Dresser Masoneilan SVI II AP-2, Masoneilan SVI II AP-3 Quick Start Manual

Warranty

Items sold by Dresser® are warranted to be free from defects in materials and workmanship

for a period of one year from the date of shipment provided said items are used according

to Dresser recommended usages. Dresser, Inc. reserves the right to discontinue manufac

ture of any product or change product materials, design or specifications without notice. This

instruction manual applies to the following instruments and approved software: SVI ® II AP

Positioner and ValVue® software.

The SVI II AP series positioners are warranted for use only with interface software approved

by Dresser Inc. Consult Masoneilan Dresser factory locations for approved software listing.

About this Guide

This Quick Start Guide applies to the following instruments and approved software:

SVI II AP -2 through SVI II AP-3

- with Firmware version 3.1.1

- with ValVue® version 2.4 or greater

- with AMS® ValVue® SNAP-ON® version 2.4 or greater

- with Model HH375 HART® Communicator with DD published for SVI II AP

- (Masoneilan Device type 202, 0, 00CA)

The information in this manual is subject to change without prior notice.

The information contained in this manual, in whole or part, shall not be transcribed or copied

without Masoneilan’s written permission.

In no case does this manual guarantee the merchantability of the positioner or the software

or its adaptability to a specific client needs.

Please report any errors or questions about the information in this manual to your local

supplier or visit www.masoneilan.com.

Copyright

All software is the intellectual property of Dresser, Inc.

The complete design and manufacture is the intellectual property of Dresser, Inc.

Masoneilan®, FVP®, SVI®, and ValVue

®

are registered trademarks of Dresser, Inc.

All information contained herein is believed to be accurate at the time of publication

and is subject to change without notice.

Copyright 2006 by Dresser, Inc. All rights reserved.

PN 055201-167 REV C

i

This section provides safety information including safety symbols that

are used on the SVI II AP and the safety symbol definition.

Important - Please Read Before Installation!

Safety

Symbols

SVI II AP instructions contain DANGER, WARNING, and CAUTION

labels and Notes, where necessary, to alert you to safety related or

other important information. Read the instructions carefully before

installing and maintaining your instrument. DANGER and WARNING

hazards are related to personal injury. CAUTION hazards involve

equipment or property damage. Operation of damaged equipment can,

under certain operational conditions, result in degraded process

system performance that can lead to injury or death. Total compliance

with all DANGER, WARNING, and CAUTION notices is required for

safe operation.

This is the safety alert symbol. It alerts you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a potentially hazardous situation, which if not avoided could

result in death or serious injury.

Indicates a potentially hazardous situation, which if not avoided could

result in serious injury.

Indicates a potentially hazardous situation, which if not avoided could

result in minor or moderate injury.

Safety Information

Masoneilan Dresser SVI II AP Quick Start Guide

ii

When used without the safety alert symbol indicates a potentially

hazardous situation, which if not avoided could result in property

damage.

Note:

Indicates important facts and conditions.

SVI II AP

Product

Safety

The SVI II AP positioner is intended for use with industrial compressed

air or, natural gas systems only. Ensure that an adequate pressure

relief provision is installed when the application of system supply

pressure could cause peripheral equipment to malfunction. Installation

must be in accordance with local and national compressed air and

instrumentation codes.

Products certified as explosion proof or flame proof equipment or for

use in intrinsically safe installations MUST BE:

Installed, put into service, used and maintained in

compliance with national and local regulations and

in accordance with the recommendations contained

in the relevant standards concerning potentially

explosive atmospheres.

Used only in situations that comply with the certifi-

cation conditions shown in this document and after

verification of their compatibility with the zone of

intended use and the permitted maximum ambient

temperature

Installed, put into service and maintained by quali-

fied and competent professionals who have undergone suitable training for instrumentation used in

areas with potentially explosive atmospheres.

Before using these products with fluids other than air or for nonindustrial applications, consult Dresser, Inc. This product is not

intended for use in life support systems.

Under certain operating conditions, the use of damaged instruments

could cause a degradation of the performance of the system which may

lead to personal injury or death.

Use only genuine replacement parts which are provided by the

manufacturer, to guarantee that the products comply with the essential

safety requirements of the European Directives mentioned on the front

cover.

