Dresser Consolidated 1900 Installation, Operation And Maintenance Manual

®

Consolidated

INST ALLATION, OPERA TION

AND MAINTENANCE MANUAL

®

Consolidated Safety Relief V alve

Type 1900

Design Options

Include:

Bellows

(-30),

O-Ring Seat

(DA),

Liquid Trim

(LA)

and

Industrial Valve Operation

Dresser Valve and Controls Division

Alexandria, Louisiana 71309-1430 (USA)

Thermodisc

®

(TD)

CON-2

Revised 7/97

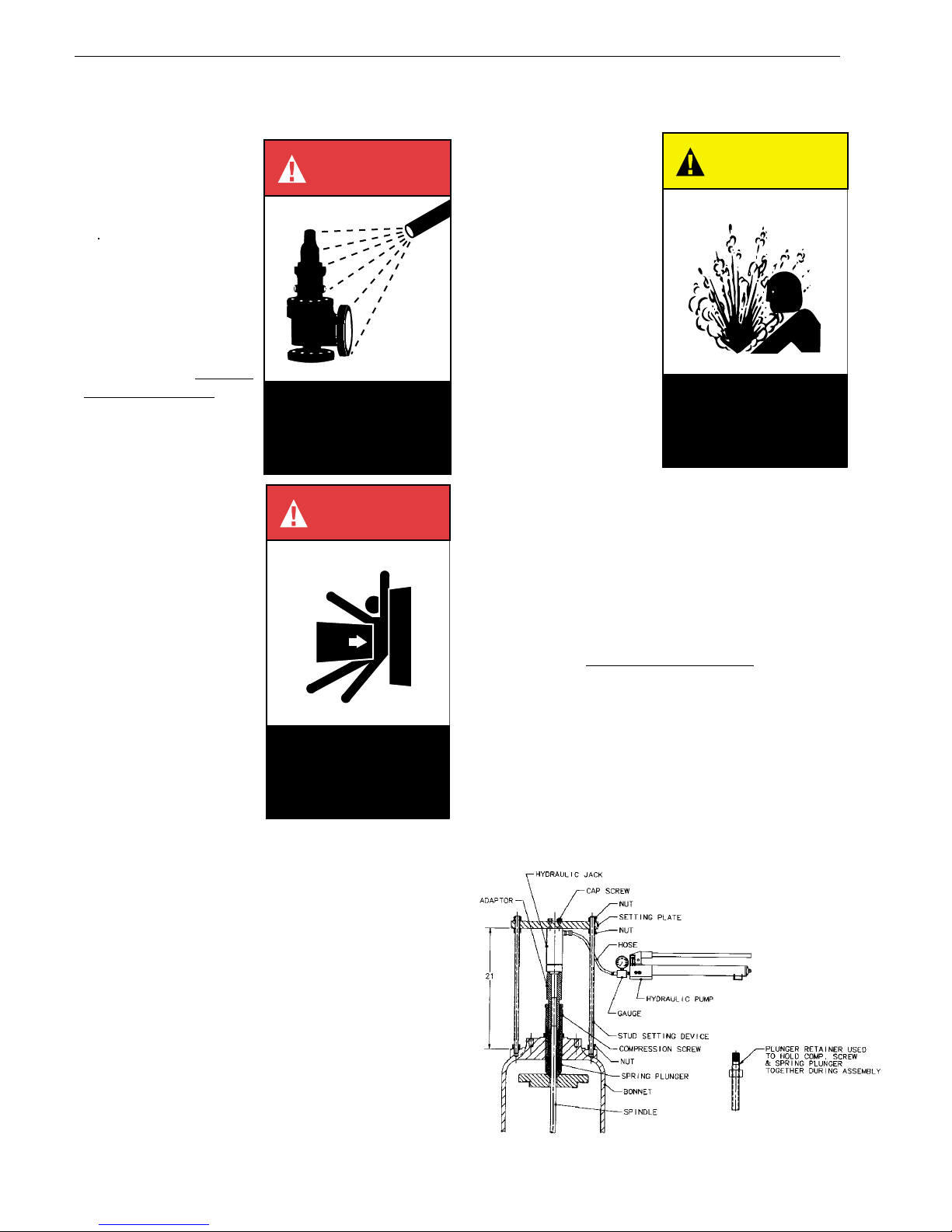

Product Safety Sign and Label System

Wear necessary

protective equipment

to prevent possible

injury .

CAUTION

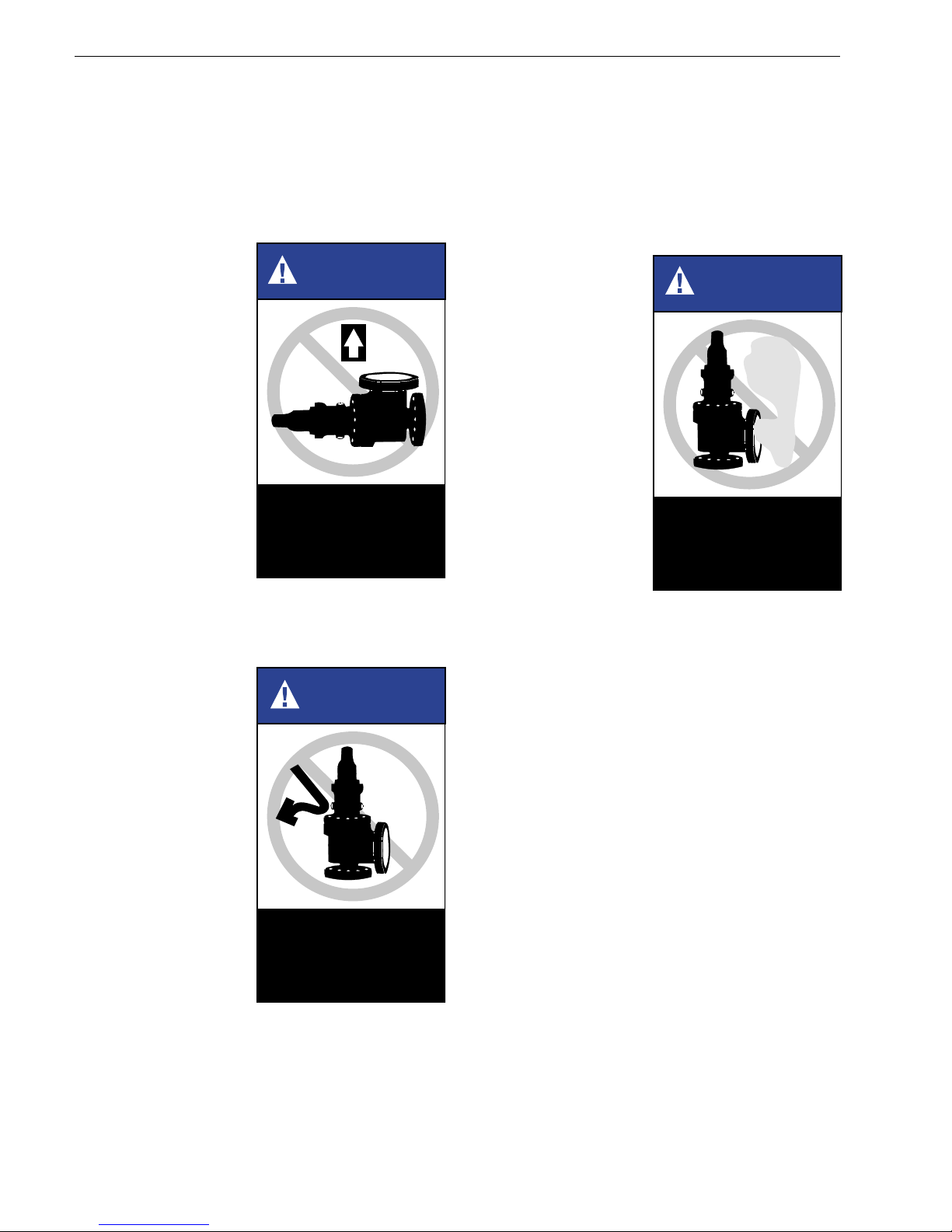

If and when required, appropriate safety labels have

been included in the rectangular margin blocks

throughout this manual. Safety labels are vertically

oriented rectangles as shown in the

examples

by a narrow border. The panels can contain four

messages which communicate:

• The level of hazard seriousness.

