DriSteem CRUV 4, CRUV 2, CRUV 8, CRUV 6, CRUV 10 Installation, Operation And Maintenance Manual

...Page 1

READ AND SAVE THESE INSTRUCTIONS

CRUV

Electric Humidifier

®

Installation, Operation,

and Maintenance Manual

Page 2

WARNINGS AND CAUTIONS

Warnings and cautions

WARNING

Indicates a hazardous situation that could result in death or

serious injury if instructions are not followed.

mc_051508_1145

WARNING

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualifi ed

HVAC and electrical contractors and in compliance with local, state, federal, and governing codes. Improper installation

can cause property damage, severe personal injury, or death as a result of electric shock, burns, or fi re.

DriSteem Technical Support: 800-328-4447

Read all warnings and instructions

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all

warnings and instructions could produce the hazardous situations described, resulting in property damage, personal injury,

or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause bacteria and mold

growth or dripping water into building spaces. Dripping water can cause property damage; bacteria and mold growth

can cause illness.

mc_011909_1215

Hot surfaces and hot water

This steam humidifi cation system has extremely hot surfaces. Water in tanks, steam pipes, and dispersion assemblies can

be as hot as 212 °F (100 °C). Discharged steam is not visible. Contact with hot surfaces, discharged hot water, or air

into which steam has been discharged can cause severe personal injury. To avoid severe burns, follow the cool-down

procedure in this manual before performing service or maintenance procedures on any part of the system.

mc_011909_1130

CAUTION

Indicates a hazardous situation that could result in damage to or

destruction of property if instructions are not followed.

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ii

Page 3

Warnings and cautions

WARNING

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any

part of the humidifi cation system. Failure to disconnect electrical power could result in fi re, electrical shock, and other

hazardous conditions. These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock

or fi re. Do not remove humidifi er electrical panel cover, heater terminal cover, or subpanel access panels until electrical

power is disconnected.

Follow the shutdown procedure in this manual before performing service or maintenance procedures on any part of the

system.

mc_052410_1510

Electric shock hazard

If the humidifi er starts up responding to a call for humidity during maintenance, severe bodily injury or death from electric

shock could occur. To prevent such start-up, follow the procedure below before performing service or maintenance

procedures on this humidifi er (after the tank has cooled down and drained):

• If the humidifi er is equipped with a Vapor-logic

• Shut off all electrical power to humidifi er using fi eld-installed fused disconnect, and lock all power disconnect switches in

OFF position.

• Close fi eld-installed manual water supply shut-off valve.

mc_050808_1540-CRUV

®

controller, use the keypad to change the control mode to Standby.

CAUTION

Hot discharge water

Discharge water can be as hot as 212 °F (100 °C) and can damage the drain plumbing.

To prevent such damage from humidifi ers without water tempering, allow the tank to cool before draining.

Humidifi ers equipped with a water tempering device such as a DriSteem Drane-kooler need fresh make-up water in order to

function properly. Make sure the water supply to the water tempering device remains open during draining.

Excessive supply water pressure

Supply water pressure greater than 80 psi (550 kPa) can cause the humidifi er to overfl ow.

mc_030910_1440

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

Page 4

Table of contents

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Supply water guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Tap/softened water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

RO/DI water option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Water type conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dispersion options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Capacities, electrical specifications, and weights . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Selecting a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CRUV in a packaged unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dispersion in a duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dispersion control devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Piping: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tap/softened water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RO/DI water option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supply water and drain piping . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drane-kooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sensor placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dispersion: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Selecting the dispersion assembly location . . . . . . . . . . . . . . . . . . . 14

High-efficiency Tube option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Drip tee installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Interconnecting piping requirements . . . . . . . . . . . . . . . . . . . . . . . . 16

Single tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Rapid-sorb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ultra-sorb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ATTENTION INSTALLER

ii

Read this manual before installing. Leave

manual with product owner.

DriSteem Technical Support

800-328-4447

Where to find more information

On our Web site:

The following related documents can be

viewed, printed or ordered from our web site,

www.dristeem.com

• Catalogs:

– CRUV

– Ultra-sorb

• Installation, Operation, and Maintenance

manuals:

– Ultra-sorb

– Vapor-logic® controller (includes humidifi er

operation and troubleshooting)

• DriSteem Design Guide (includes steam

loss tables and general humidifi cation

information)

In DriCalc:

DriCalc® is our humidifi cation system sizing

and selection software, which can be ordered

from our website. Also in DriCalc:

• Library of installation guides

• Dispersion and sensor placement in ducts

and air handlers

• Vertical airfl ows

Or call us at 800-328-4447

While obtaining documents from our web site

or from DriCalc is the quickest way to review

our literature, we will also mail to you any

literature you need.

®

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iv

Page 5

Table of contents

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Start-up checklist: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

LW series controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Vapor-logic controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Start-up and operation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

LW series controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Vapor-logic controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Tap/softened water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Water quality and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Skim duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cool down humidifier (LW series controller) . . . . . . . . . . . . . . . . . . 34

Cool down humidifier (Vapor-logic controller) . . . . . . . . . . . . . . . . . 34

Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Off-season shut-down procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 37

RO/DI water option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cool down humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Off-season shut-down procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LW series controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LW series controller and RO/DI water . . . . . . . . . . . . . . . . . . . . . . 41

Replacement parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Subpanel with LW series controller . . . . . . . . . . . . . . . . . . . . . . . . 44

Subpanel with time delay and relay . . . . . . . . . . . . . . . . . . . . . . . . 46

Subpanel with Vapor-logic option . . . . . . . . . . . . . . . . . . . . . . . . . 48

Subpanel with Vapor-logic and SSR options . . . . . . . . . . . . . . . . . . 50

Keypad/display and troubleshooting

The Vapor-logic Installation and Operation

Manual, shipped with your humidifi er if

ordered with optional Vapor-logic control, is a

comprehensive operation manual. Refer to it

for information about using the keypad/display

and Web interface, and for troubleshooting

information.

Download DriSteem literature

Most DriSteem product manuals can be

downloaded, printed, and ordered from our

web site: www.dristeem.com

mc_052410_1335

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

Page 6

OVERVIEW

Supply water guidelines

Product overview

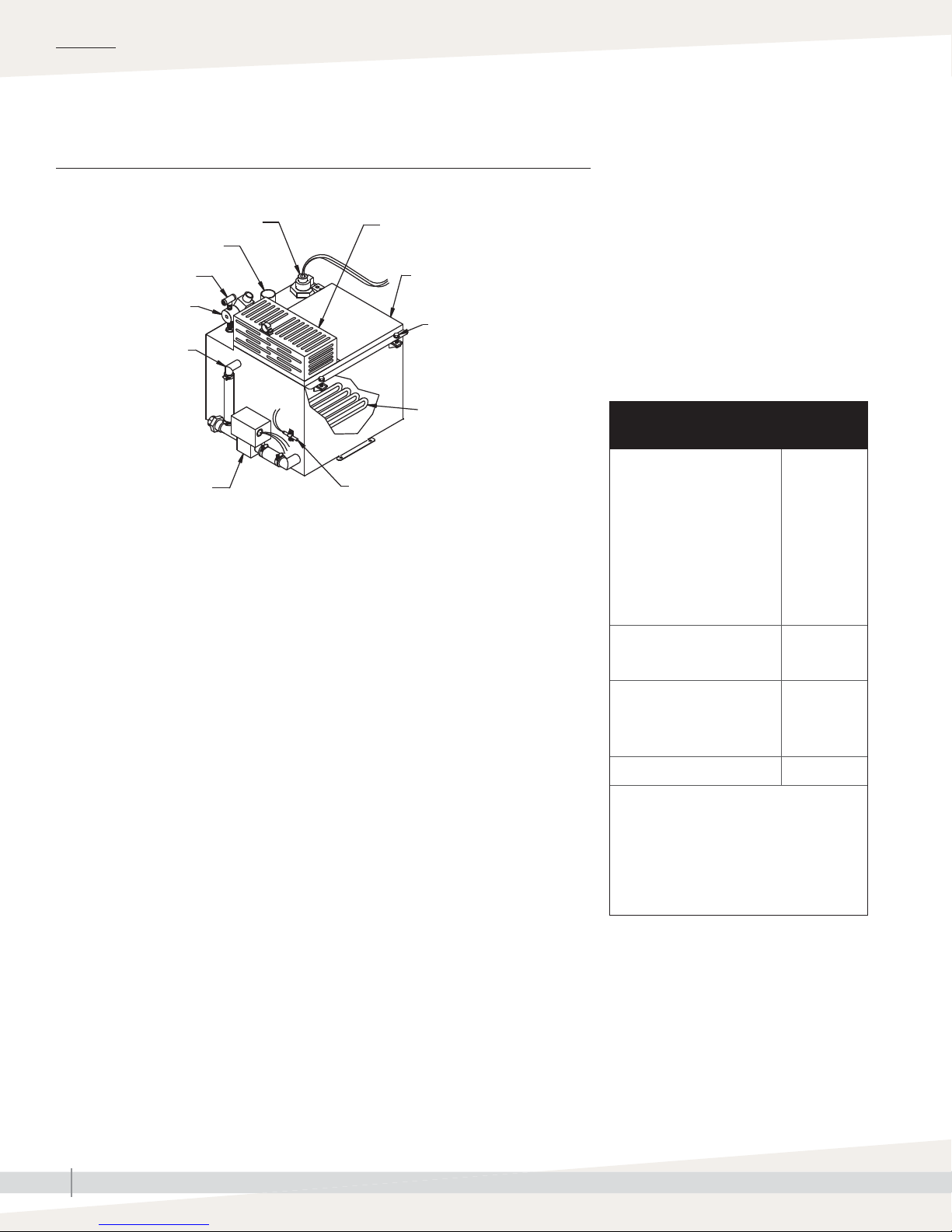

FIGURE 2-1: CRUV HUMIDIFIER

Tap/softened water model

Probe

Steam outlet

Strainer

Fill valve

Over fl ow

OM-770-1

Electric drain

TAP/SOFTENED WATER

Heater terminal cover

Cover

Cover bolts

Heater element

Tank temperature sensor

CRUV humidifi ers with tap/softened water (shown above) use electricity to

heat tap or softened fi ll water into steam for humidifi cation. A conductivity

probe monitors the water level; therefore, water conductivity must be at least

30 µS/cm for proper operation. CRUV with tap/softened water will not

operate with RO/DI water. For RO/DI water, use CRUV with the RO/DI water

option.

RO/DI WATER OPTION

CRUV humidifi ers with RO/DI water systems (systems using deionized water or

water that has been treated using reverse osmosis) use electricity to heat RO/DI

fi ll water into steam for humidifi cation. Water level is controlled with a fl oat

valve and low water cutoff switch. Float valves are compatible with RO/DI

water only.

Humidifi ers with the RO/DI water option are virtually maintenance free and

require little or no downtime.

Supply water guidelines

Supply water quality is an important component

of humidifi er reliability and maintenance.

Examples:

• Corrosive water can decrease the service life

of the humidifi er.

• Excessive water hardness can increase the

humidifi er maintenance requirements.

To maximize humidifi er service life and

minimize humidifi er maintenance, DriSteem

has established guidelines for supply water See

Table 2-1.

Table 2-1:

DriSteem supply water guidelines

Chlorides*

RO or DI water

Softened water

Tap water

* Damage caused by

chloride corrosion is

not covered by your

DriSteem warranty.

Total hardness

Tap water < 500 ppm

pH

RO, DI, or softened water

Tap water

Silica < 15 ppm

You may wish to take action to mitigate

potential negative effects to your

humidifi er. Supply water outside of these

guidelines may void your DriSteem

warranty. Please contact your DriSteem

Representative or DriSteem Technical

Support if you need advice.

< 5 ppm

< 25 ppm

< 50 ppm

7 to 8

6.5 to 8.5

WATER TYPE CONVERSION

CRUV tap/softened water humidifi ers can be converted in the fi eld for use with

RO/DI water, and CRUV RO/DI water humidifi ers can be converted in the

fi eld for use with tap/softened water. Contact your DriSteem representative or

distributor for parts and instructions.

mc_061610_1640-CRUV

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2

Notes:

See Pages 8 and 9 for detailed installation

drawings.

mc_071912_1545

Page 7

OVERVIEW

Product overview

DISPERSION OPTIONS

Dispersion options shown on this page are available for CRUV humidifi ers.

See the installation instructions beginning on Page 6.

