Page 1

WARNING

Owner’s Manual

Revolution LGR Dehumidifier

#613 - 115V

MANUFACTURED BY DRI-EAZ PRODUCTS, INC. FOR SERVPRO INDUSTRIES, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Phone: 800-932-3030 Fax: 360-757-7950 http://Revo.DriEaz.com

The Dri-Eaz® Revolution LGR Dehumidifier reduces humidity in enclosed environments by removing water vapor from the air. The Revolution is ideal for water damage restoration, structural drying, construction, and many other applications requi ring temporary, high-performance dehumidification.

Patents: http://www.LBpatents.com

READ AND SAVE THESE INSTRUCTIONS

Read and understand manual before operating.

WARNING! Do not alter or modify your Revolution in

any way. Use only replacement parts authorized by

Dri-Eaz Products, Inc. Modifications or use of unapproved parts could create a hazard and will void

your warranty. Contact your authorize d Dri-Eaz distributor for assistance.

WARNING! Electric shock hazard, rotating fan, hot

surface hazards. Unplug unit before opening cover

for cleaning or servicing.

WARNING! Unit must be grounded.

• Keep motor and wiring dry. Keep out of standing water and do not install in area likely to be subject to

water intrusion. Do not expose to rain, water or

snow.

• Insert three-prong plug on power cord into a match-

ing electrically grounded ou tlet. Do not us e adapt er .

Never cut off third prong.

• Do not use an extension cord.

• To reduce the risk of fire or electric shock, do not

use this unit with any solid-state speed control device.

FIRE HAZARD

• Keep away from open flames and heat sources.

07-01897D #613 (F413-SP) Warranty 07-00420 1 Dri-Eaz Products, Inc.

• Do not use or store where vapors from gasoline, solvents, thinners or other flammable materials may be

present.

WARNING! Unplug unit before cleaning or servicing.

• Turn off unit and unplug before lifting or moving.

• Handle the unit carefully. Always operate the unit on

a stable, level surface. Do not drop, throw, or place

where it could fall. Rough treatment can damage the

unit, and may create a hazardous condition or void

the warranty.

• Inspect the power cord before use. If cord is dam-

aged, do not use. Always grasp the plug (not the

cord) to unplug.

• The unit must be operated on a 115V/60 Hz circuit

protected by a Ground Fault Circuit Interrupter

(GFCI) device.

• Do not attempt to repair the unit. For authorized ser-

vice options, contact SERVPRO

at 866-885-6833 or email rma@servpronet.com.

®

RMA Department

BEFORE YOU BEGIN

Warranty registration

To process a warranty or repair claim, just click the

“RMA/ Warranty Form” listed under the “Products” tab

on the ServproNET

Equipment page on ServproNET.

You may contact the SERVPRO

phone at 866-885-6833 or via email at

rma@servpronet.com.

To expedite the warranty claim process, please have the

following:

• Equipment model number.

• Serial number.

• Usage hours (if applicable).

When Franchises purchase equipment from Servpro

Industries, Inc., unit date of purchase and serial numbers

are recorded on the invoice. As part of the Servpro In-

®

home page or it is also found at the

®

RMA Department by

Page 2

dustries, Inc. RMA/Warranty program, proof of purchase

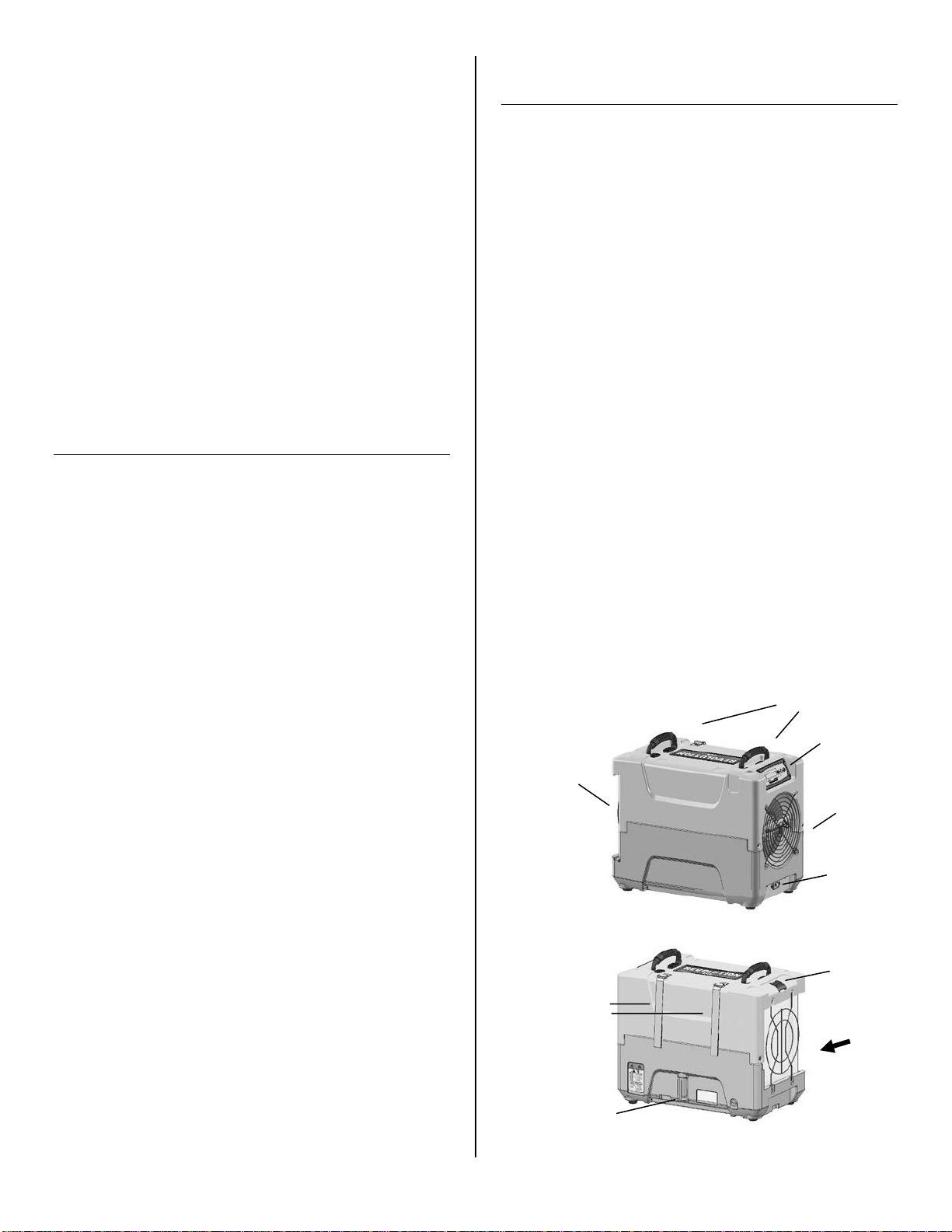

Carry handles

Fig. A: Parts Identification

Condensate

connect

Air inlet

Control

Remove/Insert

Air outlet

Power

socket

Cord and

Temp/RH

sensor

and equipment warranty records are added to the database. This service saves Franchisees time and resources spent attempting to determine warranty coverage for equipment.

After receipt of the completed Warranty/RMA Request

Form, an RMA Coordinator will check warranty status on

any listed equipment prior to submitting the claim information to the vendor(s).

If the unit is covered under warranty, the RMA Coordinator will communicate the repair and return process.

If equipment is not covered under warranty, the vendor(s) will provide a competitive repair estimate prior to

completing any non-warranty repairs. The RMA Coordinator will present repair options and receive Franchise

approval prior to authorizing non-warranty repairs.

The SERVPRO RMA Department is here to serve you!

INTRODUCTION

NOTICE: Some assembly required before use. Follow

instructions under “Controls and Operating Instructions,”

left.

The Revolution Dehumidifier reduc es humidity in enclosed structural environments by removing water vapor

from the air. With proper use, the Revolution can help to

dry out damp structural materials, insulation, and contents, and maintain a healthy level of humidity. Using the

Revolution may also prevent secondary damage caused

by high humidity.

CONTROLS AND OPERATING INSTRUCTIONS

Set unit upright

NOTICE: Always store, transport, and use the unit in

a horizontal position. If the unit is ever placed in a

vertical position, return it to the horizontal position

and let it stand for at least 30 minutes befor e turning

it on.

Positioning a Dehumidifier

For best results, operate your dehumidifiers in an enclosed area. Close all doors and windows that open to

the outside to maximize water removal efficiency. Place

your dehumidifier away from obstructions, and keep it

away from anything that could block airflow into and out

of the unit. For more information about creating an optimum drying environment, contact Dri-Eaz at

800-932-3030.

Set up drain hose

The Revolution condensate pump connects to a plastic

drainage hose. This hose is equipped with a quickconnect fitting for quick attachment to the provided 40 ft.

(12 m) drain hose. Unwrap the entire hose and place the

unattached end in a sink, drain, bucket or outdoors –

anywhere that water can drain out safel y. If you use a

bucket or other container for water collection, check it

regularly to prevent overflows.

How the Revolution works

The Revolution refrigerant dehum idif ier uses a fan to

draw moist air in and condenses it into water that collects in a tray and is automatically pumped out through a

drain hose. The unit can be set to operate continuously

or the user may select Humidistat Mode. In Humidistat

Mode, the Revolution will turn on and off automatically to

maintain the inlet humidity level the user has selected.

Features:

• Industrial-quality dehumidifier removes up to 134

pints (63 liters) of water per day.

• Automatic humidistat to set and maintain desired

humidity leve l.

• Recessed feet indents ensure secure stacking of up

to three Revolution units for storage and transport.

• Designed for convenient stacking and transporting

on a handtruck.

• Recessed handles for easy positioning in confined

spaces.

• Quiet operation and low power consumption.

hose storage

wraps.

drain quick-

panel

air filter here.

07-01897D #613 (F413-SP) Warranty 07-00420 2 Dri-Eaz Products, Inc.

Page 3

ON/OFF

DISPLAY

DISPLAY

MENU SEPURGE PUMP

NOTICE: Uncoil and straighten the entire dra in hose. Do

ON/OFF

Press and release to turn unit on

or off.

DISPLAY MENU

Press to select next item in menu.

Menu item will show in display.

MENU SELECTION /

UP KEY

Press to toggle or select values in

menu displayed.

PURGE PUMP

Press and release to start purge.

not leave any part of the hose coiled and do not place

the end of the hose higher than 20 ft. (6 m) above the

bottom of the unit. Also check for kinks or other obstructions that might restrict the flow of water. Obstructions

may cause a water backup and result in overflows.

Note that only menu items followed by a greater-than

symbol ( > ) may be adjusted.

