Drip Drop PC-2000-W User Manual

PC-2000-W

Pump controller

User manual

Version 30.56.12/101208-UK

DripDrop AB • Pipers Väg 2C • 170 73 Solna • www.dripdrop.se • Tel. +46 8 655 02 94

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 2 (71)

TABLE OF CONTENTS

1 DESCRIPTION ............................................................................................................................................................ 5

1.1 GENERAL ................................................................................................................................................................... 5

1.2 OPERATOR UNIT ......................................................................................................................................................... 5

1.2.1 Description of the display window ................................................................................................................... 6

2 HOTKEYS AND OVERVIEW SYSTEM SETTINGS ............................................................................................. 7

3 LOG IN – ACCESS CODE ▼ .................................................................................................................................... 9

4 INFORMATION MENUS P , E , A , L , X , ESC , OK , ▲ .................................................................................... 10

4.1 PUMP STATUS KEY P ................................................................................................................................................ 10

4.1.1 Pump information .......................................................................................................................................... 10

4.1.2 Running time and number of starts for pumps. .............................................................................................. 10

4.1.3 Disabling, manual start and stop of pumps.................................................................................................... 11

4.1.4 Display of time delay and service times ......................................................................................................... 11

4.2 SUMMARIZE KEY E ................................................................................................................................................... 12

4.2.1 Actual values .................................................................................................................................................. 12

4.3 ALARM HANDLING KEY A ........................................................................................................................................ 13

4.3.1 Acknowledging new alarms ........................................................................................................................... 14

4.3.2 Active alarms ................................................................................................................................................. 15

4.3.3 Alarm history ................................................................................................................................................. 16

4.4 LOGGER KEY L ........................................................................................................................................................ 17

4.5 EXTERNAL CONNECTED UNITS X ............................................................................................................................. 19

4.5.1 External units that communicate via RS-485 ................................................................................................. 19

4.6 QUICK MENU FOR THE STATUS OF I/O-SIGNALS ESC ................................................................................................ 20

4.7 QUICK MENU FOR THE STATUS OF I/O-SIGNALS OK ................................................................................................. 21

4.8 DISPLAY CONTRAST ▲ ........................................................................................................................................... 21

5 SYSTEM SETTINGS S ............................................................................................................................................. 22

5.1 MAIN MENU ............................................................................................................................................................. 22

5.1.1 How you change the values in the settings menus. ........................................................................................ 22

5.2 APPLICATION TYPE ................................................................................................................................................... 23

5.3 MENU – I/O CONFIGURATION ................................................................................................................................... 24

5.3.1 Digital inputs ................................................................................................................................................. 24

5.3.2 Digital outputs ............................................................................................................................................... 28

5.3.3 Counter inputs ................................................................................................................................................ 29

5.3.4 Analogue inputs (mA) .................................................................................................................................... 30

5.3.5 Analogue outputs ........................................................................................................................................... 32

5.4 PUMP SETTINGS ........................................................................................................................................................ 33

5.4.1 Setting of start and stop levels for pumps ...................................................................................................... 33

5.4.2 Alternation of pumps ...................................................................................................................................... 34

5.4.3 Back-up start .................................................................................................................................................. 34

5.4.4 Max. Running time ......................................................................................................................................... 34

5.4.5 Min. pause time .............................................................................................................................................. 34

5.4.6 Check starts .................................................................................................................................................... 35

5.4.7 Service time .................................................................................................................................................... 35

5.4.8 Random starts ................................................................................................................................................ 35

5.4.9 Running confirmation .................................................................................................................................... 36

5.4.10 Motor current settings ............................................................................................................................... 37

5.4.11 Pump capacity ........................................................................................................................................... 38

5.4.12 Reset motor protection .............................................................................................................................. 38

5.5 STATION SETTINGS ................................................................................................................................................... 39

5.5.1 Alternation ..................................................................................................................................................... 39

5.5.2 Time/delays .................................................................................................................................................... 40

5.5.3 Level alarms ................................................................................................................................................... 41

5.5.4 Cleaning sequences ........................................................................................................................................ 42

5.5.5 Mixer settings ................................................................................................................................................. 43

5.5.6 Flow calculation ............................................................................................................................................ 44

5.5.7 Overflow calculation ...................................................................................................................................... 45

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 3 (71)

5.5.8 Specific energy calculation type .................................................................................................................... 45

5.6 MISCELLANEOUS ...................................................................................................................................................... 46

5.6.1 Operator access code, .................................................................................................................................... 46

5.6.2 Level bar graph .............................................................................................................................................. 46

5.6.3 Logger ............................................................................................................................................................ 47

5.6.4 RS232 settings ................................................................................................................................................ 47

5.6.4.1 Communication settings .............................................................................................................................................. 47

5.6.4.2 Connection settings ..................................................................................................................................................... 47

5.6.5 Setting of RS485-port ..................................................................................................................................... 50

5.6.6 Clock settings ................................................................................................................................................. 51

5.6.7 Reset/Erase .................................................................................................................................................... 51

5.6.8 Factory settings .............................................................................................................................................. 51

6 SMS FUNCTIONS – USING MOBILE PHONE .................................................................................................... 52

6.1 ALARM BY SMS MESSAGES ..................................................................................................................................... 52

6.2 REMOTE CONFIRMATION OF THE ALARMS ................................................................................................................ 52

6.3 SENDING INQUIRIES TO THE STATION BY MOBILE PHONE. ......................................................................................... 53

7 I/O-LIST, SIGNAL TABLE ...................................................................................................................................... 54

8 TECNICAL INFORMATION .................................................................................................................................. 55

8.1 SPECIFICATION PC-2000-W ..................................................................................................................................... 55

8.2 ELECTROMAGNETIC COMPATIBILITY (EMC) ............................................................................................................ 55

9 CONFIGURATION TABLE .................................................................................................................................... 56

10 MENU STRUCTURE – SYSTEM SETTINGS ....................................................................................................... 61

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 4 (71)

Copyright © 2005 DripDrop AB. All rights reserved.

This manual and all the information within may not be copied or reproduced in any form

without the permission of DripDrop AB.

Changes

The content of this manual is for informational use only and can be subject to changes

without prior notice.

DripDrop AB products are developed continuously and we reserve the right to alter technical

specifications without prior notice.

Liability

DripDrop AB assumes no responsibility or liability for errors or incorrect information that may

appear in this document.

DripDrop AB assumes no responsibility or liability for loss of profit, working deficits or any

other indirect losses due to erroneous use or application of the information exposed in this

manual.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 5 (71)

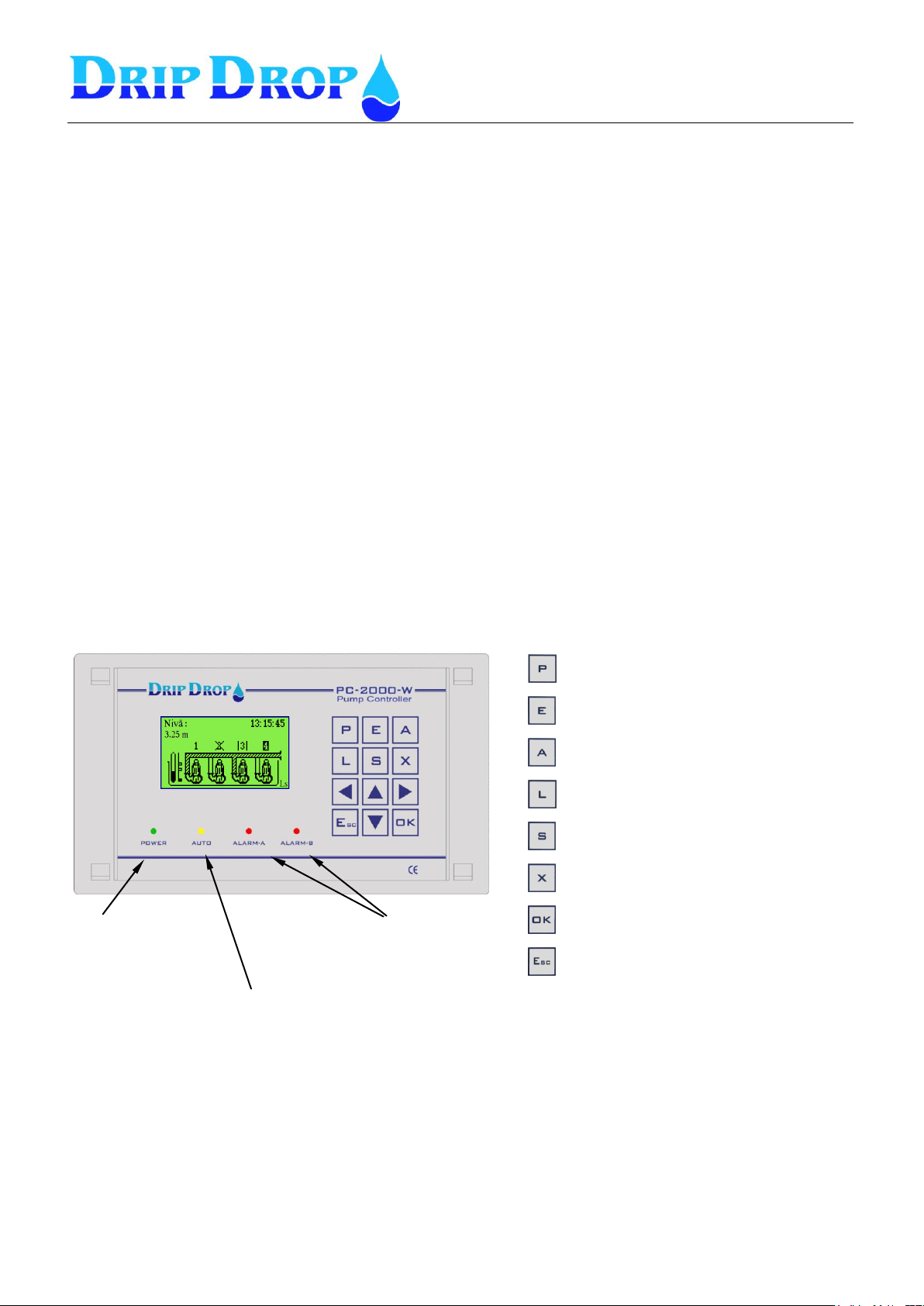

Indacation Pump in Auto

-Blinking yellow light: Pump or pumps not in Auto.

-Fixed yellow light: All pumps in Auto

Indication of A-alarm and B-alarm

-Blinking red light : Not ackn. alarms

-Fixed red light: Active ackn. alarms

Power supply indication

-Fixed green light

Shows pump status, actual and

accumulated data for the last 7 days.

Shows flows and overflows, actual and

accumulated values for up to 7 days.

Shows unconfirmed, active alarms and

alarm history.

Shows logged values, numeric and graphic

Menu where all basic settings are made for

example start- /stop levels, alternation etc.

Shows external units that can communicate

via RS-485.

Push button used to confirm choice and to

enter sub menus.

Close menus and step backwards.

1 Description

1.1 General

The pump controller PC-2000-W is an advanced computer controlled device to control and supervise

up to 4 pumps. Containing an operator unit (CPU unit PC-2000-W) and an I/O unit

(ADA 2000-E) for connecting digital and analogue signals.

