drexel und weiss aerosmart Series, aerosmart S, aerosmart M, aerosmart L Operating, Maintenance And Commissioning

aerosmart S / M / L

Operating, Maintenance and Commissioning

Contents

Technical Data __________________________________________________________2

Customer Information ____________________________________________________3

Product Description ........................................................................................................... 3

Proper Application..............................................................................................................3

Unsuitable Applications...................................................................................................... 3

Safety Instructions ............................................................................................................. 3

Operation _____________________________________________________________4

Micro-Processor Controller ................................................................................................ 4

Main Display ...................................................................................................................... 5

Operating Modes ............................................................................................................... 5

Switching On......................................................................................................................5

Switching Off ......................................................................................................................5

Analogue Room Operating Panel with Heating Mode ....................................................... 6

Digital Room Operating Panel ........................................................................................... 8

Maintenance___________________________________________________________10

Safety Instructions for Filter Changes.............................................................................. 10

Changing Coarse Particle Filters ..................................................................................... 10

Changing the Fine Particle Air Filter ................................................................................ 12

Commissioning ________________________________________________________13

Pre-Requisites for Commissioning .................................................................................. 13

Initial Commissioning ....................................................................................................... 13

Decommissioning ............................................................................................................ 13

Menu levels ___________________________________________________________14

Status Level - Viewing Operating Parameters ................................................................. 14

Technician Level - Setting Operating Parameters ...........................................................16

Manufacturer Level - Factory Settings ............................................................................. 21

Overview – Current Operating Status .............................................................................. 21

Faults ________________________________________________________________22

Error Messages .............................................................................................................. 22

Faults in the Ventilation System.......................................................................................23

Important Unit Information (Logbook) _____________________________________24

Page 1

Technical Data

General Data

Mains supply ...................................................................................... 230 VAC / 50 Hz

Recommended pre-fuse for the mains cable 1 ......................................................16 A

Recommended pre-fuse for the mains cable 2 ......................................................13 A

Heat recovery level

according to VDI 2071 with nominal volumetric fl ow .............................................85 %

Average heat provision level of the ventilation module

Maximum power consumption of the fans (total) .............................................. 100 W

Maximum power consumption of the immersion heater

Operating fl uids:

Refrigerating agent .................................................................................R134a / 2.3 kg

Refrigerating machine oil ........................................................................Triton SEZ 32

aerosmart S

Weight ................................................................................................... approx. 232 kg

Nominal air quantity ........................................................................................120 m

Minimum air quantity .......................................................................................105 m

Maximum air quantity at 100 Pa external ........................................................180 m

Sound power level at nominal air quantity and 100 Pa external:

Housing ..........................................................................................................45 dB(A)

Air inlet ............................................................................................................37 dB(A)

Air vent ............................................................................................................48 dB(A)

.........................................85–93 %

........................................2000 W

3

/h

3

/h

3

/h

aerosmart M

Weight ................................................................................................... approx. 255 kg

Nominal air quantity ........................................................................................160 m

Minimum air quantity .......................................................................................140 m

Maximum air quantity at 100 Pa external ........................................................230 m

3

3

3

Sound power level at nominal air quantity and 100 Pa external:

Housing ..........................................................................................................45 dB(A)

Air inlet ............................................................................................................48 dB(A)

Air vent ............................................................................................................48 dB(A)

aerosmart L

Weight ................................................................................................... approx. 255 kg

Nominal air quantity ........................................................................................205 m

Minimum air quantity .......................................................................................180 m

Maximum air quantity at 100 Pa external ........................................................230 m

Sound power level at nominal air quantity and 100 Pa external:

Housing ..........................................................................................................45 dB(A)

Air inlet ............................................................................................................48 dB(A)

Air vent ............................................................................................................48 dB(A)

3

3

3

/h

/h

/h

/h

/h

/h

Page 2

Customer Information

These operating instructions are part of the unit and must remain with it. This manual contains important notes and tips on operating your compact unit, which protect you from personal injury and

also guarantee a long service life of the unit. The fi gures all depict the right-hand version of the

device (supply air connection located on the right). All instructions are equally applicable to the

left-hand version (supply air connection located on the left). Please keep the operating instructions for future reference. Please pay attention to the safety instructions!

Product Description

The devices in the aerosmart series are compact units which consist of a ventilation

module with heat recovery, a domestic water storage tank and a heat pump. The unit is

used to heat the supply air and the domestic water. The aerosmart S, aerosmart M und

aerosmart L units are operated via a micro-processor controller. Although the unit types

differ in terms of their appearance, weight and managed air quantities, these differences

do not affect their operation.

Proper Application

The unit is designed for the ventilation, heating and warm water generation of living rooms

and lounges in passive houses and, if applicable, for near-passive buildings depending

on the calculation and building design.

Unsuitable Applications

No applications other than those specifi ed under proper application are permissible.

