Page 1

Putting You In Control

Instruction Manual

EM36005

07/10

36005 Series V-Max

High Capacity Control Ball Valve

®

Page 2

Table of Contents Page

IMPORTANT: SAFETy WARNINg ........................................................................................1

1.0 INTRODuCTION

NUMBERING SYSTEM ......................................................................................2

2.0 INSTALLATION

2.1 GENERAL ..........................................................................................................4

2.2 PIPELINE MOUNTING .......................................................................................4

2.3 AIR PIPING .......................................................................................................4

2.4 CHANGING ACTUATOR POSITION .................................................................4

2.5 CHANGING VALVE ACTION .............................................................................6

3.0 MAINTENANCE

3.1 BRACKET SUBASSEMBLY ...............................................................................7

3.3 BODY SUBASSEMBLY .....................................................................................9

3.3.1 PACKING ...........................................................................................................9

3.3.2 MN-7 SEAL RING .............................................................................................9

3.3.3 STANDARD METAL SEAL RING .....................................................................9

3.3.4 HEAVY DUTY METAL SEAL RING ................................................................10

3.3.5 BALL PLUG ......................................................................................................10

3.4 ACTUATOR SUBASSEMBLY ..........................................................................11

3.5 HANDWHEEL SUBASSEMBLY .......................................................................13

3.6 DIAPHRAGM REPLACEMENT ........................................................................13

LIST OF FIguRES

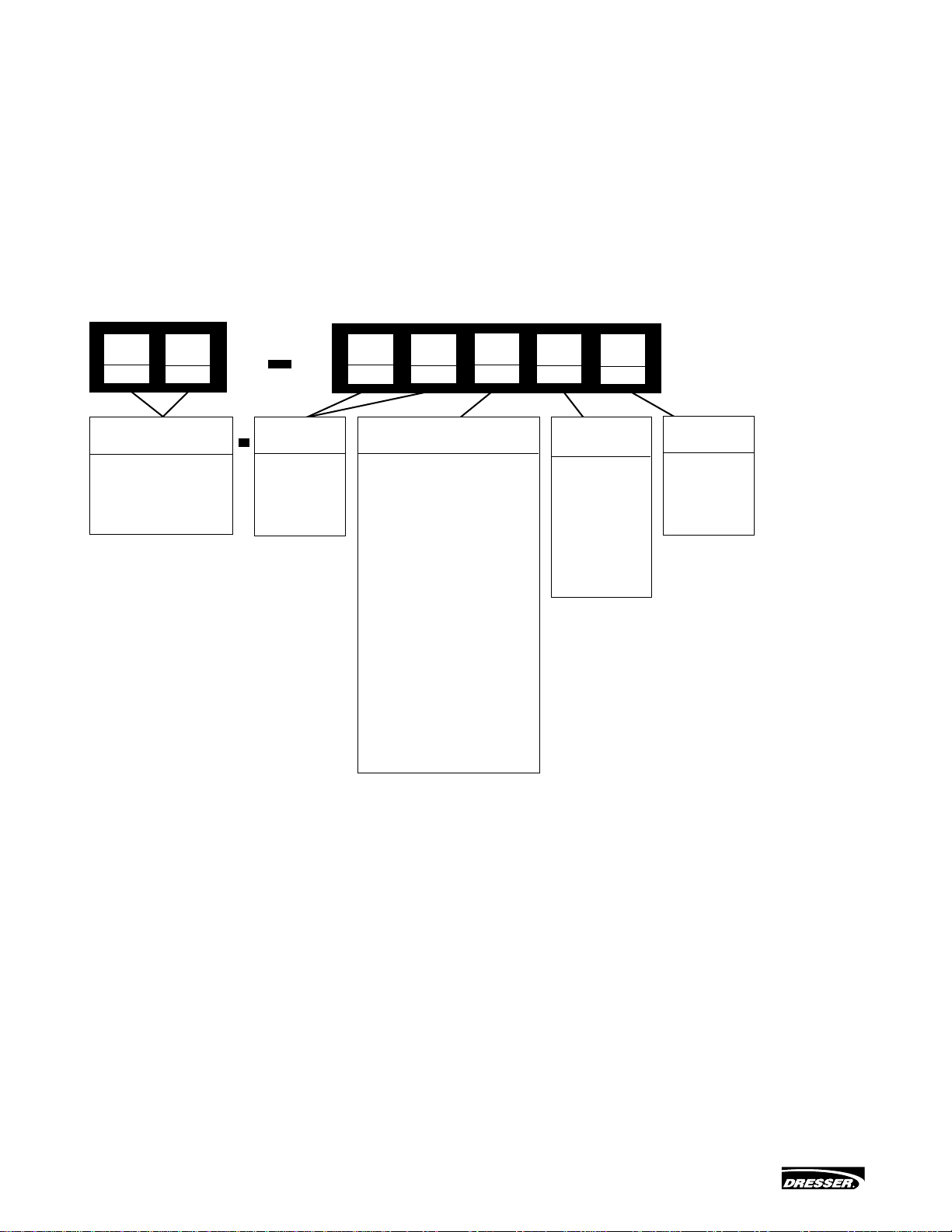

FIGURE 1 — NUMBERING SYSTEM AND STANDARD

MOUNTING POSITIONS ....................................................................2

FIGURE 2 — GENERAL ASSEMBLY .....................................................................15

FIGURE 3 — ACTUATOR SIZES B & C BRACKET & LINKAGE ..........................16

FIGURE 4 — HANDWHEEL ASSEMBLY, ACTUATOR SIZES B & C ...................16

FIGURE 5 — HANDWHEEL DETAIL, ACTUATOR SIZES B & C ..........................16

FIGURE 6 — HANDWHEEL BRACKET DETAIL, SIZES B & C ............................16

FIGURE 7 — HANDWHEEL LEVER DETAIL, SIZES B & C ..................................16

FIGURE 8 — HANDWHEEL CLEVIS DETAIL, SIZES B & C .................................16

FIGURE 9 — ACTUATOR GENERAL ASSEMBLY, SIZES B & C ........................17

FIGURE 10 — LEVER POSITION AIR TO OPEN, SIZES B & C ............................17

FIGURE 11 — LEVER POSITION AIR TO CLOSE, SIZES B & C ...........................17

FIGURE 12 — POSITION INDICATOR DETAIL, SIZES B & C ...............................18

FIGURE 13 — SIZE AC ACTUATOR ASSEMBLY ...................................................18

FIGURE 14 — SIZE AC ACTUATOR BOTTOM VIEW .............................................19

FIGURE 15 — SIZE AC ACTUATOR LINKAGE DETAIL .........................................19

FIGURE 16 — SIZE AC HANDWHEEL DETAIL.......................................................20

FIGURE 17 — INSULATION DETAIL .......................................................................20

LIST OF TABLES

TABLE 1 — BODY PARTS LIST ...............................................................................21

TABLE 2 — BRACKET AND LINKAGE PARTS LIST ..............................................21

TABLE 3 — HANDWHEEL PARTS LIST ..................................................................22

TABLE 4 — ACTUATOR PARTS LIST .....................................................................22

TABLE 5 — LINE BOLTING ......................................................................................23

Helpful Hints

1. Have spare parts on hand before starting.

2. Read the instructions carefully.

3. Study the figures carefully and identify each part.

4. Use the right tools for the job.

5. Be careful not to score the shaft, ball and guiding

surfaces.

6. Ensure all lubricants, gaskets and packing are

compatible with the service.

7. Don’t overtighten nuts or bolts.

8. Clean valve parts thoroughly before reassembly.

9. Work safely.

Copyright

Masoneilan® is a registered trademark of Dresser, Inc. All information contained herein is believed to be accurate at the time of

publication and is subject to change without notice.

Copyright 2010 by Dresser, Inc. All rights reserved.

Page 3

Safety Information

Based on general field failure data and product design analysis, a useful life period of 25 years or longer can be expected for the 36005 series V-Ported control ball valves. To

maximize the useful life of the product it is essential to conduct annual inspections, routine maintenance and ensure proper installation to avoid any unintended stresses on the

product. The specific operating conditions will also impact the useful life of the product. Consult the factory for guidance on specific applications if required prior to installation.

Important - Please Read Before Installation

Masoneilan 36005 Series instructions contain DANgER,

WARNINg, and CAuTION labels, where necessary, to alert

you to safety related or other important information. Read

the instructions carefully before installing and maintaining

your control valve. DANgER and WARNINg hazards

are related to personal injury. CAuTION hazards involve

equipment or property damage. Operation of damaged

equipment can, under certain operational conditions, result in

degraded process system performance that can lead to injury

or death. Total compliance with all DANgER, WARNINg,

and CAuTION notices is required for safe operation.

This is the safety alert symbol. It alerts you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

About this Manual

• The information in this manual is subject to change without

prior notice.