All settings and modes are discussed in detail in Control

Panel Guide, beginning on p. 5.

Error messages

Plug in electrical cord

The Revolution shou ld be plug ged int o a GFCI -protected

115 volt outlet rated for at least 15

amps. Always plug

the cord firmly into the unit first, and then plug the other

end into a suitable outlet.

Startup display and normal display modes

When unit is first plugged in to AC power, the control

panel display will briefly cycle through a series of

readouts. This is part of the unit’s self-diagnosis procedure and no user intervention is required.

To turn the unit on, press ON/OFF.

User Settings Menu

A number of display settings ma y be changed by the

user. System information can also be displayed. These

items are accessed by pressing

Each press of the key will display the next parameter.

When you reach the parameter you wish to adjust, press

MENU SELECTION to increase the val ue. Pres s

DISPLAY MENU again to accept the setting and re-start

the display cycle. If no keys are selected for 5 minutes

the display will automatically reset and return to the

normal display mode.

CONTROL PANEL

DISPLAY MENU.

If the Revolution onboard diagnostics discover a problem, the unit will display an error message. See “System

Messages,” p. 11 for an explanation of each message.

TRANSPORTATION AND STORAGE

NOTICE: Handle the unit carefully. Do not drop, throw,

or place the unit where it could fall. Rough treatment can

damage this equipment and may create a hazardous

condition or void warrant y.

• Do not expose the control panel to moisture, snow

or rain.

• Protect from freezing.

• Store and transp ort sec urel y to avoid an y dam aging

impact to internal parts.

• Secure during transport to prevent sliding and pos-

sible injury to vehicle occupants.

AT THE END OF THE JOB

To reduce the possibility of drips when moving the unit,

follow these additional steps to ensure that all water is

removed from the unit.

NOTICE: To ensure the condensate tank empties completely while purging, make sure the unit is positioned

horizontally on a flat surface.

1. If the unit is in a defrost cycle, wait until the unit has

returned to normal operating mode before proceeding.

To check, review the control panel. The control panel will

show one of the following:

07-01897D #613 (F413-SP) Warranty 07-00420 3 Dri-Eaz Products, Inc.

MENU

Display will count down seconds

remaining until purge is complete.

LECTION /

UP KEY

Defrost in progress:

UNIT ON 00 HRS

DEFROST XX

Display mode when unit is in defrost mode. XX indicates

the minutes remaining on the defrost cycle.

Shutdown Sequence

WAIT FOR

DEFROST XX

Display mode when unit is in defrost and is powered

down by the user. Unit will complete the defros t cycle to

remove any built-up ice and then purge the pump. XX

indicates the minutes remaining on the defrost cycle.

Normal Display:

UNIT ON 00 HRS

INLET XX° F

Wait until the control shows the normal display before

proceeding.

2. Gently rock the machine to ensure any water remaining on interior surfaces falls into the sump area.

Page 4

3. Press the PURGE key. When the purge cycle is

complete, turn the unit off.

4. Remove the external drain hose, drain it carefully, coil

it and secure it with one of the Velcro straps provided on

the side of the unit.

5. Unplug power cord from power supply and from base

of the machine, coil neatly, coil it and secure it with one

of the Velcro straps provided on the side of the unit. (see

Fig. A).

07-01897D #613 (F413-SP) Warranty 07-00420 4 Dri-Eaz Products, Inc.

Page 5

CONTROL PANEL GUIDE

Button Functions

ON/OFF. After plugging in the unit, the display will show

the word “OFF”. Press

When the machine is turned on, the display normally reads

NOTE: If the unit was previously unplugged or otherwise

lost power prior to turning the unit off, the display will show

OFF / POWER FAILURE. Press

clear this message.

Note that the second line of the display cycles between

inlet temperatures and %RH values.

In some conditions the unit will perform a numeral countdown when you first plug it it. The countdown will range up

to maximum of 60 seconds, and will count down to zero

before starting the compressor. Do not press any buttons

until the unit has completed the delay countdown and displays the “Unit On” message shown above. NOTE: If no

compressor delay countdown is displayed, a delay is not

necessary and the machine will begin operation immediately.

ON/OFF to turn the unit on.

MENU SELECTION to

DISPLAY MENU. Press repeatedly to cycle through the

display of additional dehumidifier conditions and user defined settings. This includes JOB HOURS>, INLET OUTLET, HUMIDISTAT MODE>, HUMIDISTAT SETPOINT>,

TEMP UNITS>, LANGUAGE>, COIL TEMP, SENSOR ID>

(this function is not used in the Revolution), and

COMPRSSR CURRENT.

Menu items marked by a caret (>) may be set by the users

using the MENU SELECTION key. See below.

To return to the main menu, press the

once.

ON/OFF key

MENU SELECTION. Press to change the values of any

of the User Defined Menu items displayed with a caret (>).

To return to the main menu, press the

once.

See User Settings Menu (below) for details.

ON/OFF key

07-01897D #613 (F413-SP) Warranty 07-00420 5 Dri-Eaz Products, Inc.

Page 6

PURGE. Press to empty water from the condensate

MENU.

pump reservoir. The display will read PUMP PURGING

with a numeral countdown. NOTE: During normal operation, the pump purges automatically every ten minutes for

25 seconds, or whenever the reservoir is full.

The PURGE function may be used at any time the unit is

connected to AC power.

User Defined Menu Items

The first line of the display shows the total number of hours

the unit has been in operation. This value may be reset to

zero to track job hours (see “Job Hours Reset” below). The

second line of the display alternates between inlet temperature and inlet RH.

Note: If no keys are selected for 20 seconds the display will

automatically reset and return to the normal display mode.

To move to the next item in the menu, press DISPLAY

To reset job hours to zero, press MENU SELECTON.

To move to the next item in the menu, press

DISPLAY MENU.

The display shows total unit operating hours. This value

cannot be reset.

To move to the next item in the menu, press

DISPLAY MENU.

07-01897D #613 (F413-SP) Warranty 07-00420 6 Dri-Eaz Products, Inc.

Page 7

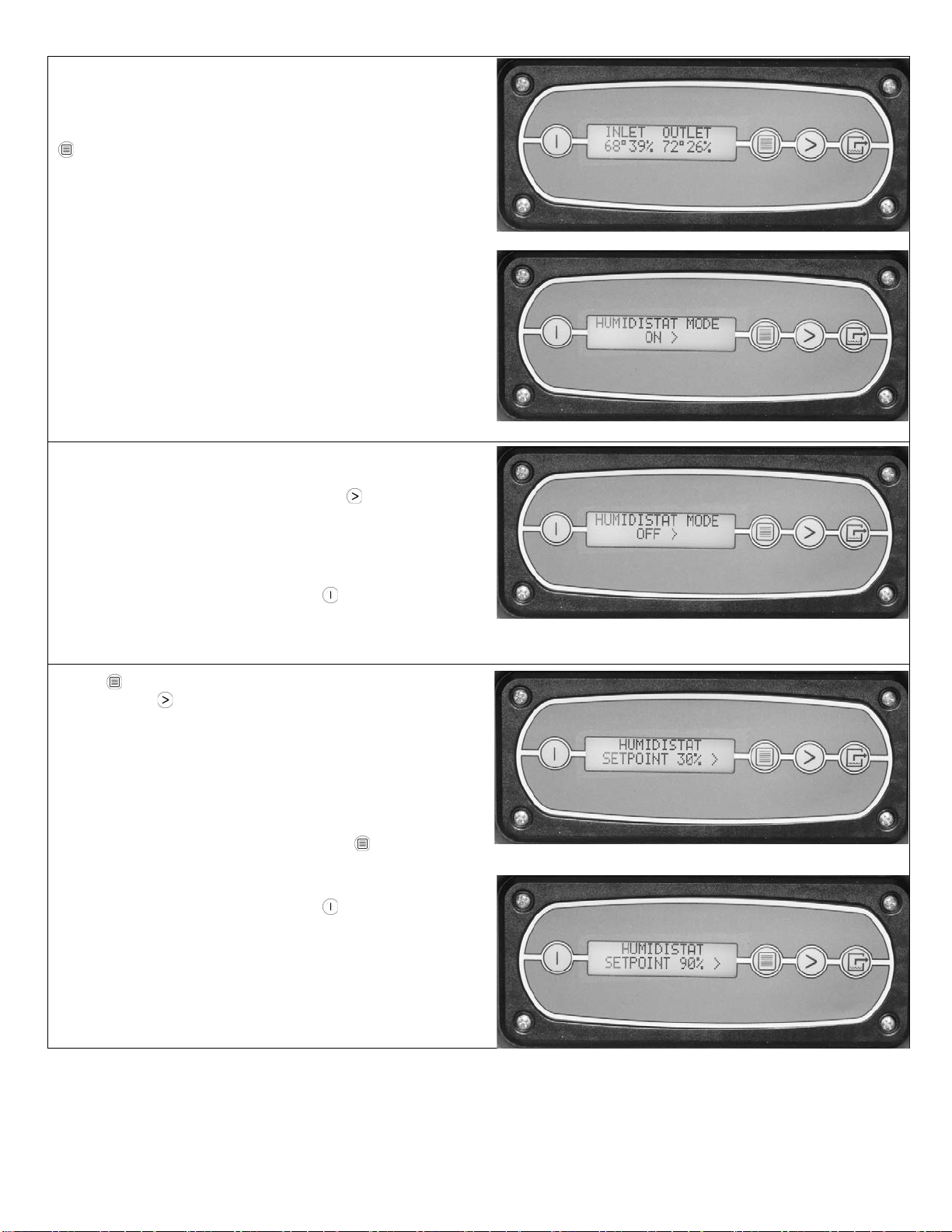

The display shows the current temperature and RH of inlet

and outlet. This item may not be reset.

To move to the next item in the menu, press

DISPLAY MENU.

HUMIDISTAT MODE

To turn the humidistat mode ON, press MENU

SELECTON. The unit will maintain the humidistat setpoint.

To change the setpoint, see the next frame below.

To return to the main menu, press the

once.

ON/OFF key

Press DISPLAY MENU to see the current setpoint.

Each press of MENU SELECTON increases the

setpoint by 5% increments, cycling through 90%RH and

starting again at 30%RH.

When the desired setpoint is shown, press DISPLAY

MENU to set and move to the next menu item.

To return to the main menu, press the

once.

ON/OFF key

07-01897D #613 (F413-SP) Warranty 07-00420 7 Dri-Eaz Products, Inc.