The unit must not be used to dehumidify buildings under construction. Drying and heating

a building structure can cause considerable damage to the unit. The ventilation of rooms

with extremely high humidity levels, such as saunas, or heavily contaminated extract air

is also not permitted.

Safety Instructions

WARNING: Indicates that the non-adherence to the recommended safety

procedures could lead to damage to the unit or personal injury.

CAUTION: Indicates that the non-adherence to the recommended safety procedures could lead to damage to the unit.

NOTE: Helpful information and useful tips.

aerosmart - Operation, Maintenance and Commissioning

Page 3

Operation

The unit is controlled, managed and operated via a micro-processor controller on the unit and a

room operating panel. Two types of room operating panels are available:

•

Analogue room operating panel with heating mode

Digital room operating panel•

If the analogue room operating panel is used, the basic settings must be made on the compact

unit (micro-processor controller) during commissioning.

If the digital room operating panel is used; the settings can all be made on either the room operating panel or the micro-processor controller.

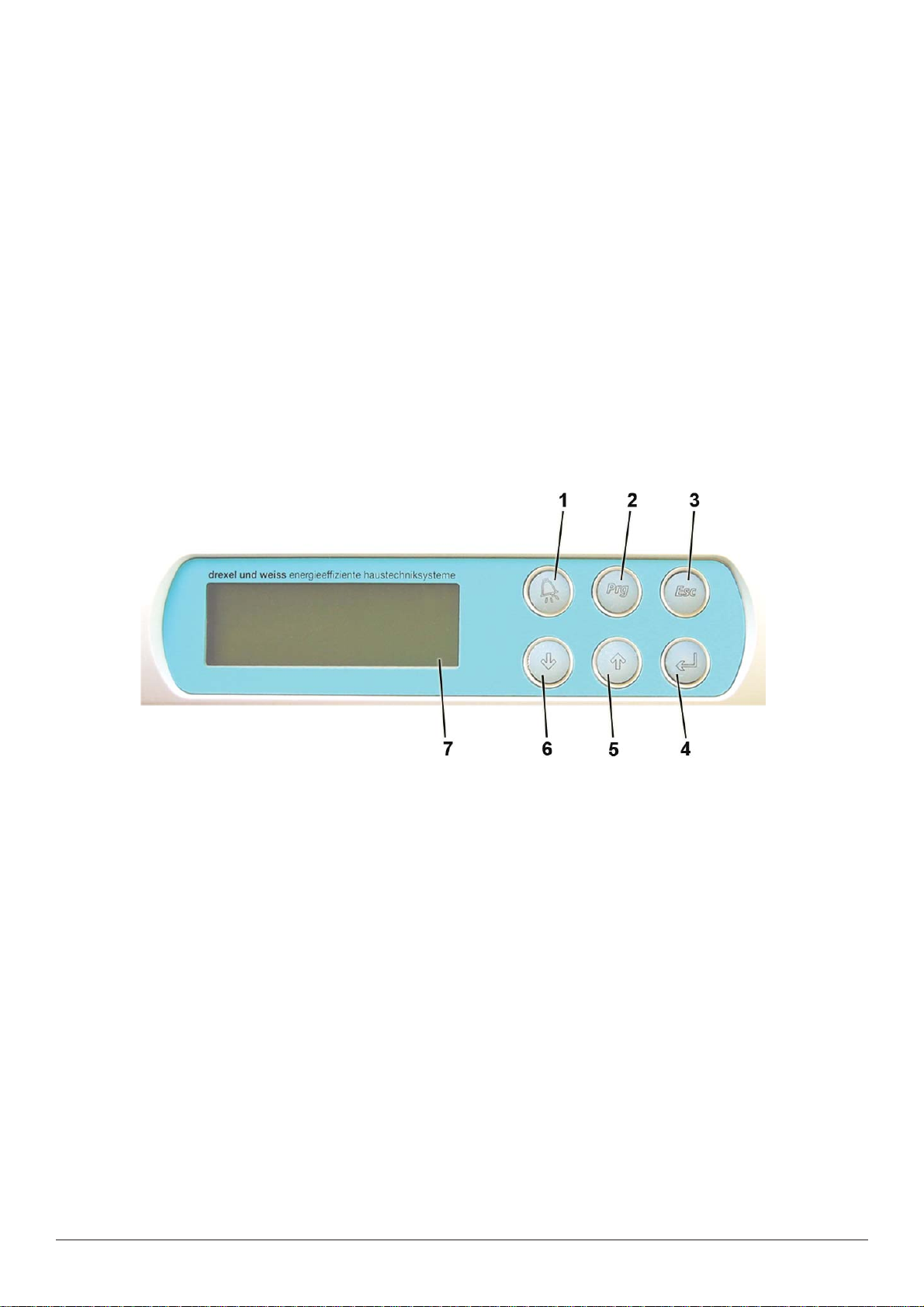

Micro-Processor Controller

The micro-processor controller is located on the ventilation module. It manages the ventilation, room heating and the heating of the domestic hot water.