• The information contained in this manual, in whole or part,

shall not be transcribed or copied without Masoneilan’s

written permission.

• Please report any errors or questions about the information

in this manual to your local supplier.

• These instructions are written specifically for the 36005

Series control valves, and do not apply for other valves

outside of this product line.

Warranty

Items sold by Dresser® are warranted to be free from defects

in materials and workmanship for a period of one year from

the date of shipment provided said items are used according

to Dresser recommended usages. Dresser, Inc. reserves the

right to discontinue manufacture of any product or change

product materials, design or specifications without notice.

This instruction manual applies to the Masoneilan 36005 Series

control valves.

The Control Valve MUST BE:

• Installed, put into service and maintained by qualified

and competent professionals who have undergone

suitable training.

• Under certain operating conditions, the use of damaged

equipment could cause a degradation of the performance

of the system which may lead to personal injury or death.

Indicates a potentially hazardous situation which, if not avoided,

could result in serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

When used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in property damage.

Note: Indicates important facts and conditions.

• Changes to specifications, structure, and components

used may not lead to the revision of this manual unless

such changes affect the function and performance of the

product.

• All surrounding pipe lines must be thoroughly flushed to

ensure all entrained debris has been removed from the

system.

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

1

Page 4

1.0 Introduction

The following instructions are designed to assist maintenance

personnel in performing most of the maintenance required on

the 36005 V-Max® valve and if followed carefully will reduce

maintenance time.

Masoneilan has highly skilled Service Engineers available for

start-up, maintenance and repair of our valves and component

parts. In addition, regularly scheduled training programs are

conducted to train customer service and instrumentation

Numbering System

personnel in the operation, maintenance and application of

our control valves and instruments. Arrangements for these

services can be made through your Masoneilan Representative

or District Office. When performing maintenance use only

Masoneilan replacement parts. Parts are obtainable through

your local Masoneilan Representative or District Office. When

ordering parts always include MODEL and SERIAL NuMBER

of the unit being repaired.

1st

DIgIT

Actuator Type

33 Spring Diaphragm.

Air to extend

action only.

2nd

DIgIT

Body

Series

36

1st

DIgIT

3

0 Undefined

1 Valve closes on stem

extension

(Air to Close, Fail Open)

2 Valve opens on stem

extension

(Air to Open, Fail Closed)

3 Valve closes on stem

extension

(Air-to-Close, Fail Open)

4 Valve opens on stem

extension

(Air-to-Open, Fail Closed)

7 Valve closes on stem

extension

(Air-to-Close, Fail Open)

8 Valve opens on stem

extension

(Air-to-Open, Fail Closed)

2nd

DIgIT

6

Actuator Mounting

(See guide on page 4)

3rd

DIgIT

4th

DIgIT

Seal Type

1 MN-7 Seal

Ring

2

316 SS

Seal Ring

Heavy Duty

3

Metal Seal

Ring

5th

DIgIT

5

Design

Series

5

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Figure 1

2

Page 5

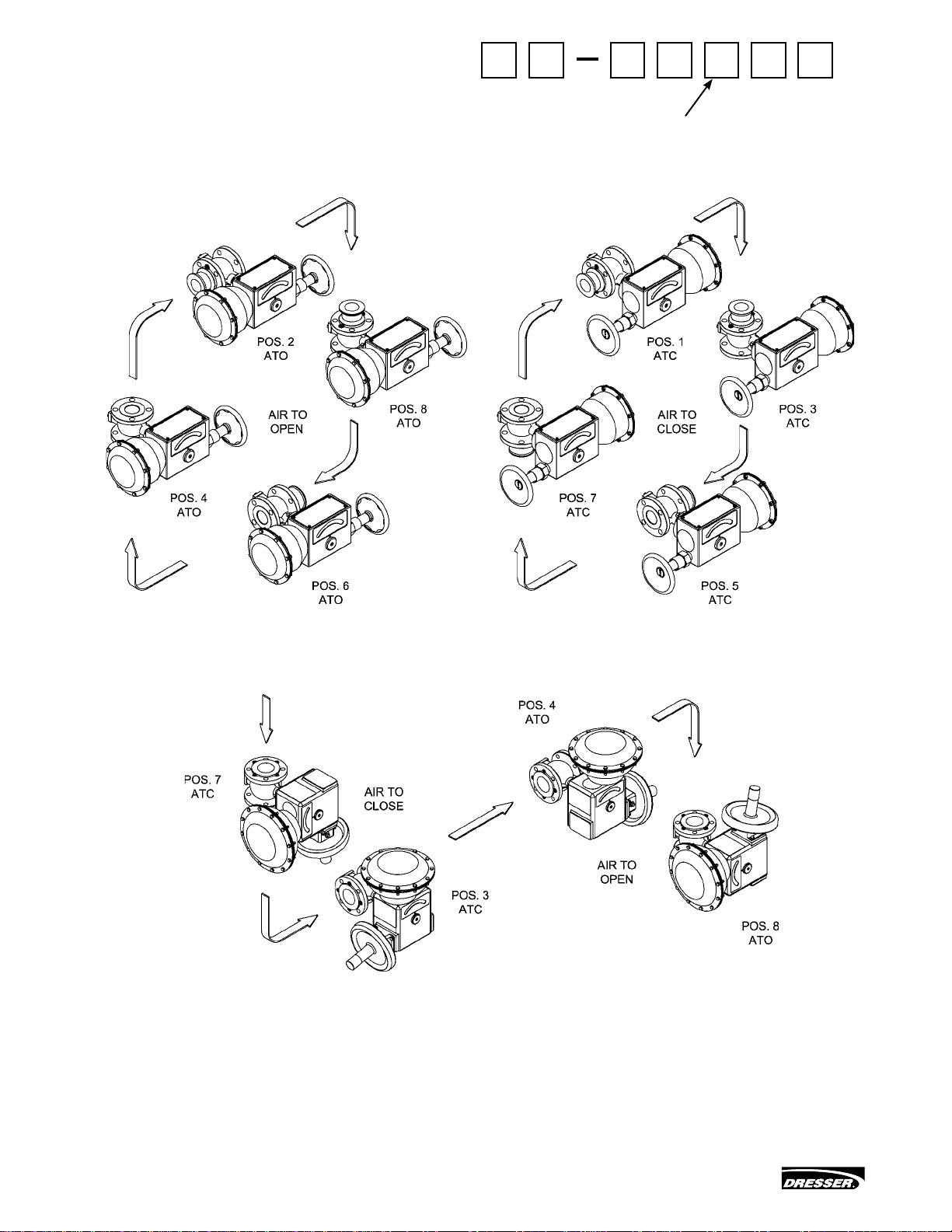

V-Max Valves

Actuator Model 33, Size AC

3 X 3 6 X 0 5

Actuator Position in Relation to Valve Body

Numbering System: 1 to 8

Actuator Model 33, Sizes B and C

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

3

Page 6

2.0 Installation

2.1 general

2.1.1 Unpack valve carefully to avoid damage to valve,

accessories, or tubing.

2.1.2 Record all valve and accessory serial plate data

for future reference. Always provide serial and model

numbers when ordering spare parts.

2.2 Pipeline Mounting

Do not remove button head screw (9) and washer (10)

during installation. The function of these parts is to hold

the retainer (3) and seal ring (8) in place and should be

removed only when the valve is to be disassembled for

maintenance (Figure 2).

A. Before installing the valve in the line, clean pipe and

valve of all foreign materials such as welding chips,

scale, oil, grease or dirt. Gasket surfaces must be

thoroughly cleaned to ensure leak free joints.

B. Install valve in a horizontal or vertical line with the flow

tending to push the seal ring (8) against the ball (2)

as indicated by the flow arrow cast into the body. It is

recommended that if adjacent walls and piping permit,

the valve be oriented such that the ball opens upward.

This is especially important when handling slurries.

See Figure 1 for actuator mounting positions and for

flow direction and Table 5 for line flange bolting lengths.

Note: Flange bolt lengths are non-standard on inlet and

standard on outlet side.

C. Tighten bolting evenly and in crisscross fashion so that

the retainer (3) held in place by the line flange will bear

evenly against the seal ring (8).

D. The linkage of the 36005 V-Max valve has been properly

adjusted at the factory and requires no further adjustment.

E. Where insulation of the valve body is required, do not

insulate the valve bonnet. See Figure 17.

2.3 Air Piping

2.3.1 Air piping must be adequately sized to provide the

regulated supply pressure specified on the nameplate.

As a general guideline, use 1/4" O.D. tubing or

equivalent for all air lines. If supply air line exceeds 25

feet in length, use 3/8" O.D. tubing.

2.3.2 The actuator is furnished with a 1/4" NPT instrument

air port on the upper case.

Do not exceed loading pressure specified on the valve

nameplate.

