Page 1

Owner’s Manual

WARNING

LGR 7000XLi Portable Dehumidifier

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Phone: 800-932-3030 Fax: 360-757-7950 www.dri-eaz.com

The Dri-Eaz® LGR 7000XLi dehumidifier reduces humidity in enclosed environments by

removing water vapor from the air. The 7000XLi is rugged, durable and highly portable, making

it ideal for water damage restoration, structural drying, construction, and other applications

requiring temporary, high-performance dehumidification.

Patents Pending – May be covered by: WOUS09/64737 and/or WOUS10/32439

READ AND SAVE THESE INSTRUCTIONS

SAFETY INSTRUCTIONS

CONTENTS GUIDE

Positioning a dehumidifier ............................. 1

Parts identification .......................................... 2

Operating your dehumidifier .......................... 2

Cleaning and maintenance ............................. 4

Transport and storage .................................... 4

Cleaning and servicing ................................... 5

Error messages ............................................... 7

Troubleshooting .............................................. 8

WARNING! Electric shock hazard, rotating fan, hot

surface hazards. Unplug unit before opening cover

for cleaning or servicing. Unit must be grounded.

• Inspect the power cord before use. If cord is

damaged, do not use. Always grasp the plug (not

the cord) to unplug.

• Insert three-prong plug on power cord into a

matching electrically grounded outlet. Do not use

adapter. Never cut off third prong. Do not use an

extension cord.

• The unit must be operated on a 115V/60 Hz circuit

protected by a Ground Fault Circuit Interrupter

(GFCI) device.

• Keep motor and wiring dry.

• Do not attempt to repair the unit. For Aut horized

Service Centers, call Dri–Eaz at 800-932-3030.

BEFORE YOU BEGIN

Warranty registration

Visit warranty.drieaz.com to register your purchas e.

Registration allows us to better assist you with using,

maintaining or servicing your equipment, as well as to

contact you in case we have important safety i nformation

concerning your Dri-Eaz product. If you determi ne

service is required, have your equipment m odel , serial

number and original proof of purchase available and call

your distributor for assistance with obtaini ng a ret urn

material authorization (RMA).

INTRODUCTION

Dri-Eaz dehumidifiers reduce humidity in enclo sed

structural environments by removing water vapor from

the air.

How LGR dehumidifiers work

Conventional dehumidifiers operate by pul l i ng m oist air

in across a very cold evaporator core. The moisture in

the air condenses on the coil and then collects in a tray

for removal, usually by an automatic pump. LGR (lowgrain refrigerant) dehumidifiers like the 7000XLi utilize a

pre-cooling system to boost water remov al efficiency,

enabling them to continue to remove moisture i n drier

environments.

POSITIONING A DEHUMIDIFIER

For best results, operate your dehumidifiers in a n

enclosed area. Close all doors and windows that open to

the outside to maximize the unit’s water removal

efficiency. Also, keep traffic though the drying chamber

to a minimum. Place your dehumidifier away f rom

obstructions, and keep it away from anyt hi ng that could

block airflow into and out of the unit. For more

information about creating an optimum dryi ng

environment, contact Dri-Eaz at 800-932-3030.

07-01776B Warranty 07-00420 1 Dri-Eaz Products, Inc.