'Alarm' button: this button illuminates red if the controller transmits an error message. 1.

Press the button to acknowledge the fault.

'Prg' button: is only required to program the software.2.

'Esc' button: use this button to exit a program item or a menu.3.

'4.

↵' (Enter) button: use this button to confi rm selected values, settings or menu items.

'5.

↑' arrow key: for scrolling in the menu. Use this button to select individual menu

items and amend the values.

↓' arrow key: for scrolling in the menu. Use this button to select individual menu

'6.

items and amend their values.

Display: the four-line display shows settings and various measurements.7.

Page 4

aerosmart - Operation, Maintenance and Commissioning

Main Display

The main display shows the time and date, the current operating mode and the current

values for the room, set-point and actual temperature.

12:11 DI. 09/12/03

Akt. Sollwert: 21.5°C

Akt. Raumtemp.: 20.3°C

If you are viewing a different menu page, simply press the 'Esc' button one or more times

to return to this main display.

Operating Modes

AUTOMATIK: all functions are fully automated in this operating mode. Fan levels acc. to programming; water and room heating acc. to the established set-point temperature.

STAND-BY SOMMER: ventilation and heating are deactivated in this operating mode. The

heat pump and the two fans are only activated if the domestic water is heated. An external

switch can be used to switch on the ventilation (or both fans) for an hour, for example, the

light switch in a windowless toilet.

ANLAGE AUSGESCHALTEN: all functions are deactivated.

Press the 'Esc' button until the main display appears.

b

Use the down '↓' or up '↑' arrows to select the desired operating mode.

b

Press '↵' (Enter) to confi rm your selection.

AUTOMATIK

Switching On

Select the operating mode AUTOMATIK.

b

Press '↵' (Enter) to confi rm your selection.

For further information, see Operating Modes.

Switching Off

Select the operating mode ANLAGE AUSGESCHALTEN.

b

Press '↵' (Enter) to confi rm your selection.

For further information, see Operating Modes.

aerosmart - Operation, Maintenance and Commissioning

Page 5

Analogue Room Operating Panel with Heating Mode

Use this room operating panel to set the room temperature and activate the special 'Party'

mode. The LED indicator lights show if the heating is activated and if a fi lter change or

fault is pending.

Setting the Room Temperature

The dial can be used to adjust the set-point temperature by +/- 3°C. On delivery of the

system, the middle setting is 21.5°C.

This means that the temperature can be adjusted from 18.5°C (dial fully to the left) to

24.5°C (dial fully to the right).

Note: Do not turn the dial too far! The left stop point is at approx. 8 o'clock, the right-

hand stop point is at approx. 4 o'clock.

What room temperature is right for me?

The setting basically depends on your needs. Temperature sensitivity in humans is subjective and differs from one person to the next. Standard settings are between 20 and

23°C.

Environmental infl uences

As the room operating panel has a temperature gauge to measure the room temperature,

no heat-emitting devices should be placed beneath it or in its immediate vicinity (e.g. televisions or computers).

Such heat-emitting devices would substantially infl uence the temperature measure-

ments.

Page 6

aerosmart - Operation, Maintenance and Commissioning

A handy hint for greater system effi ciency

If possible, fi nd your desired temperature at the start of the heating period.

The system works most effi ciently if the set-point temperature is set once and then left

unchanged. Regularly changing this setting uses the top up heater in the room more than

necessary.

Special 'Party' Mode

Pressing the 'Party' button sets the ventilation to fan level 3 for a predetermined period.

Once this period has passed, the fan level automatically returns to the currently set level.

On delivery of the system, the default period is 60 minutes, but this can be adjusted on

the micro-processor controller. The special 'Party' mode cannot be reset by pressing the

button again.

Heating (LED)

This indicator light illuminates if the heating mode is enabled.

Filter/Fault (LED)

LED continually illuminated: coarse particle fi lter needs replacing.

Please refer to the 'Maintenance' section.

LED fl ashes: a fault has occurred. The fault type can be viewed on the micro-processor

controller's display screen.

Please refer to the 'Error messages' section.

aerosmart - Operation, Maintenance and Commissioning

Page 7

Digital Room Operating Panel

The digital room operating panel on the ventilation device operates at the same time as

the micro-processor controller. The menu navigation, buttons and scope of operation are

identical.

Setting the Room Temperature

Press the 'ESC' button until the main display appears.

12:11 DI. 09/12/03

AUTOMATIK

Akt. Sollwert: 21.5°C

Akt. Raumtemp.: 20.3°C

b

Press the 'Enter' button. The cursor jumps to the 'Akt. Sollwert'.

b

Use the '↓' and '↑' arrows to set your desired room temperature.

b

Press '↵' (Enter) to save your settings.

What room temperature is right for me?

