Drip Drop PC-200 User Manual

DripDrop AB • Pipers Väg 2C • 170 73 Solna • www.dripdrop.se • Tel. +46 8 655 02 94

User manual

Version 2.12.xx/-UK

PC-200

Pump controller

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 2 (61)

TABLE OF CONTENTS ....................

1 DESCRIPTION ............................................................................................................................................................ 5

1.1 GENERAL ............................................................................................................................................................... 5

1.2 OPERATOR UNIT .................................................................................................................................................... 5

2 LOG IN – ACCESS CODE ......................................................................................................................................... 5

3 MENU OVERVIEW .................................................................................................................................................... 6

3.1 MAIN MENU – STATUS WINDOWS, SETTINGS AND ALARM HANDLING ................................................................... 6

3.1 ▼ ▲ MENU OVERVIEW – SYSTEM SETTINGS ......................................................................................................... 7

4 STATUS MENUS ......................................................................................................................................................... 8

4.1 START WINDOW (LEVEL) ................................................................................................ ................................ ....... 8

4.2 ANALOGUE INPUT 2 (FREE CHOICE) ....................................................................................................................... 8

4.3 VOLTAGE INPUT (PHASE MEASUREMENT) .............................................................................................................. 8

4.4 ATTENDANCE CHECK (PERSON- / INTRUDER ALARM) ............................................................................................. 8

4.5 PUMP STATUS ........................................................................................................................................................ 9

4.6 OVERFLOWS (ONLY SHOWN IF OVERFLOW FUNCTION IS ACTIVATED) .................................................................... 9

4.7 FLOW STATUS ........................................................................................................................................................ 9

5 SYSTEM SETTINGS ................................................................................................................................................ 10

5.1 APPLICATION ....................................................................................................................................................... 11

5.2 I/O SETTINGS ....................................................................................................................................................... 12

5.2.1 Digital inputs ................................................................................................................................................. 13

5.2.2 Digital outputs ............................................................................................................................................... 19

5.2.3 Pulse input ..................................................................................................................................................... 20

5.2.4 Analogue inputs (mA)..................................................................................................................................... 21

5.2.5 Voltage inputs ................................................................................................................................................ 22

5.2.6 Current inputs ................................................................................................................................................ 23

5.2.7 Temperature protection.................................................................................................................................. 25

5.3 PUMP SETTINGS ................................................................................................................................................... 26

5.3.1 Start and stop levels ....................................................................................................................................... 27

5.3.2 Alternation, running time and break time ...................................................................................................... 27

5.3.3 Running confirmation .................................................................................................................................... 27

5.3.4 Setting of motor currents................................................................................................................................ 28

5.3.5 Times / delay for pumps ................................................................................................................................. 29

5.4 STATION SETTINGS .............................................................................................................................................. 30

5.4.1 Alternation type of pumps .............................................................................................................................. 30

5.4.2 Level alarm settings (Low and high level alarms) ......................................................................................... 30

5.4.3 AI 2 Setpoints, Analogue setpoints ................................................................................................................. 31

5.4.4 Mixer settings ................................................................................................................................................. 32

5.4.5 Attendance check (Person alarm or Intruder alarm) ..................................................................................... 33

5.5 VOLTAGE RELAY ................................................................................................................................................. 34

5.6 MISCELLANEOUS ................................................................................................................................................. 36

5.6.1 Communication .............................................................................................................................................. 36

5.6.2 Trusted login .................................................................................................................................................. 39

5.6.3 Operator password ........................................................................................................................................ 39

5.6.4 System password ............................................................................................................................................ 39

5.6.5 Clock setting................................................................................................................................................... 39

5.6.6 Default settings ............................................................................................................................................. 39

5.6.7 Erase alarms .................................................................................................................................................. 40

5.6.8 Erase counters ............................................................................................................................................... 40

5.6.9 Erase runtimes ............................................................................................................................................... 40

5.6.10 Contrast ..................................................................................................................................................... 40

5.7 LOGIN / LOGOUT.................................................................................................................................................. 40

6 LEVEL SETTINGS ................................................................................................................................................... 41

7 MANUAL START AND STOP OF PUMPS ........................................................................................................... 41

8 ALARM STATUS ...................................................................................................................................................... 42

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 3 (61)

8.1 ALARM HANDLING............................................................................................................................................... 42

8.2 NEW ALARMS ...................................................................................................................................................... 42

8.3 ACTIVE ALARMS .................................................................................................................................................. 43

8.4 ALL ALARMS ....................................................................................................................................................... 43

9 SMS-FUNCTIONS - USE OF MOBIL PHONE ..................................................................................................... 44

9.1 ALARM BY SMS MESSAGES ................................................................................................................................. 44

9.2 REMOTE CONFIRMATION OF THE ALARMS ............................................................................................................ 44

9.3 TO ASK QUESTIONS VIA SMS TEXTS .................................................................................................................... 45

10 I/O-LIST, SIGNAL TABLE ......................................................................................................................................... 46

11 CONFIGURATION TABLE ........................................................................................................................................ 47

12 MENU STRUCTURE – SETTINGS ............................................................................................................................ 50

NOTES ................................................................................................................................................................................ 61

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 4 (61)

Copyright © 2005 DripDrop AB. All rights reserved.

This manual and all the information within may not be used or copied in any form without the

written consent of DripDrop AB.

Changes

The content of this manual is for informational use only and can be subject to changes

without prior notice.

DripDrop AB products are developed continuously and we reserve the right to alter technical

specifications without prior notice.

Liability

DripDrop AB assumes no responsibility or liability for errors or incorrect information that may

appear in this document.

DripDrop AB assumes no responsibility or liability for loss of profit, working deficits or any

other indirect losses due to erroneous use or application of the information exposed in this

manual.

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 5 (61)

1 Description

1.1 General

The pump controller PC-200 is an advanced computer controlled device to control and supervise up to

3 pumps. It is built up of a combined operator and I/O unit for connecting all digital and analogue

signals used by the unit. The level in the sump is detected by a 4-20 mA level sensor (chapter 5.2.4), or

by the use of level switches to start and stop the pumps (chapter 5.2.1).

The controller can handle a mixing device and has an integrated voltage supervision relay.

The unit has one communications port RS 232 for communication with radio/PSTN modems or

a GSM-modem to send SMS-text messages or to communicate with a supervision and SCADA

system.

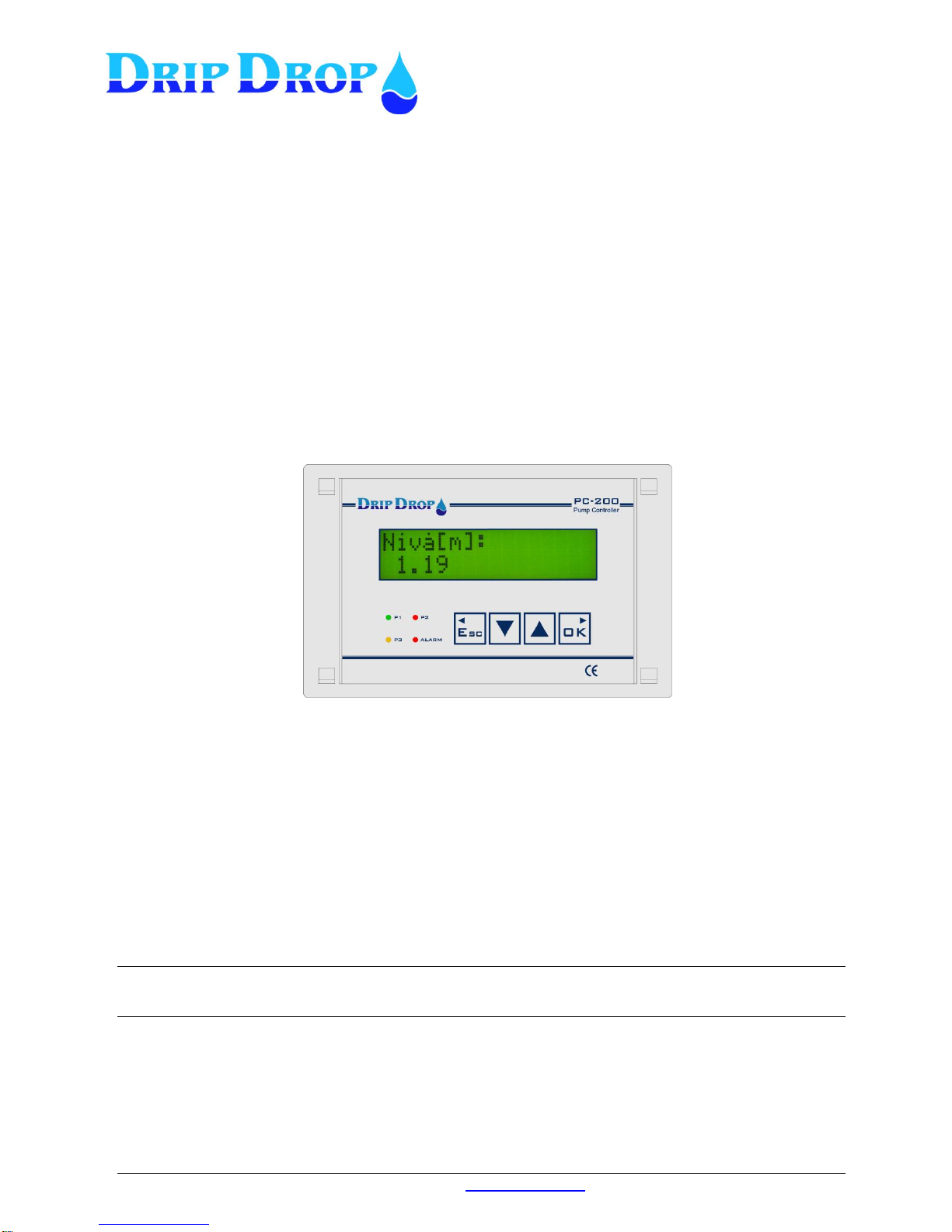

1.2 Operator unit

The operator unit is mounted in the front door of a cabinet and has 4 control keys for handling,

configuration and alarm. There are 4 light emitting diodes for indication of alarms and status and an

alphanumeric display with 2 x 16 signs for displaying all information.

