Page 1

Translation of the original

operating instructions

DRELLOSCO P 1020

Page 2

2 DRELLOSCOP 1020

Article no. of this documentation: 1.1020.2B001e

As of: 12.11.2012

DRELLO is used in these operating instructions as abbreviation for

DRELLO Ing. Paul Drewell GmbH & Co. KG.

No part of this publication may be duplicated, transmitted, transcribed,

stored to a memory device, translated into another language or computer

language in any way without prior written permission from DRELLO. Infringement of this copyright can also compromise product support from

DRELLO for this device. DRELLO reserves the right to make changes to

the product described within this manual without advanced notice. The

contents of the manual do not contain any contractual or other obligations

on the part of DRELLO and are not legally binding. This publication was

created with the utmost care. Suggestions for improvement can be submitted to DRELLO.

© DRELLO Ing. Paul Drewell GmbH & Co. KG

Andreas-Bornes-Strasse 46

D-41179 Mönchengladbach

Telephone: +49 - (0)2161 - 909 - 6

Telefax: +49 - (0)2161 - 909 - 700

Email: info@drello.de

Internet: www.drello.de

Page 3

Table of Contents

DRELLOSCOP 1020 3

1 General 5

1.1 Information on these operating instructions 5

1.2 Explanation of symbols 6

1.3 Warnings 7

1.4 Limitation of liability 8

1.5 Spare parts 8

2 Safety 9

2.1 General 9

2.2 Responsibility of the operator 9

2.3 Staff requirements 11

2.3.1 Staff qualifications 11

2.3.2 Unauthorised persons 12

2.3.3 Instruction 12

2.4 Intended use 13

2.5 Device protection 13

2.6 Particular hazards 14

2.6.1 Danger from stroboscopic lig ht flashe s 14

3 Technical specifications 15

4 Description 17

4.1 Description of functions 17

4.2 Device overview 20

4.2.1 Front view 22

4.2.2 View from underneath 22

4.3 Menu structure 23

4.4 Type plate 24

5 Transport, assembly and connection 25

5.1 Scope of supply 25

5.2 Available accessories 27

5.3 Unpacking 27

5.4 Storage 28

5.5 Requirements for the place of use 29

5.6 Mains operation 29

5.7 Connecting an external controller 30

Page 4

Table of Contents

4 DRELLOSCOP 1020

6 Operation 31

6.1 Switching the device ON/OFF 31

6.2 Operating 31

6.2.1 Selecting the operating mode 31

6.3 Further setting options for flash operation (manual control) 33

6.3.1 Setting the flash sequence display 33

6.3.2 Displaying the current flash du ration 33

6.3.3 Setting the "Duration-Auto-Modus" variable flash duration 34

6.3.4 Setting the flash duration "Duration-Fix-Modus" 35

6.4 Further setting options for flash operation (external control) 36

6.4.1 Image shift (PHASE) 36

6.4.2 Setting the slow-motion function 37

7 Maintenance and repair 38

7.1 Maintenance 38

7.2 Changing the batteries 38

7.3 Cleaning 39

7.4 Troubleshooting 39

7.5 Repairs 40

7.6 Disposal 40

Page 5

General

DRELLOSCOP 1020 5

1 General

1.1 Information on these operating instructions

These operating instructions contain important instructions on handling the DRELLOSCOP 1020 LED hand-hel d str obo sc ope, hereinafter referred to as the device, during installation, operation,

maintenance and care as well as disposal.

The requirement for safe, proper and economic work on and with

the device is compliance with all spe cif ied safe t y and handlin g instructions.

Compliance helps to avoid danger, minimise repair costs and

downtimes and increase the reliability and the service life of the device.

In addition, local accident prevention regulations and general safety

rules for the location of the device must be complied with.

Read the operating instructions carefully before beginning any

work! They are part of the product and must be kept in the immediate vicinity of the device and be accessible to operating staff at all

times.

Page 6

General

6 DRELLOSCOP 1020

1.2 Explanation of symbols

All warnings in these operating instructions are also indicated by a

warning symbol.

The following warning symbols are used throughout these operating instructions:

Symbol Meaning

General warning

Danger of electric current

General instructions and useful suggestions on

handling

Note on observing environmen tal regula tio ns

for disposal

Page 7

General

DRELLOSCOP 1020 7

1.3 Warnings

The warnings used in these operation instructions are indicated by

signal words that are intended to indicate the extent of the danger.

The warning symbol also indicates the type of danger.

The following warning symbols are used throughout these operating instructions:

WARNING

Risk of injury!

Consequences of failure to observe...

► Instructions for avoidi ng

A warning of this category indicates a potentially dangerous situation. If the dangerous situation is not avoided, it may lead to serious

injury or even death.

Follow the instructions in this warning to avoid possible danger of

serious injury or even death.

CAUTION

Damage to property by...

Consequences of failure to observe...

► Instructions for avoidi ng

This warning level indicates potential damage to property. If the situation is not avoided, it may lead to damage to property.

Follow the instructions in this warning to avoid material damage.

NOTE

Descriptive text…

A descriptive text contains additional information that is important

for further processing or for simplifying the procedure step explained.

