Page 1

READ AND SAVE THESE INSTRUCTIONS

WATER TREATMENT

200 series

reverse-osmosis systems

Installation, Operation,

and Maintenance Manual

Page 2

WARNINGS AND CAUTIONS

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

ii

Page 3

Warnings and cautions

WARNING

Warnings and Cautions

Attention installer

Read this manual before installing, and leave this manual with product owner. This product must be installed by qualifi ed

HVAC and electrical contractors. Installation must be code approved.

Disconnect electrical power

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any part

of the system. Failure to disconnect electrical power could result in fi re, electrical shock, and other hazardous conditions.

These hazardous conditions could cause property damage, personal injury, or death.

CAUTION

Operate system at above-freezing temperatures.

Operating the system at temperatures below freezing can damage the system or cause other property damage.

Maintain pumping and water treatment equipment.

Inadequately maintained pumping and water treatment equipment can cause the system to fail. Refer to the maintenance section

of this IOM for recommended maintenance.

Do not install the system using steel or galvanized-steel piping and joints.

Steel and steel-galvanized piping and joints can corrode and cause system damage. Use plastic tubing and joints when

assembling system.

Follow all instructions in this manual to maintain product warranty.

FILL IN THE FOLLOWING INFORMATION FOR YOUR RECORDS

Date of purchase

Customer's name

Model number

Serial number

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

iii

Page 4

Table of contents

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Fill in the following information for your records . . . . . . . . . . . . . . . . .iii

ATTENTION INSTALLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Where to find more information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Flow schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Line 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Line 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Line 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Line 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Line 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pre-treatment connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Series 200 controller specifications . . . . . . . . . . . . . . . . . . . . . . . . . .6

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

RO pump wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inlet wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure fault switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pretreat switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tank full switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System operation continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Initial system start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Normal operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

iv

Page 5

Table of contents

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

When to change cartridge filters . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

When to clean membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Membrane cleaning and preservative cartridges . . . . . . . . . . . . . 11

Membrane cleaning in the RO system . . . . . . . . . . . . . . . . . . . . . . . 12

How does it work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Scale cleaning cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Organic cleaning cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Membrane preservative cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preserving procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flushing out preservative/restart procedure . . . . . . . . . . . . . . . . 14

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Low pressure cut-out switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating do's and don'ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Do . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Don't . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ATTENTION INSTALLER

Read this manual before installing.

Leave manual with product owner.

DriSteem® Technical Support

800-328-4447

WHERE TO FIND MORE INFORMATION

Our website:

The following documents are available on our

web site: www.dristeem.com

• Water Treatment Systems Catalog

• Vapor-logic Controller Installation and

Operation Manual

DriCalc®:

DriCalc, our software for system sizing and

selection, can be ordered at our web site.

Call us at 800-328-4447

Obtaining documents from our web site or

from DriCalc is the quickest way to view our

literature, or we will be happy to mail literature

to you.