Front panel

2 Log in – Access code

For looking at information about pumps, running times or alarm you can go directly to the actual

information menus. But to make changes or acknowledge alarms a.s.o. you need to enter an access

code depending of what you want to do. The unit is delivered with two different access codes:

1. Operator code – allows acknowledgement of alarms. The code is ZZZZ (▼▼▼▼)

2. System code – allows changes of for example start and stop values or configuration of the unit.

The code is 0000 (▲▲▲▲)

The access codes can be changed under ”System settings”

When you enter a menu and want to change any value, the access code prompt will show when you

press the OK key to enter the changing position. When the prompt shows up you set the actual code

and accept with the OK key you enter the changing position and can make the changes you desire.

The unit will automatically log out 5 minutes after the last time you pressed a key.

If the function “Trusted logged in” is activated no log out will be made.

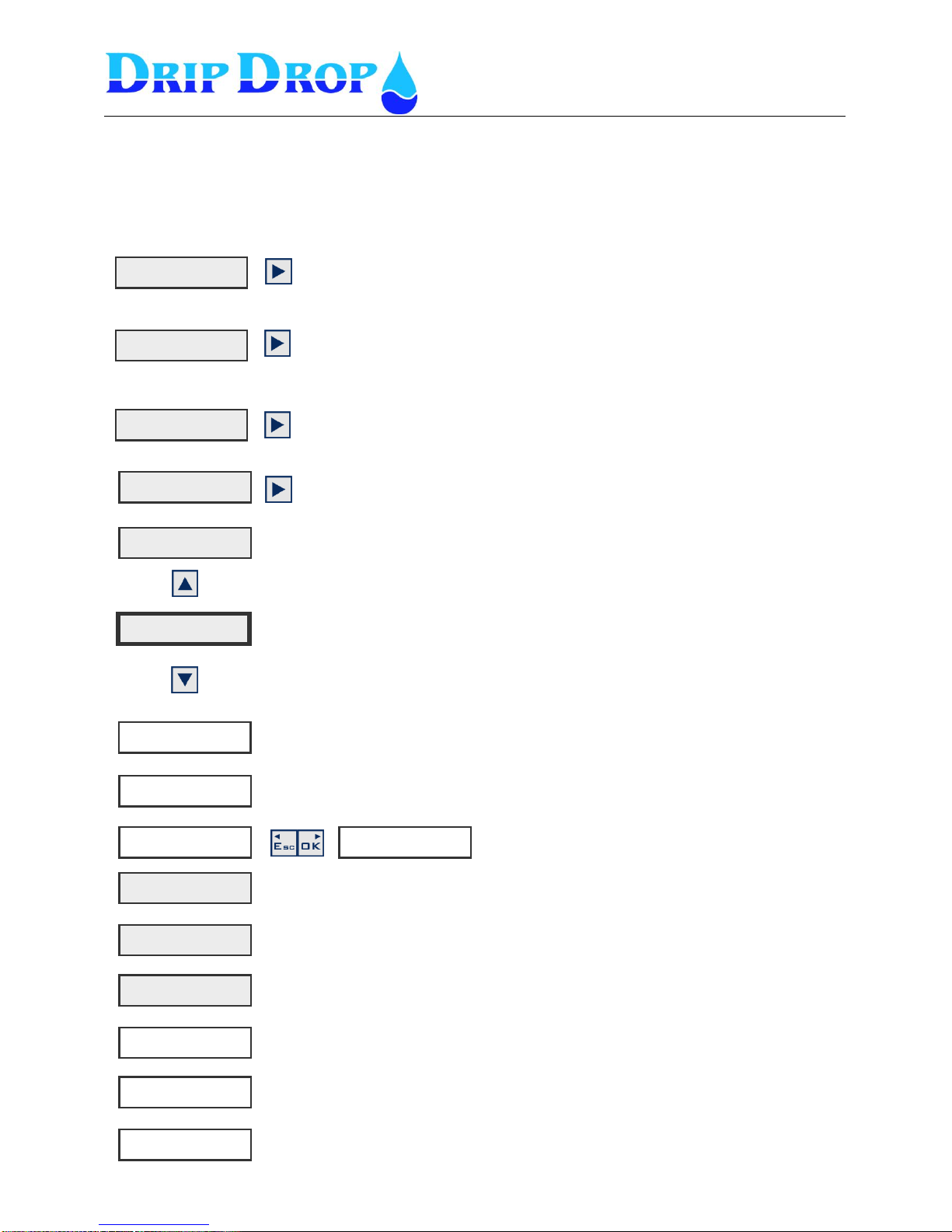

Confirm choice, enter submenus, and to go

from the start menu to the main menu.

Exit the menus and go to the left.

Used to step downwards in the submenus, and

to change values to be set.

Used to step upwards in the submenus and to

change the values to be set.

Indication diode ”P1-P3”

3 multicolour diodes show the

status for each pump.

¤ Green shows pump is running.

¤ Red shows pump alarm

¤ Orange shows pump ”Not Auto”

Indication diode ”Alarm”

1 red diode shows the alarms.

¤ Red ”blinking” not ackn. alarm.

¤ Red ”fixed” active, ackn. alarm.

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 6 (61)

D a t e : 0 5 / 0 3

T i m e : 1 2 . 3 5

O v . f l o w [ h ]

O v . f l o w N o s

V o l u m e [ m 3 ] :

0

L e v e l [ m ] :

P 1 P 2

O n o f f

A I 2 [ % ] :

