Page 1

Owner’s Manual

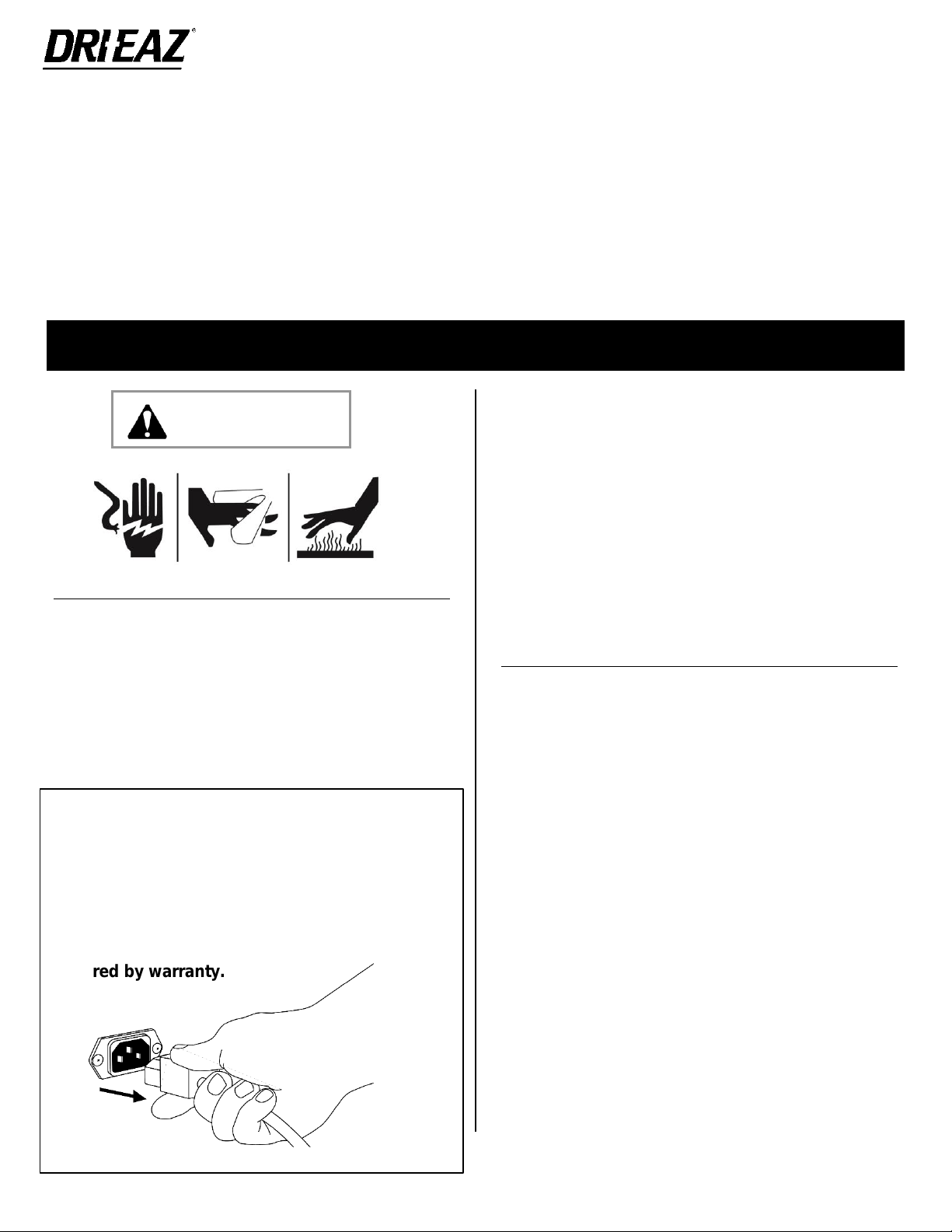

WARNING

CORRECT PLUG REMOVAL

Grasp IEC plug and pull straight out

covered by warranty.

LGR 6000Li Portable Dehumidifier

Model F600

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Phone: 800-932-3030 Fax: 360-757-7950 www.LegendBrandsRestoration.com

The Dri-Eaz® LGR 6000Li dehumidifier reduces humidity in enclosed environments by removing

water vapor from the air. The 6000Li is rugged, durable and highly portable, making it ideal for

water damage restoration, structural drying, construction, and other applications requiring

temporary, high-performance dehumidification.

Patents: http://www.LBpatents.com

SAVE THESE INSTRUC T I ON S

Inspect the power cord before use. If cord is

SAFETY INSTRUCTIONS

WARNING! Do not alter or modify your dehumidifier

in any way. Use only replacement parts authorized

by Dri-Eaz Products, Inc. Modifications or use of

unapproved parts could create a hazard and will

void your warranty. Contact your authorized

distributor for assistance.

WARNING! Electric shock hazard, rotating fan, hot

surface hazards. Unplug unit before opening cover

for cleaning or servicing. Unit must be grounded.

damaged, do not use. Always grasp the plug (not

the cord) to unplug.

Insert three-prong plug on power cord into a

matching electrically grounded outlet. Do not use

adapter. Never cut off third prong. Do not use an

extension cord.

The unit must be operated on a 115V/60Hz circuit

protected by a Ground Fault Circuit Interrupter

(GFCI) device.

Keep motor and wiring dry.

Do not attempt to repair the unit. For Authorized

Service Centers, contact Dri-Eaz.

BEFORE YOU BEGIN

Warranty registration

Visit LegendBrandsRestoration.com/Warranty to register

your purchase. Registration allows us to better assist

you with using, maintaining or servicing your equipment

and to contact you in case we have important safety

information concerning your Dri-Eaz product. If you

determine service is required, have your equipment

model, serial number and original proof of purchase

available and call your distributor for assistance with

obtaining a return material authorization (RMA).

IMPORTANT: Damage to IEC receptacle or

dehumidifier resulting from improper removal

of the power cord is not covered by warranty.

The IEC power cord is a wear item and is not

07-02300C F600 1 Dri-Eaz Products, Inc.

CONTROLS AND OPERATING

INSTRUCTIONS

Set unit upright

NOTICE: Transporting or storing the unit in a

horizontal position is not recommended. When the

machine is placed in a horizontal position, the oil

from the compressor can flow into the refrigerant

coils and reduce the ability of the dehumidifier to

function and possibly damage the unit. If the unit

has been placed in a horizontal position, set it

upright and let it stand for at least 30 minutes before

turning it on.

Page 2

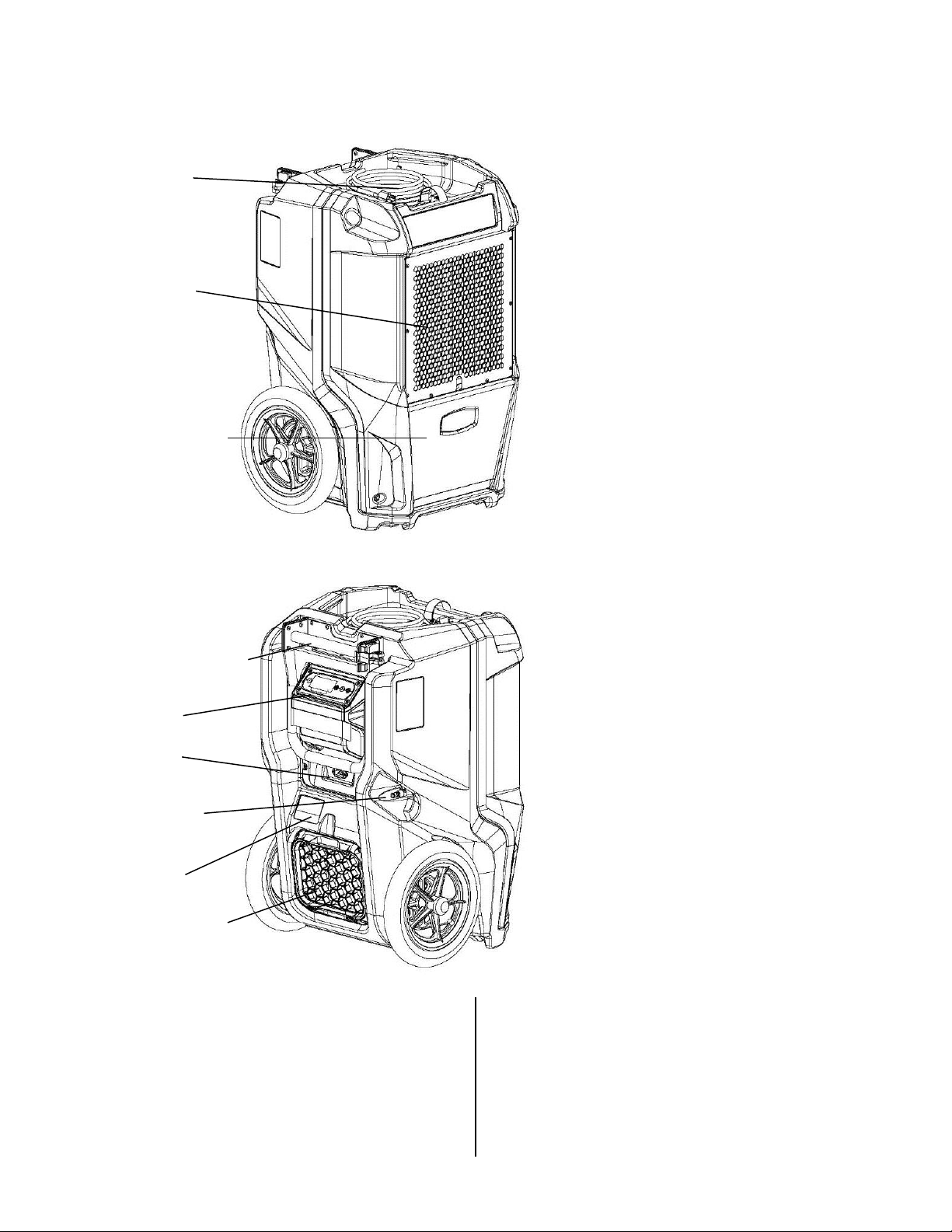

Drain hose

quick-connect.

Power cord

socket.

Model serial

number label

FRONT

REAR

Humid air inlet.

Power cord and

storage.

Process (dehumidified)

air outlet.

Front panel. Remove to

Fig. B.

Integrated handle. Use the

for loading or storage.

Control panel.

FIG A: PARTS IDENTIFICATION

Drain hose quickconnect.

Extend handle

Release the handle by rotating red locking

lever outward, then lift handle up into place.

Rotate red lever back into locked position to

secure handle in operating position.

drain hose

Air filter.

access the pump and

coils for cleaning. See

red lever to lock handle

upright for use or down

NOTICE: Do not use the extended handle to

lift the unit off the ground horizontally. Do not

use the extended handle as an attachment

point to strap the unit in a vehicle for

transport. These uses will place undue strain

on the handle attachment points in the

housing.

Set up drain hose

This unit automatically pumps out water on a

regular basis. This dehumidifier is equipped

with a quick-connect fitting for attachment to

the provided drain hose located in the tray on

top of the unit. Unwrap the entire hose and

place the open end in a sink, drain, bucket or

outdoors – anywhere that water can drain out

safely. If you use a bucket or other container

for water collection, check it regularly to

prevent overflows.

NOTICE: Uncoil and straighten the entire

drain hose. Do not leave any part of the hose

coiled on the unit and do not place the end of

the hose higher than 20 ft. (6 m) above the

bottom of the unit. Also check for kinks or

other obstructions that might restrict the flow

of water. A kink or blockage will cause the unit

to turn off produce an ER9 error code. See

“Error Messages,” below, for more

information.