2.4 Changing Actuator Position

2.4.1 Model 33, sizes B & C. For Size AC, refer to

section 2.4.2.

Before proceeding with changing actuator position, air

action or valve maintenance, isolate valve, vent process

pressure and shut off air supply and signal air lines or

electrical lines to unit. It is recommended that the valve

be removed from the pipeline prior to maintenance work.

Keep hands and tools away from the segmental ball,

particularly when disconnecting the actuator stem from

shaft arm as ball may rotate freely to its lowest position

For each valve action (air to open/air to close) the actuator

may be positioned to either side of the pipe. Actuator

position is usually determined by adjacent piping,

obstacles of various types or air piping arrangements.

To reposition the actuator and/or bracket follow the

disassembly and reassembly instructions below.

Note: Actuator positioning should be performed prior to

installing the valve in the pipeline. To change actuator

position and/or valve action refer to Figure 1 for desired

position.

A. Remove valve from process line after closing isolating

valves and disconnecting all pneumatic tubing and

electrical wiring.

B. If valve is equipped with a handwheel (Figure 4)

disengage handwheel and remove retaining clips

(63), clevis pin (66) and pivot pins (72); remove entire

hand- wheel assembly from bracket (62).

C. Remove pivot pin retaining clips (40), pivot pin (39)

and spacer rings (69). Remove actuator hex nuts

(75) and washers (76). Remove actuator.

Note: Spacer rings apply only on handwheel option.

D. Remove shaft cover (42) and screw (43). Loosen lever

cap screw (33). Remove packing flange stud nuts

(24), bracket mounting stud nuts (24) and washers

(18). Loosen ball plug indicator arm (35).

E. If necessary, scribe a witness line on the lever (32) in

relation to the slot on the end of the shaft (5).

Note: Standard lever has arrows stamped into it for

alignment. For handwheel lever use slot for alignment.

F. Slide bracket (31) away from body until it clears

bracket and packing flange studs (26 and 25),

allowing lever (32) lever arm (64) and indicator arm

(35) to be removed from shaft. Total removal of the

bracket is not required.

Before proceeding determine valve action (air to open/

air to close), refer to the appropriate figure (Figure 10 to

open, Figure 11 to close). To obtain proper alignment,

the lever must be oriented on the shaft so that the slot

in the end of the shaft and arrows or indicator lines are

aligned as shown; with the ball in the closed position,

the distance between the top of the bracket and the

top of the pivot pin must be as shown.

g. Slide lever (32) and lever arm (64) back onto

shaft in desired position. Slide indicator arm (35)

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

4

Page 7

back onto shaft. Align bracket and slide back onto

bracket mounting studs (26) and packing flange

studs (25). Replace bracket mounting stud nuts (24)

and washers (18). Slide packing flange (23) back

onto packing flange studs (25) and replace packing

flange stud nuts (24).

H. Remount actuator onto bracket and replace

actuator mounting hex nuts (75) and washers (76).

Position lever (32) and lever arm (64) so that rod

end bearing (94) lines up in lever (32). Tighten lever

cap screws (34).

I. Rotate ball plug (2) to closed position. If actuator

action is air to open loosen rod end bearing locknut

(93) and adjust position of rod end bearing (94) so

that holes in lever (32) and rod end bearing (94) line

up. Insert pivot pin (39) and replace spacer rings

(69) and retaining rings (40).

When stroking valve keep hands and equipment clear

of ball plug and seal ring to avoid injury or damage to

personnel and equipment.

J. If action is air to close place ball plug (2) in closed

position and pneumatically stroke actuator fully.

Do not exceed maximum air supply pressure. Keep

hands clear of actuator stem and linkage.

Loosen rod end bearing locknut (93) and adjust rod

end bearing (94) so that holes in lever (32) and rod

end bearing (94) line up. Insert pivot pin (39) and

spacers (69) and replace retaining rings (40).

K. For both air to open and air to close action, stroke

valve fully to ensure proper closure of ball plug and

operation of valve. It may be necessary to readjust

rod end bearing slightly by loosening locknut and

rotating stem.

L. Replace handwheel assembly in bracket (62), pivot

pins (72) and retaining clips (63).

M. Replace shaft cover (42) and screw (43).

N. Set and lock indicator arm (35) to indicate plug position.

2.4.2 Changing Actuator Position Model 33, size

AC only.

Before proceeding with changing actuator position, air

action or valve maintenance, isolate valve, vent process

pressure and shut off air supply and signal air lines or

electrical lines to unit. It is recommended that the valve

be removed from the pipeline prior to maintenance work.

Keep hands and tools away from the segmental ball,

particularly when disconnecting the actuator stem from

shaft arm as ball may rotate freely to its lowest position.

For each valve action (air to open/air to close) the actuator

may be positioned to either side of the pipe. Actuator

position is usually determined by adjacent piping,

obstacles of various types or air piping arrangements.

To reposition the actuator and/or bracket follow the

disassembly and reassembly instructions below.

Note: Actuator positioning should be performed prior to

installing the valve in the pipeline. To change actuator

position and/or valve action refer to Figure 1 for desired

position.

A. Remove valve from process line after closing isolating

valves and disconnecting all pneumatic tubing and

electrical wiring.

B. If valve is equipped with a handwheel (Figures 13 &

16) disengage handwheel and remove retaining clip

(54-7) and washer (54-4). Remove entire handwheel

assembly from actuator housing (31).

C. Remove pivot pin retaining clips (40), pivot pin (39).

Remove actuator hex nuts (75) and washers (76).

Remove actuator.

D. Remove shaft cover (42) and screw (43). Loosen lever

cap screw (33). Remove packing flange stud nuts

(24), bracket mounting stud nuts (24) and washers

(18). Loosen ball plug indicator arm (35).

E. If necessary, scribe a witness line on the lever (32) in

relation to the slot on the end of the shaft (5).

F. Slide housing (31) away from body until it clears

bracket and packing flange studs (26 and 25), allowing

lever (32) and indicator arm (35) to be removed from

shaft. Total removal of the bracket is not required.

Before proceeding determine valve action (air to

open/air to close).

g. Slide lever (32) back onto shaft in desired position.

Slide indicator arm (35) back onto shaft. Align

bracket and slide back onto mounting studs (26)

and packing flange studs (25). Replace mounting

stud nuts (24) and washers (18). Slide packing

flange (23) back onto packing flange studs (25) and

replace packing flange stud nuts (24).

H. Remount actuator onto housing and replace actuator

mounting hex nuts (75) and washers (76). Position

lever (32) so that rod end bearing (94) lines up in

lever (32) and that the pads on the lever will contact

the stop bolts (102). Tighten lever cap screw (33).

I. Rotate ball plug (2) to closed position. Adjust closed

position travel stop (102) until it contacts the pad on

lever (32). Tighten locknut (101).

J. Rotate ball plug (2) to open position. Adjust open

position travel stop until it contacts pad on lever (32).

Tighten locknut (101).

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

5

Page 8

Ensure rotation of AC actuator does not exceed

90deg. Damage to actuator rod may result.

K. If actuator action is air to open, rotate ball plug (2) to

open position. Pneumatically stroke actuator to open

position. Loosen rod end bearing locknut (93) and

adjust position of rod end bearing (94) so that holes

in lever (32) and rod end bearing (94) line up. Insert

pivot pin (39) and retaining rings (40).

When stroking valve keep hands and equipment

clear of ball plug and seal ring to avoid injury or

damage to personnel and equipment.

L. If action is air to close place ball plug (2) in closed

position. The pad on lever should contact the closed

position travel stop (102). If it does not, repeat

adjustment as noted in step I above. Return ball plug

(2) to open position. Pneumatically stroke actuator to

open position.

Do not exceed maximum air supply pressure. Keep

hands clear of actuator stem and linkage.

Loosen rod end bearing locknut (93) and adjust rod

end bearing (94) so that holes in lever (32) and rod

end bearing (94) line up. Insert pivot pin (39) and

replace retaining rings (40).

M. For both air to open and air to close action, stroke valve

fully to ensure proper closure of ball plug and operation

of valve. It may be necessary to readjust rod end

bearing slightly by loosening locknut and rotating stem.

N. Replace handwheel assembly in housing (31),

washer (54-7) and retaining clip (54-4).

O. Replace shaft cover (42) and screw (43).

P. Set and lock indicator arm (35) to indicate plug position.

washers (76). Remove actuator.

Note: Spacer rings apply only on handwheel option.

D. Loosen lever cap screw (33). Remove packing flange

stud nuts (24), bracket mounting stud nuts (24) and

washers (18). Loosen ball plug indicator arm (35).

E. Slide bracket (31) away from body until it clears bracket

and packing flange mounting studs. Remove lever

(32), lever arm (64) and indicator arm (35) from shaft.