Download DriSteem literature

Most DriSteem product manuals are available

our website: www.dristeem.com

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

1

Page 6

OVERVIEW

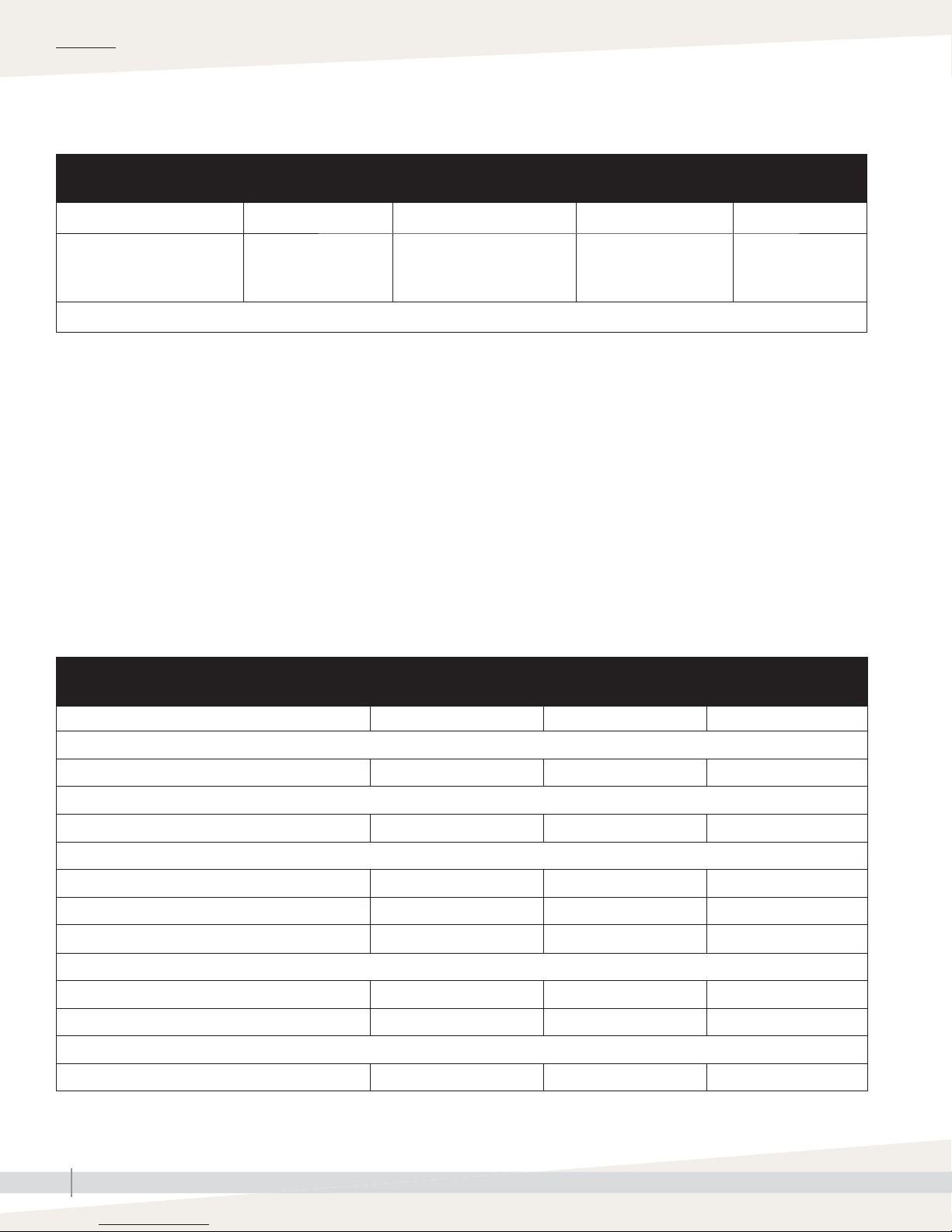

System specifi cations

Table 2-1:

Pressurized RO holding tank specifications

Model Hz Motor HP Volts*/Amps Phase/Frequency

201

202

203

* 115V or 230V must be ordered specifi cally

60 1/3

NOTES:

1. All systems rated at 50°F (10°C) using 1000 ppm sodium chloride (NaCl)

solution. System capacity decreased signifi cantly with decrease in feed

water temperature.

2. Chlorine requirements for the feed water are:

a. Thin-Film (standard) 0 ppm

3. Feed water must be filtered to a turbidity of less than 1 NTU.

4. System recovery (permeate to concentrate ratio) must be maintained at

the recommended level. A higher than recommended recovery will lead

to a premature fouling of the membrane with a loss of permeate flow and

permeate quality.

Table 2-2:

RO station specifications

Model 201 202 203

Rated capacity, permeate

110-120 VAC/5.5A

(208-240 VAC/2.8A)

1/60Hz

Gallons/minute 0.2 0.4 0.6

Concentrate fl ow (reject)

Gallons/minute 1.1 1.2 0.97

Recirc (adjustable as needed)

