Page 1

Reflection

Steam room Installation Instructions

IMPORTANT

Please read carefully the following instructions before installing your shower cabin. If you

have any questions on this shower cabin installation - please call our technical support

specialists Monday to Friday 9:00AM – 5:00PM EST at 1-866-731-8378 Option 3 or email our technical support group at support@BathAuthority.com

Our product may have changes without prior notice

Page 2

WARNING

Please, make sure you do the following:

9 Electrical grounding is required on the steam generator;

9 All electrical supplies must be disconnected when servicing the

steam generator;

9 All wiring must be installed by a licensed electrician (please

consult your local codes);

9 All plumbing must be installed by a licensed plumber (please,

consult your local codes);

9 Never shut off water while steam generator is in use;

9 Never touch the wiring while the unit is in use to avoid electric

shock due to high voltage that runs in the equipment.

Follow these steps to avoid the risk of overheating or scalding:

9 Exit the shower cabin immediately if you feel uncomfortable,

dizzy or sleepy. By staying too long in a heated area you

increase the risk of overheating;

9 Do not touch the steam head. Keep 12” distance from the steam

outlet when generator is in use;

9 Make sure children are under supervision at all times;

9 Consult your doctor before using the steam shower cabin if you

are pregnant, diabetic, in poor health or under medical care;

9 Do not use alcohol, drugs or medication in conjunction with

taking a steam shower as this may cause unconsciousness.

Rev. 1.2.

2

Page 3

Preparation

1. After opening the boxes, read this introduction carefully, check all the packed parts are

complete by cross checking all the components against the “Detailed Diagram of

Shower Cabin Components”. Examine for shipping damage. If the unit has been

damaged or has a finishing defect, please contact your local distributor within 3

business days. Please note that Bath Authority

any damaged product or parts free of charge after 3 business days or if the

product has been installed. Contact your distributor or DreamLine if you have any

questions.

2. Plea se note that you should consult your local building codes on questions on

installation compliance standards. Building and plumbing codes vary by

location, and DreamLine is not responsible for code compliance standards for

your project.

3. Install all of the required plumbing and drainage before securing the shower. Use a

competent and licensed (if required by local code) plumber for all plumbing

installation and licensed electrician for all electric installation.

4. Please insure that prior to the installation the floor is leveled and solid and will be able

to support the total weight of the unit and its occupant. Also make sure the walls are at

right angles. While some adjustment in leveling of the tray is possible, irregular floor

level or improper angle of side walls will result in serious problems for your installation.

Please, note that there are some adjustments and drilling might be necessary during

the installation proces s.

.

