DRI-AIR INDUSTRIES, INC.

APD 1-9 HPD 1-9

OPERATING MANUAL

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 1

DRI-AIR INDUSTRIES, INC.

Page 2

DRI-AIR INDUSTRIES, INC.

16 THOMPSON ROAD

P.O. BOX 1020

EAST WINDSOR, CT 060881020

Tel. (860) 627-5110

FAX (860) 623-4477

Internet http://www.dri-air.com

e-mail: sales@dri-air.com

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

CONTENTS

DRYER OPERA TION/FEATURES---------------------------4

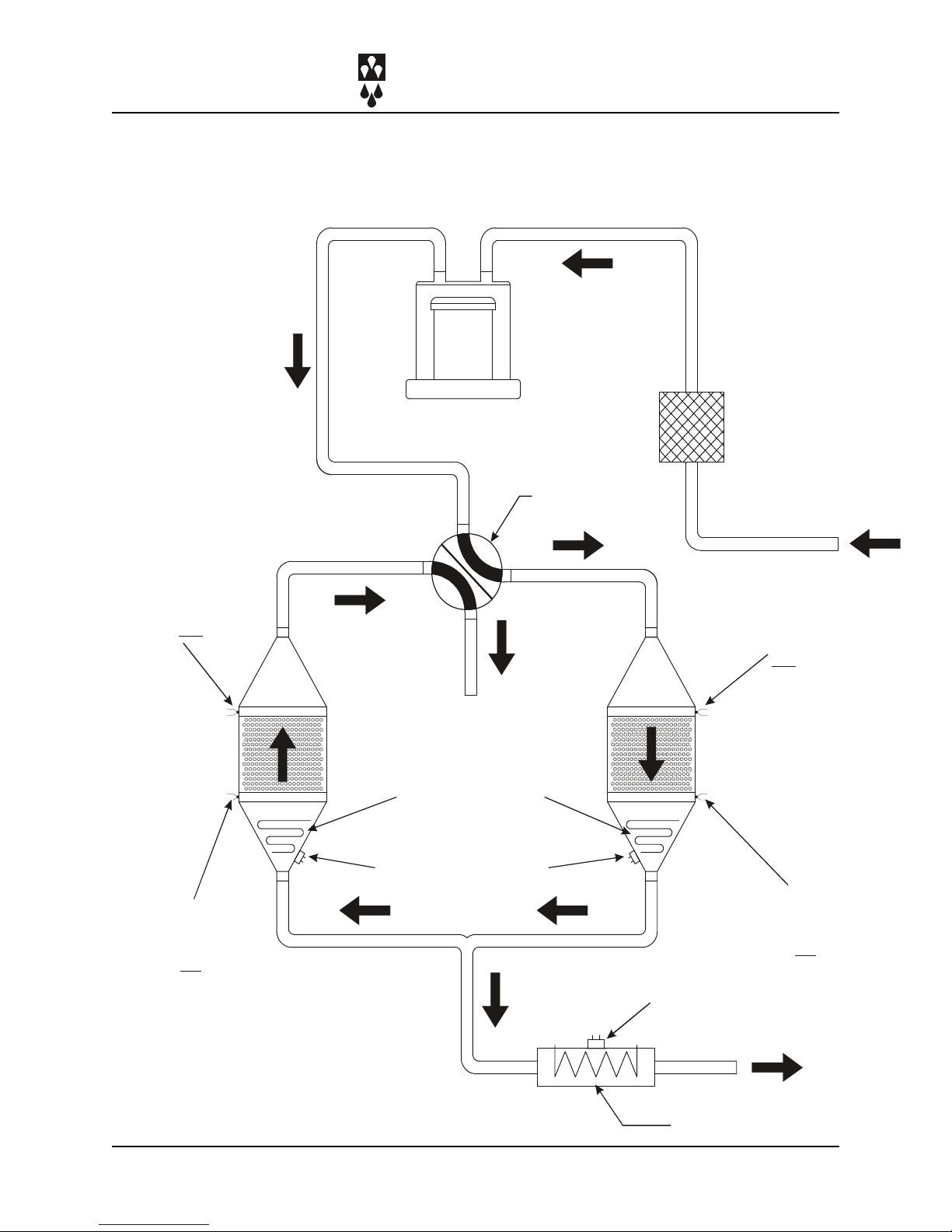

AIR FLOW SCHEMA TIC FOR APD 1-9 DRYERS-------6

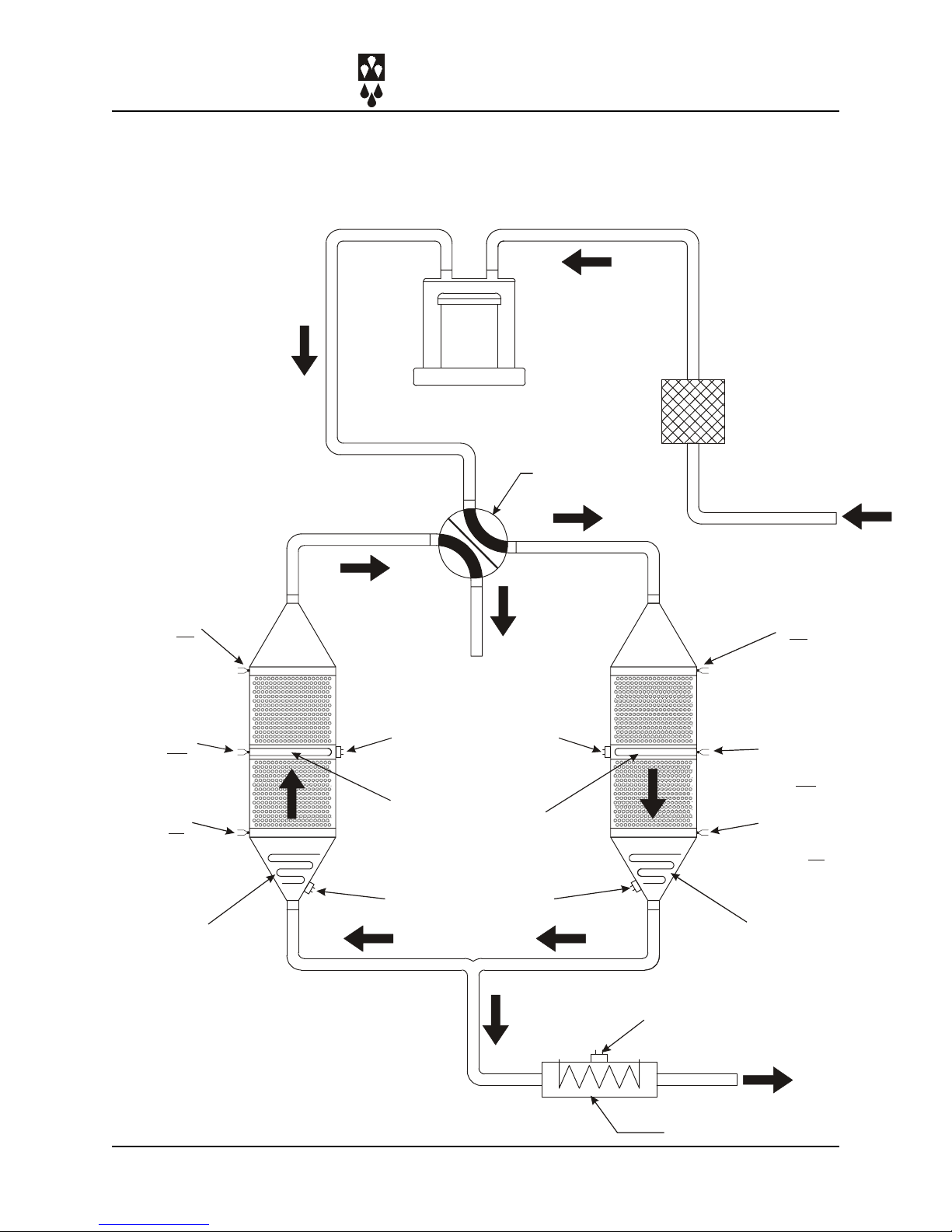

AIR FLOW SCHEMA TIC FOR HPD 1-9 DRYERS ------ 7

(HIGH PERFORMANCE MODEL SHOW)

DRYER CYCLE DIAGRAM------------------------------------8

PLC ST ANDARD ELECTRICS -------------------------------9

INST ALLATION PROCEDURE ----------------------------- 10

Electrical Connection ------------------------------------- 10

Check for correct motor rotation ----------------------- 10

Compressed Air Connection---------------------------- 10

START-UP PROCEDURE ----------------------------------- 1 1

Standard Electrics----------------------------------------- 11

To Set Temperature: -------------------------------------- 11

Microprocessor Control ---------------------------------- 12