Gallons/minute 0 - 1.0 0 - 1.0 0 - 0.8

System pressure, psi 100 - 150 100 - 150 100 - 150

°F (°C) 10/50 10/50 10/50

Pre-fi lters

Sediment cartridge - 5 micron 1 1 1

Carbon cartridge - 10 micron 1 1 1

Pressure switch settings

Low pressure (for pump protection) 8 psi 8 psi 8 psi

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

2

Page 7

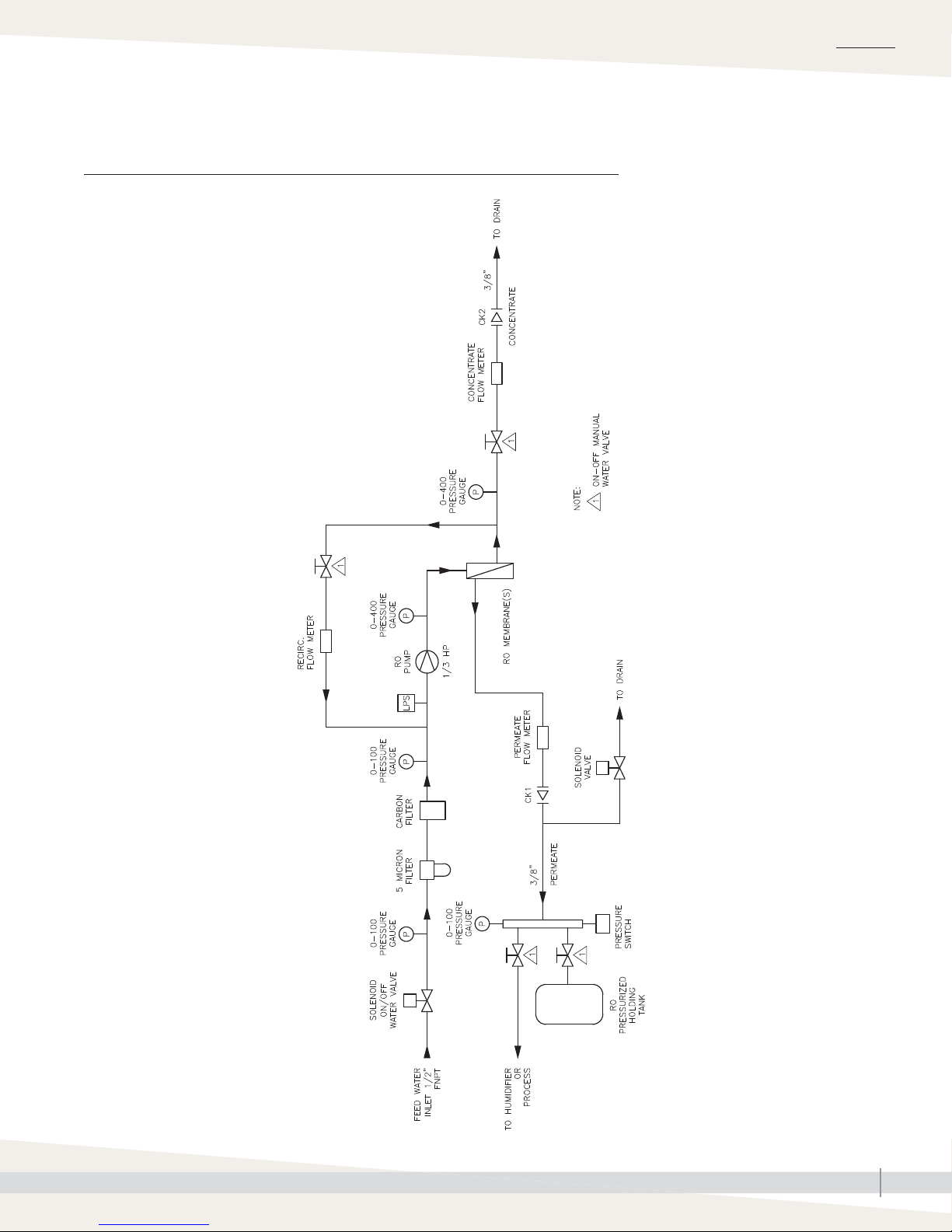

Flow schematic

FIGURE 3-1: FLOW SCHEMATIC

OVERVIEW

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

OM-7822

3

Page 8

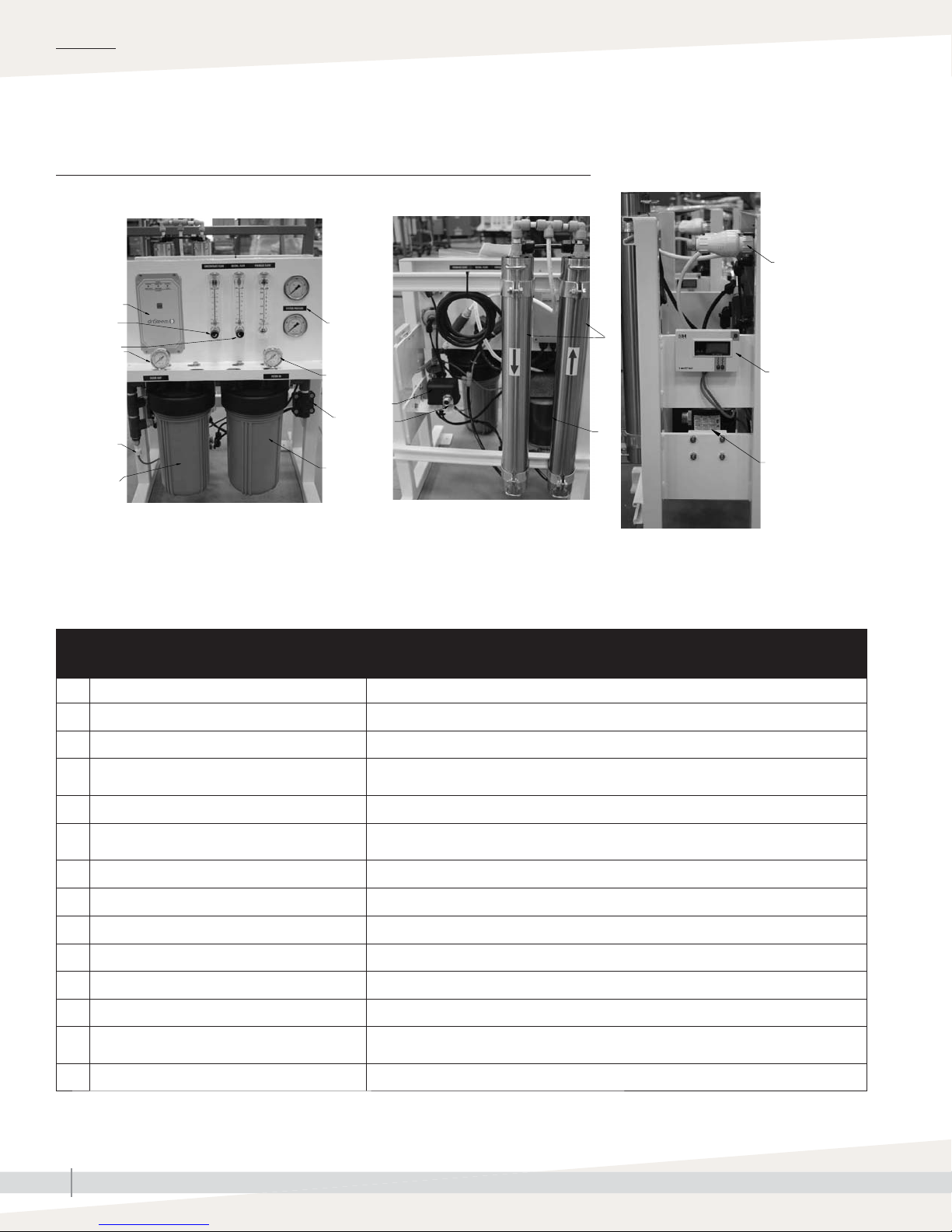

OVERVIEW

Component identifi cation

FIGURE 4-1: COMPONENT IDENTIFICATION

13

1

10

11

3

12a

5

9

8

3

12b

2

4

6

7

Table 4-2:

Component identification

Item Description

1 Controller Power On/Off and status display

2 Inlet solenoid valve Normally closed. Opens when power is applied.

3 Cartridge fi lter pressure gauges (in-right/out-left)

4 Sediment fi lter 5 micron sediment fi lter.

5 Carbon fi lter

6 Low pressure switch Shuts the system down if the inlet pressure is lower than 8 psi (adjustable).

Measure the feed and effl uent pressure of the cartridge fi lters. Pressure difference

determines when cartridge change out is required.

10 micron extruded carbon cartridge to remove chlorine and reduce organics from the feed

stream.

12

6

7 High pressure pump and motor Rotary pump and motor to pressurize the incoming water.

8 Membrane modules RO membrane elements housed in stainless steel pressure tubes.

9 System pressure gauges Measure the system (feed) and concentrate (effl uent) pressure of the membrane modules.

10 Concentrate control valve To adjust system pressure. Must not be completely closed when the system is in operation.

11 Recirc valve To adjust and maintain adequate fl ow thru membranes

12 TDS monitor

13 Permeate check valve Prevents backfl ow into RO module.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

4

Monitors the feed and permeate water quality.

12a - feed sensor; 12b - permeate sensor

Page 9

System installation

INSTALLATION

1. Locate RO system with adequate clearance from walls and other

equipment to enable membrane servicing.

2. Run five polyvinyl tube lines to the system as follows:

LINE 1

Connect raw water feed supply to the solenoid valve inlet in front of the fi rst

cartridge fi lter housing. This will require ½ inch threaded pipe fi tting and