Page 8

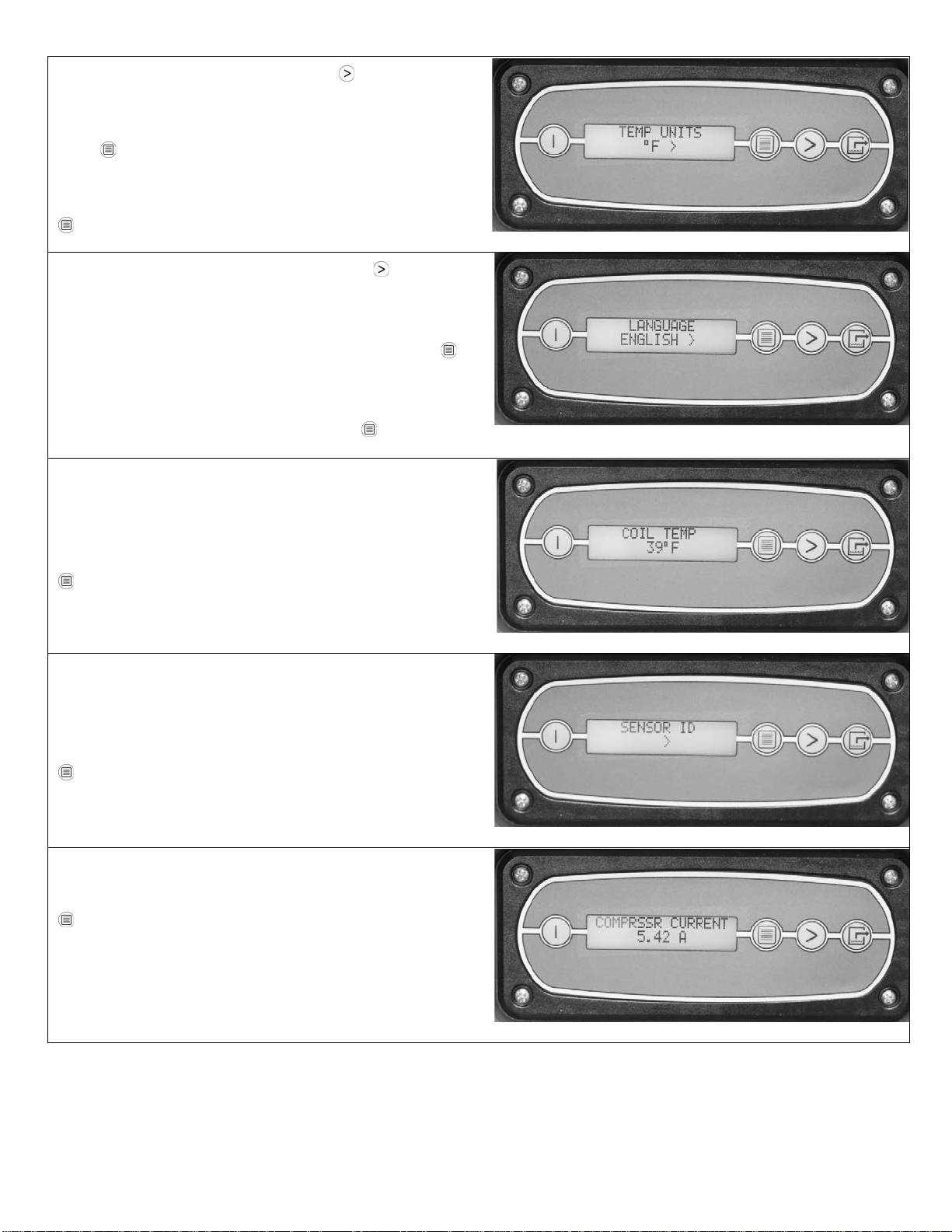

Shows current temperature scale. Press MENU

MENU.

SELECTON to select Fahrenheit or Centigrade scale.

When the temperature scale you wish to use is displayed,

press

DISPLAY MENU to select it and move to the next

menu item.

To move to the next item in the menu, press

DISPLAY MENU.

Shows current display panel langua ge. Pres s MENU

SELECTON to select Spanish, German, French or Eng-

lish.

When the language you wish to use is displayed, press

DISPLAY MENU to select it and move to the next menu

item.

To move to the next item in the menu press DISPLAY

Shows the current cold (evaporator) coil temperature in

the selected temperature scale. This value cannot be

changed.

To move to the next item in the menu, press

DISPLAY MENU.

The SENSOR ID menu item and associated submenus

(SENSOR TYPE, SENSOR CFG REV, and SENSOR

REV) are not used in the Revolution.

To move to the next item in the menu, press

DISPLAY MENU.

Shows compressor current draw in amps.

To move to the next item in the menu, press

DISPLAY MENU.

07-01897D #613 (F413-SP) Warranty 07-00420 8 Dri-Eaz Products, Inc.

Page 9

You have now reached the end of the User Setting Menu.

Remove the 4 screws

Fig. B: Disassembly for Cleaning

The unit will now show the default displa y.

NOTE: When in Humidistat mode, the unit will display HUMIDISTAT on the top line during normal operation rather

than UNIT ON 0.0 HOURS.

MAINTENANCE SCHEDULE

Refer to the SERVPRO Operations and Maintenance

Guide for helpful pictures and detailed instructions.

WARNING! ELECTRIC SHOCK HAZARD. Unplug unit

before cleaning or servicing.

WARNING: Risk of dust and contaminants exposure.

Use of respirator mask and gloves is recommended. If

unit has been exposed to potentially dangerous contaminants, clean thoroughly and sanitize before reuse.

NOTICE: The unit is fitted with sensitive electronic sensors. Protect the sensors and their lead wires from damage and do not expose them to water or cleaning solution.

The following tools and supplies are needed to

complete the maintenance procedures described in

this manual:

Philips screwdriver

10 mm wrench

6 mm hex bit

¼ in. nut driver

Cleaning cloths

HEPA vacuum cleaner with soft brush nozzle and

crevice nozzle.

Recommended

Cordless drill, small knife, small-jaw pliers, coil cleaning solution, rotomolded housing cleaning solution.

from housing and 2

top screws each from

inlet and outlet grills

and lift off cover.

Monthly

Inspect coils. Clean when dust accumulation is visible.

In normal use, dust can accumulate and can restrict airflow, reducing performance and causing the unit to overheat. Use a vacuum cleaner with a brush tool and a soft

cloth to remove any debris. Take care not to damage

any interior components.

To maintain appearance, wipe interior and exterior surfaces with a damp cloth. For deep cleaning and a lasting, protective shine, use an automotive int erior cleaner.

For your convenience, a Dehumidifier Maintenance Checklist is provided on p. 13.

Before each use

Inspect the electrical cord for damage. Look for fray-

ing, cuts, etc. Replace the cord if you find any damage.

Inspect, vacuum or replace filter. The Revolution is

provided with a 3M™ HAF High Air Flow filter (part no.

F372). HAF filters may be vacuumed clean and re-

used up to three times before replacement. Use a

HEPA vacuum and brush tool to remove any dust or debris. Do not use compressed air or expose the filter to

any liquids, as may damage the filter.

07-01897D #613 (F413-SP) Warranty 07-00420 9 Dri-Eaz Products, Inc.

Page 10

As Needed

Clean pump check valve and basin. If the unit displays

the message “ER9 PU MP BLO CKED CHECK PUMP &

HOSE”, the pump check valve and pump basin may

need to be cleaned. Remove grills and cover as shown

in Fig. B. Remove screws from pump base and lift out

pump. Wipe out pump basin with a damp cloth. Inspect

the pump base for build-up of debris and clean if needed. Unthread barbed fitting with check valve and rinse

fitting and check valve with clean water. Reins ta ll chec k

valve into barbed fitting and install the barbed fitting into

pump. Do not overtighten. Reinstall pump on base. Reinstall cover and grills. Clean coils. With the cover removed, inspect both coils. If excessive dust and debris is

present, vacuum thoroughly and/or clean with coil cleaner.

ABOUT 3M™ HIGH AIR FLOW FILTERS

HAF filters from 3M provide superior particle retention, resist microbial growth on filter surfaces and allow for maximum

airflow throughout the filter loading cycle. Follow these guidelines to ensure maximum protection for equipment, technicians and the job site:

Replace the HAF filter whenever it has been vacuumed clean and reused three times. HAF filters lose their effectiveness after

three uses.

Replace the HAF filter whenever it has been used on a mold remediation job or otherwise exposed to potentially dangerous

contaminants. Continued use of a contaminated filter risks the spread of contamination.

Do not wash or apply any liquids to the HAF filter. Exposure to liquids will reduce the effectiveness of the electrostatic material.

Do not operate without the HAF filter in place. Do not operate the unit with any other filter type. Incorrect filtration will reduce

unit efficiency and can cause damage to the unit.

07-01897D #613 (F413-SP) Warranty 07-00420 10 Dri-Eaz Products, Inc.

Page 11

System messages

ER4 √ DEFROST SENSOR

CONNECT

The Revolution control system constantly monitors internal operating conditions. If the system detects a problem, it will

produce an error (“ER”) message. If the display shows an ER message, first unplug the unit and then plug it back in. This

will usually reset the electronics, and the unit will begin operating normally. If the error message reappears, refer to the

explanation and solution shown below. If this still does not fix the problem, contact your local authorized service center or

call the Dri-Eaz Service Department at 800-932-3030.

NOTE: The message “POWER FAILURE” is not a system error. When this message is displayed, it indicates that

power to unit was interrupted and then restored. To clear the message, press the MENU SELECTION key.

CONTROL PANEL

MESSAGE

ER1 CONTACT SERVICE

CENTER

ER2 CONTACT SERVICE

CENTER

ER3 CONTACT SERVICE

CENTER

CONNECT

– alternate message –

ER4 √ OUTLET SENSOR

ER5 √ SENSOR

CONNECTION ON BD

EXPLANATION AND SOLUTION

Voltage error. Confirm that unit is connected to a suitable AC power supply and that the

circuit is not overloaded. If supply is correct, the electronic control panel may require

replacement. If error persists, contact service.

Control panel error. The electronic control panel may require replacement. If error persists, contact service.

Unit in defrost too long. Check defrost sensor cable for proper connection. If error persists, sensor assembly may require replacement. Contact service.

Sensor error. Check defrost sensor cable for proper connection. If error persists, sensor

assembly may require replacement. Contact service.

Check inlet Temp/RH sensor for proper connection. If error persists, contact service.

ER6 CONTACT

SERVICE CENTER

ER7 INVALID

MODEL SETTING

ER8 BUTTON STUCK √

ALL BUTTONS

ER9 PUMP BLOCKED √

CHECK PUMP & HOSE

07-01897D #613 (F413-SP) Warranty 07-00420 11 Dri-Eaz Products, Inc.

High voltage error. The high voltage board may require replacement. If error persists,

contact service.

Control board DIP switch settings or firmware version may be incorrect. If error persists,

contact service. Service may ask you to verify DIP switch settings.