CLOSED LOOP LOADING SYSTEM --------------------- 13

Receiver Installation -------------------------------------- 13

Vacuum Check --------------------------------------------- 14

Adjustment of Sensors ----------------------------------- 14

Material Flow Adjustment-------------------------------- 15

BASIC TROUBLE SHOOTING for

CLOSED LOOP LOADING SYSTEM --------------------- 16

Material will not feed. ------------------------------------- 16

CLL MAINTENANCE------------------------------------------ 16

Daily Maintenance:---------------------------------------- 16

Monthly Maintenance: ------------------------------------ 16

DRYER OPERATION-TROUBLE SHOOTING --------- 17

DRYER OPERA TION-DETAILED DIAGNOSIS -------- 18

DRI-AIR ROT AR Y ZONE VALVE--------------------------- 19

PARTS LISTS

ARID-X 18 - 35 APD 1-4 and HPD 1-4--------------- 20

ARID-X 50 - 100 APD 5-9 and HPD 5-9 ------------- 21

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 3

DRI-AIR INDUSTRIES, INC.

DRYER OPERATION/

FEATURES

The ARID-X dryer series is a dual bed design that provides a

constant supply of dry air to the material hopper. While one

bed is removing moisture from the process air the other is

regenerating by heating the desiccant to a high temperature.