adaptor for the feed line. If desired, install an isolation valve in this line; ensure

the valve opening does not restrict the water fl ow.

LINE 2

Run a ⅜ inch line from the open end of the concentrate valve to a drain. Ensure

that no liquids from other lines near this drain fl ow back through this line.

LINE 3

Run a ⅜ inch line from one of the two permeate outlets on the back of the

system to the pressurized permeate storage container.

NOTE: The recirc fl ow line is pre-connected at the factory.

LINE 4

Run a ⅜ inch line from the other permeate outlet to the humidifi er or end

process being fed by the system.

FIGURE 5-1: SOLENOID VALVE INLET

CAUTION

LINE 5

Run a ¼inch line from the pressurized relief solenoid to a drain. Ensure that no

liquids from other lines near this drain fl ow back through this line.

Pump and system performance will be

adversely affected if the feed/suction

line is restricted.

FIGURE 5-2: RECIRC FLOW LINE

CAUTION

Confi rm all lines are connected before

plugging in unit power.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

5

Page 10

INSTALLATION

System installation

PRE-TREATMENT CONNECTION

If you have pre-treatment equipment and you wish to shut-down the RO system

during backwash or regeneration, a microswitch is required (standard with

DriSteem water softeners).

1. Wire the microswitch to terminal labeled PreTreat inside controller.

When the equipment goes into backwash or regeneration, the pre-treat limit

switch opens and turns the power off the inlet solenoid valve, which then turns

the RO pump off (and back on) when the cycle is complete.

CAUTION

The controller is rated for maximum

20 amp total load. Terminal strip

P11 is dry contact for input signals

from tank full, pressure fault and

pretreat lockout. Use a small gauge

2 conductor cable for these wire

connections.

SERIES 200 CONTROLLER SPECIFICATIONS

POWER

Either 110-120 VAC or 208-240 VAC, 1 phase,

50/60 Hz, +10/-15%, 2.5 watts

Input power is auto selected

INPUTS

Three switch inputs, selectable normally open or normally closed

OUTPUTS

RO pump 1HP (based on service factor of 1.0 max)

Inlet solenoid 5A

20A maximum total load

NOTE: All six switches are factory set to the OFF position.

Auto reset (disabled)

Pressure fault retry (disabled)

Tank full restart time delay (two seconds)

Input contact type (NC, open to operate)

If you desire to change any switch functions, move that switch to the ON

position.