Changes to specifications, structure, and compo-

nents used may not lead to the revision of this manual unless such changes affect the function and

performance of the product.

iii

Contents

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

SVI II AP Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Section 1 Installation and Set Up . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using the Quick Start Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting the SVI II AP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Necessary Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the SVI II AP Remote Position Sensor . . . . . . . . . . . . . . . . 4

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connecting the Tubing and Air Supply . . . . . . . . . . . . . . . . . . . . . . . . 7

Single Acting Positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Double Acting Positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting the Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the SVI II AP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting to the Control Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SVI II AP Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grounding Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compliance Voltage in Single Drop Current Mode . . . . . . . . . . . . . . . 12

Verify Wiring and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Masoneilan Dresser SVI II AP Quick Start Guide

iv

SVI II AP Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tools Needed for Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 14

Display Cover Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . 15

Removing the SVI II AP Display Cover . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the SVI II AP Display Cover . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 2 Check Out, Configuration and Calibration . . . . . . 17

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Check Out Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Actuator, Linkages, or Rotary Adapter . . . . . . . . . . . . . . . . . . . . . . . 17

Verify Mounting and Linkage Adjustment . . . . . . . . . . . . . . . . . . . . . 18

Checking the Magnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Performing a Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using ValVue 2.4 to Check Magnet Position . . . . . . . . . . . . . . . . . . . . 19

Checking the Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Checking the Electronic Module Connections . . . . . . . . . . . . . . . . . . . 20

Making Connections to the Terminal Board . . . . . . . . . . . . . . . . . . . . . 22

Operational Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting to the Current Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pushbutton Locks and Configuration-Lock Jumper . . . . . . . . . . . . . . . 23

Hardware Configuration Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Powering Up the SVI II AP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ValVue 2.4 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ValVue 2.4 Lite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ValVue 2.4 Full Trial Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pushbuttons and Local Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuration with Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Viewing Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Viewing Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

VIEW DATA Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

v

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Auto Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Check-out with a HART Handheld Communicator . . . . . . . . . . . . . . . . 31

Appendix A Specifications and References . . . . . . . . . . . . . 1

Physical and Operational Specifications . . . . . . . . . . . . . . . . . . . . . . 1

Hazardous Location Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Masoneilan Dresser SVI II AP Quick Start Guide