The signals transfer between the units via three flat cables.

The unit has two communication ports RS 232 / 485 for communication with a supervision and

SCADA system or for serial communication with other units.

1.2 Operator unit

The operator unit is mounted in the front door of a cabinet and has 12 control keys for

configuration and alarm handling. The graphic 64 x 128 dot display shows information,

log values and historical log as curves.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 6 (71)

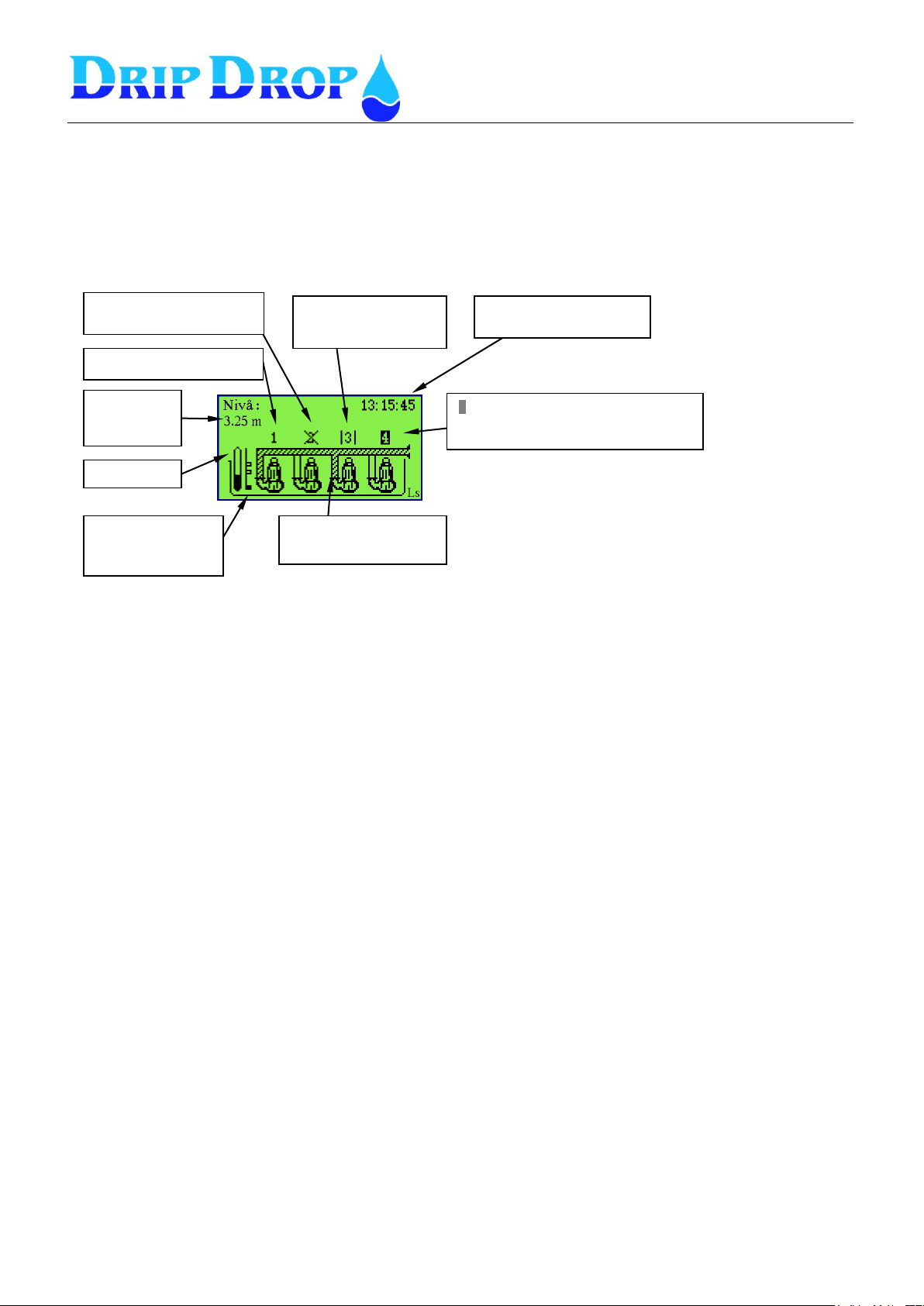

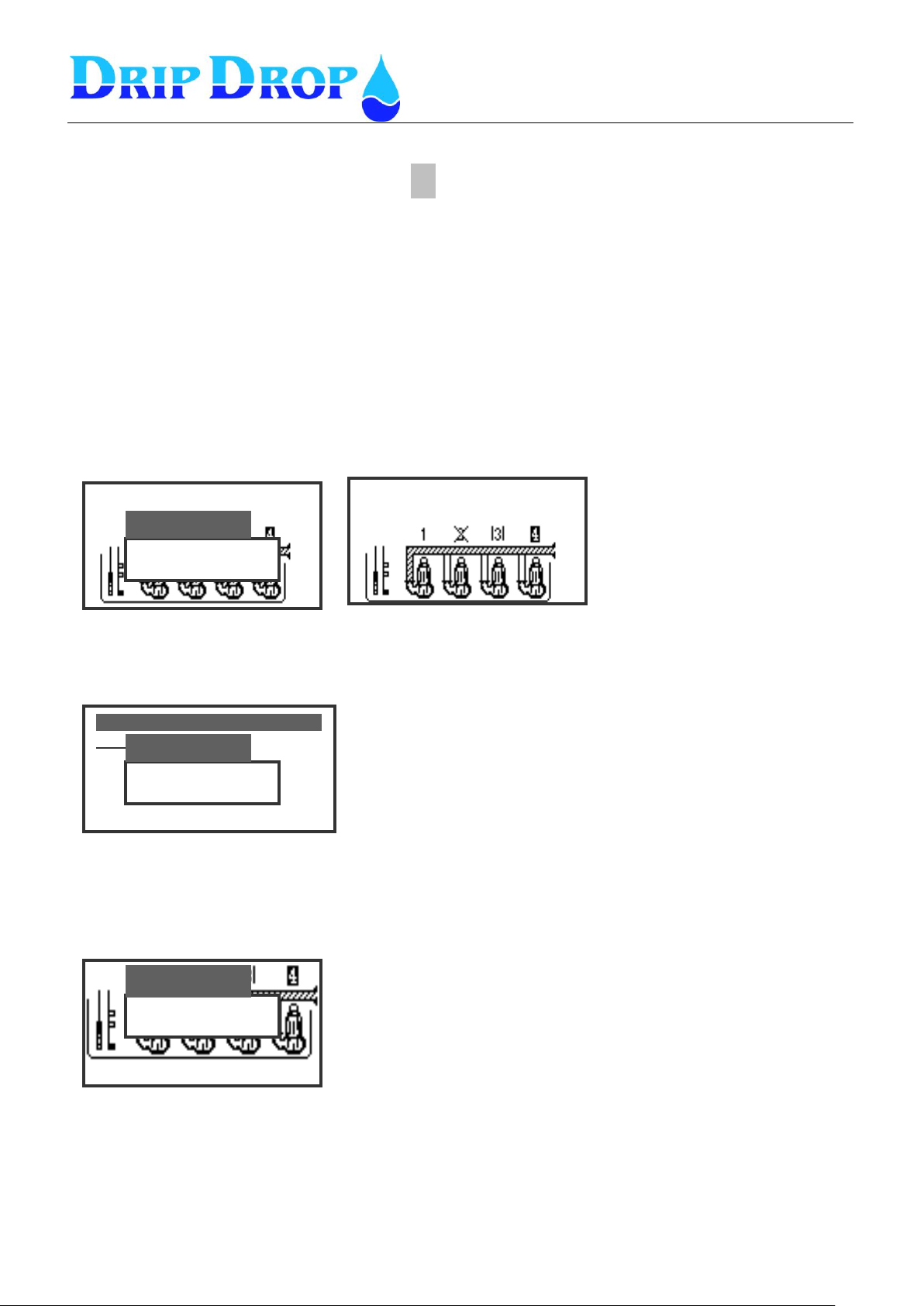

Actual level if

sensor is

connected

Level bar

Indicates level floats

and if they are

On /Off.

Movement in pipe shows

that pump is running.

1 – Indicates that pump is OK

X – Indicates that a timer is

counting.

|3| - Indicates that

pump is in Not auto

pos.

Tme and Date toggles

every 15 sec.

4 – Indcates that pump is blocked. For ex

by motor protec tor, low motor current etc.

1.2.1 Description of the display window

The back lit display shows the number of pumps in the pit and their status, water level- graphic and

numerical, in- and outflow, date/time, level switch and their status. Normally the display light is off,

but will light up when any key is pressed. The display light will shut off after 5 minutes of inactivity

Running Pump – When a pump is running, it is indicated by water running in the pipe.

Waiting mode – if a time delay or another time function is activated, it is shown by an X over the

pump number. This is to show that the pump waits for a time function before the pump is ready to

restart.

Not in Auto – indicates that pump selector switch is not in Auto position. This is shown by two

vertical lines |3|, and that the yellow Auto LED starts to blink.

Blocked Pump – certain circumstances blocks the restart of the pumps, for example certain alarms or

causes where you choose that the pump will be blocked when an error occurs. A Blocked

pump is indicated by a grayed out pump number. The blocking can be lifted by fixing the

fault and acknowledge the alarm.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 7 (71)