• The nature of the hazard.

• The consequence of human, or product, interaction

with the hazard.

• The instructions, if necessary, on how to avoid the

hazard.

(below), consisting of three panels encircled

DANGER

representative

WARNING

The top panel of the format contains a signal word

(DANGER, WARNING, or CAUTION) which

communicates the level of hazard seriousness.

The center panel contains a pictorial which

communicates the nature of the hazard, and the possible

consequence of human or product interaction with the

hazard. In some instances of human hazards the pictorial

may, instead, depict what preventive measures to take,

such as wearing protective equipment.

The bottom panel may contain an instruction message

on how to avoid the hazard. In the case of human

hazard, this message may also contain a more precise

definition of the hazard, and the consequences of

human interaction with the hazard, than can be

communicated solely by the pictorial.

Do not remove bolts if

pressure in line, as this

will result in severe

personal injury or death.

Know nuclear health

physics procedures, if

applicable, to av oid

possible severe per

injury or death.

SAFETY ALERTS!

READ – UNDERSTAND – PRACTICE

1. DANGER: High temperature/pressure can

cause injury. Be sure all system pressure is absent

before repairing or removing valves.

2. DANGER: Don’t stand in front of valve

outlet when discharging. STAND CLEAR OF VALVE

to prevent exposure to trapped, corrosive media.

sonal

DANGER

3. DANGER: When inspecting a pressure

relief valve for leakage, BE VERY CAREFUL!

CON-2

Do not remove bolts if

pressure in line, as this

will result in severe

personal injury or death.

Page 1

Contents

Section Subject Page

I. Safety Alerts .................................................................................................................................. 2

II. Terminology for Safety Relief Valves ............................................................................................ 4

III. Introduction ................................................................................................................................... 5

IV. Design Features and Nomenclature .............................................................................................5

V. Handling, Storage and Pre-Installation ......................................................................................... 8

VI. Recommended Installation Practices ............................................................................................ 9

VII. Disassembly Instructions .............................................................................................................. 12

VIII. Cleaning ........................................................................................................................................ 14

IX. Parts Inspection ............................................................................................................................ 14

X. Maintenance Instructions .............................................................................................................. 22

XI. Reassembly................................................................................................................................... 29

XII. Setting and Testing ....................................................................................................................... 35

XIII. Hydrostatic Testing and Gagging .................................................................................................. 38

XIV. Manual Popping of the Valve ........................................................................................................ 39

XV. Conversion of Type 1900 Flanged Safety Relief Valves

XVI. Trouble Shooting Type 1900 Valves ............................................................................................. 42

XVII. Maintenance Tools and Supplies .................................................................................................. 42

XVIII. Replacement Parts Planning......................................................................................................... 44

XIX. Genuine Dresser Parts.................................................................................................................. 45

XX. Recommended Spare Parts for the 1900 Safety Relief Valves .................................................... 46

XXI. Manufacturer's Warranty, Field Service & Repair Program .......................................................... 48

Product Safety Sign and Label System..................................................................... Inside Front Cover

A. Mounting Position ................................................................................................................ 9

B. Inlet Piping ........................................................................................................................... 9

C. Outlet Piping ........................................................................................................................ 11

A. General Information ............................................................................................................. 12

B. Specific Steps ...................................................................................................................... 12

A. Nozzle.................................................................................................................................. 14

B. Nozzle Seat Width ............................................................................................................... 16

C. Nozzle Bore ......................................................................................................................... 16

D. 1900, 1900-30 Standard Disc.............................................................................................. 16

E. 1900 Series Thermodisc...................................................................................................... 17

F. Disc Holder .......................................................................................................................... 18

G. Guide ................................................................................................................................... 21

H. Spindle ................................................................................................................................. 21

I. Spring .................................................................................................................................. 21

A. General Information ............................................................................................................. 22

B. Lapping Nozzle Seats (Non O-Ring Styles) ........................................................................ 22

C. Nozzle Seat Widths-Lapped ................................................................................................ 22

D. Lapping Disc Seats .............................................................................................................. 24

E. Precautions and Hints for Lapping Seats ............................................................................ 24

F. Lapping O-Ring Seating Surfaces ....................................................................................... 24

G. Reconditioning of Laps ........................................................................................................25

H. Remachining Nozzle Seats and Bores ................................................................................ 25

I. Remachining the Disc Seat ................................................................................................. 26

J. Checking Spindle Concentricity ........................................................................................... 27

K. Set Pressure Change-Disc Holder ...................................................................................... 28

L. Checking Lift on Restricted Lift Valves ................................................................................ 28

A. General Information ............................................................................................................. 29

B. Lubrication ........................................................................................................................... 30

C. Specific Steps ...................................................................................................................... 30

A. General Information ............................................................................................................. 35

B. Test Equipment ................................................................................................................... 35

C. Test Media ........................................................................................................................... 35

D. Setting the Valve ................................................................................................................. 35

E. Set Pressure Compensation................................................................................................ 35

F. Seat Tightness Testing ........................................................................................................37

From Conventional to Bellows Type, and Vice Versa ................................................................... 40

A. General Information ............................................................................................................. 40

B. Conversion From Conventional to Bellows Type................................................................. 41

C. Conversion From Bellows to Conventional Type ................................................................. 41

A. Basic Guidelines .................................................................................................................. 44

B. Replacement Parts List ....................................................................................................... 44

C. Identification and Ordering Essentials ................................................................................. 44

A. Warranty Information ........................................................................................................... 48

B. Field Service ........................................................................................................................ 48

C. Factory Repair Facilities ...................................................................................................... 48

D. Safety Relief Valve Maintenance Training ........................................................................... 48

Appendix RE: Optional Glide-Alloy® Parts ................................................................................... A.1

Service Engineers and Sales Office Locations ......................................................... Back Cover

CON-2

Page 2

SAFETY ALERTS!

READ – UNDERSTAND – PRACTICE

1. WARNING: Allow the system to cool to

room temperature before cleaning, servicing or

repairing the system. Hot components or fluids

can cause severe personal injury or death.

2. WARNING: Always read and comply with

safety labels on all containers. Do not remove or

deface the container labels. Improper handling or

misuse could result in severe personal injury or

death.

3. WARNING: Never use pressurized

fluids/gas/air to clean clothing or body parts. Never

use body parts to check for leaks or flow rates or

areas. Pressurized fluids/gas/air injected into or

near the body can cause severe personal injury or

death.

4. WARNING: It is the responsibility of the owner

to specify and provide guarding to protect persons

from pressurized or heated parts. Contact with

pressurized or heated parts can result in severe

personal injury or death.

5. WARNING: Do not allow anyone under

the influence of intoxicants or narcotics to work on

or around pressurized systems. Workers under

the influence of intoxicants or narcotics are a

hazard both to themselves and other employees

and can cause severe personal injury or death to

themselves or others.

6. WARNING: Incorrect service and repair

could result in product or property damage or

severe personal injury or death.

WARNING

Improper use or repair of

pressurized media or

steam device may result

in severe personal injury

or death.

WARNING

Provide and use guarding

to prevent contact with

heated and/or

pressurized parts

WARNING

Heed all container label

warnings.

WARNING

Do not work with valves

while under the

influence of intoxicants

or narcotics.

