Dresser Masoneilan Camflex II 35002 Series Instructions Manual

Masoneilan®

Instruction N°

Series 35002

Camflex II Valve Instructions

Includes rolling diaphragm, and manual actuator

EF 5000 E

01/2004

Instruction No EF 5000 E

01/2004

Summary

1. - INTRODUCTION ...................................... ... .. 3

2. - GENERAL .......................................... ... ... ... .. 3

3. - PRINCIPLE OF OPERATION ....................... 4

4. - UNPACKING ................................................. 5

5. - INSTALLATION........ ... ... ... .... ... ... ... .... ........... 5

6. - AIR SUPPLY PIPING .................................... 5

7. - PLACING IN SERVICE ................................. 5

8. - DISASSEMBLY..................................... ... ... .. 6

8.1 - ACTUATOR REMOVAL FROM BODY S/A...........6

8.2 - ACTUATOR COMPLETE DISASSEMBLY............7

8.3 - VALVE BODY.........................................................7

9. - MAINTENANCE .......................................... .. 9

9.1 - SPRING DIAPHRAGM REPLACEMENT...............9

9.2 - BODY S/A INTERNAL PARTS ............................10

9.3 - YOKE ASSEMBLY...............................................11

10. - REASSEMBLY PROCEDURES.................. 11

10.1 - SPRING DIAPHRAGM ACTUATOR....................11

10.2 - SPRING DIAPHRAGM ACTUATOR ON

BODY S/A.............................................................11

10.3 - HANDWHEEL REASSEMBLY.............................12

10.4 - LIMIT STOP REASSEMBLY................................12

10.5 - VALVE BODY REASSEMBLY.............................12

10.6 - SEAT RING ALIGNMENT ....................................13

10.7 - DVD PLATE REASSEMBLY................................14

11. - ACTUATOR STEM ADJUSTMENT ............ 14

12. - CHANGING BODY POSITION.................... 16

13. - CHANGING ACTUATOR ACTION ............. 16

14. - MANUAL ACTUATOR OPTION ................. 17

14.1 - DISASSEMBLY PROCEDURE ............................17

14.2 - MAINTENANCE ...................................................17

14.3 - REASSEMBLY PROCEDURE .............................17

2

1. Introduction

Instruction No EF 5000 E

01/2004

The following instructions are designed to assist

maintenance personnel in performing most of the

maintenance required on the Camflex® II valve and

if followed carefully will reduce maintenance time.

Masoneilan has highly skilled Service Engineers

available for start-up, maintenance and repair of our

valves and component parts. In addition, regularly

scheduled training programs are conducted to train

customer service and instrumentation personnel in

the operation, maintenance and application of our

control valves and instruments. Arrangements for

these services can be made through your

Masoneilan Representative or District Office. When

performing maintenance use only Masoneilan

replacement parts. Parts are obtainable through

your local Masoneilan Representative or District

Office. When ordering parts always include Model

and Serial Number of the unit being repaired.