Press each membrane key and check for proper operation. If a key doesn’t function, or

if the error persists, the membrane overlay may require replacement. Contact service.

Check for obstructions in drain hose. If clogged, remove hose from unit and blow hose

out with compressed air. Inspect and clean the pump check valve and pump basin. See

“Clean pump check valve and basin,” p. 10.

Page 12

TROUBLESHOOTING

Purge unit before moving. See PURGE in Control Panel inJob,” p. 3.

Switch unit on.

base of unit.

Power

115V / 60Hz

may be approximate.

FAULT CAUSE SOLUTION

Water drips out

when moving unit

Unit does not

operate

Unit operating,

but room not dry

Unit was unplugged before

purging was complete.

Unit not switched on.

No power to machine.

Not enough time to dry.

Poor air movement in room.

Excessive moist air infiltration.

Room air is dry.

Unit collects too

little water

Room temperature is too low.

Filter is clogged.

Coils are clogged.

If the problem you are experiencing is not listed here, call your local distributor or contact

our Service Department toll-free at 800-932-3030 for further assistance.

SPECIFICATIONS

Name

Dimensions (W × H × D)

Weight (w/ cord & hose) 65 lbs. | 29.5 kg

Amps 6.2 amps at 80°F/60% RH

Air movement 121–180 CFM | 3.43–5.1 CMM

Water removal

Operating temperature range 33–100°F |1–38°C

Safety ETL certified to CSA Standards

Specifications are subject to change without notice. Some values

Revolution LGR Dehumidifier

Model F413-115V

12.5 × 17.6 × 21.5 in.

31.8 × 44.7 × 130.8 cm

80 pts/day | 38 L/day

at 80°F/60% RH (AHAM)

134 pts/day | 63 L/day

at 90°F/90% RH

structions, p. 6. At the end of the job, see “At the End of the

Plug in unit; check power cord connection at wall outlet and at

Allow more time for drying.

Increase air movement with air movers.

Seal off area to reduce infiltration.

Confirm humidity level with hygrom et er.

Increase room temperature.

Check filter. Clean or replace as necessary.

Check coils. Clean as necessary.

PARTS INCLUDED

40 ft. (12 m) of drain hose with quick-connect fitting.

25 ft. (7.6 m) detachable power cord.

3M™ HAF High Air Flow filter

OPTIONAL

Duct Attachment Kit (F530)

FILTERS FOR REORDER

3M™ HAF High Air Flow filter F372 (24 pack)

ADDITIONAL PRODUCT INFORMATION and current

documentation is available at http://Revo.DriEaz.com.

FOR PARTS AND SERVICE CONTACT SERVPRO

RMA DEPARTMENT.

07-01897D #613 (F413-SP) Warranty 07-00420 12 Dri-Eaz Products, Inc.

Page 13

Dehumidifier Maintenance Checklist

Inspect impeller, duct ring and grill for

Inspect control panel. Toggle through dis-

Date

Note

Use this checklist to monitor the maintenance of your Dri-Eaz dehumidifiers. As each task is completed, note the date

and the operator’s initials in the boxes provided. Regular maintenance will keep your equipment operating at maximum

efficiency.

BEFORE EACH USE

Inspect the electrical cord for damage.

Look for fraying, cuts, etc. Replace damaged cords before using the unit.

Inspect filter. Look for accumulated dust

and dirt that would restrict airflow. Vacuum

out any debris.

Check drain hose for obstructions. Clear

any debris present.

IMPORTANT: HAF filters may be vacuumed and reused up to three times before replacement. Filters should be replaced after every mold job.

MONTHLY

Inspect coils and heat exchange block.

Clean when visibly dirty.

Check pump basin and drip tray. Clean

when dirt and debris are present.

Inspect and clean pump check valve.

Clean exterior housing to maintain professional appearance.

damage and/or debris and clean/replace if

required.

play screens to ensure that the unit is functioning properly.

NOTES:

Note any other maintenance tasks completed, and record any damage or operational problems that may need attention.

07-01897D #613 (F413-SP) Warranty 07-00420 13 Dri-Eaz Products, Inc.

Page 14

ADVERTENCIA

Manual de instrucciones

Deshumidificador Revolution LGR

#613 - 115V

MANUFACTURED BY DRI-EAZ PRODUCTS, INC. FOR SE RVP RO I NDUS TRIES, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Teléfono: 800-932-3030 Fax: 360-757-7950 http://Revo.DriEaz.com

El deshumidificador Dri-Eaz® Revolution LGR reduce la humedad en ambientes cerrados al eliminar el

vapor de agua del aire. El Revolution es ideal para la restauración de daños ocasionados por el agua, el

secado estructural, la construcción y muchas otras aplicaciones que requieren deshumidificación temporal de alto rendimiento.

Patentes: http://www.LB pat ents .c om

LEA Y GUARDE ESTAS INSTRUCCIONES

Lea y entienda el manual antes de operar el deshumidificador.

¡ADVERTENCIA! No altere ni modifique su deshumidificador Revolution de ninguna forma . Utilice solamente las piezas de repuesto autorizadas por DriEaz Products, Inc. Las modificaciones o e l uso de

piezas no autorizadas podrían generar riesgos y

anular la garantía. Póngase en contacto con su distribuidor Dri-Eaz autorizado para obtener ayuda.

¡ADVERTENCIA! Peligro de choque eléctrico, ventilador giratorio, riesgos por superficies calientes.

Desconecte la unid ad antes de abrir la cu bierta para

limpiarla o darle mantenimiento.

¡ADVERTENCIA! La unidad debe estar conectada a

tierra.

• Mantenga el motor y el cableado secos. Mantenga

la unidad lejos del agua estancada y no la instale en

zonas que puedan verse sometidas a entrada de

agua. No exponga el deshumidificador a la lluvia,

agua o nieve.

• Inserte el contacto de tres clavijas del cable de ali-

mentación a un tomacorriente conectado a tierra.

No use un adaptador. Nunca corte la tercera clavija.

• No utilice un cable de extensión.

• Para reducir el riesgo de incendio o descarga eléc-

trica, no use esta unidad con un dispositivo de control de velocidad de estado sólido.

PELIGRO DE INCENDIO

• Mantenga la unidad apartada de flamas abiertas y

fuentes de calor.

• No la utilice ni la almacene donde haya vapores de

gasolina, solventes, diluyentes u otros materiales inflamables.

¡ADVERTENCIA! Desconecte la unidad antes de limpiarla o darle mantenimiento.

• Apague la unidad y desconéctela antes de levantar-

la o moverla.

• Maneje la unidad con cuidado. Opere siempre la

unidad sobre una superficie estable y nivelada. No

la deje caer, no la tire ni la coloque donde pueda

caerse. Un trato brusco puede dañar la unidad y

puede generar una condición peligrosa o anular la

garantía.

• Inspeccione el cable de alimentación antes de utili-

zar la unidad. Si el cable está dañado, no utilice la

unidad. Sujete siempre la clavija (no el cable) para

desconectarla.

• La unidad debe operarse en un circuito de 115V/60

Hz protegido por un dispositivo interruptor de circuito por falla en tierra (GFCI, por sus siglas en inglés).

• No intente reparar la unidad. Para conocer las op-

ciones de servicio autorizadas, comuníquese con el

Departamento de RMA de SERVPRO®, al 866-8856833, o por correo electrónico a

rma@servpronet.com.

07-01897D #613 (F413-SP) Warranty 07-00420 14 Dri-Eaz Products, Inc.

Page 15

ANTES DE COMENZAR

Asas para

transporte

Imagen A: Identificación de las piezas

Conexión rápi-

Entrada de

Panel de

Retire o inserSalida de

aire

Tomacorriente

Soportes de

Sensor de

tempera-

Registro de la garantía

Para tramitar una reclamación con base en la garantía o

solicitar una reparación, simplemente haga clic en el

‟Formulario de la garantía/RMA” (RMA/ Warranty Form),

que se encuentra en la pestaña de ‟Productos” (Products), de la página de inicio de ServproNET®, o en la

página de Equipo (Equipment) de ServproNET.

Para comunicarse con el Departamento de autorización de devolución de mercancía (RMA, por sus siglas en inglés) de SERVPRO®, llame al 866-885-6833 o escriba un correo electrónico a rma@servpronet.com.

Para acelerar el proceso de reclam ación con base en la garantía, tenga a la mano la siguiente información:

• Número de modelo del equipo.

• Número de serie.

• Horas de uso (en su caso).

Cuando una franquicia compra equipo de Servpro Industries, Inc., en la factura se incluye la fecha de compra de

la unidad y los números de serie. Como parte del programa de garantía/RMA de Servpro Industries, Inc., en

la base de datos se agrega el comprobante de la compra y el expediente de la garantía del equipo. Este serv icio les ahorra a las franquicias el tiempo y el dinero que

perderían tratando de determinar la cobertura de la garantía del equipo.

Después de recibir el formulario de solicitud de garant-

control

aire

almacenaje

del cordón

eléctrico y la

manguera.

da del desagüe

de condensación

te el filtro de

aire aquí.

ía/RMA completo, un Coordinador de RMA comprobará

el estado de la garantía de cualquier equipo ant es de

presentar la información de la reclamación al(los) proveedor(es).

Si la unidad está cubierta por la garantía, el Coordin ad or

de RMA explicará el proceso de reparación y devolución.

Si la garantía no cubre el equipo, el(los) proveedor(es)

proporcionará(n) un presupuesto de reparación que resulte atractivo antes de realizar cualquier reparación que

no esté incluida en la garantía. Antes de autori zar las

reparaciones que no estén incluid as en la garantía, el

Coordinador de RMA presentará diferentes opciones de

reparación y deberá recibir la aprobación de la franquicia.

¡El Departamento de RMA de SERVPRO está para servirle!

INTRODUCCIÓN

El deshumidificador Revolution reduce la humedad en

entornos cerrados estructurales al eliminar el vapor de

agua del aire. Con el uso apropiado, el Revolution puede ayudar a secar materiales estructurales, aislamiento

y contenido húmedos, así como a mantener un nivel

saludable de humedad. El uso del Revolution también

puede evitar daños secundarios causados por el exceso

de humedad.

Cómo funciona el Revolution

El deshumidificador por refriger ación Revolution utiliza

un ventilador para extraer el aire húmedo y condensarlo

en agua, la cual se acumula en una bandeja y se bombea de forma automática hacia afuera a través de una

manguera de desagüe. La unidad se puede configurar

para que funcione de manera continua o el usuario puede seleccionar el modo de humidistato. En el modo de

humidistato, el Revolution se enciende y se apaga automáticamente para mantener el nivel de humedad de

entrada que el usuario haya seleccionado.

Características:

• Deshumidificador de calidad industrial que elimina

hasta 134 pintas (63 litros) de agua por día.