WARNING

All potential hazards may

not be covered in this

manual.

CON-2

WARNING

Improper tools or

improper use of right

tools could result in

personal injury or

product damage.

7. WARNING: These WARNINGS are as

complete as possible but not all-inclusive. Dresser

cannot know all conceivable service methods nor

evaluate all potential hazards.

8. WARNING: Use of improper tools or

improper use of right tools could result in personal

injury or product or property damage.

9. WARNING: Some valve products manufactured by

DVCD may be used in radioactive environments.

Consequently, prior to starting any operation in a

radioactive environment, the proper “health physics”

procedures should be followed, if applicable.

Page 3

WARNING

sonal

1. CAUTION: Heed all service manual warnings.

Read installation instructions before installing

valve(s).

2. CAUTION: Wear hearing protection when testing

or operating valves.

3. CAUTION: Wear appropriate eye and clothing

protection.

4. CAUTION: Wear protective breathing apparatus

to protect against toxic media.

NOTE:

Any service questions not covered in this manual

should be referred to Dresser’s Service Department,

Phone (318) 640-6055.

CAUTION

Heed all service manual

warnings. Read

installation instructions

before installing valve(s).

Know nuclear health

physics procedures, if

applicable, to av oid

possible severe per

injury or death.

CAUTION

Wear necessary

protective equipment

to prevent possible

injury .

▲

CON-2

Page 4

II. Terminology for Safety

Relief Valves

• Accumulation

Accumulation is the pressure increase over the

maximum allowable working pressure of the

vessel during discharge through the pressure

relief valve, expressed as a percentage of that

pressure, or actual pressure units.

• Back Pressure

Back pressure is the pressure on the discharge

side of a safety relief valve:

1. Superimposed Back Pressure

Superimposed back pressure is the pressure

in the discharge header before the safety

relief valve opens.

a) Constant - Specify single constant back

pressure (e.g., 20 psig/1.38 bar).

b) Variable - Specify variable back

pressure range using min. and max.

limits (e.g., 0 to 20 psig/1.38 bar).

2. Built-up Back Pressure

Built-up back pressure is pressure which

develops at the valve outlet as a result of

flow, after the safety relief valve has been

opened.

• Blowdown

Blowdown is the difference between set pressure

and reseating pressure of a pressure relief valve,

expressed as a percentage of the set pressure, or

actual pressure units.

• Cold Differential Set Pressure

Cold differential set pressure is the pressure at

which the valve is adjusted to open on the test

stand. This pressure includes the corrections for

back pressure and/or temperature service

conditions.

• Differential Between Operating and Set

Pressures

Valves in process service will generally give best

results if the operating pressure does not exceed

90% of the set pressure. However, on pump and

compressor discharge lines, the differential

required between the operating and set pressures

may be greater because of pressure pulsations

coming from a reciprocating piston. It is

recommended that the valve be set as high

above the operating pressure as possible.

• Lift

Lift is the actual travel of the disc away from the

closed position when a valve is relieving.

• Maximum Allowable Working Pressure

Maximum allowable working pressure is the

maximum gauge pressure permissible in a vessel

at a designated temperature. A vessel may not

be operated above this pressure, or its equivalent,

at any metal temperature other than that used in

its design. Consequently, for that metal

temperature, it is the highest pressure at which

the primary pressure safety relief valve is set to

open.

• Operating Pressure

The operating pressure is the gauge pressure to

which the vessel is normally subjected in service.

A suitable margin is provided between operating

pressure and maximum allowable working

pressure. For assured safe operation, the

operating pressure should be at least 10% under

the maximum allowable working pressure or 5 psi

(.34 bar), whichever is greater.

• Overpressure

Overpressure is a pressure increase over the set

pressure of the primary relieving device.

Overpressure is similar to accumulation when

the relieving device is set at the maximum

allowable working pressure of the vessel.

Normally, overpressure is expressed as a

percentage of set pressure.

• Rated Capacity

Rated capacity is the percentage of measured

flow at an authorized percent overpressure

permitted by the applicable code. Rated capacity

is generally expressed in pounds per hour (lb/hr)

for vapors; standard cubic feet per minute (SCFM)

or m3/min for gases; and in gallons per minute

(GPM) for liquids.

• Relief Valve

A relief valve is an automatic pressure-relieving

device, actuated by static pressure upstream

from the valve, a relief valve is used primarily for

liquid service.

• Safety Relief Valve

A safety relief valve is an automatic pressurerelieving device which may be used as either a

safety or relief valve, depending upon application.

A safety relief valve is used to protect personnel

and equipment by preventing excessive

overpressure.

CON-2

Page 5

II. (Continued)

• Safety Valve

A safety valve is an automatic pressure-relieving

device actuated by the static pressure upstream

of the valve, and characterized by rapid opening

or pop action. It is used for steam, gas or vapor

service.

• Set Pressure

Set pressure is the gauge pressure at the valve

inlet, for which the relief valve has been adjusted

to open under service conditions. In liquid service,

set pressure is determined by the inlet pressure

at which the valve starts to discharge. In gas or

vapor service, the set pressure is determined by

the inlet pressure at which the valve pops.

• Simmer

Simmer is characterized by the audible passage

of a gas or vapor across the seating surfaces just

prior to "pop". The difference between this "start

to open pressure" and the set pressure is simmer,

and is generally expressed as a percentage of set

pressure.

• Valve Trim

Valve trim includes the nozzle and disc.

III. Introduction

A safety relief valve is an automatic pressure actuated

relieving device suitable for use either as a safety valve

or relief valve, depending on application.

Safety relief valves are used on hundreds of different

applications, including liquids and hydrocarbons;

therefore, the valve is designed to meet many

requirements. The 1900 series valves included in this

manual can

requirements. It cannot be used on ASME Code

Section I steam boilers or superheaters, but may be

used on process steam.

only

be used to meet Section VIII

IV. Design Features and

Nomenclature

• Cap and Lever Interchangeability

Many times it is necessary to change the type of

cap or lever in the field after a valve has been

installed. All flanged Consolidated® Safety Relief

Valves are designed so they can be converted to

any type of lever or cap desired. It is not necessary

to remove the valve from the installation, nor will

the set pressure be affected when making such a

change.

• Design Simplicity

Consolidated Safety Relief Valves have a minimum

number of component parts. This results in a

savings by minimizing spare parts inventory and

simplifies valve maintenance.