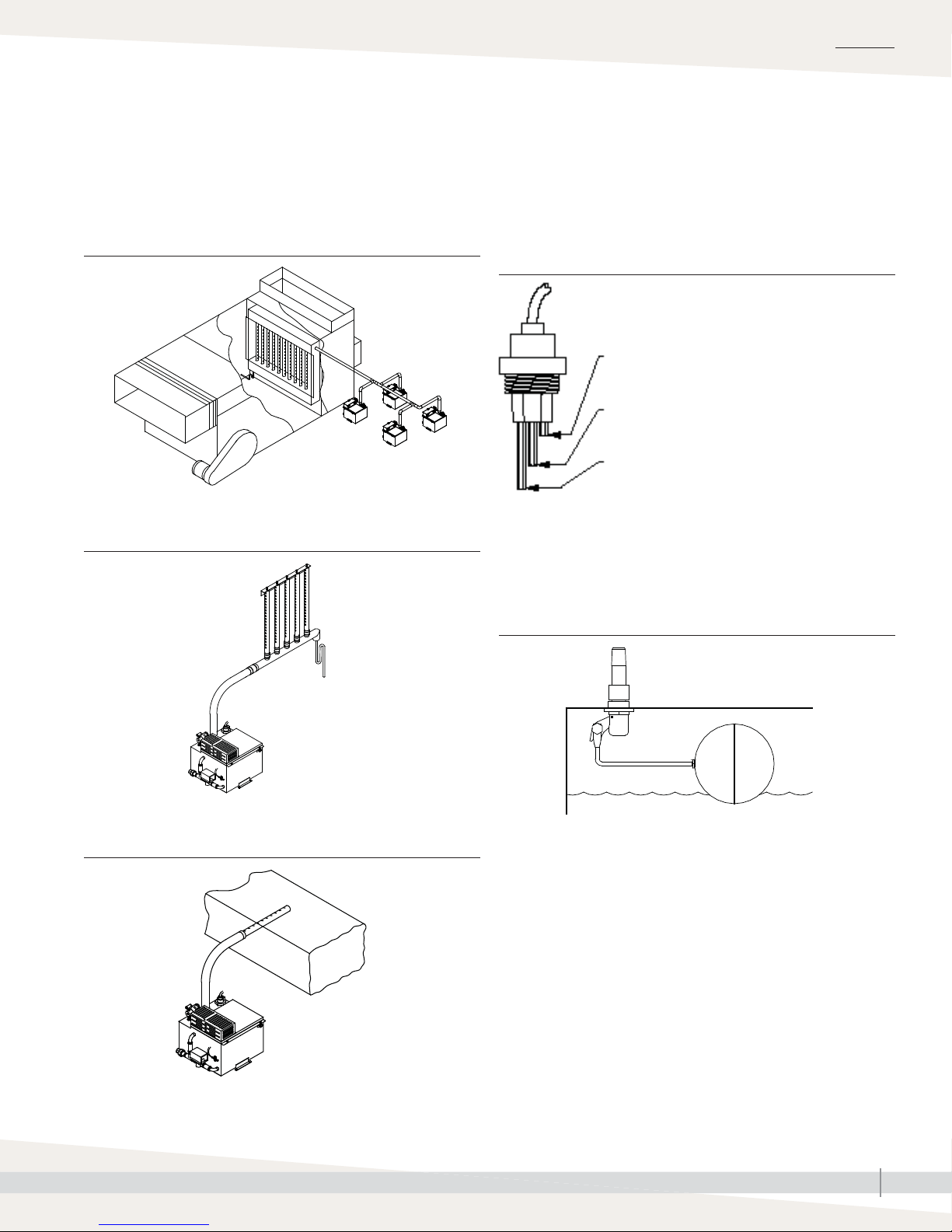

FIGURE 3-1: ULTRA-SORB DISPERSION FIGURE 3-2: WATER LEVEL CONTROL FOR TAP/SOFTENED

WATER HUMIDIFIER

OM-7475

VLC-OM-030

Fill valve closes when water level rises to this probe.

Fill valve opens when water level is below this probe.

Low-water cutoff. Power to heaters is cut if water

level drops below this probe.

FIGURE 3-3: RAPID-SORB DISPERSION

OM-2007

FIGURE 3-5: SINGLE OR MULTIPLE TUBE DISPERSION

Humidifi ers using tap or softened water control water levels electronically

using a three-rod probe. The controller responds with the above actions

when the water level reaches each rod.

mc_030910_1335

FIGURE 3-4: WATER LEVEL CONTROL FOR RO/DI WATER

OPTION HUMIDIFIER

Supply water connection

Float ball

Float rod

OM-7396

Humidifi ers using RO/DI water control water levels using a fl oat valve

and low-water cutoff switch.

mc_052710_1644

OM-2006

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

3

Page 8

OVERVIEW

Capacities, electrical specifi cations, and weights

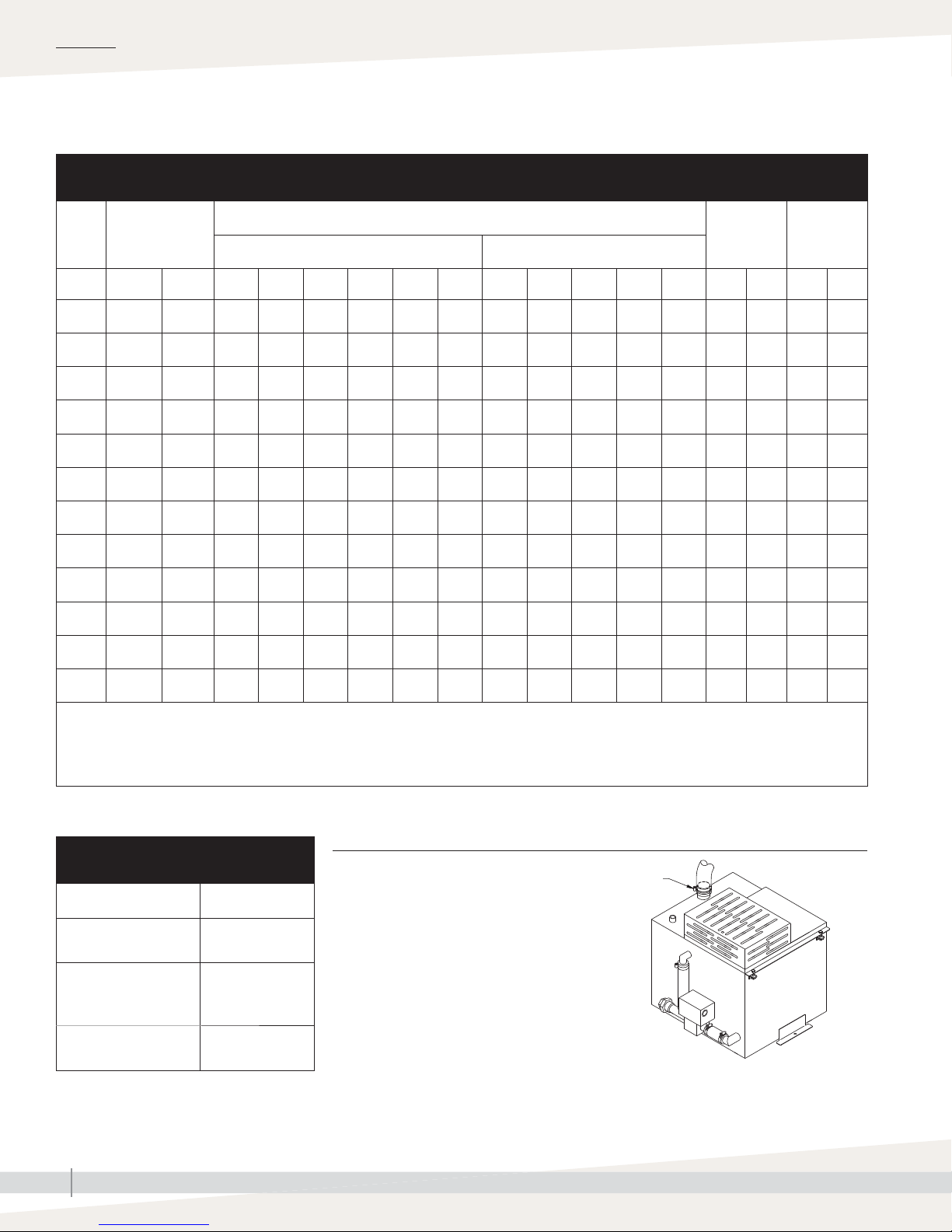

Table 4-1:

CRUV capacities, electrical specifications, and weights

CRUV

model

kW lbs/hr kg/h 120V 208V 240V 277V 480V 600V 208V 240V 277V 480V 600V lbs kg lbs kg

2 6 2.7 16.7 9.6 8.3 7.2 4.2 3.3 —————25114520

4 12 5.4 33.3 19.2 16.7 14.4 8.3 6.7 16.7* 14.4* 12.5 7.2* 5.8* 27 12 47 21

6 18 8.2 — 28.8 25.0 21.7 12.5 10.0 25.0* 21.7* 18.8 10.8* 8.7* 37 17 75 34

8 24 10.9 — 38.5 33.3 28.9 16.7 13.3 33.3* 28.9* 25.0 14.4* 11.5* 37 17 75 34

10 30 13.6 — — 41.7 36.1* 20.8 16.7 29.1* 25.3* 21.9 12.6* 10.1* 39 18 90 41

12 36 16.3 — — — 43.3 25.0 20.0 33.3 28.9 25.0 14.4 11.5 39 18 90 41

14 42 19.1 ————29.2 23.3 38.9 33.7 29.2 16.8 13.5 39 18 90 41

16 48 21.8 ————33.3 26.7 44.4 38.5 33.3 19.2 15.4 39 18 90 41

21 63 28.6 ————43.8 35.0 — — 43.8 25.3 20.2 43 20 104 47

25 75 34.0 —————41.7 — — — 30.1 24.1 43 20 104 47

30 90 40.9 —————————36.1 28.9 48 22 109 49

Maximum

steam

capacity**

Single-phase Three-phase

Current draw (amps)

Shipping

weight***

Operating

weight***

34 102 46.3 —————————40.9 32.7 48 22 109 49

* For wire sizing, the highest leg draw is shown due to current imbalance.

** Total humidifi er load = load to meet design conditions + load to compensate for steam loss from the dispersion assembly and interconnecting

piping. If total humidifi er load is more than the humidifi er’s maximum capacity, design conditions will not be met. For steam loss data see the

DriSteem Design Guide available for downloading and printing at www.dristeem.com

*** Depending on confi guration, add up to 28 lbs (13 kg) for weight of control cabinet, subpanel, and other electrical control components.

mc_071210_1440

Table 4-2:

Steam connection sizes

CRUV model Steam outlet

2, 4, 6, 8

10, 12, 14 ,16

21, 25, 30, 34

mc_052410_1705-CRUV

1 ½ " hose or

NPT connection

1 ½ " or 2" hose or

NPT connection

2" hose or

NPT connection

FIGURE 4-1: STEAM OUTLET CONNECTIONS

Hose clamp (for steam hose)

The steam outlet is designed to connect to a steam hose

or NPT connection. Tap/softened water CRUV shown.

mc_052510_1531-CRUV

DC-1168

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

4

Page 9

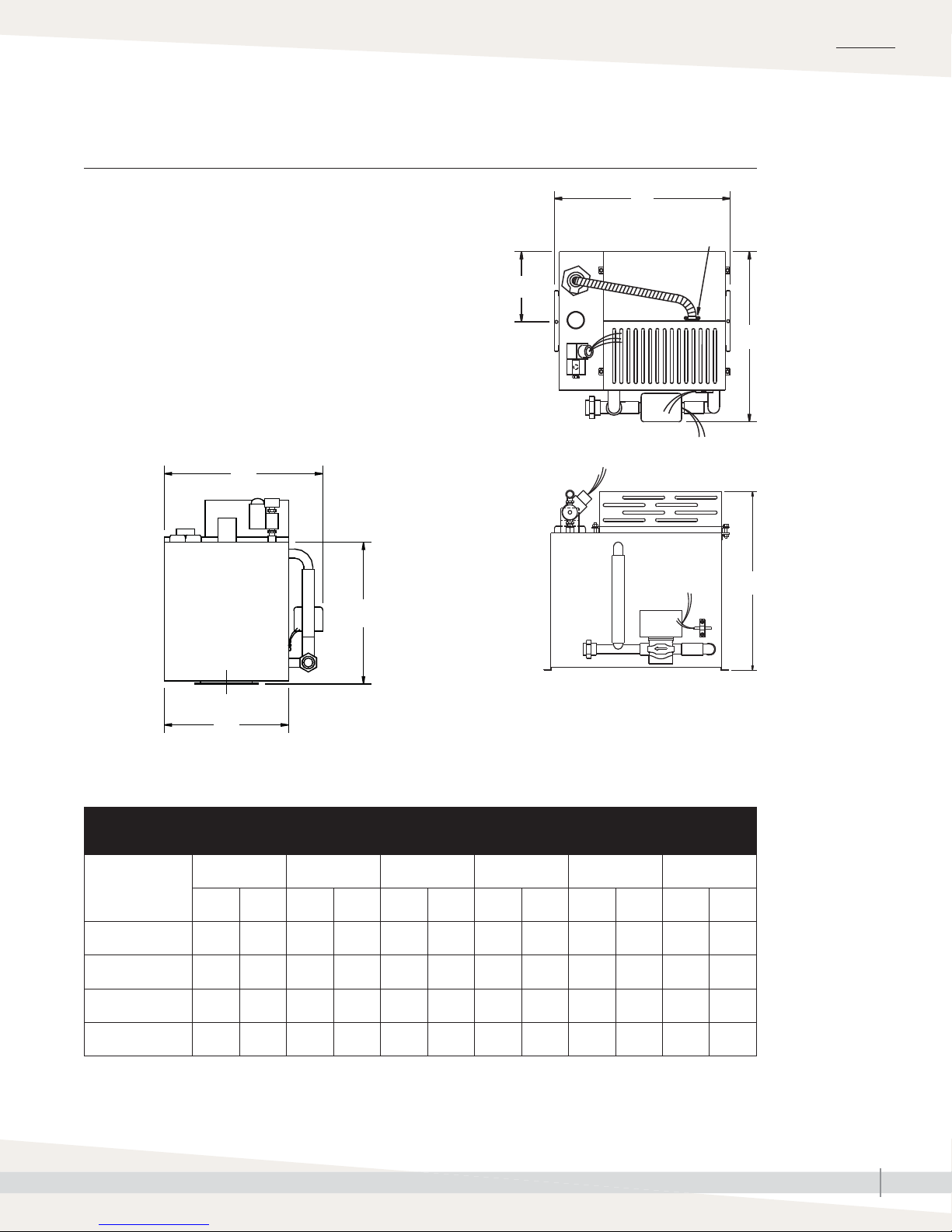

Dimensions

FIGURE 5-1: CRUV DIMENSIONS

OVERVIEW

Tap/softened water CRUV shown

Electrical conduit knockouts:

• CRUV Models 2 and 4 have combination knockout for ½" and

¾" conduit connectors; knockout diameters are 22.3 mm and

28.6 mm.