• Modo de humidistato automático para establecer y

mantener el nivel de humedad deseado.

• Hendiduras empotradas para las patas que permiten

un apilado seguro de hasta tres unidades Revolution

para su almacenaje y transporte.

• Diseñado para un cómodo apilado y transpor te

usando una carretilla.

• Manijas empotradas para facilitar su colocación en

espacios reducidos.

• Funcionamiento silencioso y de bajo consumo de

energía.

07-01897D #613 (F413-SP) Warranty 07-00420 15 Dri-Eaz Products, Inc.

Page 16

CONTROLES E INSTRUCCIONES DE

ON/OFF (ENCENDIDO

/ APAGADO)

Presione y suelte para en cender

Presione para seleccionar el siguiente

menú se mostrará en la pantalla.

MENU SELECTION /

ARRIBA)

Presione para cambiar o s eleccionar

BOMBA DE PURGADO

Presione y suelte para empe zar a

OPERACIÓN

Coloque la unidad en posición vertical

AVISO: Siempre alma cene, transporte y utilice la

unidad en posición horizontal. Si la unidad llegara a

colocarse en posición vertical, póngala en posición

horizontal de nuevo y déjela reposar durante al menos 30 minutos antes de encenderla.

Ubicación del deshumidificador

Para obtener los mejores resultados, utilice los deshumidificadores en un área cerrada. Cierre todas las

puertas y ventanas que den al exterior para maximizar la

eficiencia de la remoción de agua. Coloque el deshumidificador lejos de obstrucciones y manténgalo alejado de

DISPLAY MENU

(MENÚ DE PANTALLA)

UP KEY (SELECCIÓN DE

MENÚS / FLEC HA HACIA

cualquier objeto que pueda bloquear el flujo de aire dentro y fuera de la unidad. Para obtener más información

acerca de cómo crear un ambiente de secado óptimo,

comuníquese con Dri-Eaz al 8009323030.

Configuración de la manguera de desagüe

La bomba de condensado del Revolution se conecta a

una manguera de desagüe de plástico. Esta manguera

está equipada con una conexión de acoplamiento rápido

para conectarla rápidamente a la manguera de desagüe

de 40 pies (12 m) provista. Desenrolle toda la manguera

y coloque el extremo suelto en un lavabo, desagüe, cubo o al aire libre (en cualquier lugar donde el agua pueda drenarse de forma segura). Si utiliza un cubo u otro

recipiente para recoger el agua, revíselo con regularidad

para evitar que el agua se derrame.

AVISO: Desenrolle y enderece toda la manguera de

desagüe. No deje ninguna parte de la manguera enro-

07-01897D #613 (F413-SP) Warranty 07-00420 16 Dri-Eaz Products, Inc.

o apagar la unidad.

elemento del menú. El elemento del

los valores en el menú des plegado.

purgar. La pantalla mostr ar á una

cuenta regresiva de los segundos que

falten para que se complete l a purga.

llada ni coloque el extremo de la manguera a 20 pies (6

m) por encima de la parte inferior de la unidad. También

vea si hay torceduras u otras obstrucciones que podrían

restringir el flujo de agua. Las obstrucciones pueden

provocar una retenc ión de l agua y ocasio nar derr ames.

Conecte el cable eléctrico

El Revolution debe conectarse a un tomacorriente de

115 voltios con protección de GFCI especificado por lo

menos para 15amperios. Siempre conecte firmemente el

cable en la unidad primero y luego conecte el otro extremo a un tomacorriente adecuado.

Pantalla de inicio y modos de visualización normales

Cuando la unidad se conecta por primera vez en la alimentación de corriente alterna (CA), la pantalla del panel de control mostrará brevemente una serie de lecturas en ciclo. Esto es parte del procedimiento de autodiagnóstico de la unidad y no se requiere ninguna intervención del usuario.

Encienda la unidad

El panel de control del deshumidificador Revolution tiene

una pantalla y un panel táctil con cuatro botones . Presione el botón ON/OFF (ENCENDIDO / APAGADO) para encender la unidad. La unidad realizará un conteo

regresivo de retardo del compresor (de hasta sesenta

segundos de duración) y un proceso de autodiagnóstico.

Una vez que la cuenta regresiva del compresor y el autodiagnóstico se hayan completado, la pantalla cambiará

al modo de visualización normal.

UNIT ON 00 HRS (UNIDAD ENCEN-

DIDA 00 HRS)

INLET 00°C / INLET 00% (ENTRADA

00° C / ENTRADA 00%)

La primera línea de la pantalla muestra el número total

de horas que la unidad ha estado en operación. Este

valor puede restablecerse a cero para dar seguimiento a

las horas de trabajo (vea “Restablecimiento de horas de

trabajo” a continuación). La segunda línea de la pantalla muestra alternadamente la temperatura de entrada y

la humedad de entrada.

Menú de configuraciones del usuario

El usuario puede cambiar algunas configuraciones de la

pantalla. También se puede mostrar la información del

sistema. Se puede tener acceso a estos elementos presionando DISPLAY MENU (MENÚ DE PA NTALLA). Con

cada pulsación del botón se mostrará el siguiente parámetro. Cuando llegue al parámetro que quiera ajustar,

presione

MENÚS) para aumentar el valor. Presione

MENU (MENÚ DE PANTALLA) de nuevo para aceptar

la configuración y volver a iniciar el ciclo de visualización. Si no se selecciona ningún botón durante 5 minu-

MENU SELECTION (SELECCIÓN DE

DISPLAY

Page 17

tos, la pantalla regresará automáticamente al modo de

visualización normal.

Tenga en cuenta que sólo se pueden ajustar los elementos del menú seguidos del símbolo mayor que ( > ).

Todos los ajustes y modos se describen con detalle en

la Guía del panel de control, que se encuentra más adelante.

Mensajes de error

Si el diagnóstico incorporado al Revolution detecta un

problema, la unidad mostrará un mensaje de error. Consulte “Mensajes del sistema” en la pág. 11 para ver una

explicación de cada mensaje.

Guía del panel de control

ON/OFF (ENCENDIDO / APAGADO). Presione el

botón ON/OFF para encender o apagar la unidad.

Cuando el equipo está encendido, la pantalla indica

normalmente PLEASE WAIT COMP. DELAY (ESPERE

EL RETARDO DEL COMPRESOR) y realiza una cuenta

regresiva desde un máximo de 60 segundos hasta 0.

Este retardo da tiempo para que se iguale la presión del

refrigerante con el fin de facilitar el arranque. Una vez

que haya transcurrido el retardo del compresor, la pantalla mostrará UNIT ON XX HRS (UNIDAD ENCENDIDA XX HORAS) y alternará entre INLET XX°F (ENTRADA XX° F e INLET XX% (ENTRADA XX%). NOTA: Si no

aparece ninguna cuenta regresiva de retardo del compresor, el retardo no es necesario y la máquina comenzará a funcionar de inmediato.

DISPLAY MENU (MENÚ DE PANTALLA). Presione

para alternar entre la visualización de las condiciones

adicionales del deshumidificador y la configuración del

usuario. Para volver al menú principal, presione el botón

ON/OFF (ENCENDIDO / APAGADO) una sola vez.

MENU SELECTION (SELECCIÓN DE MENÚS).

Presione para cambiar los valores de los ajustes "User

Defined" (definidos por el usuario). El botón de MENU

SELECTION (SELECCIÓN DE MENÚS) funciona como

tecla de flecha hacia arriba para ajustar el punto de operación del funcionamiento en el modo de humidistato.

Consulte la sección Menú de configuración del usuario

(más adelante) para ver más detalles.

PURGE (PURGA). Presione para vaciar el agua del

depósito de la bomba de condensado. En la pantalla

aparecerá PURGING PUMP (PURGANDO BOMBA) con

un número de cuenta regresiva. NOTA: Durante el funcionamiento normal, la bomba se purga automáticamente cada 20 minutos, o cada vez que el depósito esté lleno.

Cambio de configuración y visualización de la información del sistema

Cambia la configuración de la pantalla y se puede tener

acceso a la información del sistema presionando

07-01897D #613 (F413-SP) Warranty 07-00420 17 Dri-Eaz Products, Inc.

DIS-

PLAY MENU (MENÚ DE PANTALLA). Con cada pulsación del botón se mostrará el siguiente parámetro (vea

la lista más adelante). Cuando llegue al parámetro que

quiera ajustar, presione

CIÓN DE MENÚS) para aumentar el valor. Presi one

DISPLAY MENU (MENÚ DE PANTALLA) de nuevo para

aceptar la configuración y volver a iniciar el ciclo de visualización. Si no se selecciona ningún botón durante 5

minutos, la pantalla regresará automáticamente al modo

de visualización normal.

Tenga en cuenta que sólo se pueden ajustar los elementos del menú seguidos del símbolo mayor que ( > ).

JOB HOURS

RESET? (¿RESTABLECER HORAS

DE TRABAJO?) >

Presione MENU SELECTION (SELECCIÓN DE

MENÚS) para restablecer las horas a cero. NOTA: En el

modo de humidistato, la unidad mostrará HUMIDISTAT

(HUMIDISTATO) en la línea superior durante el funcionamiento normal en lugar de JOB HOURS (HORAS DE

TRABAJO).

LIFE HOURS (HORAS DE VIDA)

00 HRS

Muestra el total de horas de funcionamiento de la unidad. Este valor no se puede modificar.

INLET (ENTRADA)OUTLET (SALIDA)

00° 00% 00° 00%

Muestra la temperatura actual y la RH de entrada y salida.

MENU SELECTION (SELEC-

Operación normal

El modo predeterminado de operación mantiene el

deshumidificador funcionando a su capacidad

máxima. Esto es ideal para la mayoría de las aplicaciones de restauración Para controlar la humedad a un

nivel específico, elija el modo de humidistato, que se

describe a continuación.

Modo de humidistato

HUMIDISTAT MODE (MODO DE

HUMIDISTATO)

ON/OFF (ENCENDIDO / APAGADO) >

En el modo ON (ENCENDIDO), la unidad mantendrá el

ajuste predeterminado del humidistato (vea más adelante). Presione MENU SELECTION (SELECCIÓN DE

MENÚS) para alternar entre ON (ENCENDIDO) y OFF

(APAGADO). NOTA: En el modo de humidistato, la unidad mostrará HUMIDISTAT (HUMIDISTATO) en la línea

superior durante el funcionamiento normal en lugar de

JOB HOURS (HORAS DE TRABAJ O ) .

Page 18

HUMIDISTAT

Retire los 4 tornillos

Imagen B: Desmontaje para limpieza

SETPOINT (PUNTO PREDETERMI-

NADO DEL HUMIDISTATO) 00%>

Ajusta el nivel de humedad cuando la unidad está en el

modo de humidistato. Presione MENU SELECTION

(SELECCIÓN DE MENÚS) para cambiar el valor de RH.

