Page 1

Patent

3,952,459

Brochure Includes:

• Set-up Instructions

• Operating Instructions

• Parts List

• Fundamentals of Drill Sharpening

Page 2

Accurately

Sharpens most drills bits.

Now, with this one low-cost, simple machine, several different types of drill

bits can be quickly sharpened: two, three and four fluted drill bits, Flat

Bottom and Core Drills. Precision work!

Quickly

With just a little experience, anyone can become an expert.

It takes only a few minutes to set up and have ready for operation this

Lisle 91000 Drill Grinder. A few minutes reading ALL OF THE OPERATING

INSTRUCTIONS will ensure the right start. A little practice and most every

machine shop can be doing all its own sharpening the first day. Comes

complete!

Economically

Without a major investment, every plant can own its own Drill Grinder.

The cost of commercial sharpening (to say nothing of the time it takes to get

the work done commercially) plus the rapid increases in the cost of new bits

makes owning and operating a Lisle 9100 Drill Grinder a practical,

money-making investment.

Sharpens Drills

From 1/8" up to 1 1/4" in size.

The Lisle 9100 can handle drill bits as small as 1/8" up to and

including 1 1/4". This machine will properly sharpen bits with

straight or tapered shanks. Correct tolerances for heel clearance,

1 2 3 4 5

6 7 8 9

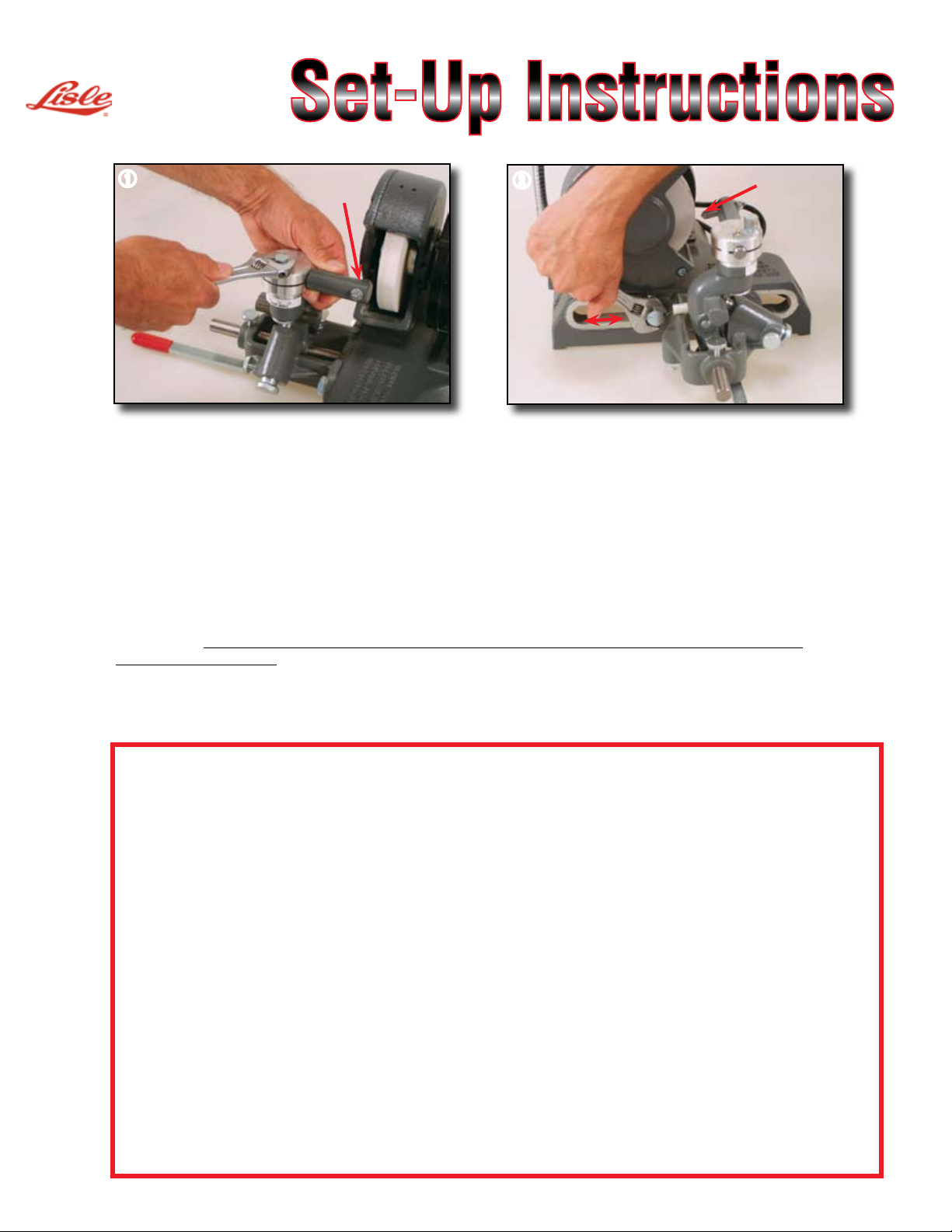

The Lisle Drill Grinder 91000 is assembled at the factory to such an extent that it takes only minutes to set-up

and be ready to operate. HOWEVER, it will pay to read through the set-up and operating instructions on a step

by step basis prior to starting. This will help assure success on the first try and will also make the set-up easier

and avoid the necessity of re-doing any work.