1 . 1 9

U R U S U T

0 2 3 0 2 3 0 V

P e r s . Ala r m ON

8 0 0 s e c

P 1 O p h r s . . : 5

P 1 N o s . : 3 5

P 2 O p h r s . : 5

P 2 N o s . : 35

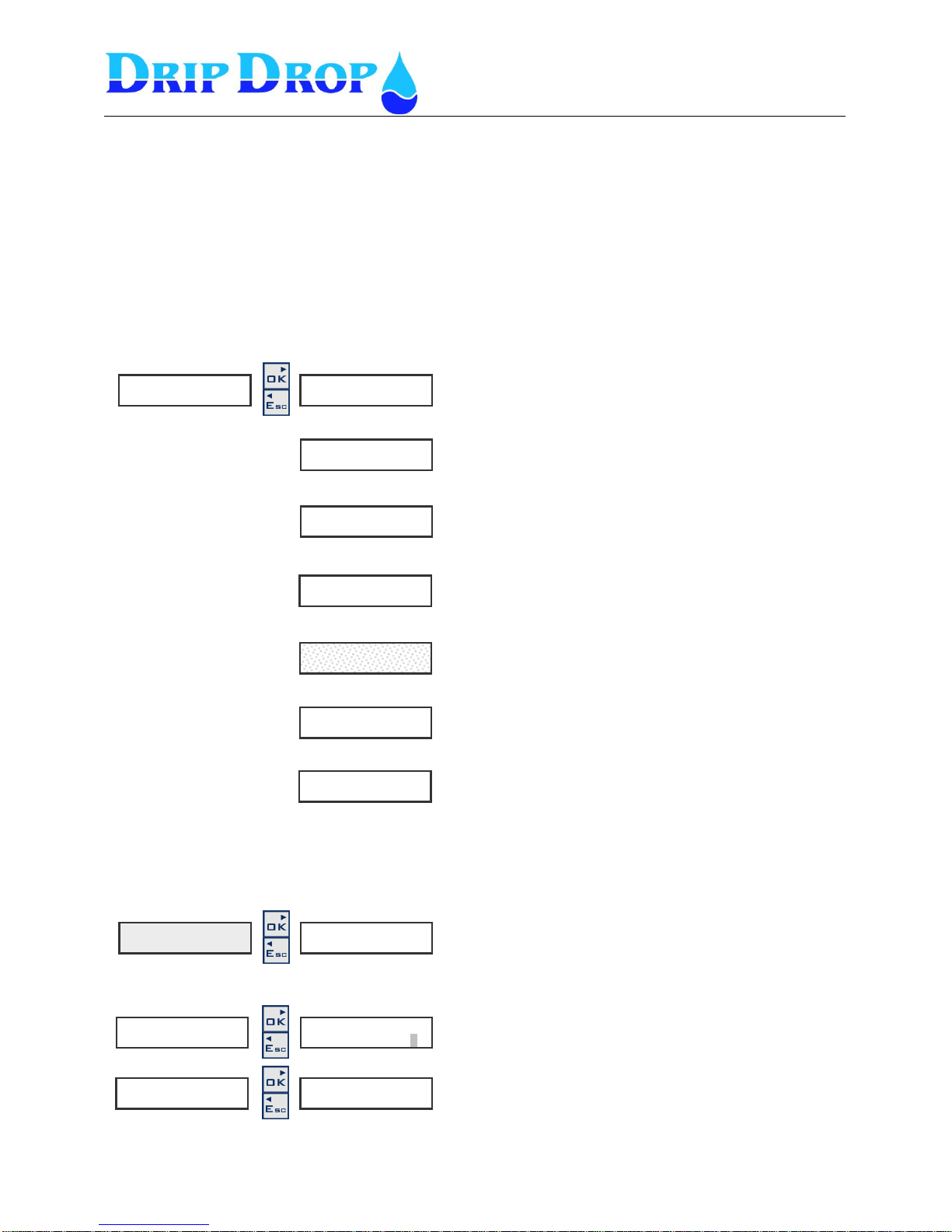

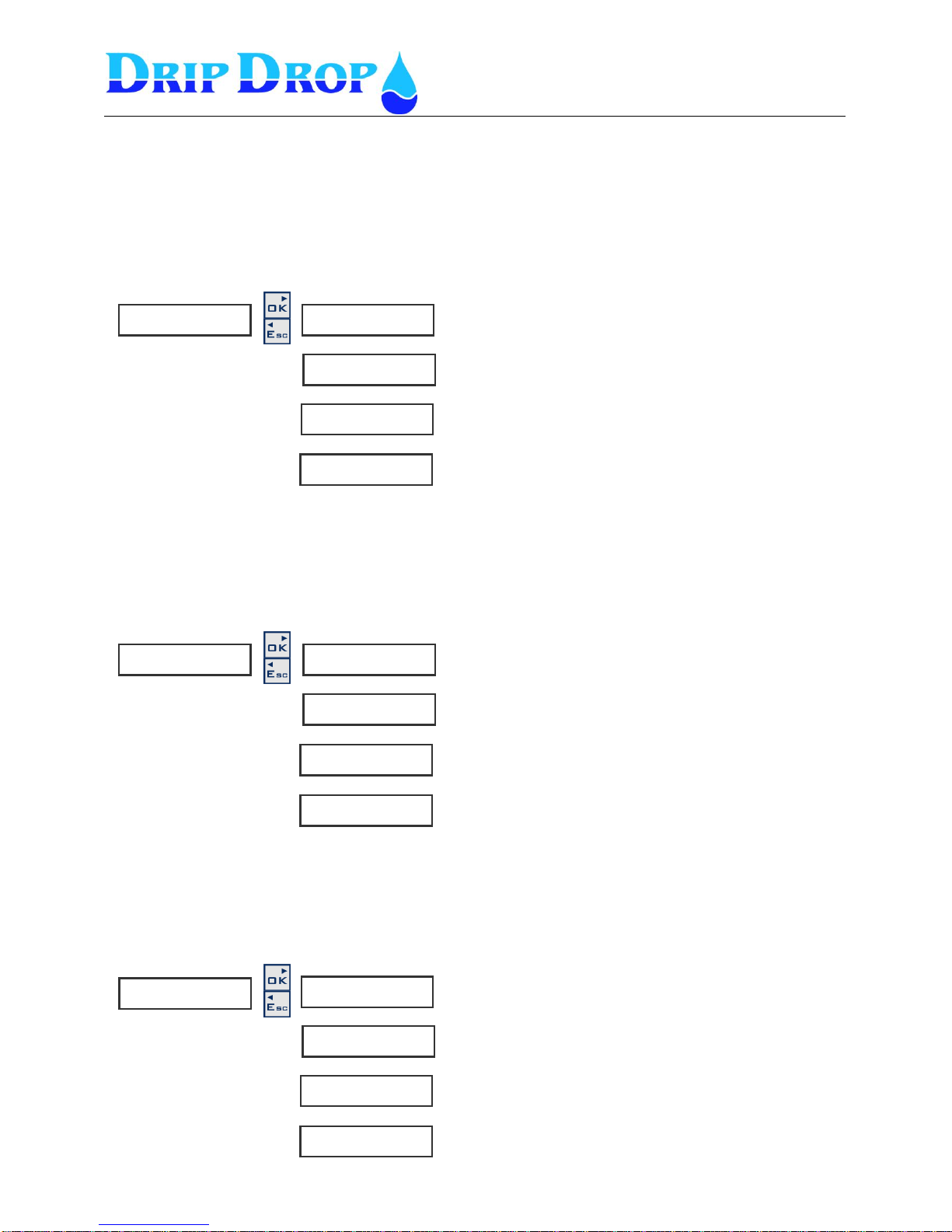

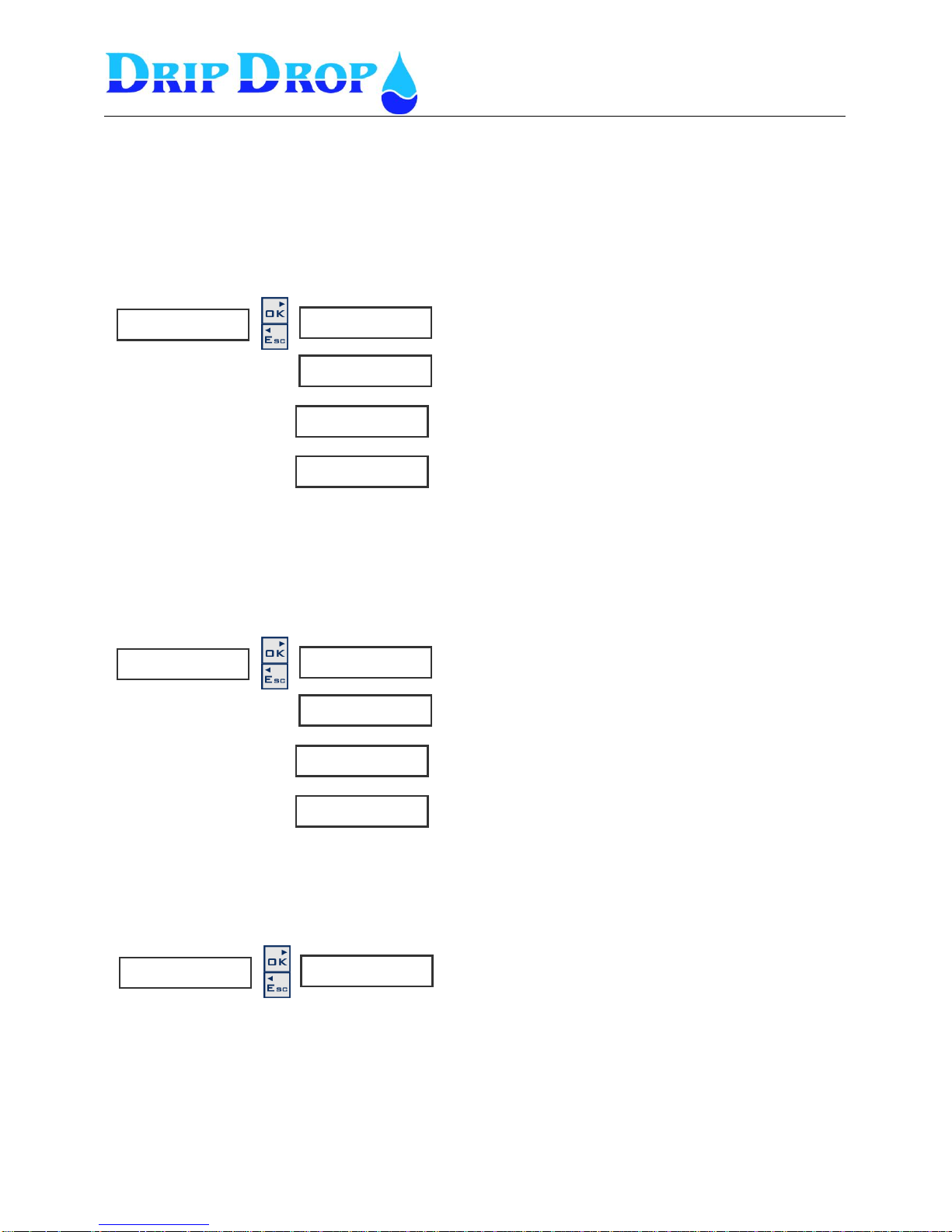

3 Menu overview

3.1 Main menu – Status windows, settings and alarm handling

A l a r m s t a t u s ►

M a n . C o n t r o l ►

L e v e l s e t t i n g s ►

S y s t e m s e t t i n g s ►

▼▲

A t t e n d a n c e ►

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

This is the start window, which always is shown.

In the menu for the system settings, all settings for Applications, In/outputs, Levels,

Pumps, Station, Voltage relay and miscelaneous settings like, communications etc.

are made. See system settings chapter 3.2 and 5.

In this menu you have fast access to set the start/ stop levels of the pumps and to

the alarm level for low and high level. See level settings chapter 7.

Menu to start and stop pumps manually.

Can only be hand started if the conditions allow this. See chapter 7

The menues for The UP key takes you to settings, alarm handling and manual control

of pumps.

The DOWN key takes you to all status windows. NOTE tat the shadowed display

windows will always be shown not depending on the setting of the functions. Not

shadowed will only be shown if the functions are activated.

Menu to look at and acknowledge alarms and look at the alarm history. See

further chapter 8

Shows actual value for analogue input 2. If input 2 is activated. See chapter 4

Shows actual voltage between all phases and neutral if the voltage relay function is

activated. See further 5.2.5 and 5.5

Shows actual status for person alarm if the function is

activated. Chapter 5.4.5

The pumpstatus window shows if the pum is running or not. If the pump current

function is activated the pump current will be display for running pump.

Shows total running time and number of starts for pump 1.

Shows total running time and number of starts for pump 2.

Shows total overflow time and numbers of overflows. Is only shown if the overflow

float function is activated. See further 5.2.1

Shows actual flow on pulse input. Only shown if pulse input is activared

See 5.2.3

Shows total pumped volume onnumber pulse input. Show only if pulse input is

activated. See 5.2.3

F l o w [ m 3 / h ] :

0 . 0

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 7 (61)

D i g i t a l i n p u t s

D i g i t a l o u t p u t s

C o u n t e r

A n a l o g u e i n p u t s

V o l t a g e i n p u t s

C u r r e n t i n p u t s

A l t e r n a t i o n

L e v e l a l a r m s

A I 2 s e t p o i n t s

M i x e r s e t t i n g s .

N o m i n a l [ V ] ( L - N)

F a i l b r e a k t i m e

P h a s e r o t a t i o n

U n d e r v o l t a g e

O v e r v o l t a g e

U n b a l a n c e

C o m m u n i c a t i o n

T r u s t e d l o g i n

O p e r a t o r p a s s w o r d

S y s t e m p a s s w o r d

C l o c k s e t t i n g s

D e f a u l t s e t t i n g s

E r a s e a l a r m s

E r a s e c o u n t e r s .

E r a s e p u l s e i n p u t .

R e s e t o p . h r s .