Once the regenerated bed cools down, the Zone V alve

switches the airflow, and the newly regenerated bed is used to

desiccate the process air stream. The saturated bed is now

regenerated in the same manner, completing the regeneration

cycle. The cycle is depicted Page 8.

The airflow design of the ARID-X dryers makes the

regeneration cycle more efficient because we utilize a small

amount of the desiccated process air rather than ambient air

to regenerate the desiccant bed. This reduces the impact of

the high moisture content of the ambient air, which would

contaminate the desiccant bed, and allows the dryer to attain

a lower dew point. Please see the Air Flow Schematic on

Page 6.

HP4-X Design

Our patented HP4-X design incorporates 4 desiccant beds

where two are stacked, one over the other. This nearly

doubles the amount of desiccant available for drying the

process air stream, and because of the tower design, the

dryer is able to regenerate the desiccant in the same time as

our ARID-X series. This allows the dryer to operate in very

high humidity conditions without affecting the process air dew

point. In fact, this design produces dew point levels of – 40’ to

-80’ C for faster more complete drying of your material. Please

see the Air FLow Diagram on Page 7.

Page 4

Hopper Design

Dri-Air’s ”all stainless” hopper design utilizes a stainless steel

inner shell surrounded by a stainless steel jacketed insulation

layer. The easily removable stainless steel spreader cone

promotes proper material flow to ensure that the material is

dried efficiently and no dried material is left at the hopper

bottom that needs to be fed out prior to operating. You must

ensure that your hopper is adequately sized for your usage

rate and is kept filled, to ensure that you have sufficient time to

dry the material.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

DRYER OPERATION/

FEATURES (Cont.)

Closed Loop Loading System

Dri-Air’s closed loop loading system utilizes a dedicated

blower, small receiver, filtration system and desiccated air to

move the material from the dryer hopper to the molding

machine. This eliminates the possibility that your material will

be contaminated with moisture as with some other material

transfer systems, helping to eliminate defects resulting from

moisture contamination. Please refer to the Closed Loop

Loader System section of this manual for the proper

installation and maintenance.

Dryer Controls

The ARID-X series can be supplied with the standard PLC

Control Module or the advanced Microprocessor Control

Module, while the HP4-X series is only available with the

Microprocessor Control Module.

The PLC Control module includes a PLC control board,

display board, temperature controller and touch pad that is

programmed for the drying cycle described above. The

controller, display board and touch pad indicate the machine

status, alarms, set points and allow you to enter operational

settings for the dryer. These are explained in more detail later

in this manual.

The Microprocessor Control Module is one of the most

sophisticated yet operator friendly controls on the market. It

has many more features than the PLC control module that

provide the operator with more control and operational

flexibility with the dryer. These features and the operating

instructions are covered in detail in the Microprocessor

Control Instruction Manual included with your dryer.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 5

AIR FLOW SCHEMATIC

FOR APD 1-9 DRYERS

DRI-AIR INDUSTRIES, INC.

CONTROL

THERMO COUPLE

H1

VORTEX BLOW ER

4-W AY ZON E

VENT

REGENERATION

AND PRO CESS

HEATER

SAFETY THERMAL

VA LVE

XX

FILTER

CONTROL

THERMO COUPLE

H2

CONTROL

THERMO COUPLE

L1

Page 6

CONTROL

THERMO COUPLE

L2

SAFETY THERMAL

TO HOPPER

PROCESS H EATER

(APD 5-9)

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

AIR FLOW SCHEMATIC

FOR HPD 1-9 DRYERS

DRI-AIR INDUSTRIES, INC.

CONTROL

THERM OCOU PLE

H1

CONTROL

THERM O CO UPLE *

M1

CONTROL

THERM OCOU PLE

L1

VORTEX BLOW ER

VENT

SAFETY THERMAL

SECOND ARY

REGENERATION

HEATER

4-WAY ZO N E

VA LVE

XX

FILTER

CONTROL

THERM OCOU PLE

H2

CONTROL

THERM O CO UPLE *

M2

CONTROL

THERM OCOU PLE

L2

REGENERATION

AND PRO CESS

HEATER

* - CONTROL THERMOCOUPLE

FOR PLC CONTROL ONLY

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

SAFETY THERMAL

REGENERATION

AND PRO CESS

HEATER

SAFETY THERMAL

TO HOPPER

PROCESS HEATER

(HPD 5-9)

Page 7

DRYER CYCLE

DIAGRAM

DRI-AIR INDUSTRIES, INC.

Zo ne 1 C o o ling

Va lv e Shif t s

Zo ne 1 H e a ti ng

Va lve Shif t s

Dryer Cycle

Diagram

D esicant Bed s

XX

Zo ne 2 H e a ti ng

Zo ne 2 C o o ling

Page 8

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

PLC ST ANDARD

ELECTRICS

DISPLAY BO ARD - P/N 83401

The control package includes a PLC controller which is

programmed for the drying cycle previously discussed. The

display board indicates the machine status, heater operation

and alarms. See section on start up for details.