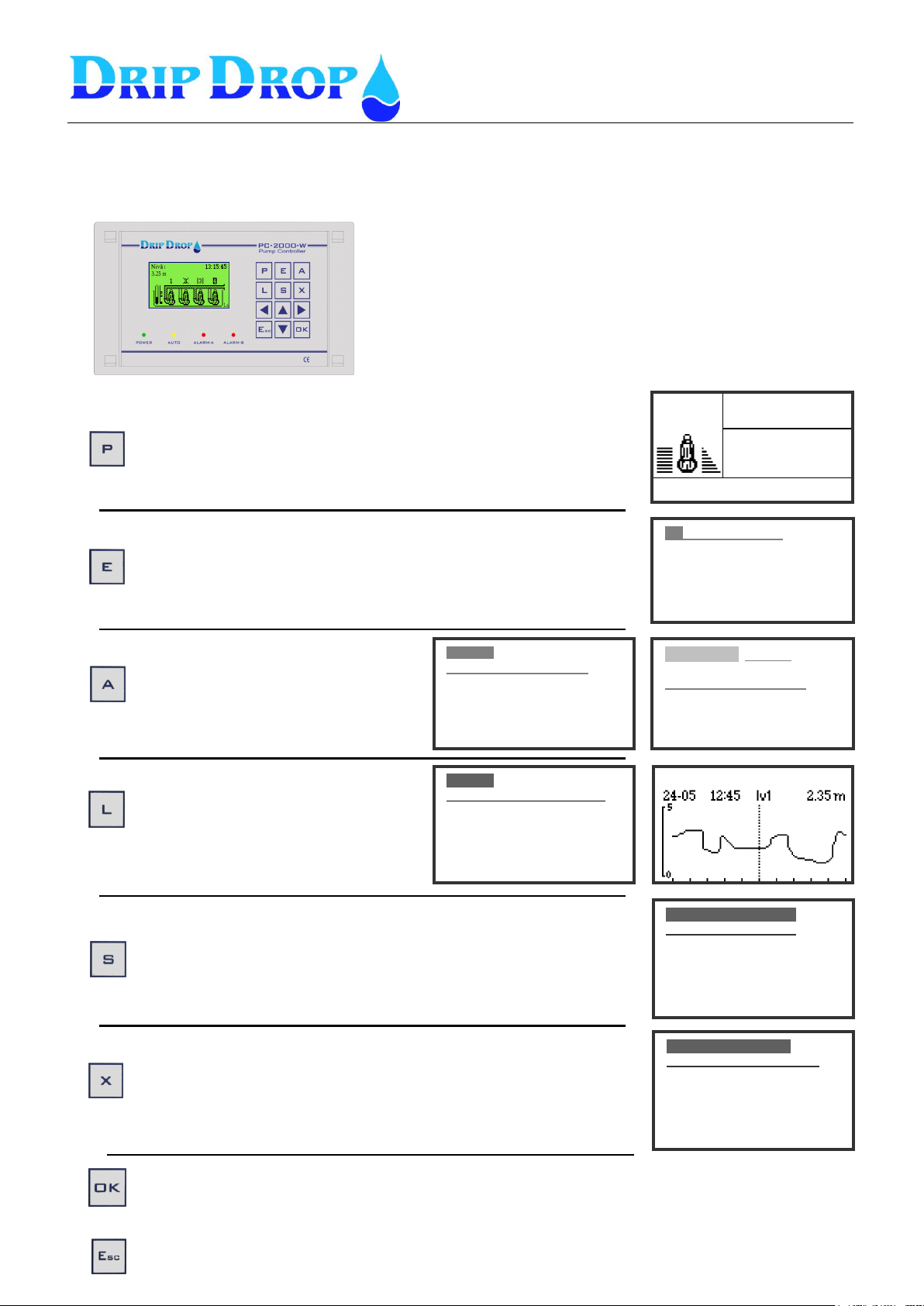

Shows pump status, actual total values as well as data up to 7 day

back. More info in chapter 4.1.

Shows flows, overflows, power and energy if the corresponding

meters are used. Actual and ackumulated values for up to 7 days

are shown . More info in chapter 4.2.

Shows unconfirmed, active alarms and

alarm history. When you enter the

alarm menu you can choose to see not

acknowledge alarms, active alarms and

a alarm history list with up to 200

alarms. More info in chapter 4.3.

Shows logged values up to 7 days.

There is one display for numeric values,

all values can also be displayed as

curves in the display window.

More info in chapter 4.4.

Menu where all basic settings are made for pumps, station and

communication, for example start- /stop levels, alternation a.s.o.

More info in chapter 5.

Shows status and information from external units that are

connected via the RS-485 port. Up to 6 units can be connected to

one PC 2000 W More info in chapter 4.5.

Push button used to confirm choice and to enter sub menues.

Close menus and step backwards in the menustructure

Cap.[m3/h] 0.0

Current[A] 25

Level[m] 1.45

Off

Time 2:16:03

Starts: 58

Pump 1

Total

η ______________Now

Flow-c: 0.0 m3/h

Power: 0.0 kW

Efficiency: 0.0Wh/m3

Not ack. alarm 001/001A

Level alarm

LOW lEVEL .

Time on:09/o1/21 18:57:05

Time off:06/11/21 18:59:08

Alarms

.

▪ Not ack. alarms

▪ Active alarms

▪ Alarm history

Settings( ) V30.56.XX

______________________

▪Application type

▪I/O Configuration

▪Pump settings

▪Station settings

▪Miscellaneous

EXT 1-PC 2000 screens

Link: ____________________

Alarms:0

Level[m]:

AI2[]:

Current P1

Logger yy-mm-dd

19:30

Level: 1.45 m

Inflow: 0.00 m³/h

Outflow: 0.00 m³/h

Overflow: 0.00 m³

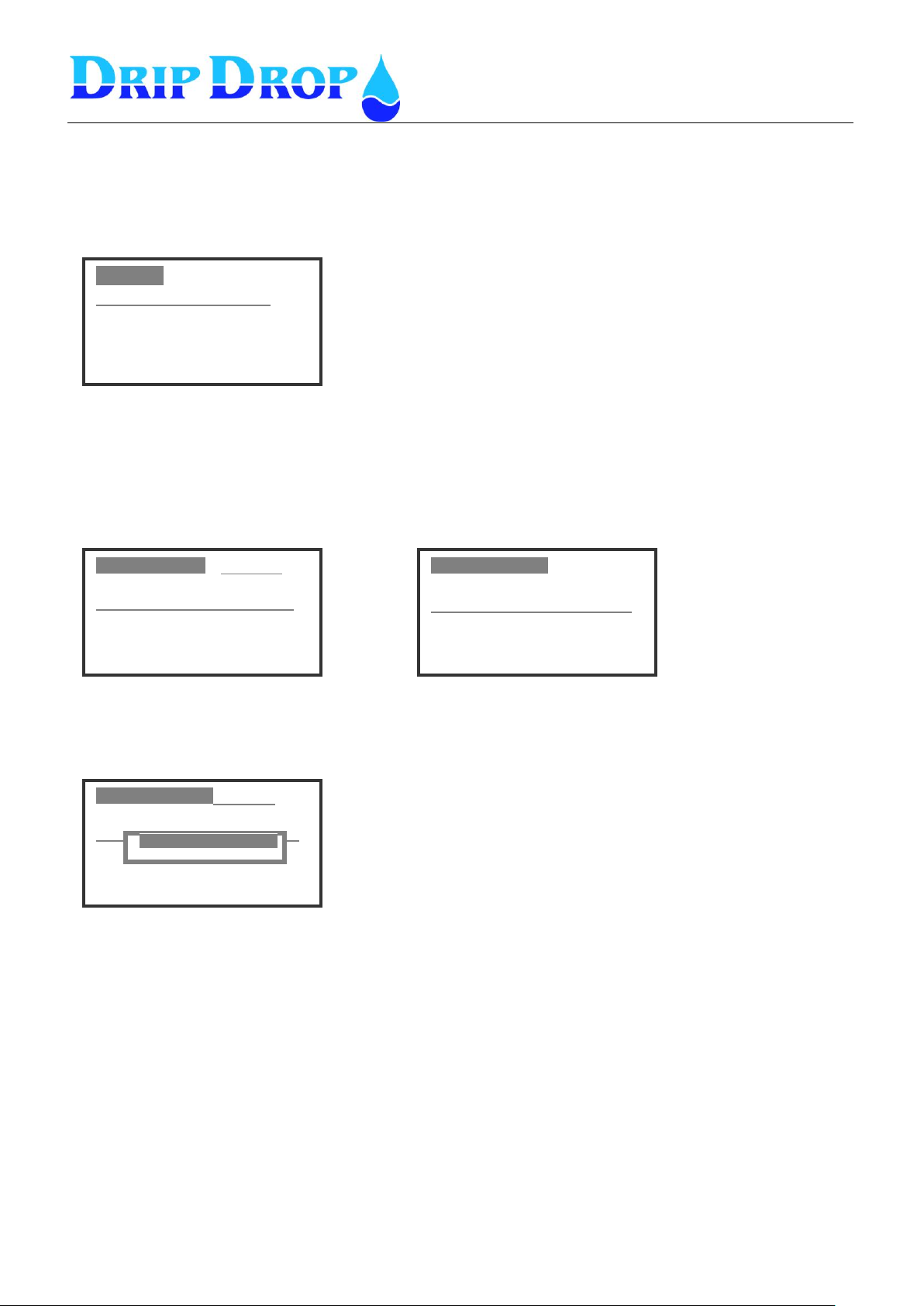

The pumpcontroller PC 2000 W uses an extensive menu to display

and handle information as well as configuration of the unit directly

from the display panel. In order to get to better understand all menu

functions, here follows a brief overwiev of the structure of the

different menues for status, information and configuration.

Through the P,E,A,L and X keys you will access status and

information regarding pumps and the pumping station. The S key is

to enter into the menu structure where all configurations are made.

2 Hotkeys and Overview system settings

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 8 (71)

Settings( ) V30.56.XX

______________________

▪Application type

▪I/O Configuration

▪Pump settings

▪Station settings

▪Miscellaneous

Settings( ) V30.56.XX

I/O Configuration_____

▪Digital inputs

▪Digital outputs

▪Counters

▪Analogue inputs

▪Analogue outputs

Settings (Ls)v30.56.xx

Station settings______

▪Alternation

▪Time/Delays

▪Level alarms

▪Cleaning sequencies

▪Mixer 1 settings

▪Mixer 2 settings

▪Inflow calculation

▪Overflow calculation

-Spec. Cons.: Flow-c

Settings (Ls)v30.56.xx

Miscellaneous_______

-Op. access code:▼ ▼ ▼ ▼

-Sys. Acces code: ▲ ▲ ▲ ▲

▪Level bargraph

▪Logger settings

▪RS232 settings

▪RS485 settings

▪Clock settings

▪Reset /Erase.

▪Default settings

Settings (Ls)v30.56.xx

Pump settings_____________

▪Pump 1

▪Pump 2

▪Pump 3

▪Pump 4

Settings( ) V30.56.XX

Application ___

- Number of pumps: 2

- Max. Running pumps: 1

- Start float: No

Settings (Ls)v30.56.xx

Pump 1_____________________

▪Day time levels

▪Night time levels

-Alternation : Yes

-Back-up start: No

-Max. runtime [min]: 240

-Min breaktime [s]: 10

-Check after[h]: 0

-Check for[s]: 0

▪Servcice time

-Random Starts[cm]:

▪Running confirmation:

