humidifier.

• The appliance and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures exceeding 0.5 psig (3.5 kPa).

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 5

Page 8

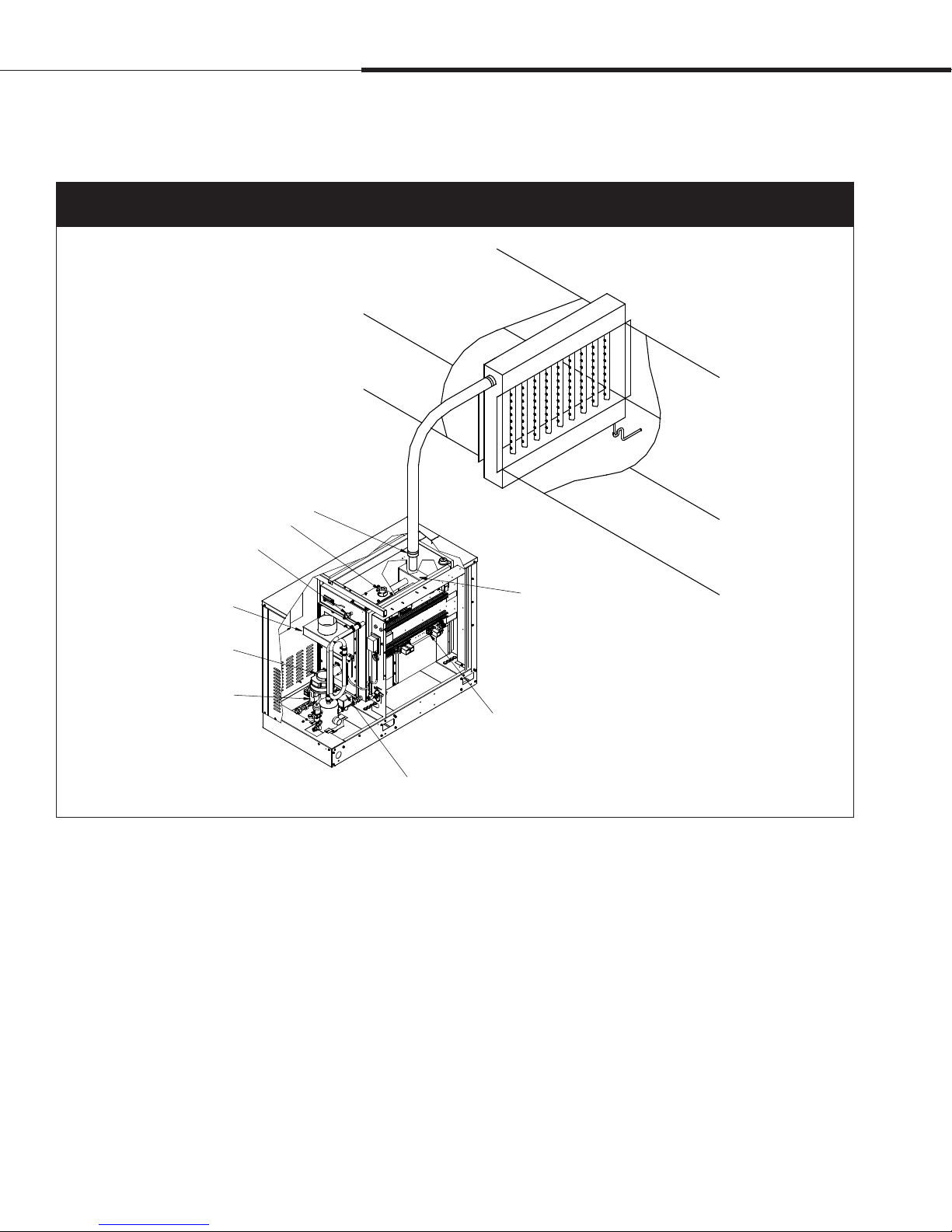

Figure 6-1:

GTS standard water model VLC

Steam outlet

Water level probe

Water supply line

P r o d u c t o v e r v i e w

Optional Ultra-sorb dispersion

panel installed in duct

Vapor hose

Flue box

Blower

Gas valve

Notes:

• GTS standard water models can be

converted in the field for use with

deionized/reverse osmosis (DI/RO) water.

GTS-DI models can be converted in the

field for use with potable or softened

water.

• Damage caused by chloride corrosion is

not covered by your DRI-STEEM warranty.

Heat exchanger

Control components

Drain valve

OM-1201

GTS standard water models

GTS standard water gas-fired humidifiers burn either natural

or propane gas to heat potable or softened fill water into steam

for humidification. The unit has from one to four burners that

fire into a heat exchanger submerged in a tank of water. When

there is a call for humidity, the burners fire and generate steam

until the call for humidity ends. A probe monitors water level,

requiring water conductivity to be at least 100 µS/cm to operate

properly. Therefore, GTS standard water models do not operate

with demineralized water (deionized or reverse osmosis treated

water). For demineralized water operation, use the GTS-DI model

(described on next page).

Pag e 6 • DRI - S TEE M G TS Hu m i difi e r Ins t a llat i on, O p e rat i o n, an d M aint e nanc e M anua l

Page 9

P r o d u c t o v e r v i e w ( c o n t i n u e d )

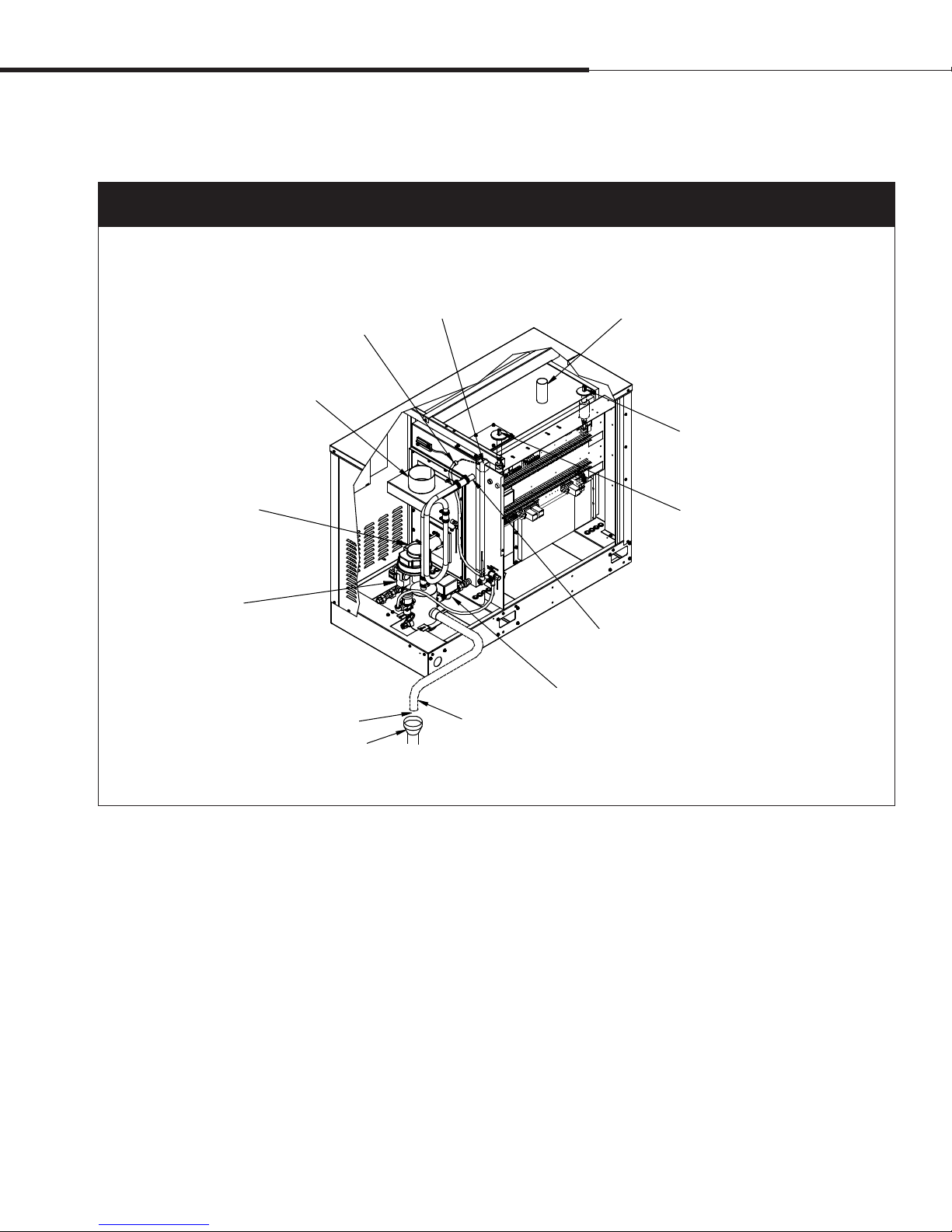

Figure 7-1:

GTS-DI (DI/RO water model)

Blower

Gas valve

Water supply line

Flue connection

Float for water fill valve

Air gap

Open drain

Steam outlet

Redundant low water

cutoff sensor

Float-operated low

water cutoff

Overflow outlet

Drain valve

Drain piping (by installer)

GTS-DI models

GTS-DI humidifiers burn either natural or propane gas to heat

deionized (DI) or reverse osmosis (RO) fill water into steam for

humidification. GTS-DI models control water level using a float

valve.

GTS-DI models are virtually maintenance-free and require very

little or no downtime.

The GTS-DI model is available for use with deionized or reverse

osmosis water. This unit produces chemical-free steam and reliable,

accurate humidification control.

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 7

OM-1202

Notes:

• GTS standard water models can be

converted in the field for use with

deionized/reverse osmosis (DI/RO) water.

GTS-DI models can be converted in the

field for use with potable or softened

water.

• Damage caused by chloride corrosion is

not covered by your DRI-STEEM warranty.

