Page 1

Owner’s Manual

WARNING

LGR 2800i Portable Dehumidifier (F410)

LGR 3500i Portable Dehumidifier (F411)

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Phone: 800-932-3030 Fax: 360-757-7950 LegendBrandsRestoration.com

The Dri-Eaz® LGR i-Series dehumidifiers reduce humidity in enclosed structural

environments by removing water vapor from the air. The i-Series product line is engineered

to be rugged, durable and highly portable, making them ideally suited for water damage

restoration, structural drying, construction, and other applications requiring temporary, highperformance dehumidification.

Patents: http://www.LBpatents.com

SAVE THESE INSTRUCTIONS

void your warranty. Contact your authorized

SAFETY INSTRUCTIONS

WARNING! Do not alter or modify your unit in any

way. Use only replacement parts authorized by

Dri-Eaz Products, Inc. Modifications or use of

unapproved parts could create a hazard and will

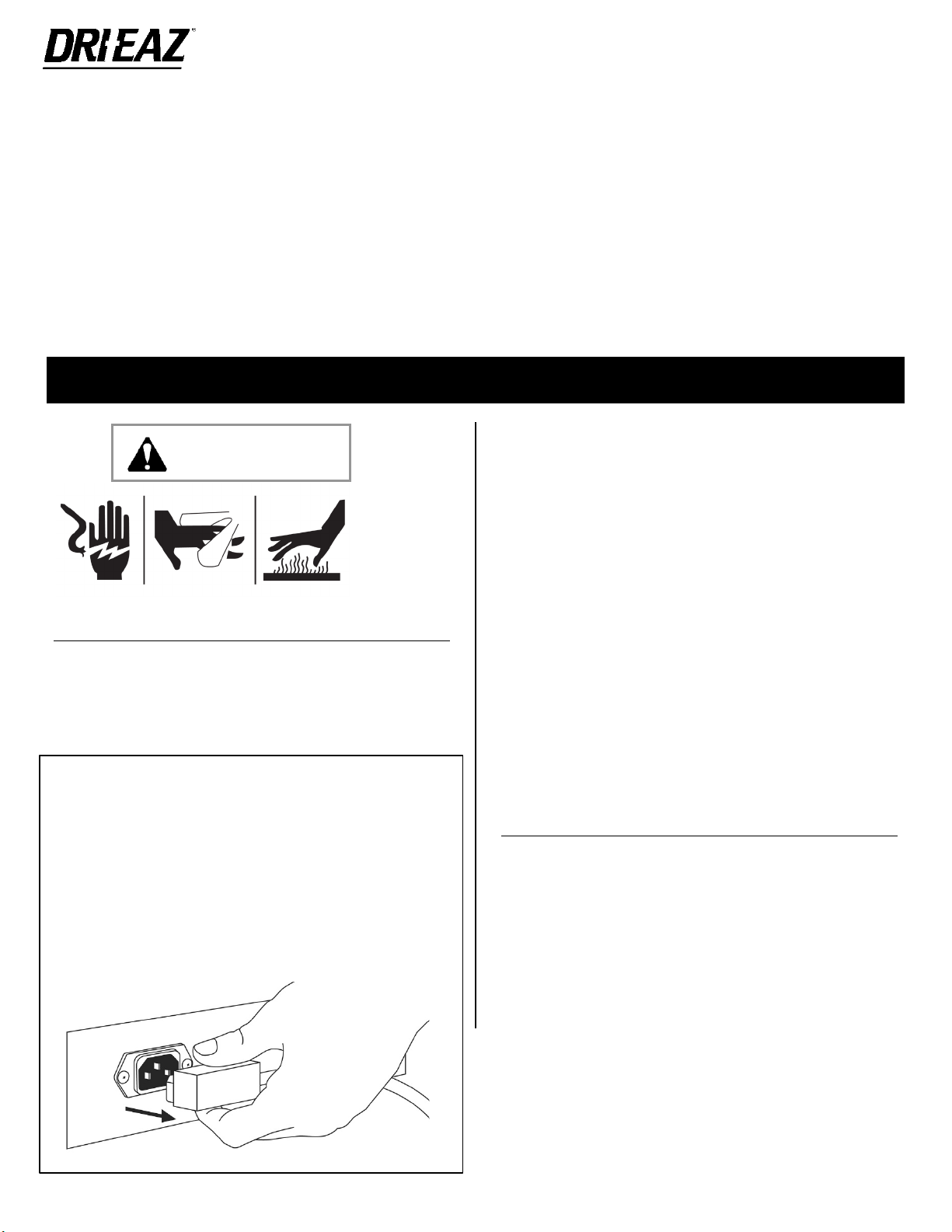

CORRECT PLUG REMOVAL

Grasp IEC plug and pull straight out

IMPORTANT: Damage to IEC receptacle or

dehumidifier resulting from improper removal of

the power cord is not covered by warranty. The

IEC power cord is a wear item and is not covered

by warranty.

distributor for assistance.

WARNING! Electric shock hazard, rotating fan, hot

surface hazards. Unplug unit before opening cover

for cleaning or servicing. Unit must be grounded.

• Inspect the power cord before use. If cord is

damaged, do not use. Always grasp the plug (not

the cord) to unplug.

• Insert three-prong plug on power cord into a

matching electrically grounded outlet. Do not use

adapter. Never cut off third prong. Do not use an

extension cord.

• The unit must be operated on a 115V/60Hz circuit

protected by a Ground Fault Circuit Interrupter

(GFCI) device.

• Keep motor and wiring dry.

• Do not attempt to repair the unit. For Authorized

Service Centers, contact Dri-Eaz.

BEFORE YOU BEGIN

Warranty registration

Visit warranty.LegendBrandsRestoration.com to register

your purchase. Registration allows us to better assist

you with using, maintaining or servicing your equipment

and to contact you in case we have important safety

information concerning your Dri-Eaz product. If you

determine service is required, have your equipment

model, serial number and original proof of purchase

available and call your distributor for assistance with

obtaining a return material authorization (RMA).

07-01674N F410, F411 1 Dri-Eaz Products, Inc.

Page 2

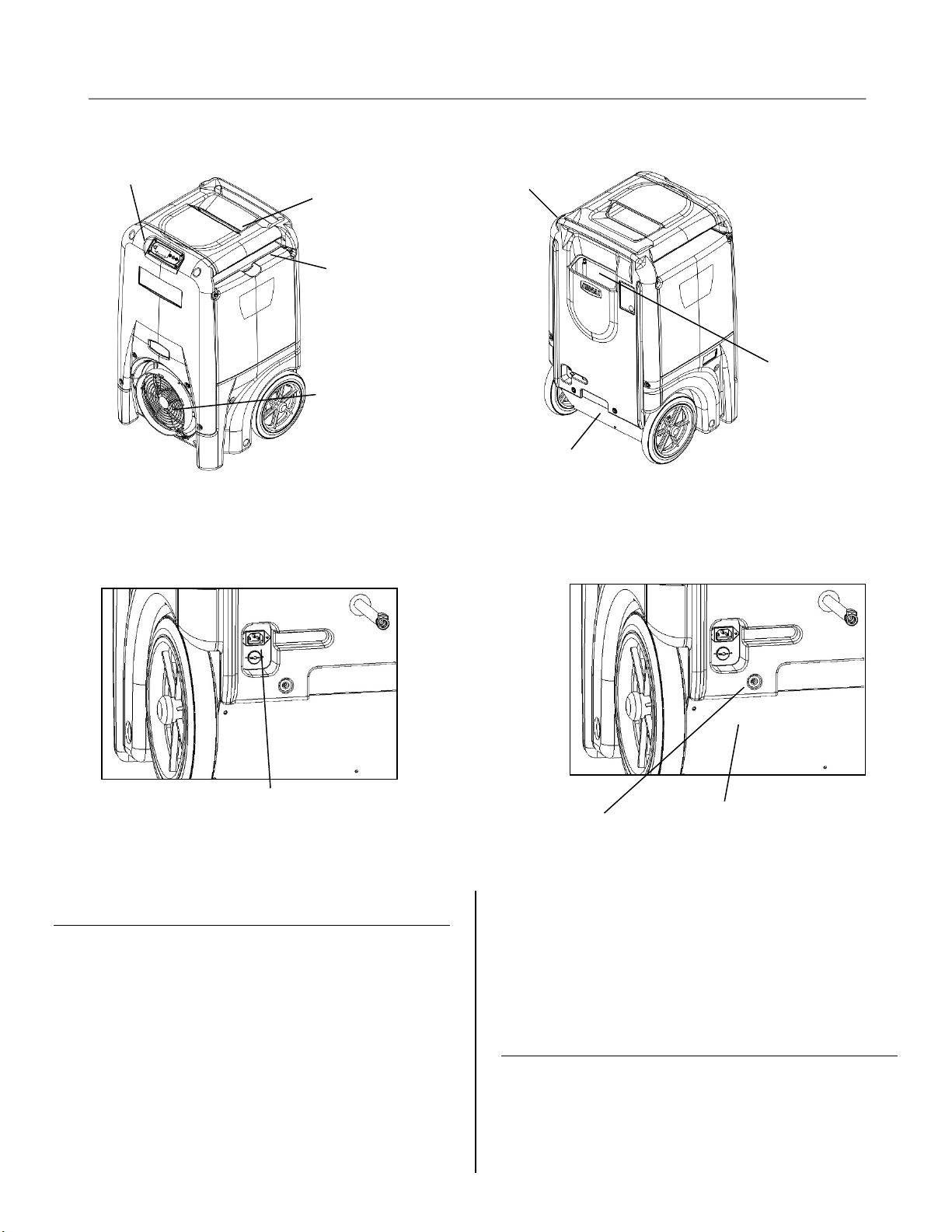

Rugged rotomolded

PARTS IDENTIFICATION

FIG. A: FRONT

FIG. B: REAR

Control panel.

FIG. C: POWER AND PUMP

ATTACHMENT POINTS

Molded pocket

for cord storage.

Humid air inlet

(both sides).

Process (dehumidified)

air outlet. May be used

with standard 12" rigid

or layflat ducting.

Integrated handle.

housing resists dents

and scratches and is

easy to maintain.

Drain hose pocket.

Lower back panel. Remove

this panel to access the

pump for servicing.