2. General

These installation and maintenance instructions

apply to 1" through 12" sizes, all available ANSI

ratings, and pneumatic actuators. The model

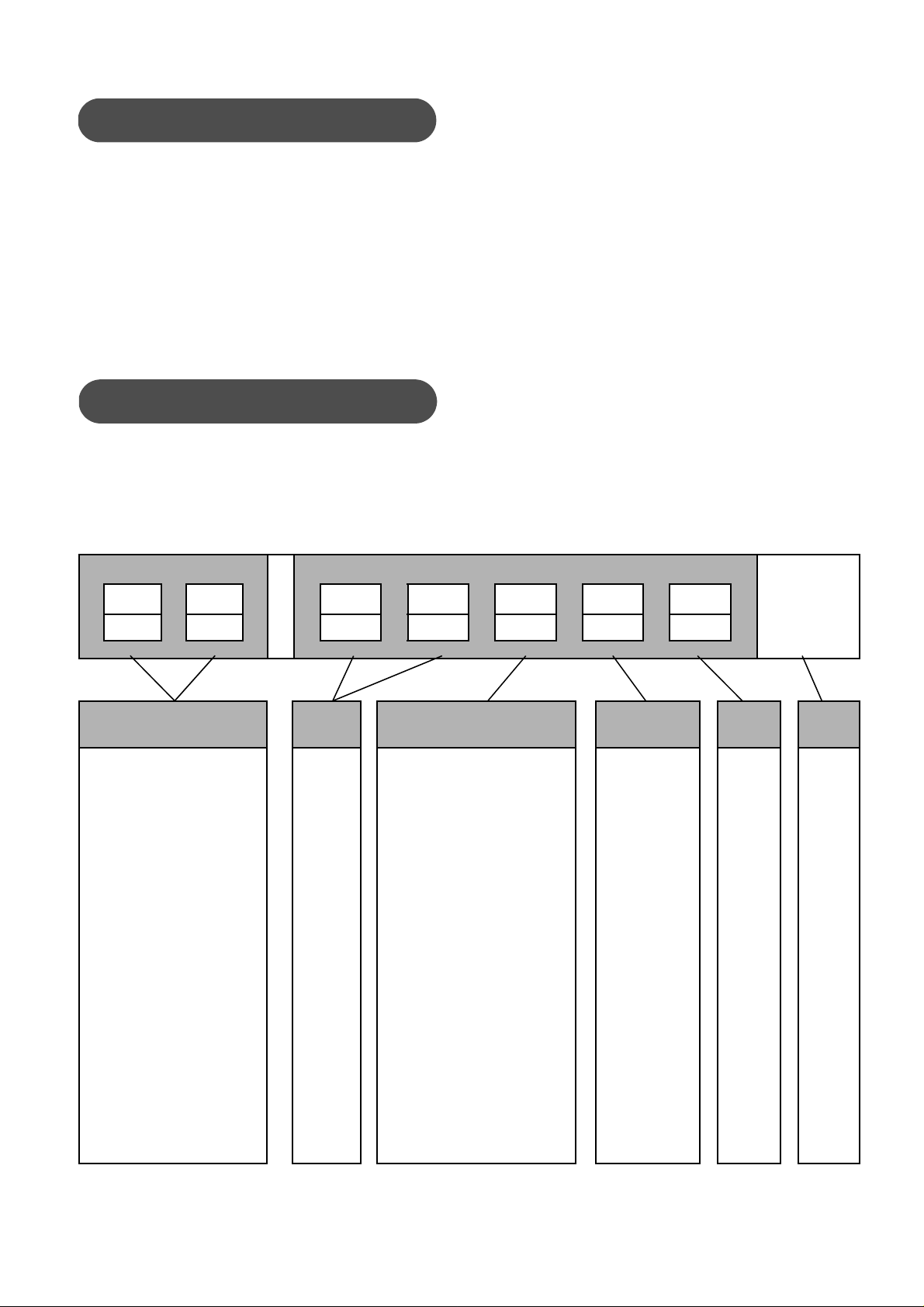

35002 Series Body Numbering System

Actuator Assembly digits Body Assembly Digits

st

1

nd

2

st

1

3 5 2

nd

2

number, size and rating of the valve are shown on

the serial plate. Refer to figure 1 to identify the valve

mode.

rd

3

th

4

th

5

SB

Actuator Type

20 Manual Actuator

35 Spring-opposed

rolling-diaphragm

(1) optional, Camflex with separable bonnet.

Body

Series

35 valve

Actuator Mounting

1. Parallel to pipe line,

valve closes on stem

extension

2. Parallel to pipe line,

valve opens on stem

extension

3. Perpendicular to pipe line,

valve closes on stem

extension

4. Perpendicular to pipe line,

valve opens on stem

extension

5. Parallel to pipe line,

valve closes on stem

extension

6. Parallel to pipe line,

valve opens on stem

extension

7. Perpendicular to pipe line,

valve closes on stem

extension

8. Perpendicular to pipe line,

valve opens on stem

extension

Figure 1

Seat

Design

1. Metal seat

2. Soft seat

3. Metal seat

Lo-dB

4. Soft seat

Lo-dB

5. Ceramic

TRIM

Design

Series

2SB (1)

