Dri-Air Industries HP4-X 400 - 750, HP4-X 400 Series, HP4-X 750 Series, HP4-X 500 Series Operating Manual

DRI-AIR INDUSTRIES, INC.

HP4-X 400 - 750

FLOOR MOUNT DRYER

OPERATING MANUAL

OPERA TING MANUAL - HP4-X 400-750 FM DR YERS

Revision 10/8/02

Page 1

DRI-AIR INDUSTRIES, INC.

Page 2

DRI-AIR INDUSTRIES, INC.

16 THOMPSON ROAD

P.O. BOX 1020

EAST WINDSOR, CT 06088-1020

Tel. (860) 627-5110

FAX (860) 623-4477

Internet http://www.dri-air.com

e-mail: sales@dri-air.com

OPERA TING MANUAL - HP4-X 400-750 FM DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

CONTENTS

DRYER OPERA TION/FEATURES---------------------------4

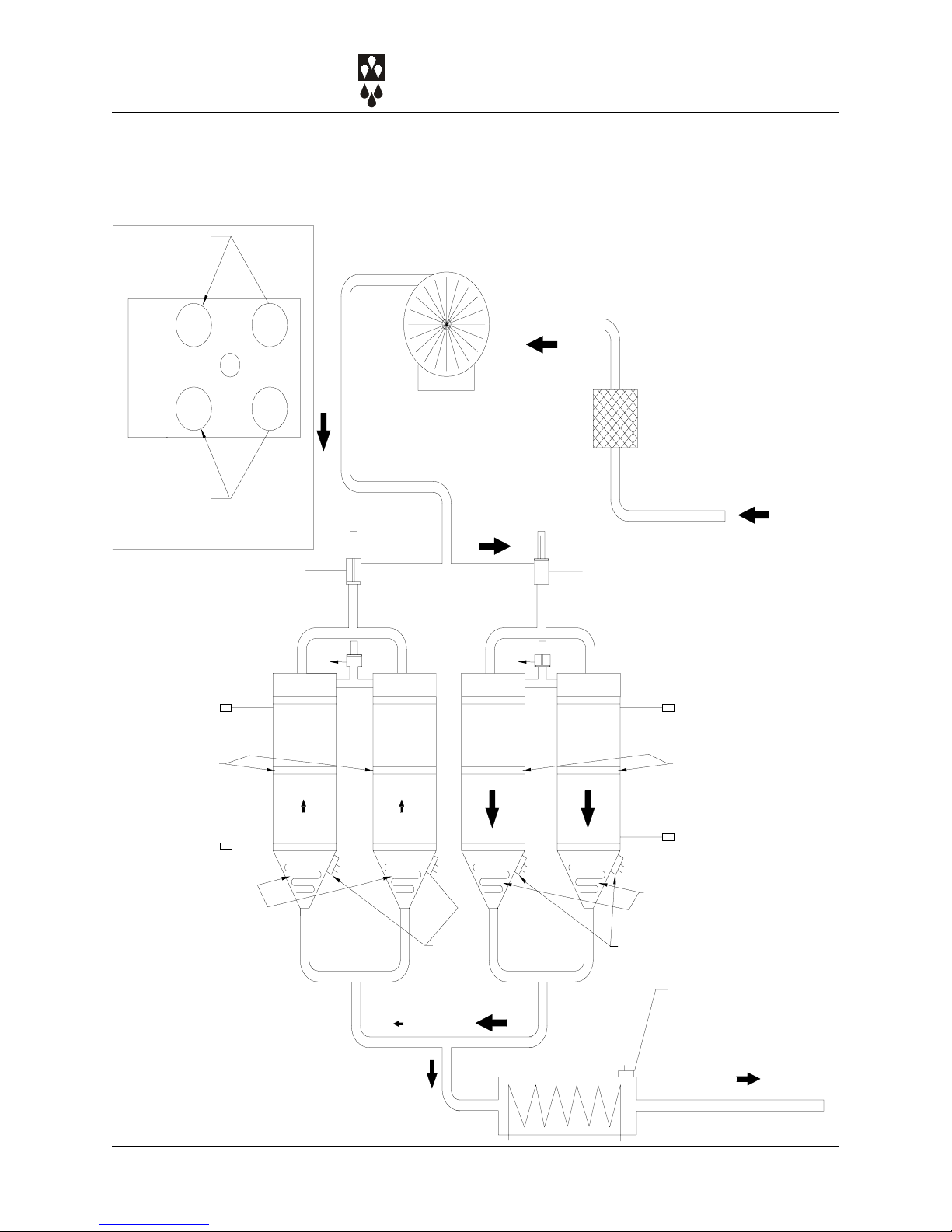

AIR FLOW SCHEMATIC FOR HP4-X DRYER -----------6

DRYER CYCLE DIAGRAM------------------------------------ 7

INST ALLATION PROCEDURE ------------------------------- 8

Electrical Connection ---------------------------------------8

Check for correct motor rotation -------------------------8

Compressed Air Connection------------------------------8

START-UP PROCEDURE -------------------------------------9

Set Temperature: -------------------------------------------- 9

DRYER OPERATION-TROUBLE SHOOTING --------- 10

DRYER OPERA TION-DETAILED DIAGNOSIS -------- 11

DRI-AIR ZONE V ALVE --------------------------------------- 12

PARTS LIST----------------------------------------------------- 13

OPERA TING MANUAL - HP4-X 400-750 FM DR YERS

Revision 10/8/02

Page 3

DRI-AIR INDUSTRIES, INC.

DRYER OPERATION/

FEATURES

The HP4-X 400/500/750 dryer series is a four bed dryer

design that is ideal for use on large molding press or extrusion

applications. This large capacity dryer combines our patented

desiccant tower design and state of the art microprocessor

controls to provide a constant supply of dry air to the material

hopper. Material drying is controlled by utilizing one zone for

removing moisture from the process air, while regenerating

the other by heating the desiccant to a high temperature.

Once the regenerated beds cool down, the Zone V alve

switches the airflow, and the newly regenerated beds are used

to desiccate the process air stream. The saturated beds are

now regenerated in the same manner, completing the

regeneration cycle. The cycle is depicted Page 7.

The airflow design of the HP4-X dryers makes the

regeneration cycle more efficient because we utilize a small

amount of the desiccated process air rather than ambient air

to regenerate the desiccant bed. This reduces the impact of

the high moisture content of the ambient air, which would

contaminate the desiccant bed, and allows the dryer to attain

a lower dew point. Please see the Air Flow Schematic on

Page 6.

HP4-X Design

Our patented HP4-X design incorporates 4 double-stacked