▪Pump capacity

▪Reset Protection

►

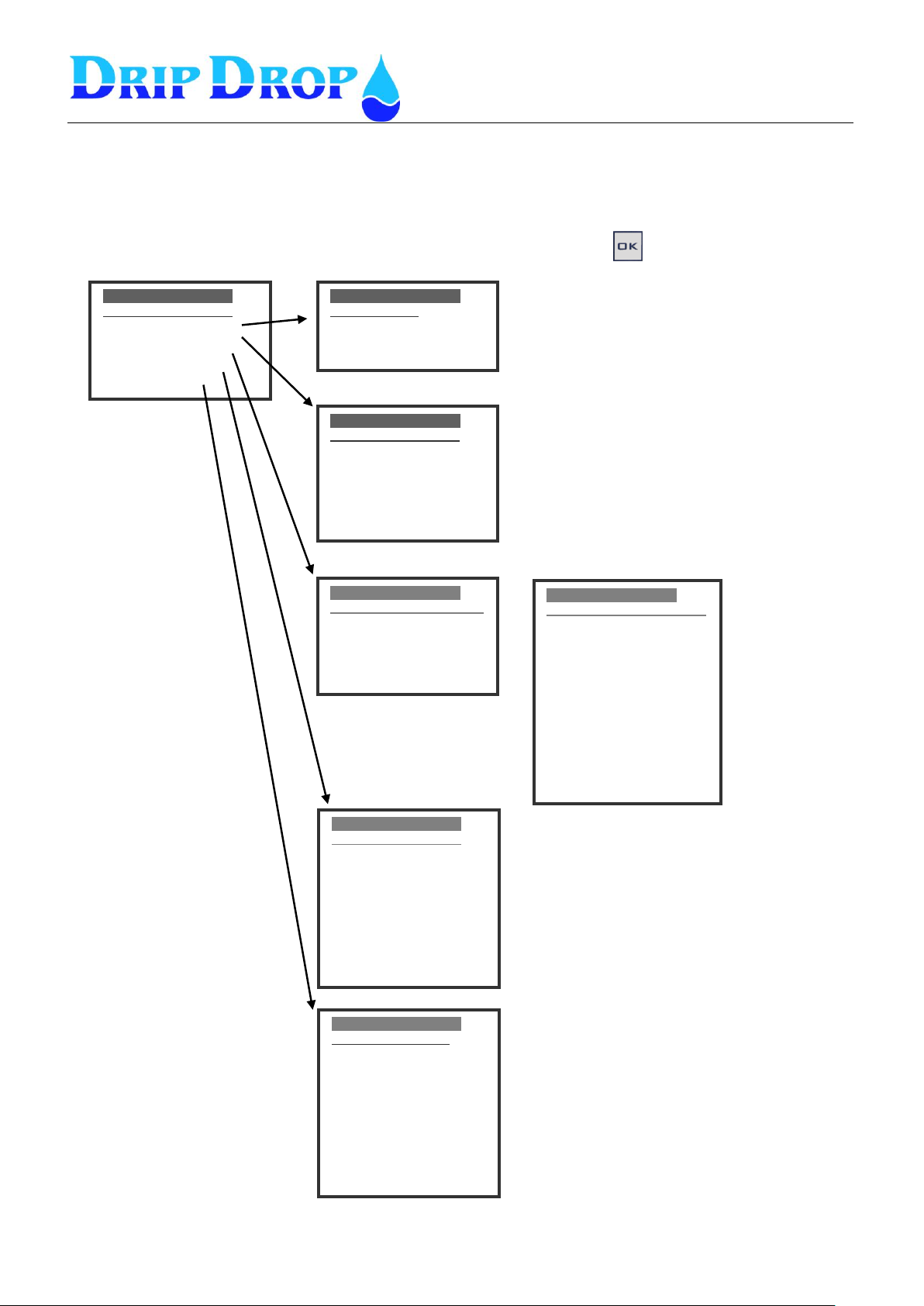

Application menu – to set how many pumps

you have in the station, how many pumps are

allowed to run simultaneously and if you use

level sensor or level switches to detect

operating levels.See chapter 5.2

I/O configuration menu – is where you

define how to use all predefined inputs and

outputs, digital and analogue.

See chapter 5.3

Pump settings menu-

This is where you set all

parameters regarding

each individual pump,

start/stop levels,

alternation, current

settings etc.

See chapter 5.4

Station setting menu- This is the menu for

setting of station specific parameters.

Alternation type, timers and delays, alarm

levels, mixing and cleaning functions,

flowcalculation functions etc.

See chapter 5.5

Miscellaneous menu – In this menu you can

make settings for access codes, logger

settings, all communication settings, reset/

erase alarmlists/counters and reset the unit to

original factory settings.

See chapter 5.6

Settings menu - overview

The Settings menu is where all the configuration of the unit is made. By pressing the S key, you

will enter the Settings main menu that consists of five submenus handling different areas in the

configuration process. You enter each submenu by moving up and down in the menu options with

the ▼▲ key, and enter the corresponding submenu by pressing the key.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 9 (71)

Level: yy-mm-dd

1.45 m

|

Log in

Settings( ) 20.54.42

.

-Función: |en uso

-Tipo señal: NC

-Tipo Alarma: alarma-A

-Delay[s]:

|

Log in

Nivel: yy-mm-dd

1.45 m

Are you sure?

Log out

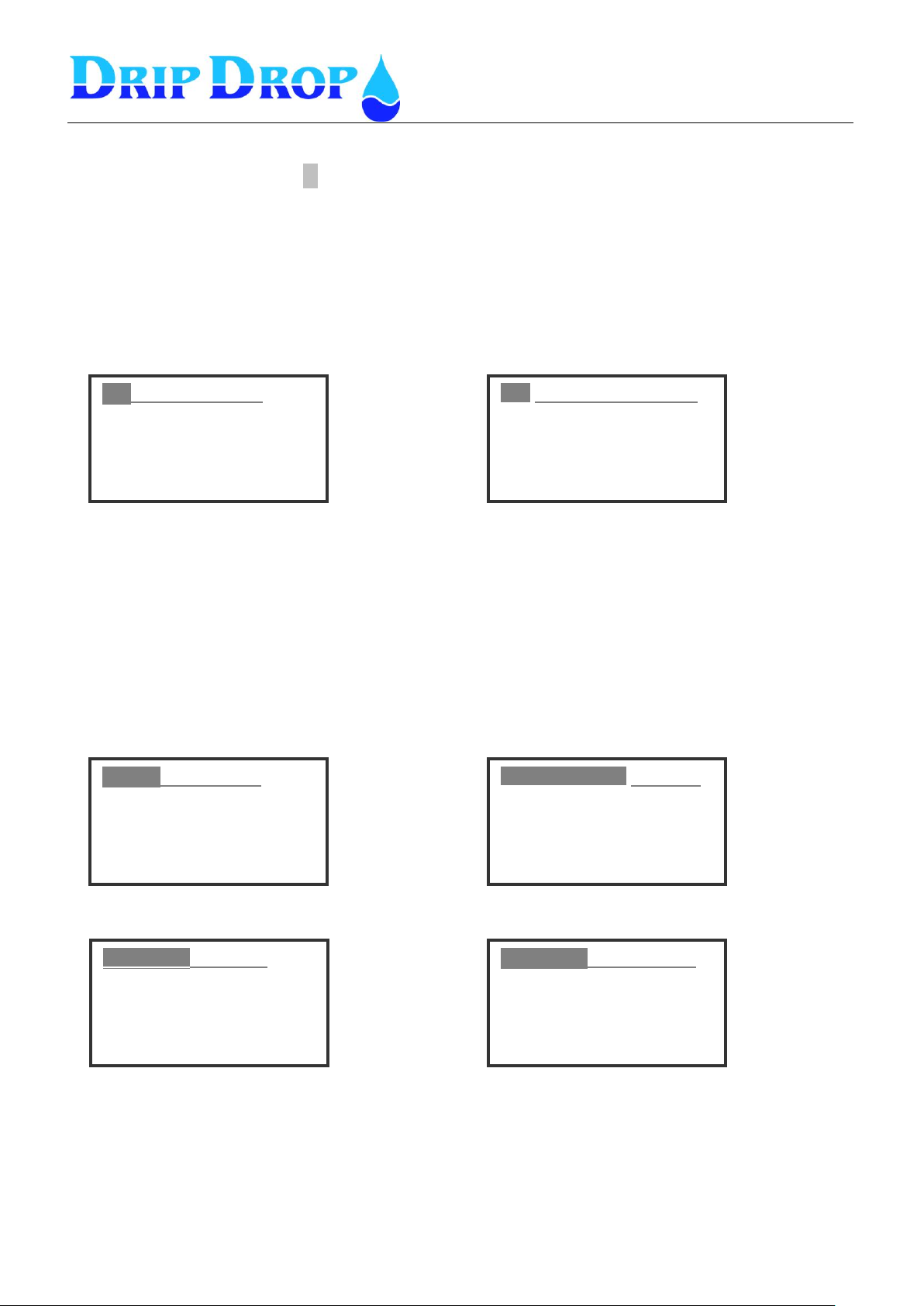

When you are logged in the

following will show up in the

lower right corner of the

display :

Ls (system)

Lo ( operator).

Level: yy-mm-dd

1.45 m

Ls

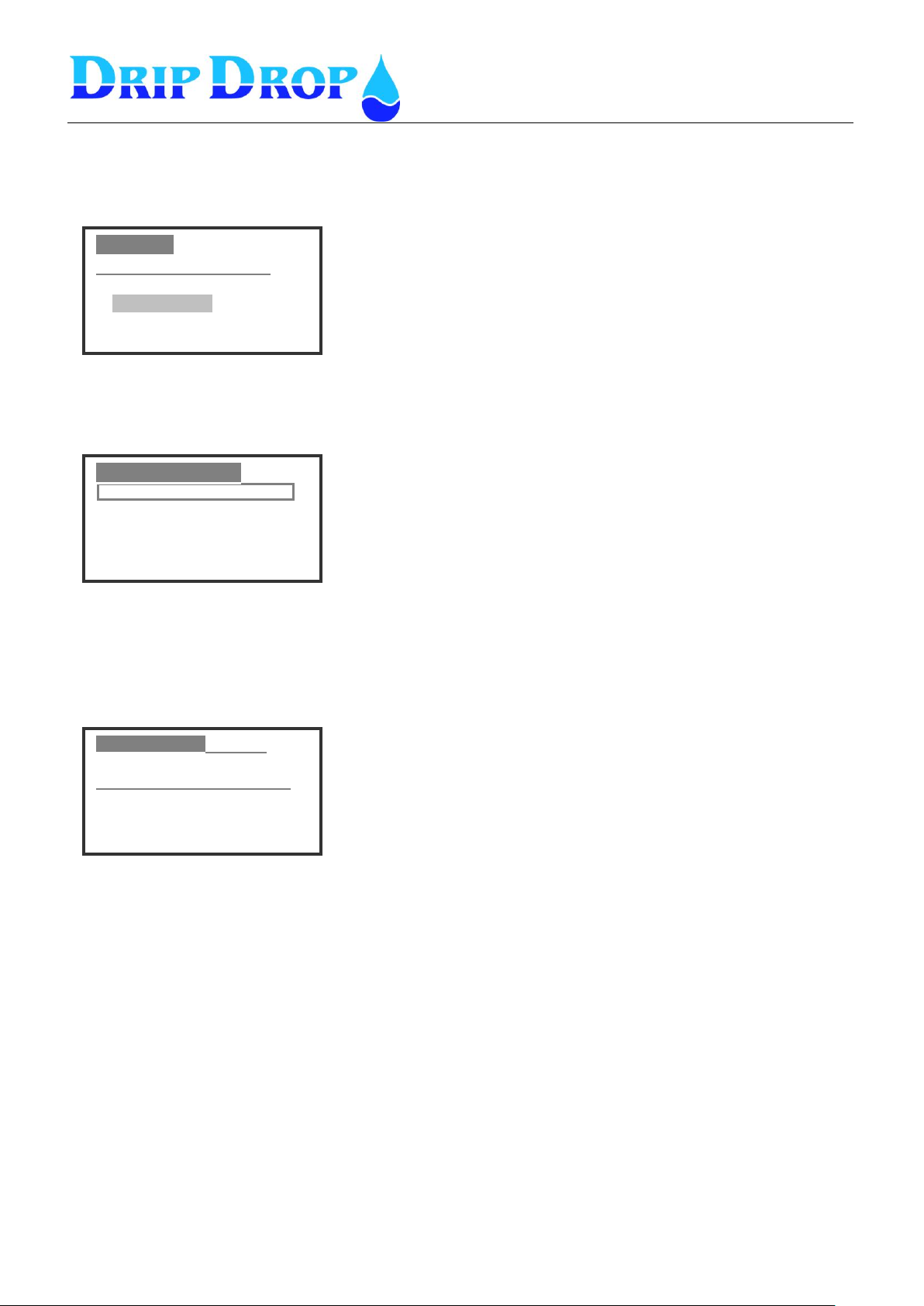

3 Log in – Access code ▼

In the information menu, you will find all information about pumps, logged values and alarms. To

make changes or to acknowledge alarms you need an access code depending on what you like to do.