Page 2

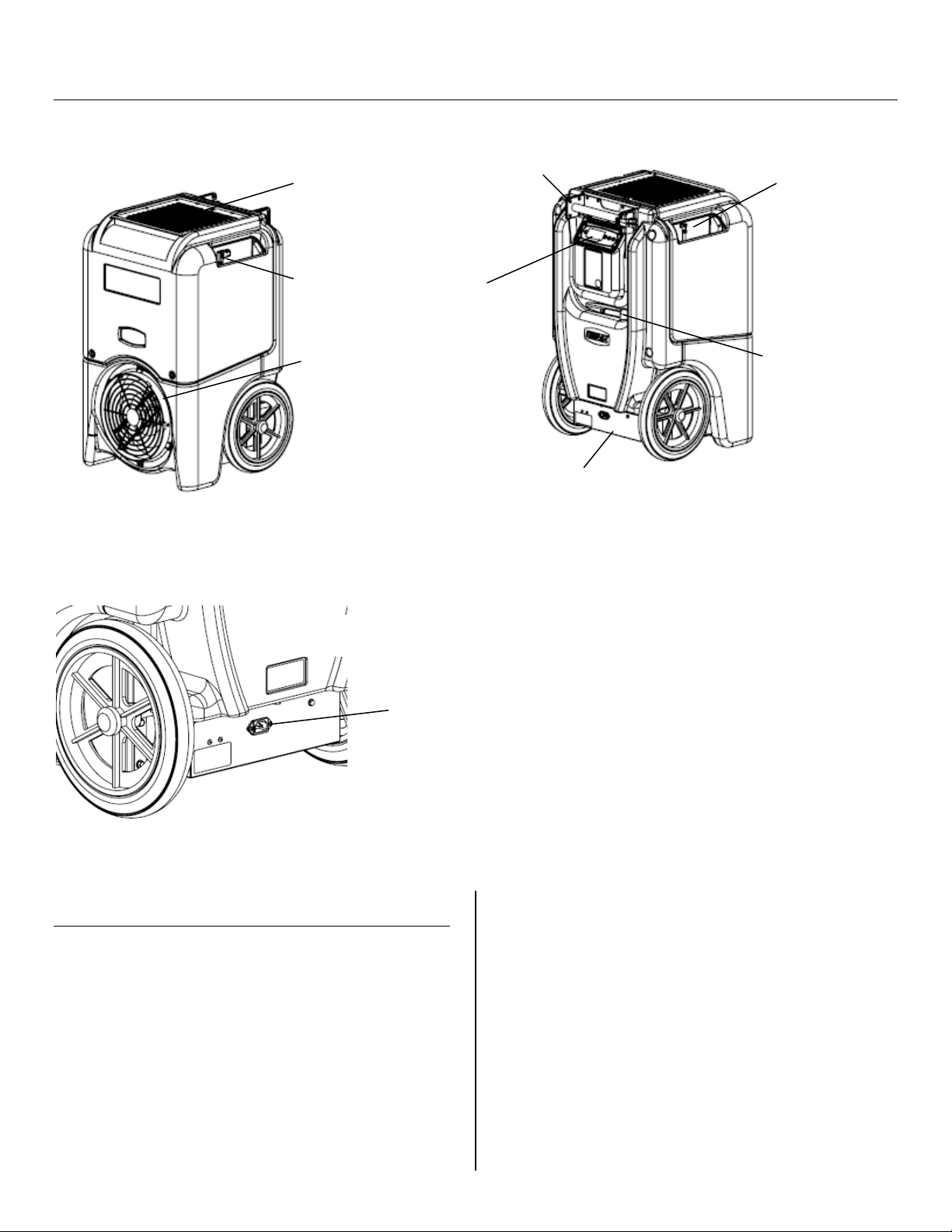

PARTS IDENTIFICATION

FIG. C: POWER

ATTACHMENT POINT

Molded pocket

FIG. B: REAR

Integrated handle.

Power cord socket.

Control panel.

FIG. A: FRONT

Humid air inlet.

3M™ HAF filter.

Drain hose pocket.

for cord storage.

Process (dehumidified)

air outlet. May be used

with standard 12 in.

rigid or layflat ducting.

Drain hose location.

Lower back panel. Remove

to access the pump.

OPERATING YOUR DEHUMIDIFIER

Set unit upright

NOTICE: If you transport or store the 7000XLi

dehumidifier in a horizontal position, set it upright and let

it stand for at least 30 minutes before you turn it on.

When the machine is placed in a horizontal position, the

oil from the compressor can flow into the refrigerant coils

and reduce the ability of the dehumidifier to function.

Set up drain hose

The 7000XLi condensate pump connects to a plastic

drainage hose that is located in the pocket on the back

07-01776B Warranty 07-00420 2 Dri-Eaz Products, Inc.

of the unit. This hose is equipped with a quick-connect

fitting for quick attachment to the provided 40 ft. (12 m)

drain hose. Unwrap the entire hose and place the

unattached end in a sink, drain, bucket or outside –

anywhere that water can drain out safely. If you use a

bucket or other receptacle for water collection, che ck it

regularly to prevent spills.