Page 8

General

8 DRELLOSCOP 1020

1.4 Limitation of liability

The manufacturer assumes no liability for damage and operational

faults resulting from:

■ failure to observe these operating instructions,

■ use for other than the intended purpose,

■ deployment of non-trained or insufficiently-trained staff,

■ use of non-approved equipment,

■ faulty connection,

■ previous work that is not part of the scope of supply,

■ failure to use original replacement and acce ssory parts,

■ technical modifications and changes not approv ed by DRELLO,

■ failure to perform prescribed maintenance work.

With the exception of further claims, DRELLO is liable for any errors or omissions within the framework of the warranty obligations

stated in the contract.

Claims for damage are excluded irrespective of the legal basis.

1.5 Spare parts

WARNING

Danger of injury due to wrong or faulty spare

parts!

Incorrect or faulty replacement parts can lead to

damage, malfunction or total breakdown of the

equipment as well endangering the safety.

► Use only the original spare parts of

the manufacturer.

Page 9

Safety

DRELLOSCOP 1020 9

2 Safety

2.1 General

This section provides important instructions on all safety aspects

for optimum protection of staff as well as safe and smooth operation.

WARNING

Danger from failure to observe the safety instructions!

Failure to observe the safety and handling instructions listed in these operating instructions can lead

to considerable danger.

► Always pay attention to all warnings and instruc-

tions specified here.

2.2 Responsibility of the operator

Since this device is used in the commercial sector, the operator is

subject to the legal requirements for occupational safety.

In addition to the occupational safety instructions in these operating

instructions, the current safety, accident prevention and environmental protection regulations relevant for operation of the device

must be complied with.

The operator must

■ be informed on the current industrial safety r egulation s and c on-

duct risk assessment to determine additional hazards specific to

the device that result from the special work conditions at its lo c ation. These must be implemented in the for m of in structions for

the operation of the device.

■ continually check during the entire per iod of serv ice that all oper-

ating instructions created by hi m comply with current regulations

and to modify them if necessary.

■ clearly regulate and determine the responsi bilitie s of t he staff f or

installation, operation, maintenance and c leaning

Page 10

Safety

10 DRELLOSCOP 1020

■ ensure that all persons handling the dev ice have r ead and un der-

stood these operating instructions. In addit ion, he mu st ensure

that persons are regularly trained and informed on all haz ar ds

when using the device.

■ check that staff observes the oper ating instru ctions a nd is aware

of safety and danger while w orking w ith the dev ice.

■ ensure that these operating instructions and all additional regula-

tions can be accessed by operating and ma intenanc e staff.

■ determine a person responsible for the dev ice and allow him to

reject instructions from third par ties that ar e prejud icial to safety!

■ make the necessary protective equipment av ailab le to staff.

The operator is also responsible that the device is always in perfect

condition and the following therefore applies:

■ The operator must ensure that the cleaning and mai ntenanc e in-

tervals stated in these operating instructions are adhered to.

Page 11

Safety

DRELLOSCOP 1020 11

2.3 Staff requirements

2.3.1 Staff qualifications

WARNING

Risk of injury due to insufficient qualification!

Improper use can result in considerabl e damag e to

persons or property.

► All activities shall only be performed by qualified

staff.

The following qualifications are stated in these operating instructions for various different fields of activities.

■ Instructed person

was instructed by the operator on their assigned responsibilities

and the possible dangers resulting from improper behaviour.

■ Specialist staff

is able to carry out assigned work tasks as well as recognise

and prevent possible dangers based on his/her technical training, knowledge and experience, including knowledge of applicable regulations.

Only those staff members are permitted who can be expected to reliably perform their task. Those staff members whose responsiveness is affected by substances such as medication shall not be

permitted.

Allow staff to be trained or instructed and/or persons undergoing

general training to work on the device only under the constant supervision of an experienced person!

NOTE

Observe age and occupational-specific reg ulations

at the location of the device when selecting staff.

Page 12

Safety

12 DRELLOSCOP 1020

2.3.2 Unauthorised persons

WARNING

Danger for and resulting from unauthorised

persons!

Unauthorised persons who do not fulfil the requirements are not familiar with the dangers at the work

location.

► Do not permit unauthorised persons to be in the

vicinity of the work area.

► In case of doubt, approach the persons and

instruct them to leave the work area.

► Do not continue with work while the unauthor-

ised person is in the vicinity of the work area.

2.3.3 Instruction

Staff must be regularly instructed by the operator.

NOTE

In order to keep track and protocol all instruction

sessions, participating members of staff are required to acknowledge with their signature.

Page 13

Safety

DRELLOSCOP 1020 13

2.4 Intended use

The device is portable and intended for visual che ck ing of mo v ing

work sequences. It is possible to connect an external controller via

machine impulse for example.

Any use other than previously stated is considered as improper

use.

WARNING

Danger from use for other than the intended

purpose!

Any use other than and/or going beyond the intended use of the device can lead to dangerous situations.

► Only use the device for its intended purpose.

► Pay attention to all specifications in these

operating instructio ns.

No claims of any kind will be accepted for damage resulting from

use of the appliance for other than its intended purpose. The risk

must be borne solely by the user.