The unit has two different access levels:

1. Operator code- that allows acknowledgement of alarms.

2. System code –which allows changing of all values and configuration of the unit.

The access codes can be changed under Settings/Miscellaneous

There are two ways to enter the access code:

1. From the main display picture by pressing the ▼ key you will enter the access code prompt. Here

you can enter the valid code and confirm by pressing the OK key.

2. When you are in a sub menu and try to enter the edit position by pressing OK, you will come to the

access code prompt. When the prompt shows, you have to enter the valid access code. You can then

enter the edit position where you can change the values.

The unit will log out automatically 5 minutes after inactivity.

As an alternative, you can press the ▼key and the log out prompt will show. Press OK .

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 10 (71)

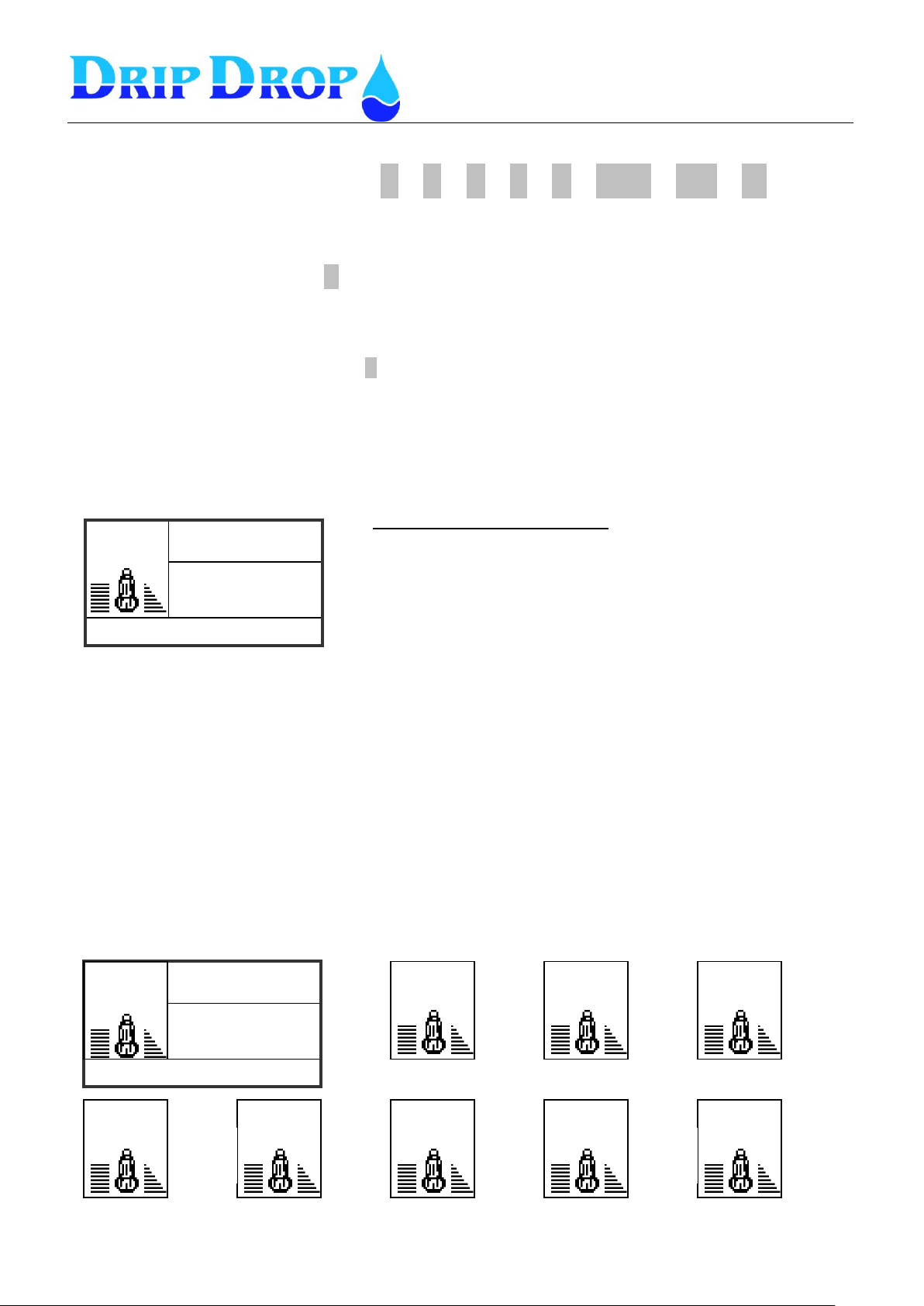

Cap.[m3/h] 0.0

Current[A] 25

Level[m] 1.45

Off (A)

Time 2:16:03

Starts: 58

Pump 1

Total

Off

Cap.[m3/h] 0.0

Current[A] 25

Level[m] 1.45

Time: 2:16:03

Starts: 58

Information window for Pump 1

Specific information for each pump.

Actual values that are shown in all pump status windows.

Information about if a pump is running or not, if a pump is

in automatic mode and if the pump has stopped becaue

of an alarm.

Pump 1

Total

Pump 1

Today

Press

►

Press

►

Pump 1

-1 Day

Press

►

Pump 1

-2 Day

Press

►

Pump 1

-3 Day

Pump 1

-4 Day

Pump 1

-5 Day

Pump 1

-6 Day

Pump 1

-7 Day

Press

►

Press

►

Press

►

Press

►

Picture 1

4 Information menus P , E , A , L , X , ESC , OK , ▲

To access information about pump status, alarms and station values quickly, you use the information

hot keys on the front panel.

4.1 Pump status key P

4.1.1 Pump information

The P key is used to get information about each pump quickly. You can access three pump

information windows by pressing the P key

The first window shows total values for running time and number of starts for the pump. This

information is given only in this window.

All other information is shown in the two following windows.

You scroll thru pump 1-4

with the ▲▼ keys.

To the right and left, between day1-7,

and total values for each pump with◄►

When you are in the information window, you scroll thru the information for pump 1-4 with the

▲▼keys.. This stepping between the pumps can be made in all information windows. You will

always get into the corresponding window for next pump.

4.1.2 Running time and number of starts for pumps.

To see running time and number of starts for pumps you press the P key. To see the values for the

other pumps press the ▲▼ keys. By pressing the ► key, you will see actual running time and number

of starts. Pressing the ► key scrolls thru the last seven days. After 7 days, you will get back to total

values.

Corresponding information for pumps 1-4 is shown by pressing the ▲▼keys.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 11 (71)

Off

Cap.[m3/h] 0.0

Currentr[A] 25

Level[m] 1.45

** Pump disable

-----------

Pump 1

Total

Picture 2 under P key

When you enter this picture the cursor will be in the

position ”Pump disable”. If you want to disable the pump press the

OK key.

Off

Cap.[m3/h] 0.0

Current[A] 25

Level[m] 1.45

** Pump disable ?

------------

Pump 1

Total

Now a question mark will appear after the disable prompt. Press OK

to confirm.

Disabled

Cap.[m3/h] 0.0

Current[A] 25

Level[m] 1.45

** Pump enable

------------

Pump 1

Total

When you have confirmed the text ”Pump enable ” will appear.

If you want to enable the pump press OK as above.

You can see that the pump is disabled in the status window at the

bottom of the display.

Off (A)

Pump 1

Total

Cap.[m3/h] 0.0

Current[A] 25

Level[m] 1.45

Delay.[s]: 10

Service[h]:06000:00

Picture 3 under P key

In this window you will see if a timer is counting down.

This example shows that it is 10 seconds left until the count down is

ended.

You can also see that there are 6000 hours left to the next

maintenance check for the pump.

Picture 2

4.1.3 Disabling, manual start and stop of pumps.

When a pump is removed for service, you can disable the pump in the controller.

When you disable a pump, the pump will disappear from the main picture.

To reach the disabling position you press the P key twice.

Picture

4.1.4 Display of time delay and service times

In picture 3 under the P key you will see if the unit is counting down on a time delay, for ex. start or

stop delay or similar. This is shown by the remaining time that is counting down in the window under

Delay. If the counter shows zero, it is not counting. If a time is counting down this may be the reason

that a pump does not start until the time is finished. If the function for service time is activated you

will see how long time is left until the next scheduled maintenance of the pump.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 12 (71)

η ______________Now

Flow-c: 0.0 m3/h

Power: 0.0 kW

Efficiency: 0.0Wh/m3

Overflow_______Now

Time: 0:00:00

Number:

Flow:

Level:

Status:

η _ ____________Total

Volume-c: 0.0 m3

Power: 0.0 kWh

Efficiency: 0.0 Wh/m3

Overflow Total

Time:

Number

Flow:

Level:

Status:

Flow Now

Inflow 0.0 m3

Outflow: 0.0 m3

Flow-AI2 0.0 m3

Rain flow: 0.0 l/s*ha

Power: 0.0 kW

Ackumulated _ Total

Inflow: 0.0 m3

Outflow: 0.0 m3

Flow-AI2 0.0 m3

Rain flow: 0.0 l/s*ha

Power: 0.0 kW

Press

►

Press

►

Press

►

4.2 Summarize key E

4.2.1 Actual values

The E-key is used to see the actual values, total values and the values for the last 7 days for efficiency,

flow and overflow.

When you press the E-key once if energy meter is used you will come to efficiency. If not you will go

directly to the flow display. When you press the E-key a second time you will come to flow and when

you press the E-key a third time you will come to overflow.

When you are in the Efficiency display, the actual values are shown first. When you press the key ►,

you will come to the total values. When you press the ► key once more, you will come to the values

for today. In the same way, you continue for the values for 7 days back. This is valid for flow as well

as overflow.

If you want to go back to previous values press ◄ key.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 13 (71)

Not ack. alarm 001/001A

Level alarm

LOW lEVEL .

Time on:09/o1/21 18:57:05

Time off:06/11/21 18:59:08

Example of alarm in the text window.

Not ack. alarm 001 of 001 alarms in the alarm list A-larm.

That it is a level alarm (has to do with the level measurement)

The alarm is a low level alarm

Time when the alarm got active started.

Time when alarm got inactive.

ALarms

.

▪ Not ack. alarms

▪ Active alarms

▪ Alarm history

Alarm handling menu – here you can see the different alarms

Not ack. alarms (new) .

Active alarms

Allarm history

With the up and down keys you can chose which type of alarms you

want to see and enter the alarm list with the OK key.

4.3 Alarm handling key A

The pump controller PC-2000-W has the capacity to handle a great number of different alarms for

pumps, station and even internal alarms. Every alarm generates an information window when

activated, with information about which alarm is activated, activation time and if it is an A or B-alarm.