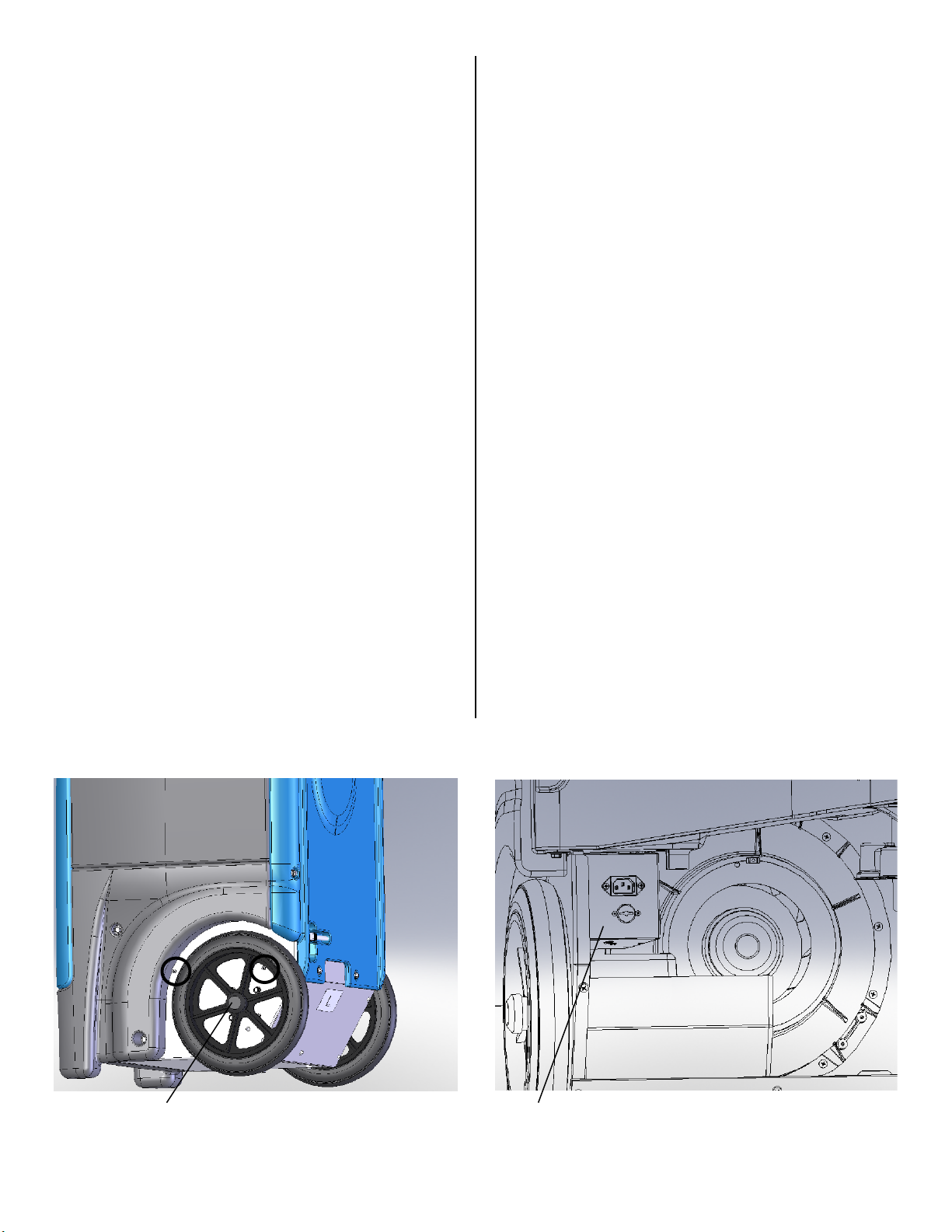

FIG. D: PUMP ACCESS PANEL

Power cord socket.

Bottom of back

polyethylene housing.

Remove two bolts to

remove pump for cleaning.

Lower back panel. Remove the

five retaining screws to remove

pump for cleaning.

including temperature and relative humidity, which can

INTRODUCTION

How LGR dehumidifiers work

Dri-Eaz LGR (low-grain refrigerant) dehumidifiers

operate by pulling moist air in across a very cold

be viewed on the display panel.

LGR dehumidifiers have better heat exchange and

defrost abilities than regular refrigerant dehumidifiers,

and are able to continue removing moisture in drier

environments.

evaporator core. The moisture in the air condenses on

the coil. In certain conditions, the machine operates in

defrost mode, warming any frost that has accumulated

on the evaporator coil back into water. The water

collects in a tray and is pumped out through a hose.

Onboard sensors continually monitor environmental

conditions and system operations of the dehumidifier,

POSITIONING A DEHUMIDIFIER

For best results, operate your dehumidifiers in an

enclosed area, as this creates a drying chamber. Close

all doors and windows that open to the outside to

maximize the unit’s water removal efficiency. Also, keep

traffic though the drying chamber to a minimum. Place

07-01674N F410, F411 2 Dri-Eaz Products, Inc.

your dehumidifier against a wall, away from obstructions,

Page 3

IMPORTANT

To help prevent drip tray overflow after using the dehumidifier, always purge the unit before moving.

1. Turn the unit off and allow the plugged in dehumidifier to rest for 10 minutes.

2. Press the PURGE key and while the purge pump is operating, tip the unit back approximately 45° and

hold the unit in place until the purge cycle is complete. The manual purge cycle lasts approximately 10

seconds.

3. Return the unit to the upright position and press PURGE one more time to empty the pump.

Remove the dehumidifier promptly from the job site once these steps have been completed.

and keep it away from anything that could block airflow

into and out of the unit. For more information about

creating an optimum drying environment, contact DriEaz at 800-932-3030.

OPERATING YOUR DEHUMIDIFIER

Set unit upright

NOTICE: If you transport an i-Series dehumidifier in a

horizontal position, set it upright and let it stand for at

least 30 minutes before you turn it on. When the

machine is horizontal, the oil from the compressor flows

into the refrigerant coils reducing the ability of the

dehumidifier to function. Letting the unit stand upright for

30 minutes allows the oil to flow back into the

compressor.

Set up drain hose

This unit automatically pumps out water on a regular

basis. This dehumidifier is equipped with a quickconnect fitting for attachment to the provided 40 ft. (12

m) drain hose located in the side pocket. Unwrap the

entire hose and place the open end in a sink, drain,

bucket or outdoors – anywhere that water can drain out

safely. If you use a bucket or other container for water

collection, check it regularly to prevent overflows.

UNIT ON 00 HRS

INLET 00°F / INLET 00%

The first line of the display shows the total number of

hours the unit has been in operation. This value may be

reset to zero to track job hours (see “Job Hours Reset”

below). The second line of the display alternates

between inlet temperature and inlet humidity.

User Settings Menu

A number of display settings may be changed by the

user. System information can also be displayed. These

items are accessed by pressing

Each press of the key will display the next parameter.

When you reach the parameter you wish to adjust, press

MENU SELECTION to increase the value. Press

DISPLAY MENU again to accept the setting and re-start

the display cycle.

Note that only menu items followed by a greater-than

symbol ( > ) may be adjusted.

All settings and modes are discussed in detail in Control

Panel Guide.

Error messages

If the onboard diagnostics discover a problem, the unit will display an error message. See “System Messages.”

DISPLAY MENU.

NOTE: Uncoil and straighten the entire drain hose.

Do not leave any of part of the hose coiled on the

unit and do not place the end of the hose higher

than 20 ft. (6 m) above the top of the unit. Also

check for kinks, or obstructions that would restrict

the flow of water. Failure to do so may cause a water

backup in the pump resulting in leakage.

Plug in electrical cord

The i-Series dehumidifier should be plugged into a

GFCI-protected 115 volt outlet rated for at least 15

Remove the cord from its storage pocket and uncoil it.

Always plug the cord firmly into the unit first, and then

plug the other end into a suitable outlet.

amps.

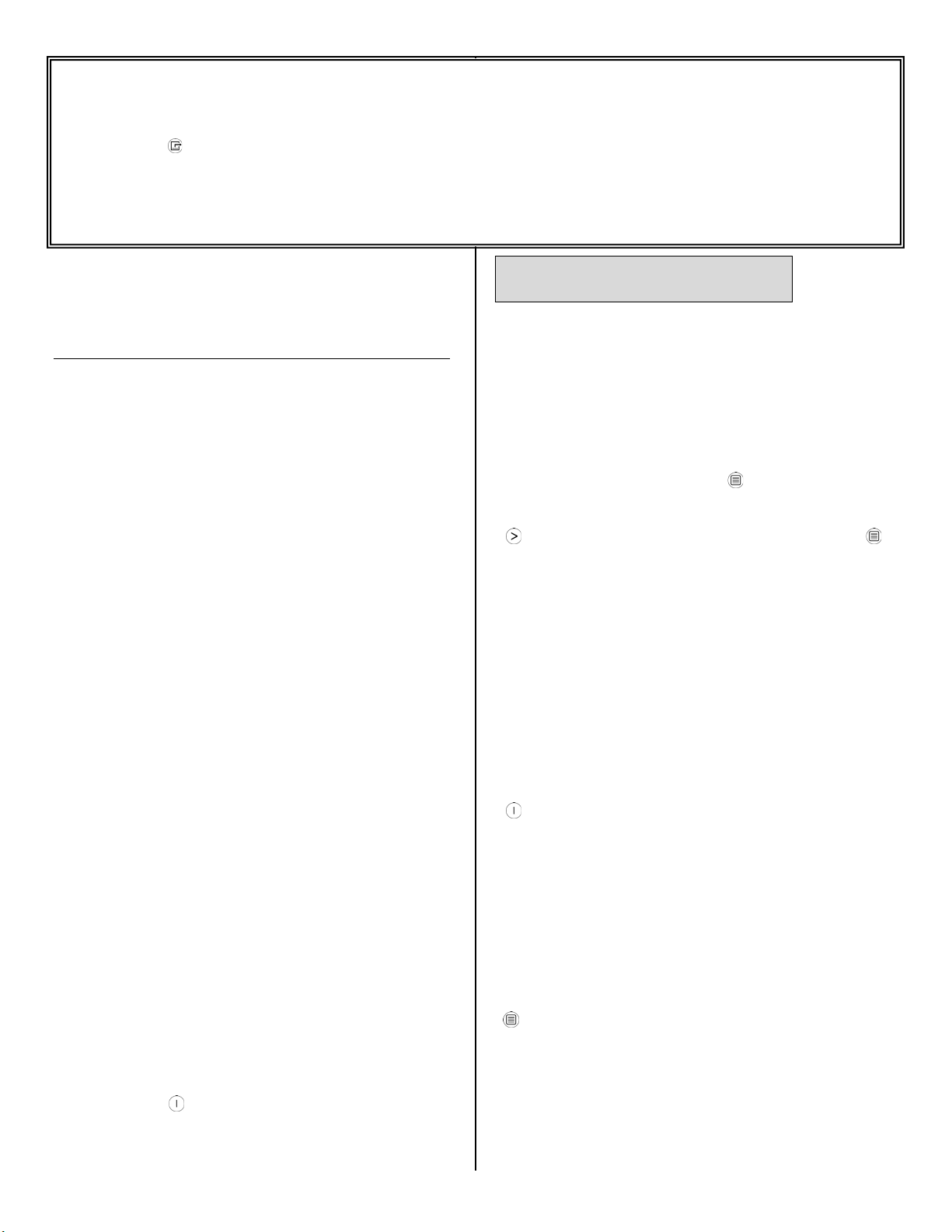

Control Panel Guide

ON/OFF. Press to turn the unit on or off. When the

machine is turned on, the display normally reads

PLEASE WAIT COMP. DELAY and performs a numeral

countdown for a maximum of 60 seconds to 0. This

delay allows time for refrigerant pressures to equalize for

easier starting. Once the unit completes the compressor

delay, the display shows UNIT ON XX HRS and cycles

between INLET XX°F and INLET XX%. NOTE: If no

compressor delay countdown is displayed, a delay is not

necessary and the machine will begin operation

immediately.

DISPLAY MENU. Press to cycle through the display

of additional dehumidifier conditions and User Settings.

Turn the unit on

The control panel has a display and a touchpad with four

keys. Press the ON/OFF to turn the unit on. The unit

will now go through a compressor delay countdown (up

to 60 seconds in duration) and a self-diagnostics

process, then switch to normal display mode.

07-01674N F410, F411 3 Dri-Eaz Products, Inc.

Page 4

ON/OFF

Press and release to turn unit

or off.

DISPLAY MENU

Press to select next item in

display.

MENU SELECTION /

UP KEY

Press to toggle or select values

in menu displayed.

PURGE PUMP

Press and release to start

purge is complete.

CONTROL PANEL

DISPLAY

ON/OFF

DISPLAY

MENU

PURGE PUMP

MENU

SELECTION /

UP KEY

on

menu. Menu item will show in

To return to the main menu, press the ON/OFF key

once.

MENU SELECTION. Press to change the values of

the "User Defined" settings. The MENU SELECTION

key acts as the UP key for adjusting the setpoint for

Humidistat mode operation. See User Settings Menu.

PURGE. Press to empty water from the condensate

pump reservoir. The display will read PUMP PURGING

with a numeral countdown.

NOTE: During normal operation, the pump purges

automatically.

Changing settings and viewing system information

Display setting changes and system information can be

accessed by pressing

of the key will display the next parameter (see list

below). When you reach the parameter you wish to

adjust, press

value. Press

MENU SELECTION to increase the

DISPLAY MENU again to accept the

setting and re-start the display cycle.

Note that only menu items followed by a greater-than

DISPLAY MENU. Each press

purge. Display will count

down seconds remaining until

symbol ( > ) may be adjusted.