2.5 Device protection

The DRELLOSCOP 1020 is protected during battery operation by

an internal self-restoring fuse, which is not replaceable. If the

DRELLOSCOP 1020 is operated via the NG-1020 mains supply,

the device is protected by the fuse of the mains supply.

Page 14

Safety

14 DRELLOSCOP 1020

2.6 Particular hazards

2.6.1 Danger from stroboscopic light flashes

WARNING

Danger from stroboscopic light flashes

In rare cases, stroboscopes can cause epileptic fits

when operated at a frequency of approx. 10 – 20 Hz.

The risk increases if the contrast between the flash

and the ambient lighting is high. Even persons who

have never experienced an epilept ic fit can be affected. Consequent injury such as falling over can

therefore not be ruled out.

► If possible, always work in normal ambient light

conditions.

► When setting the flash sequence, begin with the

highest frequency.

► Make sure that persons suffering from epilepsy

are not in the vicinity of the device during operation.

WARNING

Danger from optical illusions!

A rotating machine part appears to be stationary at

certain settings of the device. Persons who are not

informed of this effect may reach into or be caught

by the running machine, which could lead to serious

or even fatal injuries.

► Inform all persons who stand in the vicinity of

the illuminated area on the functionality of the

device and make them aware of the danger that

can result from the optical illusion.

Page 15

Technical specifications

DRELLOSCOP 1020 15

3 Technical specifications

Dimensions

Length / width 200 - 85 mm

Height / with rotary adjuster 40 - 55 mm

Weight approx. 0.5 kg

Controller

Manual controller (internal) via rotary adjuster,

120...25000 min-1 or

2...416.6 sec-1

fast finder function by multiplica-

tion/division of the set flash sequence

External controller via rectangular pulse 10...24 V

60…199999 min

-1

or 1…3333 sec-1

display up to 99999 min-1 (1666.6 Hz)

or 3333.3 sec-1

smooth real-

time image shifting 0...360°

and slow-motion function, automatic input

frequency division from 416.66 sec-1

Flash length control automatic, depending on the

flash sequence or manual by rotary

adjuster, setting range 1...250 μs

Maximum flash sequence 416.66 sec-1 or 25000 min-1

Measured value display 5-digit 7-segment display,

number height 7.6 mm

Electrics

Mains supply 3 x 1.2 V NiMH rechargeable batteries

(AA),

fast charging capability

Plug-in mains supply 5 VDC

Power consumption 400 mA @ 5 VDC

Reverse polarity protection yes

Operating time (battery) approx. 4 hours at full load

(depending on battery type, 2850 mAh)

Operating time (plug-in mains

supply)

Continuous operation

Page 16

Technical specifications

16 DRELLOSCOP 1020

Ambient conditions

Ambient temperature range 0 … +4 5 °C

Storage temperature range -20 … +60 °C

Degree of protection IP50

Illumination

LED High-performance LED, white radiating

combined with highly-efficient optics

Colour temperature 6500 K

Illumination Ø 150 mm @ 300 mm object gap

Illumination strength 3500 lx @ 200mm object gap; meas-

ured at 50 Hz and 50 µs flash length

CE declaration of conformity printed version on request

NOTE

Battery operation

Following detection of undervoltage during battery

operation (display flashes), the device can be

operated for approx. 15 minutes.

Page 17

Description

DRELLOSCOP 1020 17

4 Description

4.1 Description of functions

The DRELLOSCOP 1020 is a portable LED hand-held stroboscope

for use in a harsh industrial environment.

Switching the appliance ON/OFF

The device is switched on or off by pressing the ON/OFF button.

A display test is performed after switching on. All display elements

light up for approx. 4-5 seconds and subsequently switch to the

basic setting (LED sec

-1

lights up, display value is 50,000). P ress-

ing the "ON/OFF" button again, switches off the device.

Internal controller (hereinafter referred to as manual controller)

Flash sequence 2.00 sec-1 ...416.67 sec-1 / 120 min-1....25000 min-1.

Setting takes place via the rotary adjuster.

Turn clockwise → flash sequence increases

Turn anticlockwise → flash sequence decreases

Fast finder function

Pressing the "Double" button mult ipl ies the curr ent flas h seq uenc e

by a factor of 2. Pressing the "Halving" button divides the current

flash sequence by two. Exceeding the lower or higher flash sequence limit (2Hz / 416.67Hz) is not possible and in this case, multiplication or division by 2 is not performed. This function allows

convenient detection of the true flash sequence with respect to the

object motion sequence.

Explanation

If an intermittent moving object seems to be standing still, the flash

sequence corresponds to the motion sequence or the ratio is an integer number. However, the highest flash sequence possible

should be set in order to produce a simple stati onary image . When

this has been achieved, the flash sequence is multiplied by a factor

of 2 by pressing the "Double" button. If a doubled stationary image

is then produced, the previously set flash sequence is correct. If

however, a single stationary image is produced, the set flash sequence was too low. Repeated doubling of the flash sequence

helps to determine the correct motion sequence. If this is higher

than the flash sequence range of the stroboscope allows, the true

motion sequence can be determined using a following method:

Page 18

Description

18 DRELLOSCOP 1020

Starting with the highest flash sequence, the first two values are

determined by reducing them, which then produces simple stationary images of the object. This then results in the true motion sequence

True motion sequence f

x

[Hz] = n ∙ f1 [Hz]

with

[ ]

[ ] [ ]

HzfHzf

Hzf

n

21

2

−

=

Example:

Beginning with the highest flash sequence (416.66Hz), the flash

sequence is reduced until a simple stationary image results. The

flash sequence is named f

1

.