At the same time, one or two alarm LEDs is blinking until the alarm is confirmed.

5 minutes after the alarm text is shown on the screen the screen light go off and the alarm text

disappears.

The alarms are then indicated via the two alarm LEDs.

Blinking red light indicates a new alarm, which is not confirmed.

Fixed red light indicates that the alarm is confirmed but still active.

There are two types of alarms. A-alarms and B-alarms.

A-alarm is an alarm that calls a supervision system or sends a text message to a mobile phone.

B-alarm is an alarm that only is registered in the alarm history but is not sent to an external system.

This text is shown in the display window when the alarm starts, but will disappear after 5 minutes

when the screen light is shut down. When the screen is shut down, you will see that there is an alarm

in the alarm list by the two alarm LEDs. To access the alarm you press the A key to enter into the

alarm handling menu:

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 14 (71)

Not ack.alarm 001/003A

Level alarm

NIVEL BAJO .

Time on:06/11/21 18:57:05

Time off: 06/11/21 18:59:08

Log in

Alarm

.

▪ Not ack. alarms

▪ Active alarms

▪ Alarm history

Not ack. alarm 0001/003A

Level alarm

LOW FlOAT ON .

Time on: 09/03/24 18:57:05

Time off:09/03/24 18:59:08

The log in promt will not show up if you are already logged in to the

system. .

Not ack. alarm.

No alarms .

Time on:

Time off:

4.3.1 Acknowledging new alarms

New alarms are indicated by the blinking of one of the red alarm LEDs. To acknowledge the alarms

you have to enter Not ack. alarms option in the alarm menu.

When you are in the alarm list for Not ack. alarm, you can acknowledge the alarm by pressing the OK

key. If there are more Not acknowledged alarms in the list, you can step through the list with the up

and down keys.

When all alarms are acknowledged, the red LED stops blinking and the display will show that there

are no alarms in the list. If the alarm is still active the LED show a red fixed light.

If you have not logged in the Log In prompt will show when you press the OK key to acknowledge the

alarm.

When you have acknowledged all alarms that you want to acknowledge you quit the alarm handling

function by pressing the Esc key until you have returned to the main menu.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 15 (71)

Alarms

.

▪ Not ack. alarms

▪ Active alarms

▪ Alarm history

Active alarms

▪*Pump failure

▪*Sensor failure

▪ System alarms

▪*All alarms

In this menu you can look at all alarms or alarm groups.

Groups with active alarms are indicated with an asterics.

You enter the different alarm groups with the OK key.

Active alarm 001/003A

Level alarm

LOW LEVEL .

Alarm on:09/03/24 18:57:05

Alarm Ack:09/03/24 18:59:08

Example of active alarms in the alarm list

Shows which alarm is shown, in this case 1 of 3.

Alarm type, A-alarm.

Alarm group – Level alarm

Alarm – Low level alarm

Time when the alarm started.

Time when the alarm was acknowledged.

4.3.2 Active alarms

If you want to see active alarms, you choose active alarms in the alarm handling menu.

When you enter active alarms you come into a submenu where you can chose to look at all alarms or

just pump alarms, sensor alarms or system alarms.

When you are in the alarm list for active alarms, you can see information about number of alarms in

the list, alarm type and time when the alarm started and when it was acknowledged. The alarm shown

when you enter the list is the latest alarm.

To step forward backwards in the alarm list use the up and down keys.

When you are ready with the alarm handling you exit with the Esc key.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 16 (71)

Alarms

.

▪ Not ack. alarms

▪ Active alarms

▪ Alarm history

Alarm

▪*Pump failures

▪ Sensor failures

▪ System alarms

▪ All alarms

History alarms 001/003A

Level alarm

LOW level .

Alarm on:09/03/24 18:57:05

Time ack.;09/03/24 18:59:08

Alarm off:09/03/24 20:12:33

In this menu you can look at all alarms or look at alarms in different

alarm groups.

Groups with stored alarms are indicated with a star.

You enter the alarm groups with the OK key.

Example of alarm in the alarm history list

Shows which alarm is shown, in this case 1 of 3.

Alarm type, A-alarm.

Alarm group – Level alarm

Alarm – Low level alarm

Time when alarm started .

Time when alarm was acknowledged.

Time when alarm stopped

4.3.3 Alarm history

In the alarm history, all alarms for up to 200 alarms are listed. When the list is full, the oldest will

disappear.

To enter the alarm history you chose alarm history in the alarm-handling menu.

Even in the submenu, you can chose between all alarms or chose alarms in groups the same way as in

the active alarms menu.

In the alarm history list, you will find all registered alarms. The latest alarm is the first in the text

window and the oldest is at the bottom, maximum 200 alarms can be stored in the history list.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 17 (71)

Logger yy-mm-dd

19:30

Level: 1.45 m

Inflow: 0.00 m³/h

Outflow: 0.00 m³/h

Overflow: 0.00 m³

Logger yy-mm-dd

19:30

Flow-AI2: 0.00 l/s

Rain flow: 0.0 l/s*ha

Power: 0.0 kW

Logger yy-mm-dd

19:30

I1: 25.00 A

I2: 25.00 A

I3: 0.0 A

I4: 0.0 A

Logger yy-mm-dd

19:30

Pump1:Disabled (A)

Pump2:Off (M)

Pump 3:Disabled (A)

Pump 4:Disabled (A)

Picture 3.3 The four logger windows.

4.4 Logger key L

Logged values are stored in the PC-2000-W in 1 to 10 minutes intervals and displayed as average

values for 7 days. All logged information is found by pressing the logger key L. There are four

different windows available by pressing the L key.

Main window for logger

Below you can see the four logger windows.

Each time you press the L key you step to the next window.

Time selection for logger values.

In all logger windows, the time is shown in the upper right corner of the logger windows and shows

the time for the values. If you press the ◄ key once you will see, the logged values according to the

time interval 1-10 minutes for each time you press the◄ key you move one time interval backward in

time. If you keep the ◄ key pressed for a couple of seconds you will get intervals of 15 minutes.

If you press the key for more than 10 seconds, the time interval will be 1 hour.

For movement forward you use the ► key the same way.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 18 (71)

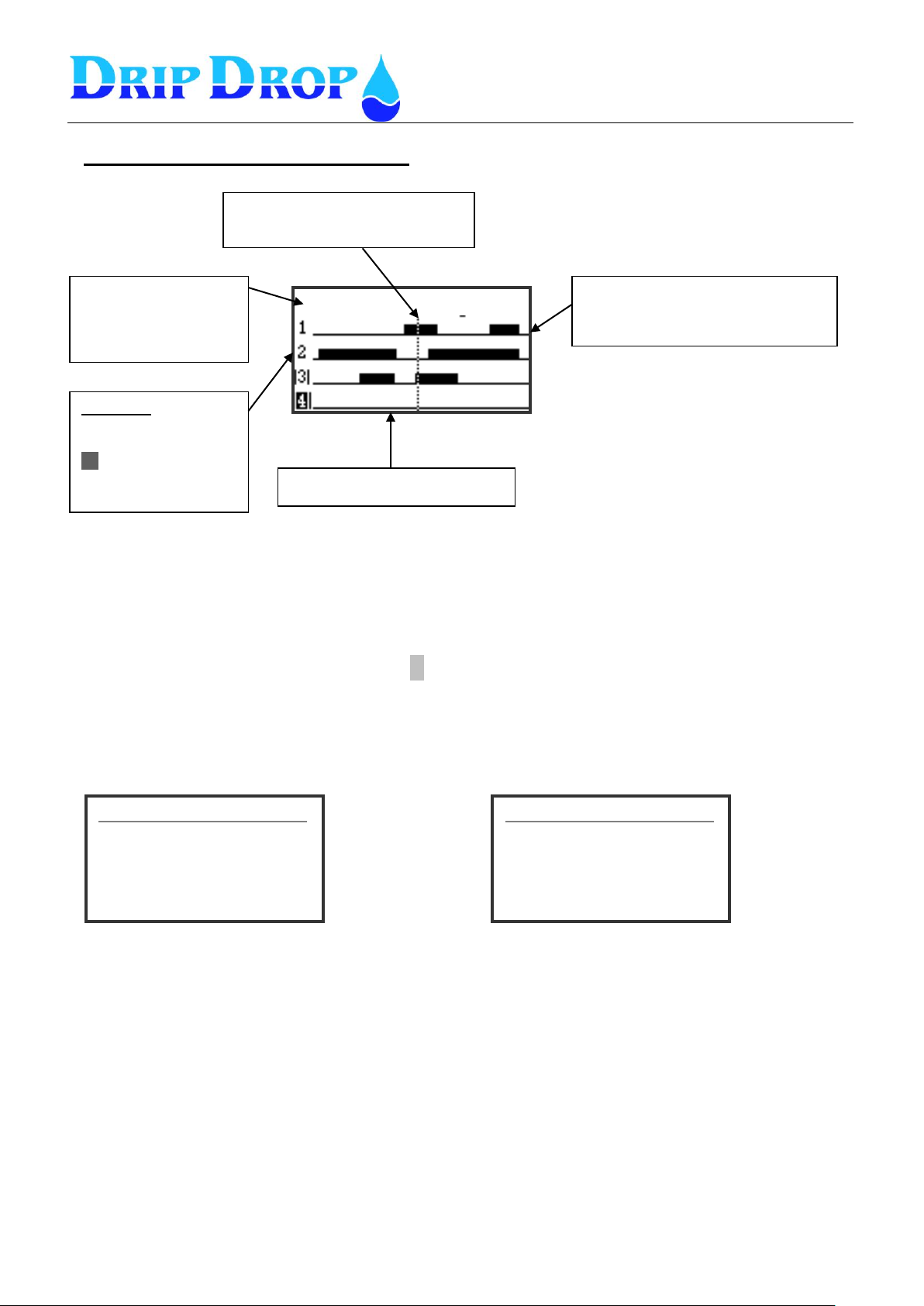

Time reference line equals the

time shown in the window.

Registered value at shown time.

Automatic scaling,

based on registered

min. and max. values.

Time scale, shows 10 hours

Average curve is shown.

Parameter shown in the window.

Logger yy-mm-dd

19:30

Level: 1.45 m

Inflow: 0.00 m³/h

Outflow: 0.00 m³/h

Overflow: 0.00 m³

Enter the logger window by pressing the L key.

Press OK key to enter graphic display.

After a couple of seconds the first value in the list, in this case the

level, is shown as a curve

To see the other curves in the logger list you use the▼▲ keys to

change viewed parameters to the next one in the logger list.

To get back to numeric values you press the Esc key.

Time indication, shows

the actual time at the

reference line.

Visualizing of log values in graphic form

All values that are shown in the logger window can be viewed as a graphic curve. This is done by

entering the logger window, which holds the information you are interested in and press the OK key.

The unit will process the information during a couple of seconds and the display the values as a curve

in the logger window, in this case, the level is shown.

Because you log both analogue and digital values, you will see two different graphic displays, usual

curves and bar graphs.