TM

/ DreamLine TM will not replace

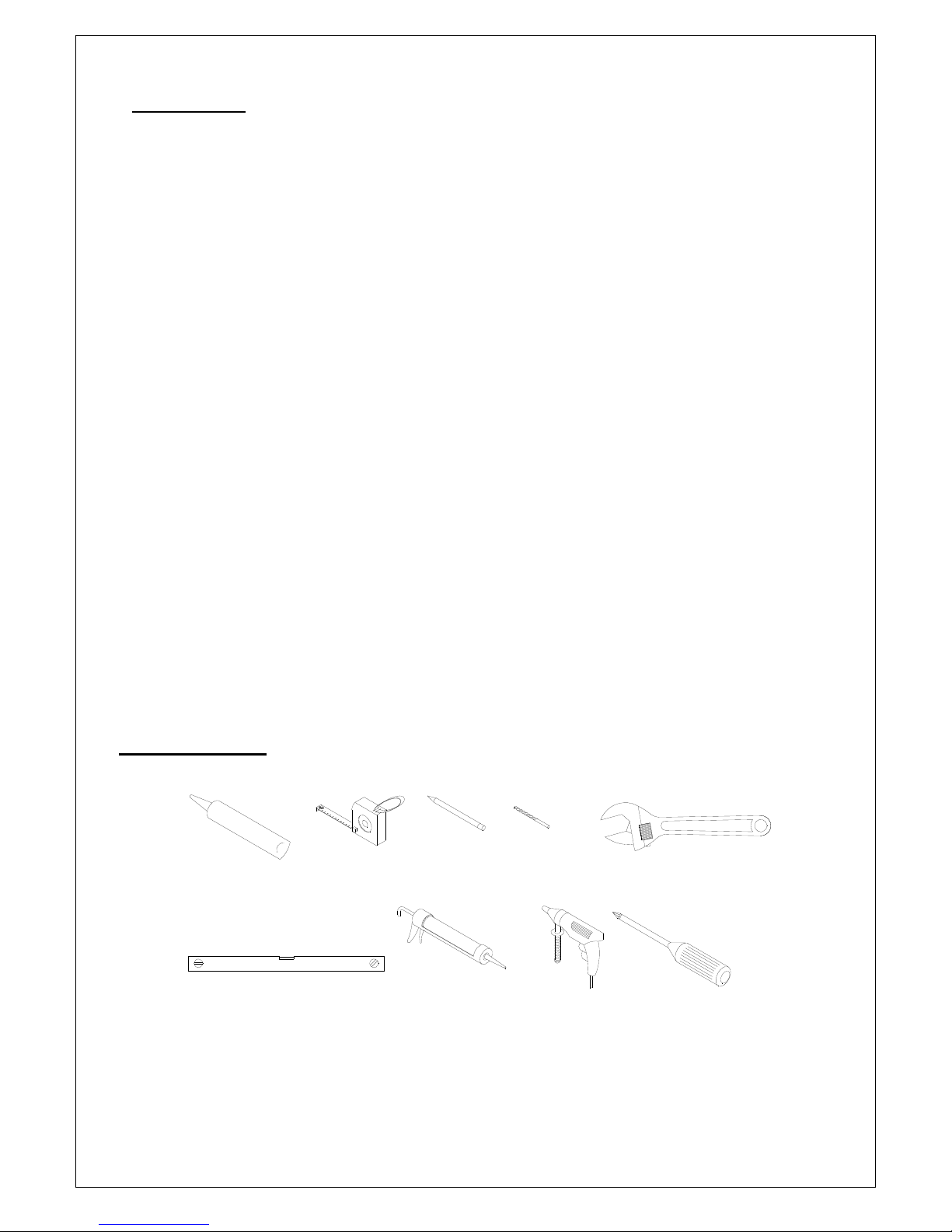

Tools Required

Tape

Caulk

Measure

Level

Rev. 1.2.

Pencil

Caulk

Gun

Drill bit

(D=3mm)