The flash sequence is then reduced further until another simple stationary image can be seen. The motion sequence is named f

2

.

To determine the "n" factor, the determined values f

1

and f2 are in-

serted into the corresponding formula. The true motion sequence f

x

cannot be determined using the formula (fx = n ∙ f1). If rotating objects are being examined, rotation-symmetric al str u ct ur e s su ch as

spoke wheels must be marked to rule out ambiguity due to symmetry.

External controller

Pressing the "External" button ( cogw heel sy mbo l) other w ise name d

Extended External Control activates the "external co ntr ol " fun ctio n.

The frequency of the impulse sequence supplied then appears in

the display. The flash sequence is synchronised to the incoming

control impulses and therefore creates the impression that the object is stationary even with heavily fluctuating movement for example. If no control signal is supplied to the "external input", the value

0.0 appears in the display after approx. 2 seconds.

If the input frequency is greater than 416.67 sec

-1

, the flash sequence is automatically split to a permissible flash sequence value.

The displayed value corresponds to the original input frequency.

Note that a frequency input greater than 1.6666 KHz (99999 min

-1

)

cannot be displayed in min-1. Input frequencies greater than

3.33 kHz are not permit ted, t h e error cod e (Err 1) is displayed.

Flash sequences that are smaller than 1 Hz are not permissible

and are indicated by an error code (Err 2). However, flash triggering still takes place irrespective of this error message.

Page 19

Description

DRELLOSCOP 1020 19

Menu control

Additional function expansions or display values can be set via the

menu control.

Menu functions for manual control:

■ Display value in sec

-1

■ Display value in min

-1

■ Flash duration display or setting

Also with extended control

■ Setting of the image position and display of the pha se angle i n

degrees

■ Setting of the slow-motion funct ion und disp lay of the slow-motion

angle in degrees

For further information, refer to the "Menu structure" section

NOTE

The menu level "Display value selection or functions" is closed after pressing the "Menu" button

directly afterwards. The original setting remains

unchanged. For all other levels, the selected menu

functions are accepted.

Generally, all settings in the menu can be confir me d

by pressing the rotary adjuster.

Sleep function

If no settings to the device are made by the user, it is switched to

sleep mode after approx. 16 minutes. This reduces the intensity of

the display field and the keyboard considerably and the flash function is switched off. Pressing a button or the rotary adjuster switches the device back to the operating mode and the flash function on.

Page 20

Description

20 DRELLOSCOP 1020

4.2 Device overview

1 Display Displays the current value of the

selected function.

2 Display for min

-1

Display of flashes per minute. The LED

lights up when the function is selected.

3 "Menu" button Menu control selection. The LED lights

up when the function is selected.

1

2

3

4

5

6

10

9

8

7

Page 21

Description

DRELLOSCOP 1020 21

4 Rotary adjuster The rotary adjuster is used to switch the

flash mode on and off and for confirming

the menu functions.

Turning clockwise or anticlockwise, settings are made for the flash sequence

during manual control, image position,

slow-motion angle, flash duration, menu

selection and the "sec

-1

" or "min-1" dis-

play.

5 Double button The current flash sequen ce is multipl ied

by a factor of 2. This is for fast retrieval

of the true object frequency.

6 ON/OFF button Switches the device ON/OFF.

7 9-pole device

plug

Connection for the NG-1020 mains

adapter and supply of the control signals

for the "external control" mode

8 Halving button The current flash sequence is divided by

a factor of 2. This is for fast retrieval of

the true object frequency if the stationary

image is displayed repeatedly.

9 External button Selection of external control. The LED

lights up when the function is selected.

10 Display for sec-1 Displays number of flashes per second.

The LED lights up when the function is

selected.

Page 22

Description

22 DRELLOSCOP 1020

4.2.1 Front view

1 LED with lens High-performance LED with integrated

lens.

4.2.2 View from underneath

1 Lid fixing Thread for removing the fixing screws of

the battery compartment lid.

2 Battery compart-

ment

Battery compartment for accommodating

3 rechargeable 1.2V AA /HR6-size batteries (see scope of delivery)