.

07-01674N F410, F411 4 Dri-Eaz Products, Inc.

Page 5

USER SETTINGS

the next menu item. ↓

1. JOB HRS RESET >

PWR INTERRUPT X

1. JOB HR RESET 0

PWR INTERRUPT 0

2. INLET OUTLET

100' 80% 115' 30%

For information only.

3. GRAIN DPR

XX GPP

Note: Unit displays GPP if set to Fahrenheit or g/kg if set to Celsius. To change this setting, see menu item 9.

4. FILTER CHECKED

XXX HRS >

5. FILTER CHECKED

0 HRS

5. COIL CLEANED

XXX HRS >

5. COIL CLEANED

0 HRS

6. HUMIDISTAT

6. HUMIDISTAT

7. HUMIDISTAT

8. LANGUAGE

8. IDIOMA

8. SPRACHE

8. LANGUE

9. TEMP UNITS

'F >

9. TEMP UNITS

‘C >

10. COIL TEMP

XX’

For information only.

11. COMP CURRENT

XX.X A

For information only.

12. FIRMWARE

3.0X FXXX-XXX

For information only.

13. LIFE HOURS

XXXX HRS

(Returns to

top menu item.)

The following section available only on wireless-equipped units.

14. SENSOR ID

(Returns to

top menu item.)

Only menu items followed by a greater-than symbol (>) can be adjusted. If no keys are selected for 5 minutes on screens: INLET

OUTLET, GRAIN DPR (INLET-OUTLET for 230V models), the display will return to normal display mode. In all the other menu items,

the display with return to the normal display mode after 20 seconds. Items without the symbol (>) are for information only and cannot be

changed or reset.

Press DISPLAY

MENU to proceed to

Press MENU SELECTION to change the setting. →

MODE OFF >

SETPOINT XX% >

ENGLISH >

MODE ON >

Press to cycle through 40%–90% at 5% increments (default is 50%).

ESPANOL >

Press to reset to 0.

Press to clear filter hours.

Press to clear coil hours.

Press to turn ON or OFF. For maximum dehumidification, make sure

HUMIDISTAT is OFF.

DEUTSCH >

FRANCAIS >

Press to change

language options.

XXXXXXXX

Press to change to °F or °C.

07-01674N F410, F411 5 Dri-Eaz Products, Inc.

Page 6

AT THE END OF THE JOB

To reduce the possibility of drips when moving the

unit, follow these additional steps to ensure that all

water is removed from the unit.

NOTICE: The unit will complete the defrost cycle even if

the unit is turned off but still plugged in. If the unit is

unplugged during the defrost cycle, excessive water may

accumulate in the unit and may drip out when you move

the unit.

NOTICE: To ensure the condensate tank empties

completely while purging, make sure the unit is placed

upright on a horizontal surface.

1. Do not turn unit off or move it until it has returned

to normal operating mode. To confirm unit status,

review the control panel. The control panel will

display one of the following messages:

Defrost in progress:

UNIT ON 00 HRS

DEFROST XX

Display mode when unit is

in defrost mode. XX

indicates the seconds

remaining on the defrost

cycle.

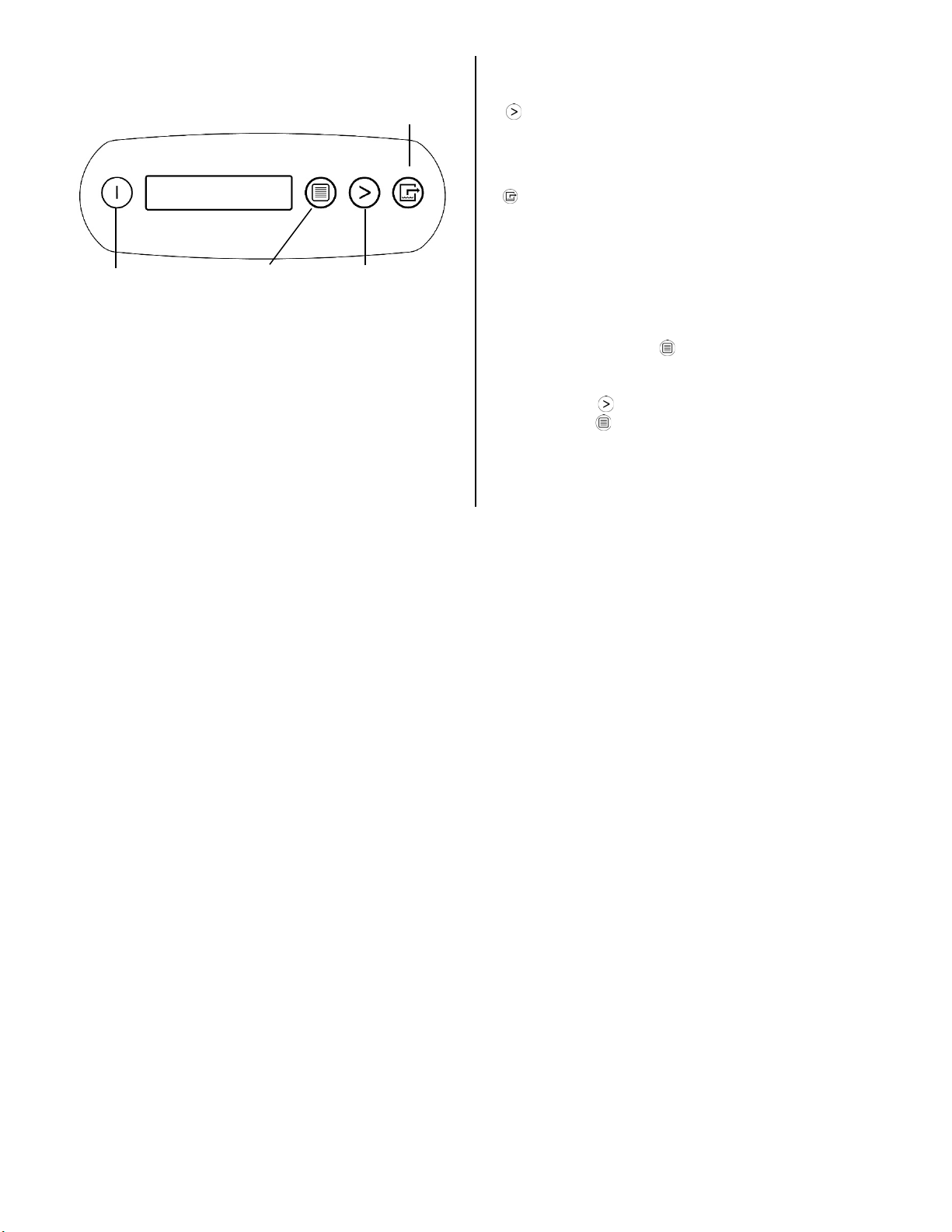

FIG. G: CLEANING

UNIT ON 00 HRS

INLET XX°C

Wait until the control shows the normal display before

proceeding.

2. Gently rock the machine to ensure any water

remaining on interior surfaces falls into the sump

area.

3. Press the PURGE key. When the purge cycle is

complete, turn the unit off.

4. Disconnect the external drain hose, drain it

carefully, coil it and secure it in the pocket or the

strap provided with your unit.

MAINTENANCE

WARNING! ELECTRIC SHOCK HAZARD. Unplug the

dehumidifier before performing any maintenance.

Before each use

Inspect the electrical cord for damage. Look for

fraying, cuts, etc. Do not use the unit if you find any

4-PRO filter

Shutdown sequence

WAIT FOR

DEFROST XX

Display mode when unit in

defrost and unit is powered

down (shut off by user).

Unit will complete the

defrost cycle to remove

any built-up ice then purge

the pump. XX indicates the

seconds remaining on the

defrost cycle.

Drying sequence

WAIT FOR

UNIT DRYING XX

Display mode when unit

not in defrost and unit is

powered down (shut off by

user). Unit will complete

the 5 minute drying cycle

then purge the pump. XX

indicates the seconds

remaining on the drying

cycle.

Air-to-air heat

exchange block.

Arrows printed on

the block indicate

correct orientation

for installation.

Condenser coil

Side cover B

Evaporator (cold) coil

Rear cover

Side cover A

Normal display:

Pump hose – thread up through

hole in bottom of rear hose

pocket before reinstalling cover.

07-01674N F410, F411 6 Dri-Eaz Products, Inc.

Page 7

damage. Call Dri-Eaz for the nearest Service Center at

FIG. F: ELECTRIC BOX LOCATION

After removing attachment screws (Fig. E), tilt the bottom of the

FIG. E: ELECTRIC BOX

ATTACHMENT SCREWS

1. After placing a firm support under the base of the unit, remove

detach the electric junction box.

800-932-3030.

Inspect filter. Replace if accumulation of dust and

debris is visible.

NOTICE: Replace used filters only with a new DriEaz filter (Dri-Eaz part no. FXXX). Other filter types

do not provide adequate filtration or airflow.

Monthly

Check coils. Dirty coils can cause the unit to overheat.

Clean when visibly dirty.

Check heat exchange block. Clean out with

compressed air only. Take care not to damage the block.

Inspect and clean the pump. To remove the

condensate pump unit:

SERVICING THE PUMP AND DRAIN PAN

To maintain proper operation, the pump and drain pan

assembly should be periodically removed and cleaned.

Follow these steps to clean the pump and drain pan

assembly:

Tools Needed

Philips screwdriver

Flat blade screwdriver

⅜ in. and

Cleaning cloths

DISASSEMBLY AND CLEANING

1. Unplug unit, then remove the power cord from the

socket at the base of the unit. Remove pump hose at

quick-connect.

2. Remove filter.

3. Remove the two bolts from the upper front cover.

15

∕

in. sockets and driver

16

4. Remove one bolt each from the upper back corner of

side covers A and B (see Fig. A)

5. Remove four bolts from the lower back panel. The

back/top panel may now be removed.

6. Remove lower back metal panel (unscrew the five

attachment screws).

7. Place a firm support under the base of the unit so that

the left wheel may be removed.

8. Using the flat blade screwdriver, carefully pry the

15

∕

center hub cap loose from the left wheel. Use the

16

in.

socket to remove the retaining nut and slide the wheel

off. See Fig. E, #1.

9. Remove the two electric box retaining screws (see

Fig. E, #2.).

10. Tilt the bottom of the electric box to the right and

slide outward (Fig. F). It is not necessary to disconnect

any electrical cables.

11. Remove drain hose from pump assembly and slide

pump and tray assembly out of the unit.

12. Lift pump body out of plastic catch tray.

13. Wipe or rinse off all surfaces of the plastic catch tray

with a damp cloth.

CLEANING THE PUMP AND PUMP TRAY

14. Remove the pump assembly from the pump tray and

set pump aside. Wipe or rinse out pump tray and wipe

dry.

15. Remove pumpout hose from the check valve outlet.

16. Unscrew check valve. Using needle nose pliers,

carefully remove bottom of check valve assembly by

inserting one side of pliers approximately ⅛ in. into hole,

grasp and pull out carefully. A small ball bearing should

fall out so be careful not to lose it. Inspect assembly for

debris in assembly and clean accordingly. Reinstall the

ball bearing and reinstall the check valve assembly.

the center hub cap and remove the axle nut. The wheel will now

slide off. 2. Remove the two screws (shown in the circles above) to

07-01674N F410, F411 7 Dri-Eaz Products, Inc.

electrical box to the right and slide it out. Set aside. It is not necessary

to disconnect any electrical cables.

Page 8

Reassemble in reverse order. The dehumidifier is now

ready for use.

Annually

Have the pump system inspected by the Dri-Eaz Service

Department (800-932-3030) or by a qualified service

center.

TRANSPORTATION AND STORAGE

IMPORTANT: Before moving, transporting or

storing, purge unit and stow hose and power cord as

described in the “At the End of the Job” section

above.

NOTICE: Handle the unit carefully. Do not drop, throw or

place the unit where it could fall. Rough treatment can

damage the dehumidifier and may create a hazardous

condition or void the warranty.