Electric

Drill

Wrench

Phillips

Screwdriver

3

Page 4

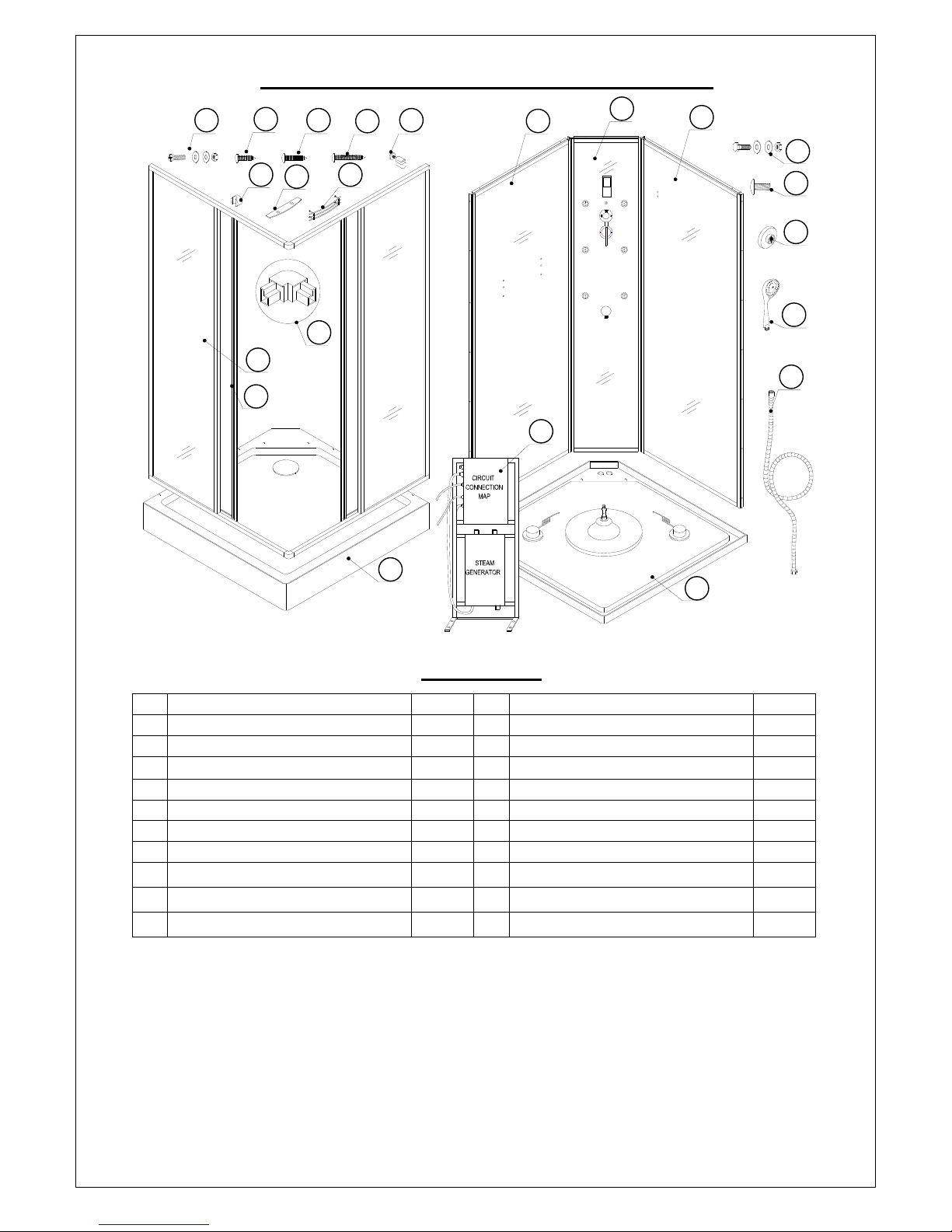

9

Detailed Diagram of Shower Cabin Component

10

14

6

7

15

11

8

16

12

13

2

17

1

3

22

21

20

19

18

5

4

Packing List

01 Control panel 1pc 12 Round head screw ST4.2×25 16pcs

02 Left stationary glass 1pc 13 Glass bracket 2pcs

03 Right stationary glass 1pc 14 Hand shower bracket 1pc

04 Roof 1pc 15 Glass shelf 1pc

05 Tray 1pc 16 Guardrail 1pc

06 Stationary glass 2pcs 17 Generator assembly 1pc

07 Glass door 2pcs 18 Shower hose 1pc

08 Connector 2pcs 19 Hand shower 1pc

09 Bolt M4×16 14pcs 20 Wheel assembly 8pcs

10 Round head screw ST4.2×10 4pcs 21 Bolt M5×8 8pcs

11 Round head screw ST4.2×16 14pcs 22 Bolt M6×25 (with washer) 2pcs

After you have checked that all components are there, you will be ready to start the

installation of your DreamLine shower cabin.

Rev. 1.2.

4

Page 5

Cabin Installation

1. Choose the location where you will be installing the tray, mark the location of the tray

because you may need to move it out from the position for better assembling

procedure. Check on the drain if it is fastened tight enough to make sure it won’t leak

after complete tray installation.

2. Also check all the hose connections to prevent leakage. Your plumber may want to

replace the drain flex hose to hard PVC pipes which is also possible (instructions are

provided in the manual).

3. For installation of the drain in the floor please refer to the Legs and frame position

(top view) diagram and fig1 (actual poison of the drain and frame on the tray).

4. Install the water outlet and power supply box. You need 1/2” minimum water supply

lines for hot and cold water with shout off valves. Power supply is required 20A

220V dedicated #12 3/1 wire line with GFCI breaker.