Plug in electrical cord

The dehumidifier should be plugged into a

GFCI-protected 115 volt outlet rated for at

least 15 amps. Remove the cord from the

storage tray and uncoil it. Always plug the

cord firmly into the unit first, and then plug the

other end into a suitable electrical outlet.

Startup display and normal display modes

When unit is first plugged into AC power, the

control panel display will briefly cycle through

a series of readouts. This is part of the unit’s

self-diagnosis procedure and no user

intervention is required.

Positioning a Dehumidifier

For best results, operate your dehumidifier in an

enclosed area. Close all doors and windows to maximize

the unit’s water removal efficiency. Place your

dehumidifier away from obstructions, and keep it away

from anything that could obstruct airflow into and out of

the unit.

07-02300C F600 2 Dri-Eaz Products, Inc.

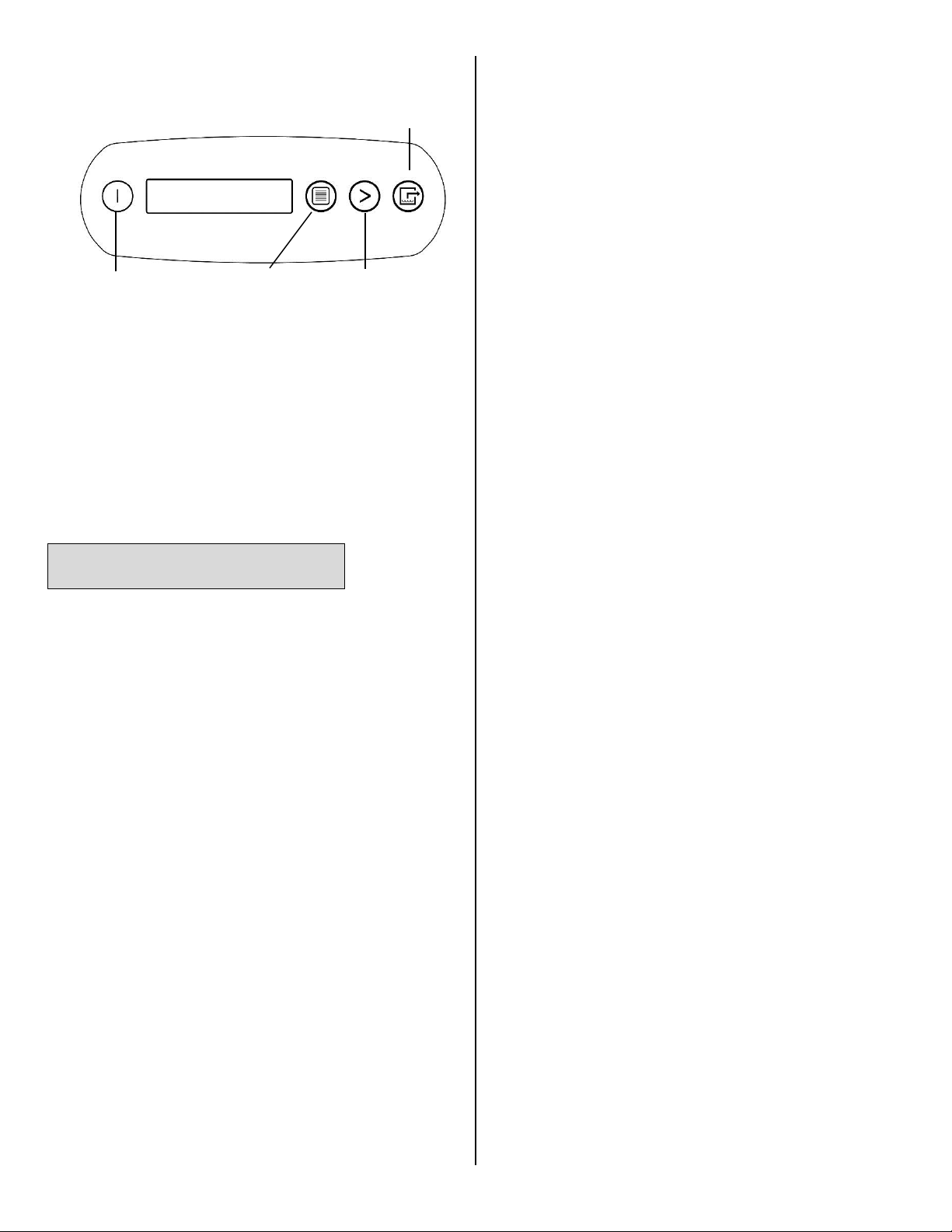

The control panel has a display and a touchpad with four

keys. Press the ON/OFF to turn the unit on. The unit will

now go through a compressor delay countdown (up to

60 seconds in duration) and a self-diagnostics process,

then switch to normal display mode.

Turn the unit on

Page 3

ON/OFF

Press and release to turn unit on

or off.

DISPLAY MENU

Press to select next item in menu.

Menu item will show in display.

MENU SELECTION /

UP KEY

Press to toggle or select values in

menu displayed.

PURGE PUMP

Press and release to start purge.

Display will count down seconds

remaining until purge is complete.

CONTROL PANEL

ON/OFF

DISPLAY

DISPLAY

MENU

MENU

SELECTION /

UP KEY

PURGE PUMP

delay, the display shows UNIT ON XXXX HRS and

cycles between INLET XXX°C and INLET XX%. NOTE:

If no compressor delay countdown is displayed, a delay

is not necessary and the machine will begin operation

immediately.

DISPLAY MENU. Press to cycle through the display of

additional dehumidifier conditions and User Settings. To

return to the main menu, press the ON/OFF key once.

MENU SELECTION. Press to change the values of the

"User Defined" settings. The MENU SELECTION key

acts as the UP key for adjusting the setpoint for

Humidistat mode operation. See User Settings Menu

(next page) for details.

PURGE. Press to empty water from the condensate

pump reservoir. The display will read PUMP PURGING

with a numeral countdown. NOTE: During normal

operation, the pump purges automatically.

NOTE: During normal operation, the pump purges automatically.

UNIT ON XXXX HRS

INLET XXX°C / INLET 00%

The first line of the display shows the total number of

hours the unit has been in operation. This value may be

reset to zero to track job hours (see “Job Hours Reset”

below). The second line of the display alternates

between inlet temperature and inlet humidity.

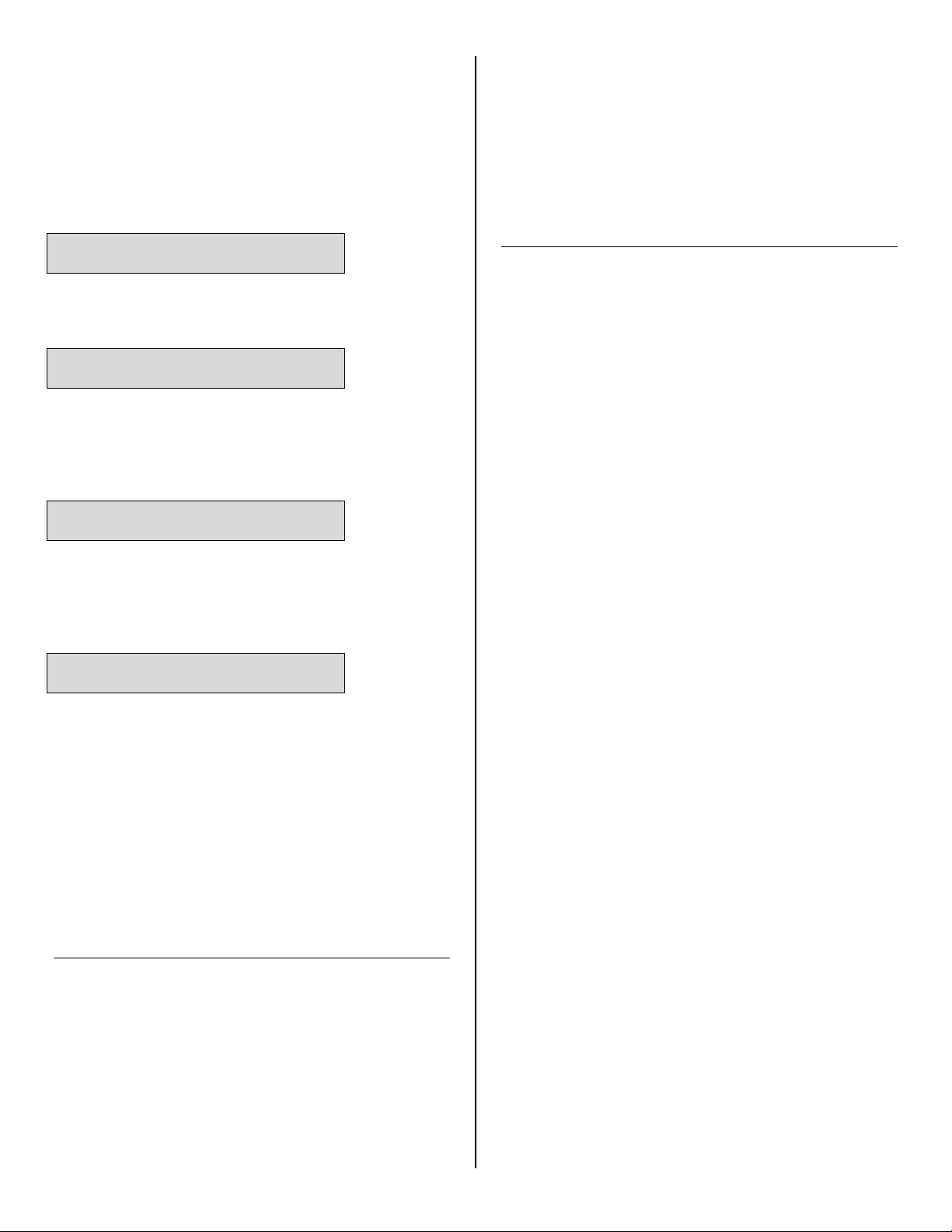

User Settings Menu

A number of settings may be changed by the user.

System information can also be displayed. These items

are accessed by pressing DISPLAY MENU. Each press

of the key will display the next parameter. When you

reach the parameter you wish to adjust, press MENU

SELECTION to increase the value. Press DISPLAY

MENU again to accept the setting and re-start the

display cycle.

Note that only menu items followed by a greater-than

symbol ( > ) may be adjusted.

Error messages

If the onboard diagnostics discover a problem, the unit

will display an error message. See “Error Messages,”

below, for an explanation of each message.

Control Panel Guide

ON/OFF. Press to turn the unit on or off. When the

machine is turned on, the display normally reads

PLEASE WAIT COMP. DELAY and performs a numeral

countdown from a maximum of 60 seconds to 0. This

delay allows time for refrigerant pressures to equalize for

easier starting. Once the unit completes the compressor

07-02300C F600 3 Dri-Eaz Products, Inc.

Page 4

Press DISPLAY

MENU to proceed to

the next menu item. ↓

Press ˃ MENU SELECTION to change the setting. →

□

1. JOB HRS RESET >

PWR INTERRUPT X

˃

1. JOB HR RESET 0

PWR INTERRUPT 0

Press ˃ to reset to 0.

2. INLET OUTLET

100ʹ 80% 115ʹ 30%

For information only.

3. GRAIN DPR

XX GPP

Unit displays GPP if set to Fahrenheit or g/kg if set to Celsius. To change this setting, see menu item 9.

4. FILTER CHECKED

XXX HRS >

˃

4. FILTER CHECKED

0 HRS

Press ˃ to clear filter hours.