Page 10

S p e c i f i c a t i o n s , ca p a c i t i e s , a n d

w e i g h t s

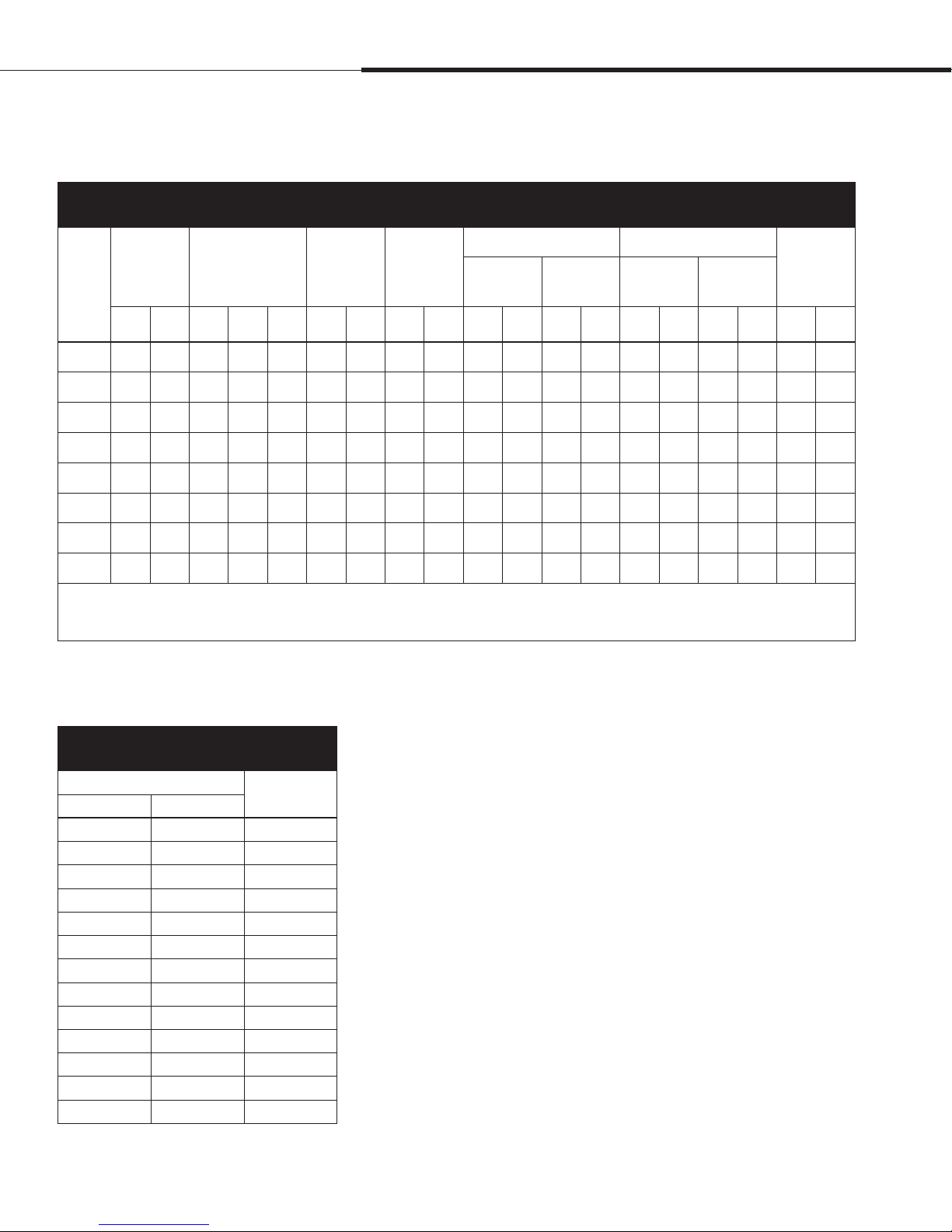

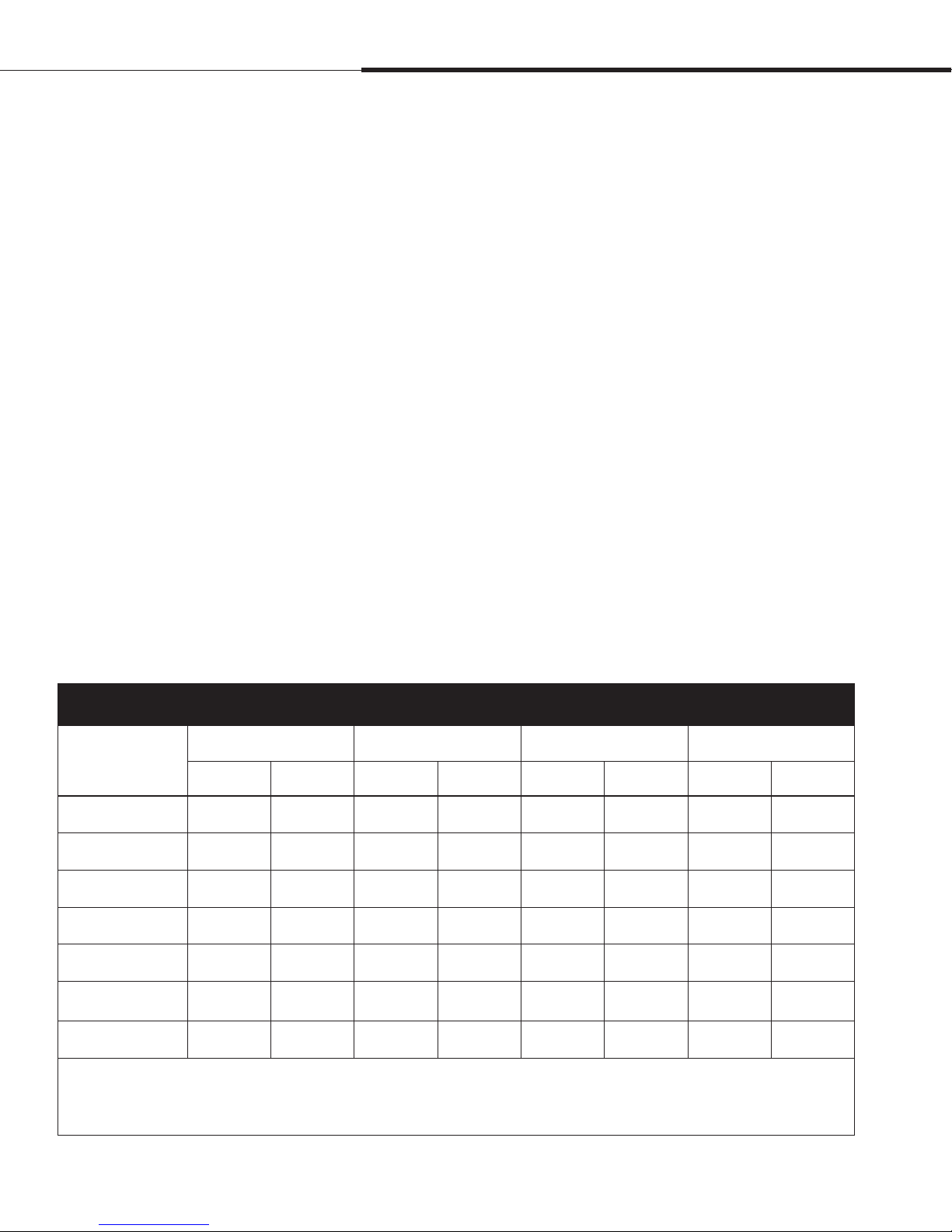

Table 8-1:

GTS specifications, capacities, and weights for North American models only

Maximum

GTS

model

GTS-100 75 34 100 29 2.76 9 34.1 48 181.7 700 320 375 170 800 365 500 230 1.8 2.8

GTS-200 150 68 200 59 5.52 18 68.1 48 181.7 700 320 375 170 800 365 500 230 1.8 2.8

GTS-300 225 102 300 88 8.28 27 102.2 52 196.8 850 385 450 205 1000 455 600 270 3.0 4.0

GTS-400 300 136 400 117 11.04 36 136.3 52 196.8 850 385 450 205 1000 455 600 270 3.0 4.0

GTS-500 375 170 500 147 13.80 45 170.3 76 287.7 1100 500 600 270 1450 660 950 430 4.5 5.5

GTS-600 450 204 600 176 16.56 54 204.4 76 287.7 1100 500 600 270 1450 660 950 430 4.5 5.5

GTS-700 525 238 700 205 19.32 63 238.5 89 336.9 1400 635 700 320 1750 795 1050 475 6.0 7.0

GTS-800 600 272 800 234 22.08 72 272.5 89 336.9 1400 635 700 320 1750 795 1050 475 6.0 7.0

Note:

* Add 15 full load amps for outdoor enclosure heater load on all GTS models

** Add 10% to account for skim and automatic drain/flush features if utilized (standard water units only).

steam

capacity

lbs/hr kg/h MBh kW m3/h

Input

I m po r t an t : See Pages 76-77 for

additional European model specifications

and capacity notes.

Water usage

at maximum

capacity**

gals/hrlitres/

hr

Tank

volume

gals litres lbs kg lbs kg lbs kg lbs kg

Operating

weight

Capacity notes

• At sea level, approximately 152 Btu are required to raise the

temperature of one pound of water from 60 °F to 212 °F. (At sea

GTS GTS with outdoor enclosure

Shipping

weight

Operating

weight

Shipping

weight

Full load

amps*

120 V

60 Hz

230 V

50 Hz

level, approximately 352 kJ are required to raise the temperature

Table 8-2:

High altitude derate

Altitude

feet meters

0–2000 0–610 0

2001–2500 610–765 2

2501–3000 765–915 4

3001–3500 915–1065 6

3501–4000 1065–1220 8

4001–4500 1220–1370 10

4501–5000 1370–1525 12

5001–5500 1525–1675 14

5501–6000 1675–1830 16

6001–6500 1830–1980 18

6501–7000 1980–2135 20

7001–7500 2135–2285 22

7501–8000 2285–2440 24

derate %

Input

of one kilogram of water from 16 °C to 100 °C.)

• An additional 970 Btu are required to change the state of one pound

of 212 °F water to vapor. (An additional 2257 kJ are required to

change the state of one kilogram of 100 °C water to vapor.)

• Another factor to consider is condensation steam loss from

piping. Use the following general steam loss guidelines:

– Vapor hose: 0.15 lbs/hr/ft (0.22 kg/h/m)

– Insulated pipe: 0.05 lbs/hr/ft (0.07 kg/h/m)

– Hard pipe and dispersion tubes: 0.50 lbs/hr/ft (0.7 kg/h/m)

– High-eciency dispersion tubes: 0.20 lbs/hr/ (0.298 kg/h/m)

For more detailed information about condensation steam loss, see

the DRI-STEEM Design Guide or our software program, Dri-calc.

LP gas

All models operate at rated input.

High altitude

An input derate exists when operating units at a high altitude. See

Table 8-2 for high altitude derate information.

Pag e 8 • DRI - S TEE M G TS Hu m i difi e r Ins t a llat i on, O p e rat i o n, an d M aint e nanc e M anua l

Page 11

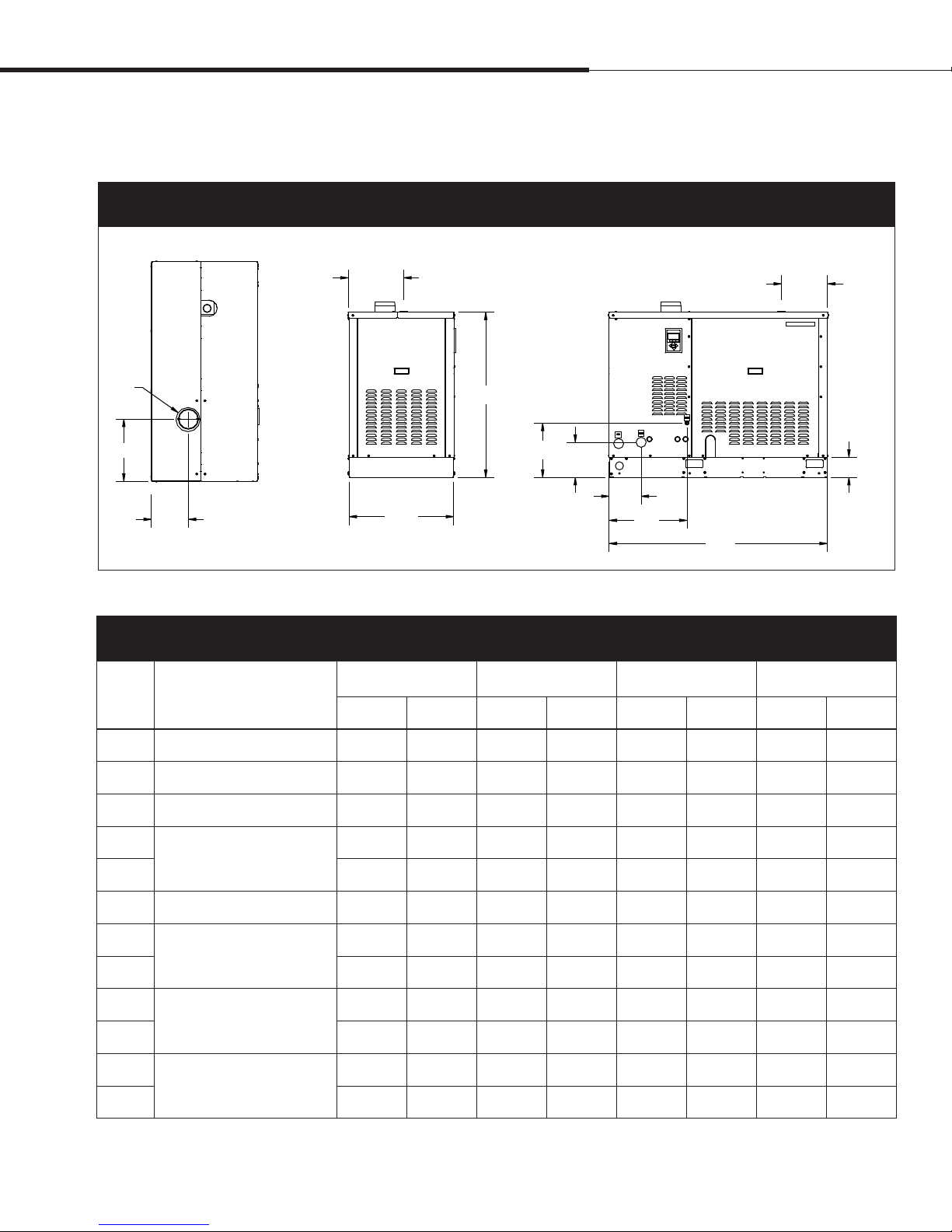

D i m e n s i o n s

Figure 9-1:

Dimensions

Side viewFront viewTop view

F

D

E

Table 9-1:

Dimensions

Description

G

C

J

L

M

B

GTS-100

GTS-200

inches mm inches mm inches mm inches mm

GTS-300

GTS-400

K

A

GTS-500

GTS-600

H

5"

(127 mm)

OM-1203

GTS-700

GTS-800

A Overall length 54.35 1380 54.35 1380 54.35 1380 54.35 1380

B Overall width 26.38 670 32.38 822 42.38 1076 48.38 1229

C Shroud height 41.00 1040 41.00 1040 41.00 1040 41.00 1040

D

Flue position

E 13.00 330 15.63 397 18.63 475 21.00 533

F Flue diameter 5.00 127 7.00 178 8.00 203 10.00 254

G

Steam outlet position

H 11.63 295 11.63 295 11.63 295 11.63 295

J

Fill valve connection position

K 13.00 330 13.00 330 13.00 330 13.00 330

L

Drain position

M 8.00 203 8.00 203 8.00 203 8.00 203

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 9

18.00 457 17.00 432 17.00 432 16.25 413

14.00 356 20.50 521 29.25 743 35.25 895

13.00 330 13.00 330 13.00 330 13.00 330

8.75 222 8.75 222 8.75 222 8.75 222

Page 12

L o c a t i n g t h e h u m i d i f i e r a n d

c l e a r a n c e r e c o m m e n d a t i o n s

Locating the humidifier

• Provide a level, solid foundation for the humidifier.

• Locate the humidifier as near as possible to a chimney or

outside wall so that the flue pipe from the humidifier is

short and direct.

• Locate the unit so it and its electrical components are

protected from water during humidifier operation and

service.

• Install the humidifier in a location away (and protected)

from drafts. If installed in a separate room, follow the

instructions concerning combustion and ventilation air.

• Locate the humidifier in an area where leakage from the

tank or its connections will not result in damage to the

adjacent structure or to lower floors of the structure.

When such locations cannot be avoided, install a suitable

drain pan (adequately drained) under the humidifier. The

pan must not restrict combustion airflow.

• Do not install the humidifier on carpeting, tile or other

combustible material other than wood flooring (indoor

application only).

• If located in an insulated space, keep the humidifier free

and clear of insulating materials. Insulating material can

be combustible. Inspect the humidifier area when the

humidifier is installed or when insulation is added.

Figure 10-1:

GTS clearance recommendations

18" (457 mm)

36" (914 mm)

30" (762 mm)

OM-1222

Note:

DRI-STEEM recommends a minimum of 1" (25 mm) clearance between hot surfaces and

combustible walls.

Pag e 1 0 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 13

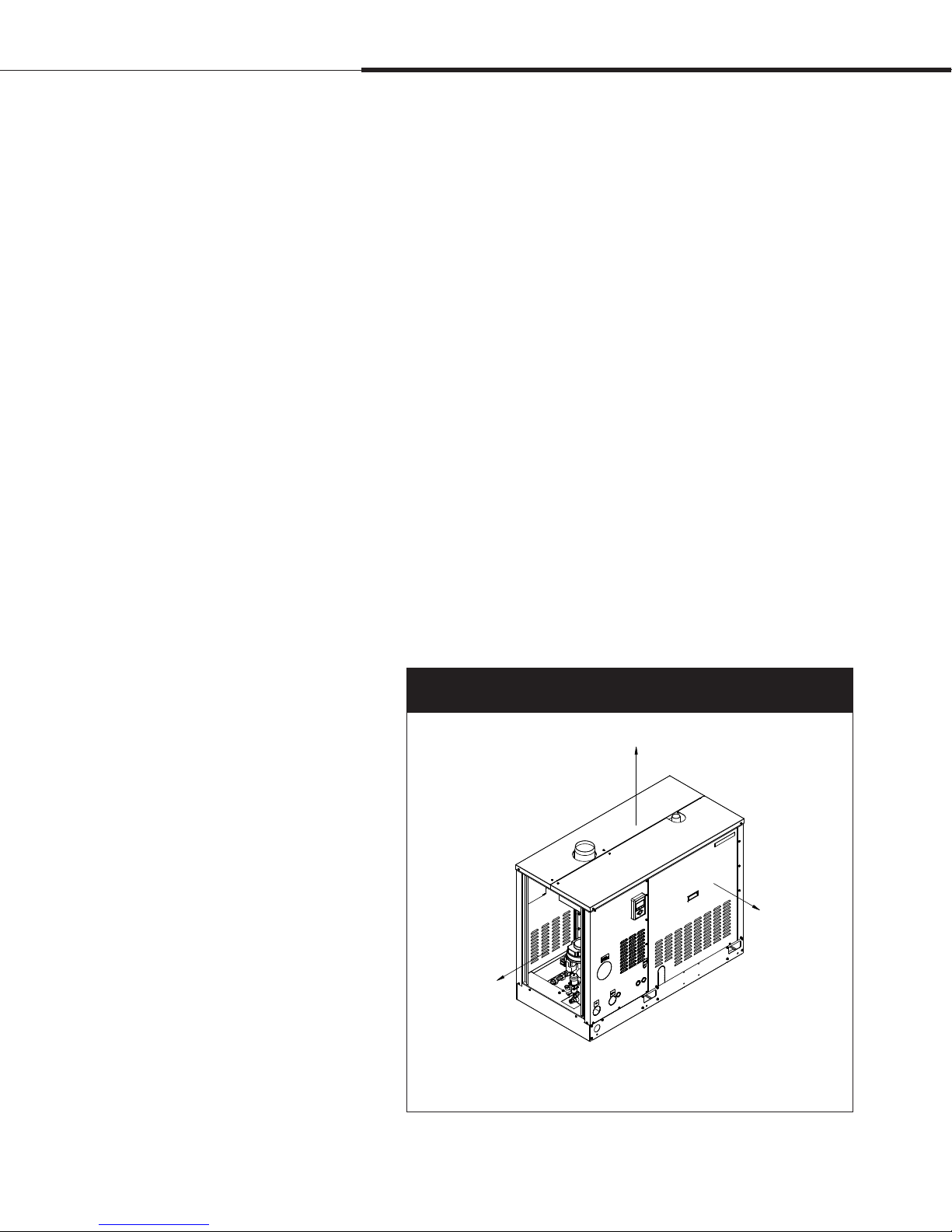

O u t d o o r e n c l o s u r e m o u n t i n g

Outdoor enclosure mounting option

The outdoor enclosure option is used when the GTS is installed

outdoors. The following information is not intended to supersede

any requirements of federal, state, or governing codes having

jurisdiction; prior to locating the unit, authorities having

jurisdiction should be consulted.