C o n t r a s t

L o g i n / l o g o u t

P a s s w o r d

Z Z Z Z

P 1 M a n u a l s t a r t

N o t a l l o w e d

S t a r t P 2

* A c t i v e a l a r m s

A l l a l a r m s

D a t e : 0 5 / 0 3

T i m e : 1 2 . 3 5

N u m b e r o f p u m p s

M a x p u m p n u m b e r

F u n c t i o n

A d v a n c e d m o d e

P u m p 1

P u m p 2

P u m p 3

T i m e / D e l a y s

S t a r t l e v e l P 1

S t o p l e v e l P 1

S t a r t l e v e l P 2

S t o p l e v e l P 2

S t a r t l e v e l P 3

S t o p l e v e l P 3

A l a r m l o w l e v e l

A l a r m h i g h l e v e l

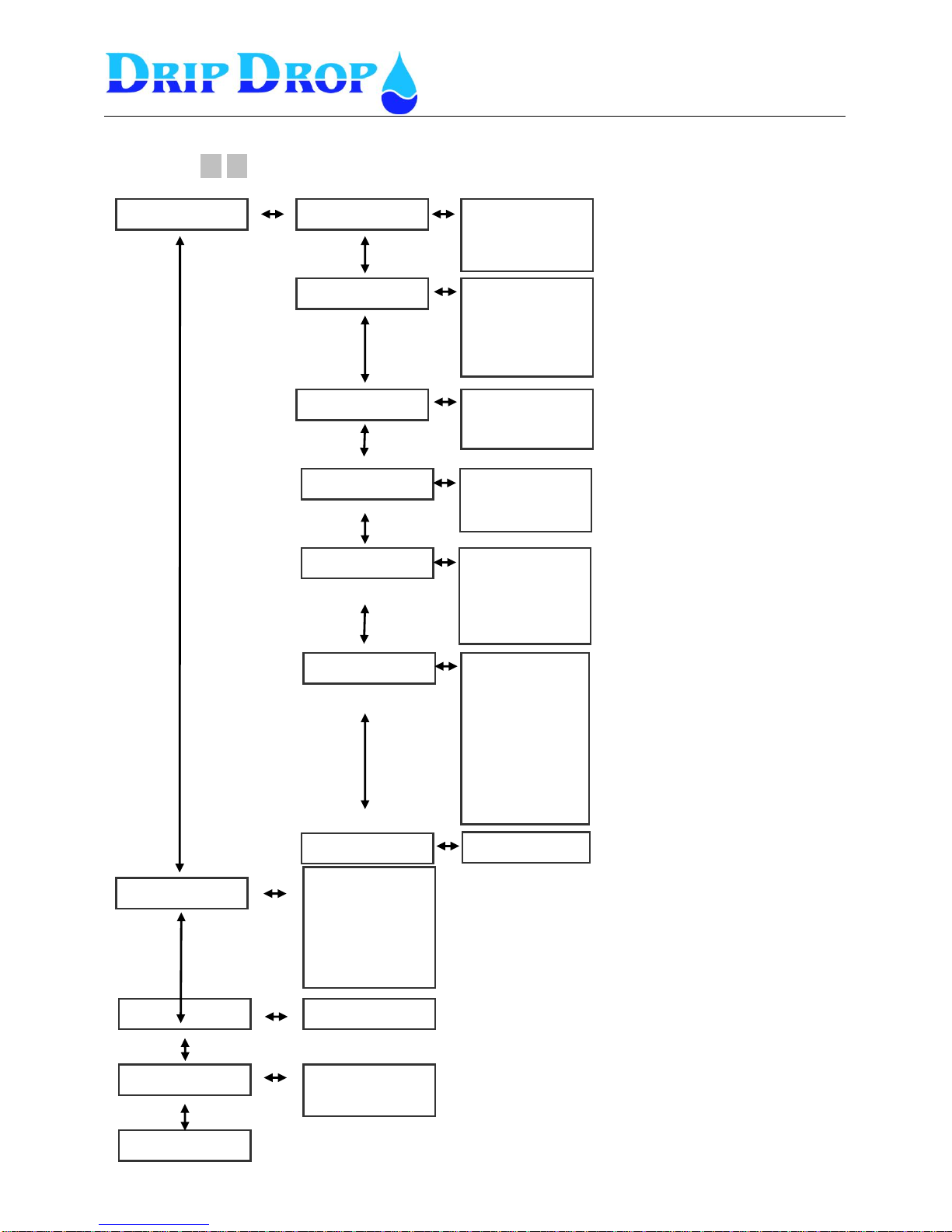

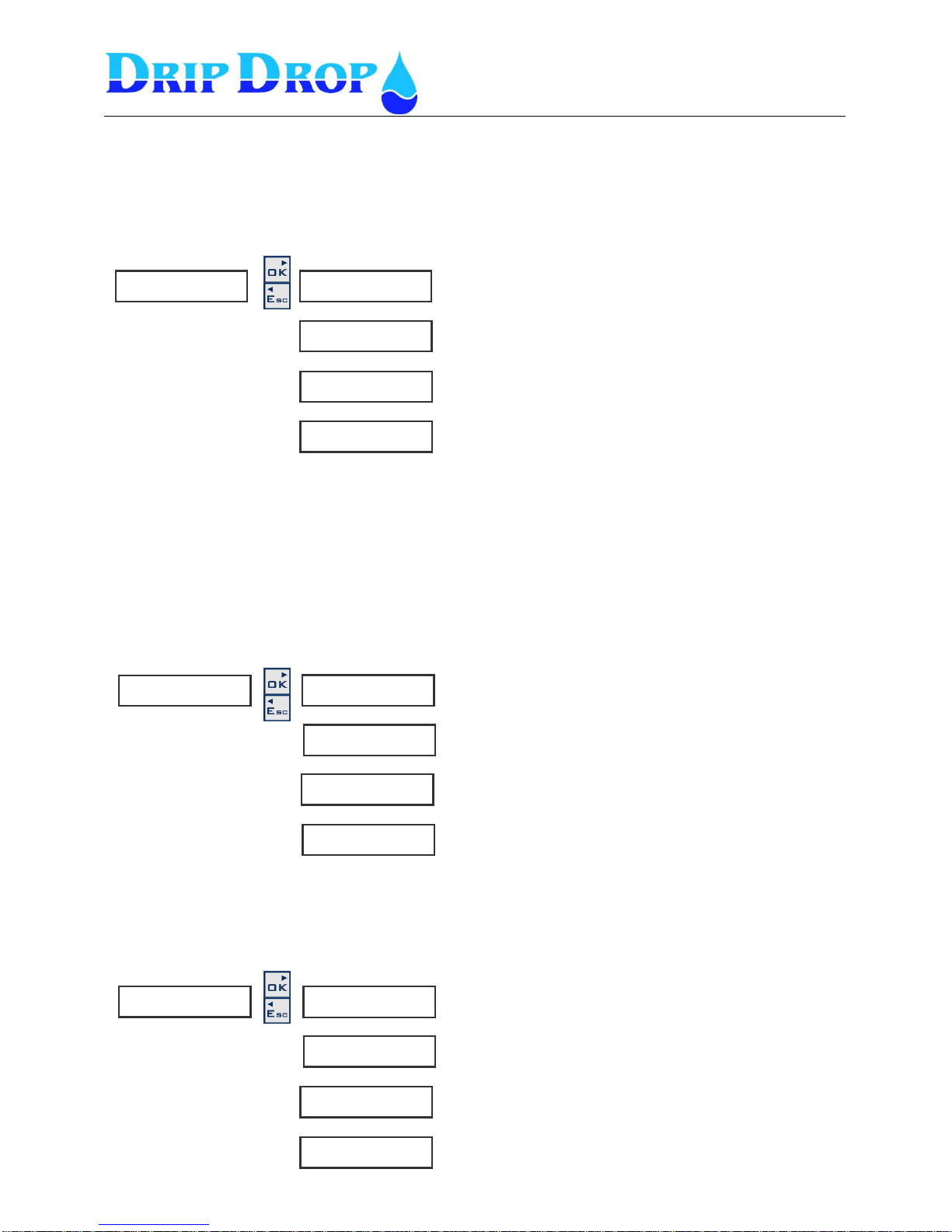

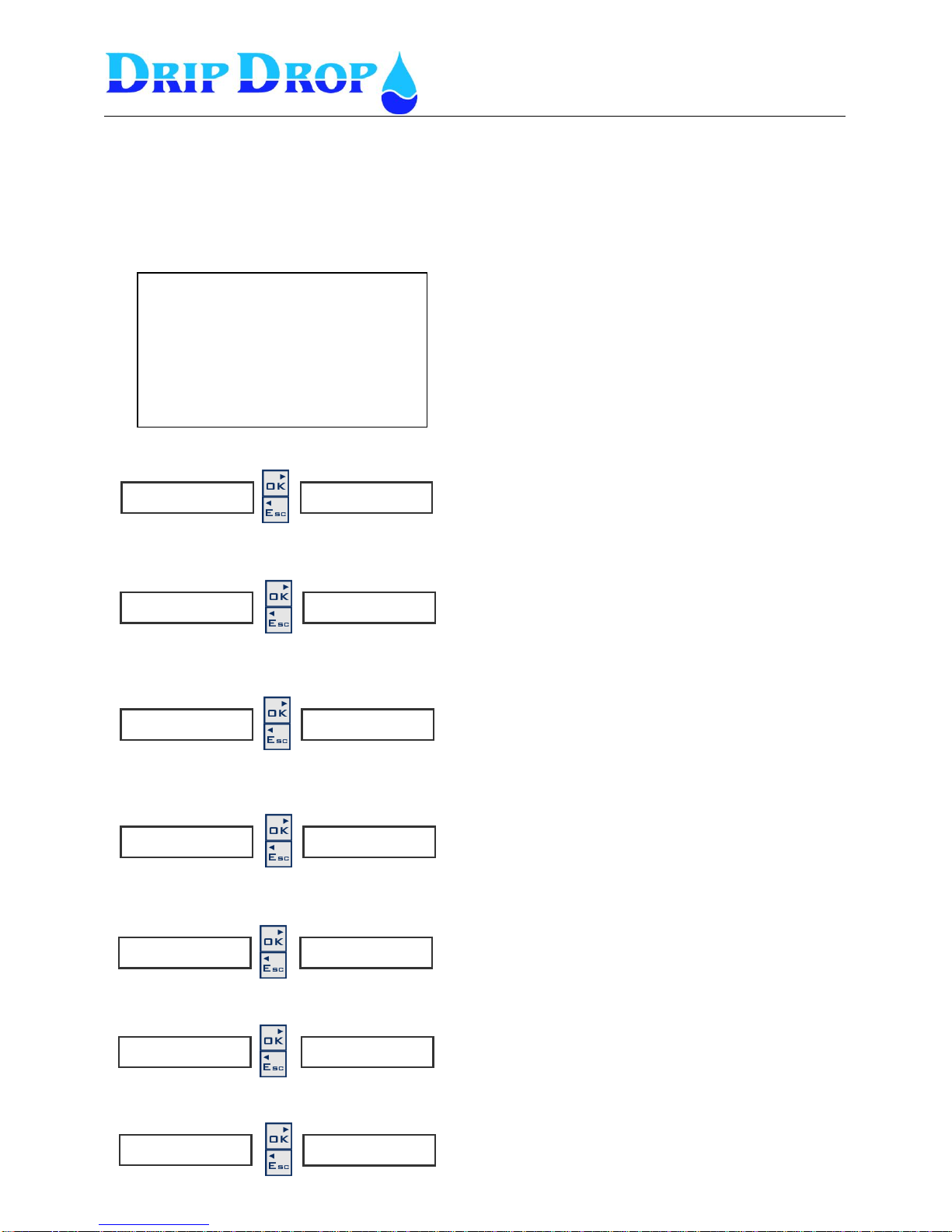

3.2 ▼ ▲ Menu overview – System settings

4

A p p l i c a t i o n ►

I / O s e t t i n g s ►

P u m p s e t t i n g s ►

S t a t i o n s e t t i n g s .►

V o l t a g e r e l a y .►

M i s c e l l a n e o u s .►

M a n u a l c o n t r o l ►

A l a r m s t a t u s ►

S y s t e m s e t t i n g s ►

L e v e l s e t t i n g s ►

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 8 (61)

L e v e l [ m ]:

1 . 19

A I 2 [ % ]:

1.19

U R US UT

2 3 1 2 3 0 2 3 0 V

P e r s . A l a r m O N

8 0 0 s e c 0

Status menus

When in the normal standby mode the controller will show the actual level in the pump pit at all times.

By pressing the down arrow ▼you will have direct access to status windows which are organized in a

loop, where, by each pressing of an arrow button you will see the next status window in the loop.

In this menu you will find information about the level, pump and station status etc.

4.1 Start window (Level)

This is the window that is always displayed when the unit is in normal working mode.

4.2 Analogue input 2 (Free choice)

Will appear only if analogue input 2 is activated and configured.

Actual value for the analogue input 2 is shown in the next window. As this input is editable regarding

texts, units and scaling and will show the configured values.

4.3 Voltage input (phase measurement)

The voltage reading for each phase (Phase-N) will be shown if the voltage relay is activated and the

corresponding wiring is done (three phases and neutral)

4.4 Attendance check (person- / intruder alarm)

If the attendance check function is activated, personal alarm or intruder alarm, in this window the

status for the function is shown, on/off and the remaining delay time for the alarm to go active.

A t t e n d . c h e c k ►

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

If the up ▲ arrow is pressed you will access the settings and alarmwindows

in the main menu.