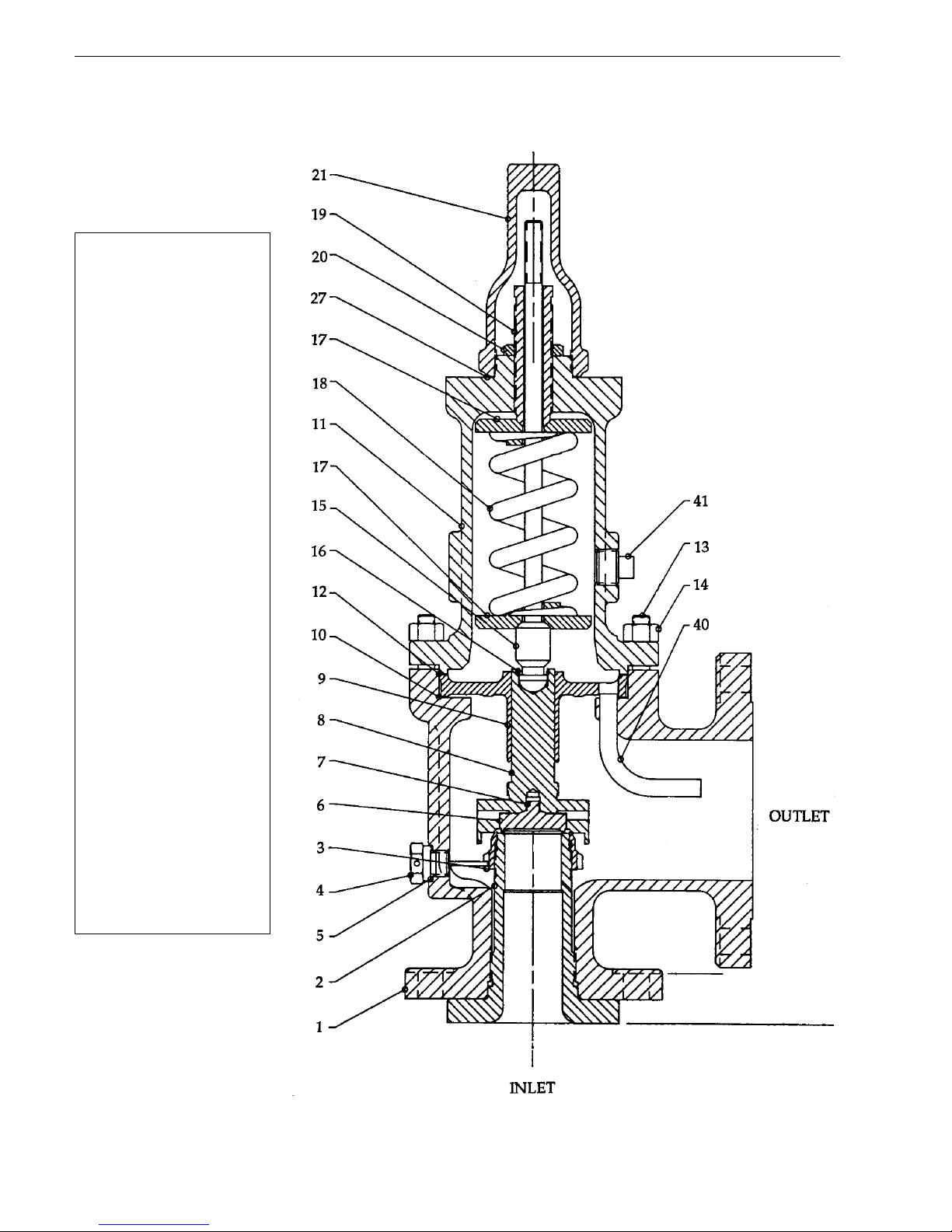

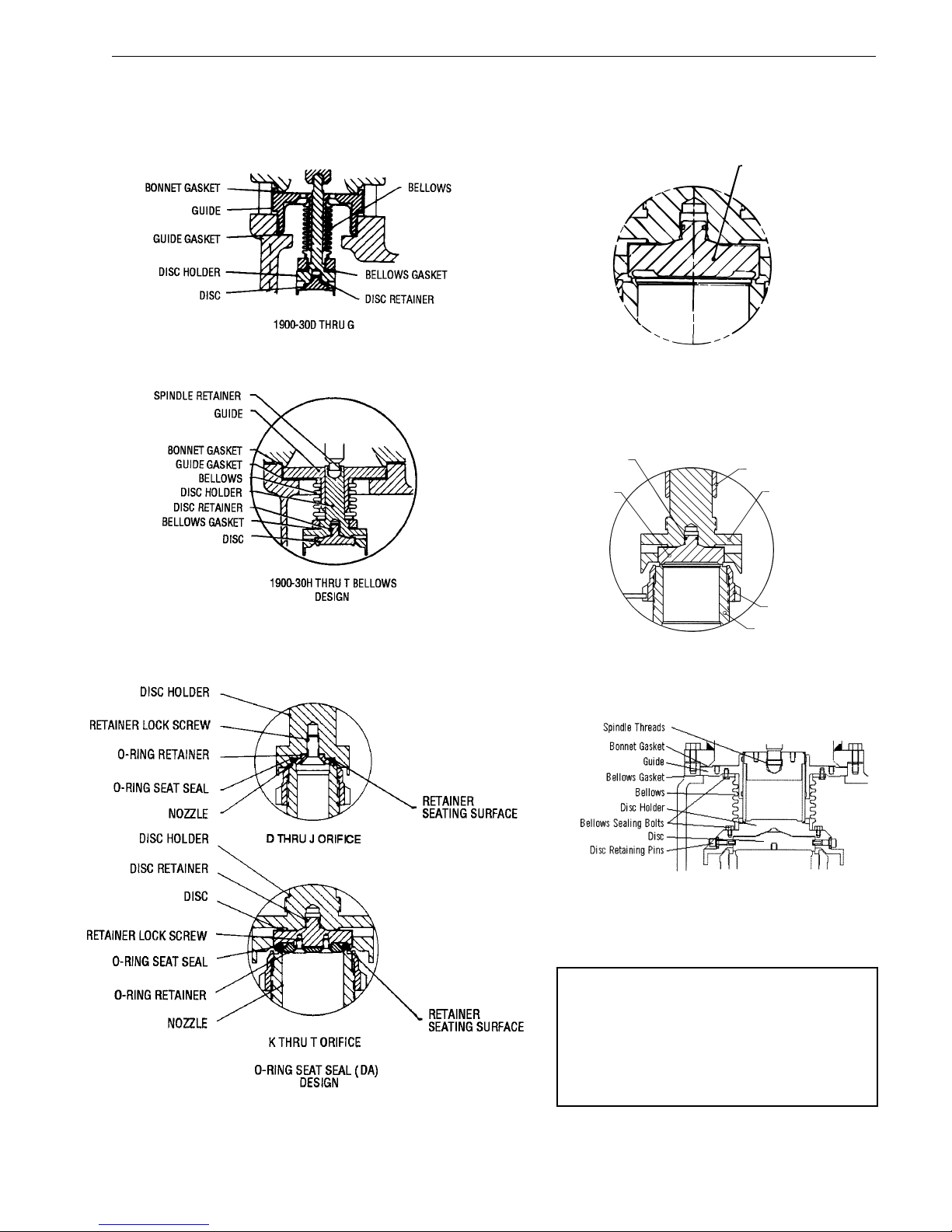

• Nomenclature Related to Design Features

Applicable nomenclature of the components of

Type 1900 valves, including those with design

options for bellows O-Ring seat, and liquid trim and

Thermodisc, is identified in Figures 1 thru 6 on

pages 6 and 7.

• Simple Blowdown Adjustment

The Consolidated single blowdown ring design

makes it possible to set and test a valve that has

been in service when it cannot be set on line and

must be taken to the customer's shop. The ring can

be positioned so that the set point can be observed

although the volume of the testing media is very

low. After the set pressure has been established,

proper blowdown can be attained by merely

positioning the ring in accordance with the adjusting

ring position shown in Tables 12-14 (as appropriate),

on page 34 of this manual.

• Valve Interchangeability

A Standard Consolidated Safety Relief Valve may

be converted to the bellows type, the O-Ring seat

seal type, etc. and vice versa. This requires a

minimum number of new parts, and results in lower

costs should conversion be required.

CON-2

Page 6

Part

No. Nomenclature

1 Base

2 Nozzle

3 Adjusting Ring

4 Adjusting Ring Pin

5 Adj. Ring Pin Gasket

6 Disc

7 Disc Retainer

8 Disc Holder

9 Guide

10 Guide Gasket

11 Bonnet

12 Bonnet Gasket

13 Base Stud

14 Stud Nut

15 Spindle

16 Spindle Retainer

17 Spring Washer

18 Spring

19 Adjusting Screw

20 Adjusting Screw Nut

21 Screwed Cap

*22 Bolted Cap

*23 Packed Cap

*24 Plain Cap

*25 Cap Bolt

*26 Cap Set Screw

27 Cap Gasket

*28 Release Nut

*29 Release Locknut

*30 Lever

*31 Lifting Fork

*32 Lever Shaft

*33 Packing

*34 Packing Nut

*35 Top Lever

*36 Drop Lever

40 Eductor Tube

41 Bonnet Vent Plug

CONSOLIDATED SAFETY RELIEF VALVE

TYPE 1900 - CONVENTIONAL

* Shown in Figures 38-42 on

page 39 of this manual.

