Drill Master 500X, 750X User Manual

THE DRILL BIT SHARPENER

USER GUIDE

GET SHARP BACK TO WORK

AND GET

⚠ Caution!

To reduce risk of injury, the user must read and understand this instruction

manual before using product. Save these instructions for future reference.

Drill Doctor® Drill Bit Sharpener

Class I - Consumer Product DD500X and DD750X

Transportable motor-operated electric drill bit sharpener

Manufactured by Darex, LLC

Maker of Drill Doctor®, Work Sharp®, Work Sharp Culinary®

and DAREX®

Designed, constructed and certied in accordance with:

IEC 61029-1: 1990 First Edition

EN 61029-1:2009+A11:2010

EN ISO 12100:2010

Additionally in compliance with the applicable

requirements of the following Directives and Standards:

EC Machinery Directive (2006/42/EC)

EC Electromagnetic Compatibility Directive (2004/108/EC)

DC DMF (Dimethylfumarate) Regulation (2009/25/EC)

RoHS2 Directive 2011/65/EC

www.drilldoctor.com 3

Thank you, for purchasing a Drill Doctor

®

. It is sure to

become a valuable tool because you will always have

sharp drill bits before a project, during a project, and after

a project.

As president of this company, I am very proud of the

quality of our products—and I am equally proud of

the great people at Darex® who design and produce

them. If you have questions or need help with your Drill

Doctor®, please contact us and one of our customer

representatives will be there to help. We support what we

build!

This User’s Guide will help you learn to operate your Drill

Doctor quickly & easily. Please visit our website at

www.drilldoctor.com to:

• View instructional videos

• Submit your warranty registration

• Review FAQs

• Contact our service department

Again, thank you for buying a Drill Doctor®.

Now go enjoy its convenience and quality.

Matthew Bernard

President, Darex

®

www.drilldoctor.com4

English ................................................................................................ 4

General Safety Rules ....................................................................... 5

Getting to Know Your Drill Doctor

®

...................................14

Identifying Basic Drill Bits ........................................................15

Anatomy of a Drill Bit ................................................................15

The Drill Doctor® Sharpening Process ...............................15

Choosing Your Drill Bit Point Angle on the

Model DD500X ..........................................................................16

Model DD750X ..........................................................................17

Aligning the Drill Bit ..................................................................17

Sharpening Drill Bits .................................................................19

Identifying Correctly Sharpened Drill Bits .........................21

Split Points ....................................................................................22

Identifying Correctly Split Drill Bits ......................................24

Grit Tube ........................................................................................25

Sharpening Bits of Dierent Lengths, Diameters,

and Types ................................................................................25

Masonry Drill Bits ....................................................................26

Adjusting Chisel and Relief Angles .....................................27

Adjusting the Material Take-O (DD750X only) ............. 29

Questions and Answers ...........................................................29

Drill Doctor

®

Maintenance ....................................................32

Parts and Accessories ...............................................................35

Warranty ........................................................................................36

Original Instructions

English

Contents

www.drilldoctor.com 5

⚠WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the

risk of fire, electric shock and personal injury. Read all

these instructions before attempting to operate this

product and save these instructions.

⚠WARNING! CHOKING HAZARD!

Small Parts – Not for children under 3-yrs.

Installation/Assembly

The Drill Doctor ® is completely assembled.

Carefully unpack the power tool and set it on the table. Check to

see that no damage has occurred in shipment. Check all packing

materials to be sure that all parts are present. See “Getting to

know your Drill Doctor

®

” for a parts indentication diagram.

⚠WARNING! Connect to properly wired (115V or 230V, as

applicable) outlet, or electrical shock may occur.

1. Work Area Safety:

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control. Do

not let persons not involved in the work touch the tool or

power cord.

d) Make workshop kid proof with padlocks, master switches

or by removing starter keys.

e) Securely place this tool on your workbench during use.

2. Electrical Safety:

⚠ DANGER! Electrical shock can kill! Read,

understand and follow ALL safety instructions.

⚠ WARNING! Do not expose power tools to rain

or wet conditions. Water entering a power tool will

increase the risk of electric shock.

General Safety Rules

www.drilldoctor.com6

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is earthed or

grounded.

c) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Never yank the cord

to disconnect it from the socket. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

d) Use proper extension cord. Use only 3-wire extension

cords that have 3-prong plugs and 3-pole receptacles that

accept the power tool’s plug. Make sure your extension cord

is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product

will draw. Use marked outdoor extension cord leads when

the tool is used outdoors.

e) Disconnect tools. Always disconnect your power tool when

cleaning, inspecting, and changing accessories. When not in

use, disconnect from the power supply. Never touch internal

parts of the sharpener when it is turned on or plugged in.