• Do not expose the control panel to moisture, snow

or rain.

• Store and transport securely to avoid any damaging

impact to internal parts.

• Secure during transport to prevent sliding and

possible injury to vehicle occupants.

• Do not transport or store the unit on its front, sides or

back. This will help to prevent any remaining moisture

from escaping from the unit or flowing into areas

outside the sump.

CLEANING COILS AND HEAT EXCHANGE BLOCK

Warning! Unplug unit before servicing.

To help keep the unit operating efficiently, keep the coils

and the air-to-air heat exchange block clean. Access

these components by removing the side and rear covers:

1. Unplug unit.

2. Unplug the power cord from the socket at the base of

the unit. Remove pump hose at quick-connect.

3. Remove filter.

4. Remove both side covers A and B (unscrew two bolts

shown for each panel).

5. Remove back cover (unscrew the four bolts shown on

the back and the two bolts on the upper front panel).

6. Remove the heat exchange block.

Inspect the heat exchange block carefully. If necessary,

use compressed air to clear the channels of the block,

taking care not to damage the block.

NOTICE: The unit is fitted with sensitive electronic

sensors. Protect the sensors from impact and do not

expose them to water or cleaning solution.

Vacuum or use compressed air on both sides of the

upright (condenser) coil until it is clean. Take care not to

let the nozzle touch the fins; as this may damage the

fins. A coil cleaner product may be used on the

horizontal cold (evaporator) coil only. Follow instructions

on product label. Take care not to spray or wipe product

on or near any electrical components or sensors. To

clean the vertical (condenser) coil, contact Service for

instructions.

To reassemble, follow the above steps in reverse. Be

sure to reinstall heat exchange block in the original

orientation. When installing the rear cover, carefully

thread the pump hose through the hole in the back

pocket before putting the cover in place.

NOTICE: Rubber strips are attached to the outside

edges of the evaporator and condenser coils to

provide an airtight seal around the heat exchange

block. When reinstalling the block, make sure the

seals are in place and are not kinked or folded.

07-01674N F410, F411 8 Dri-Eaz Products, Inc.

Page 9

INITIALIZING

Unit is powering up.

None

FIRMWARE VERSION

XXX

Indicates control board firmware version number.

None

FXXX-XXX

Model number.

None

OFF

Unit has finished powering up and is operating.

None

PLEASE WAIT

COMP. DELAY XX

60s delay before compressor turns on. Allows system

pressure to equalize.

None

UNIT ON XXXX HRS

First line: indicates total operating hours.

inlet RH every 2 seconds.

None

HUMIDISTAT

First line: indicates unit is in humidistat mode

None

LOW TEMP

Unit shuts off if inlet temp below 45°F/7°C. Turns back on

None

None

HI TEMP CYCLE

REMAINING XX MIN

Unit overload limit reached. Cool-down initiated.

None

---

DEFROST XX

Unit is defrosting, with countdown in seconds.

None

WAIT FOR

Unit turned off when coil is cold or already in a defrost

the coils of ice before storage.

None

WAIT FOR

UNIT DRYING XXX

Occurs when unit is turned off and coil is not frozen.

Clears the coils of water before storage.

None

CHECK FILTER >

---

Prompt to change filter.

Change filter. Press the > key

to reset

CLEAN COILS >

---

Prompt to clean coils and interior.

Clean coils. Press the > key

to reset

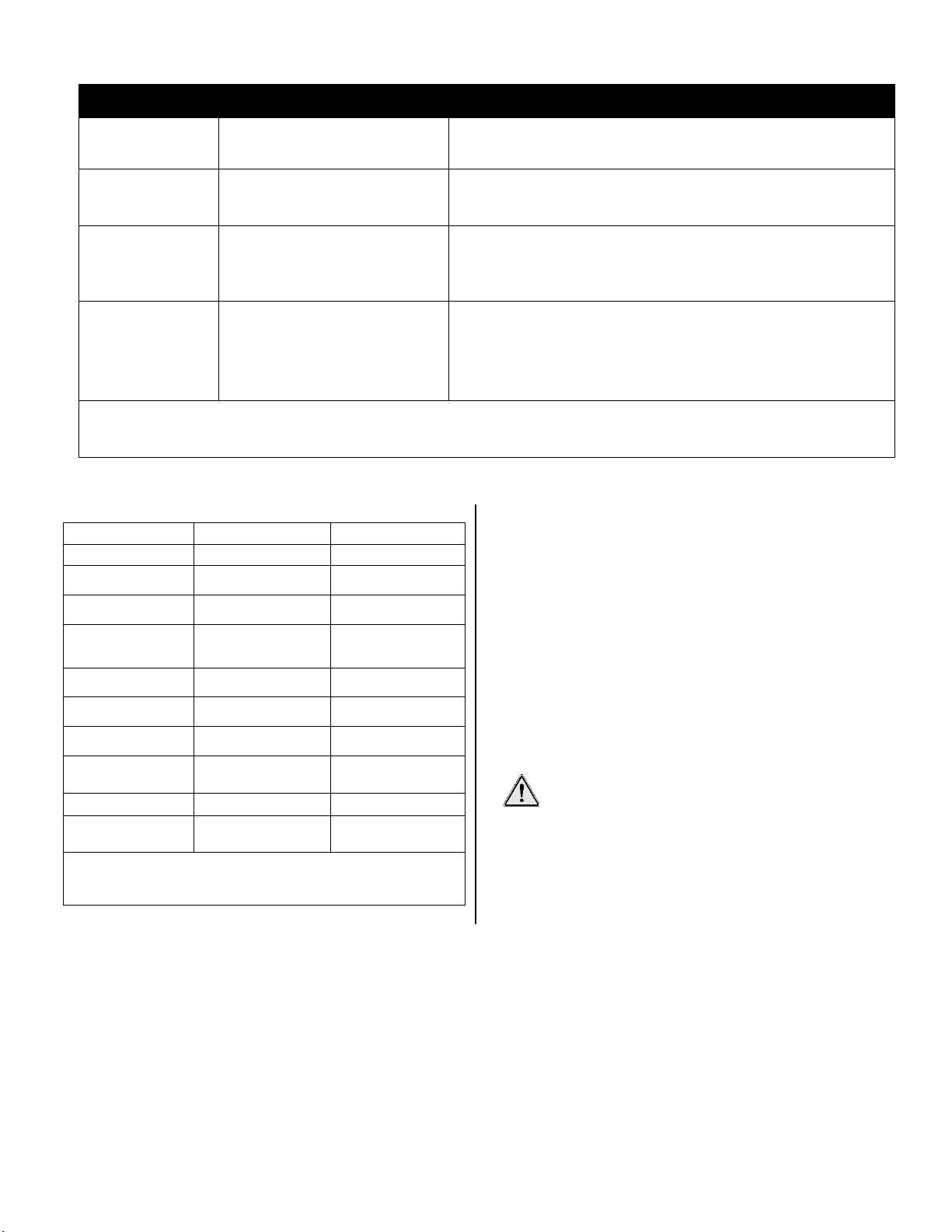

SYSTEM MESSAGES

The Control Panel will display the following messages based on system performance and environmental conditions. User

action, if any is required, is indicated in the third column.

CONTROL PANEL

MESSAGE

INLET XXX°F / XX%

INLET XXX°F / XX%

INLET XXX°F/ XX%

---

PUMP PURGING XX

EXPLANATION USER ACTION

Second line: Toggles between inlet temperature and

Second line: Toggles between inlet temperature and

inlet RH every 2 seconds.

when inlet reaches 50°F/10°C.

Pump is purging with countdown in seconds. Press key

again to stop if needed.

DEFROST XXX

cycle. Proceeds to finish cycle or initiate one to clear

07-01674N F410, F411 9 Dri-Eaz Products, Inc.

Page 10

ERROR MESSAGES

If the control system detects an error, it will produce an error (“ER”) message. If this occurs, first unplug the unit and then

plug it back in. This will usually reset the electronics, and the unit will begin operating normally. If the error message

reappears, refer to the explanations and solutions shown below. If these solutions do not fix the problem, contact your

local authorized service center.

CONTROL PANEL

MESSAGE

ER4 DEFROST

SENSOR CONNECT

or

ER4 OUTLET

SENSOR CONNECT

ER5 SENSOR

CONNECTION ON BD

ER6 CONTACT

SERVICE CENTER

ER7 INVALID

MODEL SETTING

ER8 BUTTON STUCK

ALL BUTTONS

EXPLANATION AND SOLUTION

Temp sensor is open, missing, or shorted. Check that temp sensors are installed

correctly on control panel. If error persists, contact service.

Inlet Temp/RH sensor is open, missing, or shorted. Check that inlet temp/RH sensor is

installed correctly on control panel and inlet shroud. If error persists, contact service.

Current sensor failure. If error persists, contact service.

Incorrect or unsupported DIP switch settings. Contact Dri-Eaz service department for

correct DIP switch settings.

Key is stuck or has been held down too long. Contact service.

ER9 PUMP BLOCKED

PUMP & HOSE

Check for obstructions in drain hose. Check the pump.

07-01674N F410, F411 10 Dri-Eaz Products, Inc.

Page 11

Switch unit on.

base of unit.

Make sure “Humidistat” is OFF.

Seal off area to reduce infiltration.

Dimensions

(H × D × W)

40.5 × 23 × 24 in.

103 × 58 × 61 cm

40.5 × 23 × 24 in.

103 × 58 × 61 cm

8.0 amps,

120 volts

11.2 amps,

120 volts

Water removal

RH)

Water removal max.

(90°F/90% RH)

200 pts. | 94.6 liters /

day

240 pts. | 113.6 liters

/ day

Water removal

80°F/20% RH

20 pts. | 9.5 liters /

day

24 pts. | 11.4 liters /

day

400 CFM | 679.7

CMH*

400 CFM | 679.7

CMH*

TROUBLESHOOTING

FAULT CAUSE SOLUTION

Water drips out

when moving unit

Unit does not

operate

Unit operating,

but room not dry

Unit was unplugged before

purging was complete.

Unit not switched on.

No power to machine.

Not enough time to dry.

Poor air movement in room.

Excessive moist air infiltration.

Room air is dry.

Unit collects too

little water

Room temperature is too low.

Filter is full.

Coils are clogged.

If the problem you are experiencing is not listed here, call your local distributor or contact

our Service Department at 800-932-3030 for further assistance.

SPECIFICATIONS

Model LGR 2800i F410 LGR 3500i F411

Use weight 156 lbs. | 70.8 kg 158 lbs. | 71.2 kg

Purge unit before moving. See “At the End of the Job.”

Plug in unit; check power cord connection at wall outlet and at

Allow more time for drying.

Increase air movement with air movers.

Make sure “Humidistat” is OFF.

Confirm humidity level with hygrometer.

Increase room temperature.

Check filter. Replace as necessary.

Check coils. Clean as necessary.

PARTS INCLUDED

40 ft. (12 m) of drain hose with quick-connect fitting.

25 ft. (7.6 m) detachable power cord.

4-PRO air filter (reorder F584 24 pk.)

Power

AHAM (80°F/60%

Max process air

Operating range

Construction Rotomolded shell Rotomolded shell

Safety

Specifications are subject to change without notice. Some values may

be approximate. *Automatic variable speed for optimized

performance.

130 pts. | 61.5 liters /

day

33°F–125°F

1°C–52°C

ETL certified to CSA

22.2 no. 92

170 pts. | 80.4 liters /

day

33°F–100°F

1°C–38°C

ETL certified to CSA

22.2 no. 92

ACCESSORIES

VMax Adaptor (F422)

Sto&Go Ducting (F405)

FOR PARTS AND SERVICE CALL YOUR LOCAL

DISTRIBUTOR or Dri-Eaz at 800-932-3030. Visit

warranty.LegendBrandsRestoration.com and register

your purchase to ensure you receive any important

product releases.