Cada vez que se presiona el botón, el valor aumenta en

incrementos de 5%, y después del 90% de RH comenzará de nuevo en el 40% de RH.

TEMP UNITS (UNIDADES DE TEM-

PERATURA)

F °>

Muestra la escala de temperatura actua l. Pres ion e MENU SELECTION (SELECCIÓN DE MENÚS) para seleccionar grados Fahrenheit o centígrados.

LANGUAGE (IDIOMA)

ENGLISH (INGLÉS) >

Muestra el idioma actual del panel de visualización. Presione MENU SELECTION (SELECCIÓN DE MENÚS)

para seleccionar español, alemán, francés o inglés.

COIL TEMP (TEMP DE BOBINA)

00° F

Muestra la temperatura de la bobina (evaporadora) en

frío.

SENSOR ID (ID DEL SENSOR) >

00000000

Esta función no se utiliza en el Revolution.

COMPRSSR CURRENT (CORRIENTE

DEL COMPRESOR)

0.0 A

Muestra la corriente del compresor en amperios.

AL FINAL DE LA OPERACIÓN

Para reducir la posibilidad de que la unidad got ee al moverla, siga estos pasos adicionales con el fin de garantizar que se extraiga toda el agua de la unidad.

AVISO: Para garantizar que el tanque de condensado

se vacíe por completo durante el purgado, asegúrese de

que la unidad esté en posición horizonta l sobre una superficie plana.

1. Si la unidad está en un ciclo de descongelación, espere hasta que ésta vuelva al modo normal de funcionamiento antes de proceder. Para comprobar su estado,

revise el panel de control. El panel de control m ostr ar á

uno de los siguientes mensajes:

Descongelación en curso:

UNIT ON 00 HRS (UNIDAD ENCENDI-

DA 00 HRS)

DEFROST XX (DESCONGELACIÓN

XX)

Modo de visualización cuando la unidad está en el modo

de descongelación. XX indica los minutos restantes del

ciclo de descongelación.

Secuencia de apagado

WAIT FOR

DEFROST XX (ESPERE A DESCON-

GELACIÓN XX)

Modo de visualización cuando la unidad está en descongelación y el usuario la apaga. La unidad terminará

el ciclo de descongelación para eliminar el hielo acumulado y luego purgará la bomba. XX indica los minutos

restantes del ciclo de descongelación.

Pantalla normal:

UNIT ON 00 HRS (UNIDAD ENCENDI-

DA 00 HRS)

INLET XX° F (ENTRADA XX° F)

Espere hasta que aparezca en el panel de control la

visualización normal antes de proceder.

2. Balancee suavemente la máquina para garantizar que

cualquier cantidad de agua que quede en las superficies

interiores caiga en el área del resumidero.

3. Presione el botón PURGE (PURGAR). Cuando el ciclo de purga haya terminado, apague la unidad.

4. Retire la manguera de desagüe externo, escurra con

cuidado, enróllela y asegúrela con una de las tiras de

velcro provistas a un costado de la unidad.

de la carcasa y los 2

tornillos superiores de

cada una de las parrillas de entrada y salida, y levante la cubierta.

07-01897D #613 (F413-SP) Warranty 07-00420 18 Dri-Eaz Products, Inc.

5. Desconecte el cable de alimentación de la fuente de

energía y de la base de la máquina, enróllelo con cuidado y asegúrelo con una de las tiras de velcro provistas a

un costado de la unidad (vea la Imagen A).

TRANSPORTE Y ALMACENAMIENTO

AVISO: Maneje la unidad con cuidado. No la deje caer,

no la tire ni la coloque donde pueda caerse. Un trato

brusco puede dañar el equipo y puede generar una condición peligrosa o anular la garantía.

• No exponga el panel de control a la humedad, la

nieve ni la lluvia.

• Proteja la unidad contra la conge lac ió n.

Page 19

• Almacene y transporte la unidad de forma segura

el filtro de HAF cada vez que se haya utilizado en una tarea de eliminación de moho o que se haya expuesto de

para evitar que las piezas internas se dañen.

• Asegúrela durante el transporte para evitar deslizamientos y posibles lesiones a los ocupantes del

vehículo.

rarse y reutilizarse hasta tres veces antes de tener

que reemplazarlos. Utilice una aspiradora de HEPA y

un cepillo para quitar el polvo o la suciedad. No utilice

aire comprimido ni exponga el filtro a ningún líquido, ya

que podría dañarlo.

PROGRAMA DE MANTENIMIENTO

¡ADVERTENCIA! PELIGRO DE DESCARGA ELÉCTRICA. Desconecte la unidad antes de limpiarla o

darle mantenimiento.

ADVERTENCIA: Riesgo de exposición al polvo y a con-

taminantes. Se recomienda utilizar una máscara con

respirador y guantes. Si la unidad ha estado expu es ta a

contaminantes potencialmente peligrosos, limpie y desinfecte la unidad a fondo antes de volver a utilizarla.

AVISO: La unidad está equipada con sensores electrónicos sensibles. Proteja los sensores y las puntas de

sus cables contra daños y no los exponga al agua ni a la

solución de limpieza.

Se requieren las siguientes herramientas y materiales para llevar a cabo los procedimientos de mantenimiento que se describen en este manual:

Destornillador philips

Llave de 10 mm

Punta hexagonal de 6 mm

Llave de tuercas de ¼ pulg.

Paños para limpieza

Aspiradora de absorción de partículas de alta eficiencia (HEPA, por sus siglas en inglés) con boquilla de

cepillo suave y boquilla estrecha.

Herramientas y materiales recomendados

Taladro inalámbr ico, cuc hill a peque ña, pin zas de quijada pequeña, solución de lim pie za para la bobin a,

solución de limpieza de carcasa rotomoldeada.

Antes de cada utilización

Revise si el cable eléctrico está dañado. Busque

quemaduras, cortaduras, etc. Reemplace el cable si

está dañado.

Inspeccione, aspire o cambie el filtro. El Revolution

está provisto de un filtro 3M ™ de HAF de alto flujo de

aire (pieza N.° F372). Los filtros de HAF pueden aspi-

Cada mes

Inspeccione las bobinas. Limpie cuando la acumula-

ción de polvo sea visible. Con el uso normal, el polvo

puede acumularse y puede restringir el flujo del aire, lo

cual reduce el rendimiento y ocasiona que la unidad se

sobrecaliente. Utilice una aspiradora con un cepillo y un

paño suave para eliminar cualquier residuo. Tenga cuidado de no dañar los componentes internos.

Para mantener una buena apariencia, limpie las superficies interiores y exteriores con un paño húmedo.

Para una limpieza profunda y un brillo durader o y protector, utilice un limpiador para interiores de automóviles.

Según se requiera

Limpie la válvula de retención y el depósito de la

bomba. Si la unidad muestra el mensaje “ER9 PUMP

BLOCKED CHECK PU M P & HOS E” (ER RO R 9: BOMBA BLOQUEADA; RE VIS AR LA BOMBA Y LA MANGUERA), es posible que sea necesario limpiar la válvula

de retención y el recipiente de la bomba. Quite las parrillas y la cubierta según se muestra en la Imagen B. Quite los tornillos de la base de la bomba y sáquela. Limpie

el depósito de la bomba con un paño húmedo. Revise si

hay escombros acumulados en la base de la bomba y

límpiela en caso de ser necesario. Desenros q ue la boquilla estriada de la válvula de retención y enjuague la

boquilla y la válvula de retención con agua limpia. Vuelva a instalar la válvula de retención en la boquilla estriada e instale la boquilla en la bomba. No apriete demasiado. Vuelva a instalar la bomba en la base. Vuelva a

instalar la cubierta y las parrillas.

Limpie las bobinas. Con la cubierta retirada, inspeccione las dos bobinas. Si hay polvo y suciedad, limpie a

fondo con una aspiradora o limpie con limpiador para

bobinas.

ACERCA DE LOS FILTROS DE ALTO FLUJO DE AIRE 3M™

Los fil tr os de a lto f lu j o de air e ( HA F, por sus siglas en inglés) de 3M tienen una mayor tasa de retención de partículas, resisten el crecimiento microbiano en las superficies del filtro y permiten el máximo flujo de aire durante todo el ciclo de carga

del filtro. Siga estos lineamientos para garantizar la máxima protección del equipo, de los técnicos y del lugar de trabajo:

Reemplace el filtro de HAF cada vez que haya sido aspirado y reutilizado tres veces. Los filtros de HAF p ierden su efic acia

después de utilizarlos tres veces.

Reemplace

alguna manera a contaminantes potencialmente peligrosos. El uso continuo de un filtro contaminado aumenta el riesgo de pro-

pagación de la contaminación.

No lave ni aplique ningún líquido al filtro de HAF. La exposición a líquidos reducirá la eficacia del material electrostático.

No opere la unidad si el filtro de HAF no está en su lugar. No opere la unidad con ningún otro tipo de filtro. La filtración inco-

rrecta reduce la eficiencia de la unidad y puede causar daños a la misma.

07-01897D #613 (F413-SP) Warranty 07-00420 19 Dri-Eaz Products, Inc.

Page 20

Mensajes del sistema

ER2 CONTACT SERVICE

DE SERVICIO)

ER3 CONTACT SERVICE

DE SERVICIO)

Unidad en descongelación por demasiado tiempo. Revise el cable del sensor de des-

mento de servicio.

ER4 √ DEFROST SENSOR

DE SALIDA)

ER6 CONTACT

VICIO)

LIDA DEL MODELO)

ración del interruptor DIP.

El sistema de control del Revolution supervisa de manera constante las condiciones de funcionamiento interno. Si el sistema detecta un problema, se producirá un mensaje de error (“ER”). Si la pantalla muestra un mensaje de error, primero

intente desconectar la unidad y volver a conectarla. Esto por lo general restablecerá los componentes electrónicos y la

unidad comenzará a funcionar normalmente. Si vuelve a aparecer el mensaje de error, consulte la explicación y la solución que se muestran a continuación. Si esto no soluciona el problema, póngase comuníquese a su centro de servicio

autorizado o llame al Departamento de Servicio de Dri-Eaz al 800-932-3030.

NOTA: El mensaje “POWER FAILURE” (FALLA EN LA ENERGÍA) no es un error del sistema. Cuando aparezca

este mensaje, significa que se interrumpió la energía de alimentación de la unidad y luego se restauró. Para borrar el mensaje, presione el botón MENU SELECTION (SELECCIÓN DE MENÚS).