The setting basically depends on your needs. Temperature sensitivity in humans is subjective and differs from one person to the next. Standard settings are between 20 and

23°C.

Page 8

A handy hint for greater system effi ciency

If possible, fi nd your desired temperature at the start of the heating period.

The system works most effi ciently if the set-point temperature is set once and then left

unchanged. Regular changing of this setting results in the top-up heater in the room being

used more than necessary.

aerosmart - Operation, Maintenance and Commissioning

Special 'Party' Mode

The ventilation is set to fan level 3 for a specifi c period. Once this period has passed, the

fan level automatically returns to the currently set level. On delivery of the system, the

default period is 60 minutes, but this can be adjusted in the technician level.

Press 'Esc' to go from the main display to the main menu.

Technikerebene

Herstellerebene

b

Press 'Enter' to select the 'Statusebene' submenu.

Party-Funktion

Ein mit ENTER:

b

Activate the party function by pressing 'Enter' twice.

b

Press 'Esc' several times to return to the main display.

Statusebene

Übersicht

<STATUSEBENE>

AKTIV

aerosmart - Operation, Maintenance and Commissioning

Page 9

Maintenance

System maintenance by users is mainly limited to regularly changing the coarse particle fi lters

in the ventilation module and the fi ne particle air fi lter in the outside air unit. The operating unit

provides regular fi lter change notifi cations as the system operating hours are counted in the

background. A reminder to change the coarse particle fi lters is displayed approx. every 60-180

days, according to the managed nominal air quantity (depending on the environment and the fi lter

class). The fi ne particle air fi lter only has to be changed approx. once or twice a year. As the fl ow

capacity and acoustic level generated by the compact unit are affected by the amount of dirt in the

fi lters, we recommend that fi lters are changed regularly. No tools are required.

Caution: Possible damage to the unit resulting from dust and contamination. The coarse

particle fi lters in the unit not only improve your air quality, but also protect the entire ven-

tilation system. The system must not be operated without a coarse particle fi lter.

Note: The fi lter should be changed within 2-4 weeks of the 'Filter change' message

appearing..

Safety Instructions for Filter Changes

Caution: The fi lter change intervals are only valid for a completely run-in system. After

the initial commissioning, the fi lters can sometimes become very dirty after a relatively

short time (construction dust). In this case, no error message is displayed.

Caution: Filters cannot be washed or vacuum cleaned as this would drastically affect

their functionality . Contaminated fi lters must always be replaced with clean fi lters. Filters

should be disposed of in the residual waste.

Caution: For uninterrupted operation of the ventilation unit, we recommend that the

system is serviced by an authorised service partner after two operating years. Local

laws and regulations governing maintenance intervals and procedures must be adhered to.

Changing Coarse Particle Filters

Do not switch off the device or unplug it from the mains as the controller will not detect the change

of fi lter .

Page 10

Open the ventilation module's inspection cover.

The cover is held in place by latches and can be removed at the recessed grip. With a slight

tug, without any tools, the cover latches can be released.

b

Remove both fi lter cartridges.

(See fi gure; no. 1+2).

b

aerosmart - Operation, Maintenance and Commissioning

Remove the dirty fi lter pads.

b

Insert new fi lter pads and push the cartridges back into the openings.

Take care with the insertion direction! Ensure that airtightness is guaranteed.

b

Reattach the inspection cover.

Ensure that the cover is properly locked in place.

(Contact switch on the control unit must be activated).

b

Unit starts automatically.

b

After changing the fi lter, press the 'Alarm' button to acknowledge the 'Filter or Filter change'

message on the micro-processor controller.

b

Press '↵' (Enter) to confi rm.

b

Note the fi lter change date in the logbook at the back of this manual.

Fig.: aerosmart S without

inspection cover

Spare fi lter:

Please order the coarse particle fi lters from your authorised technician.

Part description Number

Spare fi lter for aerosmart M/L ..........................................(10 per packet) 193.0200

Spare fi lter for aerosmart S .............................................(10 per packet) 193.0892

aerosmart - Operation, Maintenance and Commissioning

Fig.: aerosmart M

without inspection

cover

Page 11

Changing the Fine Particle Air Filter

y,p y

type. Fo

consid

The fi ne particle air fi lter is located in the outside air unit and not in the compact unit. De-

pending on the composition of the ventilation system, numerous fi lter types can be used. If

the error message 'Change fi ne particle air fi lter' is displayed, replace the dirty fi ne particle

air fi lter (within 2 - 4 weeks) with a new fi lter of the same type. For some

fi lter types, the ventilation direction must be taken into consideration

(marked by an arrow). The fi lter change must be ac- knowledged

on the controller.

Acknowledge Fine Particle Air Filter

Change to the Technician Level on the main menu of the control.

(The English text in the following tables is for representation only and will not be displayed

on the control.)

b

Fig.:

Examples of

external fi lters

<TECHNIKEREBENE>

Bitte beachten Sie

bei Aenderung die

Herstellerangaben!