WARNING: This product may expose you to

chemicals, including lead and phthalates, known

to the State of California to cause cancer, birth defects,

or other reproductive harm. For more information, go to

P65Warnings.ca.gov

07-01674N F410, F411 11 Dri-Eaz Products, Inc.

Page 12

ADVERTENCIA

Manual para el usuario

Deshumidificador Portátil LGR 2800i (F410)

Deshumidificador Portátil LGR 3500i (F411)

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Teléfono: 800-932-3030 Fax: 360-757-7950 LegendBrandsRestoration.com

La serie de deshumidificadores Dri-Eaz® LGR iSeries reduce la humedad en ambientes

cerrados eliminando el vapor de agua que se encuentra en el aire. El modelo iSeries está

creado de modo que sea resistente, duradero y fácil de transportar, características que lo

convierten en un elemento sumamente adecuado para la reparación de daños causados por

el agua, el secado de estructuras, la construcción y otros usos para los que se necesita

temporalmente un deshumidificador de alto rendimiento.

Patents: http://www.LBpatents.com

GUARDE ESTAS INSTRUCCIONES

mejor asistencia en el uso, el mantenimiento o la

reparación de su equipo, y también comunicarnos con

usted en caso de que tengamos información de

seguridad importante sobre su producto de Dri-Eaz. Si

considera que su producto necesita reparación, tenga a

mano el modelo del equipo, el número de serie y el

comprobante de compra original, y llame a su

distribuidor para que lo ayude a obtener una

autorización para devolver el producto (RMA, por sus

siglas en inglés).

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

ADVERTENCIA! Peligro de sufrir una descarga

eléctrica, lastimarse con el ventilador rotatorio y

quemarse con una superficie caliente. Desenchufe

la unidad antes de abrir la tapa para limpiarla o

hacerle mantenimiento. La unidad debe tener

descarga a tierra.

• Controle el cable de alimentación antes de usarlo.

Si está dañado, no lo use. Para desenchufar la

unidad, tire siempre del enchufe (nunca del

cable).

• Coloque el enchufe de tres clavijas que está en el

extremo del cable de alimentación en un

tomacorriente con descarga a tierra adecuado. No

use adaptadores. Nunca corte la tercera clavija.

No use cables prolongadores.

• La unidad debe utilizarse en un circuito eléctrico

de 115 V/60 Hz, protegido por un interruptor del

circuito de fallos de conexión a tierra (GFCI, por

sus siglas en inglés).

• No utilice el aparato en agua estancada.

Mantenga el motor y los cables secos.

INTRODUCCIÓN

Los deshumidificadores Dri-Eaz reducen la humedad en

ambientes cerrados eliminando el vapor de agua que se

ADECUADO RETIRO DEL ENCHUFE

Tome el enchufe IEC y tire recto

IMPORTANTE: Cualquier daño en el

receptáculo IEC o en el deshumidificador

consecuencia de un inadecuado retiro del

cable eléctrico no será cubierto por la

garantía. El cable eléctrico IEC es un

elemento con desgaste y no está cubierto

por la garantía.

ANTES DE COMENZAR

Registro de la garantía

Visite warranty.LegendBrandsRestoration.com para

registrar su compra. El registro nos permite brindarle

07-01674N F410, F411 12 Dri-Eaz Products, Inc.

Page 13

encuentra en el aire. Si se usa correctamente, el

deshumidificador puede ayudar a secar alfombras,

almohadillas para alfombras, pisos, paredes, elementos

en el interior de una propiedad y más. También puede

ayudar a prevenir daños secundarios causados por el

exceso de humedad. Para obtener mejores resultados,

cuando use los deshumidificadores, coloque

ventiladores TurboDryer de Dri-Eaz alrededor del

perímetro de la habitación, a fin de distribuir la energía

térmica y hacer que la humedad de las superficies

mojadas se pierda en el aire.

Cómo funcionan los deshumidificadores LGR

Los deshumidificadores refrigerantes de grano bajo

(LGR, por sus siglas en inglés) de Dri-Eaz hacen que el

aire húmedo atraviese un evaporador muy frío. La

humedad del aire se condensa en el serpentín. En

determinados momentos, la máquina funciona en modo

"descongelación", ya que calienta la escarcha

acumulada en el serpentín del evaporador y la convierte

nuevamente en agua. El agua se acumula en un

recipiente y se elimina por una manguera. Los sensores

integrados controlan permanentemente las condiciones

ambientales y las operaciones del sistema del

deshumidificador, incluidas la temperatura y la humedad

relativa, que pueden observarse en la pantalla de

visualización.

Los deshumidificadores refrigerantes de grano bajo

(LGR) poseen una mayor capacidad de intercambio de

calor y de descongelación que los deshumidificadores

refrigerantes normales; asimismo, pueden seguir

eliminando humedad en ambientes más secos.

DÓNDE COLOCAR UN DESHUMIDIFICADOR

Para obtener mejores resultados, utilice su

deshumidificador en un espacio cerrado, lo que permite

crear una cámara de secado. A fin de aumentar al

máximo la eficacia de la unidad para eliminar el agua,

cierre todas las puertas y ventanas que den al exterior.

Además, trate de que el tránsito dentro de la cámara de

secado sea mínimo. Coloque su deshumidificador contra

una pared, lejos de cualquier elemento que lo obstruya,

y manténgalo alejado de cualquier objeto que pueda

bloquear el flujo de aire que entra y sale de la unidad.

Para obtener más información sobre cómo crear un

ambiente de secado óptimo, llame a Dri-Eaz al

800-932-3030.

07-01674N F410, F411 13 Dri-Eaz Products, Inc.

Page 14

FIG. C: PUNTOS DE CONEXIÓN DE

FIG. A: PARTE DELANTERA

IDENTIFICACIÓN DE LAS PARTES

FIG. B: PARTE TRASERA

Panel de control.

LA BOMBA Y LA ENERGÍA

Cavidad moldeada

para guardar el

cable.

Entrada de aire

húmedo (ambos

lados).

Salida de aire procesado

(deshumidificado). Puede

usarse con un conducto

estándar de 12" (30.5 cm)

rígido o plano.

Entrada del cable de

alimentación.

Parte inferior del armazón

trasero de polietileno.

Quite los dos pernos para

sacar la bomba y

limpiarla.

Manija integrada.

Armazón rotomoldeado

fuerte, resistente a

abolladuras y rayones, y

fácil de mantener.

Cavidad para guardar la

manguera de drenaje.

Panel trasero inferior. Quítelo

para acceder a la bomba y realizar

tareas de mantenimiento.

FIG. D: PANEL DE ACCESO A LA BOMBA

Panel trasero inferior. Quite los

cinco tornillos que lo sostienen para

sacar la bomba y limpiarla.

CÓMO USAR SU DESHUMIDIFICADOR

Coloque la unidad en posición vertical

AVISO: Si transporta un deshumidificador i-Series en

posición horizontal, enderécelo y déjelo en posición

vertical durante al menos 30 minutos antes de

prenderlo. Cuando la máquina está en posición

horizontal, el aceite del compresor fluye hacia los

serpentines refrigerantes, lo que disminuye la capacidad

de funcionamiento del deshumidificador. Dejar la unidad

07-01674N F410, F411 14 Dri-Eaz Products, Inc.

en posición vertical durante 30 minutos permite que el

aceite vaya nuevamente hacia el compresor.

Coloque la manguera de drenaje

La bomba de condensado del modelo i-Series se

conecta a una manguera de drenaje plástica, ubicada en

la cavidad de la parte de atrás de la unidad. Dicha

manguera incluye un adaptador de conexión rápida para

ajustarla fácilmente a la manguera de drenaje de 40 pies

(12 m) proporcionada.

coloque el extremo suelto en una pila, un desaguadero,

un balde o afuera: en cualquier lugar donde el agua

Desenrolle toda la manguera y

Page 15

ON/OFF (ENCENDIDO /

Presione y suelte para

o apagar la unidad.

DISPLAY MENU (MENÚ DE

Presione para seleccionar el

mostrará en la pantalla.

MENU SELECTION /

ARRIBA)

Presione para cambiar o

BOMBA DE PURGADO

Presione y suelte para

para que se complete la purga.

pueda drenar de forma segura. Si acumula el agua en

un balde u otro recipiente, contrólelo con frecuencia

para evitar derrames.

NOTA: Desenrosque y estire toda la manguera de

drenaje. No deje ninguna parte de la manguera

enroscada en la unidad ni coloque el extremo de la

manguera a más de 20 pies (6 m) por encima de la

parte superior de la unidad. Controle también que

no haya dobleces u obstrucciones que impidan el

paso del agua. De lo contrario, es posible que la

bomba se tape y pierda agua.

Enchufe el cable eléctrico

El deshumidificador i-Series debe enchufarse en un

tomacorriente de 115 voltios, protegido por un GFCI,

con capacidad para 15 amperios como mínimo. Saque

el cable de la cavidad donde está guardado y

desenrósquelo. Conecte siempre primero y con firmeza

el cable que va a la unidad. Después, enchufe el otro

extremo del cable en un tomacorriente adecuado.

Prenda la unidad

El panel de control del deshumidificador i-Series tiene

una pantalla y una placa sensible al tacto con cuatro

teclas. Presione la tecla

para prender la unidad.

PANEL DE CONTROL

PRENDIDO/APAGADO

BOMBA DE

PURGADO

Cómo usar el panel de control

El panel de control tiene una pantalla y una placa

sensible al tacto con cuatro teclas.

PRENDIDO/APAGADO. Presione la tecla

PRENDIDO/APAGADO para prender o apagar la

unidad. Cuando se prende la máquina, suele aparecer

en la pantalla la leyenda POR FAVOR ESPERE RETAR

COMPRS y se produce una cuenta regresiva que va

desde un máximo de 60 segundos hasta 0. Esta demora

permite que las presiones de refrigerado se equilibren

para que el comienzo sea más sencillo. Si no aparece

una cuenta regresiva por el retardo del compresor,

significa que dicho retardo no es necesario y que la

máquina comenzará a funcionar de inmediato. Una vez

que finaliza el retardo del compresor, aparece en la

pantalla PRENDIDO XXXX H, y se alterna el mensaje

ENTRADA XXX °F con el mensaje ENTRADA XX%.

MOSTRAR MENÚ. Presione la tecla MOSTRAR

MENÚ para ver en la pantalla otros estados del

deshumidificador y las Configuraciones del Usuario.

Para volver al menú principal, presione la tecla

PRENDIDO/APAGADO una sola vez.

SELECCIÓN DEL MENÚ. Presione la tecla

SELECCIÓN DEL MENÚ para cambiar los valores en

las Configuraciones del Usuario. La tecla SELECCIÓN

DEL MENÚ también funciona como la tecla ARRIBA, a

fin de modificar el valor prefijado para que la unidad

funcione en modo “humidistato”. Para obtener una

descripción detallada, consulte “Menú de

configuraciones del usuario” (más abajo).

PANTALLA

ON/OFF

(ENCEND

APAGADO)

PANTALLA)

UP KEY (SELECCIÓN DE

MENÚS / FLECHA HACIA

07-01674N F410, F411 15 Dri-Eaz Products, Inc.

DISPLAY

MENU (MENÚ

DE

PANTALLA)

encender

siguiente elemento del menú.

El elemento del menú se

seleccionar los valores en el

menú desplegado.

empezar a purgar. La pantalla

mostrará una cuenta regresiva

de los segundos que falten

MENU SELECTION /

UP KEY

(SELECCIÓN DE

MENÚS / FLECHA

HACIA ARRIBA)

PURGAR. Presione el botón PURGAR para vaciar en

forma manual el agua que se encuentra en el depósito

de la bomba de condensado. AVISO: Presione siempre

la tecla de purgado antes de mover la unidad. Durante el

funcionamiento normal, la bomba se purga

automáticamente cada seis minutos, o cada vez que el

depósito esté lleno. En la pantalla se verá BOMBA

PURGANDO y una cuenta regresiva.