CON-2

FIGURE 1

DESIGN OPTIONS

Page 7

THERMODISC

THERMODISC (TD)

DESIGN

FIGURE 3

FIGURE 2

DISC RETAINER

DISC

GUIDE

NOZZLE

FIGURE 5

LA Liquid Trim Design

(See Fig. 20)

FIGURE 6

V & W Orifice Only

DISC HOLDER

PART INTEGRITY

ESPECIALLY DESIGNED

FOR SHORT BLOWDOWN

AND SMOOTH CHATTERFREE OPERATION

AT MAXIMUM CAPACITY.

ADJUSTING RING

FIGURE 4

NOTE:

A combination of the O-Ring seat

seal and liquid trim design options is

designated as DA-LA.

CON-2

Page 8

V. Handling, Storage and

Pre-Installation

• Handling

A flanged valve, either crated or uncrated, should

always be kept with the inlet flange down (i.e., in

order to prevent possible misalignment and damage

to internals).

Uncrated valves

should be moved or

hoisted by wrapping

a chain or sling

around discharge

neck, then around

upper bonnet

structure in such

manner as will

ensure the valve is in

a vertical position

during lift, i.e. not

lifted in horizontal

position.

NOTE:

Never lift the full

weight of the valve

by the lifting lever.

Crated valves should always be lifted with the

inlet flange down, i.e., same as installation

position.

WARNING

Do not lift horizontally ,

or hook to lifting lever .

• Storage

Safety relief valves should be stored in a dry

environment to protect them from the weather.

They should not be removed from the skids or

crates until immediately prior to installation.

Flange protectors and seating plugs should not be

removed until the valve is ready to be bolted into

the installation, i.e., both inlet and outlet.

• Pre-installation

When safety relief

valves are uncrated,

and the flange

protectors or sealing

plugs removed

immediately prior to

installation,

meticulous care

should be exercised

to prevent dirt and

other foreign

materials from

entering the inlet and

outlet ports while

bolting in place.

WARNING

Prevent dirt from

entering outlet or inlet

port.

Safety relief valves,

either crated or

uncrated, should

never be subjected

to sharp impact. This

would be most likely

to occur by bumping

or dropping during

loading or unloading

from a truck. While

hoisting to the

installation, care

should be taken to

prevent bumping the

valve against steel

structures and other

objects.

WARNING

Handle carefully . Do

not drop or strike.

CON-2

Page 9

VI. Recommended Installation

Practices

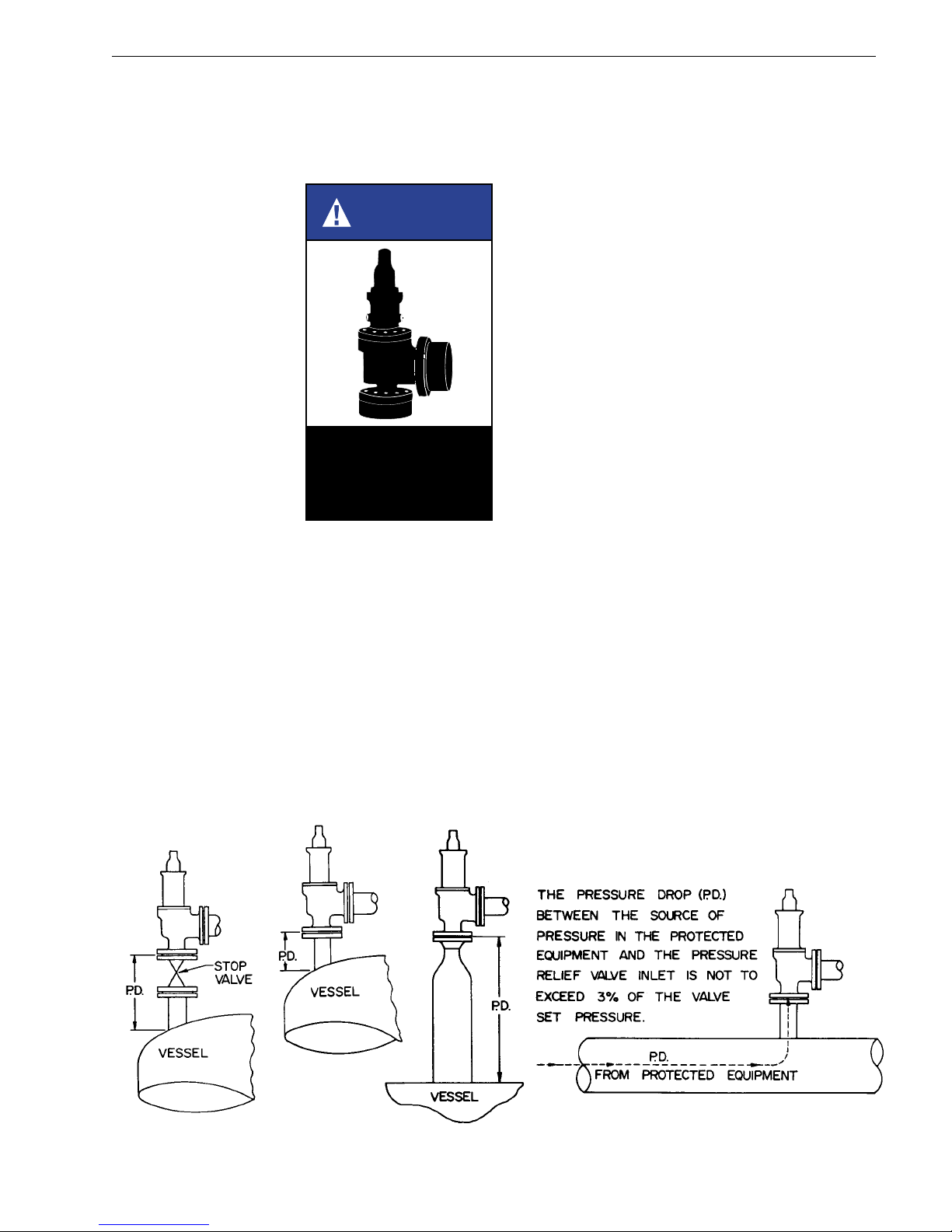

A. Mounting Position

Safety relief valves

should be mounted

in a vertical upright

position (per API

RP520). Installing

a safety relief valve

in other than a

vertical position (±1

degree) will

adversely affect its

operation in

varying degrees,

as a result of

induced

misalignment of

moving parts.

A stop valve may

be placed between

the pressure vessel

and its relief valve only as permitted by code

regulations. If a stop valve is located between

the pressure vessel and safety relief valve, the

stop valve port area should equal or exceed the

nominal internal area associated with the pipe

size of the safety relief valve inlet. The pressure

drop from the vessel to the safety relief valve

shall not exceed 3% of the valve's set pressure,

when flowing at full capacity.

WARNING

Mount safety relief

valves in only a vertical

upright position.

All flange bolts should be drawn evenly to prevent

distortion of the valve body and the inlet nozzle.

Safety relief valves should be located for easy

access and/or removal so that servicing can be

properly performed. Sufficient working space

should be provided around, and above, the valve.

B. Inlet Piping

The inlet piping (see Figure 7, below) to the valve

should be short and direct from the vessel, or

equipment, being protected. The connection to

the vessel should be provided with a radius to

permit smooth flow to the valve. Sharp corners

should be avoided. If this is not practical then the

inlet should be bored at least one additional pipe

diameter. In any event, the pressure drop from

the vessel to the valve should not exceed 3% of

valve set pressure when the valve is flowing full

capacity. In no event should the inlet piping be

smaller in diameter than the inlet connection of

the valve. Excessive pressure drop at the inlet of

a pressure relief valve in gas, vapor, or flashingliquid service will cause extremely rapid opening

and closing of the valve, which is known as

"chattering". Chattering will result in lowered

capacity and damage to the seating surfaces.