If the down ▼ arrow is pressed you will access the status windows in the

main menu.

More information under system settings page 21

More information under system settings page 21

More information under system settings page 26

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 9 (61)

P 1 P 2 P 3

o f f o n o n

P 1 O p . h : 5

P 1 N o s : 3 5

P 2 O p .h: 5

P 2 N o s : 3 5

O v . f l o w [ h ] 0

O v . F l o w N o s 3 1

F l o w [ m 3 / h ] :

0 . 0

V o l u m e [ m 3 ] :

0

P 3 O p . h : 5

P 3 N o s : 3 5

4.5 Pump status

In the pump status windows the information about all pumps is available.

The first information window shows if pumps are running, and if they are in auto or not in auto.

The following windows show the total values for operating hours and number of starts for each pump.

This information is only available in these windows. Only pumps that are used are shown.

4.6 Overflows (only shown if overflow function is activated)

If the overflow switch function is activated, the total overflow duration and total number of overflows

will be shown.

4.7 Flow status

If the digital pulse counter input for flow is used, in these two windows you will see the actual instant

flow and the accumulated total volume pumped.

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

▼▲

Shows if the pumps are on/off.

If the current measurement is activated when the pump is on the pump

current will be shown.

If the a pump is Not in auto this will be shown by the two vertical lines

surrounding thepump number │P1│.

In the second pump status window the total operation hours and number of

starts for pump 1 will be shown.

The following windows will show the corresponding values for pump 2 and 3, if

used.

If the corresonding digital input for overflow detection is activated , this

window will show the total duration of overflowing conditions and the number

occured overflows.

The instant actual flow will be shown, according to the configuration of the digital

pulse input for flow measured in m3/h or l/s.

The total pumped volume will be shown in m3/h.

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 10 (61)

N u m b e r o f p u m p s

◄ 3

F u n c t i o n

◄◄◄ ░ N o t i n u s e

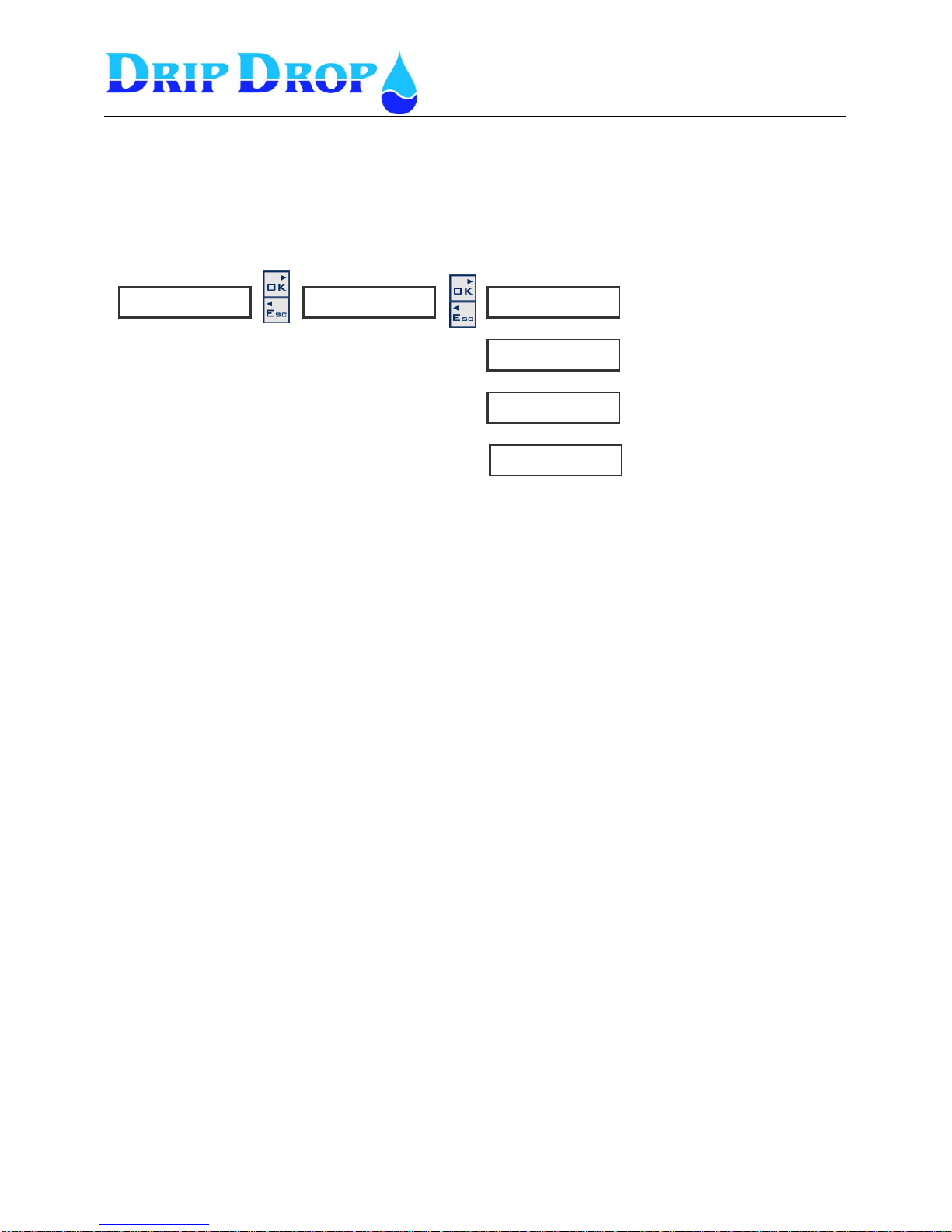

5 System settings

The unit is delivered with a factory setting, for a fast start up of a pumping station with the most used

functions activated. To adjust the controller to the application you need to configure and activate I/O s

and functions according to the specific use.

The system setting menu is built up in logic split sub menus. When you enter system settings, 7 sub

menus will be available.