• CRUV Models 6 through 34 have combination knockout for ¾"

and 1" conduit connectors; knockout diameters 28.6 mm and

34.9 mm.

C

D

Top view

A

Front viewSide view

B

Electrical conduit knockouts

C

F

E

OM-2004, OM-2002, OM-2003

mc_071210_1445

Table 5-1:

CRUV dimensions

ABCDE F

CRUV model

inches mm inches mm inches mm inches mm inches mm inches mm

2, 4 4.50 114 15.50 394 12.50 318 9.00 229 9.00 229 12.13 308

6, 8 7.18 183 16.00 406 16.88 429 10.00 254 14.34 369 13.25 337

10, 12, 14, 16 7.18 183 16.00 406 16.88 429 11.75 199 14.34 364 14.88 378

21, 25, 30, 34 7.18 183 16.00 406 16.88 429 13.25 337 14.34 364 16.38 416

mc_071210_1446

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

Page 10

INSTALLATION

Selecting a location

Locate the CRUV humidifi er near an electric power source, a water supply,

and a drain. Verify that suffi cient room is provided for a water seal in the drain

piping. See Figures 8-1 and 9-1.

Place the control cabinet or electrical subpanel in a grounded protective metal

enclosure, and mount in a dry and accessible location.

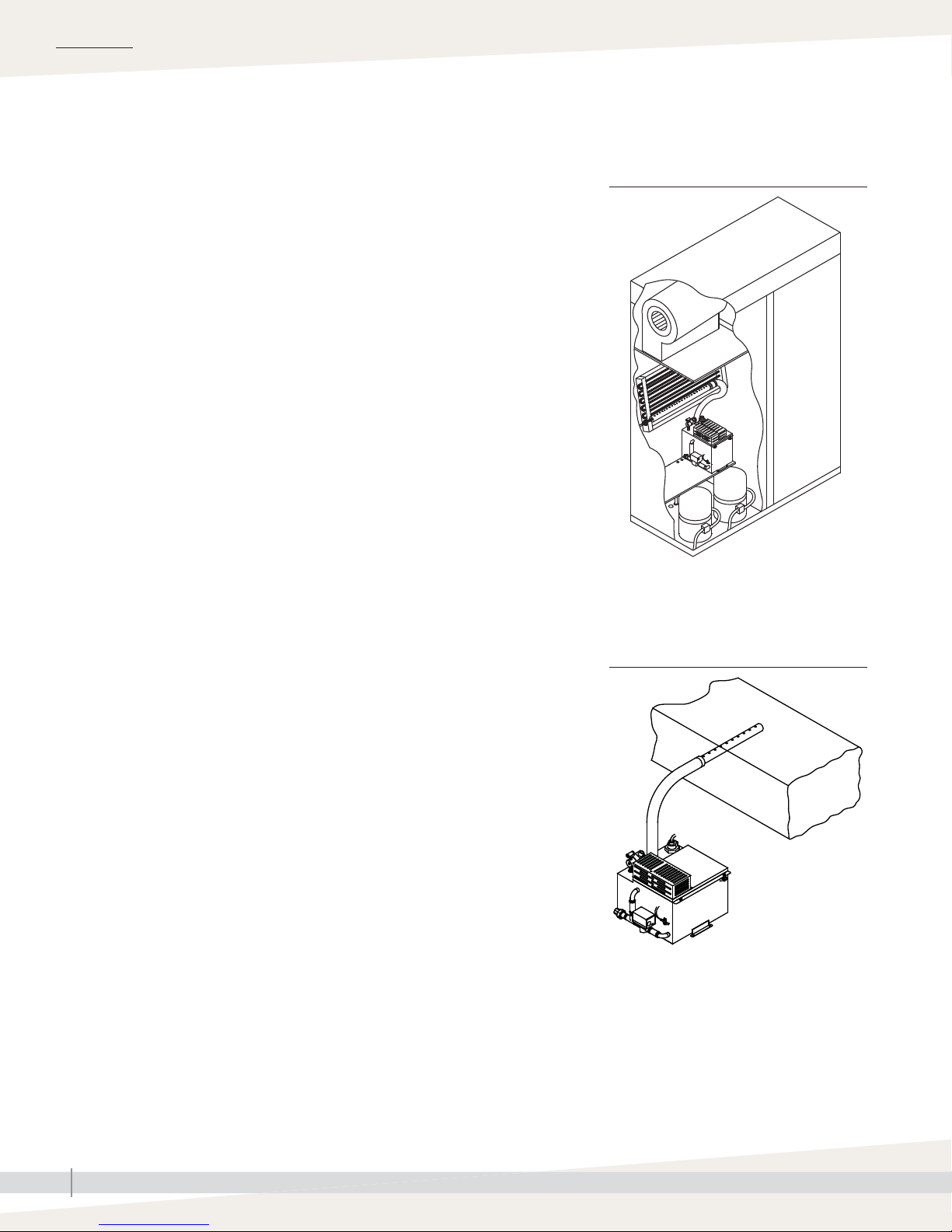

CRUV IN A PACKAGED UNIT

When installing a humidifi er inside a packaged unit, provide adequate

support. Allow easy access for removing and servicing the evaporating

chamber, and provide adequate clearance to install the steam hose and

dispersion tube and water seal.

DISPERSION IN A DUCT

When rapid absorption is extremely critical, a Rapid-sorb can provide 100%

steam absorption within three feet or less at any duct temperature. A multiple

tube or Rapid-sorb is required for CRUV Models 30 and 34 because of their

high output. See Figure 7-1 and the “Rapid-sorb” section beginning on Page

22.

When installing a dispersion tube in a duct, allow for a continuous pitch of the

steam hose back to the evaporating chamber (Figure 6-2), or use a water seal

and drain (Figure 7-1).

If draining the evaporating chamber by gravity is not possible, use a small

condensate pump rated for 212 °F/100 °C water.

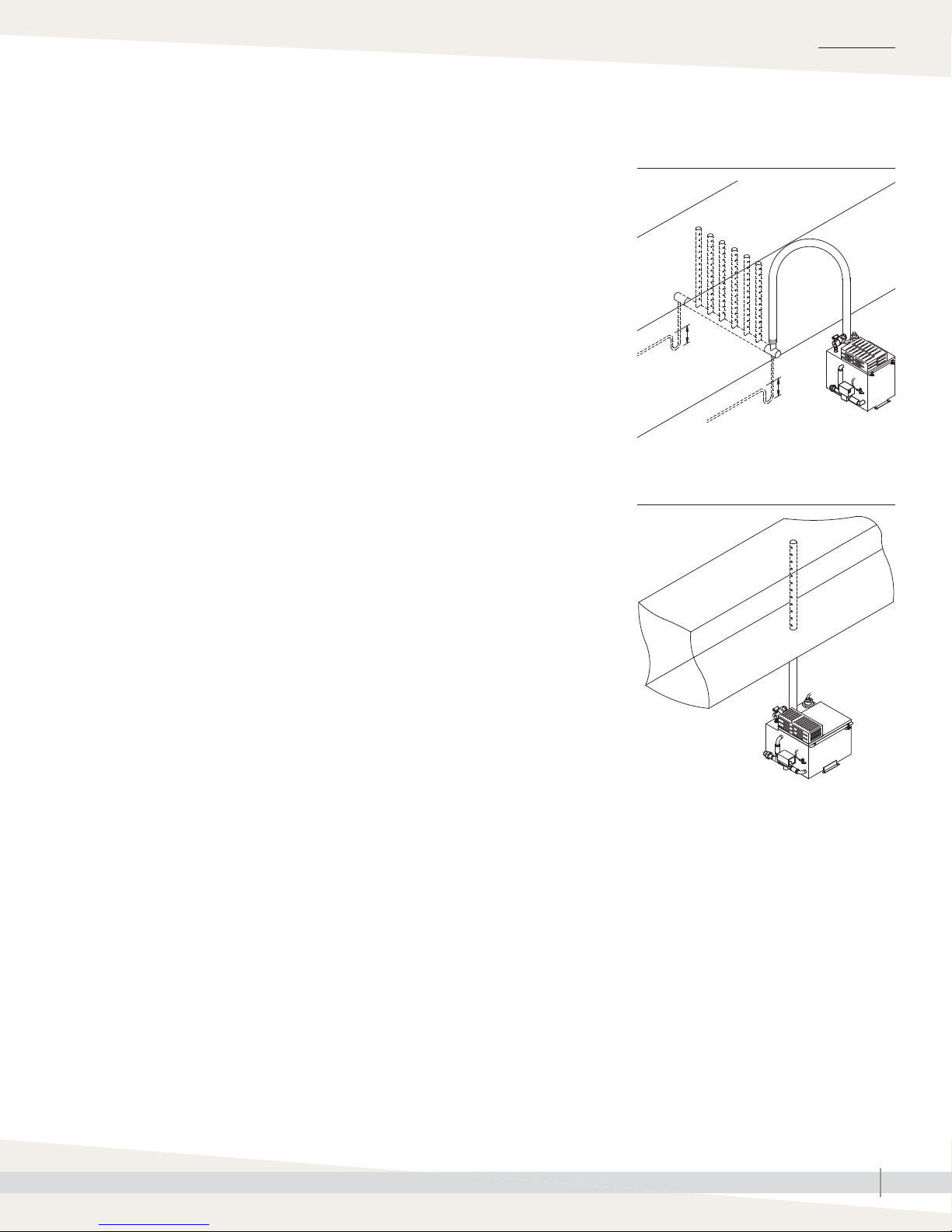

FIGURE 6-1: INSTALLATION IN AN AIR

CONDITIONING UNIT

OM-2008

CRUV with a single dispersion tube in a packaged

air conditioning unit

FIGURE 6-2:

HORIZONTAL DISPERSION TUBE

The dispersion tube can be mounted vertically in the duct (Figure 7-2).

Note: When dispersion tube is more than 10' (3 m) from unit, insulated, 1½"

(38 mm) diameter minimum rigid tubing or pipe should be used instead

of steam hose. This application is not recommended for CRUV Models

10 through 34.

Duct

Steam hose

OM-2006

Horizontal mounting of dispersion tube in a duct,

connected via steam hose to a wall-mounted

CRUV humidifi er.

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

6

Page 11

Selecting a location

INSTALLATION

HUMIDIFIER

When selecting a location for the humidifi er, consider the following:

• Proximity to the duct

Install the humidifi er near the air duct system where the dispersion assembly

will be located. The maximum recommended length for steam hose

connecting a single humidifi er to a dispersion assembly is 10' (3 m). The

maximum recommended developed length for tubing or pipe connecting a

single humidifi er to a dispersion assembly is 20' (6 m).

For more information about installing dispersion assemblies, see

“Dispersion,” beginning on Page 14.

• Elevation of the installed dispersion assembly

The recommended installation location for the dispersion assembly is at an

elevation higher than the humidifi er. However, if the dispersion assembly

must be installed at an elevation lower than the humidifi er, install a drip tee

and drain. See “Drip tee installation” on Page 15.

Before installing a dispersion assembly or interconnecting piping, review all

pitch requirements in the “Dispersion” section of this manual.

• Required clearances (see Figure 5-1)

• Electrical connections

FIGURE 7-1: RAPID-SORB DISPERSION

Duct

OM-831-1

FIGURE 7-2: VERTICAL DISPERSION TUBE

Duct

Electrical power supply connections are at the lower or upper right rear

corner of the unit. See “Wiring” on Page 12.

• Supply water and drain piping connections

Water supply piping and drain connections are at the lower left rear corner

of the unit. See the piping illustrations and instructions starting on Page 8.

• Exterior wall insulation

Install the humidifi er on an exterior wall only if the wall is properly

insulated.