FIGURE 6-1: CONTROL BOARD

Table 6-1:

Switch positions

Switch Off position On position

1 Auto reset off Auto reset on

2 Retries disabled Retries enabled

3 2 sec. restart 15 min. restart

4 N.O switches N.C. switches

Switch 5 and 6 not used.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

6

Page 11

Schematic drawing

FIGURE 7-1: CONTROLLER ELECTRICAL SCHEMATIC

INSTALLATION

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

OM-7821

7

Page 12

INSTALLATION

Control board

FIGURE 8-1: CONTROLLER ELECTRICAL SCHEMATIC

Tank full

RO PUMP WIRING

The RO pump connects to P4 (L1) and P5 (L2) RO pump terminals. This output can operate 110/240 VAC motors up to

1HP directly.

INLET WIRING

The inlet solenoid valve connects to P6 (L1) and P7 (L2) inlet terminals.

PRESSURE FAULT SWITCH

The feed pressure switch is connected to the pressure fault input. Low pressure (factory preset 8 psi) will shut system off.

PRETREAT SWITCH

In systems with pretreatment, a pretreat lockout switch can be connected to the pretreat input. This switch should operate

when the pretreatment device is out of service.

NOTE: The output from the pretreatment device must be a dry contact and must not supply voltage.

TANK FULL SWITCH

DriSteem systems use a pressure switch to keep the pressurized storage tank between 30-50 psi (207-345 kPa). The

switch is connected to the tank full input.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

8

Page 13

System operation

OPERATION

The unit has a single mode of operation ON with six sub-modes or states as

indicated by the steady or fl ashing panel lights. Any light condition other than

steady power ON indicates the unit is effectively in standby-mode. If there are

no lights, the system is OFF and all outputs are turned off. In the operating

mode, the unit operates automatically. All inputs are monitored and the outputs

are controlled accordingly. Pressing the power key will toggle the unit from

off to operate or from operate to off. If power is removed from the unit when

power is reapplied, the unit will restart in the mode it was in when the power

was removed.

When the power switch is turned ON, the center status LED will light green, the

valve will open, and the RO pump will start.

Under normal operation the RO unit will run until:

a. the storage tank is full (right LED amber) or

b. pretreat lockout has occurred (center status LED fl ashing green).

When a or b has cleared after a time delay, the RO unit will restart and the

center status LED will return to green. Switch setting three selects a two second

or 15 minute tank full restart time delay.

Upon an alarm signal for pressure fault, the left status LED will fl ash red, the

RO pump will stop, and the inlet valve will close and the RO pump will turn

OFF.

• If switch one and two are in the OFF position (disabled), the left status LED

will be a steady red and the RO will not restart until the power switch has

been manually cycled OFF then ON to reset the unit.

• If switch one is in the ON position (auto reset), every 60 minutes the RO

will start and stop again if a pressure fault continues.

• If switch two is in the ON position (pressure fault retry), the RO will attempt

to restart after 30 seconds, then fi ve minutes, then 30 minutes. If the

pressure alarm has not cleared after the third try, the RO unit will remain

OFF until manually reset.

FIGURE 9-1: PANEL LIGHTS AND

POWER BUTTON

• Power Key: Places the controller in

operating mode

• Pressure retry: Steady red light

• Pressure fault: Blinking red light

• Power on: Steady green light, system is

operating.

• Pretreat: Flashing green light

• Tank full: Steady amber light

• Flush: No flush sequence

If switch one and two are in the ON position after a pressure fault condition,

the RO unit will continually attempt to restart after each 60 minute cycle, until

the pressure switch input has cleared.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

9

Page 14

OPERATION

System operation continued

INITIAL SYSTEM START-UP

SYSTEM FLUSH

Direct permeate discharge to drain for fi rst 30 minutes of operation.

1. Connect the system to the appropriate electrical outlet, 110-120 VAC or

208-240 VAC 1 phase.

2. Ensure all plumbing connections are open to allow flow. Open the

concentrate valve (counterclockwise). Close the recirc valve (clockwise).

Ensure suffi cient pressure (40 psi recommended) is in feed line. If pressure

is less than 8 psi, the low pressure switch will disallow start-up until

pressure is adequate.

3. Press the power button; the solenoid will open and the unit will start

operating.

4. After water is flowing from the concentrate line, adjust the concentrate

control valve to obtain designated flow for the specific model (see Table

2-2 on page 2).

5. If required, adjust recirc control valve to meet desired flow rates (see

Table 2-2 on page 2).

6. Allow the unit to run for 30 minutes to ensure proper flushing of system.

7. After the flush time is over, press the power button OFF.

FIGURE 10-1: CONTROL VALVES

CAUTION

To prevent concentrate from

precipitating and causing irreversible

fouling of the RO membrane, do not

operate the system with the control

valve completely closed.

8. Redirect the permeate line to the desired location.

NORMAL OPERATIONS

1. Turn the power back ON. After the pump starts, adjust the control valve to

the desired flow/pressure (not to exceed 150 psi).

2. The recycle valve may now be adjusted to achieve desired recycle flow

rate, ensuring concentrate flow rate is as specified.

SHUTDOWN

1. Press the power button to shut unit OFF. Close the isolation valve if it is

installed on the feed line.