5. COIL CLEANED

XXX HRS >

˃

5. COIL CLEANED

0 HRS

Press ˃ to clear coil hours.

6. HUMIDISTAT

MODE OFF >

˃

6. HUMIDISTAT

MODE ON >

Press ˃ to turn ON or OFF. For maximum dehumidification, make sure

HUMIDISTAT is OFF.

7. HUMIDISTAT

SETPOINT XX% >

˃

Press ˃ to cycle through 40%–90% at 5% increments (default is 50%).

8. LANGUAGE

ENGLISH >

˃

8. IDIOMA

ESPANOL >

˃

8. SPRACHE

DEUTSCH >

˃

8. LANGUE

FRANCAIS >

Press ˃ to change

language options.

9. TEMP UNITS

ʹF >

˃

9. TEMP UNITS

ʹC >

Press ˃ to change to °F or °C.

10. COIL TEMP

XXʹ

For information only.

11. COMP CURRENT

XX.X A

For information only.

12. FIRMWARE

3.XX FXXX-XXX

For information only.

13. LIFE HOURS

XXXX HRS

(Returns to

top menu item.)

The following section available only on wireless-equipped units.

14. SENSOR ID

XXXXXXXXX

(Returns to

top menu item.)

USER SETTINGS

Only menu items followed by a greater-than symbol (>) can be adjusted. If no keys are selected for 5 minutes on screens: INLET

OUTLET, GRAIN DPR (INLET-OUTLET for 230V models), the display will return to normal display mode. In all the other menu items,

the display with return to the normal display mode after 20 seconds. Items without the symbol (>) are for information only and cannot be

changed or reset. See “System Messages” below for additional system status messages.

AT THE END OF THE JOB

To reduce the possibility of drips when moving the

unit, follow these additional steps to ensure that all

water is removed from the unit.

07-02300C F600 4 Dri-Eaz Products, Inc.

NOTICE: The unit will complete the defrost cycle even if

the unit is turned off but still plugged in. If the unit is

unplugged during the defrost cycle, excessive water may

accumulate in the unit and may drip out when you move

the unit.

Page 5

NOTICE: To ensure the condensate tank empties

completely while purging, make sure the unit is placed

upright on a horizontal surface.

1. Do not turn unit off or move it until it has returned

to normal operating mode. To confirm unit status,

review the control panel. The control panel will

display one of the following messages:

Defrost in progress:

---

DEFROST XX

Display mode when unit is in defrost mode. XX indicates

the seconds remaining on the defrost cycle.

Shutdown sequence:

WAIT FOR

DEFROST XX

Display mode when unit in defrost and unit is powered

down (shut off by user). Unit will complete the defrost

cycle to remove any built-up ice then purge the pump.

XX indicates the seconds remaining on the defrost cycle.

Drying sequence:

WAIT FOR

UNIT DRYING XXX

Display mode when unit not in defrost and unit is

powered down (shut off by user). Unit will complete the 5

minute drying cycle then purge the pump. XX indicates

the seconds remaining on the drying cycle.

Normal display:

UNIT ON XXXX HRS

INLET XXX°F / XX%

The unit has completed a defrost and drying cycle and

has returned to normal mode. You may now proceed to

step 2.

Store and transport securely to avoid any damaging

impact to internal parts.

Secure during transport to prevent sliding and

possible injury to vehicle occupants.

Do not transport or store the unit on its front, sides or

back. This will help to prevent any remaining moisture

from escaping from the unit or flowing into areas

outside the sump.

MAINTENANCE SCHEDULE

WARNING! ELECTRIC SHOCK HAZARD. Unplug the

dehumidifier before performing any maintenance.

WARNING: Risk of dust and contaminants exposure.

Use of respirator mask and gloves is recommended. If

unit has been exposed to potentially dangerous

contaminants, clean thoroughly and sanitize before

reuse.

NOTICE: The unit is fitted with sensitive electronic

sensors. Protect the sensors and their lead wires from

damage and do not expose them to water or cleaning

solution.

The following tools and supplies are needed to

complete the maintenance procedures described in

this manual:

Philips screwdriver

T-20 Torx bit

10 mm nutdriver or socket and ratchet

Cleaning cloths

HEPA vacuum cleaner with soft brush nozzle and

crevice tool.

Recommended

Cordless drill, small knife, small-jaw pliers, coil

cleaning solution, rotomolded housing cleaning

solution.

2. Gently rock the machine to ensure any water

remaining on interior surfaces falls into the sump

area.

3. Press the PURGE key. When the purge cycle is

complete, turn the unit off.

4. Remove the external drain hose, drain it carefully,

coil it and return it to the storage tray on the top of

the unit.

TRANSPORTATION AND STORAGE

IMPORTANT: Before moving, transporting or

storing, purge unit and stow hose and power cord as

described in the “At the End of the Job” section

above.

NOTICE: Handle the unit carefully. Do not drop, throw or

place the unit where it could fall. Rough treatment can

damage the dehumidifier and may create a hazardous

condition or void the warranty.

Do not expose the control panel to moisture, snow

or rain.

07-02300C F600 5 Dri-Eaz Products, Inc.

Before each use

Inspect the electrical cord for damage. Look for

fraying, cuts, etc. Replace the cord if you find any

damage.

Inspect filter. Replace if accumulation of dust and

debris is visible.

NOTICE: Replace used filters only with a new Dri-Eaz

filter part no. F579 (24-pack). Other filter types do not

provide adequate filtration or airflow. Each filter is

individually wrapped to protect filtration effectiveness.

Remove the wrapper before installing the filter into the

dehumidifier.

Monthly

Inspect coils. Clean when dust accumulation is visible.

In normal use, dust can accumulate and can restrict

airflow, reducing performance and causing the unit to

overheat.

To maintain appearance, wipe interior and exterior

surfaces with a damp cloth. For deep cleaning and a

Page 6

Remove the 4

Fig. B: Disassembly for Cleaning

lasting, protective shine, use an automotive interior

treatment product.

As Needed

Clean Pump Check Valve and Basin. If the unit

displays the message “ER9 PUMP BLOCKED PUMP

& HOSE”, the pump check valve and pump basin may

need to be cleaned. This requires removal of the front

housing.

Clean coils. Inspect the horizontal evaporator (cold)

coil with the front cover removed. If excessive dust and

debris is present, vacuum thoroughly and/or clean with

alkaline (non-acidic) coil cleaner.

screws from front

housing, and slide

off to access coils

and pump for

service.

07-02300C F600 6 Dri-Eaz Products, Inc.

Page 7

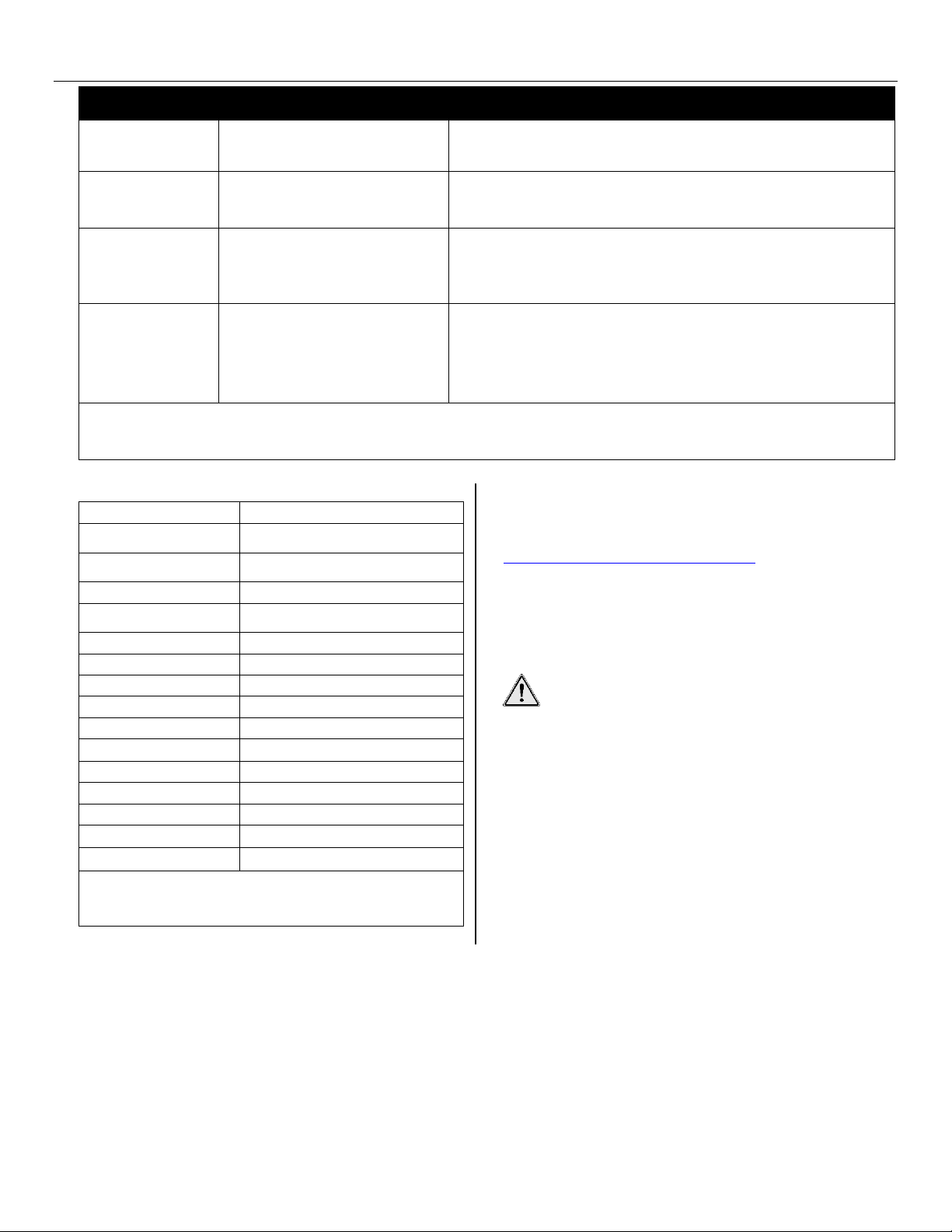

C O N T R O L P A N E L

M E S S A G E

E X P L A N A T I O N

U S E R A C T I O N

INITIALIZING

Unit is powering up.

None

FIRMWARE VERSION

XXX

Indicates control board firmware version number.

None

FXXX-XXX

Model number.

None

OFF

Unit has finished powering up and is operating.

None

PLEASE WAIT

COMP. DELAY XX

60s delay before compressor turns on. Allows system

pressure to equalize.

None

UNIT ON XXXX HRS

INLET XXX°F / XX%

First line: indicates total operating hours.

Second line: Toggles between inlet temperature and

inlet RH every 2 seconds.

None

HUMIDISTAT

INLET XXX°F / XX%

First line: indicates unit is in humidistat mode

Second line: Toggles between inlet temperature and

inlet RH every 2 seconds.

None

LOW TEMP

INLET XXX°F / XX%

Unit shuts off if inlet temp below 45°F/7°C. Turns back

on when inlet reaches 50°F/10°C.

None

---

PUMP PURGING XX

Displays when the Pump Purge button is pressed.

Shows time remaining in seconds.

None

HI TEMP CYCLE

REMAINING XX MIN

Unit overload limit reached. Cool-down initiated.

None

---

DEFROST XXXX

Unit is defrosting, with countdown in seconds.

None

WAIT FOR

DEFROST XXX

Unit turned off when coil is cold or already in a defrost

cycle. Proceeds to finish cycle or initiate one to clear the

coils of ice before storage.