NOTICE: Uncoil and straighten the entire drain hose. Do

not leave any of part of the hose coiled on the unit and

do not place the end of the hose higher than 20 ft. (6 m )

above the bottom of the unit. Also check for kinks or

other obstructions that might restrict the flow of wat er.

Obstructions may cause a water backup and re sult in

leakage.

Page 3

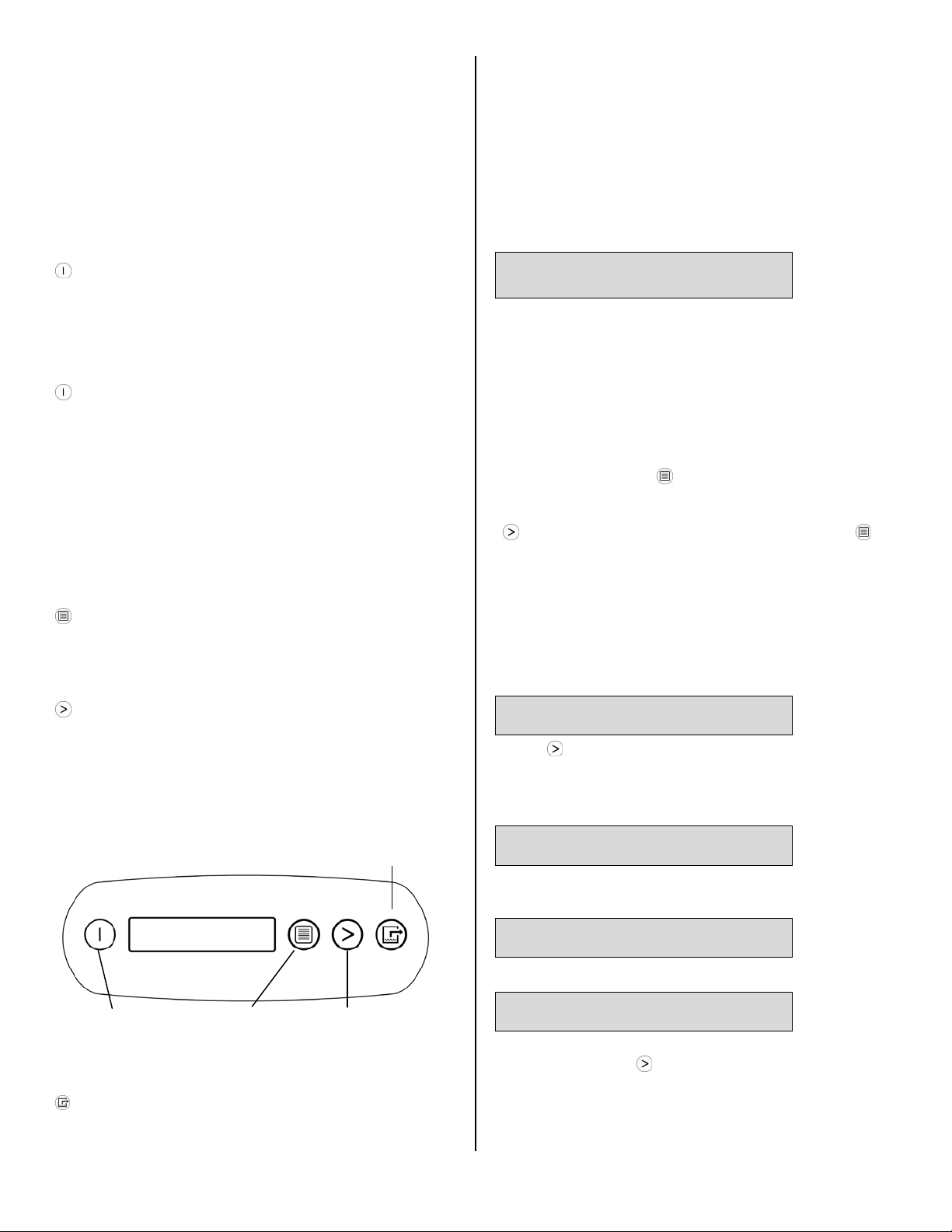

CONTROL PANEL

ON/OFF

DISPLAY

MENU

Plug in electrical cord

The 7000XLi dehumidifier should be plu gged i nto a

GFCI-protected 115 volt outlet rated for at least 15

Remove the cord from its storage pocket and uncoil it.