5. Place the Tray (5) in the required position. Adjust the legs to level the tray in case

the surface is uneven. Fasten the counter nuts on the legs to secure the height. See

Fig 2 for details.

NOTE: For steps 6, 7 and 8, it will be necessary to apply silicone sealant

between the panels and the panels and tray.

6. Move the Tray (5) out; put the Control panel (1) onto the tray; then secure them

with Round head screws ST4.2×25 (12). See Fig 3 for details.

7. Locate the Left stationary glass (2) onto the tray. Secure the left stationary glass

and the control panel with Bolt M4×16 (9). Secure the tray and the left stationary

glass with Round head screws ST4.2×25 (12). See Fig 4 for details.

8. Repeat Step 7 to install the Right stationary glass (3). Attach the Glass bracket

(13) to the left stationary glass and the Hand shower bracket (14) to right stationary

glass. See Fig 5 for details.

9. Locate the stationary glass panels from the package. Secure the Connectors (8)

and the guide r a i l of the Stationary glasses (6) with Round head screws ST4.2×10

(10). See Fig 6 for details.

10. Put two Wheel assemblies (20) into the groove of the upper guide rail; then lo cate

the Glass door (07) to the position. Secure it using Bolt M5×8 (21). See Fig 7 for

details.

11. Put the shower enclosure assembly onto the tray. Drill holes on the glass profiles of

the stationary glass; then secure them with Round head screws ST4.2×16 (11).

See Fig 8 and Fig 9 for details.

12. Apply the silicon sealant on the top aluminum profiles of the control panel (1), left

and right stationary panels (2,3) and stationary glass (6). Put the Roof (4) on the top

of the shower enclosure assembly. Secure the roof and the right and left stationary

glass with Round head screws ST4.2×25 (12). See Fig 10 and Fig 11 for details.

13. Install the Glass shelf (15) and the Guardrail (16) onto the left stationary glass. See

Fig 12 for details.

14. Place the Generator assembly (17) on the tray; then secure it to the tray with Bolt

M6×25 (with washer) (22). Connect the light, fan, speaker wire from the roof to the

generator. Connect the steam generator circuits; then connect it to the power supply.

See Fig 13 for details.

drain and steam line will be connected.

15. Connect the flexible hose to the shower head. Secure this item in place on the back

panel. Make sure all the water connections are water tight. Put the drain pipe into

the drain opening in the floor. Connect hot water to the red mark water inlet and cold

water to the blue mark water inlet.

DO NOT turn power supply on until the water supply, the

Rev. 1.2.

5

Page 6

16. Do not move the cabin into the place until you check all the components for any

leakage or problems; open each valve to see how it works, check thermostatic or

mixer valve for hot and cold water. You may need to tight some connections (during

storage and transportation connections may get loose). If you do not see any

leakage, then you can move it to the permanent position and finish your project. See

Fig 14 and Fig 15 for details.

17. Use the Phillips screwdriver #2 (do not use power screwdriver) to adjust the upper

wheels, make sure they move smoothly and the doors close tight. Connect the

flexible hose to the hand shower. Secure this item in place on the control panel. See

Fig 16 for details.

18. Seal with silicone on all connections between the vertical p rofiles and the back panel,

bottom rail and tray, tray and back panel. Let it dray for 24 hours before moving the

cabin. See Fig 17 for details.

19. Fig 19 shows the location of the handle. The upper figure is shown the outside of the

shower cabin and the bottom figure is shown the inside of the shower cabin.

945

477

240

224

44

477

945

224

240

44

Fig 1 Legs and frame position (top view)

Rev. 1.2.

6

Page 7

1

2

Fig 2 Fig 3

1

2

3

Rev. 1.2.

Fig 4 Fig 5

7

Page 8

1

1

4

2

2

¢3mm

3

Fig 6 Fig 7

5

6

¢3mm

3

1

2

Fig 8 Fig 9

Rev. 1.2.

8

Page 9

1

2

Fig 10 Fig 11

1

Rev. 1.2.