1

1 2 1

+

+

Page 23

Description

DRELLOSCOP 1020 23

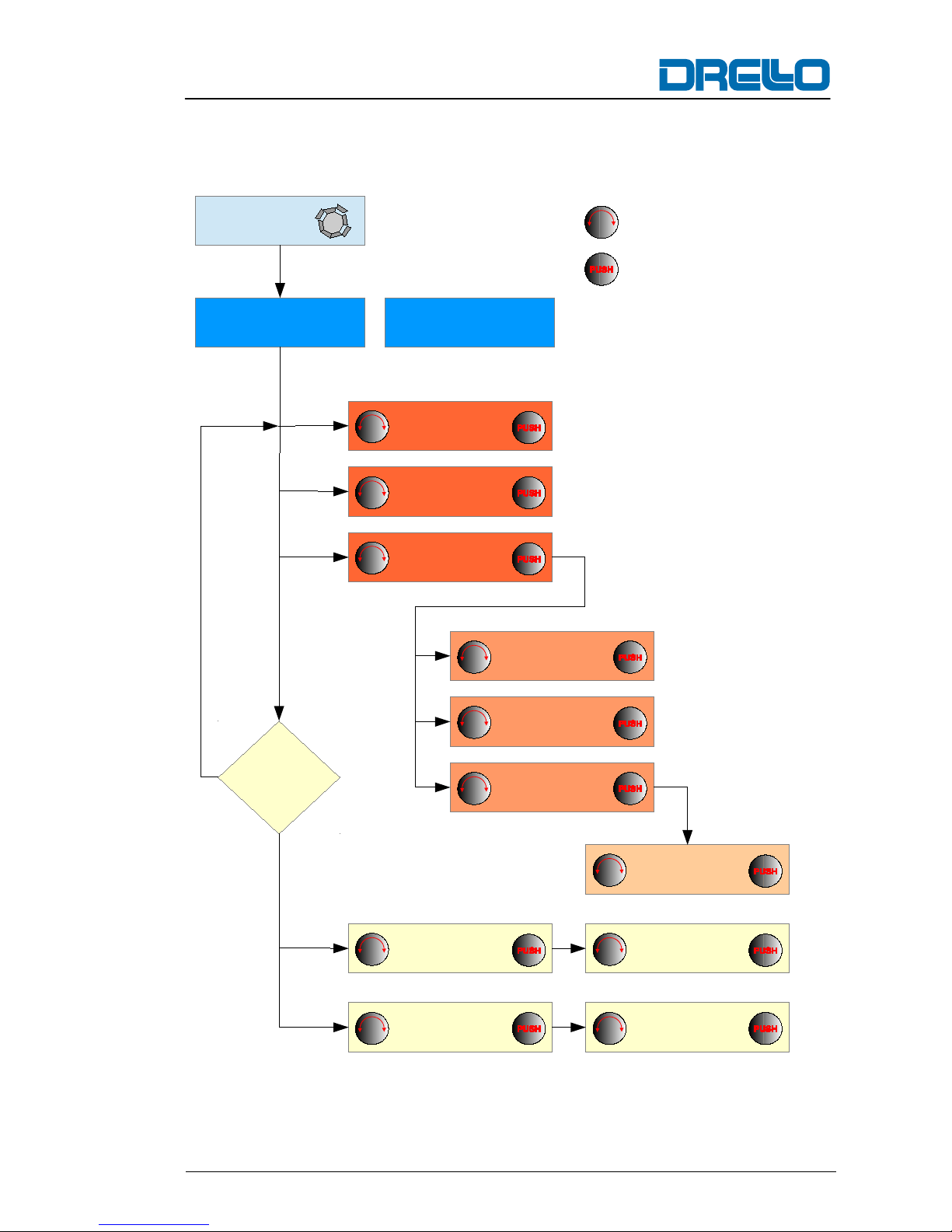

4.3 Menu structure

Menu button

M

Display secˉ1

Display min

ˉ1

Function dur.

POSITION

SL-MOTION

Display dur

Autom. dur. A

Manuel dur. F

Manuel dur. F

Press once for

selection

Press twice for

break-off

External

function

Yes

No

Selection via adjustor

Confirm entry by pressing

the button and chose

function

Rotary adjustor

Setting

position

Setting

slow motion

Page 24

Description

24 DRELLOSCOP 1020

4.4 Type plate

The type plate is located on the underneath of the device. It includes

the following information:

■ Device designation

■ Serial number

■ Connection values

■ Options

Page 25

Transport, assembly and connection

DRELLOSCOP 1020 25

5 Transport, assembly and connection

5.1 Scope of supply

The DRELLOSCOP 1020 system is supplied with the following

components depending on the system number:

DRELLOSCOP 1020 system number: 1.1020.00001

No.

Designation

Article number

1 DRELLOSCOP 1020

1.1020.60001

1 NG-1020 plug-in mains supply

1.1020.20001

3 NiMH 1.2V / 2100mAh HR6 (AA) recharge-

able battery

23.02.022

1 TK-1020-01 plastic transport case

39.1020.001

DRELLOSCOP 1020 operating manual, English

1.1020.2B001e

DRELLOSCOP 1020 system number: 1.1020.00002

No.

Designation

Article number

1 DRELLOSCOP 1020

1.1020.60001

1 LA 1020B charging device (Basic 4 plus)

59.1020.20001

6 NiMH 1.2V / 2100mAh HR6 (AA) recharge-

able battery

23.02.022

1 TK-1020-02 plastic transport case

39.1020.002

DRELLOSCOP 1020 operating manual, English

1.1020.2B001e

DRELLOSCOP 1020 system number: 1.1020.00003

No.

Designation

Article number

1 DRELLOSCOP 1020

1.1020.60001

1 LA 1020B charging device (Basic 4 plus)

59.1020.20001

3 NiMH 1.2V / 2100mAh HR6 (AA) recharge-

able battery

23.02.022

1 NG-1020 plug-in mains supply

1.1020.20001

1 TK-1020-02 plastic transport case

39.1020.002

DRELLOSCOP 1020 operating manual, English

1.1020.2B001e

Page 26

Transport, assembly and connection

26 DRELLOSCOP 1020

DRELLOSCOP 1020 system number: 1.1020.00004

No.