Description of the analogue display window

To move along the time axis use the ◄► keys.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 19 (71)

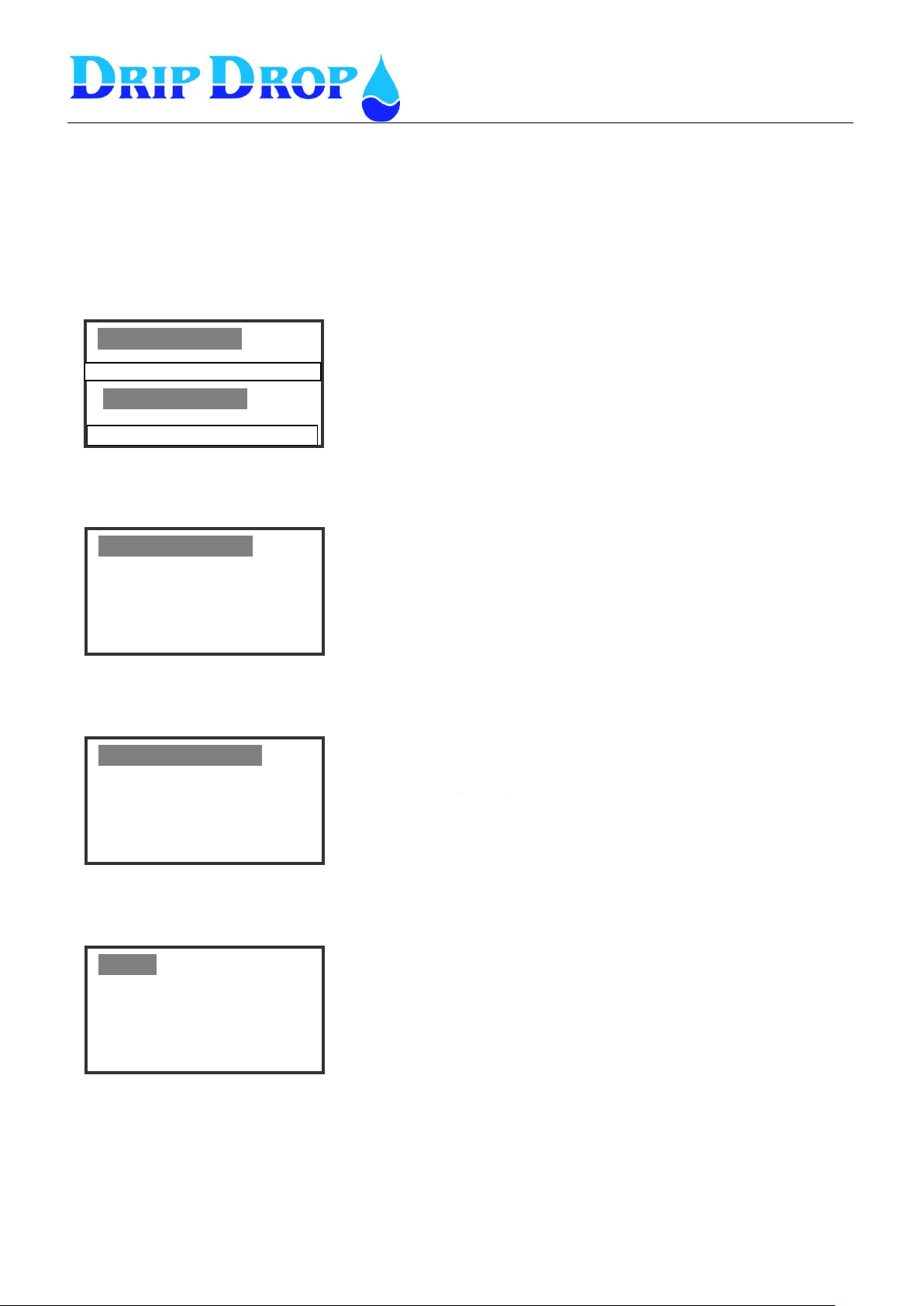

11-22 20:20 pump status

Pump info

1 = All OK

|1| = Not in auto

1 = blocked

X= in waiting pos.

Time reference line equivalent to

shown time in display

ON and OFF status for pumps.

Black staple = ON

No staple = OFF

Time scale shows 10 hours

1.PC 2000:2_____________

Link: OK

Alarm: 0

Level[m]: 0.00

Current P1[A]: 0.00

Current P2[A]: 0.00

2.PC 2000:1_____________

Link: OK

Alarm: 0

Level[m]: 0.00

Current P1[A] 0.00

Current P2[A] 0.00

Press

►

Press

►

Device 1

Device 2

Time indication,

shows the actual time

at the reference line.

Description of the digital display window

To move along the time axis use the ◄► keys.

4.5 External connected units X

4.5.1 External units that communicate via RS-485

The X-key shows the external RS485 connected devices and the values they are set to display.

Press Esc to return to main menu

By pressing the X key the first 485 device connected will be displayed. If more than one 485 devices

are connected, you will see next device by pressing the ►key. By pressing the ▲▼ keys, you can

access and look at the whole list of connected 485 devices.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 20 (71)

Digital inputs

Digital outputs

UtUtgångar

Analogue inputs

A1: 4.00 A5: 0.00

A2: 4.00 A6: 0.00

A3: 0.00 A7: 0.02

A4: 4.00

Analogue outputs

AO1: 4.0 0 mA

AO2 : 0. 00 V

Daily

CI 1 : 0 (Off)

CI 2 : 0 (Off

Press

▼

Press

▼

▪ ■ ▪ ▪ ▪ ▪ ▪ ▪ ▪ ▪ ■ ▪ ▪ ▪ ▪ ▪ ▪ ▪ ▪ ▪

▪ ▪ ▪ ▪ ▪ ▪ ▪ ▪ ■ ▪ ▪ ▪ ▪ ▪ ▪ ■

1 5 10 15 20

1 5 10 15

By pressing the ▼key, you will enter the analogue input status

window, where the real unscaled mA values will be shown on all

analogue inputs.

NOTE! Real mA values

Press

▼

By pressing the Esc key you enter the graphic display mode for the

status of digital inputs and outputs.

Active in/outputs are indicated by a dark rectangle at the input/output

number.

By pressing the ▼once more key, you will enter the analogue output

status window, where the real unscaled mA and Voltage values will

be shown on the analogue outputs.

By pressing the ▼key once more, you will enter the daily counter

status window, where the daily real pulse number will be shown.

NOTE! Real counted pulses today.

If the pulse counter does not receive any pulses this will be indicaded

by the (Off) indication.

4.6 Quick menu for the Status of I/O-signals Esc

The Esc-key is used to see the status of the digital in- and outputs. When the status is active, this is

shown with a square instead of a point in the display. There are 20 digital inputs and 16 digital outputs,

7 analogue inputs, 2 analogue outputs and 2 counters.

To change between the different input and output displays with the key ▼.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 21 (71)

Level: yy-mm-dd

1.45 m

Min Max

CONTRAST

Menu picture digital inputs

Shows a list with all digital inputs of the unit. If they are used,

configured signal type and if they are active or not

--- means that the input is not used.

NO or NC means that the input is used and that it is used as NO

(normally open) or NC (normally closed).

If the signal is shown with shaddow NO it means that the input is

active.

Menu picture digital Outputs

This list shows all digital outputs, which are used

and if they are active or not.

--- means that the input is not used.

NO or NC means that the input is used and that it is used as NO

(normally open) or NC (normally closed).

If the signal is shown with shaddow NO it means that the input is

active.

Menu picture analogue inputs

Shows list of all analogue inputs.

Values shown are all scaled according to configuration.

Digital inputs

1.Low float: NO

2.High float: NO

3.Overflow switch: NO

4.P1 Not in Auto: NC

:Digital outputs

1.P1 Start/Stop: NO

2.P1 Reset M.Protect --

3.P2 Start/Stop: NO

4.P2 Reset M.Protect --

Analogue inputs

1.Level Sensor: 1.55

2.Flow meter: --

3.P1 Motor current: 24.4

4.P2 Motor current: 35.0

You move up and down

in the menu with the ▲▼buttons

You move up and down

in the menu with the ▲▼buttons

You move up and down

in the menu with the ▲▼buttons

4.7 Quick menu for the Status of I/O-signals OK

In this menu you see the actual values and status of the in- and outputs fast, in table format.

In order to see the status of the in- and outputs fast you press the OK button. You come directly to the

menu picture for digital inputs. If you press the OK button once more, the digital outputs will be

shown. By pressing the Ok button once more, the analogue inputs will be shown. This is a loop where

you go from digital in, digital out analogue in. For analogue inputs, the scaled values are shown.

Press OK button to go to Digital Outputs.

Press OK button to go to analogue inputs, which shows scaled values.

To return to main menu press Esc.

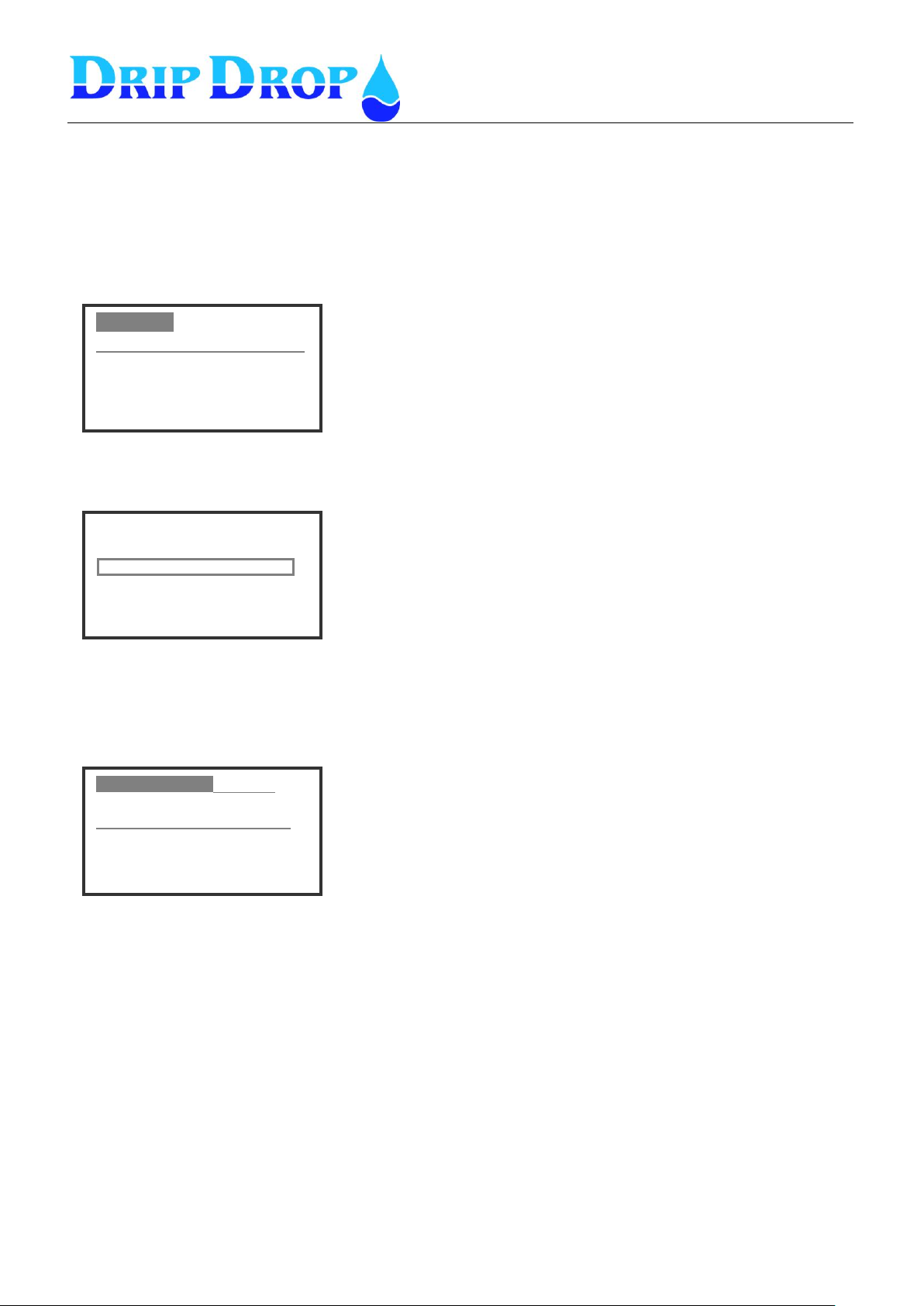

4.8 Display contrast ▲

The ▲ key is used to enter the position where you can change the contrast in the display.