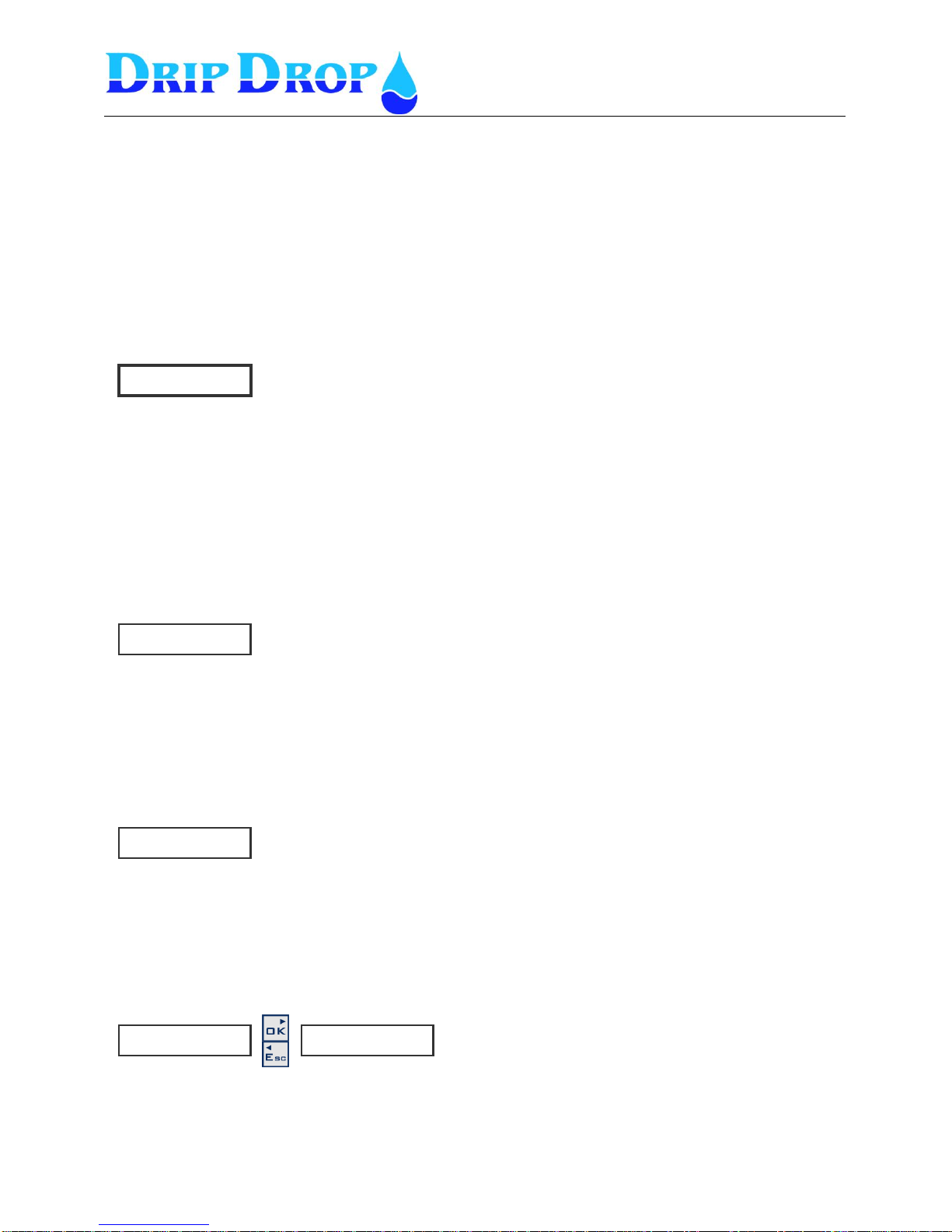

In this part the description of how to enter the different submenus and how change values is made.

During configuration of the unit it is convenient to follow the logical structure of the submenus

How to change values in the setting menus

Application type – here you set the number of pumps in

the station and how many pumps are allowed to run.

I/O setting – here is set how in and outputs are to be used.

Pump settings – here all setting for each pump is done for

start and stop levels, alternation etc..

Station setting – here all settings for alarm levels, mixer

functions are made.

Voltage relay – here the settings of how you measure the

phases of the power supply are done.

Miscelaneous – Settings for default settings,

communication settings , clock settings , alarms etc.

Login/Logout – Here log in with access codes are done.

S y s t e m s e t t i n g s ►

▼▲

A p p l i c a t i o n ►

I / O s e t t i n g s ►

▼▲

P u m p s e t t i n g ►

S t a t i o n s e t t i n g ►

▼▲

V o l t a g e r e l a y ►

M i s c e l a n e o u s ►

▼▲

L o g i n / L o g o u t ►

▼▲

▼▲

How you move in the menues?

To move in the menues you use the ▼▲keys.

To enter a menu you use the OK key.

To leave a menu you use the Esc key.

S y s t e m s e t t i n g s ►

A p p l i c a t i o n ►

A p p l i c a t i o n ►

How to change values?

Move in to the menu window where you want to change a

value and press the OK key.

You will see the actual value with blinking grey square.

To change a value go up and down with the ▼▲keys

changing the numeric value or toggling between options,

then press OK to accept the choice.

To leave a menu you use the Esc key.

1.P 1 N o t i n a u t o ►

◄◄

▲

▼

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 11 (61)