Designation

Article number

1 DRELLOSCOP 1020

1.1020.60001

1 LA 1020US charging device (Ultra Fast)

59.1020.20003

6 NiMH 1.2V / 2850mAh HR6 (AA) recharge-

able battery

23.02.022

1 TK-1020-02 plastic transport case

39.1020.002

DRELLOSCOP 1020 operating manual, English

1.1020.2B001e

DRELLOSCOP 1020 system number: 1.1020.00005

No.

Designation

Article number

1 DRELLOSCOP 1020

1.1020.60001

1 LA 1020US charging device (Ultra Fast)

59.1020.20003

3 NiMH 1.2V / 2850mAh HR6 (AA) recharge-

able battery

23.02.023

1 NG-1020 plug-in mains supply

1.1020.20001

1 TK-1020-02 plastic transport case

39.1020.002

DRELLOSCOP 1020 operating manual, English

1.1020.2B001e

NOTE

Check the entire delivery according to the delivery

note for completeness. We also refer you to our sales

and delivery conditions.

Measures in the event of transport damage

Report damage due to defective packaging or damage incurred

during transit to the haulage contractor, insurer and factory immediately after delivery .

Take steps to reduce existing damage and prevent any further

damage.

Page 27

Transport, assembly and connection

DRELLOSCOP 1020 27

5.2 Available accessories

The following accessories are av ailab le for the device:

No. Designation Article number

1 Sensors for the external controller

on request

5.3 Unpacking

Remove all packaging materials and protective foils from the product and the accessories before using it for the first time.

NOTE

► Do not remove the rating plate or any warning

signs on the appliance.

► If possible, keep the original packaging during the

guarantee period in order to be able to pack the

appliance properly in the event of a guarantee

claim. Transport damage will invalidate the guarantee.

NOTE

The packaging materials used can be recy cled. When

no longer required, dispose of the packaging materials according to local environmental regulations.

Page 28

Transport, assembly and connection

28 DRELLOSCOP 1020

5.4 Storage

The following regulations apply for storage:

■ Store at a dry place. Maximum relativ e humidity : 80%, non-

condensing

■ Protect from direct sunlight. Keep storage temp er ature

between -20 … +60 °C.

■ Store at a dust-free location.

■ Avoid mechanical vibration and damages.

NOTE

After use, store the device in the transport case supplied and also in the original packaging if possible.

CAUTION

Risk of damage to the device due to leaking batteries!

When storing for longer periods of time, ´the rechargeable batteries can leak and damage the device.

► Before storing for longer periods of time, remove

the batteries and store them in the battery compartments proved in the transport case.

Page 29

Transport, assembly and connection

DRELLOSCOP 1020 29

5.5 Requirements for the place of use

■ At the place of use, the device may not be subject to extreme

temperatures or humidity. Comply w ith the specificat ions for ambient conditions specified in the t echnical data.

■ Avoid setting up at locations with direct sunl ight .

■ Avoid strong ambient lighting at the place of u se in order to

achieve a good contrast.

■ Do not subject the device to vibration or knoc ks.

5.6 Mains operation

When using the NG-1020 plug-in mains supply (depending on the

scope of supply), battery operation is switched off automatically.

Carry out the electrical connection of the device as follows:

Insert the 9-pole cable socket of the connectin g cabl e

for the NG-1020 plug-in mains supply into the 9-pole device

connection plug of the DRELLOSCOP 1020 and secure it

against loosening by means of the locking screws.

Insert the plug of the NG-1020 plug-in mains supply into the

mains socket.

CAUTION

Risk of damage to the device due to incorrect pin

assignment!

Incorrect pin assignment of the connecting cable can

lead to destruction of the electrical components in

the device.

► Only use the NG-1020 plug-in mains supply from

the manufacturer.

Page 30

Transport, assembly and connection

30 DRELLOSCOP 1020

5.7 Connecting an external controller

If the device is to be connected to an external controller, the connections on the 9-pole plug must be undertaken by a qualified specialist electrician.

Pin assignment

The pin assignment of the connecting plug is depicted as follows:

Numbering of the device connection plug (top

view)

Pin Signal Direction Level

1 not assigned

2 not assigned

3 Supply voltage (+) Input 5 VDC

4 not assigned

5 Trigger impulse (0 V) Input 0 V trigger

6

Trigger impulse

(+)___----___ 10...24 VS

7 not assigned

8 Supply voltage (-) Input 0 V

9 Supply voltage (-) Input 0 V

Page 31

Operation

DRELLOSCOP 1020 31

6 Operation

6.1 Switching the device ON/OFF

The device is switched on or off by pressing the ON/OFF button.

After switching on, a display test is performed. All display elements

light up for approx. 4-5 seconds and subsequently switch to the

basic setting (LED sec

-1

lights up, display value 50,000). The de-

vice is subsequently ready for operation.

The device is switched off by pressing the butto n again .