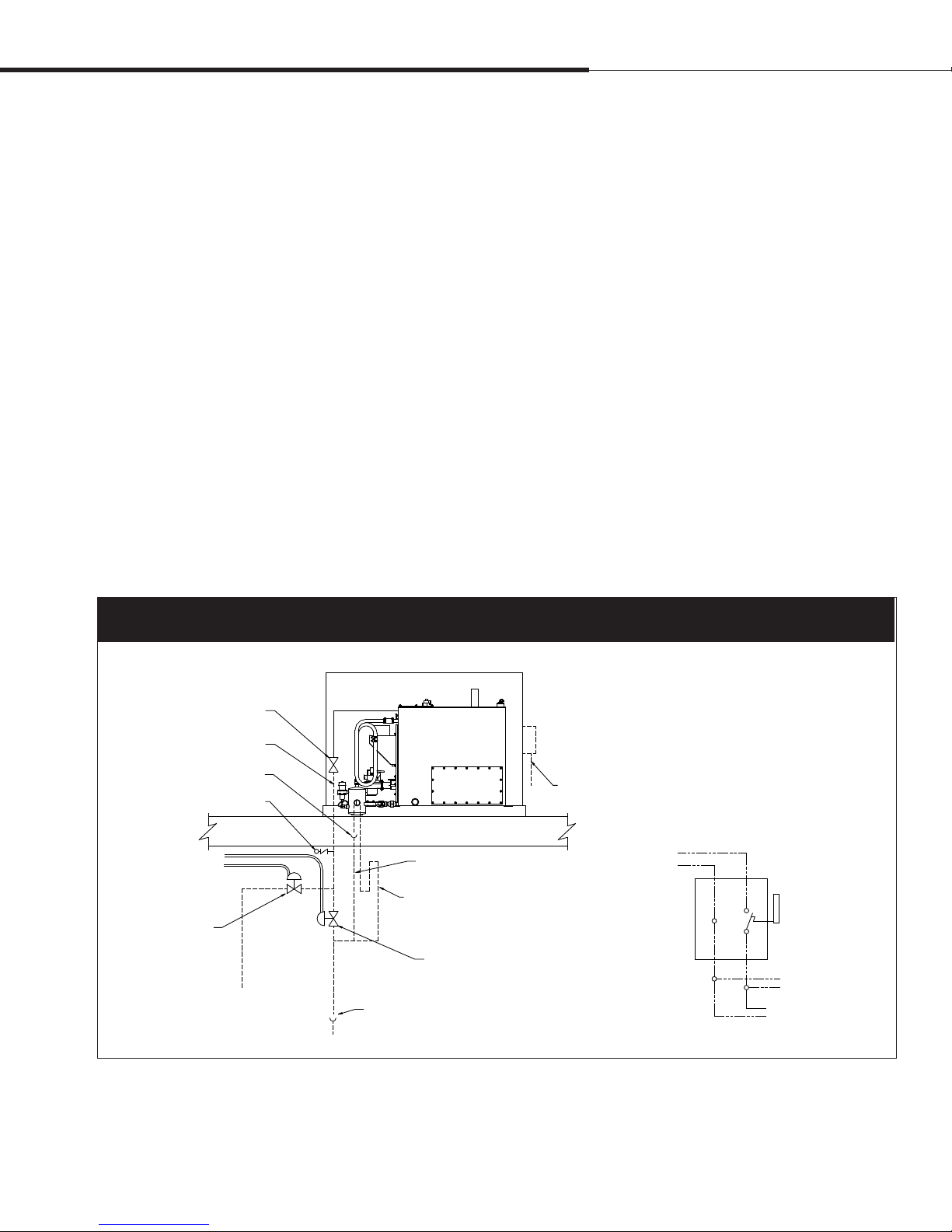

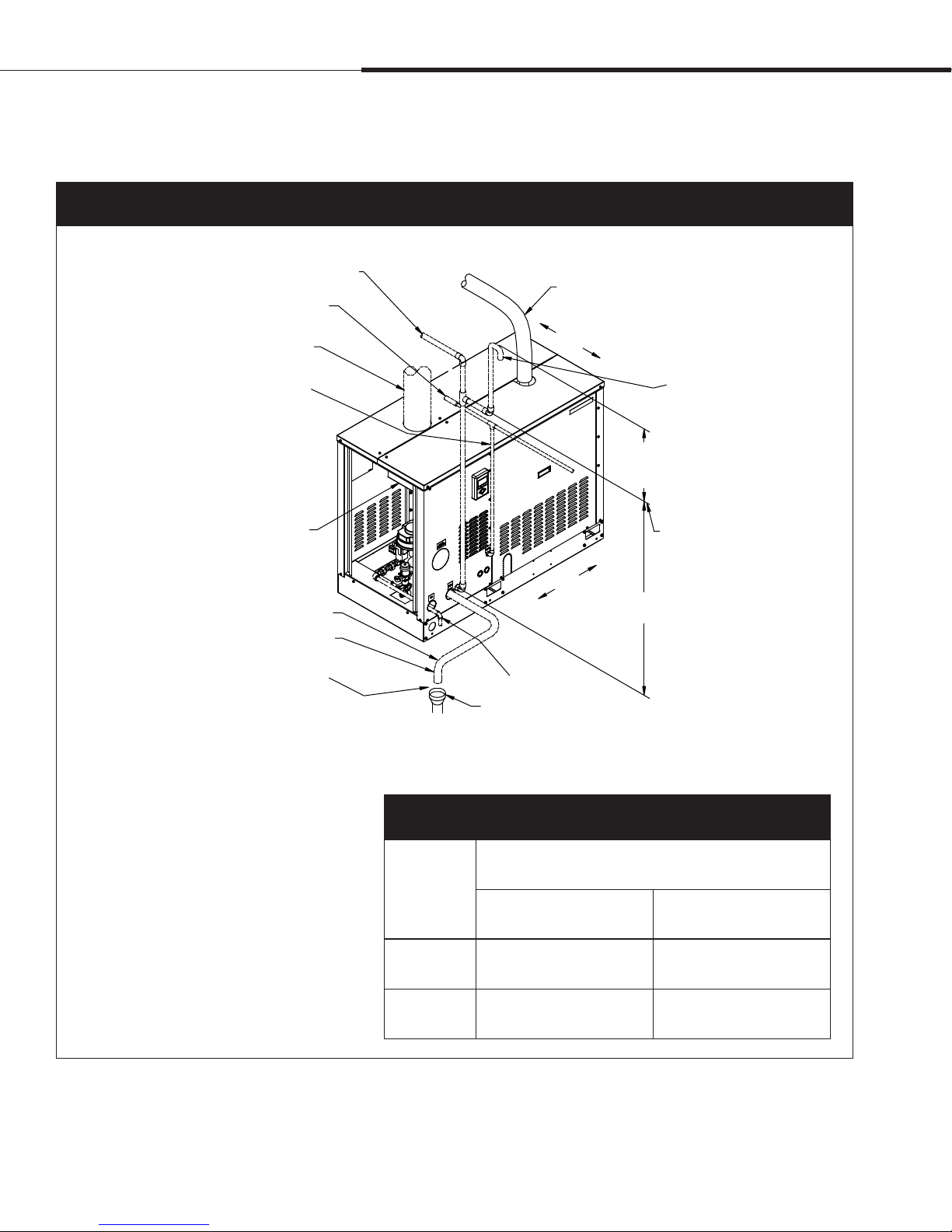

Figure 11-1:

Outdoor enclosure typical installation overview

Steam piping

GTS humidifier in outdoor

enclosure

Roof surface

Flue

Curb

Drain piping

Water piping

Electrical connections

Gas piping

Vapor-logic4 keypad shown with optional

cable length. Keypad ships standard with

5' (1.5 m) of cable

OM-1238

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 1 1

Page 14

O u t d o o r e n c l o s u r e m o u n t i n g

( c o n t i n u e d )

Handling

The GTS outdoor enclosure must be lifted from the bottom base

in a fashion that holds it level and keeps it from tipping, falling, or

twisting. If the unit is severely twisted during handling, permanent

damage can occur. It is the installer’s responsibility to verify the

handling equipment’s capability to safely handle the unit.

Lift the outdoor enclosure by using special lifting lug hooks

installed on the unit. All lifting operations must be accomplished

with a load spreader of sufficient width to ensure that the lifting

cables clear the side of the unit.

Pag e 1 2 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 15

O u t d o o r e n c l o s u r e m o u n t i n g

( c o n t i n u e d )

Location

• The GTS outdoor enclosure must be level and located so there is

enough clearance for opening the access panels.

• Verify that the position of pad or curb properly supports the

unit and that support structure dimensions coincide with unit

dimensions.

• Do not locate unit in areas where the surrounding air has high

levels of particulates, such as some industrial parks or areas near

highways.

• Locate unit so air intakes are not too close to exhaust fan outlets,

gasoline storage, or other contaminants that potentially could

cause dangerous situations. Using and storing gasoline or other

flammable vapors and liquids in open containers in the vicinity of

this appliance is hazardous.

• When located on the roof, the air intakes must be a minimum of

14" (360 mm) off the roof to prevent intake of snow or splashed

rain. The unit should be located so prevailing winds do not blow

into the air intakes.

• An emergency drain is provided. In case of any water leak, water

drains onto the roof through this emergency drain.

• A keypad with standard 5' (1.5 m) cable ships mounted to

the subpanel in the GTS outdoor enclosure. The keypad must

not come in contact with the strip heaters or block the intake

ventilation hood.

• If constant monitoring of the unit is desired, or if the unit is

located in a severe climate, install a remote mount keypad.

Additional cable lengths up to 500' (152 m) are available as an

option for this mounting configuration.

• Curbs (optional) are shipped knocked down for ease of

transporting to the roof. Curbs are manufactured of 14-gauge

galvanized steel and shipped with all hardware for bolt-together

assembly. All holes are matched before leaving the factory. Curb

is to be a minimum of 14" (360 mm) high. A closed-cell curb

gasket with adhesive on one side is supplied with hardware. An

installation drawing also is included. To prevent moisture from

leaking into the building from either driving rain or melting

snow, install the gasket between the top of the curb and the base

surface of the unit.

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 1 3

Page 16

O u t d o o r e n c l o s u r e m o u n t i n g

( c o n t i n u e d )

Before you begin

• Prior to installing the unit, remove all packaging.

• During the transit, unloading, and setting of the unit, bolts and

nuts may become loose. Check that all nuts are tightened as

required.

• There are three knockouts located on the right and left side of the

enclosure. DRI-STEEM recommends running electrical power

into the enclosure at these knockouts.

• When unit is mounted on an outdoor curb, there must be a

gasket between the top of the curb and the base surface of the

unit to prevent moisture from leaking into the building from

either driving rain or melting snow.

• The outdoor enclosure has two available steam distribution

configurations. The standard configuration has a steam outlet

at the back of the outdoor enclosure for connecting to steam

dispersion unit piping. The optional internal steam distribution

configuration routes steam within the outdoor enclosure and

down through the pipe chase into a building. See drawings on

Pages 15 and 16.

I m po r ta n t : A pipe chase is located inside the burner section

of the enclosure. DRI-STEEM recommends using this pipe chase

for both the supply water piping and drain piping. Use insulation

to completely fill the area around the pipes to maintain proper

enclosure pressure and protect unit components from elevated

moisture levels within building; insulation must serve as an

effective vapor barrier. Use the provided pipe chase cover to seal

off the pipe chase. Cut necessary holes and seal after installation.

• The heater package has two thermostat-controlled heaters:

one strip heater is located in the control section, and one strip

heater is located in the burner section to keep the enclosure at

a constant minimum temperature. Once the humidifier tank is

full and up to temperature, the tank will keep the enclosure at an

appropriate temperature. The heaters will turn off.

• Refer to the installation section of this manual for directions

on installing electrical, gas, flue, drain, and water connections.

A separate electrical service connection for the outdoor GTS is

recommended. Insulation and/or heat taping of water piping is

recommended.

Pag e 1 4 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 17

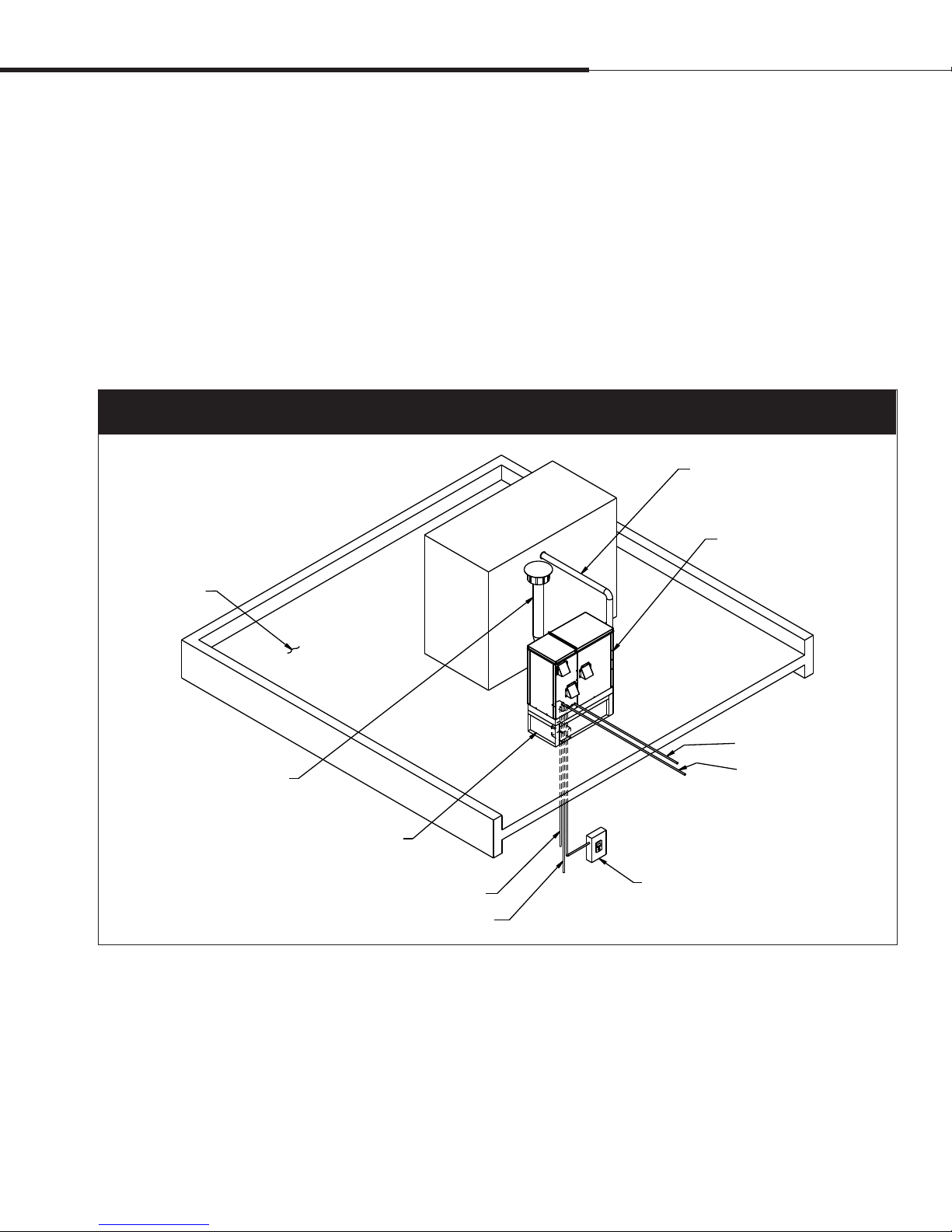

O u t d o o r e n c l o s u r e m o u n t i n g

( c o n t i n u e d )

Piping

• Insulate supply water piping to avoid dripping from

condensation. To ensure that water does not remain in the

fill line and freeze if there is a loss of power, DRI-STEEM

recommends field installing additional valves upstream of the

fill valve in a conditioned space. Power these valves on the same

circuit as the GTS; if the power goes off, water drains out of the

fill line to prevent freezing (see Figure 15-1).

• When pad-mounted or when the pipe chase cannot be used, the

supply water and drain piping can be run through the knockouts,

although preferably on the opposite side from the gas and

electric.

• Install external flue piping shall be provided by installers and

field installed. The flue of the outdoor enclosure exits out the

left side of the unit and a vertical stack must be constructed. The

stack must be a minimum of 5–10 feet (1.5–3.0 m) above the top

of the roof. However, the exact height varies depending on unit

size, climate, etc. Governing codes prevail. A UL or UL/CSA (or

equivalent) listed cap must be used and a drip tee included.