desiccant beds . This nearly doubles the amount of desiccant

available for drying the process air stream, and because of the

tower design, the dryer is able to regenerate the desiccant in

the same time as our ARID-X series. This allows the dryer to

operate in very high humidity conditions without affecting the

process air dew point. In fact, this design produces dew point

levels of – 40’ to -80’ C for faster more complete drying of your

material.

Unique to the HP4-X 400/500/750 disiccant bed design is the

use of two sets of desiccant towers per zone. The first tower

in each Zone Set is the regeneration cycle “control tower”,

while the second tower of the Zone Set is “slaved” off the first.

Please see the Air Flow Diagram on Page 7.

Hopper Design

These dryers are designed to be used with our large capacity

1000, 1500, and 2000 lb. hoppers. Dri-Air’s ”all stainless”

hopper design utilizes a stainless steel inner shell surrounded

by a stainless steel jacketed insulation layer. The easily

removable stainless steel spreader cone promotes proper

Page 4

OPERA TING MANUAL - HP4-X 400-750 FM DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

DRYER OPERATION/

FEATURES (Cont.)

material flow to ensure that the material is dried efficiently and

no undried material is left at the hopper bottom that needs to

be fed out prior to operating. Y ou must ensure that your

hopper is adequately sized for your usage rate and is kept

filled, to ensure that you have sufficient time to dry the

material.

Dryer Controls

The HP4-X series is supplied with the advanced

Microprocessor Control Module. The module includes a

mother board, display board and key pad that allow the

operator to easily monitor dryer performance and input

operational settings.

The Microprocessor Control Module is one of the most

sophisticated yet operator friendly controls on the market. It

has many more features than other PLC and Microprocessor

controls currently available. This module provides the

operator with more control and operational flexibility with the

dryer. These features and the operating instructions are

covered in detail in the Microprocessor Control Instruction

Manual included with your dryer.

OPERA TING MANUAL - HP4-X 400-750 FM DR YERS

Revision 10/8/02

Page 5

DRI-AIR INDUSTRIES, INC.

P

0

AIR FLOW SCHEMATIC FOR ARID-X 400/5

ZONE 2

ELECTRICAL BO

X

ZONE 1

PLAN VIEW

T/C

SECONDARY

HEATER

T/C

BLOWER

FILTER

ZONE VALVE ZONE VALVE

VENT

VENT

FROM

MATERIAL

HOPPER

T/C

SECONDARY

HEATER

T/C

REGENERATION

AND PROCESS

HEATER

Page 6

REGENERATION

AND PROCESS

HEATER

SAFETY

THERMAL

PROCESS HEATER

SAFETY

THERMAL

SAFETY THERMAL

TO MATERIAL HOP

OPERA TING MANUAL - HP4-X 400-750 FM DRYERS

Revision 10/8/02

Loading...

Loading...