vi

1

1

Installation and Set Up

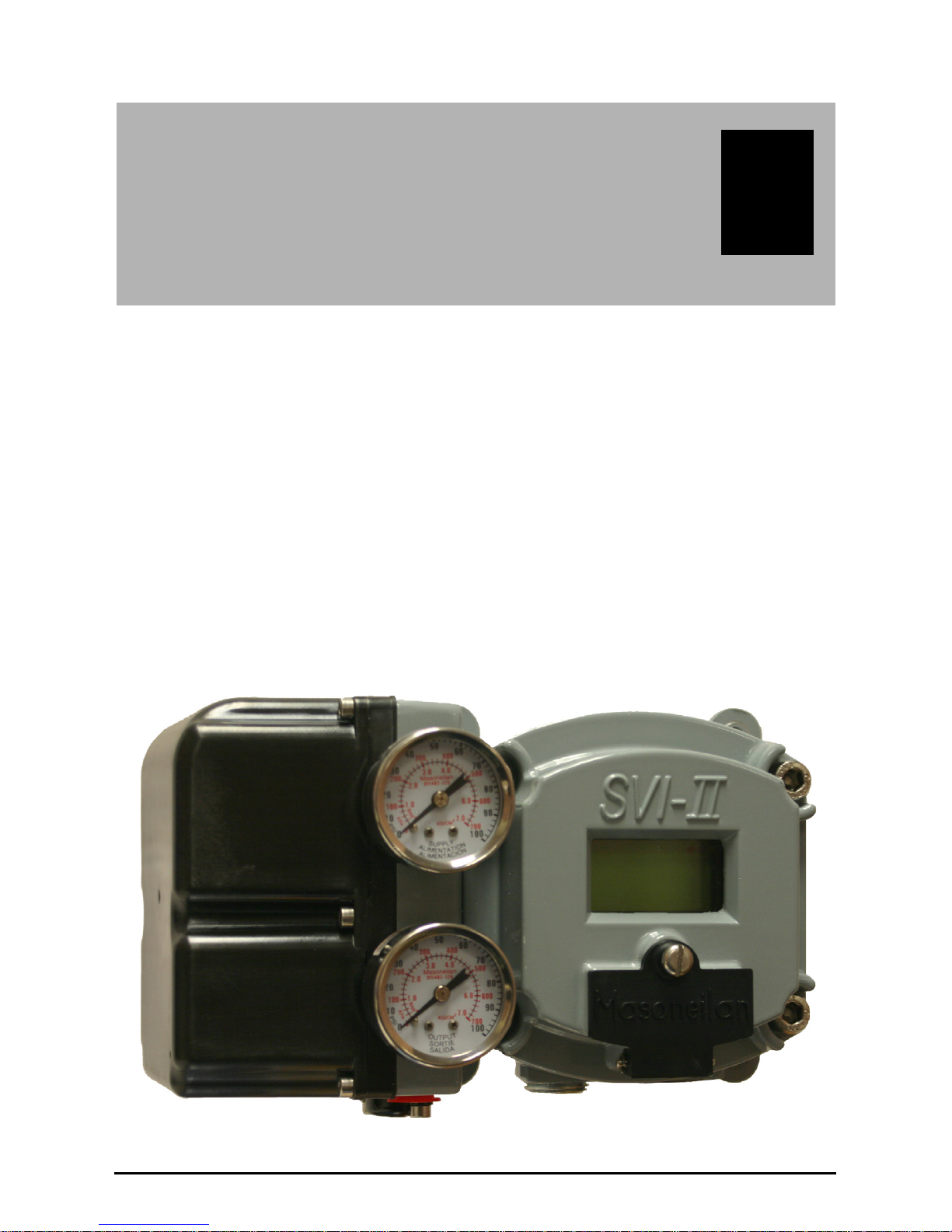

Introduction The SVI

®

II AP (Smart Valve Interface) is the next generation of

Masoneilan’s intelligent digital valve positioners. The SVI II AP is a

compact, industrial tough, high performance, digital valve positioner

that combines a local display with remote communication and

diagnostic capabilities. The SVI II AP is available with options needed

to fulfill virtually all application requirements and communicates using

the HART® protocol. The SVI II AP offers:

Extreme Accuracy

Extreme Reliability

Extreme Digital Precision

Automated Valve Commissioning

Precise, Quick, Responsive Control of Valve

Position

Sophisticated Valve Diagnostics

Figure 1 SVI II AP

SVI II AP Cover

SVI II AP Assembled

Electronics

Module

Pneumatic Train and

Cover (I/P Module, Relay)