DISPERSION CONTROL DEVICES

See Figure 13-1 for recommended installation locations for the dispersion

assembly and associated control devices.

mc_062810_0928-NA

OM-775-1

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

7

Page 12

INSTALLATION

Piping:

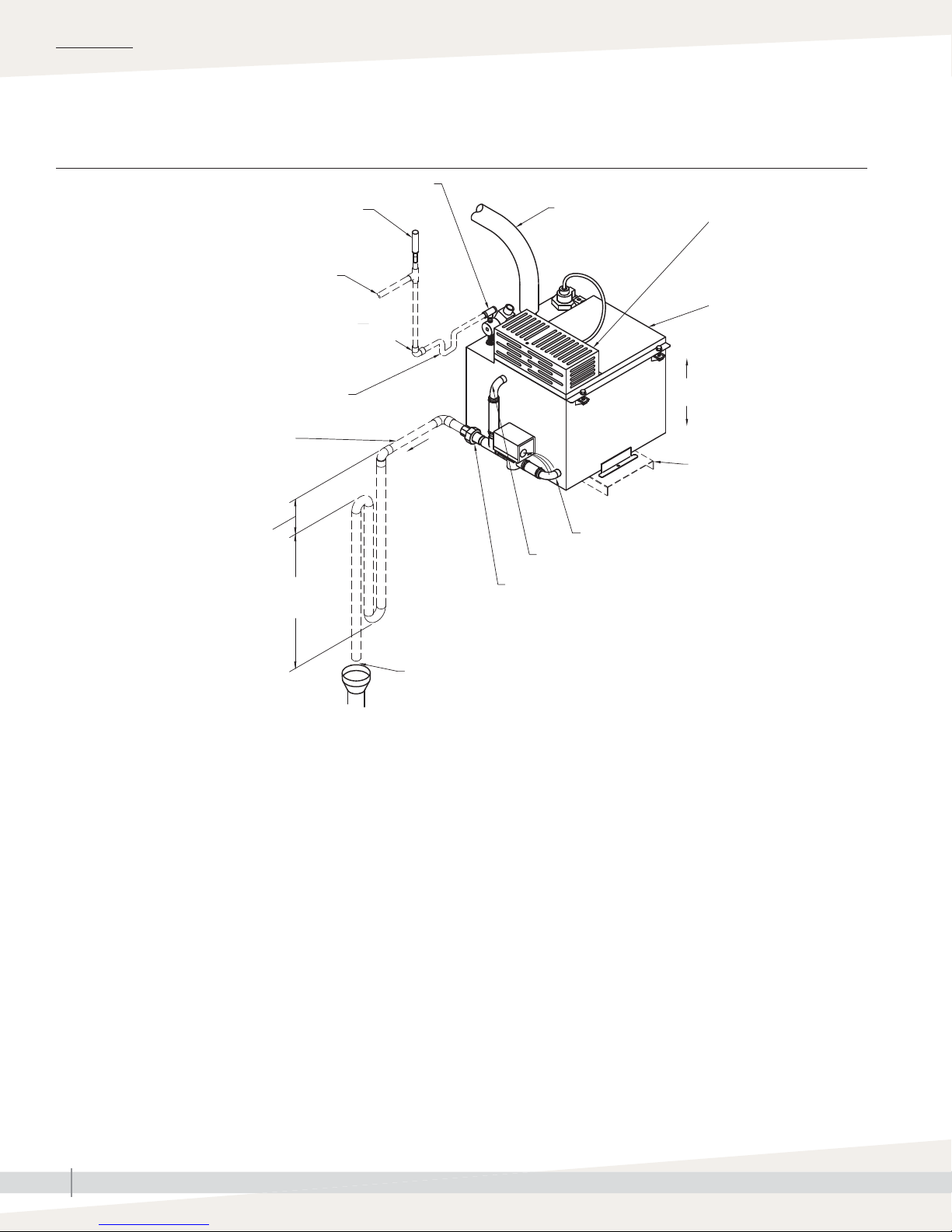

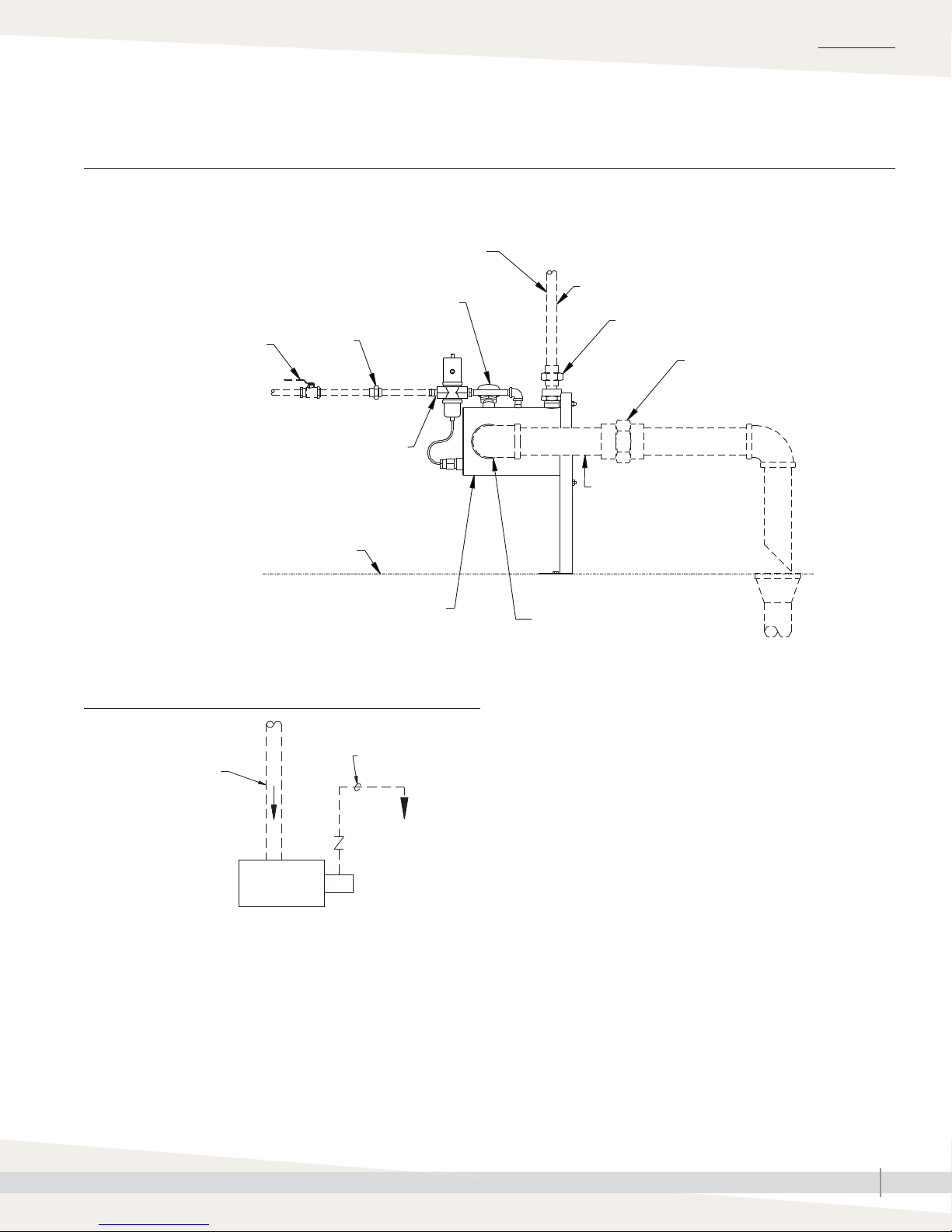

FIGURE 8-1: CRUV (TAP/SOFTENED WATER) FIELD PIPING OVERVIEW

Water supply line:

• ¼" NPT (DN8) connection size

• 25 to 80 psi (175 to 550 kPa) required water pressure

• First 3’ (1 m) of supply line must be rated for 212 ºF (100 ºC)

If water piping to humidifi er is nonmetallic, we

recommend a 2” (50 mm) metallic water seal or loop

in the supply line to isolate steam during maintenance.

Tap/softened water

Water inlet strainer

Water supply inlet

Shock arrester recommended to

reduce water hammer

If run is over 10' (3 m), increase

pipe to 1¼" (DN32)

Pitch 1/8"/ft

(1%)

2" (51 mm)

recommended

Steam steam hose

Heater terminal cover

Tank surfaces will reach

212 °F (100 °C) when

operating. Provide outer

protection from direct

contact, but allow for

natural ventilation.

Install plumb

Tank support

DC-1133

Drain

Skim/overfl ow port

12" (305 mm)

minimum

1" (25 mm) air gap

Open drain required. See fi rst note below.

Notes:

• Locate air gap only in spaces with adequate temperature and air movement to absorb fl ash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

• Offset hu mid i fi er from fl oor drain to prevent fl ash steam from rising into the hu mid i fi er.

• Dashed lines indicate provided by installer.

• The water supply inlet is more than 1" (25 mm) above the skim/overfl ow port, eliminating the pos si bil i ty of backfl ow or si phon ing from the tank.

No additional backfl ow prevention is required; however, governing codes prevail.

• Damage caused by chloride corrosion is not covered by your DriSteem warranty.

mc_071210_1603

¾" (DN20) union for skim, drain, and overfl ow connection;

plumbing rated for 212 °F (100 °C)

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

8

Page 13

INSTALLATION

Piping:

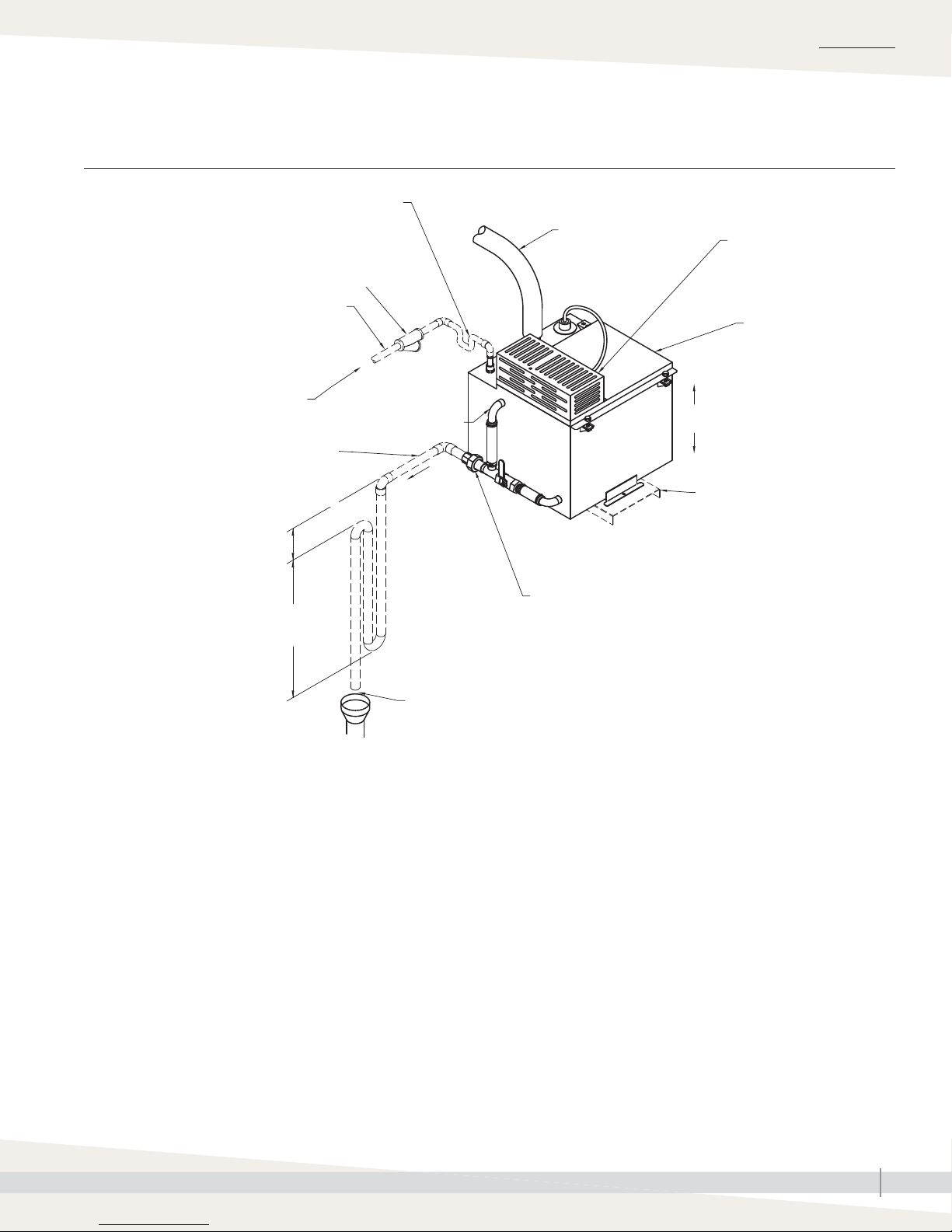

FIGURE 9-1: CRUV (RO/DI WATER OPTION) FIELD PIPING OVERVIEW

If water piping to humidifi er is nonmetallic, we recommend

a 2" (50 mm) stainless steel water seal or loop in the supply

line to isolate steam during maintenance

Water supply line:

• ¼" NPT (DN8) connection size

• 25 to 80 psi (175 to 550 kPa) required

water pressure

• First 3’ (1 m) of supply line must be

rated for 212 ºF (100 ºC)

RO/DI water option

Water inlet strainer, by installer

Water supply inlet

Skim/overfl ow

port

If run is over 10' (3 m), increase

pipe to 1¼" (DN32)

Pitch 1/8"/ft

(1%)

2" (51 mm)

recommended

Steam steam hose

Heater terminal cover

Tank surfaces will reach

212 °F (100 °C) when

operating. Provide outer

protection from direct

contact, but allow for

natural ventilation.

Install plumb

Tank support

DC-1135

¾" (DN20) union for skim, drain, and overfl ow connection;

12" (305 mm)

minimum

1" (25 mm) air gap

Open drain required. See fi rst note below.

Notes:

• Locate air gap only in spaces with adequate temperature and air movement to absorb fl ash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum discharge water temperature.

• Offset hu mid i fi er from fl oor drain to prevent fl ash steam from rising into the hu mid i fi er.

• Dashed lines indicate provided by installer.