EACH PHOTOGRAPH IN THIS BROCHURE IS NUMBERED FOR QUICK REFERENCE TO SPECIFIC

PROCEDURES, ASSEMBLIES, PARTS AND ADJUSTMENTS WHICH ARE MEANINGFUL TO BOTH SET-UP AND

OPERATION.

chisel or web angle, and cutting lip angle are locked into position

if properly set-up. Adjustments for various types and sizes of bits

are quickly and easily made. No guess work or estimates.

1. 1/8" Standard Drill, 2. 1/4" Low helix Drill, 3. Standard 1/2" Drill,

4. 1/4" High helix Drill, 5. 4 Fluted Core Drill, 6. 3 Fluted Core Drill,

7. Flat Bottom Drill, 8. Standard 1/4" Drill, 9. 1 1/4" Standard 2

Fluted Drill.

Page 3

Set-Up Instructions

q

A

1. If possible, bolt Drill Grinder to left hand corner of work bench.

2. Install protective plastic shield with screws provided. Helps meet OSHA standards.

3. FOR FEED BRACKET ADJUSTMENT: (See photo 1) First, release the feed screw (A) until the rocker

arm is in the full relaxed position. Align the marks on the diamond dresser and split bushing before

tightening in place. Slide the feed bracket assembly (See photo 2) until the diamond is

approxmately 1/4" from the stone. Tighten feed bracket in place.

4. TO DRESS THE GRINDING WHEEL: Plug motor into a three wire ground outlet and turn motor on.

CAUTION! When dressing the stone or drill sharpening it is recommended that eye protection be

worn to prevent personal injury. Advance feed screw until the diamond just touches the grinding

wheel. Loosen the cross-feed lock screw (See photo 14) and move the cross-feed lever to work the

diamond back and forth across the grinding wheel.

NOTE: As the grinding wheel becomes unevenly worn from use, regular dressing will assure quality

sharpening. Also, regular adjustment of the feed bracket to the reduced size of grinding wheel is a

necessity. (See item 3)

Diamond

Dresser

w

1/4"

If the grinding wheel housing becomes loose, tighten the two (X) set screws. (See Photo 3)

AFTER MASTERING SET-UP FOR STANDARD TWO FLUTED DRILLS, APPLY THESE VARIATIONS FOR OTHER

TYPES DRILLS.

Sharpening Special Purpose Drills

(See Photo 13)

Flat Bottom (180 degree included Angle) -- First, split bushing should be set at 180 degrees (See

operating instructions “I”). Loosen the two bolts holding the feed bracket and move it as far forward as

possible. Position the drill in the drill holder as you would for grinding a standard drill point. Place the drill

holder in the split bushing and advance the feed screw. As the drill approaches the stone, move the crossfeed lock screw. Grind the first lip in the normal manner. Set the stop sleeve, back up the feed screw, rotate

the drill and grind the second lip.

Core Drill (3 Fluted) -- Position drill in holder with first lip parallel to the center line of the “V” of the drill

holder. Do not use set-up line on stop lip for this grind. Move stop lip to margin of drill and tighten. Proceed to

grind first lip as you would on a two fluted drill. Set the stop sleeve, back up the feed screw, rotate the drill

and grind the second lip. Continue until all cutting lips have been ground.

Core Drill (4 Fluted) -- Position drill in holder with the first lip parallel to the center line of the “V” (same as 3

fluted) (See photo 9). Do not use set-up line on stop lip for this grind. Move stop lip to margin of drill and tighten.

NOTE: The grinding procedure on this drill is different because of the closeness of the cutting lips. Place drill

holder in split-bushing and position the holder so that the axis of the drill is at an angle of about 10 degrees

below the horizontal (about 2" drop at the end of the drill holder shaft) before tightening in place (See photo

13). Advance the feed screw until first lip just touches the grinding stone. Then with quick motions, advance

the feed screw slightly and back it off to avoid burning. This can best be done by rocking the feed screw

back and forth. Continue until the first lip is ground, then quickly tighten the stop sleeve and back off the

feed screw. Examine the clearance angle on the lip which was just sharpened. If the clearance angle looks

acceptable, then proceed to grind the remaining lips in the same manner. If the clearance angle is not

acceptable, then the angle of the drill with the horizontal will have to be changed. Decreasing the angle will

decrease the clearance and increasing the angle will increase the clearance.

Page 4

Operating Instructions

e

r

Loosen to

Set

Split Bushing

B

C

Set Screws X

Angle

Setting Clearance Angle

D

I. To obtain desired point angle:

The split bushing on the rocker arm is

calibrated in degrees and can be

adjusted to sharpen drills at various

included point angles. Loosen bolt

under rocker arm which holds the split

bushing in place and set at desired

angle (normally 118 degrees). Tighten

bolt (See photo 3).