Always plug the cord firmly into the unit first, and then

plug the other end into a suitable outlet.

amps.

Turn the unit on

The control panel on the 7000XLi dehumidifier has a

display and a touchpad with four keys. Press the

ON/OFF to turn the unit on.

How to use the control panel

The control panel on the 7000XLi has a display and a

touchpad with four keys.

ON/OFF. Press to turn the unit on or off . When the

machine is turned on, the display normally reads

PLEASE WAIT COMP. DELAY and performs a numeral

countdown from a maximum of 60 seconds to 0. This

delay allows time for refrigerant pressures to equalize for

easier starting. Once the unit completes the compressor

delay, the display shows UNIT ON XX HRS and cycles

between INLET XX°F and INLET XX%. NOTE: If no

compressor delay countdown is displayed, a delay is not

necessary and the machine will begin operation

immediately.

DISPLAY MENU. Press to cycle through the display

of additional dehumidifier conditions and User Settings.

To return to the main menu, press the ON/OFF key

once.

MENU SELECTION. Press to change the values of

the "User Defined" settings. The MENU SELECTON key

acts as the UP key for adjusting the setpoint for

Humidistat mode operation. See User Set tings Menu

(below) for details.

operation, the pump purges automatically every six

minutes, or whenever the reservoir is full.

Main menu display

When unit is first plugged in to AC power, the control

panel display will briefly cycle through a serie s of

displays. This is part of the unit’s self-diagnosis

procedure and no user intervention is required.

Once the self-diagnosis is complete, the display will

show the following information:

UNIT ON 00 HRS

INLET 00°F / INLET 00%

The first line of the display shows the total number of

hours the unit has been in operation. This value may be

reset to zero to track job hours (see “Job Hours Reset”

below). The second line of the display alternates

between inlet temperature and inlet humidity.

User settings menu

A number of settings may be changed by the user.

System information is also available. These items are

accessed by pressing

the key will display the next parameter (see list bel ow).

When you reach the parameter you wish to adjust, press

MENU SELECTON to increase the value. Press

DISPLAY MENU again to accept the setting and re-start

the display cycle. If no keys are selected for 20 seco nds

the display will automatically reset and ret urn to the

normal display mode.

Note that only menu items followed by a greater-than

symbol ( > ) may be adjusted.

JOB HOURS

RESET? >

Press MENU SELECTON to reset hours to zero.

NOTE: When in Humidistat mode, the unit will display

HUMIDISTAT on the top line during normal operation

rather than JOB HOURS.

DISPLAY MENU. Each press of

PURGE PUMP

Shows total unit operating hours. Value cannot be

modified.

INLET OUTLET

00° 00% 00° 00%

Shows current temperature and RH of inlet and outlet.

DISPLAY

MENU

PURGE. Press to empty water from the condensate

pump reservoir. The display will read PUMP P URGING

with a numeral countdown. NOTE: During normal

07-01776B Warranty 07-00420 3 Dri-Eaz Products, Inc.

SELECTION /

UP KEY

In ON mode, unit will maintain the humidistat setpoint

(see below). Press

between ON and OFF. NOTE: When in Humidistat

mode, the unit will display HUMIDISTAT on the top line

during normal operation rather than JOB HOURS.

LIFE HOURS

00 HRS

HUMIDISTAT MODE

ON/OFF >

MENU SELECTON to toggle

Page 4

HUMIDISTAT

SETPOINT 00% >

Sets humidity level when unit is in Humidistat M ode (see

above). Press

value. Each press of the button increases the set ting by

5% increments, cycling through 90%RH and starting

again at 30%RH.