None

WAIT FOR

UNIT DRYING XXX

Occurs when unit is turned off and coil is not frozen.

Clears the coils of water before storage.

None

CHECK FILTER >

OFF

Prompt to check filter.

Check filter. Press the > key

to reset

CLEAN COILS >

OFF

Prompt to clean coils and interior.

Clean coils. Press the > key

to reset

SYSTEM MESSAGES

The Control Panel will display the following messages based on system performance and environmental conditions. User

action, if any is required, is indicated in the third column.

07-02300C F600 7 Dri-Eaz Products, Inc.

Page 8

C O N T R O L P A N E L

M E S S A G E

E X P L A N A T I O N A N D S O L U T I O N

ER4 DEFROST

SENSOR CONNECT

–or–

ER4 OUTLET

SENSOR CONNECT

Temp sensor is open, missing, or shorted. Check that temp sensors are installed

correctly on control panel. If error persists, contact service.

ER5 SENSOR

CONNECTION ON BD

Inlet Temp/RH sensor is open, missing, or shorted. Check that inlet temp/RH sensor is

installed correctly on control panel and inlet shroud. If error persists, contact service.

ER6 CONTACT

SERVICE CENTER

Current sensor failure. If error persists, contact service.

ER7 INVALID

MODEL SETTING

Incorrect or unsupported DIP switch settings. Contact Dri-Eaz service department for

correct DIP switch settings.

ER8 BUTTON STUCK

ALL BUTTONS

Key is stuck or has been held down too long. Contact service.

ER9 PUMP BLOCKED

PUMP & HOSE

Check for obstructions. Is the hose kinked under the unit or pinched shut by a wheel?

Check the pump for blockage and service if needed.

ERROR MESSAGES

If the control system detects an error, it will produce an error (“ER”) message. If this occurs, first unplug the unit and then

plug it back in. This will usually reset the electronics, and the unit will begin operating normally. If the error message

reappears, refer to the explanations and solutions shown below. If these solutions do not fix the problem, contact your

local authorized service center.

07-02300C F600 8 Dri-Eaz Products, Inc.

Page 9

F A U L T

C A U S E

S O L U T I O N

Water drips out

when moving unit

Unit was unplugged before

purging was complete.

Purge unit before moving. See “At the End of the Job.”

Unit does not

operate

Unit not switched on.

No power to machine.

Switch unit on.

Plug in unit; check power cord connection at wall outlet and at

base of unit.

Unit operating,

but room not dry

Not enough time to dry.

Poor air movement in room.

Excessive moist air infiltration.

Make sure “Humidistat” is OFF.

Allow more time for drying.

Increase air movement with air movers.

Seal off area to reduce infiltration.

Unit collects too

little water

Room air is dry.

Room temperature is too low.

Filter is full.

Coils are clogged.

Make sure “Humidistat” is OFF.

Confirm humidity level with hygrometer.

Increase room temperature.

Check filter. Replace as necessary.

Check coils. Clean as necessary.

If the problem you are experiencing is not listed here, call your local distributor or contact

our Service Department at 800-932-3030 for further assistance.

Model

LGR 6000Li (F600)

Water removal AHAM

(80°F/60% RH)

100 pts. | 47.3 L / day

Water removal saturation

(90°F/90% RH)

204 pts. | 96.5 L / day

Process air (max.)

320 CFM

Dimensions

(H × D × W)

32.1 × 19.8 × 20.0 in.

81.5 × 50.3 × 50.8 cm

Weight

103 lbs. | 46.7 kg

Amps

6.6A

Volts

115V

Frequency

60Hz

Power

759W

Operating range

33°F–100°F | 1°C–38°C

Noise level (avg.)

53 dB

Drain hose

40 ft. | 12.2 m

Power cord

25 ft. | 7.6 m

Construction

Rotomolded shell

Safety

ETL certified CSA 22.2 no. 92

Specifications are subject to change without notice. Some values

may be approximate.

*Fan speed varies automatically for optimized performance.

TROUBLESHOOTING

SPECIFICATIONS

Order replacement air filters from your local distributor.

Part no. F579 (24 pack).

Warranty information is available at

www.LegendBrandsRestoration.com.

Be sure to visit LegendBrandsRestoration.com/Warranty

and register your purchase. Your registration will help us

provide you with updated product information as needed.

For proper disposal, this unit should be taken to a

recycler licensed to process refrigeration equipment.

WARNING: This product and other substances

that may become airborne from its use contain

chemicals, including lead and phthalates, known to the

State of California to cause cancer, birth defects, or

other reproductive harm. For more information, go to

P65Warnings.ca.gov

`

07-02300C F600 9 Dri-Eaz Products, Inc.

Page 10

ADVERTENCIA

EXTRACCIÓN CORRECTA DEL

Sostenga el enchufe macho IEC y tire

y no está cubierto por la garantía.

Manual del propietario

Deshumidificador portátil LGR 6000Li

Modelo F600

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Teléfono: 800-932-3030 Fax: 360-757-7950 www.LegendBrandsRestoration.com

El deshumidificador Dri-Eaz® LGR 6000Li reduce la humedad en ambientes cerrados al eliminar

el vapor de agua del aire. El 6000Li es robusto, durable y altamente portátil y es ideal para la

restauración tras daños por agua, el secado estructural, la construcción y otras aplicaciones

que requieran una deshumidificación temporaria de alto rendimiento.

Patentes: http://www.LBpatents.com

CO N S E R V E E S T A S I NSTR UC C I O N E S

INSTRUCCIONES DE SEGURIDAD

¡ADVERTENCIA! No altere ni modifique su

deshumidificador de ninguna forma. Use solo piezas

de repuesto autorizadas por Dri-Eaz Products, Inc.

Las modificaciones o el uso de piezas no aprobadas

podrían crear un peligro y anularán su garantía.

Comuníquese con su distribuidor autorizado para

obtener asistencia.

ENCHUFE

directamente hacia afuera

IMPORTANTE: El daño al receptáculo IEC o el

deshumidificador resultante de la extracción

incorrecta del cable no está cubierta por la

garantía. El cable IEC es un elemento de desgaste

¡ADVERTENCIA! Peligro de descarga eléctrica,

ventilador rotativo, peligros de superficie caliente.

Desenchufe la unidad antes de abrir la cubierta para

limpiar o reparar. La unidad debe estar puesta a

tierra.

Inspeccione el cable de alimentación antes de usar.

Si el cable está dañado, no lo use. Siempre

sostenga el enchufe (no el cable) para desenchufar.

Inserte el enchufe de tres patas en un tomacorriente

correspondiente con puesta a tierra. No use un

adaptador. Nunca corte la tercera pata. No use un

cable de extensión.

La unidad debe utilizarse en un circuito de

115 V/60 Hz protegido por un dispositivo de

interruptor de circuito de pérdida a tierra (GFCI).

Mantenga seco el motor y la cablería.

No intente reparar la unidad. Para conocer la

ubicación de un centro de servicio autorizado,

comuníquese con Dri-Eaz.

ANTES DE COMENZAR

Registro de la garantía

Visite LegendBrandsRestoration.com/Warranty para

registrar su compra. El registro nos permite ayudarlo

mejor con el uso, mantenimiento o reparación de su

equipo y comunicarnos con usted en caso de que

tengamos información importante sobre su producto DriEaz. Si determina que se necesita una reparación, tenga

su modelo de equipo, número de serie y comprobante

original de compra a mano y llame a su distribuidor para

obtener asistencia para obtener una autorización de

devolución del material (RMA).

CONTROLES E INSTRUCCIONES DE

OPERACIÓN

Coloque la unidad en posición vertical

AVISO: No se recomienda transportar o almacenar la

unidad en posición horizontal. Si la máquina se

07-02300C F600 10 Dri-Eaz Products, Inc.

Page 11

Conexión rápida

de la manguera

Enchufe del cable de

alimentación.

Etiqueta con el número

de serie del modelo.

FRENTE

PARTE

POSTERIOR

Entrada de aire

aire.

Lugar de

drenaje.

Salida de aire

el proceso.

Panel delantero.

limpieza. Vea la Fig. B.

Mango integrado. Use la palanca

abajo para cargar o almacenar.

Panel de control.

FIG. A: IDENTIFICACIÓN DE PIEZAS

Conexión rápida de la

coloca en posición horizontal, el aceite del

compresor puede fluir hasta las bobinas del

refrigerante y reducir la posibilidad de que el

deshumidificador funcione y puede dañar la unidad.

Si la unidad se ha colocado en posición horizontal,

colóquela en posición vertical y déjela quieta al

menos 30 minutos antes de encenderla.

almacenamiento del

cable de alimentación

y la manguera de

húmedo. Filtro de

Dónde colocar el deshumidificador

Para obtener mejores resultados, opere su

deshumidificador en un área cerrada. Cierre todas las

puertas y ventanas para maximizar la eficiencia de

eliminación de agua de la unidad. Coloque el

deshumidificador lejos de obstrucciones y manténgalo

alejado de cualquier objeto que pueda obstruir el flujo de

aire hacia y desde la unidad.

Extienda el mango

Desbloquee el mango girando la palanca roja

de bloqueo hacia afuera y luego levante el

mango hasta que esté en su lugar. Gire la

palanca roja hasta la posición de bloqueo para

que el mango quede fijo en la posición de

funcionamiento.

AVISO: No use el mango extendido para

levantar la unidad del suelo de forma horizontal.

No use el mango extendido como punto de

sujeción para sujetar la unidad a un vehículo

para su transporte. Estos usos aplicarán una

tensión indebida a los puntos de sujeción del

mango en la carcasa.

Extráigalo para acceder

a la bomba y a las

bobinas para su

roja para bloquear el mango en

posición vertical para usar o

manguera de drenaje.

Instale la manguera de drenaje

Esta unidad bombea automáticamente el agua

hacia afuera de forma uniforme. Este

deshumidificador está equipado con un

accesorio de conexión rápida para su conexión

a la manguera de drenaje provista de 40 pies

(12 m) ubicado en la bandeja sobre la unidad.

Desenrolle la manguera completamente y

coloque el extremo abierto en un lavabo,

drenaje, cubo o en el exterior: en cualquier lugar

donde el agua pueda drenarse de forma segura.

Si usa un cubo u otro contenedor para la

recolección de agua, compruébelo

constantemente para evitar derrames.

AVISO: Desenrolle y enderece toda la

manguera de drenaje. No deje ninguna parte de

la manguera enrollada en la unidad y no

coloque el extremo de la manguera a más de 20

pies (6 m) por encima de la parte inferior de la

unidad. Compruebe también que no haya

acodaduras u otras obstrucciones que puedan

limitar el flujo de agua. Una acodadura o un

bloqueo causarán que la unidad se apague y

genere un código de error ER9. Consulte los

“Mensajes de error” para obtener más

información.

Enchufe el cable eléctrico

El deshumidificador se debe enchufar en un

tomacorriente de 115 voltios protegido por un

(deshumidificado) tras

07-02300C F600 11 Dri-Eaz Products, Inc.

GFCI con una clasificación de al menos

15 amperios. Quite el cable de la bandeja de

almacenamiento y desenróllelo. Siempre

Page 12

ENCENDIDO/APAGADO

Presione y suelte para encender o

apagar la unidad.

MENÚ EN PANTALLA

Presione para seleccionar el

siguiente elemento en el menú.

El elemento del menú aparecerá

en la pantalla.

SELECCIÓN EN EL

MENÚ/TECLA HACIA

ARRIBA

Presione para alternar o

seleccionar valores en el menú

exhibido.