Press the '↑' (up) arrow button once.

Technician Level

Please consider the

manufacturers details

when making changes!

b

The operating hours counter for the fi ne particle air fi lter appears.

Press the 'Enter' button.

<BETRIEBSSTUNDEN>

FEINSTAUBFILTER

Summe: ######

Reset: N

The cursor jumps to the 'Reset' indicator..

Operating Hours

fi ne particle air fi lter

sum

Reset: No

b

Press an arrow button.

The

'Reset': N indicator changes to Y and the 'Summe' indicator is set to zero.

b

Press '↵' (Enter) to confi rm.

b

Note the fi lter change date in your in the logbook at the back of this manual.

Spare fi lter for the outside air system:

Please order the fi lters for the outside air system from your authorised technician

directly.

Page 12

aerosmart - Operation, Maintenance and Commissioning

Commissioning

Pre-Requisites for Commissioning

The compact unit's water, air, electricity and mechanical connections must conform to the

installation instructions - the boiler must be fi lled with water and the stopcocks must be

opened.

Caution: The unit must not be operated without complete insulation of the air pipes

(exhaust and outside air) as any condensation could damage the individual unit components, such as the electronics or the fans.

Initial Commissioning

Warning: Electrically conductive components can cause serious personal injury! Im-

proper working procedures could damage the unit components. The initial commissioning may only be carried out by technicians authorised by drexel und weiss.

When the controller is powered on for the fi rst time, the controller initially performs a self-

test. The main display then appears.

12:11 DI. 09/12/03

AUTOMATIK

Akt. Sollwert: 21.5°C

Akt. Raumtemp.: 20.3°C

Settings on the Overall System

After initially commissioning the unit, adjust the supply and extract air valve fl ow rates ac-

cording to the planned fl ow rates.

b

Measure and record the air quantities.

Decommissioning

Warning: Serious personal injury can result from improper working procedures.

Decommissioning may only be carried out by suitably qualifi ed and authorised

technicians.

Disconnect all electrical connectors from the unit and remove the water and ventilation

connections in accordance with local safety regulations.

The unit still contains both valuable materials and substances that may not be disposed

of in the residual waste. Please deliver your old unit for recycling to a collection point for

recyclable materials. For operating fl uids, please refer to the 'Technical Data'.

Time Weekday date

automatic

set-point temperature

current room temperature

aerosmart - Operation, Maintenance and Commissioning

Page 13

Menu levels

The individual software areas are divided into levels. Press the 'Esc' button to access the main

menu with the following submenus:

Statusebene

Technikerebene

Herstellerebene

Übersicht

Use the arrow keys to select a sub-menu.

Press 'Enter' to confi rm your selection.

Status Level - Viewing Operating Parameters

All available measurements and settings can be requested in the status level. The values

cannot be adjusted.

Statusebene

Technikerebene

Herstellerebene

Übersicht

Status Level

Technician Level

Manufacturer Level

Overview

Party-Funktion Shows if the party function is enabled

(EVU-Abschaltung) Shows if the energy supply utility shut down is enabled; only

available with double tariff control and when the surge current

cut off is enabled.

Raumtemperatur Current room temperature (measured by the gauge in the ana-

logue room operating panel or in the external gauge housing).

Temp. Boiler Unten Domestic water temperature in the lower region of the storage

tank.

Temp. Boiler Mitte Domestic water temperature in the middle region of the storage

tank.

Temp. Verdampf.block Current temperature in the heat pump's evaporator block.

Heizen Stufe 1 If the room thermostat requests “heating level 1”, 'YES' appears

here. If no cut-off is enabled (DW priority), the supply air is

heated in the aerosmart.

Heizen Stufe 2 If the room thermostat requests “heating level 2”, 'YES' appears

here. The external room heating is also enabled (start-up and

shut-down delays apply for pellet stoves)

Verdichter Current status of the compressor

MV - Fluessig Current status of the liquid solenoid valve

Page 14

MV – Heissgas Current status of the hot gas solenoid valve

MV – Luft Current status of the solenoid valve for the air capacitor

Zusatzheizung Current status of the top-up heater in the room

aerosmart - Operation, Maintenance and Commissioning

Anf. Heizstab Current status of the (optional) immersion heating element in

the boiler

Boilergrenztemp. Überwachung

The boiler is monitored for overheating. Temperature above

68°C = level 1; temperature above 73°C = level 2 (see error

messages Übertemperatur Boiler WP aus -

perature boiler heat pump off

).

Excess tem-

Aktuelle Stufe Current fan level (0/1/2/3)

Aktuelle Luftmenge Current air quantity in m³/h

Gerätetype Displays the unit type and the current software version.

aerosmart - Operation, Maintenance and Commissioning

Page 15

Technician Level - Setting Operating Parameters

All operation-related settings are made in the technician level. Use the arrow buttons to

scroll through the individual parameters on the menu pages. The cursor always fl ashes

on the value to be amended.