Shows current temperature scale. Press MENU

SELECTON to select Fahrenheit or Centigrade scale.

Shows current display panel language. Press MENU

SELECTON to select Spanish, German, French or

English.

MENU SELECTON to change RH

TEMP UNITS

F° >

LANGUAGE

ENGLISH >

NOTICE: To ensure the condensate tank em pties completely while purging, make sure the uni t is set fully upright.

TRANSPORTATION AND STORAGE

NOTICE: Handle the unit carefully. Do not drop, throw,

or place the unit where it could fall. Rough treatment can

damage this equipment and may create a hazardous

condition or void warranty.

• Do not expose the control panel to moisture, sn ow

or rain.

• Store and transport securely to avoid any damaging

impact to internal parts.

CLEANING AND MAINTENANCE

WARNING! ELECTRIC SHOCK HAZARD. Unplug the

dehumidifier before performing any mai ntenance.

COIL TEMP

00°F

Displays the cold (evaporator) coil temperature.

SENSOR ID >

00000000

This function is not used on the 7000XLi.

COMPRSSR CURRENT

0.0 A

Shows compressor current draw in amps.

Error messages

If the 7000XLi onboard diagnostics discover a problem,

the unit will display an error message. See “Error

Messages,” p. 7, for an explanation of each message.

At the end of the job

Before removing the unit from the job site, make sure the

unit is completely purged of water before mov i ng i t:

1. Press the

complete, turn the unit off.

2. Remove the external drain hose, drain it careful l y, and

return it to the pocket provided on the side of the uni t.

Special Tip:

Before transporting unit on stairs, follow t hese additional

steps to ensure that all water is removed from the unit:

1. Turn the unit off after a defrost cycle has been

completed. Gently rock the upright machine on i ts

wheels to ensure any water remaining on interior

surfaces falls into the sump area.

2. Press the

complete, turn the unit off.

3. Remove the external drain hose, drain it careful l y, and

return it to the pocket provided on the side of the uni t.

PURGE key. When the purge cycle is

PURGE key. When the purge cycle is

Before each use

Inspect the electrical cord for damage. Look for

fraying, cuts, etc. Do not use the unit if you f ind any

damage.

Inspect, vacuum or replace filter. The High Airflow

(HAF) filter may be vacuumed clean and reused up to

three times before replacement. Replace onl y with a new

HAF filter (Dri-Eaz part no. F368). See “About HAF

Filters,” below.

Monthly

Check coils. Dirty or dusty coils can cause the uni t to

overheat. Clean when dust accumulation is visible. See

“Cleaning Coils and Heat Exchange Block,” below.

Check heat exchange block. Clean out with

compressed air only. Take care not to damage the block.

See instructions below.

Inspect and clean the pump. See instructions, right.

CLEANING COILS AND HEAT EXCHANGE BLOCK

WARNING: Unplug unit before servi cing.

To help keep the unit operating efficiently, keep the coils

and the air-to-air heat exchange block clean. These

components are easily accessed by removi ng the cover

and rear panel as described below:

NOTICE: The unit is fitted with sensitive el ect ronic

sensors. Protect the sensors and their lead wires from

damage and do not expose them to water or cleaning

solution.

NOTICE: Before removing the heat exchange block for

cleaning or service, disconnect the sensor chip

assembly (Fig. D) from the block. Gently pull up on t he

07-01776B Warranty 07-00420 4 Dri-Eaz Products, Inc.

Page 5

sensor chip and mounting post, and note the sensor

mounting hole on the block for later reassembly .

Handle the sensor chip with care! It is not necessary to

disconnect the sensor cable from the controller board.

When you are finished cleaning the heat block, set the

block back in place. Once the block is back in place,

reposition the sensor assembly chip and mounting

post back in its original location on the heat block and

push down to snap the sensor post back into posit i on.

The following tools are required for disassembling

the unit:

Philips screwdriver

Flat blade screwdriver

⅜ in. and

15

∕

in. sockets and driver

16

Cleaning cloths

To disassemble the unit

1. Unplug unit.

2. Unplug the power cord from the socket at the base of

the unit. Remove pump hose at quick-disconnect.