Manifold

Relay

I/P

Masoneilan Dresser SVI II AP Quick Start Guide

2

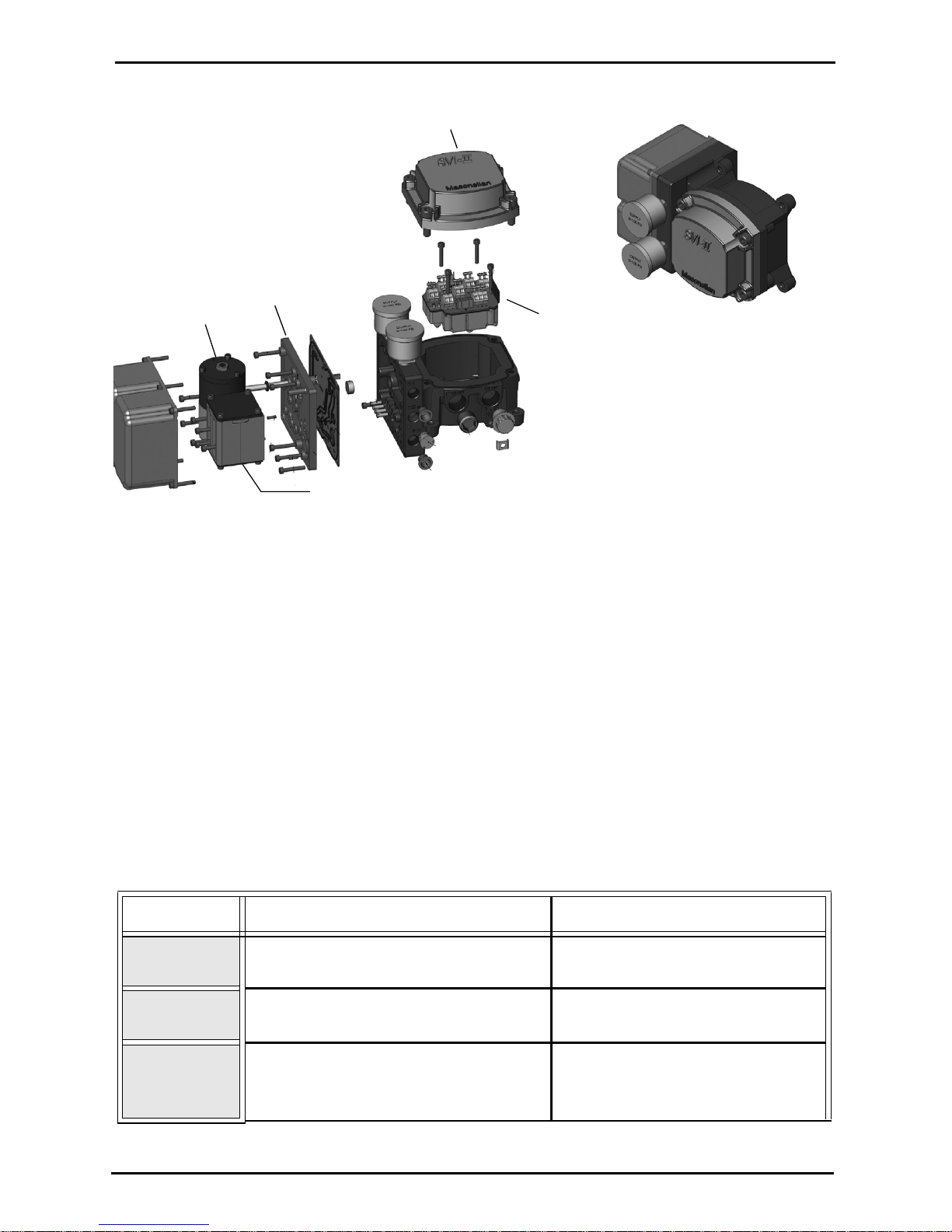

Figure 2 SVI II AP Components

Using the

Quick Start

Guide

The SVI II AP Quick Start Guide is intended to help an experienced

Field Engineer install, setup, and calibrate an SVI II AP in the most

efficient manner possible. This document provides basic installation

and setup instructions and is not intended to replace the in-depth

information contained in the SVI II AP Instruction Manual EW2002-AP.

If you experience problems that are not documented in this guide refer

to the Masoneilan SVI II AP Instruction Manual EW2002-AP, call your

local Masoneilan representative, or go to www.masoneilan.com. Sales

offices are listed on the last page of this document

The steps necessary to complete the SVI II AP installation and software

setup are outlined in Table 1 below.

Table 1 SVI II AP Installation Steps

Step No. Procedure Reference

1 Attach mounting bracket to the

actuator.

See page 3 for rotary valve and

reciprocating valve instructions.

2 Install the SVI II AP magnetic

assembly (rotary valves only).

See page 3 for instructions.

3 Assemble the SVI II AP on the

bracket that is mounted to the valve

actuator.

See page 3 for rotary valve and

reciprocating valve instructions.

Installation and Set Up Mounting the SVI II AP

3

Failure to adhere to the requirements listed in this manual may cause

loss of life and property.

Before installing, using, or carrying out any maintenance tasks

associated with this instrument, READ THE INSTRUCTIONS

CAREFULLY. (Refer to

“Hazardous Location Installation” on

page A-7 of this guide for detailed instructions.)

Mounting the

SVI II AP

This guide provides installation instructions for mounting an SVI II AP

on both rotary and reciprocating actuated valves. The mounting

process can be broken down into the following:

Attach the mounting bracket to the actuator.

Install the magnetic assembly.

Assemble the SVI II AP on the mounting bracket.

Note: The SVI II AP should be mounted with the conduit connections

down in order to facilitate drainage of condensate from the con

-

duit.

4 Install the Remote Position Sensor, if

necessary.

See page 4 for instructions.

5 Connect the pneumatic tubing to the

SVI II AP.

See page 7 for instructions.

6 Connect the air supply to the SVI II

AP.

See page 9 for instructions.

7 Connect the positioner to the HART

Control Loop segment by installing

the SVI II AP wiring.

See page 10 for instructions.

8 Configure/calibrate using ValVue.2.4 See page 24 and page 28 for

instructions

Configure/calibrate using a HART

Hand Held Communicator

See page 31 for instructions.