2

3

Fig 12 Fig 13

9

Page 10

Blue

1

3

Red

2

4

Cool

Hot

Fig 14 Fig 15

1

1

2

3

Rev. 1.2.

Fig 16 Fig 17

2

10

Page 11

a

1

2

Fig 18 Fig 19

Thermostatic Valve Using Controls

z Valv e “a” turns on water of the “tropical rain” head shower.

z Valve “b” turns on water of eight massage jets.

z Valve “c” turns on water of the hand shower. Turn the revolve cover of

the shower head will change water pattern.

z Thermostatic valve “d” adjusts water temperature on any valves you

are using.

b

OFF

d

1

3

1

1

2

2

1

F

c

0

0

5

9

Steam generator control

Temperature - Temperature +

Time setting

Function Illustration of the Control Board

Rev. 1.2.

Celsius

Ti me -

Steam

Temperature setting

Fahrenheit

Ti me +

Top light

Power

11

Page 12

Performance

z The control uses a blue color back light liquid crystal display with white back light

induction type touching key.

z Turning the steam on will fill the generator with water automatically, when system is

shut-down an automatic water draining system turn on.

z Includes steam and light and fan control functions.

z Steam temperature regulation range: Centigrade temperature 30~60C, Fahrenheit

86~140F; Steam time regulation range: 0~60 minutes.

z Automatic temperature controls also include tracking of excess temperature, over

pressure and power leakage protection function.

Operation Instructions:

Switch-on: Push the power switch, the present cabin temperature is shown on the

display, the top light turns on, and the system stays in the state of readiness.

Steam: Push the steam key directly to turn steam function on or off.

Temperature-set: Push temperature setting key, ambient temperature is shown on

the screen. Push the “temperature +” or “temperature –“key to get the wanted steam

temperature. The temperature will gradually increase or decrease within 30 ~ 60℃.

“Celsius” displays the Celsius temperature; “Fahrenheit” displays Fahrenheit

temperature. If the ambient temperature in the cabin is higher than that set by the

steam bath temperature, the steam generator can not be started.

Time-set: Push the time setting key and the steam generator and control go into the

time-set state; and push the “time +” or “time –“key to get desired time of the steam

bath. The time range is 5~60 minutes.

Lighting: Push the light key, and the light and the fan can be s w itched on or off.

Switch-off: Push the power key and switch off all the functions.

If not using steam options/control for a long time – we suggest that you switch off

the main electric power of the units

Warnings

Do not connect this steam shower with other electric appliances not recommended by

DreamLine™, and do not take ap art the hermetically sealed lines or the electric lines

from the power box.

A drainage pipeline shall be fixed to auto-drain valve of the main steam generator,

and it’s better to add a water filter before the water entr ance to increase generator’s

service life.

The steam generator should be working with water hardness levels 60-120 mg/l. If

hardness of your water more than recommended it can cause “scale” (mineral build

up in pipes and plumbing fixtures). Scale can cause of your steam unit damage. You

need to treat your water. Water soft eners are the most frequently used of all waterconditioning devices and are installed for reducing hardness for private wells and

utility supply with high levels of calcium or magnesium.

The line from the power box shall be plugged according to the digit capacity and the

size. Do not short circuit.

The steam generator is complicated option and shall be installed by the qualified and

authorized technical persons.

DreamLine™ shall not be responsible for negative consequences due to any

incorrect installation or improper operations per instructions listed above.

Rev. 1.2.

12

Page 13

Product Maintenance

1. Tempered glass can be clean with nonabrasive bathroom cleaner or any glass

cleaner you use elsewhere in your home. Rinse off any glass cleaner that gets on the

aluminum as soon as possible to avoid damage to the anodized surface. Avoid striking

it with any sharp or hard objects. Such damage can cause either immediate or delayed

breakage of tempered glass.

2. The aluminum in your shower door is durable and resistant to water damage. It is

advisable, but not necessary to wipe it with your towel after your shower. Clean it as

often as needed to keep the buildup off. Never use any type of abrasive cleaner. Use

only a soft damp cloth and nonabrasive b athroom cleaners.

Rev. 1.2.

13

Loading...

Loading...