Below are descriptions of the inputs and outputs of the PLC

which are used for trouble shooting. A lit LED indicates the

input or output is actuated. All inputs are 12 volts AC and all

outputs are 1 10 volts AC and 15 v DC to the heater relays.

Refer to the electrical schematic for more detail.

ARID-X50-100

Z2 TOP HEATER

Z1 TOP HEATER

+-

+-

SS4

SS3

J11A

U2A

Jp7

R11

R12

R13

R14

OSC1

S2

PORT

11

Rn7

OSC3

U9

+

U5

U2

OSC1

D16

J12

DRI-AIR INDUSTRIES

EXPAND ER BD REV C

R36

J5

Z2 BOTTOM HEATER

PROCESS HEATER

+

SS5

-

J11

+

C15C13

S1

Z1 BO TTOM HEATER

+

+

SS1

SS2

-

-

D8D11

J118

D9D13

J2

D10D14

D12

OSC2

D15

C14

+

D20

++

C20

U7

C11

P/N 84100

MO THER BO ARD

Tb2

C14

8 UNUSED

8A UN USED

9 UNUSED

9A UNUSED

10 ALARM (OPTIONAL)

11 HIGH TEMP. ALARM (OPTIONAL)

AL1

AL2

110 VAC

13 MAIN CON TACTOR/TEMP CONTROL

14 ZON E VALVE

12 UNUSED

T1

FROM XFORMER

CR1

M2

50

14

J1

ANALOG

TC

JP2

1

2

3

C7

C21

C19

Rgain

C20

C13C14C15C16C17

C12

TC rev B

-+-+-+-+-+-+-

THERM OCOUPLE BOARD

C8

C18

OSC1

C5

C6

JP1

1

2

3

Ch5 Ch4 Ch3 Ch2PWR Ch1 Ch0

H2H1M2M1L2L1UNUSED

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

C19 J5

C18

D8

D9

D11

D10

D12

D13

D14

XX

J2

DegC

X10

JP3

1

2

C9

C4

U10

C11

C3

U1

C10

C2

C1

NON H.P.

50-300

#9TEMP.CONTSIGNAL

TC1

UNUSED

OL1

C101234567

UNUSED

SAFETY

7DAYTIMER

HI TEMP. ALARM SIGNAL

TC1

7DAYTIMER

UNUSED

L1

UNUSED

JUMP

GROUND

UNUSED

8

9

10

J2

U8

L2

U5

QT9

QT8QT7QT6QT5

U18

C0

C1

H.P ONLY 50-100 PROCESS TUBE

11

C2

Jp7

Rn3

Rn4

U9

U1

R1R2R3R4R5

012

R38

C1

Tb1

Rn7

R2

OSC2

C15

U6

C13

OSC1

U4

U3

C8

U11

OSC3

C2

C4C5C6

C7

Rn5

C3

D16

R37

C11

C16

Jp6

Jp5

R7

Jp2

567

C17

R8

C23

Jp3

C22

C12

U2

R6

Jp1

3

4

OUTPUTS

POW ER

D15

C9

+C18

Br1+

L1

Jp4

UNUSED

UNUSED

HI TEMP

INPUTS

REV E

MAIN

SAFETY

TEMP

50-300

Rn6

D0 D1 D2 D3 D4 D5 D6 D7

NON H.P.

PLC03

mal l

S

C2

Z1

L2

+

Page 9

DRI-AIR INDUSTRIES, INC.

INSTALLATION

PROCEDURE

For all Dri-Air models except ARID-X 10, AHM-1, & PDII

Electrical Connection:

Open electrical access door on the front of the machine by

turning the disconnect off and turning the lower clamping

screw 1/2 turn counterclockwise. Locate the disconnect by

following the operating handle down to the electrical panel.

Insert the incoming power cable or conduit through the hole

provided on the side of the machine.

« use approved wire and fastening means «

Wire incoming power to the top of the disconnect as shown in

the diagrams below.

NOTE:

When 3 wire supplies are used in place of 4 wire supplies,

a control transformer is required.

XX

3 PHASE DRYER INST ALLATION

CHECK FOR CORRECT MOTOR ROTATION

BEFORE RUNNING DRYER

To check motor rotation.......

Leave the electrical cabinet door open so the blower can be

observed. Turn on the power to the dryer and press the ON/

ST ART touch pad and then immediately press the OFF/STOP

touch pad. Observe the cooling fan on the top of the blower

motor and verify the fan is turning clockwise. If the motor is

not turning clockwise, switch any two adjacent supply wires.

Compressed Air Connection:

Compressed air is only required for dryers which have the

closed loop loader as part of the system. For those units:

CONNECT COMPRESSED AIR TO INLET ON FRAME

UNDER DRYER. The closed loop system includes a

regulator that is set to the proper pressure and an automatic

drain water separator. Maximum incoming pressure not to

exceed 145 psi (1.0 mpa).

The unit is now ready for operation.