Pantalla del menú principal

Cuando la unidad se enchufa por primera vez a la

corriente alterna, la pantalla del panel de control

mostrará rápidamente una serie de datos. Este

procedimiento forma parte del autodiagnóstico de la

unidad y no se necesita la intervención del usuario.

Cuando finaliza el autodiagnóstico, la pantalla exhibirá la

siguiente información:

PRENDIDO XXXX H

ENTRADA XXX °F / ENTRADA XX%

La primera línea de la pantalla indica la cantidad total de

horas que ha funcionado la unidad. Este valor puede

llevarse a cero para hacer un seguimiento de las horas

de trabajo (vea más abajo "Reinicio de las horas de

trabajo"). La segunda línea de la pantalla alterna la

temperatura de entrada con la humedad de entrada.

Para obtener instrucciones detalladas del control.

Page 16

menú. ↓

1. HRS REINICIAR>

FALLA DE LUZ X

1. H DE TRABAJO 0

FALLA DE LUZ 0

2. ENTRADA SALIDA

100' 80% 115' 30%

Sólo para información.

3. ENTRADA-SALIDA

XX.X g/kg

4. FILTRO

XXX HR >

5. FILTRO

0 HRS

5. LIMPIAR BOBINA

XXX HRS >

5. LIMPIAR BOBINA

0 HRS

6. HIGROSTATO

6. HIGROSTATO

7. CONSIGNA

8. IDIOMA

8. SPRACHE

8. LANGUE

8. LANGUAGE

las opciones de idioma.

9. TEMPERATURA

'C >

9. TEMPERATURA

‘F >

10. TEMP BOBINA

XX’

Sólo para información.

11. CORR COMPRS

XX.X A

Sólo para información.

12. FIRMWARE

3.0X FXXX-XXX

Sólo para información.

13. TOTAL DE HRS

XXXX HR

(Regresa al

superior).

La siguiente sección está disponible sólo en las unidades equipadas con sistema inalámbrico.

14. SENSOR ID

(Regresa al

superior).

AJUSTES DE USUARIO

Solo se pueden ajustar los elementos del menú que estén seguidos de un símbolo de «mayor que» (>). Si no se selecciona ninguna tecla en las

siguientes pantallas en un lapso de 5 minutos: INLET OUTLET (ENTRADA SALIDA), DPR GRAIN (GRANO DE DPR) (INLET OUTLET para los

modelos 230V), la pantalla volverá al modo de visualización normal. En todos los demás elementos de menú, la pantalla regresará al modo de

visualización normal después de 20 segundos. Los elementos que no tienen el símbolo (>) son únicamente para información y no se pueden cambiar ni

restablecer.

Presione DISPLAY

MENU (MOSTRAR

MENÚ) para pasar a la

siguiente opción del

Presione MENU SELECTION (SELECCIÓN DEL MENÚ) para cambiar el ajuste. →

COMPROBAR

MODO APAGADO>

HIGROSTATO XX%>

ESPANOL >

COMPROBAR

MODO PRENDIDO>

Presione para alternar entre el 40% y el 90% en incrementos de 5% (el valor predeterminado es de 50%).

DEUTSCH >

Presione para restablecer a 0.

Presione para borrar las horas de limpieza del filtro.

Presione para borrar las horas de limpieza de la bobina.

Presione para poner en ON u OFF (ENCENDER o APAGAR).

FRANCAIS >

Presione para cambiar a °F o °C.

ENGLISH >

Presione para cambiar

elemento del menú

XXXXXXXX

elemento del menú

07-01674N F410, F411 16 Dri-Eaz Products, Inc.

Page 17

AL FINALIZAR EL TRABAJO

Para reducir la posibilidad de goteos al mover la

unidad, siga estos pasos adicionales para

asegurarse de que toda el agua sea retirada de la

unidad.

AVISO: Para asegurar que toda el agua sea quitada del

deshumidificador, la unidad habrá de completar el ciclo

de descongelamiento incluso si se halla apagada. Si la

unidad fuera desenchufada durante el ciclo de

descongelamiento, es posible que se acumule en la

misma el exceso de agua y gotear cuando se la

traslade.

AVISO: Para asegurarse de que el tanque de

condensado se vacíe por completo mientras se hace el

purgado, asegúrese de que la unidad esté en posición

vertical sobre una superficie horizontal.

1. Si la unidad está en un ciclo de

descongelamiento, espere hasta que regrese al

modo normal de funcionamiento antes de proceder.

Para comprobar, revise el panel de control. Éste

mostrará uno de los siguientes mensajes:

Descongelamiento en progreso:

PRENDIDO XXXX H

DESCONGELE XX

Modo de visualización cuando la unidad está en modo

de descongelamiento. XX indica los segundos restantes

en el ciclo de descongelamiento.

Secuencia de apagado

ESPERE A QUE SE

DESCONGELE XX

Modo de visualización cuando la unidad está en modo

de descongelamiento es apagada (por el usuario). La

unidad completará el ciclo de descongelamiento para

quitar cualquier hielo acumulado y luego purgará la

bomba. XX indica los segundos restantes en el ciclo de

descongelamiento.

Secuencia de secado

ESPERA PARA

SECADO DE LA UNIDAD XX

Modo de visualización cuando la unidad no está en

modo de descongelamiento y es apagada (por el

usuario). La unidad completará el ciclo de secado de

5 minutos y después purgará la bomba. XX indica los

segundos restantes en el ciclo de descongelamiento.

Visualización normal:

UNIDAD EN 00 h

ENTRADA XX °C / ENTRADA XX%

Espere hasta que el control muestre la pantalla normal

antes de proceder.

2. Mueva suavemente la máquina para asegurarse

de que cualquier resto de agua en las superficies

interiores caiga en el área del colector.

3. Pulse la tecla de PURGADO . Cuando se

complete el ciclo de purgado, apague la unidad.

07-01674N F410, F411 17 Dri-Eaz Products, Inc.

4. Desconectar el tubo de drenaje externo, escurrir

con cuidado, enrollarla y fijarlo en el bolsillo o en la

correa suministrada con la unidad.

MANTENIMIENTO

¡ADVERTENCIA! PELIGRO DE DESCARGA

ELÉCTRICA. Desenchufe el deshumidificador antes

de realizar cualquier tarea de mantenimiento.

Antes de cada uso

Controle el cable eléctrico para detectar daños.

Fíjese que el cable no esté pelado, cortado, etc. No use

la unidad si detecta algún daño. Para conocer el Centro

de Servicio Técnico más cercano, llame a Dri-Eaz al

800-932-3030.

Controle y aspire el filtro cuando sea necesario. Los

deshumidificadores i-Series están equipados con un

filtro para alto flujo de aire 4-PRO. El filtro para 4-PRO

se puede limpiar con aspiradora y volver a usar hasta

tres veces. No enjuague ni lave el filtro para 4-PRO,

ya que reducirá la eficacia del material electrostático.

Tenga siempre un filtro limpio en la unidad para proteger

los componentes internos contra la acumulación de

polvo y otras partículas. Aspire o cambie el filtro antes

de cada trabajo. Reemplácelo únicamente con un filtro

para 4-PRO nuevo (pieza n.º F584 de Dri-Eaz). Para

solicitar piezas y servicio técnico, llame al distribuidor de

su zona o al Departamento de Servicio Técnico de DriEaz, al 800-932-3030 ó 360-757-7776.

ADVERTENCIA: El polvo puede hacer que la

unidad se recaliente y se apague. No utilice el

equipo cuando haya exceso de polvo o partículas en

el aire, por ejemplo durante el lijado o la pintura con

pulverizador. Controle y limpie los serpentines y los

componentes del filtro de aire con frecuencia.

IMPORTANTE: Reemplace el filtro para 4-PRO

cuando haya sido utilizado en tareas de

eliminación de moho o haya sido expuesto a

sustancias contaminantes potencialmente

peligrosas.

Una vez al mes

Controle los serpentines. Los serpentines sucios

pueden hacer que la unidad se recaliente. Límpielos

cuando los note sucios. Consulte las instrucciones de

limpieza en la página 19.

Controle el bloque de intercambio de calor. Límpielo

con aire comprimido únicamente. Tenga cuidado de no

dañar el bloque.

Controle y limpie la bomba. Para quitar la bomba de

condensado, haga lo siguiente:

MANTENIMIENTO DE LA BOMBA Y LA BANDEJA DE

DRENAJE

A fin de que la unidad siga funcionando correctamente,

debe retirar y limpiar la bomba y la bandeja de drenaje

periódicamente; para hacerlo, siga estos pasos:

Page 18

Herramientas necesarias

Destornillador Phillips

Destornillador de punta plana

Tubos de ⅜ y

tubos

Trapos

DESARMADO Y LIMPIEZA

1. Desenchufe la unidad y luego retire el cable de

alimentación de la entrada que está en la base de la

unidad. Saque la manguera de la bomba de la conexión

rápida.

2. Quite el filtro para 4-PRO.

3. Quite los dos pernos de la tapa superior del frente.

4. Quite el perno de cada esquina trasera superior de

las tapas laterales A y B (vea la Figura A).

5. Quite los cuatro pernos del panel trasero inferior;

ahora puede retirar el panel trasero/superior.

6. Retire el panel metálico trasero inferior (desenrosque

los cinco tornillos restantes).

7. Coloque un soporte firme debajo de la base de la

unidad para sacar la rueda izquierda.

8. Con el destornillador de punta planta, afloje

cuidadosamente el tapacubos central de la rueda

izquierda. Use el tubo de

tuerca de retención y deslizar la rueda hacia afuera. Vea

la Figura E, #1.

9. Quite los dos tornillos de retención de la caja eléctrica

(vea la Figura E, #2).

10. Incline la parte de abajo de la caja eléctrica hacia la

derecha y deslícela hacia afuera (Figura F). No es

necesario que desconecte ningún cable eléctrico.

15

∕

pulgadas (9.5 y 24 mm) y llave de

16

15

∕

pulgadas para sacar la

16

11. Saque la manguera de drenaje de la bomba y

deslice la bomba y la bandeja hacia fuera de la unidad.

12. Levante la estructura de la bomba para sacarla de la

bandeja plástica de recolección y aparte la bomba.

LIMPIEZA DE LA BOMBA Y LA BANDEJA DE LA

BOMBA

13. Enjuague o limpie con un trapo húmedo todas las

superficies de la bandeja plástica de recolección.

14. Limpie con un trapo húmedo todas las superficies de

la bomba.

15. Saque la manguera de bombeo de la salida de la

válvula de retención.

16. Desenrosque la válvula de retención. Con una pinza

de punta de aguja, quite cuidadosamente la parte de

abajo de la válvula de retención; para hacerlo,

introduzca un lado de la pinza en el agujero a unas ⅛

pulgadas (3 mm), apriete y retire con cuidado. Es

probable que salga un soporte de bolas; tenga cuidado

de no perderlo. Inspeccione la unidad y límpiela

conforme sea necesario. Vuelva a colocar el soporte de

bolas y la válvula de retención.

Vuelva a armar la unidad siguiendo los pasos anteriores

a la inversa. El deshumidificador está listo para usar.

Una vez al año

Llame al Departamento de Servicio Técnico de Dri-Eaz

(800-932-3030) o a un centro de servicio técnico

habilitado para que controle el sistema de la bomba.

07-01674N F410, F411 18 Dri-Eaz Products, Inc.

Page 19

TRANSPORTE Y ALMACENAMIENTO

AVISO: Manipule la unidad con cuidado. No la tire ni la

apoye en lugares donde pueda caerse. Si no trata este

equipo con cuidado, puede dañarse y ocasionar algún

peligro, o la garantía puede quedar anulada.

• No exponga el panel de control a humedad, nieve o

lluvia cuando lo transporte en vehículos

descubiertos, tales como los camiones de

plataforma.

• Transpórtelo y almacénelo de manera segura para

evitar cualquier impacto que dañe las partes

internas.

LIMPIEZA DE LOS SERPENTINES Y DEL BLOQUE DE INTERCAMBIO DE CALOR

¡Advertencia! Desenchufe la unidad antes de

realizar cualquier tarea de mantenimiento.