Before proceeding determine valve action (air to open/

air to close), refer to the appropriate figure (Figure 10 to

open, Figure 11 to close). To obtain proper alignment,

the lever must be oriented on the shaft so that the slot

in the end of the shaft and arrows or indicator lines are

aligned as shown; with the ball in the closed position,

the distance between the top of the bracket and the

top of the pivot pin must be as shown.

F. Flip lever (32) and lever arm (64) and replace on

shaft 90 away from original position. Replace

indicator arm (35). Slide bracket back onto bracket

mounting studs (26), replace washers (18) and nuts

(24) and tighten. Slide packing flange (23) back

over packing flange studs (25) and replace packing

flange stud nuts (24) and tighten.

g. Replace actuator on bracket in correct mounting

position for air action. Replace actuator stud nuts

(75) and washers (76). Position lever (32) and lever

arm (64) so that rod end bearing (94) lines up in lever

(32). Tighten lever cap screw (33).

H. Place ball plug (2) in closed position. If actuator

action is air to open, loosen rod end bearing nut (93)

and adjust position of rod end bearing (94) so that

holes in lever (32) and rod end bearing (94) line up.

Insert pivot pin (39) and replace retaining rings (40).

I. If action is air to close, place ball plug (2) in closed

position and pneumatically stroke actuator fully.

2.5 Changing Valve Action

Note: If the valve action is to be changed it should be done

before the valve is installed in the line. This allows a positive

visual check to ensure that the ball plug is fully closed when

the actuator is in the proper position.

2.5.1 Model 33, sizes B & C only. For size AC refer

to section 2.5.2

A. If the valve is equipped with a handwheel disengage

the handwheel and remove retaining clips (63), clevis

pin (66), and pivot pins (39). Remove cap screws

(70), washers (71) and handwheel bracket (62).

B. If necessary, scribe a witness mark on the lever (32)

in relation to the slot on the end of the shaft (5).

Note: Standard lever has arrows stamped into it for

alignment. For handwheel lever use slot for alignment.

C. Remove pivot pin retaining clips (40), pivot pin (39)

and spacer rings (69). Remove shaft cover (42)

and screw (43). Remove actuator hex nuts (75) and

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Do not exceed maximum air supply pressure.

J. For both air to open and air to close action, stroke valve

fully to ensure proper closure of ball plug and operation

of valve. Tighten rod end bearing locknut (93).

When stroking valve keep hands and equipment

clear of ball plug and seal ring to avoid injury or

damage to personnel or equipment.

K. Replace handwheel bracket (62), cap screws (70)

and lockwashers (71) on opposite side of actuator

bracket from where originally found. Insert handwheel

assembly in bracket and replace clevis pin (66),

retaining rings (63), lever arm bearing (65) and pivot

pins (72). Replace shaft cover (42) and screw (43).

6

Page 9

L. Set and lock indicator (35) to indicate plug position.

2.5.2 Model 33, size AC only. For sizes B & C refer

to section 2.5.1 above.

A. If the valve is equipped with a handwheel disengage

the handwheel and remove retaining clip (54-7) and

washer (54-4). Remove handwheel assembly (54)

from housing (31) by rotating counter-clockwise.

B. Remove pivot pin retaining clips (40), pivot pin (39).

Remove actuator hex nuts (75) and washers (76).

Remove actuator.

C. Remove cover (48) from opposite side of bracket (31)

and install on side actuator was just removed from.

Note: Cover (48) is attached to yoke with contact

adhesive that is pre-applied. If a new cover is not

available, it can be re-installed by applying contact

adhesive to the cover and bracket following the

instructions for the specific adhesive used.

D. Install actuator on opposite side of yoke than it was

removed from. Attach using washers (76) and hex

nuts (75).

Before proceeding determine valve action (air to

open/air to close).

E. Rotate ball plug (2) to closed position. Verify closed

position travel stop (102) contacts the pad on lever

(32). Adjust as necessary. Tighten locknut (101).

Ensure rotation of AC actuator does not exceed

90deg. Damage to actuator rod may result.

F. Rotate ball plug (2) to open position. Verify open

position travel stop contacts pad on lever (32). Adjust

as necessary. Tighten locknut (101).

g. If actuator action is air to open, rotate ball plug (2)

to open position. Pneumatically stroke actuator to

open position. Loosen rod end bearing locknut (93)

and adjust position of rod end bearing (94) so that

holes in lever (32) and rod end bearing (94) line up.

Insert pivot pin (39) and retaining rings (40).

When stroking valve keep hands and equipment

clear of ball plug and seal ring to avoid injury or

damage to personnel and equipment.

H. If action is air to close place ball plug (2) in closed

position. The pad on lever should contact the closed

position travel stop (102). If it does not, repeat

adjustment as noted in step I above. Return ball plug

(2) to open position.

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Do not exceed maximum air supply pressure. Keep

hands clear of actuator stem and linkage.

Loosen rod end bearing locknut (93) and adjust rod

end bearing (94) so that holes in lever (32) and rod

end bearing (94) line up. Insert pivot pin (39) and

replace retaining rings (40).

I. For both air to open and air to close action, stroke

valve fully to ensure proper closure of ball plug and

operation of valve. It may be necessary to readjust

rod end bearing slightly by loosening locknut and

rotating stem.

J. Replace handwheel assembly (54) in bracket (31),

washer (54-7) and retaining clip (54-4).

K. Set and lock indicator arm (35) to indicate plug

position.

3.0 MAINTENANCE

3.1 Bracket Subassembly – Model 33, sizes B &

C only. Refer to section 3.2 for size AC

3.1.1 Disassembly

When disconnecting actuator rod end bearing from

shaft arm, the ball is likely to rotate toward the bottom of

the valve body. Keep hands and tools away from the ball.

A. Remove screw (43) and shaft cover (42) or positioner

if so equipped.

B. Remove retaining clips (40), pivot pin (39) and spacer

rings (69).

Note: Spacer rings apply only on handwheel option.

C. Remove actuator mounting nuts (75) and washers

(76) and remove actuator from bracket (31).

D. If valve has handwheel, remove retainer clips (63),

clevis pin (66), pivot pins (72). Remove handwheel

assembly from bracket.

E. Loosen cap screw (33) and indicator arm (35).

Remove packing flange stud nuts (24) and bracket

mounting stud nuts (26) and washers (18).

F. Scribe a witness mark on the lever (32) indicating

relative position to the slot in the end of the shaft (5).

g. Slide bracket (31) off studs and shaft, removing

indicator arm (35), lever (32), lever arm (64) and

packing flange (23).

H. Remove bearing (47) from bracket. Examine all

parts for wear and/or damage. Replace if necessary.

3.1.2 Reassembly

Note: If the valve is equipped with a handwheel the

lever consists of two separate arms which are a

MATCHED PAIR and are not interchangeable with any

other pair. The sequence of assembly is to place one

lever over the shaft then the lever arm (64) insert pin

7

Page 10

(68), and then the second lever arm onto the shaft then

slide the shaft into the bracket and bearing.

A. Replace ball bearing (47) in the bracket (31).

B. Place ball plug (2) in closed position. Slide bracket

(31) partially over shaft. Ensure all packing box

parts are in place and then slide packing flange

(23) onto shaft. Slide lever (32) onto shaft on its

former position. Slide handwheel lever arm (64) and

second lever (32) onto shaft if valve has handwheel.

Replace indicator arm (35). Slide bracket fully onto

mounting studs (26); ensure shaft (5) is properly

located in bearing (47). Replace lock-washer (18)

and bracket mounting stud nuts (24) and tighten.

Replace packing flange stud nuts (24).

C. Pull shaft out to bottom against bearing. Replace

actuator and install washers (76) and nuts (75). Slide

lever (32) on shaft so that it is lined up with rod end

bearing (94). Tighten lever locking screw (33).

D. If valve action is air to open place ball plug (2) in closed

position. Loosen rod end bearing locknut (93) and

adjust rod end bearing until holes in lever (32) and rod

end bearing (94) line up. Install pivot pin (39), spacers

(69) (handwheel only) and retainer rings (40). If valve

action is air to close, place ball plug (2) in closed

position and pneumatically stroke actuator fully.

Do not exceed maximum air supply pressure

specified on the valve nameplate.

E. For both air to open and air to close action, stroke valve

fully to ensure proper closure of ball plug and operation

of valve. Tighten rod end bearing locknut (93).

When stroking valve keep hands and equipment

clear of ball plug and seal ring to avoid injury or

damage to personnel or equipment. Do not exceed

pressure specified on the valve nameplate.

F. Replace shaft cover (42) and screw (43) (or positioner

if so equipped).

g. Replace handwheel assembly in bracket (62) and

replace clevis pin (66), retaining clips (63), and

pivot pins (72).