Statusebene

Technikerebene

Herstellerebene

Übersicht

Selecting the Room Operating Panel

<TECHNIKEREBENE>

Bitte wählen Sie Ihr

Raumbediengerät aus:

Technician Level

Please select your

room operating panel:

ANALOG ANALOG

Select the type of your operating unit (analogue or digital).

Press '

↵ ' (Enter) to confi rm.

Setting the Domestic Water Temperature

<TECHNIKEREBENE>

BW-Sollwert: 42.0°C

Zyklisch Aufheizen: N

Beginn: 04:00

Technician Level

Domestic water set-point

Cyclic heating process: No

Start

BW-Sollwert

The DW set-point (domestic water set-point) can be set from 37°C to 50°C. If, for example,

the set-point is set at 42.0°C, domestic water heating is enabled as soon as the temperature

in the lower area of the boiler (actual value) falls below this point. On reaching 47.0°C, i.e.

5°C above the set-point, the domestic water heating process is switched off again.

What domestic water temperature is right for me? The usual domestic water temperature is

36-38°C for showering, 37 to 42°C for having a bath and 40 to 45°C for washing dishes. Depending on the temperatures you are used to, we recommend a DW set-point temperature

of between 38 and 48°C.

Page 16

Note: If no warm water is removed for an extended period during the heating period, the do-

mestic water temperature can exceed the predetermined set-point.

Zyklisches Aufheizen

This parameter makes it possible to regularly heat domestic water to 60°C. (immersion heater must be switched on).

The function is regionally stipulated by the legislator (e.g. Switzerland) and is normally not

required.

J = Yes

N = No

Beginn

This setting is used to determine when the cyclic heating process is started. The time set

here is usually one at which a reduced rate electricity tariff is available.

aerosmart - Operation, Maintenance and Commissioning

Setting the Default Set-Point Room Temperature

Stnd. Sollwert: 21.5°C

Akt. Sollwert: 20.3°C

Nachtabsenkung: 0.0°C

Von/Bis: 22:00/06:00

Standard set-point temperature

Set-point temperature

Reduced set-point temperature

From/ To:

Stnd. Sollwert

When using the analogue room operating panel, the user can turn the dial to adjust the room

set-point temperature by +/- 3°C. The middle dial setting is programmed. The default setpoint can lie between 18 and 24°C.

Note: This option is not available when using the digital room operating panel as the de-

sired temperature is directly programmed on the room operating panel.

Akt. Sollwert

Current set-point: air temperature measured by the room gauge. This value cannot be adjusted.

Nachtabsenkung der Raumsolltemperatur

This can be used to reduce the room set-point temperature for a freely defi nable period of

the day (Default set-point) by up to 5°C.

Von/Bis: 22:00/6:00

Enter the time period for the reduction of the room set-point temperature.

Room Heating Cut-Off

This function can be used to briefl y disable the room heating if the temperature in the

domestic water storage tank falls below a specifi c level. During the cut-off, the heat pump

is only used to heat the domestic water. Two menu pages are available to set the room

heating cut-off:

<TECHNIKEREBENE>

Fühlerwahl für

Sperre Raumheizung

BOILERTEMP.MITTE

This parameter determines the temperature gauge used for the room heating cut-off. If there

is a high level of warm water usage, this parameter can be set to 'BOILERTEMP.UNTEN'.

Technician Level

Temperature gauge for

Room heating cut-off

Middle boiler temp.

BOILERTEMP.UNTEN Lower boiler temperature

BOILERTEMP.MITTE Middle boiler temperature

aerosmart - Operation, Maintenance and Commissioning

Page 17

<TECHNIKEREBENE>

Sperre Raumheizung

Soll: 35°C

Diff: 07.0°C

Technician Level

Room Heating cut-off

Set

Difference

Soll

By increasing the set-point, the warm water comfort can be increased.

Diff

The 'Difference' value describes the hysteresis, the exceeding of which deactivates the room

heating cut-off.

Setting the Nominal Air Quantities

<TECHNIKEREBENE>

Nennluftmenge:

Technician Level

Nominal air quantity

### m3/h

(Lüfterstufe 2)

This parameter is used to program the system's nominal air quantity. Please refer to the

house technology planning for the value to be set.

(fan level 2)

Note: It is only necessary to enter the nominal air quantity for fan level 2. The air quantities for levels 1 and 3 are automatically defi ned with -30% (level 1) and +30% (level 3).

Timeframe for Fan Control

There are two available menu pages for the temporal programming of the fans. The default level is fan level 2, which does not have to be programmed. This level always applies

when no timeframe is enabled.

Zeitprogramm 1

Lüfterstufe: 1

Beginn: 00:00

Ende: 00:00

Time program 1

Fan level

Start

End

Page 18

For example, program a timeframe for fan level 1 for the time of day at which the house is

usually empty.