BOMBA DE PURGA

Presione y suelte para comenzar

la purga. La pantalla mostrará

una cuenta regresiva con los

segundos que faltan para que se

complete la purga

PANEL DE CONTROL

ENCENDIDO/

APAGADO

PANTALLA

MENÚ EN

PANTALLA

ARRIBA

BOMBA DE

enchufe bien el cable en la unidad primero y luego

enchufe el otro extremo en un tomacorriente adecuado.

pantalla se alterna la temperatura de entrada y la

humedad de entrada.

Pantalla de arranque y modos de pantalla normal

Cuando la unidad se enchufe por primera vez en un

tomacorriente de CA, la pantalla del panel de control

mostrará brevemente una serie de lecturas de salida.

Esto es parte del procedimiento de autodiagnóstico y el

usuario no tiene que llevar a cabo ninguna acción.

Encienda la unidad

El panel de control tiene una pantalla y un panel táctil

con cuatro teclas. Presione el botón ON/OFF

(ENCENDIDO/ APAGADO) para encender la unidad. La

unidad comenzará una cuenta regresiva de retardo del

compresor (hasta 60 segundos de duración) y un

proceso de autodiagnóstico y luego pasará al modo de

pantalla normal.

SELECCIÓN EN EL

MENÚ/TECLA HACIA

Menú de ajustes del usuario

El usuario puede hacer varios ajustes. También se

puede mostrar información del sistema. Se puede

acceder a estos elementos presionando el DISPLAY

MENU (MENÚ EN PANTALLA). Cada vez que presione

la tecla se mostrará el parámetro que siga. Cuando

llegue al parámetro que desee ajustar, presione MENU

SELECTION (SELECCIÓN EN EL MENÚ) para

aumentar el valor. Presione DISPLAY MENU

nuevamente para aceptar el ajuste y reiniciar el ciclo de

la pantalla.

Tenga en cuenta que solo se pueden ajustar los

elementos del menú que estén seguidos por el símbolo

mayor que ( > ).

Mensajes de error

Si el diagnóstico integrado descubre un problema, la

unidad mostrará un mensaje de error. Vea “Mensajes de

error” para leer una explicación de cada mensaje.

Guía del panel de controlON/OFF: presione

esta tecla para encender o apagar la unidad. Cuando se

enciende la máquina, la pantalla normalmente muestra

el mensaje PLEASE WAIT COMP. DELAY (ESPERE A

RETRASO DEL COMPRESOR) y realiza una cuenta

regresiva desde un máximo de 60 segundos hasta 0.

Este retraso da tiempo para que las presiones del

refrigerante se equiparen para que haya un arranque

más sencillo. Una vez que la unidad complete el retraso

del compresor, la pantalla mostrará el mensaje

UNIT ON XX HRS (UNIDAD ENCENDIDA XX HORAS)

y alterna entre INLET XX°F (ENTRADA XX °F) e

INLET XX% (ENTRADA XX %). NOTA: Si no aparece la

cuenta regresiva de retraso del compresor, no se

necesita un retraso y la máquina comenzará a funcionar

de inmediato.

PRENDIDO XXXX HR

ENTRADA XXX°C / 00%

La primera línea de la pantalla muestra la cantidad total

de horas que la unidad ha estado en funcionamiento.

Este valor se puede reiniciar a cero para realizar un

seguimiento de las horas de trabajo (vea “Reinicio de

horas de trabajo” más abajo). En la segunda línea de la

07-02300C F600 12 Dri-Eaz Products, Inc.

DISPLAY MENU: presione esta tecla para alternar entre

la exhibición de condiciones adicionales del

deshumidificador y los ajustes del usuario. Para regresar

al menú principal, presione la tecla ON/OFF una vez.

MENU SELECTION: presione esta tecla para cambiar

los valores de los ajustes "definidos por el usuario". La

tecla MENU SELECTION funciona como tecla hacia

ARRIBA para configurar el punto de ajuste para el

funcionamiento en modo Humidistat. Vea el Menú de

ajustes de usuario (página siguiente) para obtener más

información. PURGE: presione esta tecla para vaciar el

agua del depósito de la bomba de condensado. La

pantalla mostrará el mensaje PUMP PURGING (LA

BOMBA ESTÁ PURGANDO) con una cuenta regresiva.

NOTA: Durante el funcionamiento normal, la bomba

purga el agua automáticamente.

Page 13

Presione MOSTRAR

MENÚ para pasar a la

siguiente opción del

menú. ↓

Presione > SELECCIÓN DEL MENÚ para cambiar el ajuste. →

1. HRS REINICIAR>

FALLA DE LUZ X

>

1. H DE TRABAJO 0

FALLA DE LUZ 0

Presione > para restablecer a 0.

2. ENTRADA SALIDA

100ʹ 80% 115ʹ 30%

Sólo para información.

3. ENTRADA-SALIDA

XX.X g/kg

4. FILTRO LIMPIAR

XXX HR >

>

4. FILTRO LIMPIAR

0 HRS

Presione > para borrar las horas de limpieza del filtro.

5. LIMPIAR BOBINA

XXX HRS >

>

5. LIMPIAR BOBINA

0 HRS

Presione > para borrar las horas de limpieza de la bobina.

6. HIGROSTATO

MODO APAGADO>

>

6. HIGROSTATO

MODO PRENDIDO>

Presione > para poner en ON u OFF (ENCENDER o APAGAR). Para una deshumidificación

máxima, vele por que HUMIDISTAT esté apagado.

7. CONSIGNA

HIGROSTATO XX%>

>

Presione > para alternar entre el 40% y el 90% en incrementos de 5% (el valor predeterminado es de 50%).

8. IDIOMA

ESPANOL >

>

8. SPRACHE

DEUTSCH >

>

8. LANGUE

FRANCAIS >

>

8. LANGUAGE

ENGLISH >

Presione > para cambiar las

opciones de idioma.

9. TEMPERATURA

ʹC >

>

9. TEMPERATURA

ʹF >

Presione > para cambiar a °F o °C.

10. TEMP BOBINA

XXʹ

Sólo para información.

11. CORR COMPRS

XX.X A

Sólo para información.

12. FIRMWARE

3.XX FXXX-XXX

Sólo para información.

13. TOTAL DE HRS

XXXX HR

(Regresa al

elemento del menú

superior).

La siguiente sección está disponible sólo en las unidades equipadas con sistema inalámbrico.

14. SENSOR ID

XXXXXXXXX

(Regresa al

elemento del menú

superior).

AJUSTES DE USUARIO

Solo se pueden ajustar los elementos del menú que estén seguidos de un símbolo de «mayor que» (>). Si no se selecciona ninguna tecla en las

siguientes pantallas en un lapso de 5 minutos: INLET OUTLET (ENTRADA SALIDA), DPR GRAIN (GRANO DE DPR), la pantalla volverá al modo de

visualización normal. En todos los demás elementos de menú, la pantalla regresará al modo de visualización normal después de 20 segundos. Los

elementos que no tienen el símbolo (>) son únicamente para información y no se pueden cambiar ni restablecer. Consulte "Mensajes del sistema" a

continuación para obtener mensajes de estado adicionales del sistema.

excesiva de agua en la unidad y puede gotear al mover

AL FINAL DE TRABAJO

Para reducir la posibilidad de goteo al mover la

unidad, siga estos pasos adicionales para velar por

la extracción de toda el agua de la unidad.

AVISO: La unidad completará el ciclo de

descongelamiento incluso si está apagada, pero aún

enchufada. Si la unidad se desenchufa durante el ciclo

de descongelamiento, puede acumularse una cantidad

la unidad.

AVISO: Para que el tanque de condensado esté vaciado

por completo tras la purga, vele por colocar la unidad en

posición vertical sobre una superficie horizontal.

1. No apague ni mueva la unidad hasta que regrese

al modo normal de funcionamiento. Para corroborar

el estado de la unidad, examine el panel de control.

El panel de control mostrará uno de los mensajes

siguientes:

07-02300C F600 13 Dri-Eaz Products, Inc.

Page 14

Descongelamiento en marcha:

---

DESCONGELE XXXX

Es el modo de la pantalla si la unidad está en el modo

de descongelamiento. XX indica los segundos restantes

del ciclo de descongelamiento.

Secuencia de apagado:

ESPERE A QUE SE

DESCONGELE XXX

Es el modo de la pantalla si la unidad está en el modo

de descongelamiento y está apagada (por el usuario).

La unidad completará el ciclo de descongelamiento para

eliminar la acumulación de hielo y luego purgará la

bomba. XX indica los segundos restantes del ciclo de

descongelamiento.

Secuencia de secado:

ESPERE A QUE SE

SECADO XXX

Es el modo de la pantalla si la unidad no está en el

modo de descongelamiento y está apagada (por el

usuario). La unidad completará el ciclo de secado de 5

minutos y luego purgará la bomba. XX indica los

segundos restantes del ciclo de secado.

Pantalla normal:

PRENDIDO XXXX HR

ENTRADA XXX°C / XX%

La unidad ha completado un ciclo de descongelamiento

y secado y ha regresado al modo normal. Ahora puede

avanzar al paso 2.

2. Agite suavemente la máquina para velar por que

el agua que quede en las superficies interiores caiga

al área del sumidero.

3. Presione la tecla PURGE (PURGAR). Cuando

finalice el ciclo de purga, apague la unidad.

4. Retire la manguera de drenaje externo, vacíela

con cuidado, enróllela y vuelva a colocarla en la

bandeja de almacenamiento en la parte superior de

la unidad.

TRANSPORTE Y ALMACENAMIENTO

IMPORTANTE: Antes de mover, transportar o

almacenar la unidad, púrguela y almacene la

manguera y el cable de alimentación tal como se

describe en la sección “Al finalizar el trabajo” más

arriba.

AVISO: Maneje la unidad con cuidado. No permita que

la unidad se caiga, no la arroje y no la coloque en un

lugar donde podría caerse. El tratamiento brusco podría

dañar el deshumidificador y puede propiciar una

situación peligrosa o anular la garantía.

No exponga el panel de control a la humedad, la

nieve o la lluvia.

Almacene y transporte de forma segura para evitar

impactos dañinos en las partes internas.

Sujete durante su transporte para prevenir su

deslizamiento y posibles lesiones a los ocupantes

del vehículo.

No almacene ni transporte la unidad apoyada sobre

el frente, los lados o la parte posterior. Esto ayudará

a prevenir que la humedad que quede salga de la

unidad o llegue a áreas fuera del sumidero.

PLAN DE MANTENIMIENTO

¡ADVERTENCIA! PELIGRO DE DESCARGA

ELÉCTRICA. Desenchufe el deshumidificador antes de

realizar tareas de mantenimiento.

ADVERTENCIA: Riesgo de exposición al polvo y a

contaminantes. Se recomienda el uso de una máscara y

guantes. Si la unidad ha estado expuesta a

contaminantes potencialmente peligrosos, limpie bien y

desinfecte antes de volver a utilizar.

AVISO: La unidad está equipada con sensores

electrónicos sensibles. Proteja los sensores y los hilos

conductores contra daños y no los exponga al agua ni a

una solución limpiadora.

Se necesitan las siguientes herramientas e insumos

para completar los procedimientos de

mantenimiento que se describen en este manual:

Destornillador Philips

Broca T-20 Torx

Llave para tuercas o llave de cubo y trinquete

(10 mm)

Paños de limpieza

Aspiradora HEPA con una boquilla con cepillo blando

y herramienta para cavidades.

Recomendado

Taladro inalámbrico, cuchillo pequeño, pinzas de

punta pequeña, solución limpiadora de bobinas,

solución limpiadora de carcasas rotomoldeadas.

Antes de cada uso

Inspeccione el cable eléctrico para detectar daños:

busque raeduras, cortes, etc. Reemplace el cable si

detecta algún daño.