H. Set and lock indicator arm (35) to indicate plug

position.

I. Check that handwheel operates valve through full

range of travel. There is a 1/2" adjustment available

at the end of the handwheel extension. Retract

handwheel, remove end cap (51) and cap screw

(55B). Rearrange stop (55A) and/or spacer (55C)

to obtain desired extension.

3.2 Bracket Subassembly – Model 33, size AC

only. Refer to section 3.1 for sizes B & C

3.2.1 Disassembly

When disconnecting actuator rod end bearing from

shaft arm, the ball is likely to rotate toward the bottom of

the valve body. Keep hands and tools away from the ball.

A. Remove screw (43) and shaft cover (42) or positioner

if so equipped.

B. Remove retaining clips (40), pivot pin (39).

C. Remove actuator mounting nuts (75) and washers

(76) and remove actuator from bracket (31).

D. If valve has handwheel, remove retainer clip (54-7)

and washer (54-4). Remove handwheel assembly

(54) from bracket.

E. Loosen cap screw (36) and indicator arm (35).

Remove packing flange stud nuts (24) and bracket

mounting stud nuts (26) and washers (18).

F. Scribe a witness mark on the lever (32) indicating

relative position to the slot in the end of the shaft (5).

Loosen cap screw (11).

g. Slide bracket (31) off studs and shaft, removing

indicator arm (35), lever (32) and packing flange (23).

H. Remove bearing (47) and grommet (106) from

bracket. Examine all parts for wear and/or damage.

Replace if necessary.

3.2.2 Reassembly

A. Replace ball bearing (47) and grommet (106) in the

housing (31). Note, the grommet has a recessed

area on one side. It should be installed with that side

should be toward the inside of the bracket.

B. Place ball plug (2) in closed position. Slide bracket

(31) partially over shaft. Ensure all packing box

parts are in place and then slide packing flange

(23) onto shaft. Slide lever (32) onto shaft on its

former position. Replace indicator arm (35). Slide

bracket fully onto mounting studs (26); ensure shaft

(5) is properly located in bearing (47). Replace lockwasher (18) and bracket mounting stud nuts (24)

and tighten. Replace packing flange stud nuts (24).

C. Pull shaft out to bottom against bearing. Replace

actuator and install washers (76) and nuts (75). Slide

lever (32) on shaft so that it is lined up with rod end

bearing (94). Tighten lever locking screw (33).

D. Place ball plug (2) in closed position. If valve action

is air to close, pneumatically stroke actuator fully.

Loosen rod end bearing locknut (93) and adjust rod

end bearing until holes in lever (32) and rod end

bearing (94) line up. Install pivot pin (39) and clips (40).

Do not exceed maximum air supply pressure specified

on the valve nameplate.

E. For both air to open and air to close action, stroke valve

fully to ensure proper closure of ball plug and operation

of valve. Tighten rod end bearing locknut (93).

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

8

Page 11

When stroking valve keep hands and equipment clear

of ball plug and seal ring to avoid injury or damage to

personnel or equipment. Do not exceed pressure

specified on the valve nameplate.

F. Replace shaft cover (42) and screw (43) (or positioner

if so equipped).

g. Replace handwheel assembly (54) in housing (31)

and replace washer (54-4) and retaining clip (54-7).

H. Set and lock indicator arm (35) to indicate plug

position.

I. Check that handwheel operates valve through full

range of travel.

3.3 Body Subassembly

3.3.1 Packing

Note: The packing follower should be held firmly, but

not too tightly against the packing.

Overtightening of the packing causes excessive friction

and may affect valve operation. The packing in a new

V-Max valve has not been tightened prior to shipment.

It is recommended that further adjustments be made

when the valve is put into service. If necessary to add

packing, proceed as follows:

Valve must be isolated and process pressure vented

before performing packing box maintenance.

3.3.1.1 Disassembly

A. Loosen and remove packing flange nuts (24) and

slide packing flange (23) and packing follower

(20) toward shaft lever (32).

Note: The lever (32) may be disconnected

from the actuator stem and pushed up against

the shaft bearing (47) (refer to section 3.1), if

necessary for clearance.

B. Using a packing hook, remove the top pieces of

packing rings.

3.3.1.2 Reassembly

A. Install new packing ring(s), making sure the skive

cut in adjacent packing rings is offset 120° apart.

B. Replace packing follower (20) packing box

flange (23) and packing nuts (24).

C. Evenly tighten packing nuts (24).

DO NOT overtighten packing nuts.

D. Place valve into service and tighten packing

nuts (24) only as much as necessary to stop any

leakage.

3.3.2 Seal Ring – MN-7 Seal

3.3.2.1 Disassembly

Note: Seal ring removal, inspection and reinstallation

must be done with the valve removed from the pipeline.

A. Remove screws (9) and washers (10), retainer

(3), MN-7 seal ring (8) and downstream back-up

ring (32).

B. Remove gasket (4) residue from body and

retainer taking care not to damage seal surfaces.

3.3.2.2 Reassembly

A. Move ball to the closed position.

Note: Use a light coating of Dow-Corning 111® or

equal on the ball plug to break in seat.

B. Replace backup ring (32), seal assembly, gasket

(4) and retainer (3). Take care that beveled edges

of seal (8) and backup ring (32) are facing the ball.

C. Replace set screws (9) and washers (10) and

tighten.

3.3.3 Seal Ring – Standard Metal Seal

3.3.3.1 Disassembly

Note: Seal ring removal, inspection and reinstallation

must be done with the valve removed from the pipeline.

A. Remove screws (9) and washers (10).

Note: The flexible metal seal assembly consists

of a seal ring (8), gasket (7), and backup ring (6).

B. Mark flexible metal seal ring (8) so that, if

reinstalled, the same side will be in contact

with the ball. Remove retainer, seal assembly

and downstream back-up ring (32). If difficulty is

encountered in removing seal assembly, rotate

the ball to open position and pull out the seal ring.

C. Remove gasket (4) residue from body and

retainer taking care not to damage seal surfaces.

D. If replacing MN-7 or flat metal seal with HD metal

version, upper and lower guide bushings (16,

17) should be replaced with satellite material.

3.3.3.2 Reassembly

Note: If retrofitting a valve originally equipped with

an MN-7 seal ring follow steps A through D. If valve

was originally supplied with a metal seal, please

proceed to step C.

A. Clean the contact surfaces of the ball plug

(2) with alcohol or other suitable degreaser to

facilitate application of the dry graphite spray

lubricant. If necessary, very mild abrasive pads

such as Scotch-Brite™ may be used to remove

any oxide layers on the ball plug (2).

B. Apply the dry graphite lubricant spray (Dow-

Corning 321®) in several light coats on the

plated seal contact surfaces of the ball plug (2).

Allow the graphite spray to dry fully – which will

produce a dull gray finish on the coated parts.

C. Move ball to the closed position.

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

9

Page 12

D. Replace downstream back-up ring (32), seal

assembly, gasket (4) and retainer (3). Take care

that beveled edge flexible metal seal (8) and

backup rings (6 & 32) are facing the ball.

E. Replace set screws (9) and washers (10) and

tighten.

3.3.4 Seal Ring – Heavy Duty Metal Seal

3.3.4.1 Disassembly

Note: Seal ring removal, inspection and reinstallation

must be done with the valve removed from the pipeline.

A. Remove screws (9) and washers (10).

Note: The Heavy Duty Metal Seal assembly

consists of a seal ring (8), radial seal (30) and

wave spring (31).

B. Note the orientation of the radial seal (30) and

wave washer (31) for reassembly.

C. Clean parts of any residue that remains from the

process. Take care not to damage or mark the

sealing surfaces of seal ring (8) or radial seal (30).

3.3.4.2 Reassembly

Note: If retrofitting a valve originally equipped with

an MN-7 seal ring follow steps A through D. If valve

was originally supplied with a metal seal, please

proceed to step C.

A. Clean the contact surfaces of the ball plug (2) with

alcohol or other suitable degreaser to facilitate

application of the dry graphite spray lubricant.

If necessary, very mild abrasive pads such as

Scotch-Brite™ may be used to remove any oxide

layers on the ball plug (2).

B. Apply the dry graphite lubricant spray (Dow-

Corning 321®) in several light coats on the

plated seal contact surfaces of the ball plug (2).

Allow the graphite spray to dry fully – which will

produce a dull gray finish on the coated parts.

C. Move ball to the closed position

D. Lubricate the Radial Seal (30) with Dow-Corning

111® Silicon grease (or equivalent) and install it

over the end of the Heavy Duty Seal Ring (8).

Note: The open lips of the radial seal (30) must

face AWAY from the seat bevel and ball.

E. Install the Wave Spring (31) over the end of the

Heavy Duty Seal Ring (8).