II. To set clearance angle: Loosen bolt

holding the pivot shaft (B). Then

loosen the screw holding the lip

clearance adjuster (C) and align the

mark with the desired clearance angle

(D) (See photo 4). The center mark

gives 12 degrees clearance and is

best for average drilling. The top

position gives 18 degrees and the

bottom position gives 6 degrees

clearance. Now, tighten the screw

(But not the bolt).

t

Setting for

Drill Size

III. To set for drill size: Align the mark on

the pivot shaft assembly (See photo

5) with the mark corresponding to the

diameter of the drill to be sharpened.

Now, tighten the assembly in place.

Page 5

Operating Instructions

IV. To clamp drill in drill holder: First,

place magnet extension gauge on

stop lip as shown (See photo 6). The

magnet gauge is made so that one

side of the magnet extends 3/32 of an

inch and the other side 1/8 of an inch.

Use the shorter 3/32 inch side for drills

up to 3/8 inch diameter and the longer

1/8 inch side for drills larger than 3/8

inch diameter. Place drill in clamp and

move the drill toward the magnet

gauge until the edge of the cutting

lip just touches the bottom of the

gauge. Tighten drill clamp.

Contact Point

y

Magnet Gauge

u i

Drill Clamp

V. To adjust end-stop and V-block: Slide

end-stop along the square shaft until it

rests firmly against the drill. Then move

the V-block so that it helps support the

shank of the drill (See photo 7). The

small rod on the end-stop is used when

sharpening short drills by reversing

end-stop on square shaft (See photo 8).

VI. To set drill rotation: (See photo 9)

Loosen the top screw (in the curved slot)

on the stop lip and turn clockwise as far

as it will pivot. Then loosen the drill clamp

just enough so that the drill may be

rotated. Turn the drill until the first cutting

lip is parallel with the scribe line (See

dotted line) on the stop lip. The cutting

lip and scribe line will not line up, but will

be parallel. Tighten drill clamp. Second

screw is for height adjustment depending

on size of drill.

‘V’ Block

End Stop

o

Setting Drill Rotation

Stop Lip

Drill

Clamp

Small Rod for short

or small Drill bits

Loosen Top Screw &

rotate stop lip cloclwise

Groove

Page 6

Operating Instructions

1) 1!

Setting Stop Lip

Loosen for

up & down

movement

1@

1#

15˚

4"

VII. To set stop lip: Move the stop lip

counter clockwise so that the edge just

catches the margin of the drill flute.

Note that the stop lip can move up and

down as well as in and out. Now,

tighten stop lip in place (See photo

10). If you have done everything

correctly, the cutting lip should be at a

15˚ angle from the pivot shaft as shown

in picture 11.

VIII. To mount drill holder in split

bushing: Slide drill holder assembly

into split bushing (just as you did the

diamond dresser) (See photo 1) until

groove in pivot shaft engages the

spring loaded plunger. Tighten the

bushing just enough so that the drill

holder assembly can freely pivot in the

bushing.

IX. To sharpen the first lip of the drill:

Loosen stop sleeve lock screw before

sharpening first lip so that the stop

sleeve can slide back against the feed

screw (See photo 14). Grasp the drill

holder with your right hand and move

the drill up and down (approximately

two times per second) as you advance

the feed screw with your left hand

(See photo 12). Slowly advance the

feed screw until the first lip is

sharpened.

X. To set the stop sleeve: Tighten stop

sleeve lock screw after sharpening the

first lip. By doing this, you will be

able to grind the second drill lip

exactly the same as the first lip. Turn

the feed screw again to be sure that

there is no slack between the feed

screw and the stop sleeve. Move the

drill holder up and down a few more

times in case any movement has taken

place.

XI. Preparing for second or additional

lips: Back off the feed screw a few

turns and shut off the motor. Loosen

the drill clamp slightly and rotate the

drill until the second lip is tight against

the stop lip. Keep the drill tight against

the stop lip and end stop as you

retighten the drill clamp.

XII. To sharpen second lip: Advance

feed screw following same procedure

as in “Paragraph IX: To sharpen the

first lip of the drill”; until stopped by the

pre-set stop sleeve. Proceed with all

lips in the same manner. Always turn

off motor to remove drill or drill

holder assembly.

Page 7

1$

Page 8

Fundamentals of Drill

Sharpening

Before sharpening a drill bit, it is important that one be familiar with basic

drill terminology and the fundamentals of drill sharpening. Figure 1 below shows

some of the basic terminology related to a standard twist drill.

A properly sharpened drill is one where the cutting edges (lips) are sharp,

equal in length and have adequate clearance behind them. This clearance is

properly referred to as lip clearance.

In Figure 2, the two cutting lips are shown as A1 and A2. The

surfaces behind the cutting lips are shown as B1 and B2.

If the surfaces B1 and B2 are higher than the cutting lips, then

the cutting lips will not contact the work and the drill will not cut.

Figure 3 shows examples of drills with correct and incorrect

lip clearance.

LISLE CORPORATION, CLARINDA, IOWA 51632 712/542-5101 FAX : 712/542-6591 www.lislecorp.com

© 2005 Lisle Corporation Form DG-05 Printed in U.S.A.

900290.86

Loading...

Loading...