• The water supply inlet is more than 1" (25 mm) above the skim/overfl ow port, eliminating the pos si bil i ty of backfl ow or si phon ing from the tank.

No additional backfl ow prevention is required; however, governing codes prevail.

• Damage caused by chloride corrosion is not covered by your DriSteem warranty.

mc_071210_1604

plumbing rated for 212 °F (100 °C)

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

Page 14

INSTALLATION

Supply water and drain piping Piping:

Supply water piping may be of any code-approved material (copper, steel,

or plastic). The fi ll valve connection size is a ¼" pipe thread (DN8) fi tting. In

cases where water hammer may be a possibility, consider installing a shock

arrestor. Water pressure must be between 25 psi and 80 psi (175 kPa and

550 kPa).

If water piping to humidifi er is nonmetallic, we recommend that the fi rst 3'

(1 m) of water supply piping from the humidifi er be metallic with a 2" (50 mm)

water seal or loop in the supply line to isolate steam from nonmetallic supply

piping.

Drain piping may be of any code-approved material (copper, steel, or plastic

rated for 212 °F [100 °C] minimum). If drainage by gravity is not possible, use

a reservoir pump rated for 212 °F (100 °C) water.

The fi nal connection size is ¾" (DN20) copper for the tank and frame drains.

Do not reduce this connection size. Pipe the tank and frame drains separately,

as shown in Figures 8-1 and 9-1, to prevent backfl ow of drain water into the

humidifi er cabinet.

If the equivalent length of pipe from the humidifi er drain to the plumbing system

drain is more than 10' (3 m), increase the pipe size to 1¼" (DN32).

CAUTION

Hot discharge water

Discharge water can be as hot as

212 °F (100 °C) and can damage the

drain plumbing.

To prevent such damage from

humidifi ers without water tempering,

allow the tank to cool before draining.

Humidifi ers equipped with a water

tempering device such as a DriSteem

Drane-kooler need fresh make-up

water in order to function properly.

Make sure the water supply to the

water tempering device remains open

during draining.

Excessive supply water pressure

Supply water pressure greater than

80 psi (550 kPa) can cause the

humidifi er to overfl ow.

mc_030910_1440

See Figures 8-1 and 9-1 for more piping instructions.

Important: Install unions in the water supply and drain lines as shown in

Figures 8-1 and 9-1 to allow tank removal.

mc_062810_0930-CRUV

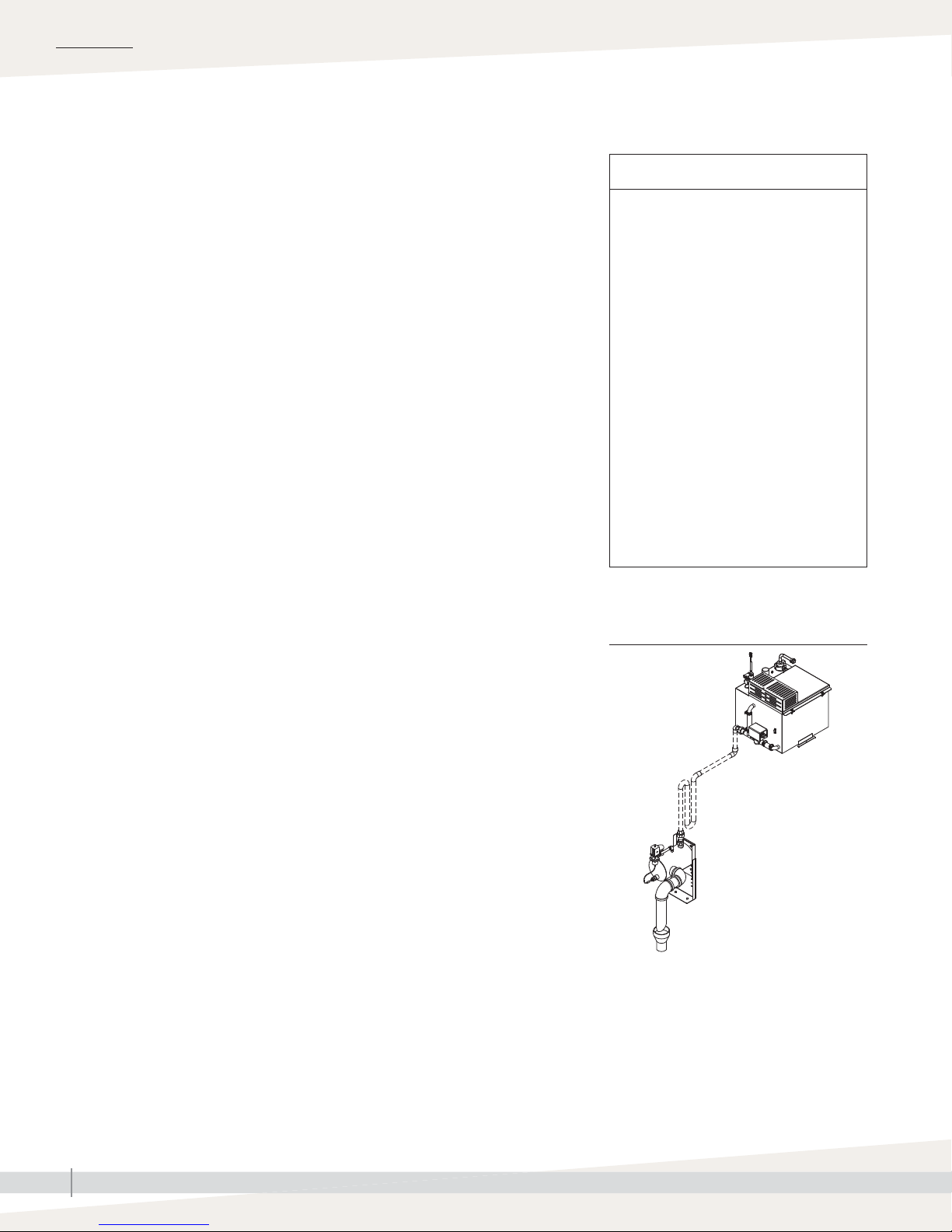

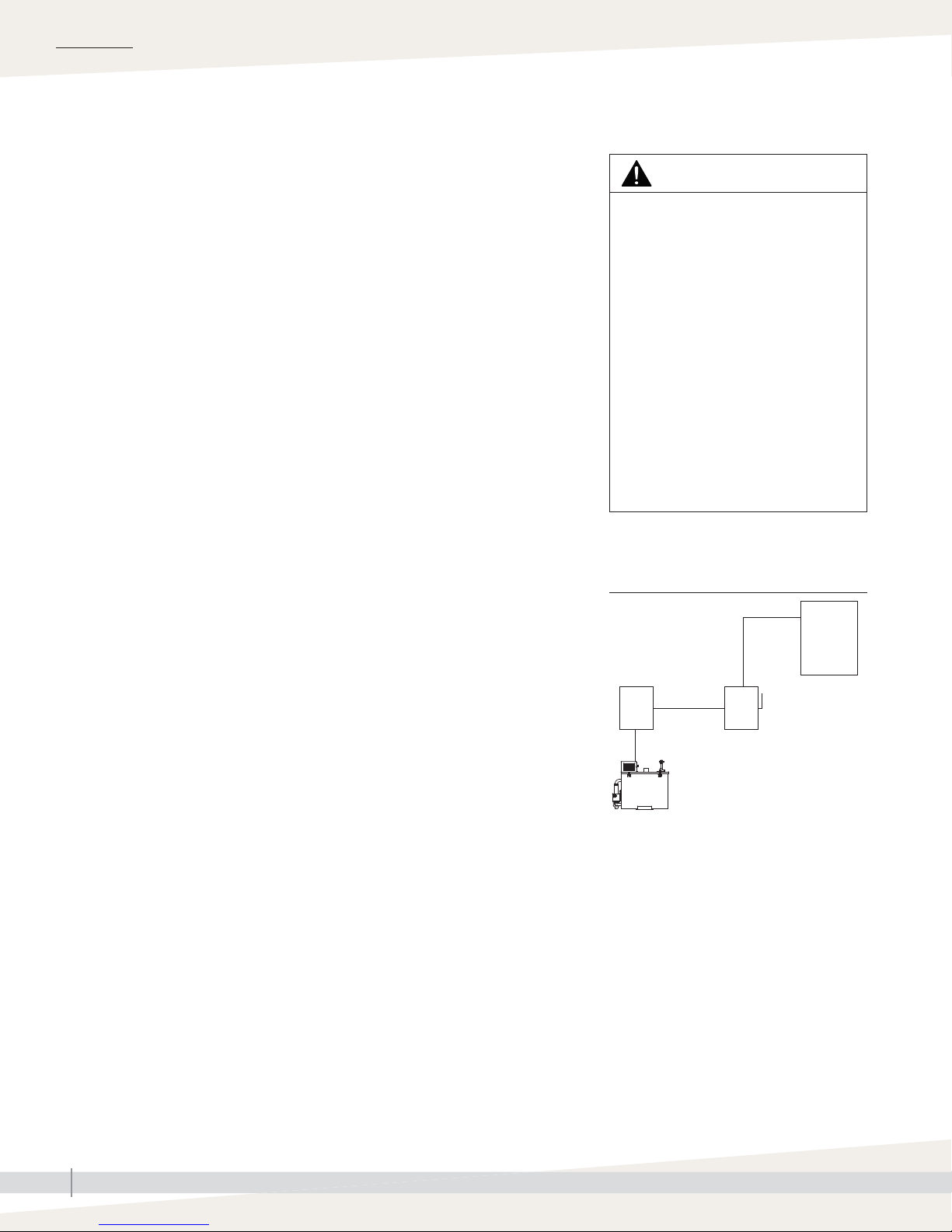

FIGURE 10-1: DRANE-KOOLER WATER

TEMPERING DEVICE

OM-7547

DriSteem's Drane-kooler, shown mounted to a

CRUV humidifi er, tempers discharged water.

For other Drane-kooler mounting options or

for more information, contact your DriSteem

representative/distributor, or view the

Drane-kooler product data sheet in the literature

section at www.dristeem.com.

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

10

Page 15

INSTALLATION

Piping:

FIGURE 11-1: FIELD PIPING CONNECTIONS, DRANE-KOOLER™ WATER TEMPERING DEVICE

Notes:

• Dashed lines indicate provided by installer

• Total length of pipe between humidifi er and Drane-kooler not to exceed 10' (3 m)

Water supply shut-off valve

Drane-kooler

Vacuum breaker

Union

3/8" NPT (DN10) cold water inlet;

water pressure 25 to 80 psi (172 to 552 kPa);

maximum temperature 70 °F (21 °C)

Floor

Field piping

3/4" NPT (DN20) hot drain water inlet.

For runs longer than 10' (3 m), increase to

1" NPT (DN25).

Union

Tempered water outfl ow

12 gpm (45.4 L/m)

at 140 °F (60 °C)

Union

Drane-kooler

Part No. 902205 (NPT connections)

Part No. 902206 (BSP connections)

mc_050610_1335-no-frame-drain

FIGURE 11-2: LIFTING DRAIN WATER

Discharge piping

(by installer)

Inlet drain water piping

(by installer)

Check valve

DC-1117

Condensate pump

Note:

Use a condensate pump rated for your application. Pumps are rated by

fl uid temperature, head (pressure), and fl ow (gpm). Contact your local

DriSteem representative for pump selection.

mc_022410_1155

2" NPT (DN50)

tempered water outlet

DC-1120

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

Page 16

INSTALLATION

Wiring

HUMIDIFIER FIELD WIRING

All wiring must be in accordance with all governing codes, and with the

humidifi er wiring diagrams. The diagrams are located inside the removable

subpanel cover on the right side of the humidifi er cabinet. Power supply wiring

must be rated for 220 °F (105 °C).

When selecting a location for installing the humidifi er, avoid areas close to

sources of electromagnetic emissions such as power distribution transformers.

The fi ll valve, drain valve, probes, and temperature sensors use Class 2,

24 VAC power.

The use of semiconductor fusing sized per the National Electric Code is

recommended with the SSR option.

GROUNDING REQUIREMENTS

The approved earth ground must be made with solid metal-to-metal connections

and must be a good conductor of radio frequency interference (RFI) to earth

(multistranded conductors).

WARNING

Electric shock hazard

Only qualifi ed electrical personnel

should perform fi eld wiring installation

procedures. Improper wiring or contact

with energized circuits can cause

property damage, severe personal

injury, or death as a result of electric

shock and/or fi re.

Do not remove the humidifi er electrical

panel cover or the heater terminal cover

until electrical power is disconnected.

Contact with energized circuits can

cause property damage, severe

personal injury, or death as a result of

electrical shock.

mc_062310_0629

Ground wire should be the same AWG (mm2) size as the power wiring or

sized per NEC requirements.

PROPER WIRING TO PREVENT ELECTRICAL NOISE

Electrical noise can produce undesirable effects on electronic control circuits,

which affects controllability. Electrical noise is generated by electrical

equipment such as inductive loads, electric motors, solenoid coils, welding

machinery, or fl uorescent light circuits. The electrical noise or interference

generated from these sources (and the effect on controllers) is diffi cult to defi ne,

but the most common symptoms are erratic control or intermittent operational

problems.

Important:

• For maximum EMC (electromagnetic compatibility) effectiveness, wire all

humidity, high limit, and airfl ow controls using multicolored shielded/

screened plenum-rated cable with a drain wire for the shield/screen.

Connect the drain wire to the shield/screen ground terminal with wire less

than 2" (50 mm) in length.