Para contribuir a que la unidad siga funcionando

eficazmente, mantenga limpios los serpentines y el

bloque de intercambio de

calor de aire a aire. Se

puede acceder fácilmente

a estos componentes

quitando las tapas laterales

y trasera de la unidad, tal

como se describe a

continuación:

1. Desenchufe la unidad.

2. Desconecte el cable

de alimentación de la

entrada que está en la

base de la unidad.

Saque la manguera de la

bomba de la conexión

rápida.

3. Quite el filtro para 4PRO.

4. Saque las dos tapas

laterales A y B

(desatornille los dos

pernos que hay en cada

panel).

5. Saque la tapa trasera

(desatornille los cuatro

pernos que hay en la

parte de atrás y los dos

pernos del panel superior

del frente).

6. Quite el bloque de

intercambio de calor.

FIG. G: LIMPIEZA

Bloque de intercambio

de calor de aire a aire.

Las flechas impresas en

el bloque indican el

sentido correcto de la

instalación.

Serpentín

condensador.

Serpentín (frío) evaporador.

Tapa lateral A.

bloque, con cuidado para no dañarlo.

AVISO: La unidad está equipada con sensores

electrónicos sensibles. Proteja los sensores contra

impactos y no los exponga a agua ni a ninguna

solución de limpieza.

Use la aspiradora o el aire comprimido en ambos lados

del serpentín (condensador) vertical hasta que esté

limpio. No permita que la boquilla toque las aletas, ya

que podría dañarlas.

AVISO: El limpiador de serpentín Dri-Eaz Coil Cleaner

(pieza n.º S402 de Dri-Eaz) puede utilizarse únicamente

para el serpentín (evaporador) frío horizontal. Respete

las instrucciones que figuran en la etiqueta del producto.

Tenga cuidado de no rociar o pasar un trapo con Coil

Cleaner en los componentes eléctricos ni en los

sensores, ni cerca de ellos. Para obtener instrucciones

sobre cómo limpiar el serpentín (condensador) vertical,

comuníquese con el Departamento de Servicio Técnico.

Para volver a armar siga los pasos anteriores, pero a la

inversa.

Asegúrese de volver a instalar el bloque de

Filtro de aire para 4-PRO.

Tapa lateral B.

Tapa trasera.

Controle con cuidado el

bloque de intercambio de

calor. De ser necesario,

use aire comprimido para

limpiar las canaletas del

07-01674N F410, F411 19 Dri-Eaz Products, Inc.

Antes de volver a colocar la tapa,

pase la manguera de la bomba por el

agujero que hay en la parte de abajo

de la cavidad trasera para la

manguera.

Page 20

---

PURGA DE AGUA XX

La bomba se está purgando con cuenta regresiva en segundos. Presione la tecla de

nuevo para parar en caso de que sea necesario.

intercambio de calor según la orientación que tenía

originalmente. Antes de volver a colocar la tapa trasera,

pase con cuidado la manguera de la bomba por el

agujero que hay en la cavidad de la parte de atrás.

AVISO: Los bordes exteriores de los serpentines

evaporadores y condensadores tienen burletes de

goma que crean un cierre hermético alrededor del

bloque de intercambio de calor. Cuando vuelva a

instalar el bloque, asegúrese de que los burletes estén

en el lugar correspondiente y no estén torcidos ni

doblados.

BOTÓN DE PURGA DE LA BOMBA

El panel de control mostrará los siguientes mensajes cuando se presione el botón de purga de la bomba.

MENSAJE DEL PANEL DE

CONTROL

EXPLICACIÓN

07-01674N F410, F411 20 Dri-Eaz Products, Inc.

Page 21

INICIALIZAR

La unidad está encendiendo.

Ninguna

VERSION FIRMWARE

XXX

Indica el número de versión del firmware del tablero de

control.

Ninguna

FXXX-XXX

Número de modelo.

Ninguna

APAGADO

La unidad ha terminado de encender y está

funcionando.

Ninguna

POR FAVOR ESPERE

RETAR COMPRS XX

60s de espera antes de que encienda el compresor.

Permite que se iguale la presión del sistema.

Ninguna

PRENDIDO XXXX HR

Primera línea: indica el total de horas de operación.

entrada.

Ninguna

HIGROSTATO

Primera línea: indica que la unidad está en modo de

entrada.

Ninguna

BAJA TEMP

F515 únicamente. La unidad se apaga si la temperatura

encender cuando la entrada alcanza los 50 °F.

Ninguna

CICLO ALTA TEMP.

MIN RESTANTES XX

Se llegó al límite de sobrecarga de la unidad. Se inició

el enfriamiento.

Ninguna

---

DESCONGELE XX

La unidad se está descongelando con cuenta regresiva

en segundos.

Ninguna

ESPERE A QUE SE

La unidad se apaga cuando la bobina está fría o si ya

antes de su almacenamiento.

Ninguna

ESPERE A QUE SE

Ocurre cuando la unidad se apaga y la bobina no está

almacenamiento.

Ninguna

LIMPIAR FILTRO >

Indica limpiar o cambiar el filtro.

Cambiar o limpiar el filtro.

restablecer

LIMPIAR BOBINA >

Indica limpiar las bobinas y el interior.

Limpiar las bobinas.

restablecer

MENSAJES DEL SISTEMA

El panel de control mostrará los siguientes mensajes con base en el desempeño del sistema y las condiciones

ambientales. En caso de que se requieran, se indican las acciones del usuario en la tercera columna.

MENSAJE DEL PANEL DE

CONTROL

ENTRADA XXX°C/ XX%

ENTRADA XXX°C/ XX%

ENTRADA XXX°C/ XX%

EXPLICACIÓN ACTION

Segunda línea: Alterna cada 2 segundos entre la

temperatura de entrada y la humedad relativa de

higrostato

Segunda línea: Alterna cada 2 segundos entre la

temperatura de entrada y la humedad relativa de

de entrada está por debajo de los 45 °F. Se vuelve a

DESCONGELE XXX

SECADO XXX

---

---

está en un ciclo de descongelación. Procede a terminar

el ciclo o a iniciar uno que libere las bobinas de hielo

congelada. Saca el agua de las bobinas antes de su

Presionar la tecla > para

Presionar la tecla > para

07-01674N F410, F411 21 Dri-Eaz Products, Inc.

Page 22

INICIALIZAR

La unidad está encendiendo.

Ninguna

VERSION FIRMWARE

XXX

Indica el número de versión del firmware del tablero de

control.

Ninguna

FXXX-XXX

Número de modelo.

Ninguna

APAGADO

La unidad ha terminado de encender y está

funcionando.

Ninguna

POR FAVOR ESPERE

RETAR COMPRS XX

60s de espera antes de que encienda el compresor.

Permite que se iguale la presión del sistema.

Ninguna

PRENDIDO XXXX HR

Primera línea: indica el total de horas de operación.

entrada.

Ninguna

HIGROSTATO

Primera línea: indica que la unidad está en modo de

entrada.

Ninguna

BAJA TEMP

F515 únicamente. La unidad se apaga si la temperatura

encender cuando la entrada alcanza los 50 °F.

Ninguna

CICLO ALTA TEMP.

MIN RESTANTES XX

Se llegó al límite de sobrecarga de la unidad. Se inició

el enfriamiento.

Ninguna

---

DESCONGELE XX

La unidad se está descongelando con cuenta regresiva

en segundos.

Ninguna

ESPERE A QUE SE

La unidad se apaga cuando la bobina está fría o si ya

antes de su almacenamiento.

Ninguna

ESPERE A QUE SE

Ocurre cuando la unidad se apaga y la bobina no está

almacenamiento.

Ninguna

LIMPIAR FILTRO >

Indica limpiar o cambiar el filtro.

Cambiar o limpiar el filtro.

restablecer

LIMPIAR BOBINA >

Indica limpiar las bobinas y el interior.

Limpiar las bobinas.

restablecer

MENSAJES DEL SISTEMA

El panel de control mostrará los siguientes mensajes con base en el desempeño del sistema y las condiciones

ambientales. En caso de que se requieran, se indican las acciones del usuario en la tercera columna.

CONTROL PANEL MESSAGE EXPLANATION USER ACTION

ENTRADA XXX°C/ XX%

ENTRADA XXX°C/ XX%

ENTRADA XXX°C/ XX%

DESCONGELE XXX

SECADO XXX

---

Segunda línea: Alterna cada 2 segundos entre la

temperatura de entrada y la humedad relativa de

higrostato

Segunda línea: Alterna cada 2 segundos entre la

temperatura de entrada y la humedad relativa de

de entrada está por debajo de los 45 °F. Se vuelve a

está en un ciclo de descongelación. Procede a terminar

el ciclo o a iniciar uno que libere las bobinas de hielo

congelada. Saca el agua de las bobinas antes de su

Presionar la tecla > para

---

07-01674N F410, F411 22 Dri-Eaz Products, Inc.

Presionar la tecla > para

Page 23

MENSAJES DE ERROR

Si el sistema de control detecta un error, se producirá un mensaje de error ("ER"). Si esto ocurre, desconecte la unidad y

luego conéctela de nuevo. Por lo general, esto restablecerá la parte electrónica, y la unidad comenzará a funcionar

normalmente. Si el mensaje de error vuelve a aparecer, consulte las explicaciones y soluciones que se muestran a

continuación. Si estas soluciones no se resuelven el problema, póngase en contacto con su centro de servicio local

autorizado.

MENSAJE DEL PANEL DE

CONTROL

ER4 CONEXION

SENSOR DESCONG

or

ER4 CONEXION

SENSOR SALIDA

ER5 CONEXION

SENSOR TABLERO

ER6 CONTACTAR

CENTRO DE SERV

ER7 INVAL

AJUSTE

ER8 BOTON

ATORADO

EXPLICACIÓN Y SOLUCIÓN

Sensor de temperatura abierto, faltante, o en cortocircuito. Compruebe que los

sensores de temperatura estén instalados correctamente en el panel de control. Si el

error persiste, comuníquese al centro de servicio.

Sensor de temperatura/humedad relativa de entrada abierto, faltante, o en cortocircuito.

Compruebe que el sensor de temperatura/humedad relativa esté instalado

correctamente en el panel de control y la cubierta de entrada. Si el error persiste,

comuníquese al centro de servicio.

Falla en el sensor de corriente. Si el error persiste, comuníquese al centro de servicio.

Configuración incorrecta o incompatible de los interruptores DIP. Comuníquese al

centro de servicio de Dri-Eaz para obtener la configuración correcta de los interruptores

DIP.

La tecla se ha atascado o se ha oprimido por demasiado tiempo. Comuníquese al

centro de servicio.

ER9 BOMBA TAPADA

BOMBA&MANGUERA

Compruebe si hay obstrucciones en la manguera de desagüe. Revise la bomba.

07-01674N F410, F411 23 Dri-Eaz Products, Inc.

Page 24

Dimensiones (altura

ancho)

Eliminación de

humedad relativa)

Eliminación de

humedad relativa)

Eliminación de

humedad relativa)

Cantidad máxima

de aire procesado

Rango de

operación

* Velocidad variable automática para optimizar el desempeño.

ESPECIFICACIONES

Modelo

Peso

× profundidad ×

Potencia

agua según AHAM

(80 °F [26.5

ºC]/60% de

agua máxima (90

°F [32 ºC]/90% de

agua (80 °F

[26.5 ºC]/20% de

LGR 2800i F410

160 lb | 72.6 kg

48.5 × 23 × 24 in

103 × 58 × 61 cm

8.0 A, 120 V

130 pt | 61.5 por día 170 pt | 80.4 l por día

200 pt | 94.6 por día 240 pt | 113.6 por día

20 pts. | 9.5 l por día 24 pt | 11.4 l por día

PIEZAS INCLUIDAS

LGR 3500i F411

160 lb | 72.6 kg

48.5 × 23 × 24 in

103 × 58 × 61 cm

11.2 A, 120 V

40 ft. (12 m) Manguera de desagüe de 40 pies (12 m)

con conexión de acoplamiento rápido.