Zeitprogramm 2

Lüfterstufe: 3

Beginn: 00:00

Ende: 00:00

You can also program a timeframe for fan level 3, for example, for fi xed cooking times.

Time program 2

Fan level

Start

End

Note: You can set two time programs for fan level 1 or two time programs for

fan level 3.

aerosmart - Operation, Maintenance and Commissioning

Setting the Time and Date

Uhr neu einstellen

Zeit: 00:00

Datum: 01/01/00

Wochentag: SO.

This window can be used to set the time and date.

MO. = Monday

DI. = Tuesday

MI. = Wednesday

DO. = Thursday

FR. = Friday

SA. = Saturday

SO. = Sunday

Setting the Time Period for the Party Mode

<TECHNIKEREBENE>

Laufzeit für

Party-Funktion:

60 min Status: Ein

Set clock

Time:

Date: day/month/year

Weekday:

Technician Level

Time period for the

Party mode

status

Use this window to set the time period for the 'Party' mode. The default value is 60 minutes;

values between 10 and 99 minutes can be entered.

Ein = On

Aus = Off

External Filters

<TECHNIKEREBENE>

Aussenfi lter: Ja

Use this window to enter whether your system has a fi ne particle air fi lter (usually in front of

the ground source heat exchanger in the external area). If so, the controller issues regular

fi lter change reminders (1 x year).

Ja = Yes

Nein = No

Technician Level

Outside air fi lter: Y es

Top-up heater

<TECHNIKEREBENE>

Pellet- o. Stückholz:

Nein

Technician Level

Pellet or Log stove

No

Use this window to enter whether a top up heater is used in the form of an ambient-air dependent pellet or log stove. If so, a special safety switch is used to deactivate the extract air

fan if the supply ventilator fails, to prevent any low-pressure in the room.

aerosmart - Operation, Maintenance and Commissioning

Page 19

Operating Hours Counter

For control, service and maintenance purposes, various operating hours for individual

operations can be viewed here.

J = Yes

N = No

<BETRIEBSSTUNDEN>

VERDICHTER

Summe: 00000 STD.

Reset: N

<BETRIEBSSTUNDEN>

Raumheizungsstufe 1

Summe: 00000 STD.

Reset: N

<BETRIEBSSTUNDEN>

Raumheizungsstufe 2

Summe: 00000 STD.

Reset: N

<BETRIEBSSTUNDEN>

Grobstaubfi lter

Summe: 00000 STD.

Reset mit Türkontakt

Operating Hours

Compressor

Sum: 00000 hours

Reset: No

Operating Hours

Room heating level 1

Sum: 00000 hours

Reset: No

Operating Hours

Room heating level 2

Sum: 00000 hours

Reset: No

Operating Hours

Coarse particle fi lter

Sum: 00000 hours

Reset with door contact switch

<BETRIEBSSTUNDEN>

Feinstaubfi lter

Summe: 00000 STD.

Reset: N

Operating Hours

Fine particle air fi lter

Sum: 00000 hours

Reset: No

Page 20

aerosmart - Operation, Maintenance and Commissioning

Manufacturer Level - Factory Settings

Statusebene

Technikerebene

Herstellerebene

Übersicht

This menu can be used to set the factory parameters. If needs be, these parameters can

be changed by the authorised customer service agents. A password is therefore required

to access the menu.

Overview – Current Operating Status

This menu provides a quick overview of the current operating status.

Statusebene

Technikerebene

Herstellerebene

Übersicht

Tr: 14.0°C Verd.: 1

Tb:-04.4°C MV-FL: 1

Tu: 34.4°C MV-HG: 0

Tm 34.4°C MV-LU: 1

Tr Current room temperature measured by the sensor on the control unit or

an external room sensor

Tb Temperature on the heat pump evaporator register

Tu Current temperature in the lower area of the boiler. Depending on this

temperature, the heat pump is activated.

Tm Current temperature in the middle area (centre) of the boiler. Depending

on this temperature, the domestic water heating can be given priority and

the room heating can be temporarily disabled by the heat pump.

Verd. Current status of the compressor or the heat pump

MV-FL Current status of the liquid line's solenoid valve. This valve is only closed

at the start of thawing; it otherwise opens when the compressor operation

starts.

MV-HG Current status of the hot gas line's solenoid valve. It is open during the

compressor's start phase (unloaded start) and during the thaw process.

MV-LU Current status of the air capacitor line's solenoid valve. Air heating is ena-

bled when this valve is open.

aerosmart - Operation, Maintenance and Commissioning

Page 21

Faults

Error Messages

The messages described here are displayed on both the micro-processor controller and

the digital room operating panel. The faults cannot be acknowledged until they have been

resolved. If several faults occur simultaneously, use the up

to scroll through the error messages.

If a fault cannot be acknowledged by holding down the Enter button (2 sec), please contact your customer service technician.