N u m b e r o f p u m p s

◄ 3

A d v a n c e d m o d e

◄ Y e s

M a x p u m p n u m b e r

◄ 2

F u n c t i o n

◄ e m p t y i n g

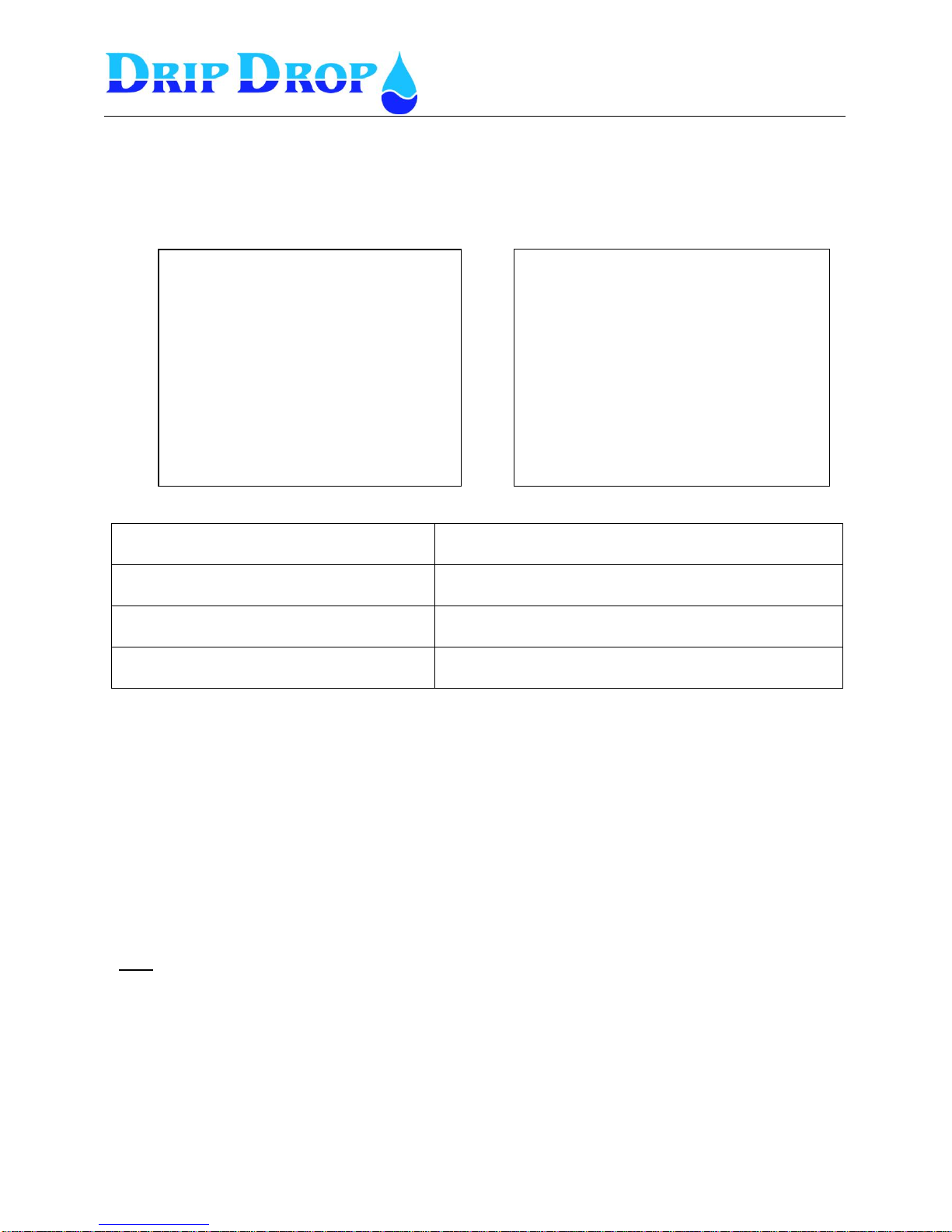

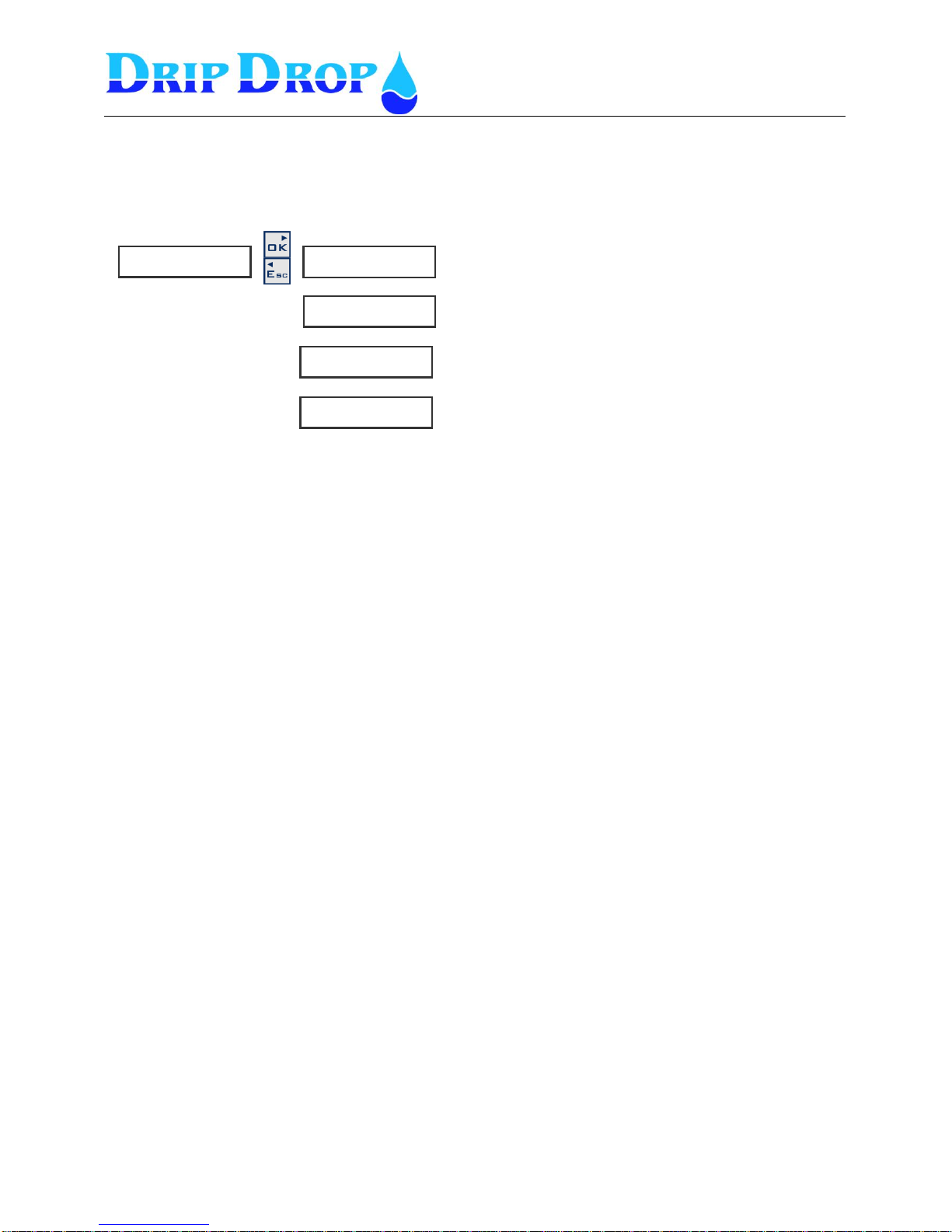

5.1 Application

The pump controller PC-200 is made to control up to 3 pumps. In the application menu you set how

many pumps the station has and how many of these pumps are allowed to run at the same time.

The unit can be configured to control the pumps with only level floats.

Advanced mode –

The advanced / not advanced mode is a mean to with just one simple settings change can convert an

advanced pump controller with many functions, to a simple controller with only basic pump control

functions.

Menu - Application

Here you set how many pumps

the station has.

Here you set how many pumps

are allowed to run at the same

time.

Here you set if the pumps are

used for filling or emptying of

pumpsump.

Here you set if you want the

unit for advanced (all functions)

mode or Basic (just the most

▼▲

▼▲

A p p l i c a t i o n ►

▼▲

S y s t e m s e t t i n g s . ►

When you are in a menu where you want to

change a value you choose the parameter you

want to change and enter the changing mode by

pressing the OK key.

Now the cursor will flash in front of the value you

want to change. Use the ▲kay to see the

alternatives and accept wanted alternative with

the OK key.

Advanced mode –NO ( Basic mode )

In Basic mode you will access the following basic

functions:

- Start and stop functions for 1 to 3 pumps.

- Alternation of pumps

- Use of analogue level sensor or level switches

- Comunication and sending of SMS alarms

- One digital pulse counter for flow, energy or rain.

- Alarm handling with alarm history (up to 15 alarms).

Advanced mode –YES

In advanced mode you will access the following

additional functions:

- One additional analogue input (free choice) with

alarm set points

- Voltage relay

- Current measurement and/or running confirmation

- Inputs for the pumps termoswitches

- Mixer functions

- Attendance check

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 12 (61)

5.2 I/O Settings

The unit has following in and outputs:

- 10 Digital inputs

- 7 Digital outputs

- 1 Digital pulse counter

- 2 Analogue inputs (4-20 mA)

- 3 Voltage inputs

- 3 Current inputs (5 A current transformers)

- 3 Temperature protection inputs (digital)

All these In and Outputs are predefined for what they are used for, but you have to select if they are to

be used or not, which shall generate alarms, signal delays, measuring ranges for analogue inputs etc.

For a complete overview of all In and Outputs refer to the table in chapter 10.

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 13 (61)

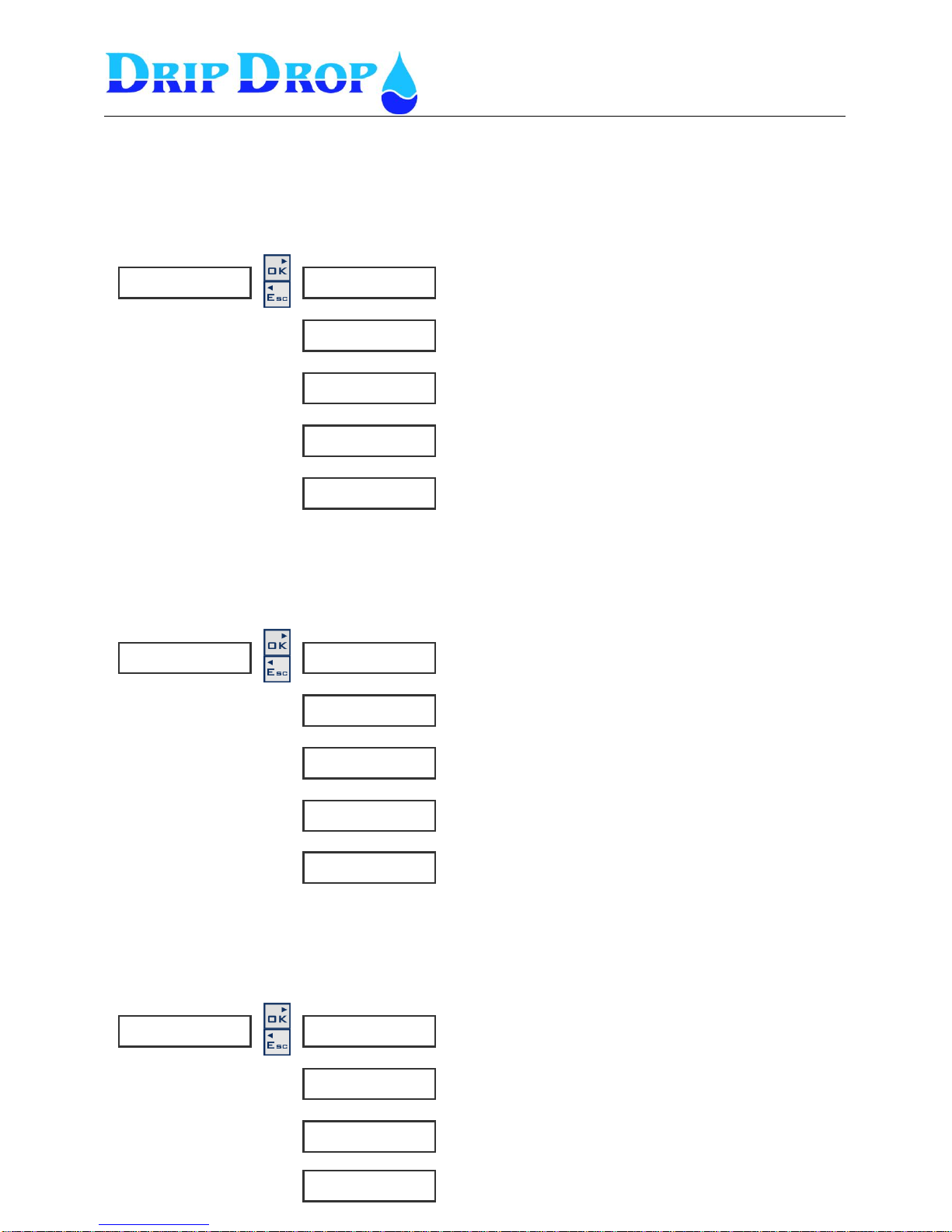

5.2.1 Digital inputs

There are totally 10 digital inputs 24 VDC available according to the list below:

1-2 Pumps 3 Pumps

Each of these inputs has following choices to be set:

Function: in use / not in use -

You can choose not to use the input.

Signal type: NC/NO

Here you specify if the input is NC or NO.

NC = normally closed and NO = normally open

Alarm function

Here you specify if you want to generate an alarm or

not, Yes or No.

Signal delay[s]:

This is a delay of the signal activation.

Backup operation / Level switch operation

DI 7 low level switch and DI 8 High level switch can be used to start and stop the pumps;

1. If level sensor is used this function can be used as a security backup to start and stop the pumps

if there is a problem with the level measuring.

2. If NO level sensor is used, the means of start and stop of the pumps will be with level switches.

With the start switch the first pump in the alternation cycle will start and it will stop with the

low level switch. If the level keeps increasing when the first pump is started (start level switch

is still active) after predefined time (see 5.3.5 Max. time starts ) a second pump will start,

when the low level switch is reached the pumps will stop with a time delay between the stops

(see 5.3.5 Min. time stops).

Note

If an alarm is activated this means that the alarm is sent either as an SMS message or to a

SCADA-system

Alarm type not activated – if you choose not to activate an alarm, no alarm will be generated when an

alarm signal goes active. If this is a signal which forces the pump to stop for ex. a motor protector or a

temperature, it can be a little confusing that a pump has stopped but that there is no alarm. If you have

configured an input this way you have to go to “alarm status” to find out why the pump has stopped.

DI1 P1 Not in Auto

DI2 P1 Motor protector

DI3 P2 Not in Auto

DI4 P2 Motor protector

DI5 Not in use

DI6 Overflow float

DI7 Low level float

DI8 High level float

DI9 Ext.Block/Ovf

DI10 Attendance check / Person alarm

Note! See chapter 5.4.5, page 33

DI1 P1 Not in Auto

DI2 P1 Motor protector

DI3 P2 Not in Auto

DI4 P2 Motor protector

DI5 P3 Not in Auto

DI6 P3 Motor protector

DI7 Low level float

DI8 High level float

DI9 Ext.Block/Ovf

DI10 Attendance check / Person alarm

Note! See chapter 5.4.5, page 33

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 14 (61)

DI 1. P1 Not in auto

A contact from the manual-0-auto switch is used to register when a pump is not in the auto position. When all

pumps are in the auto position the AUTO diode will show a fixed yellow light. If a pump is not in auto position

the Auto diode will show a blinking yellow light and the actual pump will be marked with | 1 | in the information

window.

DI 2. P1 Motor protector

Signal indicates activated motor protection for the pump. This signal does not block the pump as the motor

protector has to be reset manually externally.