Inspeccione el filtro: reemplácelo si observa que hay

acumulación de polvo y suciedad.

AVISO: Reemplace los filtros usados con un filtro nuevo

Dri-Eaz, número de pieza F579 (paquete de 24). Otros

tipos de filtros no proporcionan filtración o flujo de aire

adecuados. Cada filtro se envuelve individualmente para

conservar la eficiencia de la filtración. Quite la envoltura

antes de instalar el filtro en el deshumidificador.

Mensual

Inspeccione las bobinas: limpie si observa que hay

acumulación de polvo. Con un uso normal, el polvo

puede acumularse y puede restringir el flujo de aire, lo

07-02300C F600 14 Dri-Eaz Products, Inc.

Page 15

Retire los 4

el mantenimiento.

Fig. B: Desensamble para la limpieza

cual disminuye el rendimiento y provoca el

recalentamiento de la unidad.

Para mantener el aspecto: limpie la superficie interior y

exterior con un paño húmedo. Para una limpieza

profunda y un brillo duradero y de protección, use un

tratamiento automotriz en el interior.

Según sea necesario

Limpie la válvula de retención de la bomba y el

recipiente: si la unidad muestra el mensaje “ER9

BOMBA TAPADA BOMBA&MANGUERA,” debe limpiar

la válvula de retención de la bomba y el recipiente de la

bomba. Esto exige la extracción de la carcasa del frente.

Limpie las bobinas: inspeccione la bobina evaporadora

horizontal (frío) sin la cubierta del frente. Si observa una

cantidad excesiva de polvo y suciedad, aspire bien o

limpie con un limpiador para bobinas.

tornillos de la

carcasa delantera,

y deslice hacia

afuera para

acceder a las

bobinas ya la

bomba para hacer

07-02300C F600 15 Dri-Eaz Products, Inc.

Page 16

MENSAJE DEL PANEL DE

CONTROL

EXPLICACIÓN

ACCIÓN DEL USUARIO

INICIALIZAR

La unidad se está encendiendo.

Ninguna

VERSION FIRMWARE

XXX

Indica el número de versión del firmware del tablero de

control.

Ninguna

FXXX-XXX

Número de modelo.

Ninguna

APAGADO

La unidad ha completado el encendido y está

funcionando.

Ninguna

POR FAVOR ESPERE

RETAR COMPRS XX

Retraso de 60 segundos antes que se encienda el

compresor. Permite que se equipare la presión del

sistema.

Ninguna

PRENDIDO XXXX HR

ENTRADA XXX °C / XX%

Primera línea: indica las horas totales de

funcionamiento.

Segunda línea: alterna entre la temperatura de entrada

y la humedad relativa de entrada cada 2 segundos.

Ninguna

HIGROSTATO

ENTRADA XXX °C /

HUMISTATO

ENTRADA XX %

Primera línea: indica que la unidad está en el modo

Humidistat.

Segunda línea: alterna entre la temperatura de entrada

y la humedad relativa de entrada cada 2 segundos.

Ninguna

BAJA TEMP

ENTRADA XXX °C / XX%

La unidad se apaga si la temperatura de entrada es

inferior a 45 °F/7 °C. Se vuelve a encender cuando la

temperatura de entrada llega a 50 °F/10 °C.

Ninguna

---

PURGA DE AQUA XX

La purga de la bomba tiene una cuenta regresiva en

segundos. Presione la tecla nuevamente para

detenerla.

Ninguna

CICLO ALTA TEMP.

MIN RESTANTES XX

Se alcanzó el límite de sobrecarga de la unidad. Se

inició el enfriamiento

Ninguna

---

DESCONGELE XXXX

La unidad se está descongelando, y hay una cuenta

regresiva en segundos.

Ninguna

ESPERE A QUE SE

DESCONGELE XXX

La unidad se apaga cuando la bobina está fría o ya está

en el ciclo de descongelamiento. Avanza al ciclo final o

inicia un ciclo para eliminar el hielo de las bobinas antes

de almacenar la unidad.

Ninguna

ESPERE A QUE SE

SECADO XXX

Ocurre cuando la unidad se apaga y la bobina no está

congelada. Elimina el agua de las bobinas antes de

almacenar la unidad.

Ninguna

LIMPIAR FILTRO >

APAGADO

Indicación para cambiar el filtro.

Cambie el filtro. Presione la

tecla > para reiniciar

LIMPIAR BOBINA

APAGADO

Indicación para limpiar las bobinas y el interior.

Limpie las bobinas. Presione

la tecla > para reiniciar

MENSAJES DEL SISTEMA

El panel de control mostrará los mensajes siguientes de acuerdo con el rendimiento del sistema y las condiciones

ambientales. Si se necesita alguna acción por parte del usuario, se indicará en la tercera columna.

07-02300C F600 16 Dri-Eaz Products, Inc.

Page 17

MENSAJE DEL PANEL DE

CONTROL

EXPLICACIÓN Y SOLUCIÓN

ER4 CONEXION

SENSOR DESCONG

or

ER4 CONEXION

SENSOR SALIDA

El sensor de temperatura está abierto, no está o hay un cortocircuito. Verifique que los

sensores de temperatura están instalados correctamente en el panel de control. Si el

error continúa, comuníquese con el servicio técnico.

ER5 CONEXION

SENSOR TABLERO

El sensor de temperatura/humedad relativa de entrada está abierto, no está o hay un

cortocircuito. Verifique que el sensor de temperatura/humedad relativa de entrada esté

instalado correctamente en el panel de control y la cubierta de entrada. Si el error

continúa, comuníquese con el servicio técnico.

ER6 CONTACTAR

CENTRO DE SERV

Falla del sensor de corriente. Si el error continúa, comuníquese con el servicio técnico.

ER7 INVAL

AJUSTE

Ajuste incorrecto o no admitido del interruptor DIP. Comuníquese con el servicio de

atención al usuario de Dri-Eaz para conocer el ajuste correcto del interruptor DIP.

ER8 BOTON

ATORADO

Se ha atascado una tecla o se ha mantenido presionada por demasiado tiempo.

Comuníquese con el servicio técnico.

ER9 BOMBA TAPADA

BOMBA&MANGUERA

Compruebe que no haya obstrucciones ¿La manguera está acodada debajo de la

unidad o aplastada por una rueda? Verifique que no haya bloqueos en la bomba y

repare de ser necesario.

MENSAJES DE ERROR

Si el sistema de control detecta un error, mostrará un mensaje de error (“ER”). Si esto sucede, primero desenchufe la

unidad y luego vuelva a enchufarla. Esto habitualmente reiniciará los componentes electrónicos, y la unidad volverá a

funcionar como siempre. Si el mensaje de error vuelve a aparecer, consulte las explicaciones y soluciones que se

muestran a continuación. Si estas soluciones no resuelven el problema, comuníquese con su centro de servicio

autorizado local.

07-02300C F600 17 Dri-Eaz Products, Inc.

Page 18

FALLA

CAUSA

SOLUCIÓN

Gotea agua al

mover la unidad

La unidad se desenchufó

antes de completar la purga.

Purgue la unidad antes de moverla. Vea “Al final del trabajo”.

La unidad no

funciona.

Unidad no encendida.

La unidad no está enchufada.

Encienda la unidad.

Enchufe la unidad; compruebe la conexión del cable de

alimentación en el tomacorriente y en la base de la unidad.

La unidad

funciona, pero la

sala no está seca

No se asignó un tiempo

suficiente para secar.

Movimiento de aire deficiente

en la sala.

Entrada de aire

excesivamente húmedo.

Verifique que “Humidistat” esté apagado.

Asigne más tiempo al secado.

Aumente el movimiento de aire con ventiladores.

Cierre la sala para reducir el ingreso de aire.

La unidad recoge

muy poca agua

El aire de la sala es seco.

La temperatura de la sala es

demasiado baja.

El filtro está lleno.

Las bobinas están obstruidas.

Verifique que “Humidistat” esté apagado.

Confirme el nivel de humedad con un higrómetro.

Aumente la temperatura de la sala.

Examine el filtro. Reemplácelo de ser necesario.

Examine las bobinas. Límpielas de ser necesario.

Si el problema que experimenta no figura en esta lista, llame a su distribuidor local o comuníquese con

nuestro Servicio de Atención al Cliente al 800-932-3030 para obtener asistencia.

Modelo

LGR 6000Li (F600)

Extracción de agua

AHAM (80 °F/60 % de

humedad relativa)

100 pintas | 47,3 l/día

Saturación de la

extracción de agua

(90°F/90 % de humedad

relativa)

204 pintas | 96,5 l/día

Dimensiones

(altura × ancho ×

profundidad)

32,1 × 19,8 × 20,0 in | 81,5 × 50,3

× 50,8 cm

Peso

103 lbs. | 46.7 kg

Amperios

6,6 A

Voltios

115 V

Frecuencia

60 Hz

Potencia

759 W

Intervalo de

funcionamiento

33 °F–100 °F | 1 °C–38 °C

Aire tratado (máx.)

320 pies cúbicos por minuto

Nivel sonoro (promedio)

53 dB

Manguera de drenaje

40 pies | 12,2 m

Cable de alimentación

25 pies | 7,6 m

Construcción

Carcasa rotomoldeada

Seguridad

Certificación ETL CSA 22.2 n.º 92

Las especificaciones técnicas pueden cambiar sin previo aviso.

Algunos valores pueden ser aproximados.

*La velocidad del ventilador varía automáticamente para un

rendimiento optimizado.

RESOLUCIÓN DE PROBLEMAS

ESPECIFICACIONES TÉCNICAS

Filtro de aire N.º de pieza F579 (paquete de 24).

Puede encontrar información de la garantía en

www.LegendBrandsRestoration.com.

Vele por visitar LegendBrandsRestoration.com/Warranty

y registrar su compra. Su registro nos ayudará a

brindarle información actualizada del producto en

función de sus necesidades.

Para desecharla de forma adecuada, esta unidad debe

llevarse a un reciclador licenciado que se encargue de

equipos de refrigeración.

ADVERTENCIA: Este producto y otras sustancias

que pueden desprenderse del aire por su uso

contienen productos químicos, entre ellos plomo y

ftalatos, que el estado de California sabe que causan

cáncer, defectos congénitos u otros daños durante la

gestación. Para obtener más información, visite

P65Warnings.ca.gov.

07-02300C F600 18 Dri-Eaz Products, Inc.

Page 19

AVERTISSEMENT

RETRAIT CORRECT DE LA PRISE

Manuel d’utilisation

Déshumidificateur portatif LGR 6000Li

Modèle F600

DRI-EAZ PRODUCTS, INC.

15180 Josh Wilson Road, Burlington, WA 98233

Téléphone : 800-932-3030 Fax : 360-757-7950 www.LegendBrandsRestoration.com

Le déshumidificateur Dri-Eaz® LGR 6000Li réduit l’humidité dans des endroits fermés en éliminant la

vapeur d’eau dans l’air. Le 6000Li est robuste, durable et hautement portatif, ce qui en fait l’équipement

idéal pour réparer des dégâts causés par l’eau, sécher des structures, les travaux de construction et

d’autres applications qui nécessitent une déshumidification temporaire, hautement performante.

Brevets : http://www.LBpatents.com

CO N S E R V E R C E S I NSTR U C T I O N S

INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT ! En aucun cas, vous ne devez

altérer ou modifier votre déshumidificateur. Utilisez

seulement des pièces de rechange autorisées par

Dri-Eaz Products, Inc. Des modifications ou

l’utilisation de pièces non approuvées peuvent

entraîner un risque de danger et annuleront votre

garantie. Contactez votre distributeur agréé pour

une assistance.