6.2 Operating

6.2.1 Selecting the operating mode

The device can be operated in two modes:

Manual controller

This function is active when the LED of the "EXTERN" button is not

lit up. If the LED of the "EXTERN" button lights up, press the "EXTERN" button to activate manual control.

In manual control, the flash sequence is set with the rotary adjuster.

The object to be controlled should speed up to its target speed

in order to adjust the flash sequence.

Press the rotary adjuster to switch on the flash trigger.

Set the flash sequence via the rotary adjuster so that a stationary image is seen by the observer.

The flash sequence speed is increased by turning the rotary adjuster clockwise and decreased by turning anticlockwise.

If multiple images the object are seen, press the "Halving" button. Repeat this procedure until a single stationary image of the

object is achieved.

Page 32

Operation

32 DRELLOSCOP 1020

External controller

This function is available when the device is connected to a pulse

generator, from which it obtains control impulses. This type of flash

sequence control also generates the desired stationary image even

if the machine speed changes.

Press the "EXTERNAL" button . T he ex ternal control ler is act ivated when the LED of the button lights up.

The frequency of the supplied pulse sequence appears in the

display. If no control signal is suppl ied to the "ex ternal inp ut ",

the value 0.0 appears in the display after approx. 2 seconds.

NOTE

► If the input frequency is greater than 416.67 sec-1,

the flash sequence is split down to a permissi ble

flash sequence value automatically. The value

displayed corresponds to the original input frequency.

► An input frequency greater than 1.666 KHz can-

not be displayed in min

-1

.

► Input frequencies greater than 3.333 kHz are not

permissible and are indicated by an error code

"Err 1".

► Flash sequences that are smaller than 1 Hz are

not permissible and are indicated by an error

code "Err 2". However, flash triggering still takes

place irrespective of this error message.

NOTE

If the menu button is pressed, the measured value

can be depicted also for input signals smaller than

1Hz or greater than 3.333Khz in sec

-1

or up to

1.666KHz in min

-1

respectively.

Page 33

Operation

DRELLOSCOP 1020 33

6.3 Further setting options for flash operation

(manual control)

6.3.1 Setting the flash sequence display

Press the "Menu" button. The LED lights up when the function

is selected.

Turn the rotary adjuster until the lights up with "Display min-1" or

"Display sec

-1

".

If the desired display (min-1 or sec-1) was selected, press the rotary adjuster to confirm selection.

NOTE

The menu is closed automatically and all settings are

stored.

6.3.2 Displaying the current flash duration

Press the "Menu" button. The LED lights up when the function

is selected.

Turn the rotary adjuster until the "dur." function is displayed.

Press the rotary indicator.

The current flash duration is displayed in [μs]. Either "dA" for

Duration-Automatic-Mode or "dF" for Duration-Fix-Mode is in

front of the number.

If the setting is to be changed, select the corresponding function

(refer to following section).

Press the rotary adjuster to either set the flash duration

(Fix-Mode) or to exit the function. The changed setting is saved.

NOTE

To exit the function, press the Menu button again.

The menu is closed.

Page 34

Operation

34 DRELLOSCOP 1020

6.3.3 Setting the "Duration-Auto-Modus" variable flash duration

The flash duration is adjusted automatically to the flash sequence

with this function. Automatic adjustment gives the impression of a

constant brightness irrespective of the flash sequence.

NOTE

Use this function if a continual impression of brightness is desired irrespective of the flash sequence

used.

Press the "Menu" button. The LED lights up when the function

is selected.

Turn the rotary adjuster until "dur." is displayed.

Press the rotary indicator.

The current flash duration is displayed in [μs]. Either "dA" for

Duration-Automatic-Mode or "dF" for Duration-Fix-Mode is in

front of the number.

Turn the rotary adjuster until "dA" is displayed.

Press the rotary indicator. The device is in automatic mode and

the current flash duration is displayed in [μs].

Press the "Menu" or rotary adjuster button. The menu control is

closed and the settings saved.

Page 35

Operation

DRELLOSCOP 1020 35

6.3.4 Setting the flash duration "Duration-Fix-Modus"

This function allows the flash duration to be set to a fixed value irrespective of the flash sequence. Adjustment of the fla sh sequen ce

makes it possible to eliminate possible motion blur while depicting

the moving object.

NOTE

Use this function if significant motion blur is detected

or the brightness needs to be reduced.

Press the "Menu" button. The LED lights up when the function

is selected.

Turn the rotary adjuster until "dur." is displayed.

Press the rotary indicator.

The current flash duration is displayed in [μs]. Either "dA" for

Duration-Automatic-Mode or "dF" for Duration-Fix-Mode is in

front of the number.

Turn the rotary adjuster until "dur F" is displayed.

Press the rotary indicator. The device is in fix mode.

Set the flash duration by turning the rotary adjuster.

Press the "Menu" or rotary adjuster button. The menu control is

closed and the settings saved.

NOTE

Manual setting of the flash duration may not exceed

the maximum permissible flash duration for the respective flash sequence.

An additional protective function (overload protection)

reduces the manually set flash duration automatically

when this reaches a non-permissible value as a result of a change in the flash sequence.

Page 36

Operation

36 DRELLOSCOP 1020

6.4 Further setting options for flash operation

(external control)

6.4.1 Image shift (PHASE)

The object to be controlled can be "shifted" into the optimum

position. The flash moment is changed electro nic al ly that another

image position of the object can be viewed.