3. Remove HAF filter.

4. Remove the four cover bolts (Fig. D) from the Cover

then lift off.

5. Lift the heat exchange block straight up off the base.

Note orientation of block for reassembly.

Inspect the heat exchange block carefully. Use a

vacuum to gently clear the channels of the block. Take

care not to damage the block.

Vacuum or use compressed air on both sides of the

upright condenser coil until it is clean. We recommend

the use of a HEPA vacuum. Take care not to bend or

damage the fins.

NOTICE: Dri-Eaz Coil Cleaner (Dri-Eaz part no. S402)

may be used on the horizontal evaporator (cold) coil

only. Follow instructions on product label. Take care

not to spray or wipe Coil Cleaner on or near any

electrical components or sensors.

To reassemble the unit

1. Reinstall the heat exchange block. Make sure to

position it in the original orientation and be sure to reseat

the heat exchange block fully into the sheet metal baffle

over the evaporator coil (Fig. D). When properly

installed, the top of the block will be level wit h the top of

the condenser coil.

2. Now slide the top cover straight down into pl ace.

3. Install and tighten the front two cover bolts. After they

are tight, install and tighten the two rear cov er bolts.

NOTICE: Foam strips are attached to the front and

rear edges of the evaporator coil to provide an airtight

seal against the heat exchange block. When

reinstalling the block, make sure the seals are in place

and are not kinked or folded.

Foam gaskets are also attached to the inside top edges

of the cover. Before reinstalling the cover, m ake sure the

gaskets are in place and straight.

CLEANING AND SERVICING THE PUMP

To access the pump, remove the Cover. Then remov e

the four Rear Panel Bolts and the five base plate b ol ts

(Fig. D). Now remove the Rear Panel. It is not necessary

to disconnect the wire harness from the rear panel or

from the electrical box. For easier access to the pump,

lay the panel its back.

Wipe out the pump basin with a clean, dry cloth.

To reassemble, follow the above steps i n r everse. Be

sure all cables are properly routed and take care t o

thread drain hose back into the sump liner. Take car e

not to cross-thread or over-tighten the bolts.

ABOUT HAF FILTERS

Dri-Eaz dehumidifiers are desig ned to be used with High Airflow Filters from 3M. HAF filters allow for maximum airflow,

provide superior particle retention, and resist microbial growth on filter surfaces. To ensure maximum protection for

equipment, technicians, and the job site, follow these HAF filter guidelines:

Replace the HAF filter whenever it has been vacuumed clean and reused three times. HAF filters lose their effectiveness after

three uses.

Replace the HAF filter whenever it has been used on a mold remediation job or otherwise exposed to potentially dangerous

contaminants. Continued use of a contaminated filter risks the sprea d of contamination.

Do not wash or apply any liquids to the HAF filter. Exposure to liquids will reduce the effectiveness of the electr ostatic material.

Do not operate without the HAF filter in place. Do not operate the unit with any other filter type. Incorrect filtration will reduce

unit efficiency and can cause damage to the unit.

Do not operate the unit when excessive dust or airborne particles are presen t. The high volumes of particulates present during

sanding, spray painting, or similar operations can clog the unit and cause damage.

07-01776B Warranty 07-00420 5 Dri-Eaz Products, Inc.

Page 6

Heat exchange block.

Rear panel

Condenser (hot) coil

Evaporator (cold) coil

Electrical box.

Rear panel base

Cover fasteners (×4)

FIG. D: CLEANING & SERVICING

Sump liner

back of control panel.

Cover

HAF filter

Sensor chip. Lead cable

(not shown) is attached to

Control panel

Rear panel

fasteners (×4)

Cover

fasteners (×4)

plate fasteners

(×5, not shown)

Remove four

screws for access.

Pump location

07-01776B Warranty 07-00420 6 Dri-Eaz Products, Inc.

Page 7

CONNECT

ERROR MESSAGES

The table below shows error (“ER”) messages that the system may display. If the display shows an ER message, first

unplug the unit and then plug it back in. This will usually reset the electronics, and the unit will begin operating normall y. If

the error message reappears, refer to the expl anation and solution shown below. If this still does not fix the problem,

contact your local authorized service cent er or call the Dri-Eaz Service Department at 800-932-3030.