Design

3

Instruction No EF 5000 E

01/2004

3. Principle of operation

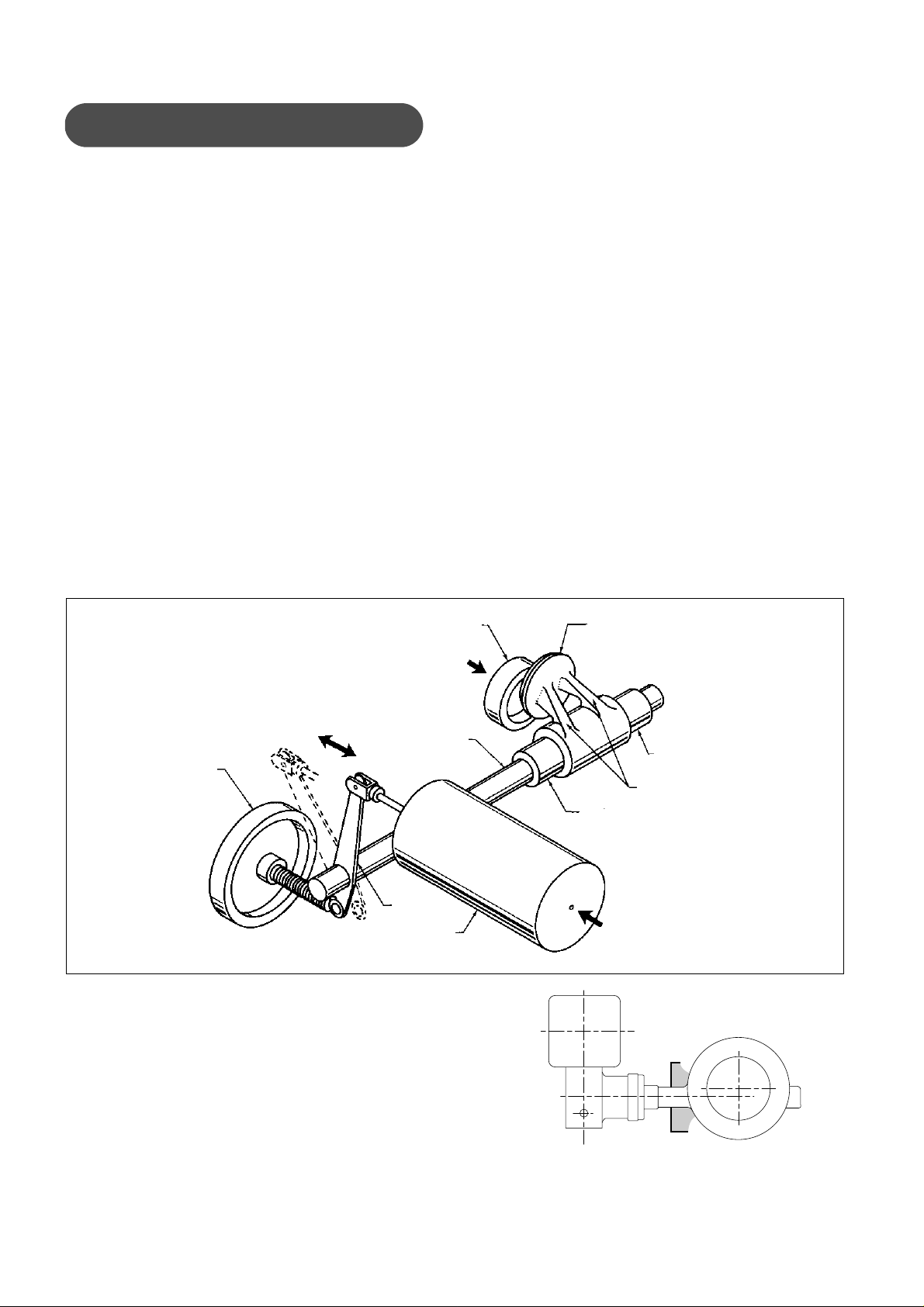

The concept of the Camflex® II valve is based on an

eccentrically rotating spherical plug contained in a

free flow design ANSI Class 600 body. The plug

seating surface is joined by flexible arms to a hub

which slides onto a rotating shaft. The plug is free to

center itself along the axis of the shaft. A positive

seal between plug and seat is achieved by elastic

deformation of the plug arms. The chamfered seat

ring is fixed in the valve body by a threaded retainer.