Page 10

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

START-UP PROCEDURE

Standard Electrics

Operating this unit is very simple. Once the dryer is

connected to the facility power supply, the unit can be started

by turning the disconnect located on the electrical panel

enclosure to the ON position and pressing the ON button on

the Control Panel Key Pad. To shut the dryer off, simply push

the OFF button on the Control Panel Key Pad and turn the

disconnect to the OFF position.

Setting the process air temperature is done using the Digital

Controller.

For a more detailed explanation, see the following sections.

Control Panel - Operating Display

Turn power on at dryer using disconnect.

1. POWER light indicates power to the unit is on.

Press ON button on key pad

2. Illuminated BLOWER Light indicates Blower is on.

3. Flashing ZONE light indicates bed is in

Regeneration cycle.

4. Steady ZONE light means bed is in cooling cycle.

5. Illuminated HEATER light indicates heater is on.

Alarm Conditions:

6. Flashing HIGH TEMP . ALARM indicates an over or

under temp alarm. Unit shuts down.

7. Steady HIGH TEMP. ALARM light indicates thermocouple has failed. Further diagnostics are required.

8. Flashing ALARM light indicates a safety override

condition has occured. Dryer shuts down.

XX

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Digital Controller - Setting Process Air T emperature:

Press SET button - temperature set display will flash.

Press up arrow to increase temperature and down arrow to

decrease temperature.

Press SET again to enter the new temperature.

If the display flashes, the temperature is out of the control

range.

If the display shows 0000 the thermocouple is not connected

or is faulty .

Page 11

DRI-AIR INDUSTRIES, INC.

Microprocessor Control

1. Power light indicates there is power on.

2. After initializing, dri Air will be displayed.

3. Press

4. To set the temperature:

5. Left display indicates actual temperature

6. Right display shows dewpoint or set temp

7. To set high temp alarm: (degrees over setting)

8. Status block indicates heater on or fault

9. See manual for setting 7-day timer .

10. Configuration of the dryer parameters is done

START to start the dryer.

press SET - right display shows set temp

change setting using arrow keys

press ENTER to input new setting

press TEMP D.POINT button to change

press ALARM - right display shows setting

change setting using arrow keys

press ENTER to input new setting

using the setup button. see manual.

Page 12

For a more detailed explanation of the features and operation

of our Microprocessor Controller, please consult the

Microprocessor Operating manual enclosed with this unit.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

CLOSED LOOP

LOADING SYSTEM

DRI-AIR INDUSTRIES, INC.

The closed loop loading system uses a separate vortex blower

to provide the vacuum and “pressure assist” necessary to

move the dried resin from the hopper take-off box to the

receiver mounted on the feed throat of the molding machine.

At the start of the loading sequence, the lower proximity switch

on the receiver senses there is no material. The blower starts,

and the loader valve on the inlet line to the blower is opened.

Because the receiver is sealed to the feed throat, a vacuum is

created within the take off box, pulling material from the

hopper.

The outlet of the blower ( pressure side) blows air into the take

off box to help move the material to the receiver and close the

air loop. When the upper proximity switch on the receiver

senses material, the blower is stopped and the loader valve is

closed to prevent anymore material from being conveyed and

left in the hose to possibly be contaminated with moisture.

To operate the system, complete the installation steps detailed

below and turn on the system by actuating the toggle switch

labeled LOADER on the front of the electrical panel enclosure.

If the Dual Closed Loop Loading option has been installed,

please consult the

enclosed with your dryer.

Dual Closed Loop Loader Operating Manual

RECEIVER

INSTALLATION

Prior to installing the receiver, you must inspect the surface of

the molding press feed throat that the receiver is being installed

upon to ensure that it is clean and flush. Surface irregularities

must be removed, or a gasket installed, so that there will be no

vacuum leaks between the receiver and feed throat after

installation.

IMPORTANT

If the molding machine is equipped with a slide gate, swing

arm, starve feeder, additive feeder, or feed throat vent, you

must ensure these are sealed, as the system may not work

properly . If it is impractical, or impossible to seal of f the

aforementioned equipment, Dri Air Industries has a Flap V alve,

available for purchase, that will enable the loading system to

function properly .

To install the receiver, simply drill holes in the bottom flange of

the receiver to match the hole pattern on the molding press

feed throat and affix the receiver with bolts sufficient to

accommodate the operating stresses. A silicone gasket is

provided with the receiver to ensure a tight seal between the

receiver bottom and the feed throat. Connect the plug for the

upper proximity switch into the line labeled H and connect the

lower proximity switch plug into the line labeled L. Connect the

material feed hose and vacuum hose as shown in drawing

82222 in the appendix to this manual.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 13

VACUUM CHECK

DRI-AIR INDUSTRIES, INC.

Prior to production operation of the loading system, we strongly

recommend that you ensure the loading system is properly

sealed. To test the seal, follow the steps detailed below.

While the loader is running, close the hopper slide gate

and remove the material wand and attached hose from

the takeoff box. Check the vacuum level by placing

your hand over the wand. Return the wand to the takeoff box.

Remove the hose from the bottom port of the blowback

filter canister. Place your hand over the filter canister

port. Compare this vacuum level to the level observed

at the material wand. The two vacuum levels should be

the same.