The most desirable installation is that in which

the nominal size of the inlet piping is the same as,

or greater than, the nominal size of the valve inlet

flange, and in which the length does not exceed

the face-to-face dimensions of a standard tee of

the required pressure class.

The flanges and sealing faces of the valve and all

connecting piping must be free from dirt, sediment

and scale.

FIGURE 7

CON-2

Page 10

VI.B. (Continued)

Safety relief valve

inlets should not be

located at the end

of a long, horizontal

inlet pipe through

which there is

normally no flow.

Foreign matter

may accumulate,

or liquid may be

trapped, and may

interfere with the

operation of the

valve or be the

cause of more

frequent valve

maintenance.

Safety relief valve

inlets should not be located where excessive

turbulence is present such as near elbows, tees,

bends, orifice plates, or throttling valves.

Section VIII of the ASME Boiler and Pressure

Vessel Code requires that the design of the inlet

connection consider stress conditions induced

by reaction forces during valve operation, by

external loading, by vibration and by loads due to

thermal expansion of discharge piping.

1. The determination of reaction forces during

valve discharge is the responsibility of the

vessel and/or piping designer. DVCD

publishes certain technical information

about reaction forces under various fluid

flow conditions, but assumes no liability for

the calculations and design of the inlet

piping.

WARNING

Do not locate valve at

end of pipe thru which

there is normally no

flow, or near elbo ws,

tees, bends, etc.

3. Vibrations in the inlet piping systems may

cause valve seat leakage and/or fatigue

failure of the piping. These vibrations may

cause the disc seat to slide back and forth

across the nozzle seat and result in damage

to the seating surfaces. Vibration may also

cause separation of the seating surfaces

and premature wear to certain valve parts.

High-frequency vibrations are more

detrimental to pressure relief valve tightness

than low-frequency movements. This effect

can be minimized by providing a larger

difference between the operating pressure

of the system and the set pressure of the

valve, particularly under high-frequency

conditions.

4. Temperature changes in the discharge

piping may be caused by fluid flowing from

the discharge of the valve, prolonged

exposure to the sun, or heat radiated from

nearby equipment. Any change in

temperature of the discharge piping will

cause a change in the length of the piping.

The resulting change in length may cause

stresses which will be transmitted to the

pressure relief valve and its inlet piping.

Stresses caused by thermal changes in the

discharge piping can be avoided by proper

support, anchoring, or provision for flexibility

of the discharge piping. Fixed supports

should not be used.

2. External loading by poorly designed

discharge piping and support systems can

be the cause of excessive stresses and

distortions in the valve as well as the inlet

piping. The stresses set up in the valve

may cause malfunctioning or leakage of

the valve. Forced alignment of the

discharge piping will also induce such

stresses. Discharge piping should be

independently supported and carefully

aligned.

▲

CON-2

Page 11

VI. (Continued)

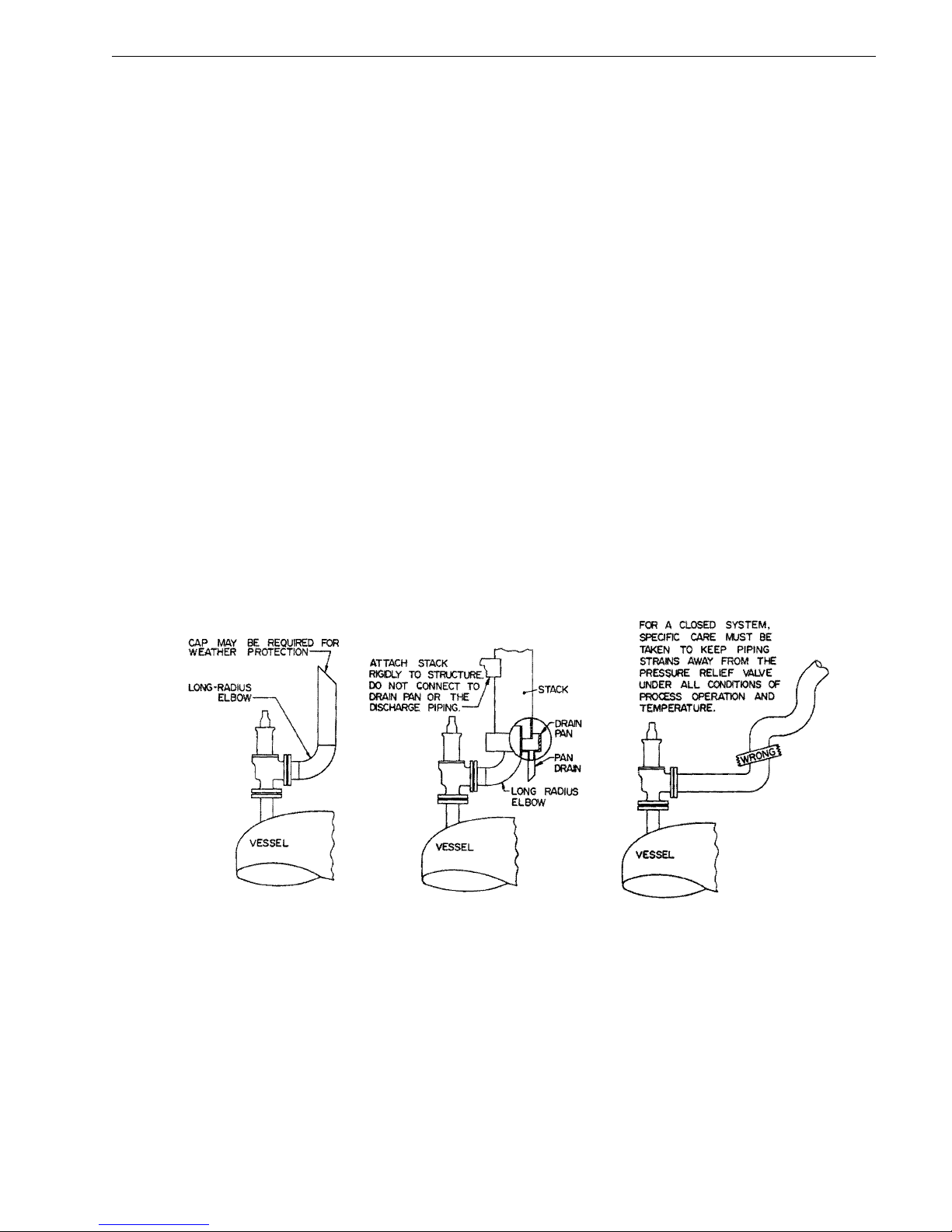

C. Outlet Piping

Alignment of the internal parts of a safety relief

valve is important to ensure proper operation

(see Figure 8, below). Although the valve body

will withstand a considerable mechanical load,

unsupported discharge piping consisting of more

than a companion flange, long radius elbow and

a short vertical pipe is not recommended. Care

should be taken to ensure thermal expansion of

piping and support system does not produce

strains in a valve. Spring supports are

recommended where this may be the case. The

discharge piping should be designed to allow for

vessel expansion as well as expansion of the

discharge pipe itself. This is particularly important

on long distance lines.

Consideration should be given to discharge pipe

movement resulting from wind loads. A continual

oscillation of the discharge piping introduces

stress distortion in the valve body and the resultant

movement of the internal parts may cause

leakage.

Where possible, drains should be piped away to

prevent the collection of water or corrosive liquid

in the valve body. Attention should be given to

the support of the drainage piping.