DI 3. P2 Not in auto

A contact from the manual-0-auto switch is used to register when a pump is not in the auto position. When all

pumps are in the auto position the AUTO diode will show a fixed yellow light. If a pump is not in auto position

the Auto diode will show a blinking yellow light and the actual pump will be marked with | 1 | in the information

window.

1 . P 1 N o t i n A u t o ►

◄◄

F u n c t i o n

◄◄◄ n o t i n u s e

S i g n a l t y p e

◄◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

▼▲

▼▲

- Here you set if the function is used or not.

- Here you set the signal type NO or NC.

- Here you set if the alarm function shall be used or

not. Yes or No

- Here you set the alarm delay.

▼▲

2 . P 1 M o t o r p r o t . ►

◄◄

F u n c t i o n

◄ ◄ ◄ n o t i n u s e

S i g n a l t y p

◄◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

▼▲

▼▲

- Here you set if the input is used or not.

- Here you set the signal type NO or NC

- Here you set the alarm function : Yes or No

- Here you set the alarm delay.

▼▲

▼▲

▼▲

- Here you set if the function is used or not.

- Here you set the signal type NO or NC.

- Here you set the alarm function Yes or No

- Here you set the alarm delay

▼▲

3 . P 2 N o t i n A u t o ►

◄◄

F u n c t i o n

◄ n o t i n u s e

S i g n a l t y p e

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 15 (61)

DI 4. P2 Motor protector

Signal indicates activated motor protection for the pump. This signal does not block the pump as the motor

protector has to be reset manually externally.

.

DI 5. Not used / P3 Not in Auto

If only two pumps are set in the application setting this input will not be used and you will see “Not in

use” text in the digital input 5 menu.

A contact from the manual-0-auto switches used to register when a pump is not in the auto position. When all

pumps are in the auto position the AUTO diode will show a fixed yellow light. If a pump is not in auto position

the Auto diode will show a flashing yellow light and the actual pump will show with | 1 | in the information

window.

DI 6. Overflow / P3 Motor protector

Depending on if the application is for two pumps, the function for this input is

Overflow input

▼▲

▼▲

- Here you set if the input is used or not.

- Here you set the signal type NO or NC

- Here you set the alarm function : Yes or No

- Here you set the alarm delay.

▼▲

6 . O v e r f l o w ►

◄◄

▼▲

▼▲

- Here you set if the input is used or not.

- Here you set the signal type NO or NC

- Here you set the alarm function Yes or No

- Here you set the alarm delay.

▼▲

▼▲

▼▲

-- Here you set if the input is used or not.

- Here you set the signal type NO or NC

- Here you set the alarm function : Yes or No

- Here you set the alarm delay.

▼▲

F u n c t i o n

◄ n o t i n u s e

S i g n a l t y p e

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

4 . P 2 M o t o r p r o t . ►

◄◄

F u n c t i o n

◄ n o t i n u s e

S i g n a l t y p

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

F u n c t i o n

◄ i n u s e

S i g n a l t y p e

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

5 . P 3 N o t i n A u t o ►

◄◄

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 16 (61)

When used as P3 Motor Protection the signal indicates activated motor protection for the pump. This signal

does not block the pump as the motor protector has to be reset manually.

.

6 . P 3 M o t o r p r o t . ►

◄◄

▼▲

▼▲

- Here you set if the input is used or not.

- Here you set the signal type NO or NC

- Here you set the alarm function Yes or No

- Here you set the alarm delay.

▼▲

F u n c t i o n

◄ n o t i n u s e

S i g n a l t y p e

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 17 (61)

DI 7. Low level float

The low level float is used to signal low level or to stop the pumps if you have activated stop pump function. If

the “stop pump” function is not used, only an alarm is given but the pumps will not stop.

DI 8. High float Overflow

In 2 pump applicatioin thi input is only used for High level float

The high level float is used to signal high level and if the start pump option is activated, to start the pump. If you

don’t activate the “start pump” function only alarm will be given, but not start the pumps.

t

In 3 pump applications this input can be used either as a high float input (as shown above )or as

overflow input

If the input is used as Overflow input input it will measure when the stationis in overflow, number of

overflows and total overflow time

t

Here you set if the input is used or not.

Here you set the signal type NO or NC

Here you set the alarm function Yes or No

Here you set if the pumps are going to be stopped

Yes or No (backup operation or with levelswitch operation).

Here you set the alarm delay to prevent false alarms due to

unstable surface in the pit.

7 . L o w f l o a t ►

◄◄

F u n c t i o n

◄◄◄ i n u s e

S i g n a l t y p e

◄◄◄ N O

▼▲

A l a r m f u n c t i o n

◄◄◄ Y e s

▼▲

S t o p p u m p

◄◄◄ N o

▼▲

A l a r m d e l a y

◄◄◄ 5

▼▲

- Here you set if the input is used or not.

For three pump application you can set the function

as high level float or overflow float.

- Here you set the signal type NO or NC

- Here you set the alarm function : Yes or No

- Start pump: Yes or No (For backup operation or

levelswitch operation).

- Here you set the alarm delay to prevent false

alarms due to ripple on the surface in the pit.

8 . H i g h f l o a t ►

◄◄

F u n c t i o n

◄◄◄ h i g h f l o a t

S i g n a l t y p e

◄◄◄ N O

▼▲

A l a r m f u n c t i o n

◄◄◄ Y e s

▼▲

S t a r t p u m p

◄◄◄ N o

▼▲

A l a r m d e l a y

◄◄◄ 5

▼▲

- Here you set if the input is used or not.

For three pump application you can set the function

as overflow float or not used

-Here you set the signal type NO or NC

- Here you set the alarm function : Yes or No

- Here you set the alarm delay to prevent false

alarms due to ripple on the surface in the pit.

8 . H i g h f l o a t ►

◄◄

F u n c t i o n

◄◄◄ o v e r f l o w

S i g n a l t y p e

◄◄◄ N O

▼▲

A l a r m f u n c t i o n

◄◄◄ Y e s

▼▲

▼▲

A l a r m d e l a y

◄◄◄ 5

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 18 (61)

DI 9. Block / Overflow

For2 and 3 pump applications this input can be used for external blocking of the pumps

External block is a signal input which will stop all pumps when activated with a built in delay between each

pump.

Alternativ

Fot 3 pump applications this input can be used as Overflow input,( if DI8is used for High level float)

If the input is used as Overflow input input it will measure when the stationis in overflow, number of

overflows and total overflow time

Alternativ

DI 10. Attendance check (the settings for this function are made under Station settings \ attendance

check. chapter 5.4.5)

F u n c t i o n

◄◄◄ E x t . B l o c k

9 . B l o c k / O v e r f l ►

◄◄

F u n c t i o n

◄◄◄ p e r s o n a l

1 0 . A t t e n d c h e c k ►

◄◄

See further details in Station settings – Attendance check

S i g n a l t y p e

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

▼▲

▼▲

▼▲

- Here you set if the input is used Ext. Block or not used.

- Here you set the signal type NO or NC

- Here you set the alarm function Yes or No

- Here you set the alarm delay.

▼▲

F u n c t i o n

◄◄◄ O v e r f l o w

9 . B l o c k / O v e r f l ►

◄◄

S i g n a l t y p e

◄◄ N C

A l a r m f u n c t i o n

◄◄◄ N o

A l a r m d e l a y [ s ]

◄◄◄ 1 . 0

▼▲

▼▲

▼▲

- Here you set if the input is used for overflow or not.

- Here you set the signal type NO or NC

- Here you set the alarm function Yes or No

- Here you set the alarm delay.

MANUAL PC-200

Ver. 2.12.xx/10/22/2010-UK

Page 19 (61)

5.2.2 Digital outputs

The pump controller PC-200 has 5 digital relay outputs which handle a max load off 6A at 250

VAC/30 VDC, and 2 open collector outputs 50 mA at 30 VDC. The configuration alternatives for the

digital outputs are to set the signal type i.e. NO or NC signal on each output.

Below you see an overview of the outputs and their predefined functions.

DO 1. P1 Start/Stop

DO 2. P2 Start/Stop

DO 3. P3 Start/Stop

DO 4. Mixer.

DO 5. Not ack. alarm

DO 6. Attendance

DO 7. Modem control

DO1 Pump 1 Start/Stop

DO2 Pump 2 Start/Stop

DO3 Pump 3 Start/Stop

DO4 Mixer.

DO5 Not ackn. Alarm

DO6 Attendance (open collector)

DO7 Modem control (open collector)

1.P 1 S t a r t / S t o p ►

◄◄

S i g n a l t y p e

◄◄◄ NO

2 . P 2 S t a r t / S t o p ►

◄◄

S i g n a l t y p e

◄◄◄ NO

3 . P 3 S t a r t / S t o p ►

◄◄

S i g n a l t y p e

◄◄◄ NO

4 . P 2 S t a r t / S t o p p ►

◄◄

S i g n a l t y p e

◄◄◄ NO

5 . N o t a c k . a l a r m ►

◄◄

S i g n a l t y p e

◄◄◄ NO

6 A t t e n d a n c e ►

◄◄

S i g n a l t y p e

◄◄◄ NO

7 . M o d e m c o n t r . ►

◄◄

S i g n a l t y p e

◄◄◄ NO

The signal type is changed by pressing the OK key and

change between NO and NC with the ▲ key. Confirm with

the OK key

The signal type is changed by pressing the OK key and

change between NO and NC with the ▲ key. Confirm with

the OK key

The signal type is changed by pressing the OK key and

change between NO and NC with the ▲ key. Confirm with

the OK key

The signal type is changed by pressing the OK key and

change between NO and NC with the ▲ key. Confirm with

the OK key

The signal type is changed by pressing the OK key and

change between NO and NC with the ▲ key. Confirm with

the OK key

The signal type is changed by pressing the OK key and

change between NO and NC with the ▲ key. Confirm with

the OK key

The signal type is changed by pressing the OK key and

use the ▲ key to change between NO and NC, confirm with

the OK key.

For automatic switching off /on of the power to the modem

Loading...

Loading...