• Do not ground shield at the device end.

mc_061610_0625-CRUV

FIGURE 12-1:

FIELD WIRING REQUIREMENTS

Power

Fused

Control

cabinet

Notes:

• Control wiring and power wiring must be

run in dedicated or separate earthed metal

conduit, cable trays, or trunking.

• Separate the line voltage wiring from low

voltage control circuit wiring when routing

electrical wiring inside the humidifi er

cabinet.

• Do not use chassis or safety grounds as

current-carrying commons. Never use a

safety ground as a conductor or neutral to

return circuit current.

mc_062310_0630-CRUV

disconnect

(provided by

installer)

OM-7552

supply

(provided

by installer)

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

12

Page 17

Sensor placement

INSTALLATION

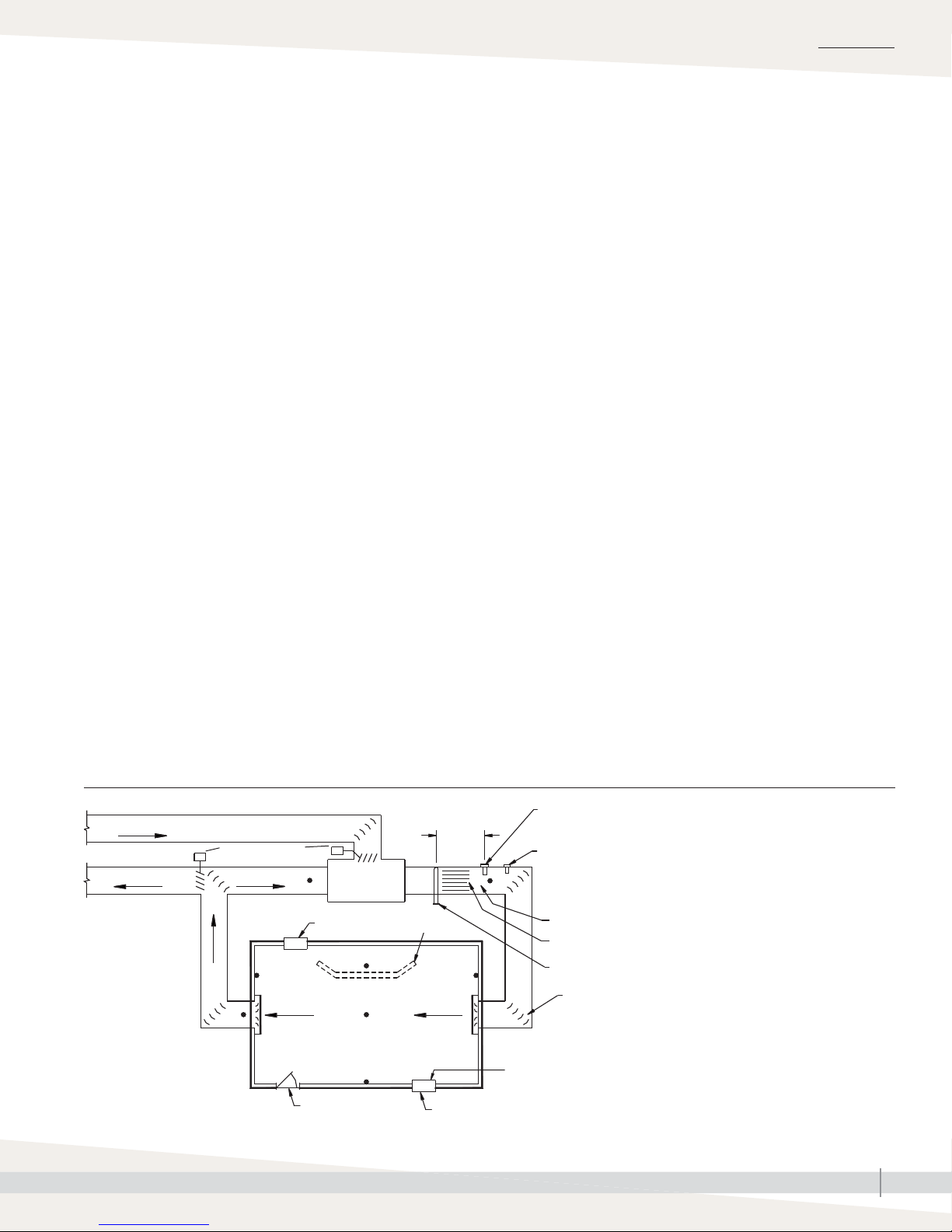

SENSOR LOCATION IS CRITICAL

Sensor location has a signifi cant impact on humidifi er performance. See the

recommendations below and Figure 13-1.

Note: DriSteem recommends that you do not interchange room and duct

humidity devices. Room humidity devices are calibrated with zero or

little airfl ow, whereas duct humidity devices require air passing across

them.

Recommended humidity control (transmitter/humidistat) locations:

A Ideal. Ensures the best uniform mix of dry and moist air with stable

temperature control.

B Acceptable, but room environment can affect controllability, such as when

sensor is too close to air grilles, registers, or heat radiation from room

lighting.

C Acceptable. Provides uniform mixture of dry and moist air. If extended time

lag exists between humidity generation and sensing, extend sampling time.

D Acceptable (behind wall or partition) for sampling entire room if sensor is near

an air exhaust return outlet. Typical placement for sampling a critical area.

E Not acceptable. These locations might not represent actual overall

conditions in the space.

Other factors affecting humidity control

Humidity control involves more than the

controller’s ability to control the system. Other

factors that play an important role in overall

system control are:

• Size of humidifi cation system relative to load

• Overall system dynamics associated with

moisture migration time lags

• Accuracy of humidistats and humidity

transmitters and their location

• Dry bulb temperature accuracy in space or

duct

• Velocities and airfl ow patterns in ducts and

space environments

• Electrical noise or interference

mc_072011_1656

F Not acceptable. Do not place sensors near windows, door passageways,

or areas of stagnant airfl ow.

Recommended safety (airfl ow and high limit) sensor location:

G Best sensing location for high limit humidistat or humidity sensor and airfl ow

proving switch.

mc_072011_1655

FIGURE 13-1: RECOMMENDED SENSOR LOCATIONS

Outside air

Relief air

Damper control

Return air

E

A

C

Air handling

unit

Window

Wall or

partition

D

B

8' to 12'

(2.4 m to 3.7 m)

min.

G

F

High limit humidistat or high limit transmitter (set at 90% RH

maximum) for VAV applications

Airfl ow switch or differential pressure switch (sail type

recommended for VAV applications)

Vapor absorption has taken place

Point of vapor absorption

Humidifi er dispersion assembly

Turning vanes

DC-1084M

mc_060508_0750

F

Doorway

E

F

Window

Temperature compensation option: Place a temperature compensation

sensor on the lower corner of the inside surface of double-pane window

glass on north- or northeast-facing window.

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

13

Page 18

INSTALLATION

Dispersion:

Selecting the dispersion assembly location

DriSteem humidifi ers operate with several types of dispersion assemblies for

open spaces and for ducts and air handling units.

Dispersion assemblies in ducts and air handling units must be positioned where

the water vapor being discharged is carried off with the airstream and is

absorbed before it can cause condensation or dripping.

• Non-wetting distance is the dimension downstream from the leaving

side of the steam dispersion assembly to the point where wetting will

not occur, although wisps of steam may be present. This distance was

calculated during humidifi cation system design and is dependent on

several application parameters. To determine your dispersion assembly’s

non-wetting distance, consult your system’s design engineer or project

documentation. Non-wetting distance can also be calculated using

DriSteem’s DriCalc sizing and selection software, available at www.

dristeem.com. Note that your current design conditions may vary from

conditions used for system design.

• In general, the dispersion assembly is best placed where the air can absorb

the moisture being added without causing con den sa tion at or after the unit.

This normally will be after the heating coil or where the air tem per a ture is

highest.

• Place the dispersion assembly such that absorption will occur

– before the intake of a high effi ciency fi lter, because the fi lter can remove

the visible moisture and become waterlogged;

– before coming in contact with any metal surface;

– before fi re or smoke detection devices;

– before a split in the duct; otherwise, the dispersion assembly can direct

more moisture into one duct than the other.

• When draining dispersion condensate to an open drain, provide a 1"

(25 mm) air gap between the condensate drain piping and the drain.

Locate the gap only in spaces with adequate temperature and air movement

to absorb fl ash steam; otherwise, condensation may form on nearby

surfaces.

mc_060210_0838

FIGURE 14-1: ULTRA-SORB WITH THE

HIGH-EFFICIENCY TUBE OPTION

HIGH-EFFICIENCY TUBE OPTION

Dispersion assemblies with the High-effi ciency

Tube option are designed to produce

signifi cantly less dispersion-generated

condensate and airstream heat gain, which

reduces wasted energy by up to 85%.

These improvements are accomplished by

reducing the thermal conductivity of the tubes

with 1/8" of polyvinylidene fl uoride (PVDF)

insulating material on the outside of the tubes.

These assemblies require careful unpacking,

installation, and handling. If your dispersion

assembly has the High-effi ciency Tube option,

be sure to read this section carefully.

mc_060208_1320

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

14

Page 19

INSTALLATION

Dispersion:

Drip tee installation

Install a drip tee as shown below when the humidifi er is mounted higher than

the dispersion assembly, when interconnecting hose or piping needs to go over

an obstruction, or when interconnecting piping runs are long.

Important: Steam hose must be supported to prevent sagging or low spots.

FIGURE 15-1: DRIP TEE INSTALLATION

90° long sweep or two 45° elbows

Obstruction

Insulate tubing and hard pipe to

reduce steam loss

Pitch

CRUV humidifi er

DC-7548

WARNING

Hot surface and steam hazard

Dispersion tube, steam hose, tubing,

or hard pipe can contain steam, and

surfaces can be hot. Discharged steam

is not visible. Contact with hot surfaces

or air into which steam has been

discharged can cause severe personal

injury.

mc_060110_1555

To dispersion assembly

6" (150 mm) recommended

8" (200 mm) minimum

1" (25 mm) air gap

Open funnel or fl oor drain. See fi rst note below.

Notes:

• Locate air gap only in spaces with adequate temperature and air movement to absorb fl ash

steam; otherwise, condensation may form on nearby surfaces. Refer to governing codes for

drain pipe size and maximum discharge water temperature.

• Support steam hose so there are no sags or low spots.

• Dashed lines indicate provided by installer.

mc_062810_0645-CRUV

Tubing or pipe drip tee, by installer.

DriSteem part numbers for 304

stainless steel inline tees:

• 1½" (DN40): No. 162710

• 2" (DN50): No. 162712

¾" (DN20)

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

15

Page 20

INSTALLATION

Dispersion:

• The steam outlet on the humidifi er is sized to the output of the humidifi er.

DO NOT use interconnecting piping with an inside diameter smaller than

the humidifi er steam outlet.

• See the maximum steam carrying capacities and maximum piping lengths

in Table 16-1.

• See the steam loss data in Table 17-1.

Interconnecting piping requirements

Important:

Failure to follow the recommendations in this

section can result in excessive back pressure on

the humidifi er. This will result in unacceptable

humidifi cation system performance such as

leaking gaskets, blown water seals, erratic

water level control, and spitting condensate

from dispersion tubes.

mc_060210_0843

• See Figures 18-1 and 19-1 for interconnecting tubing and pipe

pitch requirements for single tube applications. See Table 21-1 for

interconnecting tubing and pipe pitch requirements for Rapid-sorb

applications.

• If the humidifi er must be located higher than the dispersion assembly, use

the recommended installation shown in Figure 15-1.

• For single tube applications, see the capacities in Table 19-1.

Table 16-1:

Maximum steam carrying capacity and length of interconnecting steam hose, tubing and pipe*

Steam hose

Hose I.D. Maximum capacity Maximum length

inches DN lbs/hr kg/h ft m inches DN lbs/hr kg/h ft m

1½ 40 150 68 10 3 1½ 40 150 68 20 6.1

1

2

Tubing size Maximum capacity

Copper or stainless steel tubing

3

Maximum developed length

4

2 50 250 113 10 3 2 50 220 100 30 9.2

1. When using steam hose, use DriSteem steam hose for best

results. Field-supplied hose may have shorter life and may cause

foaming in the evaporating chamber resulting in condensate

discharge at the dispersion assembly. Do not use steam hose for

outdoor applications.

2. Maximum recommended length for steam hose is 10' (3 m).

Longer distances can cause kinking or low spots.

Note: Capacities and lengths in this table are based on total maximum pressure drop in hose or tubing of 5" wc (1250 Pa)

mc_091410_1050-VM

3. Insulate tubing to minimize loss of capacity and effi ciency.

4. Developed length of tubing equals measured length plus 50% of measured

length, to account for fi ttings.

Longer tubing lengths are possible at capacities lower than listed maximums.

Consult factory.

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

16

Page 21

INSTALLATION

Dispersion:

CONNECTING TO DISPERSION ASSEMBLY WITH STEAM HOSE

Interconnecting piping requirements

• Support steam hose to prevent sags or low spots and to maintain a

minimum pitch of 2"/ft (15%) back to the humidifi er.

• Use DriSteem steam hose. Other manufacturers of steam hose may use

unacceptable release agents or material mixes that can affect humidifi er

system performance adversely. Using hose from alternative manufacturers

increases the possibility of tank foaming and accelerated aging. Foaming

causes condensate discharge at the dispersion assembly.

• Do not use steam hose in outdoor applications.