Any difference between the vacuum levels is caused from

leaks in the loading system. Check for loose hoses, missing

gasket on the cyclone, or other possible sources of leaks

described below.

PROXIMITY SENSOR

ADJUSTMENT

Page 14

The most likely source is the seal between the feed throat and

receiver, or the configuration of the feed throat and material

feeder associated with the molding press. The presence of

vacuum leaks at these locations may exhibit the following

characteristics:

n Material in the receiver may be seen to bubble or

move when loading, as a leak at the feed throat causes

air to be drawn in at the bottom of the receiver rather

than from the take off box.

n Poor transfer of material from the take-off box to

the receiver.

n Large amounts of material or dust being pulled

into the blowback filter cannister.

If any of these occurrences are observed, the steps to improve

the vacuum seal detailed in the previous section on Receiver

Installation will be required.

The proximity sensors supplied with the receiver may require

adjustment to operate properly . When positioning the sensors,

ensure that they are placed as close as possible to the outer

surface of the receiver as they operate by sensing the density

of the material in the receiver. Vertically position the lower

sensor to set the material level at which the load cycle will

initiate and the upper sensor to set the material level at which

the load cycle will stop. CAUTION: Do not overfill the

reciever as material may be drawn back into the blowback

filter canister.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

To adjust the sensor’s sensitivity, turn the adjustment screw on

the back of the sensor. The adjustment screw turns a 20 turn

potentiometer with a clutch to prevent over adjustment. If you

are unsure as to the current setting of the sensor, turn the

screw 20 turns counterclockwise. The LED should light with

no material in front of the sensor. Turn the screw 4-6 turns

clockwise and proceed as directed below .

With no material in front of the sensor , the LED on the back of

the sensor should be lit. If not, turn the adjustment screw

located on the end of the sensor counterclockwise until the

LED turns on.

With material in front of the sensor, the LED on the back of the

sensor should be off. If not, turn the adjustment screw

clockwise, until it turns off.

MATERIAL FLOW

ADJUSTMENT

Material flow to the receiver should be continuous and smooth.

Irregularities in flow rate and volume can be affected by the

position of the material wand inserted into the take-off box or

the density of the resin. To adjust the flow, take the steps

detailed below.

Upon initial operation of the loading system, push the wand in

until it stops. Then pull it out 1 to 2 inches and tighten the set

screw on the take-off box material outlet. Operate the loading

system and observe how the material flows into the receiver. If

the flow rate is not as desired, the wand can be adjusted out to

reduce the flow of material conveyed, or in, to increase the

amount. Typically, loading times are 5-6 seconds for a 2”

receiver and 15-20 seconds for the 4” receiver.

If the material flow is irregular, with “slugs” of resin being

delivered to the receiver, the wand is most likely pushed too far

into the take-off box. This “chokes” off the air flow required to

convey the material, causing the irregular flow. To remedy this

condition, pull the wand out slightly and the material will flow

more evenly and quickly .

If little or no material is conveyed and there are no blockages in

the take-off box or material hose the wand may be pulled too

far out of the take-off box. Push the wand in until you get the

desired flow rate.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 15

DRI-AIR INDUSTRIES, INC.

Material will not feed.

BASIC TROUBLE

SHOOTING for

CLOSED LOOP

LOADING SYSTEM

1. Ensure the proximity sensors are adjusted and working

properly . Both sensors LED’s should be lit when the

receiver is empty . Check that the sensors are tightened

on the bracket and the cable connectors are tight and

correct.

2. Check system for leaks. Tighten hose clamps. Check

seal at receiver/feed throat interface by comparing

vacuum levels as directed in previous section on

Receiver Installation.

3. Ensure the blower operates. Check the electrical

system to see if the relay is working and that the blower

overload is not tripped. Trip window will be orange/yellow

if tripped. Check to see that the blower rotation is

correct (clockwise).

4. Ensure that the compressed air is connected to the

system and the pressure regulator is set to 60 psi. Does

the air valve open when the system calls for material?

The air line to the valve can be easily disconnected by

pushing in on the plastic sleeve and removing the hose.

The air line should be pressurized when the system is

loading.

CLOSED LOOP LOADER

MAINTENANCE

5. Ensure the drain valve at the bottom of the filter is

closed properly .

Daily Maintenance:

Clean filter when loader is not working.

The filter is cleaned automatically with an air blast at the start

of each loading cycle. The canister needs to be drained

periodically by opening the valve at the bottom of the canister.

Gently bang on the side of the cannister with your hand to

loosen any fines and

Monthly Maintenance:

Clean filter sock by removing the quick clamp on the filter and

removing the top cover. Remove the bag assembly and blow

off with an air gun. Install bag assembly, top cover and quick

clamp checking that the seal is proper. This maintenance may

need to be performed more frequently if your material is dusty ,

or less frequent if your material is clean. We strongly

recommend it be performed every 6 months regardless of

material conditions

Tighten all hoses and hose clamps and check for leaks.

close the valve.