F. Insert the Seat Retainer (3) over the end of the

Seat (8) and apply even pressure to overcome

the resistance of the radial seal (30) until the

wave spring (31) is compressed.

g. Install the retainer/body gasket (4).

H. Install the seat (8), retainer (3), radial seal (101) and

wave spring (102) assembly into the body counterbore until contact is made with the ball plug (2).

I. Install retainer screws (9) and washers (1) and

tighten to secure the retainer and seal assembly

in the body.

3.3.5 Ball Plug

3.3.5.1 Ball Plug Disassembly

A. Remove bracket (see section 3.3.2).

B. Remove screws (9) and washers (10). Slide

the retainer (3) out of the valve body. Remove

seal assembly (refer to Para. 3.2.2.1 Seal Ring Disassembly).

C. Remove safety pin (27). Remove the shaft (5) from

the valve body. The packing (19), packing adaptor

(28) and packing follower (20) will slide out with the

shaft. If the shaft will not move, thread nuts (24) on

the packing studs, then place the packing flange

(23) on top of the nuts. Slide the lever (32) onto the

shaft (5) up against the packing flange (23) and

tighten screw (34). By unscrewing the packing nuts

(24) evenly, ample force is developed to move the

shaft (5). Once shaft has been started, it should be

possible to remove the shaft completely. If not, a

suitable size bolt screwed into the tapped hole on

the shaft end can be used as a shaft “puller”.

D. Remove nuts (13), end flange (14), pin shaft

(11) and gasket (15). If the pin shaft will not

move, push it out with a rod inserted through the

bonnet end of the valve.

E. Remove the ball (2) and separate the lower

bushing (16) from it. Remove the upper bushing

(17). If it sticks, the upper bushing (17) can be

pushed out with a rod of suitable size inserted

into the pin shaft end of the body.

F. Examine all parts for damage due to erosion,

corrosion, or wear. Replace the seal ring if

damaged, worn or distorted. Replace all defective

parts and all packing and gaskets. Clean the valve

parts thoroughly before reassembly. Remove

gasket (4) and (15) residue from body and

retainer taking care not to score sealing areas.

3.3.5.2 BaIl Plug Reassembly

Note: If installing a new ball plug into a valve equipped

with either the standard metal or Heavy Duty metal

seal rings, the ball plug must be first coated with dry

graphite lubricant as described in steps A and B. If

equipped with an MN-7 seal ring, proceed to step C.

A. Clean the contact surfaces of the ball plug

(2) with alcohol or other suitable degreaser to

facilitate application of the dry graphite spray

lubricant. If necessary, very mild abrasive pads

such as Scotch-Brite™ may be used to remove

any oxide layers on the ball plug (2).

B. Apply the dry graphite lubricant spray (Dow-

Corning 321®) in several light coats on the

plated seal contact surfaces of the ball plug (2).

Allow the graphite spray to dry fully – which will

produce a dull gray finish on the coated parts.

C. Replace lower bushing (16) in the ball and

position ball in the body. Replace gasket (15).

D. Lubricate pin shaft (11) and insert through body and

into the ball. Secure with end flange (14) and end

flange nuts (13). Tighten nuts alternately to assure

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

10

Page 13

tight seal against the gasket. (Recommended

lubricant SAF-T-EZE Anti-Seize or equal.)

E. Replace ring (29), and upper bushing (17)

on the shaft (5). Install shaft in the body and

engage the ball such that when the ball is in the

closed position, the machined slot in the shaft

end is vertical (perpendicular to the body axis).

Coat shaft below ring groove and bushing with

lubricant (SAF-T-EZE Anti-Seize or equal).

F. Install packing adaptor (28), bevel side out over

the shaft (5) and into the valve bonnet so that the

hole through the side of the adaptor is aligned

with the tapped hole through the bonnet for the

safety pin (27).

g. Apply pipe sealant to the safety pin, install into

bonnet and tighten.

Safety pin must engage hole in packing adaptor.

Test by manually pulling on shaft to verify pin

engagement.

H. Install packing (19) so that skive cut of each

piece of packing is offset approximately 120°

from that of adjacent piece.

I. Install packing follower (22) over shaft and into

bonnet with bevel side out. Install packing box

flange (23) and nuts (24).

J. Install seal ring and retainer assembly as

described in section 3.3.2, 3.3.3 or 3.3.4

depending on seal type.

K. Install mounting bracket (31) and lever (32).

Follow instruction 3.1.2 Bracket Reassembly.

L. Evenly tighten packing flange nuts (24) against

packing flange (23) before placing valve into

service.

DO NOT over tighten packing flange nuts. After

valve has been in service, retighten packing

flange nuts evenly until any leaks are stopped.

3.4 Actuator Subassembly.

3.4.1 Model 33, sizes B & C. Refer to section 3.7

for size AC actuators.

3.4.1.1 Disassembly

The upper diaphragm case (84) is under spring

tension. A warning tag (97) is attached to each of

the three (3) long cap screws (95). The tension nuts

(96) attached to cap screws (95) must be evenly

removed last. The following procedure must be

followed to avoid injury.

A. Isolate the valve, vent process pressure and

shut off all electrical, signal air and supply air

lines to the valve.

B. If equipped with a handwheel, it must be rotated

to the disengaged position.

C. Remove air supply piping to upper diaphragm

case (84).

D. Remove side covers (46).

E. Remove retaining clips (40) and remove pivot

pin (39) and spacers (69) (handwheel only) to

free rod end bearing (94).

F. Loosen and remove all short cap screws (86) and

hex nuts (87). Mark upper case (84) and lower

case (20) so that they can be reassembled with

the same orientation of air inlet and mounting bolts.

g. Loosen each tension nut (96) approximately

three full turns.

The upper diaphragm case (84) should separate

from the lower case (91) as the tension nuts are

loosened the three turns. If it does not, before

proceeding, separate the upper diaphragm case

(84) by tapping it around the circumference or

inserting a screwdriver between the upper (84)

and lower case (91). If the cases still do not

separate, check that the actuator stem is not

hung up inside the bracket. DO NOT PROCEED

WITH DISASSEMBLY UNLESS THE CASES

CAN SEPARATE FREELY.

H. Continue loosening the tension nuts (96) evenly

approximately three turns each time ensuring

that the upper diaphragm case (84) and

diaphragm (85) continue to separate.

Note: Continue Step H until the tension nuts (96)

can be easily removed by hand indicating the

upper diaphragm case (84) is not under spring

tension.

I. Remove tension bolts (95) and upper diaphragm

case (84).

J. Remove diaphragm (85) and diaphragm plate

subassembly from the actuator.

K. Remove retaining clip (78). Remove clevis pivot

pin (79). Inspect for damage and/or wear in

clevis (80), lever (32), clevis pins (79, 39) and

rod end bearings (94). Replace if necessary.

L. Clean all mating/sealing surfaces which will

come in contact with the diaphragm (85).

3.4.1.2 Reassembly

A. Connect rod end bearing (94) to diaphragm

plate clevis (80) by installing clevis pin (79) and

retaining clips (78). Ensure that the stem (77)

is installed such that the wrench flats are at the

end furthest from the diaphragm plate (88).

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

11

Page 14

B. Ensure spring (90) and spring guide (89) are

properly aligned in lower case (91) and install

the diaphragm plate and stem subassembly.

Replace diaphragm (85).

C. Align marks for correct orientation of upper

case (84) and lower case (91). Replace upper

diaphragm case (84) and install long cap screws

(95), warning plate (97) and tension nuts (96).

Note: These bolts must be equally spaced at

120° intervals.

D. Take up tension nuts (96) evenly and sufficiently

to allow installation of short cap screws (83) and

hex nuts (87).

E. Tighten tension nuts (96) and then tighten all hex

nuts (87) using a criss-cross tightening pattern.

Note: Nuts should be tightened only enough to

seal the diaphragm between the upper and lower

case. Do not overtighten.

F. Connect rod end bearing (94) to lever (32) by

installing pivot pin (39), spacers (69) (handwheel

only), and retaining clips (40).

g. Replace side covers (46) and reconnect signal

and supply lines.

H. Place back in service and, if so equipped, rotate

handwheel to desired position.

3.4.2 Actuator Subassembly – Model 33, size AC.

Refer to section 3.4.1 for sizes B & C. Figures 13,

14, 15 & 16.

3.4.2.1 Disassembly

The upper diaphragm case (84) is under spring

tension. A warning tag (97) is attached to each of

the three (3) long cap screws (95). The tension nuts

(96) attached to cap screws (95) must be evenly

removed last. The following procedure must be

followed to avoid injury.

A. Isolate the valve, vent process pressure and

shut off all electrical, signal air and supply air

lines to the valve.

B. If equipped with a handwheel, it must be rotated

to the disengaged position.

C. Remove air supply piping to upper diaphragm

case (84).