When two or more valves are piped to discharge

into a common header, the built-up back pressure

resulting from the opening of one (or more)

valve(s) may cause a superimposed back

pressure in the remaining valves, unless the

bonnet is vented. Under these conditions, use of

bellows valves is recommended. Bellows valves

may also permit use of a smaller size manifold.

In every case, the nominal discharge pipe size

should be as large as, or larger than, the nominal

size of the pressure relief valve outlet flange. In

the case of long discharge piping, it sometimes

must be much larger.

NOTE:

Bonnet vent is to be plugged for all nonbellows valves. Bellows valves must have

open bonnet vent.

▲

FIGURE 8

CON-2

Page 12

Valve caps and bonnets

can trap fluids. Use

caution when removing

to prevent injury or

environmental damage.

CAUTION

VII. Disassembly Instructions

NOTE:

Many pressure vessels

that are protected by

Consolidated® Safety

Relief Valves contain

dangerous materials.

Decontaminate and

clean the valve inlet and

outlet and all external

surfaces in accordance

with the cleaning and

decontaminating

recommendations in

the appropriate Material

Safety Data Sheet.

A. General

Information

Consolidated

Safety Relief

Valves can be

easily

disassembled for

inspection,

reconditioning

seats, or replacing

internal parts.

Appropriate set

pressure can be

established after

reassembly.

(Again, refer to

Figures 1-6, on

pages 6 and 7, for

parts nomenclature.)

®

Decontaminate or clean if

necessary before pretesting or

disassembly . Safety and

environmental precautions must

be taken for the decontamination

or cleaning method used.

DANGER

DANGER

Do not remove bolts if

pressure in line, as this

will result in severe

personal injury or death.

B. Specific Steps

1. Remove the

cap (including lifting

gear); then,

remove the

cap gasket, if

applicable.

2. Remove the

adjusting

ring pin and

gasket. If the

existing

blowdown is

to be

restored

upon

reassembly,

the position

of the

adjusting

ring, with respect to the disc holder, should

be determined. To do this, turn the adjusting

ring counterclockwise (i.e., move notches

on the adjusting ring from left to right).

Record the number of notches passing the

ring pin hole, which are required for the ring

to contact the disc holder. This information

will be used in setting the ring upon

reassembly of the valves.

3. a. For D-T Orifice Valves: Loosen the

adjusting screw nut. Using a Depth

Micrometer or a Dial Caliper, measure the

distance from the top of the spindle to the

top of the Adjusting Screw. This allows the

adjusting screw to be re-adjusted close to

the proper spring compression without

excessive testing. Record the

measurement for reference when reassembling the valve. Note: This

procedure does not substitute for actual

NOTES:

• Before starting to disassemble the valve, be sure

that there is no media pressure in the vessel.

• Parts from one valve should not be interchanged

with parts from another valve.

CON-2

Ram In Use

FIGURE 9

Page 13

VII.B. (Continued)

pressure testing. Remove the

Compression Screw from the Bonnet. Use

pliers to prevent the Spindle from turning

when removing the Compression Screw.

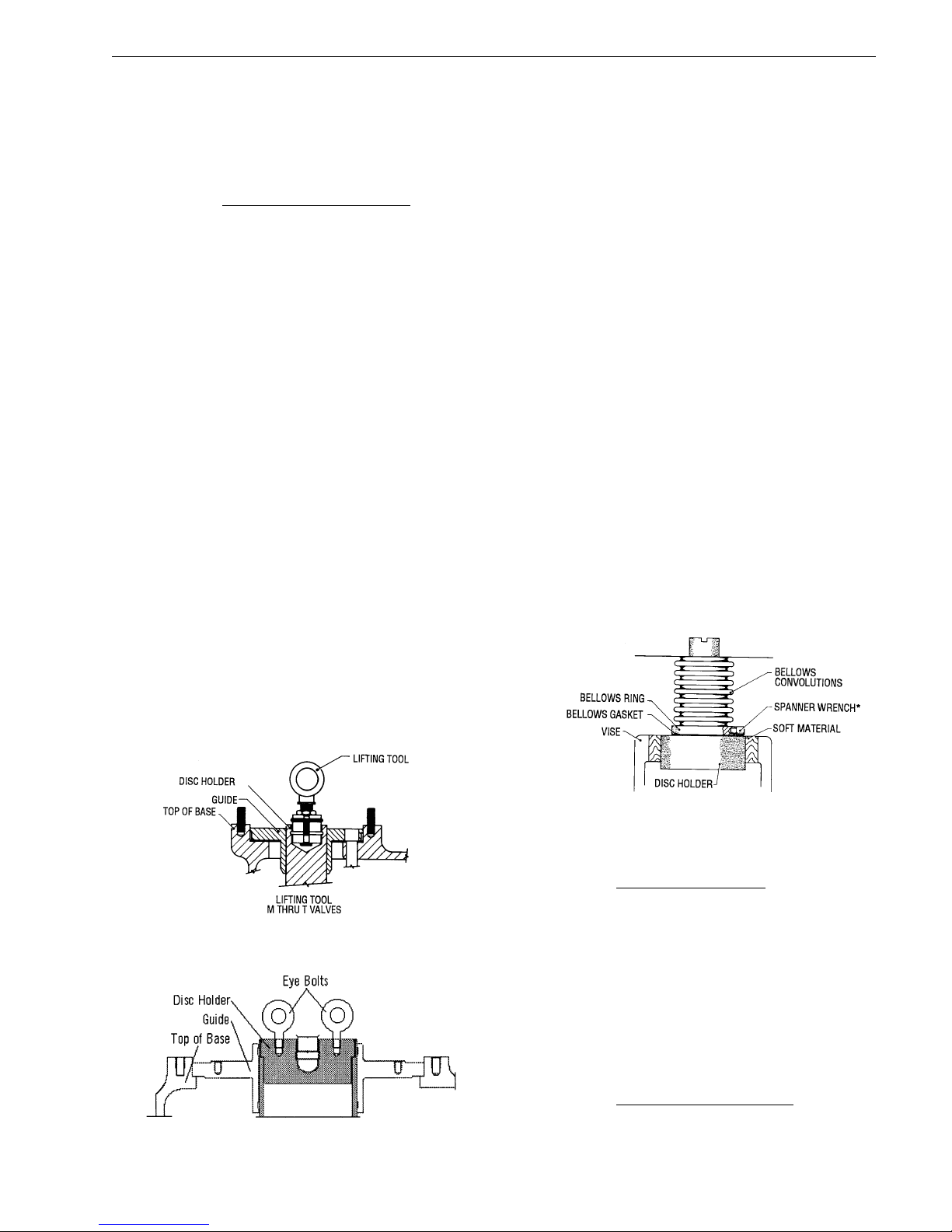

b. For V and W Orifice Valves: Attach the

setting device. Apply enough pressure to

the plunger using the ram to free the

compression screw. Unscrew the

compression screw completely out of the

bonnet. The valve should be set using the

setting procedure after reassembly.

4. Remove the stud nuts and lift off the bonnet.

Next, remove the bonnet gasket.

5. Remove the spring and spring washers.

The spring and spring washers should

be kept together, as a unit, at all times.

6. For D thru M orifice valves, remove the

upper internal parts by carefully pulling

“straight up” on the spindle. For bellows

valves, care should be taken to avoid

damaging the bellows or its flange. If parts

are fouled, use a suitable solvent for

loosening the components. For the P thru

T orifice valves, special lifting tools are

available for ease of upper, internal-parts

removal. First, remove the spindle by

using a screwdriver to compress the spindle

retainer. Then insert the lifting tool (see

Figure 10, below) into the disc holder spindle

pocket and tighten the eyebolt. Remove

the disc holder and disc by lifting up on the

lifting tool. For V and W orifice valves, use

the lifting lugs to lift the disc holder top and

remove all internals.