• Do not insulate steam hose. Insulation causes accelerated heat aging,

causing the steam hose to become hard and susceptible to failure due to

cracks.

CONNECTING TO DISPERSION ASSEMBLY WITH TUBING

• Support interconnecting piping between the humidifi er steam outlet and the

dispersion system with pipe hangers. Failure to properly support the entire

steam piping weight may cause damage to the humidifi er tank and void the

warranty.

• 90° elbows are not recommended; use two 45° elbows, 1' (0.3 m) apart.

WARNING

Excessive moisture hazard

DriSteem strongly recommends

installing a duct airfl ow proving switch

and a duct high limit humidistat. These

devices prevent a humidifi er from

making steam when there is low airfl ow

in the duct or when the RH level in the

duct is too high. Failure to install these

devices can result in excessive moisture

in the duct, which can cause bacteria

and mold growth or dripping through

the duct.

mc_060310_0725

• Insulate tubing to reduce the loss in output caused by condensation.

mc_060310_1145

Table 17-1:

Steam loss of interconnecting steam hose, tubing, and pipe

Nominal hose, tubing or pipe

Description

inches DN lbs/hr/ft kg/h/m lbs/hr/ft kg/h/m inches mm

Hose

Tubing

Pipe

Note: These data are based on an ambient air temperature of 80 °F (27 °C), fi berglass insulation, copper tubing, and Schedule 40 pipe.

mc_051310_1215

size

1½ 40 0.15 0.22 N/A N/A N/A N/A

2 50 0.20 0.30 N/A N/A N/A N/A

1½ 40 0.11 0.164 0.02 0.03 2 50

2 50 0.14 0.21 0.025 0.037 2 50

1½ 40 0.22 0.33 0.02 0.03 2 50

2 50 0.25 0.38 0.025 0.037 2 50

Noninsulated Insulated

Steam loss

Insulation thickness

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

17

Page 22

INSTALLATION

Dispersion:

FIGURE 18-1: SINGLE DISPERSION TUBE WITHOUT CONDENSATE DRAIN

Steam hose, tubing or pipe. Insulate

tubing and hard pipe to reduce steam

loss. Do not insulate steam hose. See

Table 16-1 for maximum piping

lengths.

CRUV humidifi er

* Pitch steam hose, tubing, or pipe toward humidifi er:

– 2"/ft (15%) when using steam hose

– ½"/ft (5%) when using 1½" tubing or pipe

– ¼"/ft (2%) when using 2" tubing or pipe

mc_062810_0720-CRUV

Single tube

Single dispersion tube without condensate drain

Pitch*

Secure and seal

escutcheon plates

90° long sweep or

two 45° elbows

See fi rst bullet in

Installation notes

OM-7554

Dashed lines indicate provided by installer.

Duct

Dispersion tube escutcheon plate

A

A

OM-7554

Mounting nut

3/8"–16 (M10)

Tube pitch: 2"/ft (15%)

Dimension A:

• 3.25" (82.5 mm) for 1½" tubes

• 5" (127 mm) for 2" tubes

INSTALLATION NOTES

• Use DriSteem’s hard pipe adapter kit to connect the steam outlet to hard

pipe. Use a hose clamp to connect the steam outlet to steam hose. Use a

hose cuff and clamps to connect the steam outlet to tubing.

• Thin-walled tubing heats up faster than heavy-walled pipe causing less

steam loss at start-up.

• Hard pipe or tubing diameter must match Vapormist steam outlet size

1½" (DN40), 2" (DN50), or NPT connection.

• See the Maximum Steam Carrying Capacity and Steam Loss tables on

Pages 16 and 17.

• Orient dispersion tube with tubelets (steam orifi ces) pointing up.

• If mounting the humidifi er above the level of dispersion tube, see “Drip tee

installation” on Page 15.

• Table 18-1 lists hose kit sizes by humidifi er model. Note that the capacities

of Models 30 and 34 require multiple tube assemblies and cannot use

a hose kit. For multiple tube assemblies, see “Rapid-sorb,” beginning on

Page 20.

mc_062810_1030-NA

WARNING

Hot surface and steam hazard

Dispersion tube, steam hose, tubing,

or hard pipe can contain steam, and

surfaces can be hot. Discharged steam

is not visible. Contact with hot surfaces

or air into which steam has been

discharged can cause severe personal

injury.

mc_060110_1555

Important:

Failure to follow the recommendations in this

section can result in excessive back pressure on

the humidifi er. This will result in unacceptable

humidifi cation system performance such as

leaking gaskets, blown water seals, erratic

water level control, and spitting condensate

from dispersion tubes.

mc_060210_0843

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

18

Page 23

INSTALLATION

Dispersion:

FIGURE 19-1: SINGLE DISPERSION TUBE WITH CONDENSATE DRAIN

Steam hose, tubing or pipe. Insulate

tubing and hard pipe to reduce steam

loss. Do not insulate steam hose. See

Table 16-1 for maximum piping

lengths.

90° long sweep or

two 45° elbows

See fi rst bullet in

Installation notes

CRUV humidifi er

* Pitch steam hose, tubing, or pipe toward humidifi er:

– 2"/ft (15%) when using steam hose

– ½"/ft (5%) when using 1½" tubing or pipe

– ¼"/ft (2%) when using 2" tubing or pipe

Dashed lines indicate provided by installer.

mc_062810_0725-CRUV

Single tube

OM-7549

Secure and seal

escutcheon plates

Pitch*

6" (150 mm)

recommended

Water seal

5" (125 mm)

1" (25 mm) air gap

OM-351-1

Duct

¼" NPT (DN8)

¾" (DN20) (minimum) condensate drain tube by installer.

Must be suitable for 212 °F (100 °C) water.

Open drain required. Locate air gap only in spaces with

adequate temperature and air movement to absorb fl ash

steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size

and maximum discharge water temperature.

Escutcheon plates

Dispersion tube

A

A

Dimension A:

• 3.25" (82.5 mm) for 1½" tubes

• 5" (127 mm) for 2" tubes

Single dispersion tube without

condensate drain

Mounting nut

3/8" - 16 (M10)

Pitch tube toward

drain 1/8"/ft (1%)

½" O.D. (DN15) condensate

drain tube. Pitch ¼”/ft (2%)

toward escutcheon plate.

Condensate drain

3.25"

(82.5 mm)

3.25"

(82.5 mm)

Table 19-1:

Single dispersion tube capacities*

Insulated

Tube size

inches DN lbs/hr kg/h lbs/hr kg/h lbs/hr kg/h lbs/hr kg/h

1½ 40 29 13.2 65 29.5 28 12.7 62 28.2

2 50 65 29.5 97 44.1 62 28.2 93 42.3

Note:

Single dispersion tube available with face width between 6" (152 mm) up to 120" (3048 mm)

in 1" (25 mm) increments.

* If face width is <19" (483 mm), tube capacity may be reduced. Consult DriSteem or see

DriCalc for the correct capacity.

* Hose kits are available that include dispersion tube, 10 ft (3 m) of steam hose, and hardware

(High-Effi ciency Tubes)

Without drain With drain Without drain With drain

Uninsulated

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

19

Page 24

INSTALLATION

Dispersion: Rapid-sorb

Read all dispersion instructions in this manual, and follow the installation

instructions below:

WARNING

• Unpack shipment and verify receipt of all Rapid-sorb components

with packing list. Report any shortages to DriSteem immediately. The

components typically include the following:

– Multiple dispersion tubes

– Header

– ¾" × 2" (19 mm × 51 mm) L-bracket

Note: Dispersion tubes, header, and L-bracket are each tagged with the

customer requested identifi cation number.

– A single duct escutcheon plate the size of the header

– Slip couplings or hose cuffs and clamps

– Accessories such as duct plates, slip couplings, or hose cuffs

– Bolts and washers for mounting the dispersion tubes to the bracket

• L-bracket mounting holes (see note at left):

– L-bracket 50" (1270 mm) long or shorter has a mounting hole 4"

(100 mm) from each end for mounting the L-bracket to the duct or air

handler wall.

– L-bracket longer than 50" (1270 mm) has an additional mounting hole

in the center.

Note: Hardware for mounting the L-bracket to the duct or air handler

wall and the hardware for the header support bracket is not

provided.

• Select an installation location that provides necessary access in and around

the ductwork or air handler.

• The Rapid-sorb typically is installed centered side to side in a duct, or is

installed across the face of a coil in an air handler.

Hot surface and steam hazard

Dispersion tube, steam hose, tubing,

or hard pipe can contain steam, and

surfaces can be hot. Discharged steam

is not visible. Contact with hot surfaces

or air into which steam has been

discharged can cause severe personal

injury.

mc_060110_1555

Important:

Before marking and drilling holes in the duct

or air handler, refer to ALL pitch re quire ments

for the Rapid-sorb as sem bly you received

(see Table 21-1). The size, quan ti ty, and

location of penetrations are determined by the

dimensions and confi guration of the Rapid-sorb

assembly you received.

mc_060210_0937

Important:

Failure to follow the recommendations in this

section can result in excessive back pressure on

the humidifi er. This will result in unacceptable

humidifi cation system performance such as

leaking gaskets, blown water seals, erratic

water level control, and spitting condensate

from dispersion tubes.

mc_060210_0843

• The center line of the outer dispersion tubes should never be closer than

4.5" (114 mm) from the side of the ductwork or air handler wall.

• The following instructions are for a typical Rapid-sorb installation —

horizontal-airfl ow duct with Rapid-sorb header either inside or outside

the duct. See the DriCalc Installation Guides library or contact your

representative/distributor or DriSteem for installation instructions for air

handler or vertical airfl ow applications.

mc_060210_0945-NA

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

20

Page 25

Dispersion: Rapid-sorb

PITCH REQUIREMENTS

• For Rapid-sorb with the header outside a horizontal-airfl ow duct, consider

the following:

– 1½" (DN40) dispersion tubes: Use a fastener of suffi cient length to

ac com mo date the 1/8"/ft (1%) pitch requirements toward the ¾" pipe

thread (DN20) header drain fi tting.

– 2" (DN50) dispersion tubes: The bracket can be mounted fl ush to the

ductwork. The 1/8"/ft (1%) pitch typically can be accomplished in the

length of the hose cuffs used to connect the tubes to the header.

• See Table 21-3 and the drawings on the following pages for pitch

requirements.

mc_060210_0953-NA

INSTALLATION

Table 21-1:

Rapid-sorb tube capacities*

Tube

diameter

inches DN lbs/hr kg/h lbs/hr kg/h

1½ 40 43 19.5 40 18.2

2 50 80 36.4 77 35

Note:

* Capacities shown are for horizontal airfl ow. See DriCalc for vertical

airfl ow capacities.

If face height is <22” (559 mm), tube quantity per panel may need to

increase to compensate for reduced capacity of short tubes. Consult

DriSteem or see DriCalc for the correct calculation.

Insulated

(High- Effi ciency Tubes)

Uninsulated

Table 21-2:

Rapid-sorb header capacities

Header capacity Header diameter

lbs/hr kg/h inches DN

≤ 250 ≤ 113 2 50

251-500 114-227 3 80

501-800 228-363 4 100

801-1300 364-591 5 125

1301-2100 592-955 6 150

mc_060210_0936

Table 21-3:

Pitch of interconnecting piping, dispersion tubes, and headers for Rapid-sorb evaporative dispersion units

Airfl ow

Horizontal

Type of

interconnecting piping

Steam hose

Tubing or pipe

Diameter of

interconnecting piping

1½" (DN40)

2" (DN50)

1½" (DN40)

2" (DN50)

Pitch of

interconnecting piping

2"/ft (15%)

toward Rapid-sorb

1/8"/ft (1%)

toward Rapid-sorb

Pitch of

dispersion tubes

Vertically plumb

Pitch of

header

1/8"/ft (1%)

toward condensate

drain

Steam hose

Vertical

Tubing or pipe

mc_060310_1000

1½" (DN40)

2" (DN50)

1½" (DN40)

2" (DN50)

2"/ft (15%)

toward Rapid-sorb

1/8"/ft (1%)

toward Rapid-sorb

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

2"/ft (15%)

toward header

1/8"/ft (1%)

toward condensate

drain

21

Page 26

INSTALLATION

Dispersion: Rapid-sorb

FIGURE 22-1: RAPID-SORB IN A HORIZONTAL AIRFLOW WITH HEADER OUTSIDE THE DUCT

Position L-bracket so that fl ange is upstream of dispersion tubes.

Drawing shows L-bracket positioned for airfl ow back to front.

L-bracket

Dispersion tube

Point tubelets perpendicular to airfl ow

90° long sweep

or two 45° elbows

Steam hose, tubing or

pipe. Insulate tubing and

hard pipe to reduce steam

loss. Do not insulate steam

hose. See Table 16-1 for

maximum piping lengths.

Notes:

1 Pitch steam hose, tubing, or pipe toward Rapid-sorb:

– 2"/ft (15%) when using steam hose

– 1/8"/ft (1%) when using tubing or pipe

2 Use DriSteem’s hard pipe adapter kit to connect steam outlet to hard

pipe. Use a hose clamp to connect steam outlet to steam hose. Use a

hose cuff and clamps to connect steam outlet to tubing.

mc_062810_0815-CRUV

Slip coupling or hose cuff

Pitch

(see Note 1)

Header pitch: 1/8"/ft (1%) min.