2. If the unit is to be shut down for more than one week, a membrane

preservative should be used. To accomplish this, perform 30 second flush

using cartridge filter insert (see page 14 for more information). After

30 seconds, press the power button OFF, and close the concentrate valve.

This will hold the preservative in the pressure vessel.

3. When the system is restarted after an extended shutdown, follow initial

system start-up procedures.

CAUTION

Do not exceed recommended

maximum recovery.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

10

Page 15

Maintenance information

MAINTENANCE

MAINTENANCE TIPS

Maintain proper operating conditions:

• Do not exceed 150 psi on the system inlet pressure gauge.

• Do not over use recycle fl ow. This can cause premature scaling of the

membrane. A proper concentrate fl ow is required for a long membrane life.

• To ensure no chlorine reaches the RO membranes, test the water from

your carbon fi lter periodically for chlorine break through. To do this, a

sample could be obtained by briefl y removing the Feed TDS probe at the

downstream side of the cartridge fi lters. Brief power ON/OFF will be

needed to perform this.

WHEN TO CHANGE CARTRIDGE FILTERS

Cartridge fi lters (both sediment and carbon) should be changed regularly to

maintain proper pressure and fl ow.

The carbon fi lter removes chlorine and will exhaust its capacity over time. This

is dependent upon feed source concentration and fl ow rate. Check chlorine

removal effi ciency regularly.

Change the fi lters when the difference between the two cartridge fi lter pressure

gauges increase by 10 psi over the initial pressure difference. For example, if

initial readings are 60 psi in and 58 psi out, the difference is 2 psi. Therefore,

when that difference reaches 12 psi, it is time to replace the sediment and

carbon cartridges.

FIGURE 11-1: 4" X 10" SEDIMENT FILTER

DriSteem replacement

part number 550026-004.

FIGURE 11-2: 4" X 10" BIG BLUE

DECHLORINATOR CARTRIDGE

WHEN TO CLEAN MEMBRANES

In normal operation, the membrane in reverse osmosis elements can become

fouled by mineral scale, biological matter, and grime. These deposits build

up during operation until it causes loss in water output or loss of salt rejection,

or both. Elements should be cleaned or replaced whenever the water output

rate drops by 10 percent from its initial fl ow rate (the fl ow rate established

during the fi rst 24 to 48 hours of operation) or when TDS in the product water

(permeate) rises above 50. Use the factory mounted TDS sensor located on the

right side of the system.

It should be noted that the water output rate will drop if feed water temperature

decreases (about 1.5% per °F). This is normal and does not indicate membrane

fouling. A malfunction in the pretreatment, pressure control or pump can cause

a drop in feed water delivery pressure, feed water fl ow, product water output,

or an increase in salt passage. If such adjustments are needed, the element

may not require cleaning.

MEMBRANE CLEANING AND PRESERVATIVE CARTRIDGES

• Clean and preserve membranes without removing them from your system

• Reduce downtime

• Maintain your system performance at a higher level

• Prolong membrane life by regular use of cleaning cartridge

DriSteem replacement

part number 550027-004.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

11

Page 16

MAINTENANCE

Maintenance continued

MEMBRANE CLEANING IN THE RO SYSTEM

Membrane cleaning cartridges:

• Clean membranes without having to remove them from the RO system

• Reduce downtime

• Maintain the system performance at a higher level

• Prolong membrane life by regular use of cleaning cartridges

HOW DOES IT WORK?

NOTE: Clean monthly to obtain optimum results.

1. Exchange the system's pre-filter cartridge with a cleaning cartridge

2. Follow the instructions.

3. Restart the system.

4. Repeat the process if required.

SCALE CLEANING CARTRIDGE

The scale cleaning cartridge is for removal of mineral scale and build-up.

CLEANING PROCEDURE

1. Shut down the RO system.

2. Disconnect permeate line and divert to drain before any cleaning

cartridge is installed.

FIGURE 12-1: 10 INCH BIG BLUE SCALE

CLEANING CARTRIDGE

DriSteem replacement

part number 550045-202.

3. Remove the filter cartridge from the pre-filter housing.

4. Replace the filter cartridge with the cleaning cartridge and assemble into

the filter housing.

5. Turn the system ON. After 30-40 seconds, shut down the system.

OPTIONAL: Instead of time, use one of the following criteria:

a. Run the system until the pH of the concentrate is almost the same as the

cleaning solution (pH=3)

b. Permeate rate for the system drops to a very low value.

6. Let the membrane(s) soak in the cleaning solution overnight.

7. Remove the empty cleaning cartridge and replace it with the original filter.

8. Restart the system. Direct the permeate to drain for five minutes.

9. Go back to normal operations.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

12

Page 17

Maintenance continued

MAINTENANCE

ORGANIC CLEANING CARTRIDGE

The organic cleaning cartridge is for removal of organics/fouling.

CLEANING PROCEDURE

1. Shut down the RO system.

2. Disconnect permeate line and divert permeate to drain during cleaning.

3. Remove the pre-filter cartridge from the filter housing.

4. Replace the sediment pre-filter cartridge with the cleaning cartridge and

assemble into the filter housing.