The rotating diamond wheel can result in injury.

f) Grounding instructions. In the event of a malfunction or

breakdown, grounding provides a path of least resistance for

electric current to reduce risk of electric shock. This power

tool is equipped with an electric cord having an equipmentgrounding conductor and grounding plug. Do not modify

the plug provided. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance

with all codes and ordinances. Improper connection of

the equipment-grounding conductor can result in a risk of

electric shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect

the equipment-grounding conductor to the live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded. Repair

or replace damaged or worn cord immediately.

g) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

www.drilldoctor.com 7

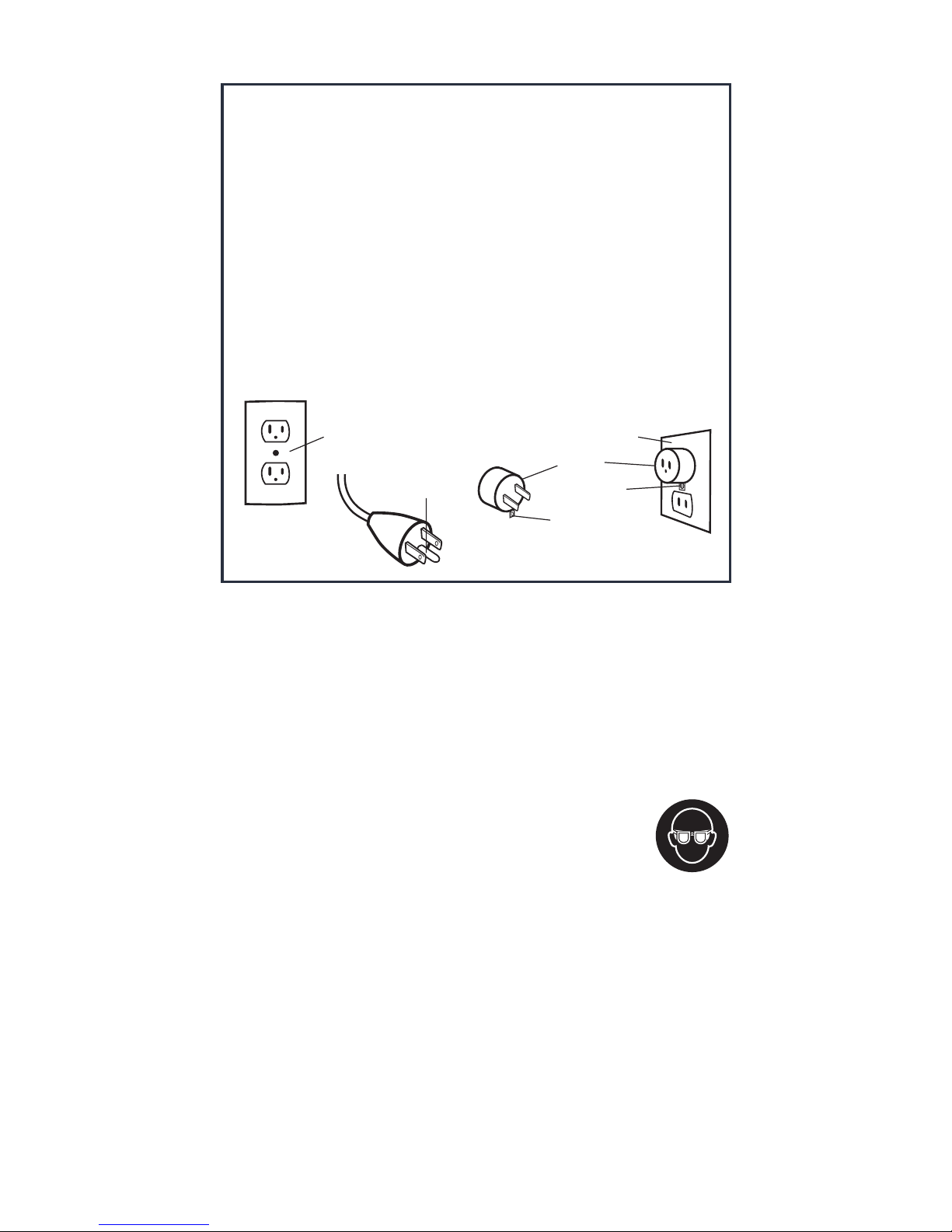

Fig. A

Fig. C

Cover of Grounded

Outlet Box

Cover of Grounded

Outlet Box

Grounding Pin

Grounding Means

Metal Screw

Adapter

Fig. D

Fig. B

USA Only

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in Fig. A. It has a grounding

plug that looks like the one in Fig. B. A temporary adapter,

which looks like the adapter illustrated in Fig. C & Fig. D, may

be used to connect this plug to a 2-pole receptacle as shown

in Fig. D if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

3. Personal Safety:

Sharpening operations can create hot sparks and metal debris,

loud noises and dust.

a) Stay alert - watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment (PPE).

Always wear eye protection. Protective

equipment such as dust mask, non-skid safety

shoes, hard hat or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Use ear protection during use. Drill Doctor® unit can

generate in excess of 85 dB(A) noise emissions when in

operation.

d) Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source and/

or battery pack, and when picking up or carrying the tool.

Carrying power tools with your finger on the switch, or

energizing power tools that have the switch on invites

accidents.

www.drilldoctor.com8

e) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

f) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations. Nonslip footwear is recommended.

g) Dress properly. Wear closed, non-flammable protective

clothing. Do not wear loose clothing or jewelry. Keep your

hair, clothing and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in moving parts.

h) Secure Work. Use clamps or a vise to hold work when

practical. It’s safer than using your hand and it frees both

hands to operate tool.