D. Remove covers (44 & 46).

E. Remove retaining clips (40) and remove pivot

pin (39) to free rod end bearing (94).

F. Loosen and remove all short cap screws (86) and

hex nuts (87). Mark upper case (84) and lower

case (91) so that they can be reassembled with

the same orientation of air inlet and mounting bolts.

g. Loosen each tension nut (95) approximately

three full turns.

The upper diaphragm case (84) should separate

from the lower case (91) as the tension nuts are

loosened the three turns. If it does not, before

proceeding, separate the upper diaphragm case

(84) by tapping it around the circumference or

inserting a screwdriver between the upper (84)

and lower case (91). If the cases still do not

separate, check that the actuator stem is not

hung up inside the bracket. DO NOT PROCEED

WITH DISASSEMBLY UNLESS THE CASES

CAN SEPARATE FREELY.

H. Continue loosening the tension nuts (95) evenly

approximately three turns each time ensuring

that the upper diaphragm case (84) and

diaphragm (85) continue to separate.

Note: Continue Step H until the tension nuts (95)

can be easily removed by hand indicating the upper

diaphragm case (84) is not under spring tension.

I. Remove tension bolts (95) and upper diaphragm

case (84).

J. Remove diaphragm (85) and diaphragm plate

subassembly from the actuator.

K. Remove retaining clip (78). Remove clevis pivot

pin (79). Inspect for damage and/or wear in

clevis (80), lever (32), clevis pins (79, 39) and

rod end bearings (94). Replace if necessary.

L. Clean all mating/sealing surfaces which will

come in contact with the diaphragm (85).

3.4.2.2 Reassembly

A. Connect rod end bearing (94) to diaphragm plate

clevis (80) by installing clevis pin (79) and retaining

clips (78). Ensure that the stem is installed such

that the wrench flats are at the end furthest from

the diaphragm plate (88).

B. Ensure spring (90) and spring guide (98) are

properly aligned in lower case (91) and install

the diaphragm plate and stem subassembly.

Replace diaphragm (85).

C. Align marks for correct orientation of upper

case (84) and lower case (91). Replace upper

diaphragm case (84) and install long cap screws

(95), warning plate (97) and tension nuts (96).

Note: These bolts must be spaced as equally as

possible.

D. Take up tension nuts (96) evenly and sufficiently

to allow installation of short cap screws (86) and

hex nuts (87).

E. Tighten tension nuts (96) and then tighten all hex

nuts (87) using a criss-cross tightening pattern.

Note: Nuts should be tightened only enough to seal

the diaphragm between the upper and lower case.

Do not overtighten.

F. Connect rod end bearing (94) to lever (32) by

installing pivot pin (39), and retaining clips (40).

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

12

Page 15

g. Replace covers (44 & 46) and reconnect signal

and supply lines.

H. Place back in service and, if so equipped, rotate

handwheel to desired position.

3.5 Handwheel Subassembly

3.5.1 Model 33 sizes B & C only. Refer to section

3.5.2 for size AC actuators.

3.5.1.1 Disassembly

Turn handwheel to disengage position before

proceeding with handwheel maintenance. Refer to

Figures 13 through 16.

A. Remove retaining clips (63) and push out pin (66).

Make sure bushing (65) remains in the arm (64).

B. Remove the pivot pins (72) and remove

handwheel subassembly.

C. Remove handwheel shaft subassembly (55)

retaining ring (59) and unscrew nut (58).

Remove needle bearing and race (60). Clean

and check needle bearing and race for signs of

wear. Replace if necessary.

D. Remove handwheel pivot (56) and thrust washer

(61). Check washer and replace if necessary.

Check 0-ring (57) and replace if necessary.

E. Clean ACME threads on handwheel (54) and

shaft S/A (55) and grease with Molykote G.

3.5.1.2 Reassembly (Figure 5)

A. Install thrust washer (61) and 0-ring (57). Apply

silicone lubricant sparingly to 0-ring.

B. Slide handwheel pivot (56) onto the handwheel

subassembly. Lubricate and install bearing race,

needle bearing and outer race.

C. Install nut (58) bevel side toward bearing race

and screw down tight. DO NOT OVERTIGHTEN.

Replace retaining ring (59). Correct assembly

should have the nut (58) touching the retaining

ring (47).

Do not rotate handwheel prior to replacing pivot

pins (72) into the handwheel mounting bracket (62).

D. Install assembly into handwheel mounting

bracket (62) and replace pivot pins (72).

E. Connect handwheel shaft S/A (55) to handwheel

(54) and to the lever arm with pin (66) and

replace clip (63).

3.5.2 Handwheel Subassembly – Model 33, Size

AC. Refer to section 3.5.1 for sizes B & C. Refer to

Figures 13, 14 & 16.

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

3.5.2.1 Disassembly

Turn handwheel to disengage position before

proceeding with handwheel maintenance.

A. Remove retaining ring (54-7) and shaft washer

(54-4).

B. Rotate Handwheel (54) counterclockwise until it

is removed from housing (31).

C. Clean ACME threads on handwheel shaft (54-3)

and grease with Molykote G.

3.5.2.2 Reassembly. Refer to Figures 13, 14 & 16.

A. Thread handwheel assembly (54) into housing

(31) until it extends through the housing and the

groove in the stem (54-3) is visible.

B. Place shaft washer (54-4) over stem (54-3).

C. Install retaining ring (54-7) into groove on stem

(54-3).

3.6 Diaphragm Replacement

Spring diaphragm actuators contain large forces due to

their preloaded powerful springs. Failure to carefully follow

this procedure can result in personal injury!

3.6.1 Model 33 sizes B & C only. Refer to section

3.6.2 for size AC actuators.

3.6.1.1 Disassembly

A. Relieve actuator pressure and disconnect air

supply. Do not remove pivot pin (39).

B. Verify that all three tension bolts (95) and nuts

(96) are in place and secure.

C. Remove nuts (87) and cap screws (86) following

a criss-cross pattern.

D. Verify actuator stem (77) and rod end (94) are

securely connected to lever (32) through pivot

pin (39) and that retaining clips (40) are in place.

E. Loosen tension nuts (96) evenly in sequence.

Do not exceed three turns of any one nut (96)

before proceeding to the next one. Do not vary

the sequence.

Failure to evenly unload tension nuts may result

in personal injury!

F. Continue loosening tension nuts (96) until further

loosening of the tension nuts (96) is no longer

accompanied by an increase in separation of the

upper diaphragm case (84) from the lower case

(91). At this point the tension nuts (96), bolts (95)

and warning plates (97) can be removed.

13

Page 16

g. Remove the upper diaphragm case (84) and

diaphragm (85).

The diaphragm plate (88) remains under spring

load.

3.6.1.2 Reassembly

A. Ensure that sealing surfaces of diaphragm cases

(84) and (91) are clean and free of any dirt or

debris. Check that there are no foreign objects that

may interfere with travel or damage diaphragm.

B. Install diaphragm (85) on diaphragm plate (88).

Align bolt holes with holes in lower case (91).

C. Install three tension bolts (95) with warning

plates (97) into upper case (84). Ensure bolts

are equally spaced at 120° to each other.

D. Mount upper case (84) onto diaphragm plate

(88) such that the tension bolts pass through

holes in diaphragm (85) and lower case (91).

E. Install tension nuts (96) finger tight onto tension

bolts (95).

F. Tighten each tension nut (96) three turns before

proceeding to the next to ensure actuator spring

(90) is evenly loaded. Continue until the diaphragm

is firmly sandwiched between the flanges of the

upper and lower diaphragm cases. Torque tighten

tension bolts to 50 in. lbs.

g. Install cap screws (86) and nuts (87). Torque

tighten to 50 in. lbs. in a criss-cross pattern. As this

will tend to unload the tension bolts (96) repeat

torque tightening of tension bolts and cap screws

(86) to 50 in. lbs. in a criss-cross pattern until joint

is evenly loaded to specified torque values.

H. Reconnect air supply.

I. Stroke actuator to confirm operation.

3.6.2 Model 33 size AC actuators only. Refer to

section 3.6.1 for sizes B & C.

3.6.2.1 Disassembly

A. Relieve actuator pressure and disconnect air

supply. Do not remove pivot pin (39).

B. Verify that all three tension bolts (95) and nuts

(96) are in place and secure.

C. Remove nuts (87) and cap screws (86) following

a criss-cross pattern.

D. Verify actuator stem (15) and rod end (94) are

securely connected to lever (32) through pivot

pin (39) and that retaining clips (40) are in place.

E. Loosen tension nuts (96) evenly in sequence.

Do not exceed three turns of any one nut (96)

before proceeding to the next one. Do not vary

the sequence.

Failure to evenly unload tension nuts may result

in personal injury!