Saisissez la prise IEC et tirez tout droit.

IMPORTANT : Des dommages de la prise IEC ou du

déshumidificateur résultant d’un retrait incorrect du câble

d’alimentation ne sont pas couverts par la garantie. Le

câble d’alimentation IEC est une pièce d’usure et n’est

pas couvert par la garantie.

AVERTISSEMENT ! Risques de choc électrique,

ventilateur rotatif, surface brûlante. Débranchez

l’unité avant d’ouvrir le couvercle pour procéder à

un nettoyage ou un entretien. L’appareil doit être

mis à la terre.

Inspectez le câble d’alimentation avant utilisation. Si

le câble est endommagé, ne l’utilisez pas. Saisissez

toujours la prise (pas le câble) pour débrancher.

Insérez la fiche triphasée du câble d’alimentation

dans une prise de terre correspondante. N’utilisez

pas d’adaptateur. Ne coupez jamais la troisième

broche. N’utilisez pas de rallonge.

L’appareil doit fonctionner sur un circuit 115V/60Hz

protégé par un disjoncteur différentiel de fuite à la

terre (DDFT).

Maintenez le moteur et le câblage au sec.

Ne tentez pas de réparer l’appareil. Pour les centres

d’entretien et de réparation agréés, contactez DriEaz.

AVANT DE COMMENCER

Enregistrement de la garantie

Visitez LegendBrandsRestoration.com/Warranty pour

enregistrer votre achat. L’enregistrement de la garantie

nous permet de mieux vous assister avec l’utilisation,

l’entretien ou la réparation de votre équipement et de

vous contacter dans le cas où nous avons des

informations de sécurité importantes à vous

communiquer concernant votre produit Dri-Eaz. Si vous

estimez qu’une réparation ou entretien est nécessaire,

ayez à portée de main le modèle de l’appareil, le numéro

de série et la preuve originale d’achat avant d’appeler

votre distributeur pour assistance qui vous donnera une

autorisation de retour de matériel (RMA).

07-02300C F600 19 Dri-Eaz Products, Inc.

Page 20

Fiche du câble

d’alimentation

Étiquette du numéro de

série du modèle

AVANT

ARRIÈRE

Entrée d’air humide.

Filtre d’air

Rangement du câble

d’alimentation et du

tuyau de vidange.

Sortie d’air de

traitement

Panneau avant. Retirez

pour accéder à la pompe

et aux serpentins pour le

nettoyage. Voir la Fig. B.

Poignée intégrée. Utilisez la manette

rouge pour bloquer la poignée en

position verticale pour le

fonctionnement ou l’abaisser pour le

chargement ou le rangement.

Panneau de commande.

FIG. A : IDENTIFICATION DES

PIÈCES

Raccord rapide du

tuyau de vidange.

COMMANDES ET INSTRUCTIONS DE

FONCTIONNEMENT

Mettez l’unité debout en position verticale.

NOTICE : Le transport ou l’entreposage de l’unité

dans la position horizontale n’est pas recommandé.

Lorsque la machine est placée en position

horizontale, l’huile du compresseur peut s’écouler

dans les serpentins du réfrigérant et cela peut

réduire les capacités de fonctionnement du

déshumidificateur et causer des dommages

éventuels de l’appareil. Si l’unité a été placée en

position horizontale, mettez-la debout en position

verticale et laissez-la dans cette position pendant au

moins 30 minutes avant de la mettre en marche.

Positionner un déshumidificateur

Pour obtenir des résultats optimaux,

faites fonctionner votre

déshumidificateur dans un endroit

fermé. Fermez toutes les portes et les

fenêtres pour maximiser l’absorption

d’eau de l’appareil. Éloignez votre

déshumidificateur des obstructions et

de tout objet pouvant gêner le flux d’air

dans et hors de l’appareil.

Poignée d’extension

Relâchez la poignée en tournant la

manette rouge vers l’extérieur, puis

positionnez la poignée vers le haut.

Tournez la manette rouge de nouveau

pour la bloquer en positionnement de

fonctionnement.

NOTICE : N’utilisez pas la poignée

d’extension pour soulever l’appareil du

sol, de manière horizontale. N’utilisez

pas la poignée d’extension comme

dispositif de fixation pour attacher

l’unité dans un véhicule pour le

transport. Une telle utilisation exerce

une pression excessive sur les points

d’attache de la poignée dans le

logement.

Mise en place du tuyau de

vidange

Cet appareil pompe de l’eau

automatiquement sur une base

régulière. Ce déshumidificateur est

équipé d’un raccord à connexion

rapide pour l’attachement au tuyau

de vidange fourni (12 m - 40 ft), situé

sur le plateau sur le dessus de

l’unité. Déballez le tuyau entier et

placez l’extrémité ouverte dans un

bac, drain ou seau, ou dehors, dans

un endroit où l’eau peut s’écouler

en toute sécurité. Si vous utilisez un

seau ou un autre contenant pour la

collecte de l’eau, vérifiez

régulièrement pour éviter un

débordement.

NOTICE : Déroulez et redressez le

tuyau de vidange entier. Ne laissez

07-02300C F600 20 Dri-Eaz Products, Inc.

aucune partie du tuyau enroulée sur

l’unité et ne placez pas l’extrémité du

Page 21

ON/OFF

Appuyez sur la touche et

relâchez pour mettre l’unité en

marche ou l’arrêter.

MENU D’AFFICHAGE

Appuyez pour sélectionner

l’élément suivant dans le menu.

L’article du menu s’affiche.

SÉLECTION DE MENU /

TOUCHE VERS LE HAUT

Appuyez pour basculer ou

sélectionnez les valeurs

affichées dans le menu.

POMPE DE PURGE

Appuyez sur le bouton et

relâchez pour commencer la

purge. Un compte à rebours

affiche les secondes restantes

jusqu’à ce que la purge soit

terminée.

PANNEAU DE COMMANDE

ON/OFF

AFFICHAGE

MENU

D’AFFICHA

GE

SÉLECTION DE

MENU / TOUCHE

VERS LE HAUT

POMPE DE

PURGE

tuyau à une hauteur de plus de 6 m (20 ft), à partir du

bas de l’unité. Vérifiez aussi qu’il n’y ait pas de torsion

ou d’obstructions qui puissent restreindre le flux d’eau.

Une torsion ou une obstruction du câble peut entraîner

un arrêt de l’unité et produire un code d’erreur ER9. Voir

« Messages d’erreur » pour plus d’informations.

durée d’au plus 60 secondes) et un processus d’auto-

diagnostic, puis passera en mode d’affichage normal.

XXXX HRS TRAVAIL

ENTREE XXX°C

La première ligne de l'affichage indique le nombre total

d’heures pendant lesquelles l’unité a fonctionné. Cette

valeur doit être réinitialisée sur zéro pour suivre les

heures de travail (voir « Réinitialisation des heures de

travail » ci-dessous). La deuxième ligne de l’affichage

alterne entre la température en entrée et l’humidité en

entrée.

Menu des paramètres d’utilisateur

Un certain nombre de paramètres peuvent être changés

par l’utilisateur. Les informations du système peuvent

aussi être affichées. Appuyez sur DISPLAY MENU

(menu d’affichage) pour accéder à ces éléments.

Chaque pression sur la touche fait afficher le paramètre

suivant. Lorsque vous obtenez le paramètre que vous

voulez ajuster, appuyez sur MENU SELECTION

(sélection de menu) pour augmenter la valeur. Appuyez

de nouveau sur DISPLAY MENU (menu d’affichage)

pour accepter le paramètre et redémarrer le cycle

d’affichage.

Brancher le câble électrique

Le déshumidificateur doit être branché sur une prise de

115 volts avec protection DDFT, d’au moins 15 amps.

Retirez le câble du plateau de rangement et déroulez-le.

Branchez toujours le câble fermement sur l’unité

d’abord, puis branchez l’autre extrémité sur une prise

électrique appropriée.

Modes d’affichage de démarrage et d’affichage

normal

Lorsque l’unité est d’abord branchée sur une prise AC,

le panneau de commande affiche brièvement une série

de valeurs. Cela fait partie d’une procédure d’autodiagnostic et aucune intervention de l’utilisateur n’est

nécessaire.

Notez que seulement des éléments de menu suivis du

symbole supérieur à ( > ) peuvent être ajustés.

Messages d’erreur

Si le système de diagnostics embarqué découvre un

problème, l’unité affichera un message d’erreur. Voir

« Messages d’erreur » pour une explication de chaque

message.

Guide du panneau de commande

ON/OFF. Appuyez pour mettre l’unité en marche ou à

l’arrêt. Lorsque la machine est en marche, l’écran affiche

PLEASE WAIT COMP. DELAY (veuillez patienter

jusqu’à la fin du délai) et effectue un compte à rebours

numérique d’un maximum de 60 secondes à 0. Ce délai

laisse le temps suffisant pour équilibrer les pressions du

réfrigérant et permettre un démarrage facile. Une fois

que l’unité termine le délai du compresseur, l’affichage

montre UNIT ON XX HRS (unité en marche xx heures)

et passe de INLET XX°F (entrée xxºF) à INLET XX%

(entrée xx%). REMARQUE : Si aucun compte à rebours

n’est affiché, un délai n’est pas nécessaire et la machine

commence à fonctionner immédiatement.

MENU D’AFFICHAGE. Appuyez pour afficher les

conditions supplémentaires du déshumidificateur et les

paramètres utilisateur. Pour revenir au menu principal,

appuyez une fois sur la touche ON/OFF

Mettre l’unité en marche

Le panneau de commande contient un écran d’affichage

et un pavé tactile de quatre touches. Appuyez sur le

bouton ON/OFF pour mettre l’unité en marche. L’unité

va maintenant effectuer un compte à rebours (d’une

07-02300C F600 21 Dri-Eaz Products, Inc.

SÉLECTION DE MENU. Appuyez pour changer les

valeurs des paramètres « définis par l’utilisateur ». La

touche MENU SELECTION agit comme la touche vers le

haut pour régler le point de consigne pour un

fonctionnement en mode « Humidistat » (hygrostat). Voir

le menu des paramètres utilisateur (page suivante) pour

Page 22

plus de détails. PURGE. Appuyez pour vider l’eau du

réservoir de la pompe à condensat. L’écran affiche

PUMP PURGING (purge de pompe) avec un compte à

rebours. REMARQUE : En mode de fonctionnement

normal, la pompe purge automatiquement.

REMARQUE : En mode de fonctionnement normal, la

pompe purge automatiquement.

07-02300C F600 22 Dri-Eaz Products, Inc.

Page 23

Appuyer sur MENU

AFFICHAGE pour

passer à l’option

suivante du menu. ↓

Appuyer sur > SÉLECTION DE MENUS pour modifier les paramètres. →

1. RÉINIT. HRS >

PANNE COURANT X

>

1. HRS RÉINIT. 0

PANNE COURANT 0

Appuyer sur > pour réinitialiser à 0.

2. ENTREE SORTIE

100' 80% 115' 30%

Pour information seulement.

3. ENTRÉE-SORTIE

XX.X g/kg

L’unité affiche GPP si elle paramétrée en ºFahrenheit ou g/kg si elle est paramétrée en ºCelsius. Pour changer ce

paramètre, voir l’élément de menu 9.

4. FILTRE NETT.

XXX HRS >

>

4. FILTRE NETT.

0 HRS >

Appuyer sur > pour effacer les heures du filtre.

5. INT NETTOYER

XXX HRS >

>

5. INT NETTOYER

0 HRS

Appuyer sur > pour effacer les heures de la bobine.