The plug and shaft are rotated through an angle of

50° by a lever linked to a powerful spring-opposed

rolling diaphragm actuator.

The solid disk-type handwheel and locking lever,

provided as standard features on the Camflex® II

valve and are mounted on the yoke opposite the

actuator. The handwheel may be used as a manual

actuator or as a limit stop. A threaded hole in the

opposite side of the yoke accommodates a cap

screw and locknut which may be inserted as a limit

stop in the other direction, or in combination with the

handwheel to lock the valve in a selected position.

Figure 2

Seat Ring

The handwheel on Camflex® II is designed to be

used for emergency action only.

The actuator is generally mounted with air-loading to

counter the dynamic torque on the plug. In figure 2

the flow direction tends to open the plug and the

actuator is oriented to close it with increasing air

pressure. The actuator spring fo rce assists plu g offbalance forces to open the valve on air failure. If the

valve is to close on air failure, the body would be

turned around in the line so that flow tends to close

the plug and the actuator position would be reversed.

The Camflex® II valve has a modified linear flow

characteristic, which is the same in either flow

direction. It can be easily transformed to an equal

percentage when equipping the valve with a

positioner 4700 series, 8000 series, SVI (Smart

Valve Interface) or FVP.Reduced TRIM factors 0.4

and 0.6 are available on all sizes. The flow capacity

of a 0.4 factor is 40% of the nominal capacity of the

valve and it is 60% for the 0.6 factor. Factors 0.1 and

0.2 are available on the DN 25 (1") valve.

Plug

Fluid flow

Handwheel

Lever

Actuator

The ability of the Camflex® II valve to handle a wide

range of process fluid temperatures is due to the

long integrally cast bonnet. This affords ample

radiation surface to normalise the packing

temperature. Therefore, with self-lubricating TFE

Aramid fiber packing, the valve handles

temperatures from - 200°C to + 400°C (-320°F to

+750°F). When insulating the valve, do not insulate

the body neck (see figure 3).

Shaft

Guide Bushing

Flexible arms

Guide Bushing

Air

Figure 3

4

4. Unpacking

Care must be exercised when unpacking the valve to

prevent damage to the accessories and component

parts. Should any problems arise, contact the

Masoneilan Representative or District Office.

Note: For ease of shipment and to prevent damage,

valves equipped with the spring diaphragm actuator

are shipped with the handwheel unassembled. Refer

to section 10.3 for handwheel assembly procedures.

Instruction No EF 5000 E

01/2004

E. If the valve is to be installed in a horizontal

position, install the lower flange bolting to

provide a cradle, which will help support, the

valve while installing the remaining bolts.

F. Place the valve in the line.

G. Select and install correct gaskets.

Note: Spiral wound gaskets, suitable for service

conditions are recommended.

H. Insert remaining flange bolting insuring that the

bolts align with the special bosses on the body,

which assure the valve is centered in the line and

also prevent rotation.

5. Installation

The Camflex® II valve has been assemb led at the

factory in accordance with specify instructions

concerning flow direction and actuator mode. The

valve must be installed so that the controlled

substance will flow through the valve in the direction

indicated by the flow arrow (25), which is loca ted on

the upper part of the valve body neck. The valve

actuator should be installed so the actuator is above

the centerline of the shaft. To install the valve in the

line, proceed as follows:

Caution: Any change in flow direction or

actuator mode must be accomplished as

outlined. In this instruction otherwise

equipment malfunction could result.

A. Check the model number on the serial plate (56)

against the numbering System described in

figure 1 to determine the valve mode.

B. Clean piping and valve of ail foreign material

such as welding chips, scale, oil, grease or dirt.