Figure 15-1:

Outdoor enclosure installation detail

Normally closed fill

valve (by factory)

Make-up water supply

piping (by installer)

Open to drain

Vent with check

valve (by installer)

120 V (230 V in Europe)

from unit disconnect or

other source

Normally closed

(fail closed) min

3/8" electric valve

(by installer)

Domestic water,

80 psig (582 kPa)

maximum

OM-4045

GTS humidifier in

outdoor enclosure

installed on roof top

Roof decking

Drain line, min. 1½" electric valve

Optional water seal (P-trap)

drain line, min. 1½" (DN40)

Normally open (fail open)

min ½" electric valve

(by installer)

Open drain

Disconnect (by installer); see Detail A

120 V supply (230 V in Europe)

Heated building interior

120 V

(230 V in Europe)

Disconnect

box

Detail A

N

To valves

(by installer)

To GTS humidifier

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 1 5

Page 18

O u t d o o r e n c l o s u r e m o u n t i n g

( c o n t i n u e d )

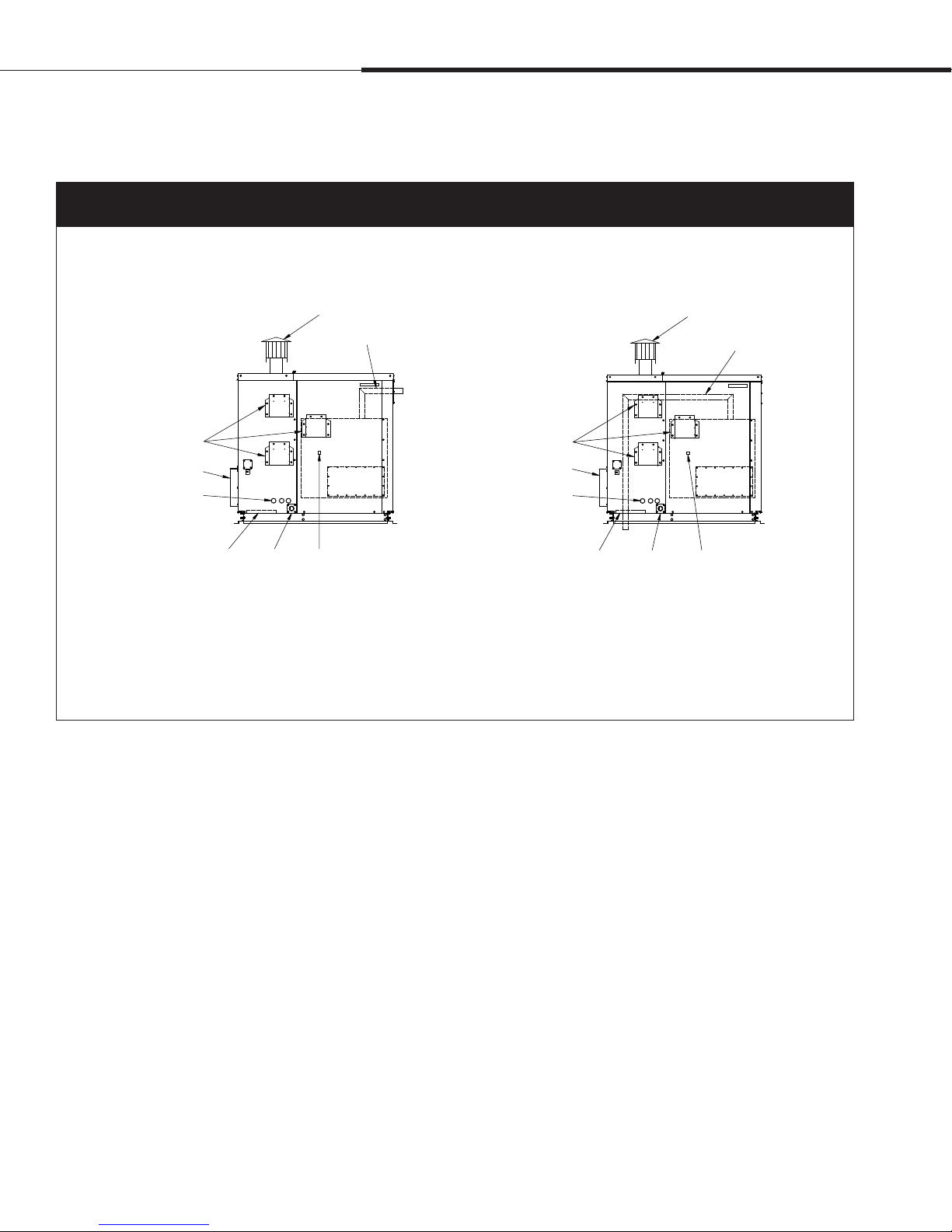

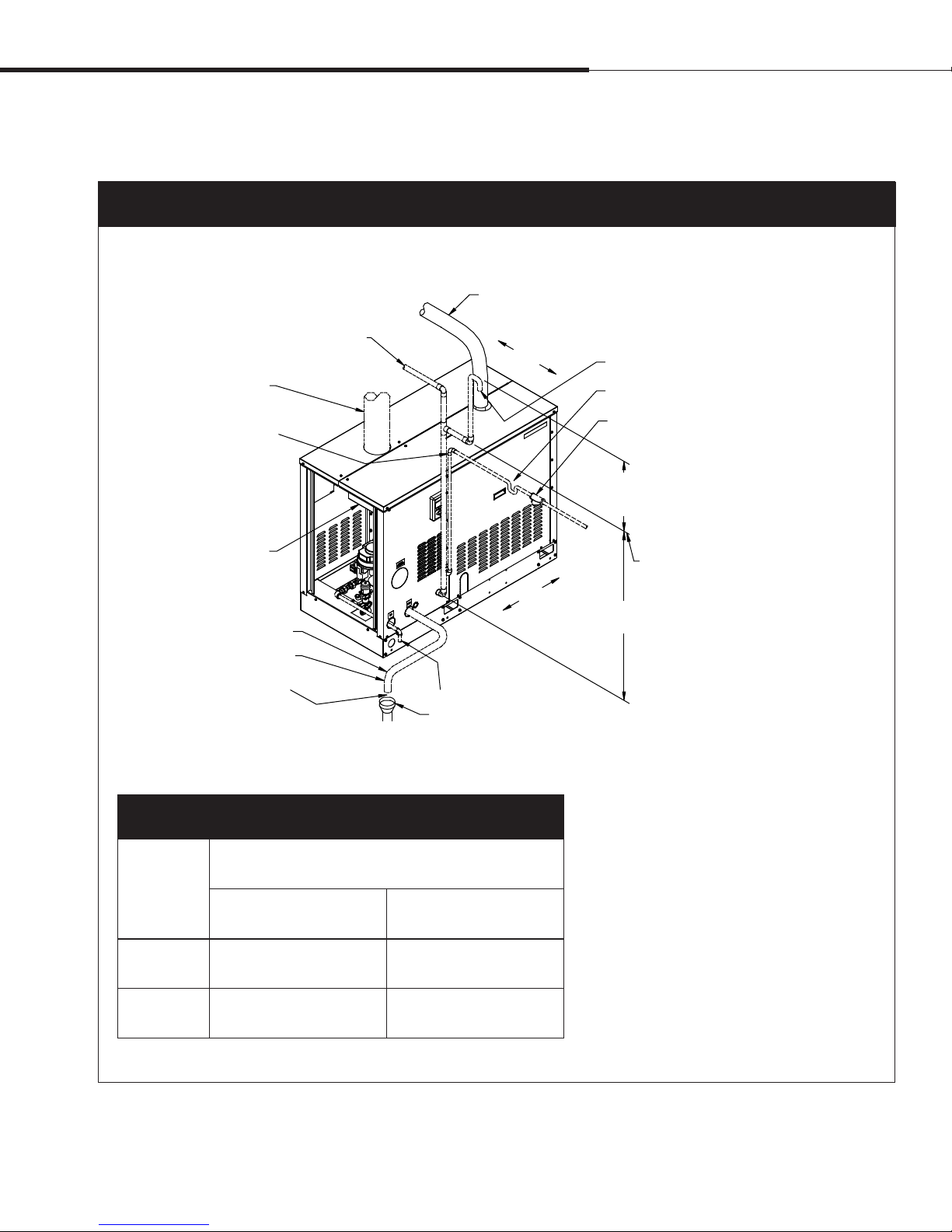

Figure 16-1:

GTS outdoor enclosure with standard or optional steam outlet, elevation view

Standard steam outlet Optional steam outlet

Flue piping (by installer)

Steam outlet (See Note 1)

Ventilation fans

Combustion

air intake

1½" (38 mm) knockouts

4" (102 mm) o.c.

Pipe chase

Notes:

1. The outdoor enclosure has two available steam distribution configurations. The standard configuration has a steam outlet at the back of the outdoor enclosure

for connecting to steam dispersion unit piping. The optional internal steam distribution configuration routes steam within the outdoor enclosure and down

through the enclosure pipe chase into a building.

2. There are three knockouts located on the right and left side of the enclosure. Run the electrical power and gas piping into the enclosure at these knockouts.

3. Piping from the GTS unit to the steam outlet is stainless steel pipe. Piping from the steam outlet to the dispersion assembly is provided by the installer.

Choose interconnecting steam piping material that is appropriate for the application (e.g., for high-purity steam applications, consider using stainless steel

interconnecting steam piping). See Page 22 for steam outlet sizes.

4. The GTS housed in an outdoor enclosure will operate properly in operating temperature of –40 °F to 122 °F (–40 °C to 50 °C).

Emergency

drain

GTS

humidifier

Power block

OM-1228M

Ventilation fans

Combustion

air intake

1½" (38 mm) knockouts

4" (102 mm) o.c.

Pipe chase

Emergency

drain

Flue piping (by others)

Steam outlet

(See Note 1)

GTS

humidifier

Power block

OM-1227M

Pag e 1 6 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 19

O u t d o o r e n c l o s u r e m o u n t i n g

( c o n t i n u e d )

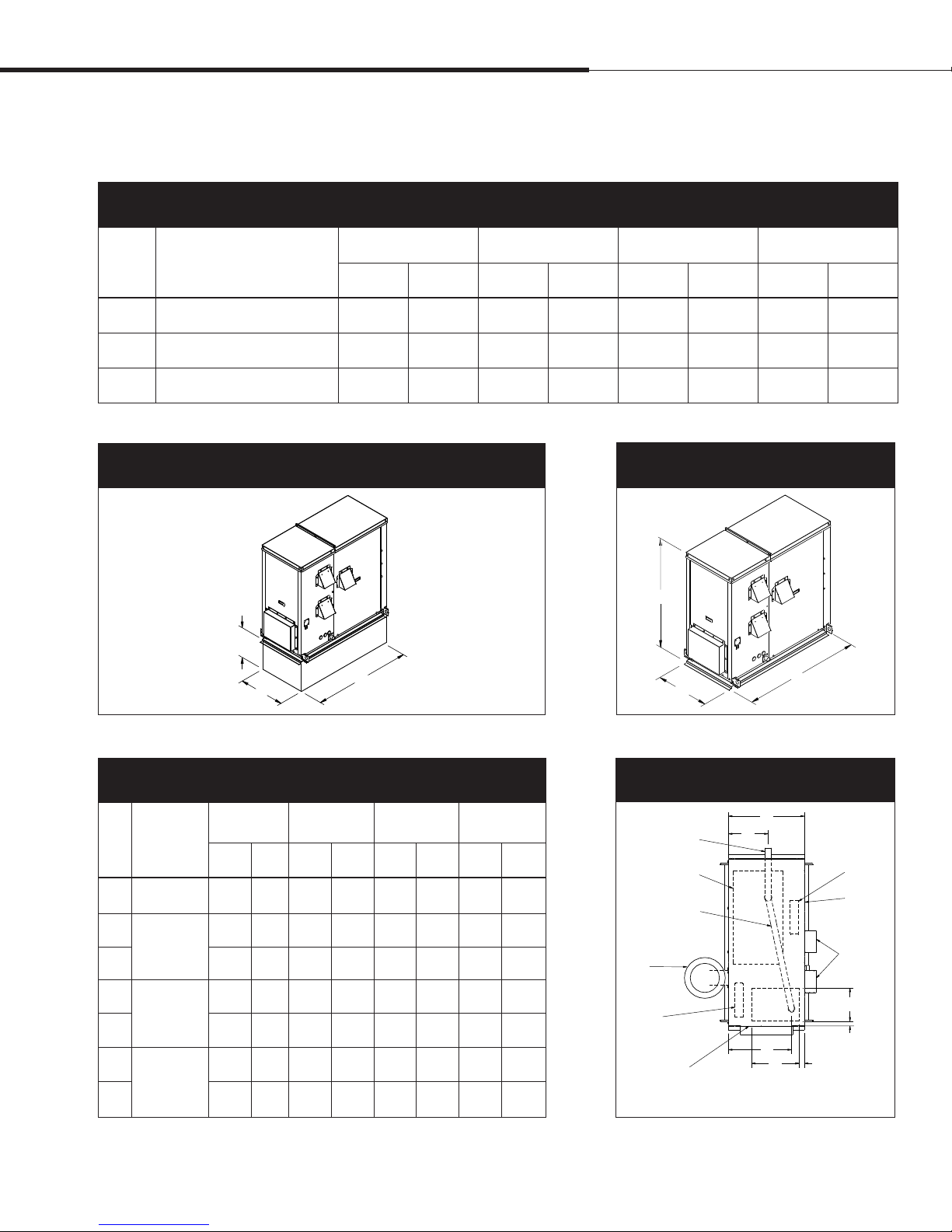

Table 17-1:

Outdoor enclosure dimensions

GTS-100

Description

A Enclosure height 54.63 1388 54.63 1388 54.63 1388 54.63 1388

B Enclosure width 26.00 660 32.00 813 42.00 1067 48.00 1219

C Enclosure length 57.25 1454 57.25 1454 57.25 1454 57.25 1454

GTS-200

inches mm inches mm inches mm inches mm

GTS-300

GTS-400

GTS-500

GTS-600

GTS-700

GTS-800

Figure 17-1:

Outdoor enclosure mounted on a curb

14"

(356 mm)

B

C

OM-7431

Table 17-2:

Outdoor enclosure top view dimensions

GTS-100

Description

Enclosure

T

width

U

Pipe chase

position

V 3.00 76 3.00 76 3.00 76 3.00 76

W

Pipe chase

size

X 11.00 279 11.00 279 11.00 279 11.00 279

Y

Steam pipe

position

Z 21.00 533 27.00 686 37.00 940 43.00 109

GTS-200

inches mm inches mm inches mm inches mm

26.00 660 32.00 813 42.00 1067 48.00 1219

3.00 76 3.00 76 3.00 76 3.00 76

16.00 406 16.00 406 16.00 406 16.00 406

14.12 359 20.12 511 30.12 765 36.12 917

GTS-300

GTS-400

GTS-500

GTS-600

GTS-700

GTS-800

Figure 17-2:

Outdoor enclosure mounted flush

A

B

C

Figure 17-3:

Outdoor enclosure top view

Exit for standard

steam outlet

GTS

humidifier

Exit for optional

steam outlet

(through pipe chase)

Flue

(by installer)

Burner

section

heater

Access panel

door

T

Y

Z

W

U

OM-7430

Control

panel

heater

Access

panel

door

Intake

ventilation

fans

X

V

OM-7432

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 1 7

Page 20

O u t d o o r e n c l o s u r e o p e r a t i o n

GTS outdoor enclosure sequence of operation

• Power is applied to the outdoor enclosure.

• If the ambient temperature in the enclosure is below

50 °F (10 °C), the strip heaters are powered up. If the enclosure

temperature reaches 35 °F (2 °C), power is allowed to the GTS

subpanel and the GTS unit is enabled. The strip heaters remain

on until the enclosure reaches 50 °F (10 °C) to ensure that

the temperature inside the enclosure does not drop below the

freezing point.

• When the enclosure temperature is at or above 50 °F (10 °C), the

GTS tank heats the enclosure. When there is no call for humidity,

an aquastat maintains tank temperature at the factory default

of 70 °F (21 °C). This temperature can be reset in the field to be

from 40-180 °F (4-82 °C).

• When the ambient temperature in the enclosure reaches 85 °F

(29 °C), two ventilation fans turn on to cool the electronic

components. A high limit is also provided to power down the

GTS if the enclosure temperature reaches 150 °F (66 °C). In a

high limit situation, the ventilation fans continue to run and once

the enclosure temperature falls below 130 °F (54 °C), the GTS

automatically resumes normal operation.

• A normally open drain valve is provided on the GTS outdoor

enclosure to drain the tank in the event of a power loss.

Pag e 1 8 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 21

W i r i n g : E l e c t r i c a l co n n e c t i o n s

W A R N I N G !

Installation must meet the requirements of governing codes or, in the

absence of governing codes, in accordance with the National Electrical

Code, ANSI/NFPA 70, or Canadian Electrical Code, CSA C22.1, or IEE

wiring regulations (BS7671). The electrical subpanel must have an

uninterrupted or unbroken ground to minimize personal injury if an

electrical fault should occur. This ground can consist of electrical wire

or conduit approved for electrical ground when installed in accordance

with existing electrical codes. Do not use gas piping as an electrical

ground.

• GTS humidifiers must be supplied with 120-volt AC, 60 Hz

(North American models) or 230-volt AC, 50 Hz (European

models) separately fused electrical service. The GTS humidifier is

equipped with a transformer to step down the voltage to 24 VAC

control voltage.

• When installed, the GTS humidifier must be electrically

grounded in accordance with governing codes or, in the absence

of governing codes, in accordance with the National Electrical

Code, ANSI/NFPA 70; or Canadian Electrical Code, CSA C22.1;

or IEE wiring regulations (BS7671).

In North America, the electrical conductors shall be Type MTW

(105 °C) AWG #14 (2.5 mm2) wire for 120 V line voltage , with

BLACK WIRE for HOT, WHITE WIRE for NEUTRAL, GREEN

AND YELLOW WIRE for GROUND. Units with outdoor

enclosure must use AWG #12 (4 mm2) for 120 V line voltage.Use

#18 gauge (1 mm2) for control wiring.

In Europe, the electrical conductors shall be Type MTW (105 °C)

2.5 mm2 wire for line voltage (230V), with BLACK WIRE for

LINE, BLUE WIRE for NEUTRAL, GREEN AND YELLOW

WIRE for GROUND, and 2.5 mm2 wire for control wiring.

• All electrical components and wiring must be protected from

mechanical damage and water. The control system requires an

earth ground for proper operation.

• The GTS humidifier is adjusted for correct performance. Only a

qualified gas appliance technician may alter throttle setting.

• Check the electric current characteristics and capacity

requirements against the nameplate. All wiring must be in

accordance with all governing codes and with the GTS wiring

diagrams located inside the control cabinet. See table on Page 8

for information on the various models.

• Refer to the Vapor-logic4 Installation and Operation Manual for

additional information on the controller furnished with this GTS

humidifier.

W A R N I N G !

Do not connect aluminum wire between

disconnect switch and humidifier. Use

only copper wire. Failure to follow these

instructions could cause a fire, resulting in

severe bodily injury, death, or significant

property damage.

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 1 9

Page 22

Figure 20-1:

Field piping overview for GTS standard water models

Optional condensate return piping from dispersion

unit; ¾" pipe thread (DN20) fitting at humidifier

Shock arrester recommended to

reduce water hammer, by installer

Flue size per governing codes.

Do not reduce.

Water supply line; water

pressure range 25 psi to 80 psi

(172 kPa to 582 kPa); water

conductivity minimum 100 µS/cm

G T S p i p i n g , s t a n d a r d w a t e r m o d e l s

Steam hose, pipe or tubing

Install level

Air vent tube

6" (150 mm)

minimum vent height

Flue connection

Offset humidifier from floor

drain to prevent flash steam

from rising into the humidifier

1½" NPT (DN40) drain piping must be

rated for 212 °F (100 °C) (by installer)

1" (25 mm) air gap

Notes:

• Locate air gap only in spaces with adequate

temperature and air movement to absorb flash steam;

otherwise, condensation may form on nearby surfaces.

Refer to governing codes for drain pipe size and

maximum discharge water temperature.

• Dashed lines indicate provided by installer.

• Humidifier flue gases must be vented to the outside

atmosphere.

• The water supply inlet is more than 1" (25 mm) above

the skim/overflow port, eliminating the possibility of

backflow or siphoning from the tank. No additional

backflow prevention is required; however, governing

codes prevail.

• Damage caused by chloride corrosion is not covered by

your DRI-STEEM warranty.

• See the next page for recommended water supply

piping for DI/RO water models.

Air vent height must be equal to

or greater than dimension “H”

(see table below)

Install level

H

Gas inlet connection

Open drain required.

See first note below.

Table 20-1:

Height required to overcome GTS internal pressure (H)

H = Height required to overcome humidifier internal pressure

GTS model

number

inches mm

100, 200 35 889

300, 400,

500, 600,

700, 800

41 1041

OM-1208

Pag e 2 0 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 23

G T S p i p i n g , D I / R O w a t e r m o d e l s

’

Figure 21-1:

Field piping overview for GTS DI/RO water models

Optional condensate return

piping from dispersion unit;

¾" pipe thread (DN20)

fitting at humidifier

Flue size per governing codes.

Do not reduce.

Water supply line; water

pressure range 25 psi to 80 psi

(172 kPa to 582 kPa); first 3'

(1 m) of supply line must be

rated for 212 °F (100 °C)

Steam hose, pipe or tubing

Install level

minimum vent height

Air vent tube

If water piping to humidifier is nonmetallic, we recommend

a 2" (50 mm) water seal in the supply line to isolate steam

during DI/RO water system maintenance.

Inlet strainer by installer

6" (150 mm)

Flue connection

Offset humidifier from floor

drain to prevent flash steam

from rising into the humidifier

1½" (DN40) drain piping must be

rated for 212 °F (100 °C)

1" (25 mm) air gap

Gas inlet connection

Open drain required. See first note below.

Table 21-1:

Height required to overcome GTS-DI internal pressure (H)

H = Height required to overcome humidifier internal pressure

GTS-DI model

number

inches mm

100, 200 35 889

300, 400,

500, 600,

700, 800

41 1041

Install level

Air vent tube height must

be equal to or greater than

dimension “H“ (see table below)

H

OM-1223

Notes:

• Locate air gap only in spaces with adequate

temperature and air movement to absorb flash

steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size

and maximum discharge water temperature.

• Dashed lines indicate provided by installer.

• Humidifier flue gases must be vented to the outside

atmosphere.

• The water supply inlet is more than 1" (25 mm)

above the overflow port, eliminating the possibility of

backflow or siphoning from the tank. No additional

backflow prevention is required; however, governing

codes prevail.

• Damage caused by chloride corrosion is not covered

by your DRI-STEEM warranty.

• In order to minimize DI/RO water use, disconnect

factory piping to the water tempering device and pipe

directly to tap water.

• See the previous page for recommended water supply

piping for standard water models.

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 2 1

Page 24

S u p p l y w a t e r a n d d r a i n o v e r f l o w

c o n n e c t i o n s

Supply water and drain overflow connections

Regardless of the type of water used, the following general

instructions MUST be followed:

• Make union connections at the humidifier on the make-up water

supply and drain/overflow lines.

• Provide a shutoff valve in the supply water line to isolate the

humidifier from the water system while servicing.

• Shock arrester, provided by installer, is recommended to reduce

water hammer.

• A 1" (25 mm) opening is provided in the humidifier tank to

accommodate skim and/or overflow protection. (Note: Follow

governing code requirements regarding size of drain pipe.)

• Use insulating unions or bushings to make connections between

copper and other dissimilar metal fittings, such as galvanized

steel. These insulating fittings are required to minimize

electrolytic corrosion, which results from the direct connection of

dissimilar metals in a water system.

• Before beginning ignition sequence of the humidifier at a new

installation, make sure the humidifier tank is full of water and the

water is free to flow into the tank.

• If planning to use heated supply water, disconnect the water

supply line to the water tempering device at the fill manifold

and reconnect it to a cold water supply. This will ensure that the

water tempering device operates properly.