5. Turn the system ON. After 30-40 seconds, shut down the system.

OPTIONAL: Instead of time, use one of the following criteria:

a. Run the system until the pH of the concentrate is almost the same as the

cleaning solution (pH=10-12)

b. Permeate rate for the system drops to a very low value.

6. Let the membrane(s) soak in the cleaning solution overnight.

7. Remove the empty cleaning cartridge and replace it with the original filter.

8. Restart the system. Direct the permeate to drain for five minutes.

9. Go back to normal operations.

FIGURE 13-1: 10 INCH BIG BLUE

ORGANIC CLEANING CARTRIDGE

DriSteem replacement

part number 550045-701.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

13

Page 18

MAINTENANCE

Storage

To prevent bacterial growth and help maintain fl ux, it is recommended that

elements be immersed in a preservative solution if the system will be OFF for

more than one week.

MEMBRANE PRESERVATIVE CARTRIDGE

PRESERVING PROCEDURE

1. Shut down the RO system.

2. Disconnect the permeate line and direct permeate to drain during

cleaning/preserving.

3. Remove the 5M filter cartridge from the pre-filter housing.

4. Replace the filter cartridge with the preservative cartridge and assemble

into the filter housing.

5. Turn the system ON. After 30-40 seconds, shut down the system.

6. Drain the system of the permeate solution as much as possible by opening

a valve/fitting at a low point in the system.

7. Close OFF the inlet and outlet to the membrane/system.

FLUSHING OUT PRESERVATIVE/RESTART PROCEDURE

8. Open valves and put the system back in the position it was before

preserving.

FIGURE 14-1: 10 INCH BIG BLUE

CLEANING CARTRIDGE

DriSteem replacement

part number 550045-902.

9. Remove the empty preservative cartridge and replace it with a new

cartridge filter.

10. Restart the system. Direct permeate to drain for 15-30 minutes.

11. Go back to normal operation.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

14

Page 19

Replacing membranes

MAINTENANCE

TOOLS

• Rubber mallet

• Flat blade screwdriver

• Open end wrench, ⅞ inch

• Food grade RT-111 silicone

• Safety glasses

PROCEDURE

1. Turn OFF the RO system.

2. Relieve pressure on the membrane arry by opening the control valve.

3. Remove all lines from both ends of the pressure vessel(s). Make sure the

fittings are marked so the fittings go back to the correct locations after

replacing.

4. Remove u-pins from the vessel. Slowly and carefully pull the end plugs out

from the fitting with a channel lock.

5. Remove end plugs by pulling carefully.

FIGURE 15-1: DRISTEEM REVERSE

OSMOSIS MEMBRANES

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

DriSteem replacement

part number

550035-025.

15

Page 20

MAINTENANCE

Replacing prefi lters

PROCEDURE

1. Shut down the RO system.

2. Close field supplied inlet supply valve.

3. Turn the blue pressure housings counterclockwise. Filter cartridge should

come free from the housing top and remain in the housing.

4. Remove and replace cartridges.

5. Before replacing the housing, insure the o-ring seal is lubed and placed in

groove of housing. Inspect seal and replace as needed.

6. Rotate the housing clockwise until hand tight.

FIGURE 16-1: PRE-FILTER

1

2

1. Carbon filter:

Primarily to remove chlorine; also

removes organics and sediments down

to 10 microns.

2. Sediment filter:

Removes sediments and particles down

to 5 micron size.

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

16

Page 21

Adjustment of pressure switch

TOOLS

• Flat blade screw driver

LOW PRESSURE CUT-OUT SWITCH

1. Loosen nut and remove cover plate.

2. Use a box wrench to adjust nut on left side counterclockwise to lessen

pressure; clockwise to raise pressure.

3. Do not tamper with the nut on the right side.

MAINTENANCE

CAUTION

Pressure switch has been factory

preset to 8 psi. This switch should not

be adjusted unless recommended by

DriSteem.

CAUTION

4. Replace the cover.

Operating do's and don'ts

DO

1. Change the cartridge filters regularly.

2. Monitor the system and keep a daily log.

3. Run the system as much as possible, on a continuous basis.

4. Adjust the system recovery to recommend value.

DON'T

1. Permit chlorine in the feed water.

2. Shut down the system for extended periods without preserving the

membranes.

3. Close the concentrate control valve completely.

4. Operate the system with insufficient feed flow.

High voltage shock hazard.

FIGURE 17-1: LOW PRESSURE CUT-OUT

SWITCH

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

17

Page 22

MAINTENANCE

System monitoring and record keeping

The system should be monitored and all pertinent data recorded on a daily

basis. This includes cartridge fi lter pressure in/out, system pressure in/out,

fl ow and water quality (TDS) in/out. Data is needed to determine operating

effi ciency and for performing system maintenance. The latter includes cleaning

of the membranes, adjusting the operating conditions as well as replacement

of cartridge fi lters and RO membranes.