Warning: Electrically conductive components can cause serious personal injury! Improper working procedures could damage unit components. The inner inspection cover

may only be opened by authorised technicians.

Alarm Niederdruck-Pressostat:

Check if the air quantity is too low due to a closed air line. (E.g. very dirty exhaust air fi lter,

contaminants in the air line).

The following operating conditions are not permissible for the heat pump: room temperature

too low; outside air entrance temperature from the ground source heat exchanger too low;

lack of cooling agents

'↑' and down '↓' arrow buttons

Alarm Hochdruck-Pressostat:

Air quantity too low. The heat cannot be dispersed via the air. (E.g. minimum air quantity set

too low, frozen outside air grid in winter)

Zuluftventilator ausgefallen / Abluftventilator ausgefallen

A valve has failed. If the fault cannot be acknowledged by holding down the Enter button

(2 sec), please contact your customer service technician.

Blocktemperatur zu tief

The following operating conditions are not permissible for the heat pump: room temperature

too low; outside air entrance temperature from the ground source heat exchanger too low;

block gauge faulty; extract air fan faulty or dirty.

Low air quantity and very damp extract air

Closed extract or exhaust air line

Fühlerfehler Verdampfer / Boiler unten / Mitte

Temperature gauge/cable faulty / connector loose; all the system's temperature gauges are

monitored. If the lead to a sensor is disconnected, a gauge provides meaningless values

or a short-circuit occurs, a relevant error message is issued and an emergency program is

enabled.

Übertemperatur Boiler Wärmepumpe aus

1. Storage tank temperature above 68°C - unit automatically switches to fan level 3; blocked

supply air fi lter or fi ne particle air fi lter, authorised technicians to check ground source heat

exchanger.

2. Storage tank temperature above 73°C - storage tank overheats, system switches off;

shortly after the initial commissioning (approx. 20 minutes), check if the DW storage tank is

fi lled with water. If necessary, fi ll the DW storage tank with water.

While heating the building envelope; if no warm water has been taken from the DW storage

tank for a long time. Remove warm water.

If the fault reoccurs within a short timeframe, check if the coarse particle fi lter and the fi ne

particle air fi lter have become extremely dirty (possibly through construction dust). If the fault

reoccurs, contact customer service technician.

Page 22

aerosmart - Operation, Maintenance and Commissioning

No Link (or no text in the digital room operating panel)

Fault with addressing the digital room operating panel; the digital room operating panel is

already correctly addressed on delivery. It is, however, possible that the message 'No link'

appears after commissioning or changing the room operating panel. To create a link to the

micro-processor controller, the address must be corrected on the operating panel:

Hold down the '↓', '↑' and '↵' buttons at the same time until the text: '

SETTING' appears.

DISPLAY ADDRESS

b

Confi rm your selection by pressing '↵' (cursor fl ashes on the address)

b

Use the '↓', '↑' arrows to set the correct address (I/O board address 00: display address: 00

or I/O board address 01: display address: 32)

b

Confi rm the new value by pressing '↵'.

The following message appears: 'DISPLAY ADDRESS CHANGED'

b

The room operating panel now has the correct address and operates alongside the microprocessor controller in the ventilation unit.

Other

The display shows 'Automatik' but the compressor is not operating; Press '↵' (Enter) to

confi rm the operating mode change. T o check this fault, press 'Esc' twice. The current operat-

ing mode will appear on the display.

After a fi lter change: check if the inspection cover is fully closed (contact switch).

Automatik Automatic mode

Faults in the Ventilation System

Noises

The unit is becoming louder by the day since its initial commissioning: exhaust air fi lter / sup-

ply air fi lter very dirty - fans working at an increased speed to try to achieve the minimum air

quantity. Check the condition of all fi lters.

Unit becomes louder during operation: impermissible resistance in an air line (e.g. contaminant blocking air inlets, outside air inlet frozen over in winter)

aerosmart - Operation, Maintenance and Commissioning

Page 23

Important Unit Information

(Logbook)

Your authorised technician has handed over the unit to you with the following settings. Please

keep this data handy in case of queries.

Customer:

Location:

Unit type / version:

Serial number:

Initially

commissioned on:

Installation company:

Authorised

technician:

Set

air quantity (m³/h)

Time program 1 Fan level Start End

Time program 2 Fan level Start End

Filter change

(Date):

Maintenance (Date):

Page 24

aerosmart - Operation, Maintenance and Commissioning

aerosmart - Operation, Maintenance and Commissioning

Page 25

Legal notice

Publisher:

drexel und weiss energieeffi ziente

haustechniksysteme gmbh.

Achstrasse 42, 6922 Wolfurt

T 05574 47895-0

F 05574 47895-4

E-mail: offi ce@drexel-weiss.at

www.drexel-weiss.at

ATU 35542007; FN 192604t;

Company Accounts Registrar: Feldkirch

Document number: 20080908.01 BWI-EN

Loading...

Loading...