6. MODE

HYGROSTAT

ETEINT >

>

6. MODE

HYGROSTAT

EN MARCHE >

Appuyer sur > pour allumer ou éteindre. Pour une déshumidification maximale,

vérifiez que HUMIDISTAT est sur OFF.

7. REGLAGE

HYGROSTAT XX% >

>

Appuyer sur > pour faire défiler de 40% à 90% par incréments de 5% (le défaut est 50%).

8. IDIOMA

ESPANOL >

>

8. SPRACHE

DEUTSCH >

>

8. LANGUE

FRANCAIS >

>

8. LANGUAGE

ENGLISH >

Appuyer sur > pour

modifier l’option de

langue.

9. TEMPERATURE

'C >

>

9. TEMPERATURE

'F >

Appuyer sur > pour passer de °F à °C.

10. TEMPERATURE

SERPENTIN XX'

Pour information seulement.

11.COMPRESSEUR

AMPERAGE XX.X A

Pour information seulement.

12.MICROLOGICIEL

3.XX FXXX-XXX

Pour information seulement.

13. HRS TOTALES

XXXX HRS

(Retour aux éléments

du menu principal.)

La partie suivante n’est disponible que pour les unités équipées sans fil.

14. ID CAPTEUR

XXXXXXXXX >

(Retour aux éléments

du menu principal.)

Paramètres de l’utilisateur

Seuls les éléments du menu suivis du symbole « supérieur à » (>) peuvent être réglés. Si aucune touche n’est sélectionnée pendant 5

minutes pour les écrans : ENTRÉE-SORTIE, GRAIN DPR, l’affichage reviendra au mode d’affichage normal. Pour tous les autres

éléments du menu, l’affichage reviendra au mode d’affichage normal après 20 secondes. Les éléments sans le symbole (>) ne sont là

que pour information et ne peuvent pas être modifiés ou réinitialisés. Voir «Messages système» ci-dessous pour d'autres messages sur

l'état du système.

supplémentaires pour vous assurer que toute l’eau

À LA FIN DE LA TÂCHE

Pour réduire la possibilité d’égouttement lors du

déplacement de l’unité, suivez ces étapes

07-02300C F600 23 Dri-Eaz Products, Inc.

est éliminée de l’unité.

NOTICE : L’unité termine le cycle de dégivrage même si

elle est à l’arrêt mais reste toujours branchée. Si

Page 24

l’unité est débranchée durant le cycle de dégivrage, un

excédent d’eau peut s’accumuler dans l’unité et peut

s’égoutter lorsque vous déplacez l’unité.

NOTICE : Pour s’assurer que le bac de condensat se

vide complètement durant la purge, vérifiez que l’unité

est positionnée debout, à la verticale sur une surface

horizontale.

1. Ne mettez pas l’unité à l’arrêt ou ne la déplacez

pas jusqu’à ce qu’elle revienne en mode de

fonctionnement normal. Pour confirmer l’état de

l’unité, passez en revue le panneau de commande.

Le panneau de commande affiche l’un des

messages suivants :

Dégivrage en cours :

---

DEGIVRAGE XXXX

Mode d’affichage lorsque l’unité est en mode de

dégivrage. XX indique les secondes restantes pour le

cycle de dégivrage.

Séquence d’arrêt :

ATTENDRE

LE DEGIVRAGE XXX

Mode d’affichage lorsque l’unité est en mode de

dégivrage et que l’unité est à l’arrêt (éteinte par

l’utilisateur). L’unité termine le cycle de dégivrage pour

éliminer toute accumulation de glace puis purge la

pompe. XX indique les secondes restantes pour le cycle

de dégivrage.

Séquence de séchage :

ATTENDRE

LE SECHAGE XXX

Mode d’affichage lorsque l’unité n’est pas en mode de

dégivrage et qu’elle est à l’arrêt (éteinte par l’utilisateur).

L’unité termine le cycle de séchage de 5 minutes puis

purge la pompe. XX indique les secondes restantes pour

le cycle de séchage.

Affichage normal :

XXXX HRS TRAVAIL

ENTREE XXX°C

L’unité a terminé un cycle de dégivrage et de séchage et

est revenue en mode normal. Vous pouvez maintenant

passer à l’étape 2.

2. Secouez doucement la machine pour vérifier que

l’eau restante sur les surfaces intérieures s’écoule

dans le puisard.

3. Appuyez sur la touche PURGE. Lorsque le cycle

de purge est terminé, arrêtez la machine.

4. Retirez le tuyau de vidange externe, drainez-le

soigneusement, enroulez-le et remettez-le sur le

plateau de rangement en haut de l’unité.

TRANSPORT ET RANGEMENT

IMPORTANT : Avant de déplacer, transporter ou

ranger l’unité, purgez l’unité et rangez le tuyau et le

câble d’alimentation tel qu’il est décrit dans la

section ci-dessus « À la fin de la tâche ».

NOTICE : Manipulez l’unité avec précaution. Ne faites

pas tomber l’unité ou ne la placez pas dans un endroit

d’où elle pourrait tomber. Un traitement sans précautions

peut endommager le déshumidificateur et causer un

risque de danger ou annuler la garantie.

N’exposez pas le panneau de commande à

l’humidité, la neige ou la pluie.

Entreposez et transportez l’unité de manière sûre

pour éviter des dommages des pièces internes.

Sécurisez l’unité durant le transport pour éviter

qu’elle ne glisse et cause des blessures aux

occupants du véhicule.

Ne transportez pas ou n’entreposez pas l’unité sur sa

face avant, sur les côtés ou sur le dos. Ceci permet

d’éviter que l’humidité restante ne s’échappe de

l’unité ou s’égoutte dans des parties en dehors du

puisard.

PROGRAMME DE MAINTENANCE

AVERTISSEMENT ! RISQUE DE CHOC ÉLECTRIQUE.

Débranchez le déshumidificateur avant d’effectuer une

opération de maintenance.

AVERTISSEMENT : Risque d’exposition à la poussière

et à des contaminants. L’utilisation d’un masque

respiratoire et de gants est recommandée. Si l’unité a

été exposée à des contaminants potentiellement

dangereux, nettoyez en profondeur et désinfectez avant

réutilisation.

NOTICE : L’unité est équipée de capteurs électroniques

sensibles. Protégez les capteurs et leurs fils conducteurs

des dommages et ne les exposez pas à l’eau ou à une

solution de nettoyage.

Les outils et les fournitures suivants sont

nécessaires pour effectuer les procédures de

maintenance décrites dans ce manuel :

Tournevis Philips

Embout T-20 Torx

Tournevis 10 mm ou douille et cliquet

Chiffons de nettoyage

Aspirateur HEPA avec embout à brosse douce et

suceur plat.

Recommandé

Perceuse sans fil, petit couteau, petites pinces,

solution de nettoyage de serpentin, solution de

nettoyage de logement rotomoulé.

Avant chaque utilisation

Inspecter le câble électrique pour détecter les

dommages. Détectez les coupures, effilochages, etc.

Remplacez le câble s’il est endommagé.

07-02300C F600 24 Dri-Eaz Products, Inc.

Page 25

Retirez les 4 vis du

panneau avant et

faites coulisser

pour accéder aux

serpentins et à la

pompe pour

effectuer une

opération

Fig. B : Démontage pour le nettoyage

Inspecter le filtre. Remplacez le câble si une

accumulation de poussière et de débris est visible.

NOTICE : Remplacez les filtres usés seulement avec

un nouveau filtre Dri-Eaz nº F579 (boîte de 24). Les

autres types de filtre n’offrent pas une filtration ou un

flux d’air adéquat. Chaque filtre est emballé

individuellement pour préserver l’efficacité de la

filtration. Retirez l’emballage avant d’installer le filtre

dans le déshumidificateur.

Tous les mois

Inspecter les serpentins. Nettoyez lorsque

l’accumulation de poussière est visible. Durant une

utilisant normale, de la poussière peut s’accumuler et

restreindre le flux d’air, réduire la performance et

causer une surchauffe de l’unité.

Pour préserver l’aspect de l’unité, essuyez les

surfaces intérieures et extérieures avec un chiffon

humide. Pour un nettoyage approfondi et obtenir un

lustre protecteur et durable, utilisez un produit de

traitement d’intérieur automobile.

Si nécessaire

Nettoyer le clapet antiretour de la pompe et le bac Si

l’unité affiche le message « ER9 BLOCAGE

POMPE/BOYAU », il se peut que le clapet antiretour de

la pompe et le bac de la pompe doivent être nettoyés.

Cela nécessite le retrait du logement avant.

Nettoyer les serpentins. Inspectez le serpentin

d’évaporateur horizontal (froid) avec le couvercle avant

retiré. Si un excédent de poussière et de débris est

présent, aspirez en profondeur et/ou nettoyez avec un

produit nettoyant pour serpentin.

07-02300C F600 25 Dri-Eaz Products, Inc.

Page 26

MESSAGES DU

PANNEAU DE

COMMANDE

EXPLICATION

INTERVENTION DE

L’UTILISATEUR

INITIALISER

L’unité est mise sous tension.

Aucune

MICROLOGICIEL

VERSION XXX

Indique le numéro de version du progiciel du panneau

de commande.

Aucune

FXXX-XXX

Numéro de modèle.

Aucune

ETEINT

L’unité est maintenant sous tension et en marche.

Aucune

SVP ATTENDRE COMP

DIFFERE XX

Délai de 60 secondes avant l’activation du compresseur.

Permet l’équilibrage de la pression du système.

Aucune

XXXX HRS TRAVAIL

ENTREE XXX°C / XX%

Première ligne : indique le nombre total d’heures de

fonctionnement.

Deuxième ligne : Permet de passer de la température

d’entrée à RH d’entrée toutes les 2 secondes.

Aucune

HYGROSTAT

ENTREE XXX°C / XX%

Première ligne : indique que l’unité est en mode

hygrostat

Deuxième ligne : Permet de passer de la température

d’entrée à RH d’entrée toutes les 2 secondes.

Aucune

BASSE TEMP

ENTREE XXX°C / XX%

L’unité s’arrête si la température d’entrée est en

dessous de 45°F/7°C. Elle est activée de nouveau

lorsque la température d’entrée atteint 50°F/10°C.

Aucune

---

PURGE POMPE XX

La pompe est en train de purger et un compte à rebours

est affiché en secondes. Appuyez de nouveau sur la

touche si nécessaire.

Aucune

CYCLE HAUTE TEMP

XX MIN RESIDUEL

La limite de surcharge de l’unité est atteinte. Le

refroidissement est initié.

Aucune

---

DEGIVRAGE XXXX

L’unité est en cours de dégivrage et un compte à

rebours est affiché en secondes.

Aucune

ATTENDRE

LE DEGIVRAGE XXX

L’unité s’arrête lorsque le serpentin est froid ou est déjà

dans un cycle de dégivrage. L’unité termine le cycle ou

initie un cycle pour éliminer la glace des serpentins

avant l’entreposage.

Aucune

ATTENDRE

LE SECHAGE XXX

S’affiche lorsque l’unité est à l'arrêt et que le serpentin

n’est pas gelé. Élimine l’eau des serpentins avant

l’entreposage.

Aucune

NETTOYER FILTRE>

ETEINT

Ce message apparaît pour indiquer qu’il faut changer le

filtre.

Changez le filtre. Appuyez

sur la touche > pour

réinitialiser

NETTOYER INT >

ETEINT

Ce message apparaît pour indiquer qu’il faut nettoyer

les serpentins et l’intérieur.

Nettoyer les serpentins.

Appuyez sur la touche > pour