Table 1 SVI II AP Installation Steps

Step No. Procedure Reference

Masoneilan Dresser SVI II AP Quick Start Guide

4

Necessary Precautions

To avoid injury or the process being affected when installing or

replacing a positioner on a control valve, ensure that:

If the valve is located in a hazardous area make

sure the area has been certified as “safe” or that all

electrical power to the area has been disconnected

before removing any covers or disconnecting any

leads.

Shut off air supply to the actuator and to any valve

mounted equipment.

Ensure the valve is isolated from the process by

either shutting off the process or using bypass

valves for isolation. Tag shutoff or bypass valves to

guard against a “turn-on” while work is in progress.

Bleed air from actuator and check that valve is in its

unenergized position.

It is now safe to disconnect and remove any valve mounted equipment

that is being replaced.

For the procedure to mount rotary and reciprocating valves, refer to the

Mounting Instructions contained in the valve’s Mounting Box kit.

Installing the

SVI II AP

Remote

Position

Sensor

An option that is available for the SVI II AP is the Remote Position

Sensor. The Remote Position Sensor, is a remotely mounted positionsensing device, that is connected electrically to an SVI II AP valve

positioner. It is used as position feedback in applications where direct

mounting of an SVI II AP to a valve actuator is not practical due,

typically but not limited to, extreme vibration, heat or radiation.

The Remote Position Sensor is a potentiometer located in an enclosure

which can be mounted on a valve or damper to indicate stem position

when connected to a suitable receiver. There is a three wire connection

provided on a screw terminal block to interconnect to the receiving

device.

The SVI II AP Remote Position Sensor is suitable for installation

outdoors in an industrial environment. Mounting kits are provided to

permit mounting on a variety of valves.

Do not remove the instrument cover or connect to an electrical circuit in

a Hazardous Area unless the power is disconnected.

Comply with current national and local regulations

for electrical installation work.

Installation and Set Up Installing the SVI II AP Remote Position Sensor

5

Comply with national and local explosive

atmosphere regulations.

Before carrying out any work on the device, power

off the instrument or make sure that the locale

conditions for potentially explosive atmosphere

permit the safe opening of the cover.

Installation Procedure

For the Remote Position Sensor installation procedure refer to the

mounting instructions provided with the Remote Position Sensor.

1. Remove the cover from the Remote Position Sensor

assembly by turning the cover in a counter-clockwise (fac

-

ing the cover) direction.

2. Connect the Remote Position Sensor to the mounting

bracket by inserting four M6 x 20 mm Socket Head Cap

Screws through the appropriate screws holes (according

to the valve) on the Remote Position Sensor bracket and

using a 3⁄16 inch Hex Key with tee handle.