Table 18-1:

Troubleshooting

Issue Possible Cause Solution

Inlet pressure low Low supply pressure Correct incoming supply pressure

Cartridge fi lters plugged Change fi lters

Solenoid valve malfunction Replace solenoid valve and/or coil

Permeate fl ow low Low water temperature Adjust water temperature

Low system pressure Adjust concentrate control valve

Membranes fouled Clean membranes

Pump noisy Low inlet fl ow See "Inlet pressure low"

Permeate quality poor Low inlet fl ow Adjust concentrate control valve

Low system pressure See "Inlet pressure low"

Recovery too high Reduce recovery

Membranes fouled Clean membranes

Membranes damaged Replace membranes

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ........

18

Page 23

System operating log

Table 19-1:

System operating log

Date

Time

Chlorine

Cartridge in psi

Cartridge out psi

Water temperature

TDS in

TDS out

System psi

MAINTENANCE

Concentrate psi

Cartrdige fi lter change

Membrane change

Recorded by

Notes

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________

DRISTEEM WATER TREATMENT SYSTEMS INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

19

Page 24

W

ARRANTY

Expect quality from the industry leader

Since 1965, DriSteem has led the industry

with innovative methods for humidifying and

cooling air with precise control. Our focus on

ease of ownership is evident in the design of

our Water Treatment Systems, which feature

low maintenance and comprehensive control.

DriSteem also leads the industry with a Twoyear Limited Warranty and optional extended

warranty.

For more information

www.dristeem.com

sales@dristeem.com

For the most recent product information

visit our Web site: www.dristeem.com

Two-year Limited Warranty

DRI-STEEM Corporation (“DriSteem”) warrants to the original user that its products will be free from

defects in materials and workmanship for a period of two (2) years after installation or twentyseven (27) months from the date DriSteem ships such product, whichever date is the earlier.

If any DriSteem product is found to be defective in material or workmanship during the applicable

warranty period, DriSteem’s entire liability, and the purchaser’s sole and exclusive remedy, shall

be the repair or replacement of the defective product, or the refund of the purchase price, at

DriSteem’s election. DriSteem shall not be liable for any costs or expenses, whether direct or

indirect, associated with the installation, removal or reinstallation of any defective product. The

Limited Warranty does not include cylinder replacement for electrode steam humidifi ers.

DriSteem’s Limited Warranty shall not be effective or actionable unless there is compliance with

all installation and operating instructions furnished by DriSteem, or if the products have been

modifi ed or altered without the written consent of DriSteem, or if such products have been subject

to accident, misuse, mishandling, tampering, negligence or improper maintenance. Any warranty

claim must be submitted to DriSteem in writing within the stated warranty period. Defective parts

may be required to be returned to DriSteem.

DriSteem’s Limited Warranty is made in lieu of, and DriSteem disclaims all other warranties,

whether express or implied, including but not limited to any IMPLIED WARRANTY OF

MERCHANTABILITY, ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, any

implied warranty arising out of a course of dealing or of performance, custom or usage of trade.

DriSteem SHALL NOT, UNDER ANY CIRCUMSTANCES BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, LOSS OF PROFITS, REVENUE OR BUSINESS) OR DAMAGE OR INJURY TO PERSONS OR

PROPERTY IN ANY WAY RELATED TO THE MANUFACTURE OR THE USE OF ITS PRODUCTS. The

exclusion applies regardless of whether such damages are sought based on breach of warranty,

breach of contract, negligence, strict liability in tort, or any other legal theory, even if DriSteem has

notice of the possibility of such damages.

By purchasing DriSteem’s products, the purchaser agrees to the terms and conditions of this Limited

Warranty.

DRI-STEEM Corporation

a subsidiary of Research Products Corporation

DriSteem is an ISO 9001:2000 certifi ed company

U.S. Headquarters:

14949 Technology Drive

Eden Prairie, MN 55344

800-328-4447 or 952-949-2415

952-229-3200 (fax)

European offi ce:

Grote Hellekensstraat 54 b

B-3520 Zonhoven

Belgium

+3211823595 (voice)

E-mail: dristeem-europe@dristeem.com

Continuous product improvement is a policy of

DriSteem; therefore, product features and

specifi cations are subject to change without

notice.

DriSteem and Vapor-logic are registered

trademarks of Research Products Corporation

and are fi led for trademark registration in

Canada and the European community.

Product and corporate names used in this

document may be trademarks or registered

trademarks. They are used for explanation only

without intent to infringe.

© 2014 Research Products Corporation

Extended warranty

The original user may extend the term of the DriSteem Limited Warranty for a limited number of

months past the initial applicable warranty period and term provided in the fi rst paragraph of this

Limited Warranty. All the terms and conditions of the Limited Warranty during the initial applicable

warranty period and term shall apply during any extended term. An extended warranty term of

an additional twelve (12) months or twenty four (24) months of coverage may be purchased. The

extended warranty term may be purchased until eighteen (18) months after the product is shipped,

after which time no extended warranties are available.

Any extension of the Limited Warranty under this program must be in writing, signed by DriSteem,

and paid for in full by the purchaser.

mc_051308_0630

Form No. WTS-200-IOM-E-0115

Part No. 890000-870 Rev A

Loading...

Loading...