This is done by using the ◄► keys.

MANUAL PC-2000-W

Ver. 30.56.12-UK/101208

Page 22 (71)

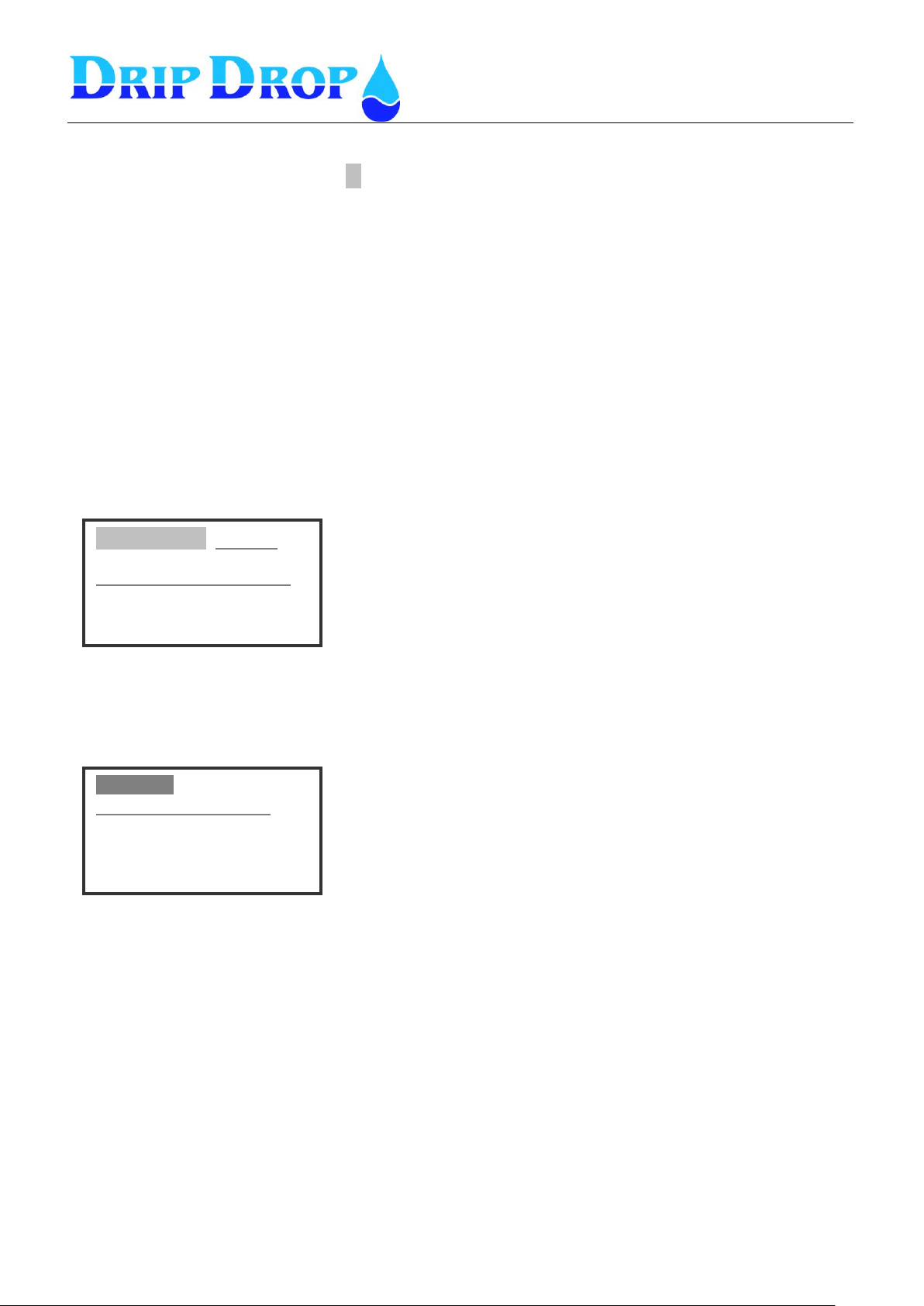

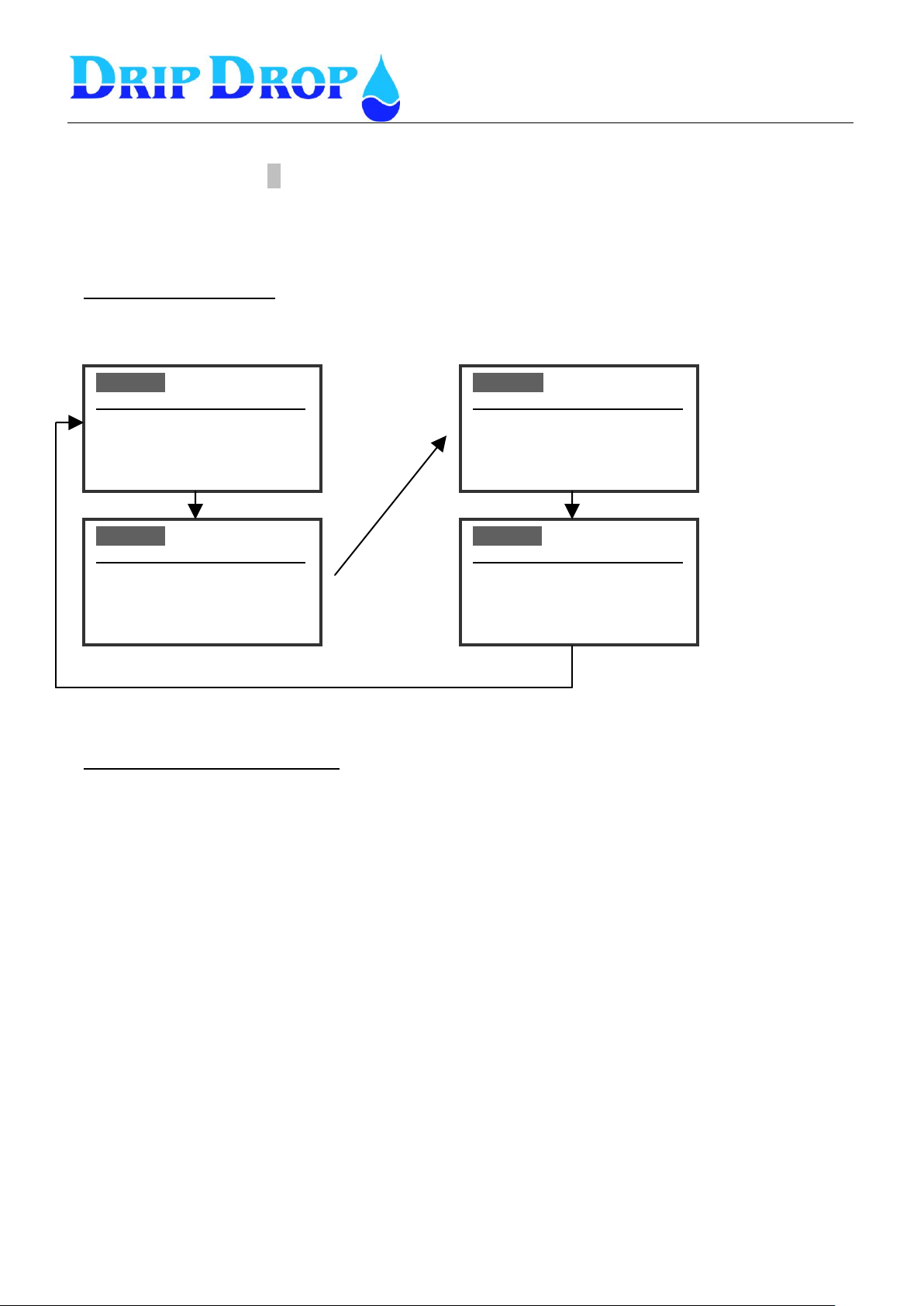

How you move within the menus?

All menu alternatives with a ■ symbol in front have sub menus which

you can enter.

Alternatives with a – sign in front means that you have reached

the level were settings can be made.

To move in the menus you use the arrow keys up and down ▼▲.

To enter the menu you use the OK key.´

To exit the menu you use the Esc key.

Settings( ) V30.56.XX

I/O Configuration__________

▪Digital inputs

▪Digital outputs

▪Counters

▪Analogue inputs

▪Analogue outputs

ettings V30.56.XX

Digital inputs__________

01. Low float

02. High float

03. Overflow

04. P1 Not in Auto

05. P1 Motor Protect

06. P1 Temp. Protect

Sub menu In- and Outputs

You enter the sub menu by pressing the OK key.

The example shows the sub menu for in and outputs.

Sub menu digital inputs

You enter the submenu by pressing the OK key.

In the example the digital submenu for digital inputs is shown

Settings ( ) V30.56.XX

▪Application type

▪I/O Configuration

▪Pump settings

▪Station settings

▪Miscellaneous

Main menu – description.

Application type – here you set how many pumps the

pumpingstation has and how many pumps are allowed to run at the

same time.

I/O configuration - here you define how the in and outputs shall be

handled.

Pump settings – here all settings for each pump are made, for ex,

start and stop levels, alternation etc.

Station settings – here all setting for the station are made, for

example alarm levels, mixer functions, in/outflow calculations.

Miscellaneous – here are all other settings made, factory settings,

communication settings, resetting of counters etc.

Settings( ) V30.56.XX

▪Application type

▪I/O Configuration

▪Pump settings

▪Station settings

▪Miscellaneous

5 System settings S

PC-2000-W has a factory default setting for a quick start with most normally used functions activated.

To adapt the PC-2000-W to the actual location you might have to activate more I/Os and configure

functions accordingly.

5.1 Main menu

The settings menu is divided into logically grouped submenus. You enter the settings menu by

pressing the S key (settings).

Here we will describe how you enter the different sub menus and how you can change the values.

It is convenient when configuring the unit to follow the logic structure of the menus.

5.1.1 How you change the values in the settings menus.

Here we show how you move in the menus and how you change the values by choosing different

alternatives and numeric values.

Loading...

Loading...