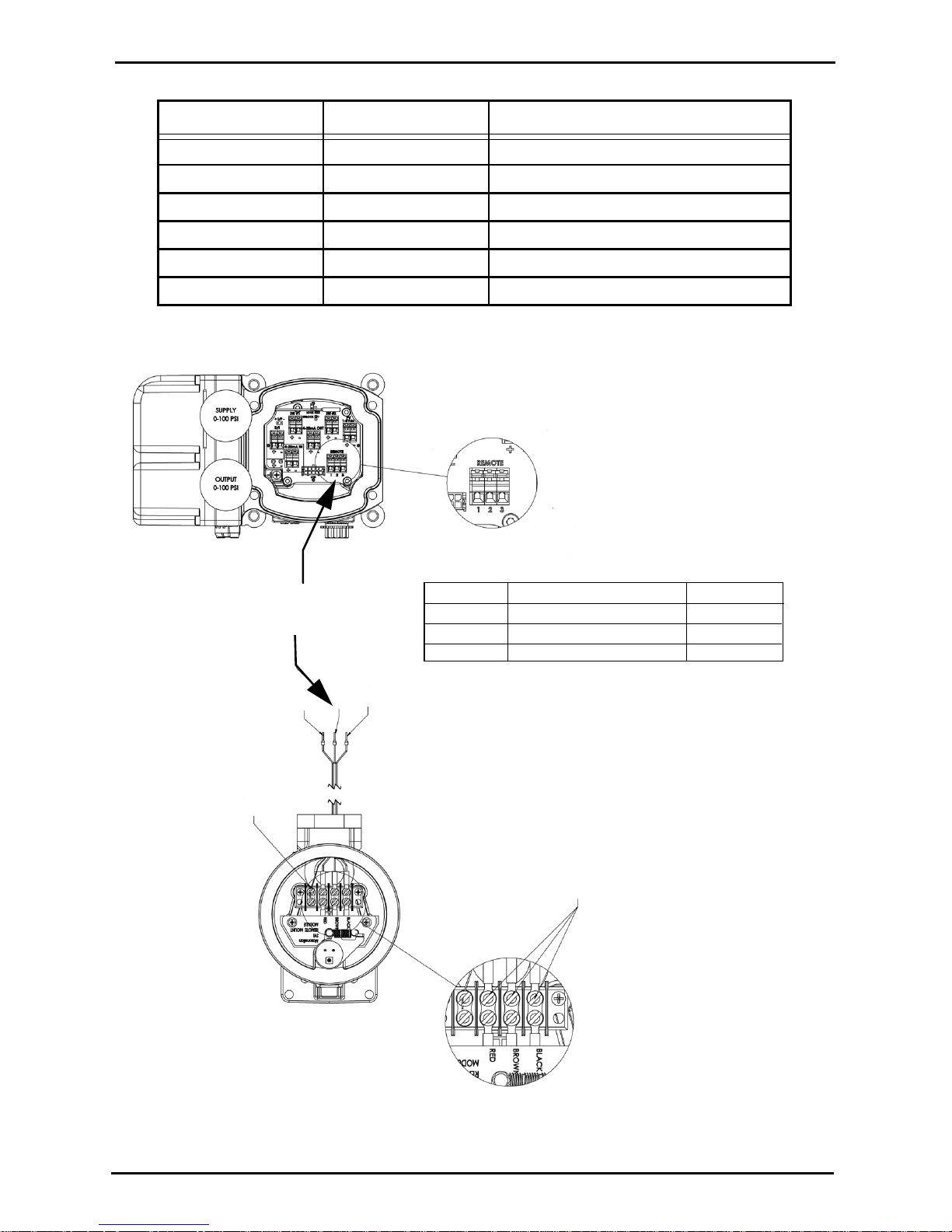

3. Route the instrument cable from the SVI II AP to the

Remote Position Sensor (see Figure 3 on page 6 for

installation instructions).

4. Thread the cable through the conduit at the bottom of the

Remote Position Sensor.

5. Using a blade screwdriver, loosen the screws on the

terminal block and connect the black, brown and red wires

to the appropriate labelled connectors.

6. Tighten the screws.

7. Attach the feedback lever to the Remote Position Sensor

shaft. From the cover side, the lever should be pointing to

the left for reciprocating valves and to the right for rotary

valves.

8. Place the Remote Position Sensor on the mounting

bracket.

9. Attach the Remote Position Sensor and secure the

turnbuckle to the lever ensuring that the shaft at the rear of

the Remote Position Sensor is inserted into the valve

actuator. (Refer to

Table 2 “Remote Position Sensor

Turnbuckle Length” below for turnbuckle length.)