NOTE

This function is useful when the object does not need

to be completely illuminated.

NOTE

The "image shift" function is deactivated in the "external controller" mode after switching on the device.

The "PHASE" function must called first to enable it.

Switching off the function is only possible if either the

"slow-motion" functi on is selec ted or the dev ice is

briefly switched off and on again.

Press the "Menu" button. The LED lights up when the function

is selected.

Turn the rotary adjuster until "PHASE" is displayed.

Press the rotary adjuster to activate the image shift setting and

to read the current "phase angle" (image position) with respect

to the input signal.

Turn the rotary adjuster to set the desired image position.

Press the "Menu" or rotary adjuster button. The menu control is

closed and the settings saved.

NOTE

After closing the "PHASE" menu functi on, the set

image position remains and can be further modified

with the rotary adjuster. However, the phase angle is

no longer displayed.

Page 37

Operation

DRELLOSCOP 1020 37

6.4.2 Setting the slow-motion function

With external control of the flash sequence a continual, apparent

image shift can be set. The eye perceives this as a sequence in

slow motion.

NOTE

The "scrolling" is deactivated after switching on the

device in "external control" operating mode. The

"SLO" function must be called first to enable it.

Switching the function on/off is only possible when

either the "PHASE" function (image shift) is selected

or the device is switched off briefly and then switched

on again.

Press the "Menu" button. The LED lights up when the function

is selected.

Turn the rotary adjuster until "SLO" is displayed.

Press the rotary adjuster to activate the slow-motion function

and to read the current "slow-motion angle" with respect to the

input signal.

Set the slow-motion speed by turning the rotary adjuster

Press the "Menu" or rotary adjuster button. The menu control is

closed and the settings saved.

NOTE

The apparent slow-motion effect (scrolling) remains

after switching off this function and can be further

modified with the rotary adjuster. However, the "slowmotion angle" is no longer displayed.

NOTE

The "slow-motion angle" serv es as a setting aid.

Once set, it is adjusts itself automatically to the

changing object speed. This automatic adjustment

keeps the apparent circulation speed constant irrespective of the object speed.

Page 38

Maintenance and repair

38 DRELLOSCOP 1020

7 M aint en an ce and rep air

7.1 Maintenance

No maintenance work on the device is necessary. Only the rechargeable batteries used must be charged as required with the

charging station supplied.

NOTE

If the DRELLOSCOP 1020 is not to be used for a

longer period of time, remove the batteries from the

device and insert them into the battery compartment

provided in the transport case.

7.2 Changing the batteries

Switch off the device.

Unscrew both screws of the battery lid and remove it.

Remove any batteries.

Insert the loaded batteries according to polarity into the battery

compartment, replace the lid and the screws.

Charging the batteries

NOTE

When the battery voltage is too low, the indicator in

the display starts flashing. If the voltage sinks further,

flash operation switches off automatically and "dc Lo"

appears in the display. The batteries must be replaced.

The device switches off automatic ally w ithin 30 seconds.

NOTE

If the DRELLOSCOP 1020 is not to be used for a

longer period of time, remove the batteries from the

device and insert them into the battery compartment

provided in the transport case.

Page 39

Maintenance and rep ai r

DRELLOSCOP 1020 39

7.3 Cleaning

Clean the lens (light emitting surface) with a damp cloth as required.

If dirty, clean the housing of the device with a slightly damp, lintfree cloth. Do not use cleaners containing solvents.

7.4 Troubleshooting

Fault Cause Remedy

No display Batteries discharged. Recharge batteries

No voltage supply. Check

connecting cable.

Stroboscope not

switched on.

Switch on

stroboscope.

Display is flashing

Battery voltage in

lower permitted range.

Change the batteries

immediately.

Display is flashing, "dc Lo" is

displayed and

operation not

possible.

Battery voltage too

low.

Replace batteries

immediately.

The device does

not flash with

manual controller.

"External controller"

operating mode is activated without a trigger impulse.

Switch over to "manual controller" operating mode.

The device does

not flash with external controller.

There is no trigger

impulse.

Check external impulse generator

"Err 1" display Input frequency above

3.33 kHz.

Reduce input frequency.

"Err 2" display Input frequency below

1.00 Hz.

Increase input frequency.

Page 40

Maintenance and rep ai r

40 DRELLOSCOP 1020

7.5 Repairs

Do not perform repairs on the device yourself. Contact customer

service at DRELLO. Improper work can result in personal injuries,

damage to property or damage to the device itself.

If repairs must be performed, please cont act:

DRELLO Ing. Paul Drewell GmbH & Co. KG

Customer service

Andreas-Bornes-Strasse 46

D-41179 Mönchengladbach

Telephone: +49 - (0)2161 - 909 - 6

Telefax: +49 - (0)2161 - 909 - 700

Email: service@drello.de

Internet: www.drello.de

7.6 Disposal

This product may not be disposed of in the domestic refuse within

the European Union.

Dispose of the device in accordance with the EC Directive Waste

Electrical and Electronic Equipment 2002/96/EC. Questions on disposal can be answered by the responsible local authority.

Loading...

Loading...