Gasket surfaces should be thoroughly cleaned to

insure leak proof connections.

C. To allow for in-line inspection, maintenance or

removal of the valve without service interruption,

provide a manually operated stop valve on each

side of the Camflex® II valve with a manually

operated throttling valve mounted in the by-pass

line.

Note: If a flanged Camflex® II is being installed

and the distance between flanges is established

by ANSI or DIN, spool pieces (spacers) are

inserted between the line flange and the valve

body flange. Gaskets and valve bolting are then

installed and torqued using standard flange and

line bolting criteria.

Note: For certain flange standards, through

bolting is not possible because of the valve body

neck or bonnet. To accommodate flange bolting,

guide arms with threaded holes or slots are

provided on the valve body to receive flange

bolts (refer to figure 22).

I. Tighten flange bolts e ve nly and firmly.

Cantion: If the valve is to be insulated, do not

insulate the valve body neck.

Note: If the valve is equipped with manual

handwheel, it may now be placed in service.

6. Air Supply Piping

Air is supplied to the actuator through the 1/4" NPT

tapped connection in the diaphragm case. Refer to

figure 14 to determine the correct supply pressure

and tubing size, then connect air supply piping.

Caution: Do not exceed maximum air

pressure indicated. Personal injury and

equipment malfunction could result.

Note: When the valve is equipped with regulators or

other accessories supplied by Masoneilan, only

connections to those accessories are required since

the piping to the actuator is connected at the factory.

Some valves equipped with electrical accessories

will require appropriate wiring. Refer to

manufacturer's instructions for correct wiring

information.

7. Placing in Service

D. For flangeless valves, refer to figure 23 and

determine the correct size and quantity of bolts

to be used for the valve and flange rating.

With the valve properly installed in the line and all air

or electrical service connected, it is recommended

5

Instruction No EF 5000 E

01/2004

that the valve be run through one cycle to insure

proper functioning. Proceed as follows:

A. Back off the handwheel (53) so that it will not

interfere with the operation of the valve and

tighten the handwheel lock (52).

Note: If the valve is equipped with the optional

limit stop (77), it should also be backed off to

prevent interference with the operation of the

valve.

B. Apply correct air pressure to the actuator.

Note: Valve should function smoothly and with

maximum pressure, the valve indicator (6)

should show full open or full close depending on

valve mode.

C. Relieve air pressure and return valve to normal

mode.

D. Gradually open process lines to place the valve

in service.

E. Check for leaks. Repair as required.

Caution: Always insure process pressure, a

pressure and electrical service are off and the

valve is isolated and relieved of pressure

before performing maintenance on the valve.

F. If desired, the handwheel may be used as a limit

stop. Set in desired position and lock.

G. If the optional limit stop (77) is used, set and

tighten locknut.

8. Disassembly

orientation and the actuator to yoke orientation be

marked in relation to each other. This will simplify

reassembly.

A. If required, remove the valve from the line.

B. Remove rear cover (29) and front cover (32) by

removing the two cover screws (30).

C. Remove bottom cover (11) and spring barrel

boss cover (58).

D. Remove indicator (88) by removing the two

screws (89).

E. Loosen handwheel lock (52) and turn handwhe el

(53) so it does not interfere with the movement of

the lever (34).

Note: On valves supplied with the optional limit

stop, (figure 17) loosen nut (78) and back off the

limit stop screw (77) so it will not interfere with

the movement of the lever (34).

F. Connect an air line to the actuator supply port

and using a manual loading panel or regulated

air supply, apply enough air pressure to the

actuator so the lever will move to an intermediate

position.

Caution: Do not exceed pressure listed in

figure 14 for actuator used. Do not use

handwheel to move the lever.

Note: If the valve is to be reassembled using the

same orientation, it is recommended that the

yoke (33) and lever (34) alignment, in the clo sed

position, be marked to simplify reassembly and

alignment of the lever and shaft to insure proper

valve functioning. See figure 17.