Page 16

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRYER OPERATION

TROUBLE SHOOTING

DRI-AIR INDUSTRIES, INC.

The new Dri-Air Standard PLC and MICROPROCESSOR

Electrics were designed for quick diagnosis of problems.

The following steps should be done before proceeding with

other diagnostic steps.

1. Check the Power Circuit:

a. Incoming fuses or circuit breaker

b. All dryer fuses:

Each fuse, with the exception of the main fuses, has

a blown fuse indicator light that illuminates when the

fuse is blown.

c. Is power supplied to the unit?

d. Check heater continuity using a volt ohmmeter.

2. Compressed Air:

For those models that require compressed air.

a. Is compressed air connected with at least 60 PSI

b. Check water separator and drain if necessary

c. Pressure gage should read 60 PSI

3. Air Flow Circuit:

a. Ensure Zone V alve position corresponds to the

regeneration cycle by comparing the Zone position lights

on the Zone V alve to the ZONE position lights on the

dryer panel.

b. Make sure that all hoses are connected, not crushed,

and free from obstructions.

c. Inspect filter and make sure cover is tight and the filter is

clean.

4. Control Circuit:

a. Using the PLC/MICRO Display Panel ZONE indicator

lights as a guide for the dryer regeneration cycle, check

that all inputs/outputs are proper for the part of the

regeneration cycle that the machine is in.

b. Monitor the PLC output lights to ensure the

corresponding LED on the power board is illuminated

and there is an output voltage to the heater.

5. Operating Conditions:

a. Check the process temperature. It should not be set

below 140° F (60° C) because the unit will go into high

temp alarm.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 17

DRYER OPERATION

DETAILED DIAGNOSIS

(PLC Controlled Dryer)

For MicroControlled dryers please see the

Microprocessor Control Instruction Manual

DRI-AIR INDUSTRIES, INC.

Machine will not start: Power light is not on.

1. Check circuit breakers (CB1) or incoming fuses inside

control box to see if they are tripped or blown. Reset

circuit breakers by turning them off and then on.

2. Check small fuses (FU1 & FU2) next to contactor. The

LED will be lit if they are blown. Replace if necessary by

opening the fuse holder and put new fuse into holder.

3. Check that incoming power to the unit is proper.

4. Check safety snap discs.

Alarm light is flashing: Unit will not run.

Main contactor is not pulling in.

1. Check the motor overload OL1 located in the panel. If it

is tripped, the window will show as orange/yellow. Reset

overload by pushing in the reset button.

Machine will not run: High T emp Alarm Light flashing.

This indicates that the temperature has exceeded the high

limit programmed into the temperature control or the set

temperature can not be reached.

Press stop and restart machine holding in the start button.

Monitor the actual temperature to see if it exceeds the set

point or can not reach the set point. If it can not reach set

point, see section below.

Machine will not run: High T emperature Alarm Light on, not

flashing:

1. This indicates an “open” thermocouple or the

temperature in the desiccant tower exceeded 900° F.

Machine will not reach temperature:

1. If the process heater light is not lit.

A.Check output from temperature controller and input to

PLC.

B.Check the thermocouple. The tip should be in the

middle of the hose.

2. If the process heater light is lit.

A.Check fuses on power board

B.Check solid state relays on power board.

C.Check that the air flow is not obstructed.

D.Check blower rotation

E.Check heater for continuity.

Page 18

Check the limit first by pressing the SET button on the

temperature control and holding until AL is displayed. The

setting shown indicated the amount over set point that the

alarm will be actuated. It is factory set to 50°F (30°C) and

should not be set below 30°F (16°C) or it will actuate too soon.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

If the temp exceeds the set point check the following:

1. Remove the hose from the top of the hopper to check air

flow. There should be air flow out of the hopper with a

suction on the hose. If there is little or no flow, check the

inlet hose.

2. Inspect the filter to make sure that it is clean and not

affecting the air flow .

3. Check the power boards to see if one of the solid state

relays has failed on. Using an ammeter or voltmeter on

the output to the heater, see if there is power when the

LED is not lit which will indicate a failed relay .

4. Check the valve position.

DRI-AIR

ROTARY ZONE VALVE

The Dri-Air rotary valve is designed to provide very little flow

restriction and no leakage. It incorporates high temperature,

self adjusting seals for years of trouble free service. The

electrical controls are built into the end of the valve and

include position lights.

Trouble shooting is easy. If the lights indicating position do not

match the zone displayed on the control panel, or there are no

lights, the valve is not working properly. See if the cam is

actuating a switch.

DO NOT PUT FINGERS INTO VALVE WITH POWER ON

Check all electrical connections to make sure they are tight.

Contact factory with the serial number of the dryer for a

replacement valve.

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 19

DRI-AIR INDUSTRIES, INC.

APD 1-4 and , HPD-1-4

PARTS LISTS

GENERAL

CLOSED LOOP LOADER

ELECTRICAL

NOTE:

TO ORDER BLOWERS OR

OVERLOAD REFER TO

P AR T NUMBER ON ITEM.