10. Replace the Remote Position Sensor cover.

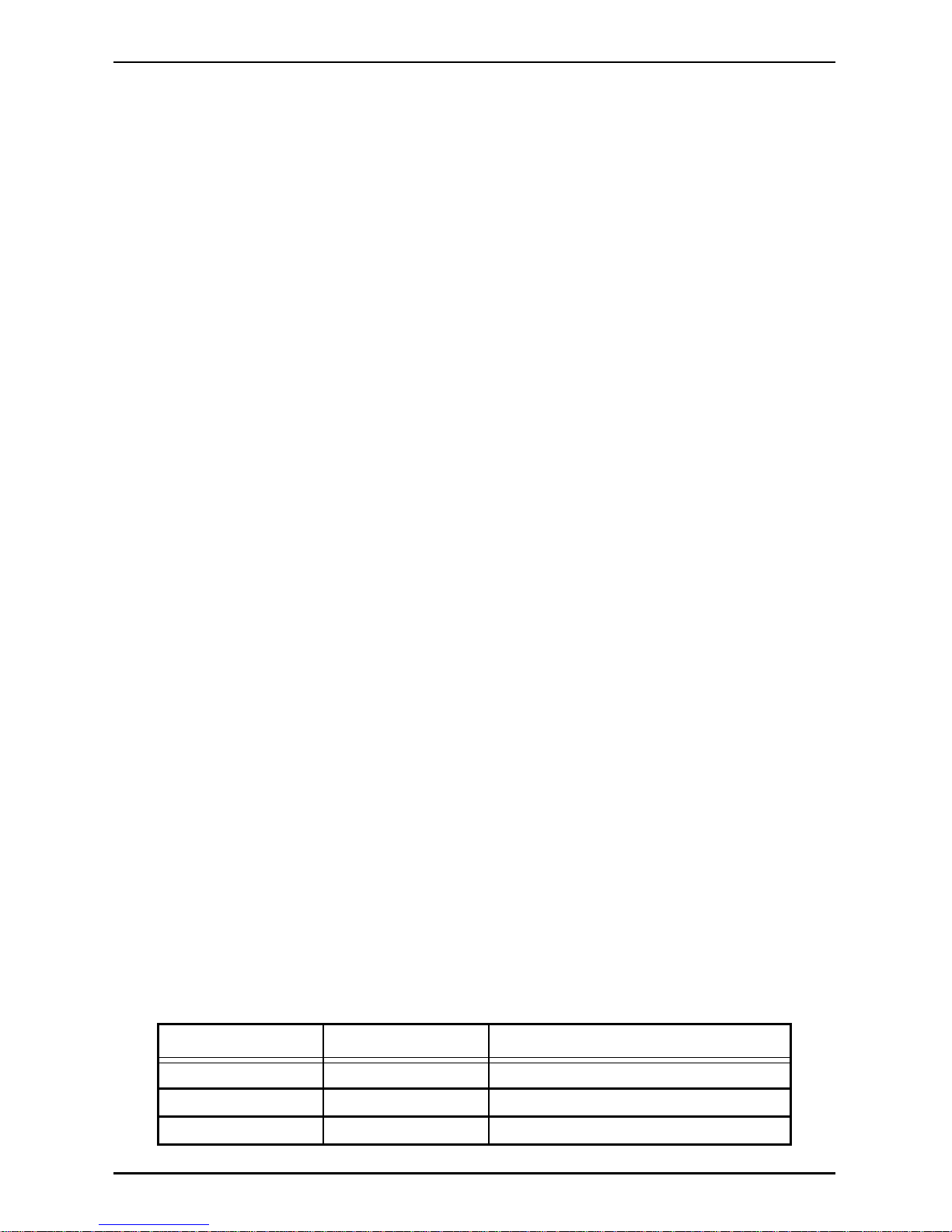

Table 2 Remote Position Sensor Turnbuckle Length

Actuator Size Stroke Turnbuckle Length

6 and 10 0.5 - 0.8 inch 1.25 inch

10 0.5 - 0.8 inch 1.25 inch

10 >0.8 – 1.5 inch 1.25 inch

Masoneilan Dresser SVI II AP Quick Start Guide

6

Figure 3 SVI II AP Remote Position Sensor Installation

16 0.5 - 0.8 inch 2.90 inch

16 >0.8 – 1.5 inch 2.90 inch

16 >1.5 – 2.5 inch 2.90 inch

23 0.5 - 0.8 inch 5.25 inch

23 >0.8 – 1.5 inch 5.25 inch

23 >1.5 – 2.5 inch 5.25 inch

Step 1

Connect Drain Wire

to Open Terminal

Step 2

When connecting cable to

Remote Position Sensor make sure wire

colors match:

- Red to Red

- Brown to Brown

- Black to Black

Step 3

Insert Ferrules into “Remote”

Terminal Block according to

Wire Color SVI II AP Terminal Number Function

Red

Brown

Black

1

2

3

Positive

Signal

Ground

the chart at the right:

Remote Terminal Block

123

Table 2 Remote Position Sensor Turnbuckle Length

Actuator Size Stroke Turnbuckle Length

Installation and Set Up Connecting the Tubing and Air Supply

7

Connecting

the Tubing

and Air

Supply

The last step in hardware installation for the SVI II AP is to connect the

air supply to the positioner. This section describes the process for

connecting the tubing and air supply to a single and double acting

positioner.

Isolate the valve from the process and disconnect air tubing from the

positioner. Disconnect air fully to avoid injury or process damage.

1. Install the pneumatic tubing using a regulated, clean,

instrument air supply to the air supply port (S

←)

2. For a single acting actuator - pipe the outbound air from

the output pressure port (←I) to the valve actuator.

3. For a double acting actuator - pipe the air going out of

each side of valve actuator. Use both output pressure port

one (

←I) for one side of the actuator and output pressure

port two (←II) for the other side of the actuator.