25 ft. (7.6 m) Cable de alimentación extraíble

4-PRO filter (reorder F584 24 pk.)

ACCESSORIES

VMax Adaptor (F422)

Sto&Go Ducting (F405)

PARA PEDIR INFORMACIÓN SOBRE PIEZAS Y

SERVICIO, LLAME A SU DISTRIBUIDOR LOCAL o a

Dri-Eaz al 800-932-3030.LegendBrandsRestoration.com

Visite el sitio warranty.LegendBrandsRestoration.com y

registre su compra para garantizar que reciba

información sobre los lanzamientos de productos

importantes.

400 cfm | 679.7 m3/h* 400 cfm | 679.7 m3/h*

temperatura de

Construcción

Seguridad

Las especificaciones están sujetas a cambios sin previo aviso. Algunos

valores pueden ser aproximados.

33°F–125°F

1°C–52°C

Carcasa rotomoldeada Carcasa rotomoldeada

Certificación de ETL

conforme a las normas

CSA 22.2 n.º 92

33°F–100°F

1°C–38°C

Certificación de ETL

conforme a las normas

CSA 22.2 n.º 92

ADVERTENCIA: Este producto puede exponerlo

a sustancias químicas entre las que se incluyen

plomo y ftalatos, los cuales son considerados en el

estado de California como causantes de cáncer,

defectos congénitos u otros daños durante la gestación.

Para obtener más información, visite

P65Warnings.ca.gov

07-01674N F410, F411 24 Dri-Eaz Products, Inc.

Page 25

AVERTISSEMENT

Guide d’utilisation

Déshumidificateur portable LGR 2800i (F410)

Déshumidificateur portable LGR 3500i (F411)

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233 (États-Unis)

Téléphone : 800-932-3030 Fax : 360-757-7950 LegendBrandsRestoration.com

La gamme de déshumidificateurs Dri-Eaz® LGR « i » réduit l’humidité dans les

environnements structurels fermés en éliminant la vapeur contenue dans l’air. La gamme « i »

est conçue pour être robuste, durable, facilement transportable et, par conséquent, ces

appareils sont les outils parfaits pour les restaurations à la suite de dégâts causés par l’eau,

pour le séchage structurel et la construction, ainsi que pour d’autres applications exigeant

une déshumidification temporaire à hautes performances.

Patents: http://www.LBpatents.com

CONSERVER CES INSTRUCTIONS

• Ne pas mettre l’appareil en marche lorsque de l’eau

stagne en surface. Le moteur et le câblage doivent

rester secs.

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT! Ne pas modifier d’aucune

façon. Utiliser seulement des pièces de

rechange autorisées par Dri-Eaz Products, Inc.

Toute modification ou l’utilisation de pièces non

approuvées peut constituer un danger et

annulera votre garantie. Contactez votre

distributeur autorisé Dri-Eaz pour obtenir de

l’aide.

AVERTISSEMENT! Danger de décharge

électrique, ventilateur tournant et surfaces très

chaudes. Débrancher l’appareil avant d’ouvrir

le couvercle pour le nettoyage ou l’entretien.

L’appareil doit être mis à la terre.

• Vérifier l’état du cordon d’alimentation avant

utilisation. Ne pas l’utiliser si le cordon est

endommagé. Pour débrancher, toujours saisir

la prise (et non le cordon).

• Enfoncer les trois fiches de la prise du cordon

dans une prise de courant mise à la terre. Ne

pas utiliser d’adaptateur. Ne jamais sectionner

la troisième fiche. Ne pas utiliser de rallonge.

• L’appareil doit fonctionner sur un circuit de

115V/60 Hz protégé par un disjoncteur de fuite

à la terre.

PRÉLIMINAIRES

Enregistrement de la garantie

Enregistrez votre appareil sur le site

warranty.LegendBrandsRestoration.com.

L’enregistrement nous aidera à vous donner des

conseils judicieux quant à l’utilisation, l’entretien ou la

réparation de votre appareil et de vous contacter au cas

où nous aurions des renseignements importants en

matière de sécurité touchant à votre produit Dri-Eaz. Si

vous estimez qu’une réparation s’impose, procurez-vous

COMMENT BIEN ENLEVER LE

CORDON ÉLECTRIQUE

Saisir la prise IEC et tirer en la tenant droite

IMPORTANT : Les dommages occasionnés

au récipient ou au déshumidificateur IEC en

raison d’un retrait incorrect du cordon

électrique ne sont pas couverts par la

garantie. Le cordon électrique IEC étant une

pièce d’usure, il n’est pas couvert par la

garantie.

07-01674N F410, F411 25 Dri-Eaz Products, Inc.

Page 26

FIG. A : AVANT

le modèle de l’appareil, le numéro de série et la preuve

d’achat originale, puis appelez votre distributeur pour

obtenir une autorisation de retour d’article (RMA).

INTRODUCTION

capteurs incorporés surveillent continuellement les

conditions ambiantes et le fonctionnement du système

de l’humidificateur, y compris la température et

l’humidité relative; ces données peuvent être visualisées

sur le panneau d'affichage.

Les déshumidificateurs Dri-Eaz réduisent l’humidité dans

les environnements structurels fermés en éliminant la

vapeur d'eau contenue dans l’air. Lorsqu'ils sont utilisés

correctement, les déshumidificateurs peuvent aider à

sécher les moquettes, les sous-tapis, les planchers, les

murs, le contenu d’un bâtiment, et bien plus. L’utilisation

de déshumidificateurs DriEaz peut également aider à

prévenir des dommages secondaires causés par des

taux d’humidité élevés. Pour obtenir les meilleurs

résultats possibles, utilisez les déshumidificateurs avec

les appareils aérauliques TurboDryer de Dri-Eaz, en les

plaçant sur le périmètre de la pièce afin de distribuer

l’énergie thermique et de dégager l’humidité provenant

des surfaces mouillées dans l’air.

Fonctionnement des déshumidificateurs de la gamme LGR

Les déshumidificateurs réfrigérants à grains Dri-Eaz

fonctionnent en attirant l’air humide à travers un noyau

d’évaporation extrêmement froid. L’humidité de l’air se

condense sur le serpentin. Sous certaines conditions,

l’appareil fonctionne en mode de dégivrage, réchauffe

tout le givre qui aurait pu s’accumuler sur le serpentin de

l’évaporateur et le transforme en eau. L’eau est recueillie

dans un plateau et est pompée à travers un tuyau. Les

Les déshumidificateurs réfrigérants à grains (LGR - Low

Grain Refrigerant) offrent de meilleures capacités

d’échange thermique et de dégivrage que les

déshumidificateurs standard réfrigérants. Ils peuvent

donc continuer à éliminer l’humidité dans des

atmosphères plus sèches.

MISE EN PLACE D’UN DÉSHUMIDIFICATEUR

Pour obtenir les meilleurs résultats possibles, faites

fonctionner vos déshumidificateurs dans une zone

fermée, vu que ceci crée une chambre de séchage.

Fermez toutes les portes et toutes les fenêtres qui

s’ouvrent vers l’extérieur afin de permettre à l’appareil

d’éliminer l’eau de manière la plus efficace possible.

Assurez-vous également que les allées et venues dans

la chambre de séchage sont rares. Placez le

déshumidificateur contre un mur, loin de toute

obstruction, et loin de tout objet qui pourrait bloquer le

débit d’air qui entre et sort de l’appareil.

Pour obtenir de l’information supplémentaire sur la

création d’un environnement de séchage optimal,

contactez Dri-Eaz au 800-932-3030.

IDENTIFICATION DES PIÈCES

Panneau de commande

Réceptacle moulé

pour rangement du

cordon.

Entrée d’air humide

(2 côtés)

Sortie d’air traité

(déshumidifié). Peut être

utilisé avec des conduits

plats ou rigides standard de

12 po

FIG. B : ARRIÈRE

Poignée intégrée

Boîtier rotomoulé

solide résistant aux

bosses et aux rayures

et d’entretien aisé

Réceptacle de tuyau

de vidange

Panneau arrière inférieur.

Retirez-le pour accéder à la

pompe à des fins d’entretien.

07-01674N F410, F411 26 Dri-Eaz Products, Inc.

Page 27

FIG. C : POINTS DE FIXATION DE

L’ALIMENTATION ET DE LA POMPE

Prise femelle du cordon

Bas du boîtier en

polyéthylène. Retirez deux

boulons pour déposer la

pompe pour nettoyage

FIG. D : PANNEAU D’ACCÈS DE LA

POMPE

Panneau arrière inférieur. Retirez les

cinq vis de retenue pour déposer la

pompe pour nettoyage.

FONCTIONNEMENT DU DÉSHUMIDIFICATEUR

Placement vertical de l’appareil

AVIS - Si vous transportez un déshumidificateur de

gamme « i » en position horizontale, placez-le en

position verticale et laissez-le ainsi pendant 30 minutes

au moins avant de le mettre en marche. Lorsque

l’appareil est à l’horizontale, l’huile en provenance du

compresseur s’écoule dans les serpentins réfrigérants,

diminuant la capacité de fonctionnement du

déshumidificateur. L’huile retourne dans le compresseur

lorsque l’appareil est en position verticale pendant 30

minutes.

Pose du tuyau de vidange

La pompe à condensats des déshumidificateurs de

gamme « i » est raccordée à un tuyau de vidange en

plastique qui se trouve dans le réceptacle situé à

l’arrière de l’appareil. Ce tuyau est doté d'un raccord

rapide qui permet de le fixer rapidement au tuyau de

vidange de 40 pieds fourni. Déballez le tuyau au complet

et placez l’extrémité non attachée dans un évier, un

drain, un seau, ou à l’extérieur, dans un endroit où l’eau

peut s’écouler sans danger. Si vous utilisez un seau ou

un autre récipient pour recueillir l’eau, vérifiez-le souvent

pour éviter tout débordement.

REMARQUE - Déroulez et redressez le tuyau de

vidange au complet. Ne laissez aucune partie du

tuyau enroulé sur l’appareil et ne placez pas

l’extrémité du tuyau à une hauteur supérieure à 6 m

(20 pieds) au-dessus de l’appareil. Assurez-vous

également de l’absence d’entortillements et

d’obstructions qui pourraient restreindre le débit de

l’eau. L’eau pourrait remonter dans la pompe si cela

se produisait, et vous auriez des fuites.

Branchement du cordon électrique

Le déshumidificateur de gamme « i » doit être branché

sur une prise de 115 volts protégée par un disjoncteur

de fuite de terre avec un régime nominal minimum de

15 ampères. Retirez le cordon de son réceptacle de

rangement et déroulez-le. Commencez toujours par

brancher le cordon fermement sur l’appareil, puis

branchez l’autre extrémité sur une prise appropriée.

Mise sous tension de l’appareil

Le panneau de commande des déshumidificateurs de

gamme « i » présente un afficheur et quatre touches de

commande. Appuyez sur le bouton

MARCHE/ARRÊT pour mettre l’appareil sous

tension.

Mode d’emploi du panneau de commande

Le panneau de commande comprend un écran et un

clavier tactile avec quatre touches.

MARCHE/ARRÊT. Appuyez sur la touche

Marche/Arrêt pour mettre l’appareil en marche ou pour

l’arrêter. Lorsque l’appareil se met en marche, l’écran

indique généralement SVP ATTENDRE COMP.

DIFFERE XX et effectue un compte à rebours

numérique d’un maximum de 60 secondes jusqu’à 0. Ce

délai fournit le temps nécessaire pour l’équilibrage des

pressions du fluide frigorigène afin de faciliter le

démarrage. Si vous ne voyez pas de compte à rebours

du compresseur différé, aucun délai n’est nécessaire et

l’appareil commence à fonctionner immédiatement.

07-01674N F410, F411 27 Dri-Eaz Products, Inc.

Page 28

ou éteindre l’appareil.

MENU D’AFFICHAGE

Appuyez pour sélectionner l’article

apparaitra sur l’affichage.