*:

IEC CONTACTOR USED IN ALL

FM, PD & HM DRYERS AND CLL

POWER PACKS WITH SERIAL

NUMBERS GREA TER THAN

D14650

DESCRIPTION APD HPD

Dryer Filter Element 81055 81055

Zone V alve 83705 83705

Thermocouple (Process) 82174 82174

Desiccant 80082 (Lbs/Machine) 8 lbs. 14 lbs.

Tower Clamp 81017 81017

Tower Gasket 81028 81028

Regeneration V alve NR NR

Pressure Switch NR NR

Regulator NR NR

MAC V alve NR NR

Caster (Swivel) 81799 81799

Caster (Fixed) 81798 81798

Filter Element 82389 82389

Blowback V alve 82695 82695

Proximity Switch (K10203 Std. El.) 81 18 0 8118 0

Proximity Switch (K15208 Micro) 82298 82298

Regulator 82995 82995

Air V alve (SMC) 84220 84220

Load V alve 84229 84229

STD MICRO

Disconnect 82308 82308

Temperature Control (RKC CB-100) 84016 NR

Main Board 84100 82071

Display Board 83401 82072

Thermocouple Board 84049 NR

Transformer 83437 84131

Current Transformer NR 82246

Main Contactor 82270 82270

Solid State Relay 82302 82302

IEC Contactor 80576 80576

IEC Contactor * 84860 84860

Power Board 83493 83493

Power Board (208 & 230 v Dryers) 84080 84080

Single Pole Relay 82496 82496

Double Pole Relay 80587 80587

Dual Solid State Board NR 82870

Toggle Switch 80466 80466

Safety Thermal Switch (Tower) 80221 80221

Thermocouple (Tower) 82174 82174

TRI-Solid State Board NR 83468

Dewpoint Sensor 81908 81908

Solid State Timer (Blowback) 83318 83318

Solid State Timer (Cleanout) 83527 83527

Solid State Timer (Auger Delay) 83442 83442

HEATERS

Page 20

208V 230V 400V 480V 575V

Regeneration (Cone Style) 83342 83373 83982 83374 84235

HP Center (Flat Style) 82373 82373 83958 82505 84260

Process NR NR NR NR NR

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

APD 5-9 and , HPD-5-9

DESCRIPTION APD HPD

GENERAL

CLOSED LOOP LOADER

ELECTRICAL

NOTE:

TO ORDER BLOWERS OR

OVERLOAD REFER TO

P AR T NUMBER ON ITEM.

*:

IEC CONT ACT OR USED IN ALL

FM, PD & HM DRYERS AND CLL

POWER P ACKS WITH SERIAL

NUMBERS GREA TER THAN

D14650

Dryer Filter Element 81331 81331

Zone V alve 83705 83705

Thermocouple (Process) 82174 82174

Desiccant 80082 (Lbs/Machine) 30 lbs. 50 lbs.

Tower Clamp 81172 81172

Tower Gasket 82795 82795

Regeneration V alve NR NR

Pressure Switch NR NR

Regulator NR NR

MAC V alve NR NR

Caster (Swivel) 81799 81799

Caster (Fixed) 81798 81798

Filter Element 82389 82389

Blowback Valve 82695 82695

Proximity Switch (K10203 Std. El.) 81 180 81 180

Proximity Switch (K15208 Micro) 82298 82298

Regulator 82995 82995

Air V alve (SMC) 84220 84220

STD MICRO

Disconnect 82308 82308

Temperature Control (RKC CB-100) 84016 NR

Main Board 84100 82071

Display Board 83401 82072

Thermocouple Board 84049 NR

Transformer 83437 84131

Current Transformer NR 82246

Main Contactor 82270 82270

Solid State Relay 82302 82302

IEC Contactor 80576 80576

IEC Contactor * 84860 84860

Power Board 83493 83493

Power Board (208 & 230 v Dryers) 84080 84080

Single Pole Relay 82496 82496

Double Pole Relay 80587 80587

Dual Solid State Board NR 82870

T oggle Switch 80466 80466

Safety Thermal Switch (Tower) 80221 80221

Safety Thermal Switch (Process) 80551 80551

Thermocouple (Tower) 82175 82175

Transformer .050 82245 82245

TRI-Solid State Board NR 83468

Dewpoint Sensor 81908 81908

Solid State Timer (Blowback) 83318 83318

Solid State Timer (Cleanout) 83527 83527

Solid State Timer (Auger Delay) 83442 83442

HEATERS

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

230V 400V 480V 575V

Regeneration (Cone Style) 81351 81766 81366 81432

HP Center (Flat Style) 82364 83934 82493 83372

Process 82343 84204 82319 84065

Page 21

DRI-AIR INDUSTRIES, INC.

NOTES:

Page 22

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

DRI-AIR INDUSTRIES, INC.

NOTES:

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Page 23

DRI-AIR INDUSTRIES, INC.

NOTES:

Page 24

OPERA TING MANUAL - APD 1-9, HPD 1-9 POR TABLE DRYERS

Revision 10/8/02

Loading...

Loading...