4. Power Tool Use and Care

⚠ WARNING! Use recommended accessories. Use the power

tool, accessories, abrasives, and tool bits etc., in accordance

with these instructions, taking into account the working

conditions and the work to be performed. Use of the power tool

for operations different from those intended could result in a

hazardous situation.

⚠ CAUTION! Keep power tools and work space clean for

best performance and safety. Do not let sharpening debris

accumulate on, in, or around the tool. Accumulated fine metal

sharpening debris can be very hot and may present a fire danger

if the machine or your workspace is not properly cleaned and

maintained. Accumulated sharpening debris can also degrade the

life of the tool and cause premature wear on some components. If

sharpening debris has accumulated, do not immediately throw it

into a trash receptacle without ensuring the debris is completely

cool and free of heat. Improperly disposing of the accumulated

sharpening debris may present a fire risk. Do not collect the

sharpening debris during sharpening. This increases the risk of

heat build-up in the debris and the potential for fire.

a) Do not force the power tool or attachment. Use the

correct power tool for your application. Do not force small

tools to do the job of a heavy duty tool. The correct power

tool will do the job better and safer at the rate for which it is

designed.

b) Use the right tool. Do not force tool or attachment to do a

job for which it is not designed.

c) Do not use the power tool if the switch does not turn it

on or off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

d) Never leave tool running unattended – Turn power off.

Do not leave the tool until it comes to a complete stop.

www.drilldoctor.com 9

e) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventative safety measures reduce the risk of

starting the power tool accidentally.

f) Store idle power tools out of reach of children and do

not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power tools

are dangerous in the hands of untrained users.

g) Keep cutting tools sharp and clean for better and safer

performance.

h) Follow instructions for lubricating (if applicable) and for

changing accessories.

i) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged, have

the power tool repaired by an authorized service center

before use. Keep handles dry, clean and free from oil and

grease. Many accidents are caused by poorly maintained

power tools.

j) Inspect tool cord periodically and if damaged have

it repaired by an authorized service center. Inspect

extension cords periodically and repair if damaged.

k) Keep guards in place and in working order. A guard or

other part that is damaged should be properly repaired or

replaced by an authorized service center unless otherwise

indicated in the instruction manual.

l) Never stand on the power tool. Serious injury could

occur if the tool is tipped or if the sharpening edge is

unintentionally contacted.

m) Check damaged parts. Before further use of the tool,

any part that is damaged should be carefully checked to

determine that it will operate properly and perform its

intended function. Check the alignment of moving parts,

binding of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation. Any

damaged part, including the switch, should be properly

repaired or replaced by an authorized service center.

n) Do not use if the grinding wheel is damaged. Use only

grinding wheels recommended by Drill Doctor

®

www.drilldoctor.com10

5. Service

a) Have your tool serviced by a qualified repair person

using only identical replacement parts. This will ensure

that the safety of the power tool is maintained.

b) Do not dispose of electrical products with

household waste. Waste electrical products

should not be disposed of with household

waste. Please recycle where facilities exist.

Check with your local authority or retailer for

recycling advice.

Specic Safety Rules

⚠ WARNING! ALWAYS use proper safety glasses. Everyday

eyeglasses are NOT safety glasses. Also use face or dust mask if

operation is dusty. ALWAYS wear certified safety equipment:

• ANSI Z87.1 eye protections (CAN/CSA Z94.3)

• ANSI 512.6 (53.19) hearing protection

• NIO5H/OSHA respiratory protection

⚠ WARNING! Use of this tool can generate and/or disperse

dust, which may cause serious permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles

away from face and body.

For Service in the USA, Contact:

Darex, LLC

PO Box 730

210 E Hersey St

Ashland OR 97520

Phone: (800) 418-1439

Fax: (541) 552-1377

Email: info@darex.com

www.drilldoctor.com 11

12

12

14

0

115V

0-25

(0-7.6m)

101-200

(30.4-60.9m)

51-100

(15.2-30.4m)

26-50

(7.6-15.2m)

Volts

6

10

10 12

12

Not Recommended

Ampere Rating

Minimum Gauge Cord Sets

Total Length of Cord in Feet

Save These Instructions

Not More Than

More Than

American Wire Gauge

12 16

16

1618

1618

16

14

14

14

16

6

Motor

Be sure your power supply agrees with the nameplate marking.

115 Volts means your tool will only operate on standard 60HZ

household power. 230 Volts means your tool will only operate

on standard 50 HZ household power. Do not operate AC tools

on DC. Lower voltage will cause loss of power and can result in

overheating. Using a machine on an unmatched power source

voids your warranty.

Extension Cords

Make sure your extension cord is in good condition. When using

an extension cord, be sure to use on heavy enough to carry the

current voltage resulting in loss of power and overheating. The

Drill Doctor® has a 1.75 ampere rating. The following table shows

the correct size to use depending on cord length and nameplate

ampere rating. If in doubt use the next heavier gauge. The smaller

the gauge number the heavier the cord.

Loading...

Loading...