CONTROL PANEL

MESSAGE

EXPLANATION AND SOLUTION

ER1 CONTACT SERVICE

CENTER

ER2 CONTACT SERVICE

CENTER

ER3 CONTACT SERVICE

CENTER

ER4 √ DEFROST SENSOR

CONNECT

– or –

ER4 √ OUTLET SENSOR

ER5 √ SENSOR

CONNECTION ON BD

SYSTEM ERROR

ER6 CONTACT

SERVICE CENTER

Voltage error. Check AC power for correct voltage. The ele ct ronic control panel

may require replacement. Contact service.

The electronic control panel may require replacement. Contact service.

Unit in defrost too long. Check defrost sensor for proper connection. Check

sensor cable for damage. Sensor assembly may require repla cement. Contact

service.

Sensor error. Check defrost sensor or outlet sens or for proper connection.

Check sensor cables for damage. Sensor assembly may require replacement.

Contact service.

Low voltage board error. Temp/RH sensor connections may be loose. Contact

service.

The high voltage board may require replacement. Contact service.

ER7 INVALID

MODEL SETTING

ER8 BUTTON STUCK √

ALL BUTTONS

ER9 PUMP BLOCKED √

CHECK PUMP & HOSE

Control board DIP switch settings or firmware version may be incorrect.

Contact service.

Press each membrane key and check for proper operation. If a key doesn’t

function, the membrane overlay may require replacem ent. Contact service.

Check for obstructions in drain hose. Check the pump.

07-01776B Warranty 07-00420 7 Dri-Eaz Products, Inc.

Page 8

Purge unit before moving. See “At the End of the Job,”

Dimensions

Water removal AHAM

(80°F/60% RH)

Water removal low grain

(80°F/20% RH)

bacteria, mold and mildew.

TROUBLESHOOTING

FAULT CAUSE SOLUTION

Water drips out

when moving unit

Unit does not

operate

Blower wheel not

turning

Unit operating,

but room not dry

Unit collects too

little water

Unit was unplugged before

purging was complete.

No power to machine.

Unit not switched on.

Obstructed blower.

Not enough time to dry.

Poor air movement in room.

Excessive moist air infiltration.

Room air is dry.

Room temperature is too low.

If the problem you are experiencing is not list ed here, call your local distributor or contact

our Service Department toll-free at 800-932-3030 for further assistance.

SPECIFICATIONS

Model LGR 7000XLi (F412)

Weight 107 lbs. | 49 kg

(H × D × W)

Power 8.3 amps, 115V

Maximum process air 325 CFM* Ductable floor-level outlet.

Air filter

Drain hose

Power cord 25 ft. | 7.6 m

Construction

33.5 × 20 × 20 in. | 85 × 51 × 51 cm

130 pts. | 61.5 liters / day

17 pts. | 8 liters / day

3M HAF filter

Part no. F368 (DrizAir 1200 24 pack)

40 ft. | 12.2 m

Rotomolded shell. Pump basin is

infused with Microban® antimicrobial

product protection to inhibit the

growth of stain- and odor-causing

p. 4.

Plug in unit; check power at outlet and at base of unit .

Switch unit on.

Remove duct ring and grill.

Remove obstruction.

Replace duct ring and grill.

Allow more time for drying.

Increase air movement with air movers.

Reduce infiltration.

Check humidity with hygrometer.

Increase room temperature.

Check filter and coils; clean as necessary.

Warranty information is available at www.dri-eaz.com.

Be sure to visit warranty.drieaz.com and regist er your

purchase. Your registration will help us provide you with

updated product information as needed.

MICROBAN

®

is a registered trademark of Microban

Products Company.

Safety

Specifications are subject to change without notice. Some values

may be approximate.

*Fan speed varies automatically for optimized performance.

ETL certified to UL 474

and CSA 22.2 no. 92

07-01776B Warranty 07-00420 8 Dri-Eaz Products, Inc.

Loading...

Loading...