MENSAJE DEL PANEL DE

CONTROL

ER1 CONTACT SERVICE

CENTER (ERROR 1: COMUNÍQUESE AL CENTRO

DE SERVICIO)

CENTER (ERROR 2: COMUNÍQUESE AL CENTRO

CENTER (ERROR 3: COMUNÍQUESE AL CENTRO

CONNECT (ERROR 4: √

CONECTOR DEL SENSOR

DE DESCONGELACIÓN)

– mensaje alterno –

ER4 √ OUTLET SENSOR

CONNECT (ERROR 4: √

CONECTOR DEL SENSOR

EXPLICACIÓN Y SOLUCIÓN

Error de voltaje. Confirme que la unidad esté conectada a una fuente de alimentación

de CA adecuada y que el circuito no esté sobrecargado. Si la alimentación es la correcta, es posible que sea necesario reemplazar el panel de control electrónico. Si el error

persiste, póngase en contacto con el departamento de servicio.

Error del panel de control. Es posible que sea necesario reemplazar el panel de control

electrónico. Si el error persiste, póngase en contacto con el departamento de servicio.

congelación para verificar que la conexión sea la correcta. Si el error persiste, es posible que sea necesario reemplazar el ensamble del sensor. Comuníquese al departa-

Error en el sensor. Revise el cable del sensor de descongelación para verificar que la

conexión sea la correcta. Si el error persiste, es posible que sea necesario reemplazar

el ensamble del sensor. Comuníquese al departamento de servicio.

ER5 √ SENSOR

CONNECTION ON BD

(ERROR 5: √ CONEXIÓN

DEL SENSOR EN BD

SERVICE CENTER

(ERROR 6: COMUNÍQUESE AL CENTRO DE SER-

ER7 INVALID

MODEL SETTING (ERROR

7: CONFIGURACIÓN INVÁ-

ER8 BUTTON STUCK √

ALL BUTTONS (ERROR 8:

BOTÓN ATORADO √ TODOS LOS BOTONES)

07-01897D #613 (F413-SP) Warranty 07-00420 20 Dri-Eaz Products, Inc.

Revise que el sensor de temperatura / RH de entrada tenga la conexión adecuada. Si

el error persiste, póngase en contacto con el departamento de servicio.

Error de alto voltaje. Es posible que sea necesario reemplazar el tablero de alt o v oltaj e.

Si el error persiste, póngase en contacto con el departamento de servicio.

Es posible que la configuración del interruptor DIP de la tarjeta de control o la versión

del firmware sea incorrecta. Si el error persiste, póngase en contacto con el departamento de servicio. El departamento de servicio puede pedirle que verifique la configu-

Presione cada tecla de la membrana y verifique que funcionen correctamente. Si alguna tecla no funciona, o si persiste el error, es posible que sea necesario reemplazar la

membrana. Comuníquese al departamento de servicio.

Page 21

ER9 PUMP BLOCKED √

CHECK PUMP & HOSE

BOMBA Y LA MANGUERA)

Gotea agua

la unidad

La unidad no está encendida.

máquina.

Encienda la unidad.

ción en el tomacorriente de la pared y en la base de la unidad.

El tiempo no es suficiente para

húmedo.

80 pts/día | 38 L/día

gunos valores pueden ser aproximados.

(ERROR 9: BOMBA BLO-

QUEADA √ REVISE LA

Revise si hay obstrucciones en la manguera de desagüe. Si está obstruida, retire la

manguera de la unidad y aplique aire comprimido en su interior. Revise y limpie la

válvula de retención y el depósito de la bom ba. Vea “Limpieza de la válvula de retención y del depósito de la bomba” en la pág. 19.

SOLUCIÓN DE PROBLEMAS

FALLA CAUSA SOLUCIÓN

cuando se mueve

La unidad no

funciona

La unidad funciona, pero la habitación no se seca

La unidad recoge

muy poca agua

Se desconectó la unidad antes

de terminar de purgar.

No hay alimentación a la

el secado.

Poco movimiento del aire en la

habitación.

Infiltración excesiva de aire

El aire ambiente está seco.

La temperatura ambiente es

demasiado baja.

El filtro está obstruido.

Las bobinas están obstruidas.

Purgue la unidad antes de moverla. Vea “Al final del trabajo”

en la pág. 18.

Conecte la unidad, revise la conexión del cable de alimenta-

Permita más tiempo para el secado.

Aumente el movimiento del aire con ventiladores.

Selle el área para reducir la infiltración .

Confirme el nivel de humedad con un higrómetro.

Aumente la temperatura de la habitación.

Revise el filtro. Limpie o reemplace según sea necesario.

Revise las bobinas. Límpielas en caso de ser necesario.

Si el problema que experimenta no está en esta lista, llame a su distribuidor local a

la línea sin costo de nuestro departamento de servicio al 8009323030 para obtener más ayuda.

ESPECIFICACIONES

Nombre

Dimensiones (ancho x alto x

fondo)

Peso (c/cable y manguera) 65 libras. | 29.5 kg

Amperios 6.2 amperios a 80° F / 60% de RH

Energía 115V / 60 Hz

Movimiento del aire 121–180 CFM | 3.43–5.1 CMM

Deshumidificador Revolution LGR

Modelo F413-115V

12.5 × 17.6 × 21.5 cm

31.8 × 44.7 × 54.6cm

PIEZAS INCLUIDAS

Manguera de desagüe de 40 pies (12 m) con conexión

de acoplamiento rápido.

Cable de alimentación extraíble de 25 pies (7.6 m).

Filtro de HAF de 3M™ de alto flujo de aire. Reordenar

N.° F372 (24 paquetes)

OPTIONAL

Duct Attachment Kit (F530)

Eliminación del agua

Rango de temperatura de

operación

Las especificaciones están sujetas a cambios sin previo aviso. Al-

a 80° F / 60% HR (AHAM)

134 pts/día | 63 L/día

a 90° F / 90% RH

33–100° F |1–38° C

Hay INFORMACIÓN ADICIONAL DEL PRODUCTO y

documentos actualizados disponibles en

http://Revo.DriEaz.com.

PARA PEDIR INFORMACIÓN SOBRE PIEZAS Y

SERVICIO, LLAME A SERVPRO RMA DEPARTMENT

07-01897D #613 (F413-SP) Warranty 07-00420 21 Dri-Eaz Products, Inc.

Page 22

Lista de revisión para el mantenimi ento de los

Verifique el colector d e la bomba y la ban-

Verifique que ni el rotor, ni el anillo del tu-

Revise el panel de cont rol. Navegue entre

Fecha

Nota

deshumidificadores

Utilice esta lista par a verificar el mantenimiento de los deshumidificadores Dr i-Eaz. A medida que real ice cada tarea,

anote la fecha y las inic iales del operador en las casil las correspondientes. El m antenimiento periódico m antendrá su

equipo funcionando a su máxima eficiencia.

ANTES DE CADA USO

Revise que el cable eléctrico no esté dañado. Si está desgastado, roto o tiene

algún otro daño, reemplácelo antes de utilizar la unidad.

Revise el filtro. Verifique que no haya polvo

acumulado ni suciedad que limiten el flujo

del aire. Elimine cualquier residuo.

Revise que no haya obstrucciones en la

manguera de drenaje. Retire los residuos.

IMPORTANTE: Los filtros H AF se pueden aspirar y volver a utilizar máximo tres veces antes de cambiarlos. Los filtros deben reemplazarse

después de cada trabajo de limpieza de moho.

UNA VEZ AL MES

Revise las bobinas y el bloque de intercambio de calor. Lím pielos cuando s e vea n

sucios.

deja de goteo. Lím pielos cuando estén sucios y tengan residuos.

Revise y limpie la válvula de retención de

la bomba.

Limpie la caja exterior para mantener una

apariencia profesional.

bo, ni la parrilla estén dañados o sucios, y

límpielos o cámbielos si es necesario.

las distintas pantallas para asegurarse de

que la unidad esté funcionando correctamente.

NOTAS:

Anote cualquier otro tipo de mantenimiento que se haya realizado, y registre cualquier daño o problema que requiera atención.

07-01897D #613 (F413-SP) Warranty 07-00420 22 Dri-Eaz Products, Inc.

Page 23

AVERTISSEMENT

Manuel du propriétaire

Déshumidificateur Dri-Eaz® Revolution LGR

#613 - 115V

MANUFACTURED BY DRI-EAZ PRODUCTS, INC. FOR SERVPRO INDUSTRIES, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Téléphone : 800-932-3030 Fax : 360-757-7950 http://Revo.DriEaz.com

Le déshumidificateur Dri-Eaz® Revolution LGR réduit l'humidité dans des environnements clos en

éliminant la vapeur d'eau de l'air. Le déshumi d ificateur Révolution est idéal pour la restaurati o n d es

dommages causés par l'eau, le séchage de la structure, la construction, et de nombreuses autres applications nécessitant une déshumidification temporaire, de haute performance.

Brevets : http://www.LBpatents.com

LIRE ET CONSERVER CES INSTRUCTIONS

Bien lire et comprendre le manuel avant l’utilisation.

AVERTISSEMENT! Ne jamais altérer ou modifier

d’aucune façon votre Revolution. Utilisez

uniquement des pièces de rechange autorisées par

Dri-Eaz. Les modifications ou l'utilisation de pièces

non approuvées pourraient créer un danger et

annulera votre garantie. Pour obteni r de l'assistance,

contactez votre distributeur Dri -Eaz agréé.

AVERTISSEMENT! Risque de choc électrique, pales

de ventilateur en rotation, surface c haude.

Débrancher l'appareil avant d'ouvrir le couvercle

pour le nettoyage ou l'entretien.

AVERTISSEMENT! L'unité doit être mise à la terre.

• Garder le moteur et le câblage sec. Garder hors de

l'eau stagnante et ne pas installer dans une zone

susceptible à l'intrusion d'eau. Ne pas exposer à la

pluie, l'eau ou la neige.

• Insérer la fiche à trois broches du cordon

d'alimentation dans une prise électrique appropriée

mise à la terre. Ne pas utiliser un adaptateur. Ne

jamais couper la troisième broche.

• Ne pas utiliser une rallonge.

• Pour réduire le risque d'incendie ou de choc

électrique, ne pas utiliser cet appareil avec un

dispositif de contrôle de la vitesse à semiconducteurs.

RISQUE D'INCENDIE

• Tenir à l'écart des flammes nues et des sources de

chaleur.

• Ne pas entreposer et ne pas utiliser d'essence ni

d'autres vapeurs, solvants, dil uan ts ou autres

matériaux inflammables près de cet appareil.

AVERTISSEMENT! Débrancher l'appareil avant le

nettoyage ou l'entretien.

• Éteindre l'appareil et le débrancher avant de le

soulever ou de le déplacer.