8.1 ACTUATOR REMOVAL FROM

BODY S/A

(Refer to figure 16 and figure 17)

Maintenance required on the internal components of

the valve or re-orientation of the actuator and body,

requires that the actuator and yoke be removed from

the valve. On the 6", 7" and No 9 actuators, for ease

of handling and reassembly, it is recommended that

the spring barrel be removed from the yoke and then

the yoke separated from the valve body.

Caution: Prior to performing maintenance on

the valve, isolate the valve, vent the process

pressure and shut off supply and signal air

lines to the actuator.

Note: If the valve will be reassembled in the same

orientation, it is recommended that the body to yoke

G. Remove clevis pin clips (5).

H. Remove clevis pin (7).

I. Relieve air pressure from actuator enabling

clevis (35) to disengage from lever (34).

Note: If the valve is equipped with a positioner,

refer to the appropriate positioner instruction for

procedures on cam or lever removal. Then

proceed to step K.

J. Remove shaft cover (9) by removing cover

screw (10).

Caution: Depending on the size and weight of

the actuator. It is recommended that proper

lift and support procedures be utilised when

removing the spring barrel or yoke.

K. Insure spring barrel is properly supported.

6

Instruction No EF 5000 E

01/2004

L. Loosen and remove cap screws (36) and

lockwashers (37), then remove spring

barrel (38).

M. Loosen lever capscrew (49).

N. Loosen the stud nuts (94) and disengage the

packing flange.

O. Loose the stud nuts (27) to separate the actuator

from the body S/A.

Note: With body secure, grasp lever and yoke and

separate. Yoke, lever and packing flange are

removed at the same time. The yoke may have to be

struck with a soft face mallet to break it loose.

8.2 ACTUATOR COMPLETE

DISASSEMBLY

The spring diaphragm actuator used on the

Camflex® II valve was designed basically as a low

cost non-replaceable item and therefore

disassembly is not recommended. However, in

some instances and for emergency purposes,

disassembly may be required. Proceed as follows.

A. In case of 35000 SB (Separable Bonnet) before

continuing in D it is necessary to loose and

remove the nut 104 to separate the bonnet with

the packing and the packing follower (15) from

the body.

B. Remove packing follower (15).

C. Remove safety pin (16).

Caution: The purpose of the safety pin is to

prevent the shaft from being pushed out if the

yoke is removed while the valve is still

pressurised. The internal components of the

valve cannot be removed without first

removing the safety pin.

D. Pull on the shaft (19) to remove it.

Note: Difficulty is sometimes encountered when

removing the shaft from the plug mainly due to

an excessive accumulation of deposits between

the plug splines and the shaft. Applica tion of heat

to the plug shaft bore while using one of the

following methods will facilitate removal.

A. If the actuator is not removed from the body

proceed to the paragraph 9.1 A. to 9.1 L.

B. Loosen locknut (46) then remove the clevis (35)

and the locknut (46).

C. Loosen and remove capscrew (41) and remove

diaphragm case (42) and diaphragm (40).

D. Using a deep socket, loosen and remove locknut

(45) and washer (44).

E. Remove piston (43) and spring (39) and inspect

all components.

F. Proceed to section 10.2 for reassembly.

8.3 VALVE BODY (Refer to fig. 4 & 16)

Maintenance to the internal components required on

the Camflex® II Valve can normally be easily

determined since the seat ring and plug can be see n

once the valve is removed from the line. Although it

may be determined that the seat ring does not need

replacement, it must be noted that the new plug and

seat ring must be lapped thus requiring the

disassembly of the body. It is recommended that

both seat ring and plug be replaced if one or the

other is damaged due to service.

After the actuator has been removed from the body,

disassemble the valve using the following

procedure:

Caution: When using heating devices. Insure

that proper safety practices are observed.

Such items as the flammability and t oxicity o f

the controlled substance must be considered

and proper precautions taken.

If the shaft is not removed easily, replace the

lever (34) on the splined end of the shaft (19), tighten

the lever capscrew (49) and using a mallet, tap the

lever (34) as close to the shaft as possible and

remove the shaft (19).