4. Connect air supply and actuator outports (1⁄4 inch NPT)

Supply pressure for single acting SVI II AP:

20 -100 psi (1.4 - 6.9 bar) (138 - 690 kPa)

Supply pressure for double acting SVI II AP:

20 - 150 psi (1.4 - 10.4 bar) (138 - 1035 kPa)

Minimum tubing diameter 1⁄4 inch (6mmx4mm)

Note: The SVI II AP Digital Positioner is designed to operate with

clean, dry, oil-free, instrument grade air to ANSI-ISA-57.3 1975

(R1981) or ISA-S7.3-1975 (R1981) or with a sweet natural gas

supply (SVI II AP models SVI II AP-2 through SVI II AP-3).

Table 3

Dew Point At least 18° F (10° C) below minimum anticipated ambient

temperature

Particulate Matter Filtered to 5 microns

Oil Content Less than 1 ppm w/w

Contaminants Free of all corrosive contaminants

Air Supply Requirements

Masoneilan Dresser SVI II AP Quick Start Guide

8

Single Acting Positioner

The supply and output connections for the SVI II AP, located on bottom

of the pneumatic block, are tapped 1⁄4 inch NPT. Output is toward the

front, supply is toward the back. Two pressure gauges, output on top,

supply on bottom, are located on the front of the pneumatic block.

Maximum allowable air supply pressure to the SVI II AP varies

according to actuator, valve size, and valve type. See Pressure Drop

tables in valve specification sheets to determine the correct positioner

supply pressure. Minimum supply pressure should be 5 to 10 psi above

maximum spring pressure but may not exceed the rated actuator

pressure.

Output

Supply

Figure 4 Air Ports on Single Acting Positioner

Installation and Set Up Connecting the Tubing and Air Supply

9

Double Acting Positioner

Connect Output 1, labeled “(←I)” to the inlet port of the actuator and

connect Output 2 labeled “(

←II)” to the opposing actuator port (see

Figure 5 below for double acting ports.

Output

I

Connector

Supply

Connector

Connector

Output

II

Figure 5 Air Ports on Double Acting Positioner

Connecting the Air Supply

After the tubing is installed, use the following procedure to connect the

air supply.

1. Connect a supply of clean, dry compressed air to the filter

regulator.

2. Turn on the air supply.

3. Adjust the filter regulator.

4. Supply pressure must be 5 - 10 psi greater than the spring

range of the actuator but may not exceed the rated

actuator pressure. Refer to the valve or actuator

instruction manual.

Masoneilan Dresser SVI II AP Quick Start Guide

10

Wiring the

SVI II AP

In order for the SVI II AP to communicate the positioner data the SVI II

AP must be physically connected to a HART communication. The

procedure below outlines wiring the SVI II AP.

Comply with current national and local regulations

for electrical installation work.

Comply with national and local explosive

atmosphere regulations.

Before carrying out any work on the device, power

off the instrument or make sure that the locale

conditions for potentially explosive atmosphere

permit the safe opening of the cover.

Connecting to the Control Loop

The SVI II APpositioner MUST BE grounded according to local

regulations. It is important to maintain correct polarity at all times,

otherwise the positioner may not operate properly. The SVI II AP

should be physically connected to the HART loop using a cable

specified by the HART Communication Foundation. A shielded cable

is recommended.

To connect the Control Loop to the SVI II AP:

1. Connect one end of the cable to the control loop's

4 - 20mA output

2. Remove the threaded wiring covers on the positioner.

3. Connect the other end of the cable to the SVI II AP. There

are two threaded openings on the positioner. Use the

opening with the red plastic insert.

4. Maintain polarity + and - respectively.

Wiring Guidelines

This list contains eight guidelines for a successful implementation of DC

current signal, DC power, and HART communication to the SVI II AP:

1. Compliance voltage at the SVI II AP must be 9 volts at the

maximum current of 20 mA.

2. Signal to the SVI II AP must be a regulated current in the

range 3.2 to 22 mA.

3. Controller output circuit must be unaffected by the HART

tones which are in the frequency range between 1200 and

2200 Hz.

4. Frequency range of the HART tones must have a circuit

impedance of more than 220 Ohms, typically 250 Ohms.

5. HART tones may be imposed by the positioner and a

communication device located anywhere on the signaling

circuit.

Loading...

Loading...