Table 22-1:

Connection sizes

GTS-100

Description

Gas supply

Sealed combustion

piping (optional)

Flue vent 5 125 7 180 8 200 10 250

Water supply to fill valve

and tempering device*

Drain

Steam outlet

Condensate return

(recommended)

Notes:

* In order to minimize DI/RO water use, disconnect factory piping to the water tempering device and pipe directly to tap water.

If planning to use heated supply water, disconnect the water line to the water tempering device at the fill manifold, and reconnect it to a cold water supply.

This will ensure that the water tempering device operates properly.

(pipe thread)

(pipe thread)

(pipe thread)

(pipe thread or

(pipe thread)

GTS-200

inches DN inches DN inches DN inches DN

½

4 100 4 100 4 100 4 100

3/8

1½

2

hose)

¾

15

10

40

50

20

(pipe thread)

(pipe thread)

(pipe thread)

(pipe thread)

1

3/8

1½

3

(flange)

¾

GTS-300

GTS-400

GTS-500

GTS-600

25

10

40

80

20

1

(pipe thread)

3/8

(pipe thread)

1½

(pipe thread)

4

(flange)

¾

(pipe thread)

25

10

40

100

20

(pipe thread)

(pipe thread)

(pipe thread)

(pipe thread)

1¼

3/8

1½

4

(flange)

¾

GTS-700

GTS-800

32

10

40

100

20

Pag e 2 2 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 25

Wa t e r s u p p l y p i p i n g

Water supply piping general instructions

The GTS humidifier has a 1" (25 mm) internal air gap to prevent

back siphoning into a potable water system. However, some

governing codes may require additional protection such as a

vacuum breaker or backflow preventer.

The supply water pressure range must be 25 psi to 80 psi (172 kPa

to 552 kPa). When nonmetallic water piping is used, it must be

rated to withstand 212 °F (100 °C) or greater temperature. If not,

the final three feet of piping connected to the humidifier should be

metallic and should not be insulated.

GTS (standard water) water supply piping

The water supply assembly has a 3/8" pipe thread (DN10)

connection. Since the primary component of the water supply

assembly is a solenoid valve, there may be noise issues that surface

during a fill cycle.

During a fill cycle, the supply water drops the water temperature in

the tank and may collapse the steam, which can cause a low rolling

sound. To diminish this, adjust the factory-supplied needle valve

(installed prior to the fill valve) to decrease the water fill rate, and/

or use hot supply water.

In cases where water hammer occurs when the fill solenoid closes,

a shock arrester is recommended. Reducing the supply water

pressure (minimum 25 psi [172 kPa]) or using flexible tubing (rated

for 212 °F [100 °C] minimum continuous operating temperature)

may diminish the noise, but installing a shock arrester is the best

solution.

The minimum water conductivity for the GTS standard water

model is 100 µS/cm.

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 2 3

Page 26

Wa t e r s u p p l y p i p i n g ( c o n t i n u e d )

I m po r t an t : Damage caused by

chloride corrosion is not covered by your

DRI-STEEM warranty.

GTS-DI water supply piping

GTS-DI models control water level with a float valve, and have

a 3/8" pipe thread (DN10) connection. For DI models with the

end-of-season drain option, a solenoid valve is installed prior to

the float valve. The end-of-season feature shuts off the fill water

supply and drains the tank when there is no demand for humidity

for 72 hours. (This length of time is a default setting and is

user-adjustable. See the Vapor-logic4 Installation and Operation

Manual for more information.)

When using nonmetallic tubing for supply water, it must be

rated for 212 °F (100 °C) minimum continuous operating

temperature. DRI-STEEM recommends installing a 3' (1 m) piece

of noninsulated stainless steel pipe directly off the humidifier prior

to connecting to the nonmetallic tubing. When using nonmetallic

tubing, DRI-STEEM recommends the installer place a 2" (50 mm)

water seal/loop in the supply line to isolate steam during DI/RO

water system maintenance. (See Figure 21-1 on page 21.)

DRI-STEEM recommends installing a strainer in the water supply

line to prevent clogging of the solenoid valve or float valve orifice.

A strainer is highly recommended when the humidifier has the

end-of-season drain option. The strainer prevents particulate from

collecting at the solenoid valve seat.

In order to minimize DI/RO water use, disconnect factory piping

to the water tempering device and pipe directly to tap water.

W A R N I N G !

If the GTS-DI humidifier is supplied with tap water, the float valve

assembly will become clogged and particulate will accumulate on the

low water cutoff switch (float switch). This will cause failure of a critical

safety circuit and the potential for a dry tank fire. A dry tank fire can

cause heat exchanger, vapor hose, and wire insulation failure, severe

property damage, severe personal injury, or death.

Pag e 2 4 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 27

D r a i n p i p i n g

The drain line piped from the humidifier must be run to

an approved sanitary waste or suitable drain. Although the

GTS humidifier is equipped with integral water tempering, if

nonmetallic drain pipe or hose is used, DRI-STEEM recommends

it be rated for 212 °F (100 °C) minimum continuous operating

temperature.

Minimum drain pipe size is 1½" (DN40) inside diameter. If the

length of the drain piping exceeds 10' (3 m), increase the pipe size.

Do not locate the humidifier directly above a floor drain — skim

and drain water dumped into the drain will cause flash steam.

This steam will rise and saturate electrical components, adversely

affecting component life and performance.

An open drain with a 1" (25 mm) air gap between the drain piping

and the drain is required. Locate air gap only in spaces with

adequate temperature and air movement to absorb flash steam;

otherwise, condensing on nearby surfaces may occur.

Drain piping after the water seal must be pitched a minimum of

1/8"/ft (1%) toward the drain. Governing codes may require more

pitch.

If the proximity of a drain requires the humidifier drain and skim

water to be lifted, use a water pump with capacity of at least

12 gallons per minute (gpm) or 45.4 litres per minute (L/m).

Contact DRI-STEEM to order a drain pump suitable for your

installation. A check valve is required on the discharge of the pump

(see Figure 25-1). Electrical power for the pump is independent

of the humidifier.

The GTS humidifier has an auxiliary 1½" (DN40) drain outlet

located below the subpanel. This drain outlet can be hardpiped during installation to enable rapid tank draining before

maintenance. This outlet can also provide access for removing scale

from the tank bottom.

Figure 25-1:

Lifting drain water

Discharge

piping, by

Inlet

drain

water

piping,

by installer

installer

Check valve

Integral water tempering chamber

Governing codes may require that the

212 °F (100 °C) drain and skim/overflow

water from the humidifier be tempered

before it is discharged into the building

drain piping. The GTS humidifier has an

integral water tempering chamber that

tempers 6 gpm (22.7 L/m) of 212 °F

(100 °C) water to 140 °F (60 °C). The water

tempering sequence of operation is:

1. Hot water discharged from the humidifier

enters the water tempering chamber

from either the skim/overflow port or the

tank drain.

2. Cold water enters the water tempering

chamber through a temperature-actuated

valve to mix with the hot discharged

water.

3. Tempered water at 140 °F (60 °C)

maximum exits through the water

tempering chamber side outlet for safe

discharge into a municipal sewer system

or PVC pipe.

4. In order to minimize DI/RO water use,

disconnect factory piping to the water

tempering device and pipe directly to tap

water.

5. If planning to use heated supply water,

disconnect the water line to the water

tempering device at the fill manifold,

and reconnect it to a cold water supply.

This will ensure that the water tempering

device operates properly.

Table 25-1:

Integral water tempering

specifications

Water type

Hot water

inflow

Cold water

inflow*

Tempered

water outflow

Maximum

low rate

U.S.

gpm

12 45.4 140 60

L/m °F °C

6 22.7 212 100

6 22.7 70 21

Maximum

temperature

Water pump

Note:

Size water pump to handle a minimum of 12 gpm (45.4 L/m).

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 2 5

DC-1117

Note:

* Cold water inflow pressure must be between 25 psi

and 80 psi (172 kPa and 552 kPa).

Page 28

G a s p i p i n g

C a ut i o n! Supply the humidifier only

with the gas type (natural gas or LP gas)

listed on the humidifier name plate or

burner failure will result. To convert the

humidifier to natural gas or LP gas, contact

DRI-STEEM technical support or your

DRI-STEEM representative/distributor.

C a ut i o n! Gas pressure to the

humidifier controls must never exceed

24" wc (6 kPa, 60 mbar) or the gas

valve will become damaged and require

replacement. Install a 1/8" pipe thread

(DN6) plugged tapping, accessible for test

gauge connection, immediately upstream of

the gas supply connection to the appliance.

I m po r t an t : For North American

models, the recommended supply pressure

is 7" wc (1.75 kPa) for natural gas or

11" wc (1.83 kPa) for LP gas.

For European models, the required supply

pressure is 20 or 25 mbar for natural gas

and 30, 37, or 50 mbar for propane gas.

Gas piping guidelines

• After threading and reaming the ends of the pipes, inspect piping

and remove loose dirt and chips.

• Support piping so there are no strains imposed on unit

or controls.

• Use two wrenches when connecting piping to unit or controls.

• Provide a drip pocket before each unit and in the line where low

spots cannot be avoided.

• Takeoff to unit should come from top or side of main to avoid

trapping condensate.

• Piping that is subject to wide temperature variations should be

insulated.

• Pitch piping up toward unit at least ¼" (6 mm) per 15' (4.5 m) of

horizontal run.

• Compounds used on threaded joints of gas piping must be

resistant to the harmful action of liquefied petroleum gases.

W A R N I N G !

Purge air before lighting unit by disconnecting piping at gas control.

In no case should line be purged into heat exchanger. Failure to follow

these instructions could cause an explosion or fire resulting in bodily

injury, death, or significant property damage.

• After installation, check field piping and humidifier gas train for

gas leaks.

• Do not use soap solution or open flame on humidifier gas train.

A gas leak detector is recommended.

• Install a ground joint union and a manual shutoff valve

immediately upstream of the unit. Install a plugged tapping

upstream of the shut-off valve, accessible for test gauge

connection. Pressure tappings for test gauges are located on all

gas valves.

• Allow at least 5' (1.5 m) of piping between any high pressure

regulator and unit pipe connection.

• Piping installation must conform to the requirements of

the authority having jurisdiction or, in the absence of such

requirements, must conform to:

In the United States: The National Fuel Gas Code, ANSI Z223.1

(latest edition).

In Canada: Local plumbing or waste water codes and other

applicable codes and with the current code CAN/CGS-B149.1,

More gas piping instructions on the next page ▶

Pag e 2 6 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 29

G a s p i p i n g ( c o n t i n u e d )

“Installation Code for Natural Gas Burning Appliances and

Equipment,” or CAN/CGA-B149.2, “Installation Code for

Propane Burning Appliances and Equipment.”

In Europe: The National Gas Safety (Installation & Use)

Regulations.

• Do not use flexible connectors.

• Piping to units should conform with local and national

requirements for type, volume, and gas handled and for pressure

drop allowed in the line. Refer to the tables on this page to

determine the gas flow in ft3/hr or m3/hr for the type of gas and

size of unit to install. Using this value and the length of pipe

necessary, determine the pipe diameter. Where several units are

served by the same main, the total capacity, gas flow, and length

of main must be considered. Avoid pipe sizes smaller than ½"

(DN15). Table 27-2 below allows for the usual number of

fittings with a 0.3" wc (0.07 kPa) pressure drop.

• When the specific gravity of the gas is other than 0.60 for natural

gas or 1.53 for propane, use Table 27-1.

Table 27-2:

Gas pipe capacities for gas pressures of 0.5 psig (3.45 kPa) or less

Gas flow in piping in ft3/hr and m3/hr at

pressure drop of 0.3" wc (0.07 kPa)

Length

of pipe

Nominal iron pipe diameter in inches (DN)

Specific gravity = 0.60

Table 27-1:

Specific gravity conversion factors

Natural gas

Specific gravity Factor

0.55 1.04

0.60 1.00

0.65 0.962

Propane gas

Specific gravity Factor

1.50 0.633

1.53 0.626

1.60 0.612

Note:

Use the above multiplying factor with Table: 27-2

when the specific gravity of gas is other than 0.60

(natural gas) or 1.53 (propane).