Note: If the shaft cannot be removed by tapping the

tightened lever, figure 20 illustrates an alternative

method of removal. Using a pipe nipple of suitable

size and length and reversing the packing flange and

stud nuts as shown, the shaft may be jacked out of

the body. For larger valves the use of an additional

washer and nipple to assist in holding the tightened

Lever is recommended. The lever should be

tightened at a point where the hub on the lever is

flush with the end of the spline.

E. The components which should come out with the

shaft (19) are: the packing (17), packing box ring

(23 or 100), spacer tube (20) and upper guide

bushing (21).

Caution: Prior to performing maintenance on

the valve, isolate the valve, vent the process

pressure.

7

Instruction No EF 5000 E

01/2004

Note: The spacer tube (20) and upper guide

bushing (21) may remain in the body. They

should be removed. The spacer tube (20) can

only be removed by pulling it out the bonnet end

of the body. The upper guide bushing (21) may

be pushed through the body after removing the

plug or pulled through the bonnet end of the

body. On valves designed for use on slurry or

viscous service, the upper guide bushing ha s an

inner "O" ring (92) and an outer "O" ring (93) and

the lower guide bushing has inner "O" ring (95)

and outer "O" ring (96) (Refer to figure 4).

93

92

Figure 4 - Optional “O” ring arrangement

21 22 96

95

F. Remove the plug (4) through the end of the body

opposite the seat ring.

G. Remove the lower guide bushing (22).

Note: A groove is provided in the bushing for

prying out the bushing using a screwdriver. If the

bushing will be pried out it should be pried from

two sides to prevent jamming the bushing during

removal. If the bushing does not come out easily,

fill the bushing with grease, insert the shaft (19)

into the valve insuring that the machined portion

of the shaft starts into the lower guide bushing.

Using a soft faced mallet, strike the end of the

shaft lightly until the bushing is pushed out

partially. Remove the shaft and complete

removal of the bushing by prying out using the

groove provided.

Caution: Do not pry the bushing using the

seat for leverage. If the bushing cannot be

easily removed, proceed to section 8.3.1 and

remove the seat ring retainer and seat ring

then remove the bushing. Place a piece of

soft stock (brass, etc.) between the inner seat

shoulder and prying device to prevent

damage to the seat sealing area of the body.

8.3.1 Seat Ring Removal (Refer to figure 16)

The following procedures outline the recommended

method for removing the seat ring retainer (3) with

the use of retainer wrenches. Masoneilan

manufactures and has available, for a nominal price,

seat ring retainer wrenches for the Camflex® II, 1"

through 4" sizes. lt is highly recommended that

wrenches be purchased or fabricated to facilitate

removal and reassembly of the seat ring (2) since

SPECIFIC TORQUES MUST BE ACHIEVED to

obtain tight shutoff and insure proper functioning of

the valve.