• Manipuler l'appareil avec précaution. Faire

toujours fonctionner l'appareil sur une surface

plane et stable. Ne pas laisser tomber l’appareil et

ne pas le placer où il pourrait tomber. Un mauvais

traitement peut endommager l'appareil et créer

une condition dangereuse ou annuler la garantie.

• Inspecter le cordon d'alimentation avant

l’utilisation. Si le cordon est endommagé, ne pas

l’utiliser. Toujours saisir la fiche (pas le cordon)

pour débrancher.

• L'appareil doit être branché sur un circuit 115V/60

Hz protégé par un disjoncteur différentiel de fuite à

la terre (DDFT).

• Ne tentez pas de réparer l'appareil. Pour des op-

tions de service autorisé, contacte z SE RV PRO ®

RMA Department au 866 885-6833 ou par courriel

rma@servpronet.com.

à

AVANT DE COMMENCER

Enregistrement de la garantie

Pour traiter une réclamation de garantie ou de

réparation, cliquez sur le « Formulaire de

garantie/RMA » affiché sous l'onglet « Produits » sur la

page d'accueil de ServproNET

« Équipement » de ServproNET.

Vous pouvez contacter SERVPRO

par téléphone au 866 885-6833 ou par courriel à

rma@servpronet.com

.

®

ou sur la page

®

RMA Department

07-01897D #613 (F413-SP) Warranty 07-00420 23 Dri-Eaz Products, Inc.

Page 24

Pour accélérer le processus de réclamation de la

garantie, veuillez avoir les renseignements suivants :

• Numéro du modèle de l'appareil

• Numéro de série

• Heures d'utilisation (le cas échéant)

Quand le franchisé achète un équipement chez Servpro

Industries, inc., la date d'achat de l'appareil et le numéro

de série sont inscrits sur sa facture. Dans le cadre du

programme de garantie/RMA de Servpro Industries, inc.,

la preuve d'achat et le document de garantie de

l'appareil sont ajoutés à la base de données. Ce service

permet au franchisé d'économiser du temps et des

ressources pour obtenir la couverture de garantie de

l'équipement.

Après avoir reçu le formulaire de demande de

garantie/RMA dûment rempli, un coordonnateur RMA

examinera l'état de la garantie de l'équipement

mentionné avant de soumettre les renseignements de la

demande au(x) vendeur(s).

Si l'appareil est couvert par la garantie, le coordonnateur

RMA communiquera le processus de réparation et de

retour.

Si l'équipement n'est pas couvert par la garantie, le(s)

vendeur(s) fourniront un devis de réparation

concurrentiel avant d'effectuer toute réparation hors

garantie. Le coordonnateur RMA présentera les options

de réparation et recevra l'approbation du franchisé avant

d'autoriser toute réparation hors garantie.

Le SERVPRO RMA Department est là pour vous servir!

INTRODUCTION

Le déshumidificateur Revolution réduit l'humidité dans

des environnements structurels clos en éliminant la

vapeur d'eau de l'air. Lorsqu'il est utilisé de façon

approprié, il peut aider à sécher les matériaux structurels

humides, les matériaux d'isolation, et le contenu, et à

maintenir un niveau d'humidité sain. L’utilisation du Revolution peut également empêcher des dommages

secondaires causés par une humidité élevée.

Comment fonctionne le Revolution

Le réfrigérant déshumidificateur Revolution utilise un

ventilateur pour aspirer l'air humide à l'intérieur et le

condense pour le transformer en eau qui s'accumule sur

un plateau et qui est automatiquement pompée à travers

d’un tuyau de vidange. L'appareil peut être configuré

pour fonctionner en continu ou l'utilisateur peut

sélectionner le mode Humidistat (Hygrostat). En mode

Humidistat, le Revolution se met en marche et s'éteint

automatiquement pour maintenir le niveau d'humidité

d'entrée sélectionné par l'utilisateur.

Caractéristiques :

• Déshumidificateur de qualité industrielle élimine

jusqu'à 63 litres d'eau par jour.

• Hygrostat automatique qui permet de fixer et

maintenir le niveau d'humidité désiré.

• Des pieds encastrés assurent l’empilage sécurisé

jusqu'à trois appareils Revolution pour le stockage

et le transport.

• Conçu pour l'empilage et le transport pratique sur

un chariot manuel.

• Poignées encastrées pour faciliter l’emplacement

dans des espaces confinés.

• Fonctionnement silencieux et faible consommation

d'énergie.

COMMANDES ET MODE D'EMPLOI

Placer l'appareil en position horizontale

AVIS : Toujours stocker, transporter et utiliser

l'appareil en position horizontale. Si l'appareil a été

placé en position verticale, le retourner à la position

horizontale et le laisser se reposer pendant au

moins 30 minutes avant de l'allumer.

Positionnement du déshumidificateur

Pour de meilleurs résultats, placer le déshumidificateur

dans un espace clos. Fermer toutes les portes et

fenêtres qui s'ouvrent vers l'extérieur afin de maximiser

l'efficacité de l'élimination de l'eau. Placez votre

déshumidificateur à l’écart de toute obs tr uction et de tout

ce qui pourrait bloquer la circulation d'air d’entrée et de

sortie de l’appareil. Pour plus d'informations sur la

création d'un environnement de séchage optimal,

contacter Dri-Eaz au 800 932 3030.

07-01897D #613 (F413-SP) Warranty 07-00420 24 Dri-Eaz Products, Inc.

Page 25

peut s'écouler en toute sécurité. Si vous utilisez un seau

ON/OFF (Marche/Arrêt)

Appuyer brièvement pour

allumer/ét eindre l’appareil.

Menu d’affichage

Appuyer pour passer à l'élément suivant

l'écran.

Touche de sélection de menu /

Vers le haut

Appuyer pour basculer ou sélectionner

des valeurs dans le menu affiché.

Pompe d’évacuation

Appuyer et relâcher pour commencer

Poignées de transport

Fig. A : Identification des pièces

Connexion rapide

condensat

Entrée d’air

Panneau de

Retirer/Insérer

ici

Sortie d’air

Prise

d’alimentation

Pour le

tuyau.

Capteur

Temp/HR

Panneau de commande

ON/OFF

Marche/Arrêt

AFFICHAGE

Menu

d’affichage

Touche de sélection

de Menu/ Vers le

haut

Pompe d’évacuation

ou un autre récipient pour la collecte de l'eau, le vérifier

régulièrement pour éviter les débordements.

stockage du

cordon et du

pour le tuyau de

Mettre en place le tuyau de vidange

La pompe à condensat du Revolution se connecte à un

tuyau de vidange en matière plastique. Ce tuyau est

équipé d'un raccord rapide pour une connexion rapide

au tuyau de vidange de 40 pieds (12 m) inclus. Déballer

du menu. Élément du menu s’affiche à

l’évacuation. L’affichage affiche les

secondes restantes av ant que

soit terminée.

l'ensemble du tuyau et placez l'extrémité libre dans un

évier, un drain, un seau ou à l'extérieur - partout où l'eau

07-01897D #613 (F413-SP) Warranty 07-00420 25 Dri-Eaz Products, Inc.

commande

le filtre d’air

l’évacuation

AVIS : Dérouler et redres s er le tuyau de vidange. Ne

laisser aucune partie du tuyau enroulée et ne pas placer

l'extrémité du tuyau supérieur à plus de 20 pieds (6

mètres) au-dessus du fond de l'appareil. Vérifier

également s’il existe des plis ou autres obstacles

susceptibles de limiter le débit d'eau. Les obstructions

peuvent causer des débordements.

Brancher le cordon électrique

Le Revolution doit être branché dans une prise de 115

volts protégée par DDFT évaluée au moins à 15

ampères. Toujours brancher le cordon fermement

d’abord dans l’appareil unité, puis brancher l'autre

extrémité dans une prise de courant appropriée.

Écran de démarrage et modes d'affichage normaux

Lorsque l'appareil est branché à une prise secteur,

l'affichage du panneau de commande affichera

brièvement une série d’affichages. Cela fait partie de la

procédure d'autodiagnostic de l'appareil et aucune intervention de l'utilisateur n'est requise.

Allumer l'appareil

Le panneau de commande sur le déshumidificateur

Revolution dispose d'un écran et d'un pavé tactile à

quatre touches. Appuyer sur le bouton

(Marche/Arrêt) pour allum er l'appar eil. L' appareil

commencera à effectuer un compte à rebours pour le

démarrage différé du compresseur (jusqu'à soixante

secondes) et le processus d'autodiagnostic. Une fois le

compte à rebours pour le démarrage différé du

compresseur et le processus d'autodiagnostic terminés,

l'écran passe en mode d'affichage normal.

UNIT ON 00 HRS

INLET 00°C / INLET 00%

La première ligne de l'écran affiche le nombre total

d'heures de fonctionnement de l'appareil. Cette valeur

peut être remise à zéro pour faire le suivi des heures de

travail (voir «Remise à zéro des heures de travail » cidessous). La deuxième ligne de l'affichage alterne entre la température de l’air d'entrée et l'humidité de l’air

d’entrée.

Menu des paramètres utilisateur

L’utilisateur peut modifier certains paramètres

d'affichage ainsi que les Informations système. Ces

éléments sont accessibles en appuyant sur

MENU. Chaque pression sur la touche affiche le

paramètre suivant. Lorsque vous atteignez le paramètre

que vous souhaitez régler, appuyez sur

LECTION pour augmenter la valeur. Appuyez

PLAY MENU de nouveau pour valider le réglage et

redémarrer le cycle. Si aucune touche n'est sélectionnée

pendant 5 minutes, l'écran se réinitialise et retourne au

mode d'affichage normal.

ON/OFF

DISPLAY

MENU SE-

DIS-

Page 26

Veuillez noter que seuls les éléments de menu suivis du

symbole supérieur à (>) peuvent être réglés.

Tous les paramètres et les modes sont décrits en détail

dans le Guide Panneau de commande, ci-dessous.

Messages d'erreur

Si le système de diagnostics embarqué du Revolution découvre un problème, l'appareil affiche un message d'erreur. Voir « Messages système », à la page 7 pour une explication de chaque message.

Guide du Panneau de commande

ON/OFF. Appuyer pour allumer ou éteindre

l’appareil. Lorsque l'appareil est allumé, l'écran affiche

normalement « PLEASE WAIT COMP. DELAY »

(Veuillez attendre la fin du compte à rebours) et effectue

un compte à rebours pour un maximum de 60 secondes

à 0. Ce délai permet aux pressions du réfrigérant à

s’égaliser pour faciliter le démarrage. Une fois que le

délai de démarrage du compresseur est terminé, l'écran

affiche UNIT ON XX HRS (Appareil a fonctionné pendant XX heures) et alterne entre INLET XX °F et INLET

XX% (température de l’air d’entrée et l'humidité de l’air