7. To remove the spindle from the disc holder

for D thru M orifice valves, clamp the skirt

portion of the disc holder snugly between

two wooden V-blocks in a suitable vise

(see Figure 11, below). Then compress

the spindle retainer with a screwdriver or

similar tool through the slots provided, and

remove the spindle.

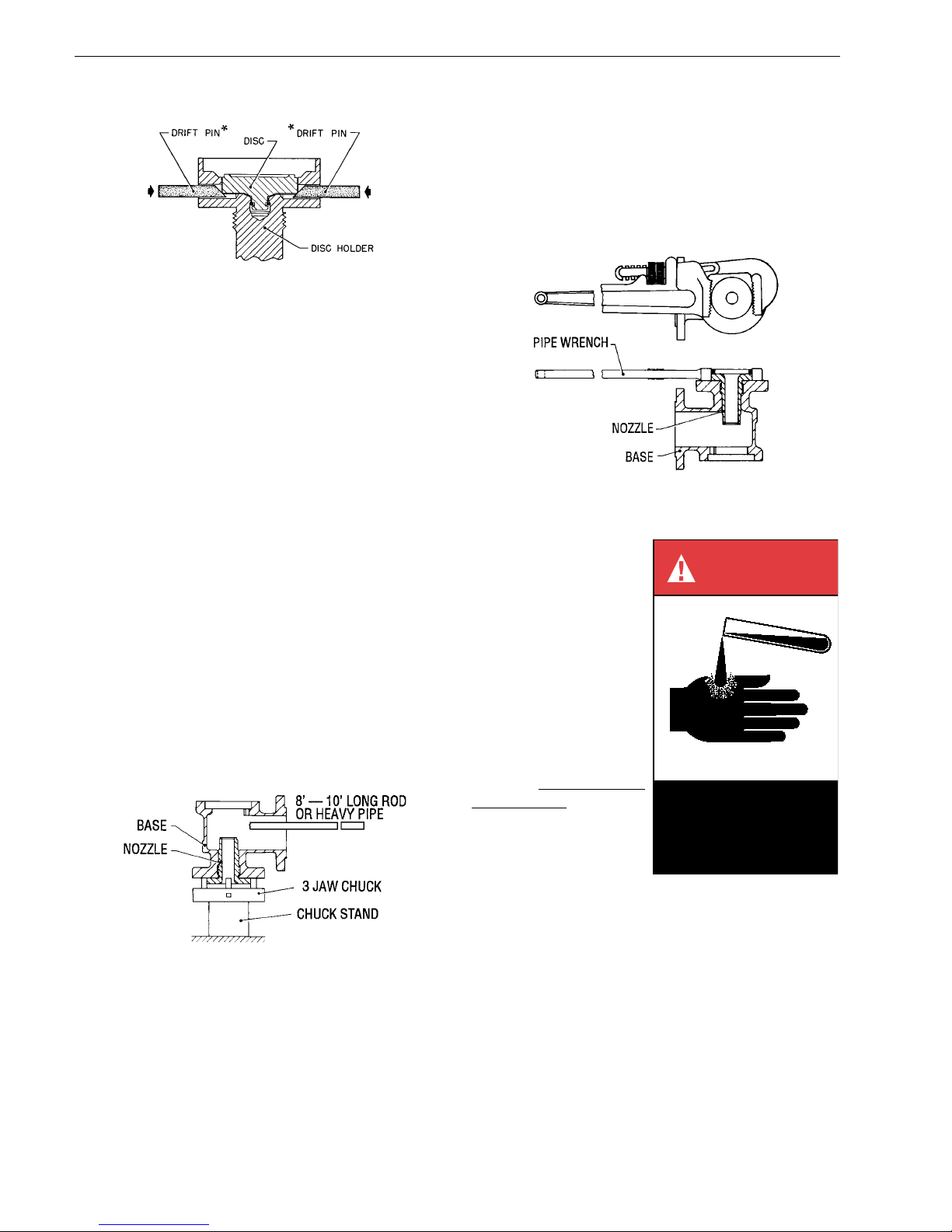

8. Remove guide from the disc holder. (For

restricted lift valves, refer to Paragraph

X.L., on page 28 of this manual.) For V and

W orifice, unbolt bellows from guide before

guide removal.

9. For D-T orifice bellows valves, the bellows

is attached to the disc holder by right-hand

threads. Apply a special spanner wrench*

to the bellows ring, and remove by turning

counterclockwise (again, see Figure 11,

below). The bellows convolutions are very

thin, and fragile, and care should be taken

to protect them from damage at all times.

Next, remove the bellows gasket. For V

and W orifice bellows valves, the bellows is

bolted to the guide and disc holder. These

bolts should be removed before removal of

the guide.

FIGURE 10

FIGURE 10 b

* Drift Pins, See Section XVII, page 43 for details.

FIGURE 11

10. a. For D-T Orifice Valves: Remove the disc

from the disc holder in the following manner.

Clamp the stem portion of the disc holder,

disc end up, firmly between two wooden Vblocks in a vise. Then start special drift

pins* into the holes in the disc holder (see

Figure 12) with the tapered portion of the

pins working against the top of the disc as

indicated. Tap each pin alternately, with a

light machinist’s hammer, until the disc

snaps out of the recess in the disc holder.

b. For V and W Orifice Valves: Turn the disc

holder on its side. Remove the retaining

bolts. Attach the lifting lug to the disc and lift

out.

CON-2

Page 14

Follow recommendations for

safe handling in the solvent’s

Material Safety Data Sheet and

observe safe practices for any

cleaning method.

DANGER

VII.B. (Continued)

FIGURE 12

11. For O-Ring seat seal valves only, remove

the retainer lock screw(s), retainer and ORing.

12. Remove the adjusting ring by turning it

counterclockwise (left-handed).

13. The nozzle should be removed from the

base. (Reference nozzle removal methods

in paragraph 14.)

14. The nozzle is normally removed for routine

maintenance and service. The nozzle is

assembled to the base with threads and

may be removed by turning it

counterclockwise. To facilitate removal of

the nozzle from the base, it may be found

beneficial to first soak the threaded joint

with a suitable penetrating liquid or solvent.

In instances where the nozzle is frozen into

the base, its removal may be helped by

sufficiently heating the base from the outside

with a blowtorch in the area of the nozzle

threads, while dry ice or other cooling

medium is applied to the inside of the

nozzle.

NOTE:

Exercise care when inserting a rod or

pipe in the outlet, in order to ensure that

the valve nozzle is not damaged during

this operation.

16. Use a large pipe wrench on nozzle flange

to remove the nozzle from the base (see

Figure 14).

FIGURE 14

VIII. Cleaning

1900 Series Safety Relief

Valve internal parts may

be cleaned with industrial

solvents, cleaning

solutions and wire

brushes. If you are using

cleaning solvents, take

precautions to protect

yourself from potential

danger from breathing

fumes, chemical burns, or

explosion. See the

solvent’s Material Safety

Data Sheet for safe

handling recommendations and equipment.

FIGURE 13

NOTE:

Should heat be applied, use care to

prevent cracking of cast parts.

15. Utilize a 3 or 4 jaw chuck welded vertically

to a stand bolted to a concrete floor. Chuck

on nozzle flange and break the body loose

CON-2

from the nozzle with a heavy rod or pipe

(see Figure 13).

It is not recommended to

“sand blast” internal parts as it can reduce the dimensions

of the parts. The base, bonnet and cap castings may be

sand blasted with care not to erode internal surfaces, or

damage machined surfaces.

IX. Parts Inspection

A. Nozzle Inspection

Criteria

Nozzle should be replaced if:

1. Dim. from seat to first thread after

remachining and lapping is less than D min. on Table 1.

2. Both thread sections are damaged from

pitting and/or corrosion.

Loading...

Loading...