OM-7550

CRUV humidifi er

¾" pipe thread (DN20) copper

Airfl ow

Duct

Secure and seal

escutcheon plates

Support bracket that has 0.421"

(11 mm) mounting holes at top,

bottom and end

Condensate drain

1" (25 mm) air gap

Open drain required.

Locate air gap only in spaces with adequate temperature and air movement

to absorb fl ash steam; otherwise, condensation may form on nearby

surfaces. Refer to governing codes for drain pipe size and maximum

discharge water temperature.

Dispersion tube escutcheon plates

A

OM-351-1

Dimension A:

• 3.25" (82.5 mm) for 1½" tubes

• 5" (127 mm) for 2" tubes

A

6" (150 mm) recommended

5" (125 mm) recommended

HEADER OUTSIDE OF DUCT, HORIZONTAL AIRFLOW

1. Mark and cut holes in the ductwork for the dispersion tubes. Use the

L-bracket as a tem plate to mark the holes on the duct floor.

2. Temporarily, loosely suspend or support the header below the final

location. Vertical balance point of the dispersion tube length dictates

where the header should be suspended or temporarily supported.

3. Mount the dispersion tubes to the header with the slip coupling or hose cuff

(provided).

• When installing slip couplings for 1½" (DN40) dispersion tubes, take

care not to shear the O-rings.

• Set the slip coupling on the header stub or dis per sion tube so the O-ring

is resting on the face of the tubing.

• Rotate the slip coupling as you push it onto the tubing.

• The O-rings are lubricated at the factory. If additional lubrication is

necessary, DO NOT use a petroleum-based lubricant.

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

22

WARNING

Hot surface and steam hazard

Dispersion tube, steam hose, tubing,

or hard pipe can contain steam, and

surfaces can be hot. Discharged steam

is not visible. Contact with hot surfaces

or air into which steam has been

discharged can cause severe personal

injury.

mc_060110_1555

Page 27

Dispersion: Rapid-sorb

INSTALLATION

4. Position the flange of the L-bracket so it is upstream of the tubes when the

assembly is raised and fastened into po si tion. Fasten the L-bracket to the

end of the dispersion tubes with the provided bolt, lock washer, and flat

washer.

5. Before tightening the L-bracket bolts to the dispersion tubes:

• For 1½" (DN40) dis per sion tubes:

– Dispersion tube will rotate in slip coupling. Verify that dispersion tube

orifi ces are directed perpendicular to airfl ow.

– Dispersion tube and slip coupling must be fully engaged on header

stub for O-rings to provide a seal.

• For 2" (DN50) dispersion tubes:

Before securing hose cuff in place with hose clamps on dis per sion tube

and the header stub, verify that dis per sion tube orifi ces are directed

perpendicular to airfl ow.

6. Slide the assembly up until the L-bracket aligns with the mount ing holes in

the duct.

• For 1½" (DN40) dispersion tubes:

– Header pitch is duplicated in the L-bracket.

– Dispersion tube and slip coupling must be fully engaged on header

stub for O-rings to provide a seal.

– High end of L-bracket can be fastened tight to duct or air handler.

– Fastener on low end of L-bracket must be long enough to compensate

for pitch. Use a nut on both sides of L-bracket and duct or air handler

for stability.

• For 2" (DN50) dis per sion tubes:

– Fasten bracket to top of duct and use hose cuffs to compensate for

header pitch.

– Before securing hose cuffs with hose clamps on dispersion tube and

header stub, verify that header pitch, 1/8"/ft (1%) toward drain, is

maintained.

Note:

See Page 26 for steam supply and condensate

drain line connection instructions.

7. Permanently secure both ends of header, and verify that header pitch,

1/8"/ft (1%) toward drain, is maintained.

8. Verify that all fasteners are secure:

• L-bracket to duct

• Dispersion tubes to L-bracket

• Hose clamps on 2" (DN50) tubes

9. Secure and seal the dispersion tube escutcheon plate and condensate

drain tube escutcheon plate around the respective tubes, if applicable.

mc_060210_1015-NA

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

23

Page 28

INSTALLATION

Dispersion: Rapid-sorb

FIGURE 24-1: RAPID-SORB IN A HORIZONTAL AIRFLOW WITH HEADER INSIDE THE DUCT

Position L-bracket so that fl ange is upstream of dispersion tubes. This

drawing shows the L-bracket positioned for airfl ow back to front

Dispersion tube

Point tubelets (steam orifi ces) perpendicular to airfl ow

Airfl ow

90° long sweep or

two 45° elbows

Steam hose, tubing or pipe.

Insulate tubing and hard pipe

to reduce steam loss. Do not

insulate steam hose. See Table

16-1 for maximum piping

lengths.

* Pitch steam hose, tubing, or pipe toward Rapid-sorb:

– 2"/ft (15%) when using steam hose

– 1/8"/ft (1%) when using tubing or pipe

mc_062810_0820-CRUV

HEADER INSIDE OF DUCT, HORIZONTAL AIRFLOW

Slip coupling or hose cuff

Pitch*

Secure and seal

escutcheon plate

OM-7551

CRUV humidifi er

Pitch header toward

drain 1/8"/ft (1%)

¾" pipe thread

(DN20) drain

¾" (DN20) copper

1" (25 mm) air gap

Open drain required.

Locate air gap only in spaces with adequate temperature and

air movement to absorb fl ash steam, or condensing on nearby

surfaces may occur. Refer to governing codes for drain pipe size

and maximum discharge water temperature.

1. Mark and cut holes in ductwork or air handler for steam header

pen e tra tion, con den sate drain piping, and head er support bracket fastener.

Allow 1/8"/ft (1%) header pitch toward the support bracket when you drill

the hole for the header support bracket fastener.

2. Loosely fasten the header in place.

3. Rotate the header 90° so the header stubs point hor i zon tal ly in the duct.

4. When installing in an air handler, the rotation of the header is often less

than 90°. Typically, due to the condensate drain piping re quire ments, the

header can be set on the floor of the air handler, assembled in the vertical

position, and then raised and mounted in place.

Duct

Support bracket

6" (152 mm)

5" (127 mm)

WARNING

Hot surface and steam hazard

Dispersion tube, steam hose, tubing,

or hard pipe can contain steam, and

surfaces can be hot. Discharged steam

is not visible. Contact with hot surfaces

or air into which steam has been

discharged can cause severe personal

injury.

mc_060110_1555

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

24

Page 29

Dispersion: Rapid-sorb

INSTALLATION

5. Mount the dispersion tubes on the header with the slip couplings or hose

cuffs:

• When installing slip couplings for 1½" (DN40) dispersion tubes, take

care not to shear O-rings.

• Set slip coupling on header stub or dis per sion tube so O-ring is resting

on face of tubing.

• Rotate slip coupling while pushing it onto the tubing.

• O-rings are lubricated at factory. If additional lubrication is necessary,

DO NOT use petroleum-based lubricant.

6. Allow the dispersion tubes to rest against the bottom of the duct.

7. Position the flange of the L-bracket so it is upstream of the tubes when the

assembly is rotated into position. Fasten the L-bracket to the end of the

dispersion tubes with the provided bolt, lock washer, and flat washer.

8. Rotate the assembly up until the L-bracket aligns with the mounting holes in

the duct or air handler.

• For 1½" (DN40) dispersion tubes:

– Header pitch is duplicated in the L-bracket.

– Dispersion tube and slip coupling must be fully engaged on header

stub for O-rings to provide a seal.

– High end of L-bracket can be fastened tight to duct or air handler.

– Fastener on low end of L-bracket must be long enough to compensate

for pitch. Use a nut on both sides of L-bracket and duct or air handler

for stability.

• 2" (DN50) dispersion tubes

– Fasten bracket to top of duct and use hose cuffs to compensate for

header pitch.

– Before securing hose cuffs with hose clamps on dispersion tube

and header stub, verify that dispersion tube orifi ces are directed

perpendicular to airfl ow.

Note:

See Page 26 for steam supply and condensate

drain line connection instructions.

9. Verify that all fasteners are secure:

• L-bracket to duct

• Dispersion tubes to L-bracket

• Hose clamps on 2" (DN50) tubes

• Header support bracket fastener

10. Secure and seal the header escutcheon plate around the header.

mc_060210_1050 -NA

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

25

Page 30

INSTALLATION

Dispersion: Rapid-sorb

STEAM SUPPLY CONNECTIONS TO RAPID-SORB HEADER

Connect the steam supply interconnecting piping from the humidifi er to the

Rapid-sorb. The steam supply piping requires a minimum of 1/8"/ft (1%) pitch

toward the header.

If multiple humidifi ers are supplying one Rapid-sorb, a multiple steam supply

connector is needed. Typically, the multiple steam supply connector attaches to

the Rapid-sorb header supply end with hose cuff and clamps:

1. Route the necessary number of steam supplies from the humidifiers to the

steam supply connector.

2. Position the steam supply connector to accept the steam supplies while

maintaining the necessary pitch.

3. Make sure the hose clamps on the steam supply connector and header are

tight.

CAUTION

Operate Rapid-sorb within rated steam

capacity

Excessive steam fl ow to the Rapid-sorb

steam dispersion assembly can

cause condensate to exit the tubelets,

which can cause water damage and

standing water in the duct or air

handler.

To avoid condensate exiting the

tubelets, do not operate the Rapid-sorb

beyond its rated capacity.

mc_072010_0930

CONDENSATE DRAIN CONNECTIONS TO RAPID-SORB HEADER

Piping must be minimum ¾" I.D. (DN20) and rated for 212 °F (100 °C)

minimum continuous operating temperature.

The condensate drain line must be piped as shown in Figures 8-1 and 8-1.

Provide a 6" (152 mm) drop prior to a 5" (127 mm) water seal to:

• Ensure drainage of condensate from the header

• Keep steam from blowing out of the drain line

After the water seal, run the drain line to an open drain with a 1" (25 mm)

vertical air gap.

• Cut the drain line at a 45° angle on the end above the drain to permit a

direct stream of water into the drain pipe while maintaining a 1" (25 mm)

air gap.

• Locate air gap only in spaces with adequate temperature and air movement

to absorb fl ash steam, or condensing on nearby surfaces may occur.

All drain lines must be installed and sized according to governing codes.

ULTRA-SORB

For Ultra-sorb steam dispersion panel instructions, see the installation,

operation, and maintenance manual shipped with the Ultra-sorb.

mc_060210_1300-NA

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

26

Page 31

Start-up procedure

The CRUV humidifi er is available with either the LW series controller or the

optional Vapor-logic control system. If your system is equipped with the

Vapor-logic system, refer also to the Vapor-logic Installation and Operation

Manual as noted in the instructions below.

After the system is installed and connected properly:

1. Verify that the humidifier, controls, piping, electrical connections, steam

supply, and dispersion units(s) are installed according to the following:

• Installation instructions in this manual

• Vapor-logic Installation and Operation Manual (if using the Vapor-logic

control option):

– Installation section

– Pre-installation checklist

• Wiring diagrams shipped with humidifi er

• All governing codes

OPERATION

WARNING

Electric shock hazard

Only qualifi ed electrical personnel

should perform start-up procedure.

Contact with energized circuits can

cause property damage, severe

personal injury or death as a result of

electrical shock or fi re.

Make sure that all electrical covers

are in place and secure before turning

on electrical power. These include the

heater terminal cover, electrical panel

cover, and subpanel access panels.

2. Confirm that proper grounding and an approved earth ground are

provided.

3. Verify that all electrical connections are secure before applying power.

4. Make sure all electrical covers are in place and secure. See Warning at

right.

5. Verify that the humidifier is mounted level and securely supported before

filling with water (see the operating weights in Table 4-1).

6. Verify that the humidifier is level front to back and side to side after it is full

of water.

7. Refer to “LW series controller” on Page 28 or the “Operation” section of

the Vapor-logic Installation and Operation Manual.

8. Perform all applicable “Start-up checklist” items on Page 28 or 29.

Note: During start-up, do not leave the humidifi er unattended.

9. Monitor humidifier operation through multiple fill cycles.

10. On tap/softened water units, water skims from the humidifier after every

fill cycle. Adjust the amount of skim by increasing or decreasing the skim

time. See "Skim duration" on Page 33.

At start-up, DriSteem recommends initially running the humidifi er with the

factory default setting for skim time.

CAUTION

Damage from dry startup

In the event the humidifi er tank does

not contain water and the heaters

are energized, turn main power off.

Operation of the heaters without water

will cause damage to the humidifi er.

Before turning main power on, verify

that all wiring has been completed per

the wiring instructions in this manual

and the unit wiring diagrams.

mc_052410_1325

Continue reading this section before proceeding to “Maintenance” beginning

on Page 34.

mc_060210_1400-CRUV

CRUV INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

27

Page 32

OPERATION

Start-up checklist:

TAP/SOFTENED WATER

☐ Adjust humidistat setting to create a call for humidity.

☐ Open shut-off valve on water supply line, and confi rm that drain valve is

closed. Tank should begin fi lling with water through fi ll valve.

☐ Shortly before fi ll valve shuts off, rising water level causes water to come

in contact with the bottom probe, and heating element contactor(s) will be

actuated.

☐ Check heater cut-off circuit as follows:

1. Close manual water supply valve, then open drain valve and start

draining tank.

2. When water level drops below bottom probe, the heating element

contactor(s) drop out.

3. When Step 2 above has completed, close drain valve.

☐ Check function of fi eld-installed safety controls, such as fan proving switch.

Contactor(s) should drop out when proving switch is open.

☐ Check heater draw by testing and recording voltage and amperage in each