½" (DN15) ¾" (DN20) 1" (DN25) 1¼" (DN32) 1½" (DN40)

ft m ft3/hr m3/hr ft3/hr m3/hr ft3/hr m3/hr ft3/hr m3/hr ft3/hr m3/hr

10 3 132 3.7 278 7.9 520 14.7 1050 29.7 1600 45.3

20 6 92 2.6 190 5.4 350 9.9 730 20.7 1100 31.1

30 9 73 2.1 152 4.3 285 8.1 590 16.7 890 25.2

40 12 63 1.8 130 3.7 245 6.9 500 14.2 760 21.5

50 15 56 1.6 115 3.3 215 6.1 440 12.5 670 19.0

60 18 50 1.4 105 3.0 195 5.5 400 11.3 610 17.3

70 21 46 1.3 96 2.7 180 5.1 370 10.5 560 15.9

80 24 43 1.2 90 2.5 170 4.8 350 9.9 530 15.0

90 27 40 1.1 84 2.4 160 4.5 320 9.1 490 13.9

100 30 38 1.1 79 2.2 150 4.2 305 8.6 460 13.0

See example on page 28.

More gas piping instructions

on the next page ▶

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 2 7

Page 30

G a s p i p i n g ( c o n t i n u e d )

Gas leak testing

• When leak-testing the gas supply piping

system, disconnect the humidifier and

its gas shutoff valve during any pressure

in excess of 24" wc (6 kPa). Isolate the

humidifier from the gas supply piping

system by closing its field-installed

manual shutoff valve during any pressure

not equal to 24" wc (6 kPa).

• With all burners running, check gas

supply pressure at the inlet pressure tap

of the combination gas control valve.

For North American models, the

recommended supply pressure is

7" wc (1.75 kPa) for natural gas or

11" wc (1.83 kPa) for LP gas. Perform

gas piping purging as described in ANSI

Z223.1 (latest edition) or in Canada, CAN/

CGA-B149 codes. The minimum supply

pressure is 6" wc (1 kPa) for natural gas

or LP gas.

For European models, the required supply

pressure is 20 or 25 mbar for natural gas

and 30, 37, or 50 mbar for propane gas.

Example

For this example, refer to the tables on the previous page.

To determine gas piping size, begin by calculating the cubic

feet/hour (ft3/hr) or m3/hr using the following formula:

Btuh (kW) input

Calorific value of gas

Calorific values are:

• Natural gas: 1025 Btu/ft3 (10.6 kW-hr/m3)

• Propane: 2500 Btu/ft3 (25.9 kW-hr/m3)

For example, if you have a GTS-400 operating on natural gas,

3

calculate the ft

400,000 Btuh

1025 Btu/ft

117.2 kW

10.6 kW-hr/m3

/hr or m3/hr as follows:

= 390 ft3/hr

3

= 11.1 m3/hr

If you need to run your gas piping 60 feet (18 m), see Table 27-2 on

the previous page and look horizontally across the 60 ft (18 m) row

until you locate the next highest value above your calculated ft3/hr

or m3/hr. In this example, you are looking for the next highest value

above 390 ft3/hr (11.05 m3/hr), which is 400 ft3/hr (11.3 m3/hr) and

indicates the use of a 1¼" (DN32) pipe for this application.

Using the same example, if the specific gravity of your natural

gas was 0.55 (instead of the 0.60 standard), see Table 27-2 for an

adjustment factor. In this case, the factor would be 1.04, which you

multiply by the 390 ft3/hr (11.05 m3/hr) value. This gives you a new

value of 406 ft3/hr (11.49 m3/hr). Referring again to the gas pipe

capacities table (Table 27-2), you see that for the same 60 ft (18 m)

length, you now need to use 1½" (DN40) pipe due to the change in

the specific gravity of the gas.

More gas piping instructions on the next page ▶

Pag e 2 8 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

Page 31

G a s p i p i n g ( c o n t i n u e d )

Figure 29-1:

GTS gas piping

GTS or GTS-DI models 100, 200

½” pipe thread (DN15) piping

Plugged test

gauge connection

Gas cock

3” (76 mm) min.

GTS or GTS-DI models 300-800

Gas manifold (by DRI-STEEM)

Drip pocket

OM-1236

See Table 22-1 for

pipe size by model

Plugged test

gauge connection

Gas cock

3” (76 mm) min.

Note:

Dashed lines indicate supplied by installer

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 2 9

Drip pocket

OM-1235

Page 32

C o m b u s t i o n a n d v e n t i l a t i o n a i r

W A R N I N G !

Air for combustion must not be

contaminated by halogen compounds, which

include fluoride, chloride, bromide, and

iodide. These elements are found in aerosol

sprays, detergents, bleaches, cleaning

solvents, salts, air fresheners, and other

household products.

When the GTS is located in an environment

with negative pressure or toxic air, it must

have sealed combustion.

Failure to follow these instructions could

cause severe bodily injury or death.

Combustion and ventilation air

The GTS supports both room air and sealed combustion.

Requirements and recommendations for each follow.

Room air combustion

• All fuel burning equipment must be supplied with air for

combustion of the fuel. Sufficient air must be provided to ensure

there is not a negative pressure in the equipment room or space.

• Provide adequate combustion and ventilation air in accordance

with Section 5.3, Air for Combustion and Ventilation, of the

National Fuel Gas Code, ANSI Z223.1 or applicable provisions

of governing codes. Canadian installations must be installed in

accordance with sections 7.2, 7.3, and 7.4 of the CAN/CGA.B149

Installation Codes and all authorities having jurisdiction.

• For proper and safe operation this appliance needs air for

combustion and ventilation. Do not block or obstruct air

openings on the appliance, spaces around the appliance, or air

openings communicating with the appliance area.

• Do not locate in a dusty environment.

• Do not block the flow of combustion and ventilation air. To

provide for necessary oxygen for proper combustion, openings

must be provided to allow outside air to enter the space where the

humidifier is located. Enclosed spaces, such as equipment rooms,

must be vented for combustion air. The size of air openings must

be based on all gas-burning equipment installed in the space

involved. Table 30-1 outlines four types of locations, and the

requirements of each.

Sealed combustion

Table 30-1:

Location of humidifier and required air openings

Location description Required air opening

Confined space with all air from inside the

building; conventional frame, brick or stone

construction with normal infiltration (Note:

this location rarely provides enough air for

higher capacity units.)

Confined space with all air from outside the

building through air ducts

Confined space with all air from outside the

building from through-wall openings only

(no ducts)

Unconfined space with all air from outside

the building

Note:

* The minimum dimension of any opening is 3" × 3" (76 mm × 76 mm).

Pag e 3 0 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

More instructions on the next page ▶

Two openings, 1 sq. in. (6.5 cm2) per

opening per 1000 Btu/hr (293 W) input

The minimum free area of all openings

combined is 100 sq. in. (645 cm2).

Two openings, 2 ducts, 1 sq. in. (6.5 cm2)

per opening per 2000 Btu/hr (586 W) input*

Two openings, 1 sq. in. (6.5 cm2) per

opening per 4000 Btu/hr (1172 W) input*

Same as confined space; all air from outside

the building

Page 33

C o m b u s t i o n a n d v e n t i l a t i o n a i r

( c o n t i n u e d )

The GTS supports sealed combustion using 4" (DN100) PVC or

CPVC piping (see Figure 31-1). All GTS models have a single

point connection to the blower below the humidifier shroud.

When running PVC or CPVC piping for sealed combustion,

the maximum allowable distance to the outdoor air source is 70'

(21.3 m) including 7' (2.1 m) equivalent length for each elbow.

The outside air source can be either a final connection outside

the building or a connection to an outdoor air plenum within the

building. When the combustion air origination point is outside the

building, the opening must be covered with a large mesh screen to

prevent the introduction of unwanted materials without restricting

airflow.

If sealed combustion piping is less than 20 ft (6 m), we recommend

insulating piping to prevent condensation.

Figure 31-1:

GTS optional sealed combustion connection

W A R N I N G !

When installing sealed combustion piping

for more than one GTS humidifier, do

not commonly manifold multiple sealed

combustion piping runs without having the

manifold sized for the specific installation by

a licensed engineer. Failure to follow these

instructions could starve the GTS humidifier

of combustion air resulting in either the

unit not being able to light or high carbon

monoxide (CO) levels, which may cause

severe personal injury or death.

DRI - STEE M G TS Hu m idif i e r Ins t alla t i on, O p erat i o n, and Main t e nanc e Manu a l • Pag e 3 1

4" dia. (DN100) PVC

or CPVC combustion

air intake

OM-1225

Page 34

W A R N I N G !

The humidifier must be installed by

a qualified technician and meet the

requirements of all governing codes. Failure

to follow these instructions could cause

severe bodily injury or death.

Note:

For European models, contact your

distributor for horizontal venting parts.

Ve r t i c a l a n d h o r i z o n t a l v e n t i n g

Vertical and horizontal venting guidelines (stack connection)

• The GTS is a Fan Assisted Category I (natural draft) Appliance.

Installations where the vent terminates in a side wall of the

building, or where the overall horizontal run exceeds the overall

vertical run require a power venter. See Page 34.

• Maximum flue temperature is 400 °F (205 °C) + ambient.

• Flue draft negative pressure greater than 0.2" wc (50 Pa) may cause

unacceptable post ignition.

• Vent piping must be UL or UL/CSA listed type B, B-W, or any

other vent type approved for a Category I appliance.

– Type B: Double wall construction, inner wall aluminum, outer

wall galvanized steel

– Type B-W: Same as type B except fabrication in oval shapes only

Do not use more than one type of venting per application Required

clearance for Type B and B-W vent piping is 1" (25 mm).

• Do not use vent equipment from more than one manufacturer.

• When connecting the humidifier to a gas vent or chimney,

installation must be in accordance with Part 7, Venting of

Equipment, of the National Fuel Gas Code, ANSI Z223.1; or

Section 7, Venting Systems and Air Supply Appliances, of the

CAN/CGA B149 Installation Codes; or National Gas Safety Code

(Installation & Use) Regulations (latest revision); governing codes,

and the vent manufacturer’s instructions.

• When applying the codes, reference also the venting

manufacturer's instructions, the service gas supplier's regulations,

and the specific instructions provided in this manual.

C A UT I O N! Install a drip tee or flue box condensate drain for startup flue condensate removal. Failure to follow these instructions could

cause water to accumulate in the flue box.

• The purpose of venting the gas humidifier is to completely remove

all products of combustion and ventilation gases to the outside air.

• For vertical vent pipe terminations only: Do not reduce the vent

diameter and avoid short turns in the vent piping. Use the same

size stack as the vent furnished with the humidifier. Maintain a

minimum upward slope of ¼" per linear foot (2%) on all horizontal

runs. Maintain proper support of vent connections and joints.

Observe clearances (in accordance with applicable codes) from all

combustible materials and install an approved cap for the stack

outlet. The bottom of the cap must be one stack diameter above the

top of the stack.

• Inspect for proper and tight construction. Remove any restrictions

or obstructions. An existing chimney may require cleaning.

• For vertical vent pipe terminations only: Extend chimney or vent at

least 3' (1 m) above its passage through a roof and at least 2' (0.6 m)

above any ridge within 10' (3 m) of the chimney (governing codes

apply).

• Do not connect this humidifier to a chimney flue servicing a

separate appliance designed to burn solid fuel.

Pag e 3 2 • DR I - STE E M GTS H u m idif i er In s t alla t ion, O p era t i on, a n d Main t enan c e Manu a l

More instructions on the next page ▶

Page 35

Ve r t i c a l a n d h o r i z o n t a l v e n t i n g

( c o n t i n u e d )

• Never connect this humidifier to a chimney serving a fireplace,

unless the fireplace opening is permanently sealed off.

• Code prohibits venting into an unlined masonry or concrete

chimney.

• If this humidifier is connected to a lined, masonry chimney, the

chimney must be sized and installed according to the provisions

of the National Fuel Gas Code or Canadian CAN/CGA.B149

requirements, or governing codes.

• Vent connector serving this appliance shall not be connected into