F. Continue loosening tension nuts (96) until further

loosening of the tension nuts (96) is no longer

accompanied by an increase in separation of the

upper diaphragm case (84) from the lower case

(91). At this point the tension nuts (96), bolts (95)

and warning plates (97) can be removed.

g. Remove the upper diaphragm case (84) and

diaphragm (85).

The diaphragm plate (88) remains under spring

load.

3.6.2.2 Reassembly

A. Ensure that sealing surfaces of diaphragm cases

(84) and (91) are clean and free of any dirt or

debris. Check that there are no foreign objects that

may interfere with travel or damage diaphragm.

B. Install diaphragm (85) on diaphragm plate (88).

Align bolt holes with holes in lower case (91).

C. Install three tension bolts (95) with warning plates

(97) into upper case (84). Ensure bolts are equally

spaced around the circumference of the case.

D. Mount upper case (84) onto diaphragm plate

(88) such that the tension bolts pass through

holes in diaphragm (85) and lower case (91).

E. Install tension nuts (96) finger tight onto tension

bolts (95).

F. Tighten each tension nut (86) three turns before

proceeding to the next to ensure actuator spring

(90) is evenly loaded. Continue until the diaphragm

is firmly sandwiched between the flanges of the

upper and lower diaphragm cases. Torque tighten

tension bolts to 50 in. lbs.

g. Install cap screws (86) and nuts (87). Torque

tighten to 50 in. lbs. in a criss-cross pattern. As this

will tend to unload the tension bolts (95) repeat

torque tightening of tension bolts and cap screws

(86) to 50 in. lbs. in a criss-cross pattern until joint

is evenly loaded to specified torque values.

H. Reconnect air supply.

I. Stroke actuator to confirm operation.

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

14

Page 17

ALTERNATE VIEW C

SCALE 2 : 1

SECTION A-A

ALTERNATE VIEW C

SCALE 2 : 1

Figure 2 - general Assembly

DETAIL C

SCALE 2 : 1

DETAIL B

SCALE 2 : 1

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

15

Page 18

Figure 3 - Sizes B & C Bracket and Linkage

Figure 5 - Handwheel Detail, Actuator Sizes B & C

Figure 4 - Handwheel general Assembly,

Actuator Sizes B & C

Figure 7 - Handwheel Lever Detail,

Actuator Sizes B & C

Figure 6 - Handwheel Bracket Detail,

Actuator Sizes B & C

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Figure 8 - Handwheel Clevis Detail,

Actuator Sizes B & C

16

Page 19

Figure 9 - Actuator general Assembly,

Actuator Sizes B & C

Figure 10 - Lever Position Air to Open,

Actuator Sizes B & C

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Figure 11 - Lever Position Air to Close,

Actuator Sizes B & C

17

Page 20

Figure 12 - Position Indicator Detail,

Actuator Sizes B & C

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Figure 13 - Size AC Actuator

18

Page 21

Figure 14 - Size AC Actuator Bottom View

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Figure 15 - Size AC Actuator Linkage Detail

19

Page 22

Figure 16 - Handwheel Assembly, Size AC Actuator

Do Not

Insulate

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Figure 17 - Insulation detail

20

Page 23

Table 1 – Body Parts List

Table 2 – Bracket and Linkage Parts List

Ref. No. Description

1 Body

2 Ball Plug

3 Retainer (ISA S75.04)

Retainer (ANSI B16.10)

4 Gasket (Retainer/Body)

5 Shaft

6 Backup Ring (Std. Metal Seal)

7 Gasket (Std. Metal Seal)

8 Seal Ring

9 Slot Button Head Screw

10 Flat Washer

11 Pin Shaft

12 Stud, End Flange

13 Nut, End Flange

14

15

16

17

18

19

20

21

22

23 Packing Box Flange

24 Nut, End Flange

25 Stud, Packing Flange

26 Stud, Bonnet

27 Safety Pin

28 Packing Adapter

29 Shaft Ring

30 Radial Seal

31

32

End Flange

Gasket, Pin Shaft

Lower Bushing

Upper Bushing

Lockwasher

Packing

Packing Follower

O-Ring

O-Ring

Wave Spring

Backup Ring

Ref. No. Description

33 Cap Screw

34 Lockwasher

35 Indicator Arm

36 Machine Screw

37 Hex Nut

38 Indicator Dot

39 Pivot Pin

40 Retaining Clip

41 Front Cover S/A

42 Shaft Cover

43 Machine Screw

44 Bottom Cover

45 Boss Cover

46 Side Cover

47

48

49

50

99

100

101

102

103

104 Roller

105 Thread Plug

Bearing

Hole Cover

Yoke

Lever

Lockwasher

Screw

Hex Nut

Adjusting Screw

Pin

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

21

Page 24

Table 3 – Handwheel Parts List

Table 4 – Actuator Parts List

Ref. No. Description

32 Lever Set

33 Lockwasher

34 Cap Screw

51 End Cap

52 Plate

53 Screw

54 Handwheel S/A

Handwheel

*

54-1

Lock, Handwheel

*

54-2

Handwheel Shaft

*

54-3

Washer

*

54-4

Key

*

54-5

Screw

*

54-6

Retaining Ring

*

54-7

54-8

*

Handwheel Plate

*

54-9

55

55A

55B

55C

56

57

58

59 Retaining Ring

60 Needle Bearing

60A Bearing Race

61 Thrust Washer

62 Handwheel Bracket

63 Retaining Clip

64 Lever Arm

65 Lever Arm Bearing

66

67

68

69

70

71

72

Size AC Actuator Only

*

Screw

Handwheel Shaft S/A

Handwheel Stop

Cap Screw

Spacer

Handwheel Pivot

O-Ring

Locknut

Clevis Pin

Guide

Lever Arm Pin

Spacer

Cap Screw

Lockwasher

Pivot Pin

Ref. No. Description

75 Hex Nut

76 Lockwasher

77 Stem

78 Clip

79 Clevis Pin

80 Clevis

83 Button Head Cap Screw

84 Upper Diaphragm Case

85 Diaphragm

86 Cap Screw

87 Nut

88 Diaphragm Plate

89 Spring Guide

90 Spring

91

92

93

94

95

96

97

98

Lower Diaphragm Case

Stop

Nut

Rod End Bearing

Tension Bolt

Tension Nut

Warning Plate

Spring Button

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

22

Page 25

Table 5 – Line Bolting (Inlet Side)

Size ANSI

in DN in mm in mm

1 25

1-1/2 40

2 50

3 80

4

6 150

8 200

10 250

12 300

100

150 2 1/2" 64 3 1/2" 89

300 3" 76

150 3" 76 5" 130

300 3 1/2" 89 – –

150 3 3/4" 95 5 1/2" 140

300 4" 100 – –

150 4" 100 5 1/4" 134

300

150 4"

300 5" 130 – –

150 4 1/2" 114 6" 153

300 6" 153 – –

150 4 3/4" 121 6 3/4" 172

300 6" 153 – –

150 5 1/4" 134 6 1/2" 165

300 7" 178 – –

150 5 1/2" 140 6" 153

300 7 1/2" 191 – –

ISA S75.04

Face to Face

121

4 3/4"

100

ANSI B16.10

Short Pattern

Face to Face

–

– –

5 1/4"

–

134

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

23

Page 26

Notes

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

24

Page 27

Notes

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

25

Page 28

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CANADA

Ontario

Phone: +905-335-3529

Fax: +905-336-7628

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Viersen

Phone: +49-2162-8170-0

Fax: +49-2162-8170-280

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +31-15-3808666

Fax: +31-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8139-200

Fax: +971-4-8838-038

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Dresser Direct

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Dresser Flow Technologies

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

California

Phone: +1-562-941-7610

Fax: +1-562-941-7810

About Dresser, Inc.

Dresser Inc. is a global leader in providing highlyengineered infrastructure products for the global energy

industry. Leading brand names within the Dresser portfolio

include Dresser Wayne® retail fueling systems, Waukesha®

natural gas-fired engines, Masoneilan® control valves, Consolidated® pressure relief valves, and ROOTS® blowers

and rotary gas meters. The company has manufacturing

and customer service facilities strategically located

worldwide and a sales presence in more than 150 countries.

www.dresser.com

Dresser Masoneilan

Dresser, Inc., Flow Technologies

10343 Sam Houston Park Drive

Houston, Texas 77064 U.S.A

T. +1-281-671-1640

F. +1-281-671-1735

E. sales@ masoneilan.com

About Dresser Masoneilan

Dresser Masoneilan, headquartered in Houston, Texas, has

been the leading global partner in process control valves

and solutions for more than 100 years. A business segment

of Dresser, Inc., the company delivers customized products,

services and diagnostic solutions for oil and gas, process

and power generation applications. www.dresser.com

© 2010 Dresser, Inc. All rights reserved.

EM36005 07/10

www.dresser.com

Loading...

Loading...