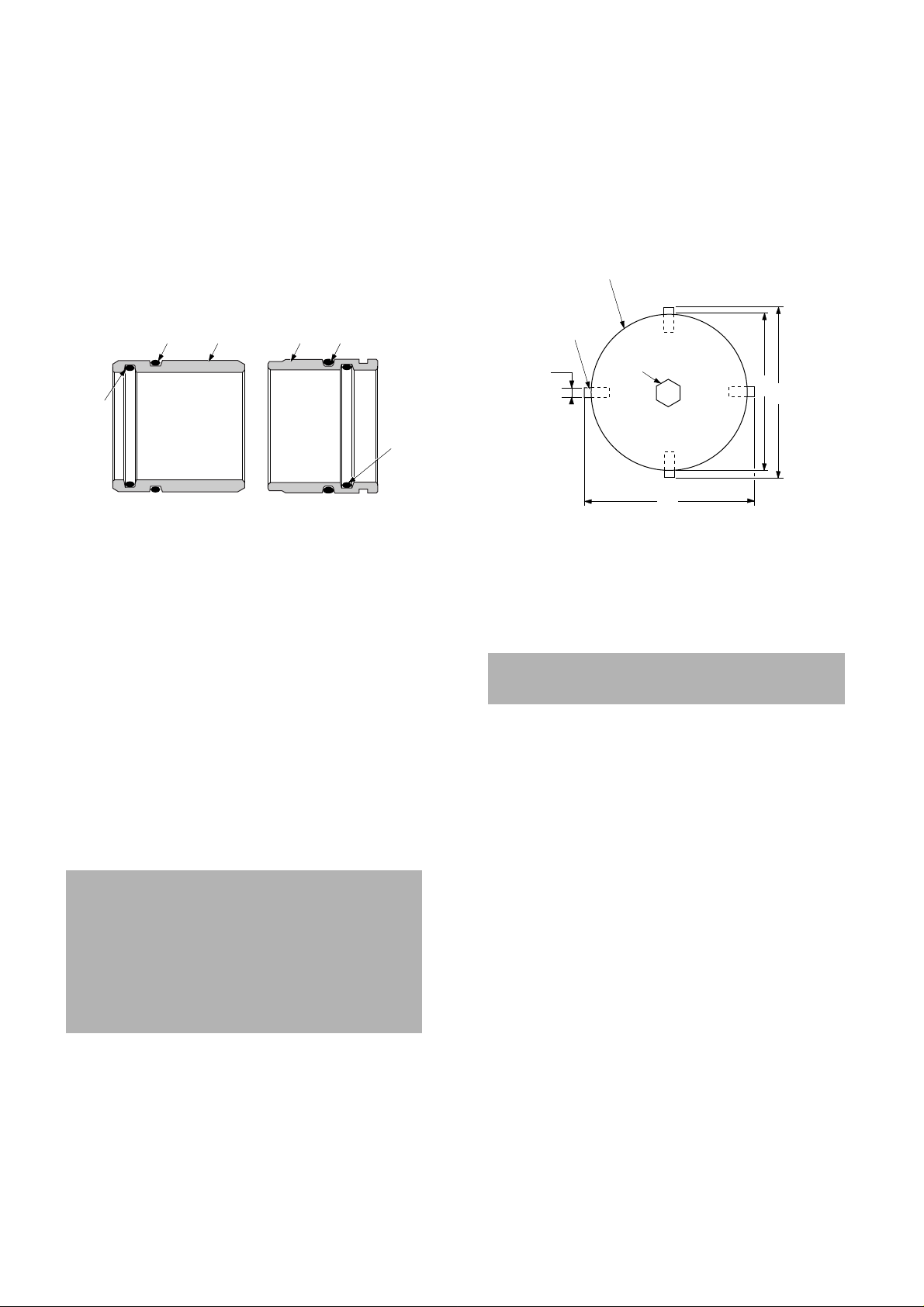

Figure 5 shows the recommended materials,

thickness and method of construction along with

specific dimensions to facilitate construction.

3/16" STEEL PLATE

WELDED

KEY

STOCK

B

WELDED

HEX NUT

A

A = O.D. Seat Ring Retainer

B = Width of slot in Retainer

C = I.D. of Seat Ring Retainer

Figure 5

C

A

A. Secure the valve body in a vise or appropriate

holding device with the seat ring facing up.

Care must be taken to avoid damage to the

gasket face on the valve body.

B. Place retainer wrench so it engages retainer

lugs.

C. Engage the retainer wrench with an impact

wrench or suitable wrench and loosen, then

remove retainer (3) by turning counterclockwise.

D. Lift out seat ring.

Note: In an emergency, drifts may be used to

remove the seat ring retainer. However, two

drifts should be used and placed in the slots 180°

apart and struck simultaneously.

8.3.2 DVD Removal (Refer to figure 16)

In case of Camflex® with the DVD option, model

number 35x3x or 35x4x, the DVD is installed in the

body, it is recommended to use the DVD wrenches to

remove this device (105). Masoneilan manufactures

and has available, for a nominal price, DVD wrenches

for the Camflex® II, 1" through 12" sizes. lt is highly

recommended that wrenches be purchased or

fabricated to facilitate removal and reassembly of the

DVD (105) since SPECIFIC TORQUES MUST BE

ACHIEVED to insure proper clamping of this DVD

plate.

8

Loading...

Loading...