DreamGEAR HY13-1518-M1-USA User Manual

HY13-1518-M1/USA

Hydraulics

TK Series

Service Procedure

Effective: July , 2001

Low Speed High Torque,

Hydraulic Motors

HY13-1518-M1/USA

Low Speed High Torque, Hydraulic Motors

TK Series

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or

system options for further investigation by users having technical expertise. It is important that you analyze all aspects of your application

and review the information concerning the product or system in the current product catalog. Due to the variety of operating conditions and

applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection

of the products and systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to

change by Parker Hannifin Corporation and its subsidiaries at any time without notice.

Offer of Sale

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors.

This offer and its acceptance are governed by the provisions stated in the "Offer of Sale".

Copyright 2001 Parker Hannifin Corporation, All Rights Reserved

2

Hydraulics

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

Table of Contents

Low Speed High Torque, Hydraulic Motors

TK Series

Definitions...............................................................................................................................................................3

Design Features......................................................................................................................................................4

Introduction .............................................................................................................................................................5

Troubleshooting Guide.............................................................................................................................................6

Troubleshooting Checklist .......................................................................................................................................7

T ools and Material Required for Servicing................................................................................................................8

Bolt T orque ..............................................................................................................................................................9

Exploded Assembly View...................................................................................................................................... 10

TK Service Parts List Chart ..................................................................................................................................11

Disassembly & Inspection ............................................................................................................................... 12-19

T orqmotor Assembly ........................................................................................................................................20-27

Final Checks.........................................................................................................................................................28

Hydraulic Fluid ......................................................................................................................................................28

Filtration................................................................................................................................................................28

Oil T emperature .....................................................................................................................................................28

Tips for Maintaining the System............................................................................................................................29

Offer of Sale .........................................................................................................................................................31

Definitions

NOTE: A NOTE provides key information to make a procedure easier or quicker to complete.

CAUTION: A CAUTION refers to procedure that must be followed to avoid damaging the Torqmotor or other system

components.

WARNING: A W ARNING REFERS T O PROCEDURE THAT MUST BE FOLLOWED FOR THE SAFETY OF THE

EQUIPMENT OPERA T OR AND THE PERSON INSPECTING OR REP AIRING THE TORQMOTOR.

Disclaimer

This Service Manual has been prepared by Parker Hannifin for reference and use by mechanics who have been trained to

repair and service hydraulic motors and systems on commercial and non-commercial equipment applications. Parker

Hannifin has exercised reasonable care and diligence to present accurate, clear and complete information and instructions

regarding the techniques and tools required for maintaining, repairing and servicing the complete line of Parker TK

Torqmotor Units. However, despite the care and effort taken in preparing this general Service Manual, Parker makes no

warranties that (a) the Service Manual or any explanations, illustrations, information, techniques or tools described herein

are either accurate, complete or correct as applied to a specific Torqmotor unit, or (b) any repairs or service of a particular

Torqmotor unit will result in a properly functioning Torqmotor unit.

If inspection or testing reveals evidence of abnormal wear or damage to the Torqmotor unit or if you encounter circumstances

not covered in the Manual, STOP – CONSULT THE EQUIPMENT MANUFACTURER’S SERVICE MANUAL AND WARRANTY. DO NOT TRY TO REP AIR OR SER VICE A TORQMOTOR UNIT WHICH HAS BEEN DAMAGED OR INCLUDES ANY

P ART THAT SHOWS EXCESSIVE WEAR UNLESS THE DAMAGED AND WORN PARTS ARE REPLACED WITH ORIGINAL

P ARKER REPLACEMENT AND SERVICE PAR TS AND THE UNIT IS RESTORED TO PARKER SPECIFICA TIONS FOR THE

TORQMOTOR UNIT.

It is the responsibility of the mechanic performing the maintenance, repairs or service on a particular Torqmotor unit to (a)

inspect the unit for abnormal wear and damage, (b) choose a repair procedure which will not endanger his/her safety, the

safety of others, the equipment, or the safe operation of the Torqmotor, and (c) fully inspect and test the Torqmotor unit and

the hydraulic system to insure that the repair or service of the Torqmotor unit has been properly performed and that the

Torqmotor and hydraulic system will function properly.

Hydraulics

3

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

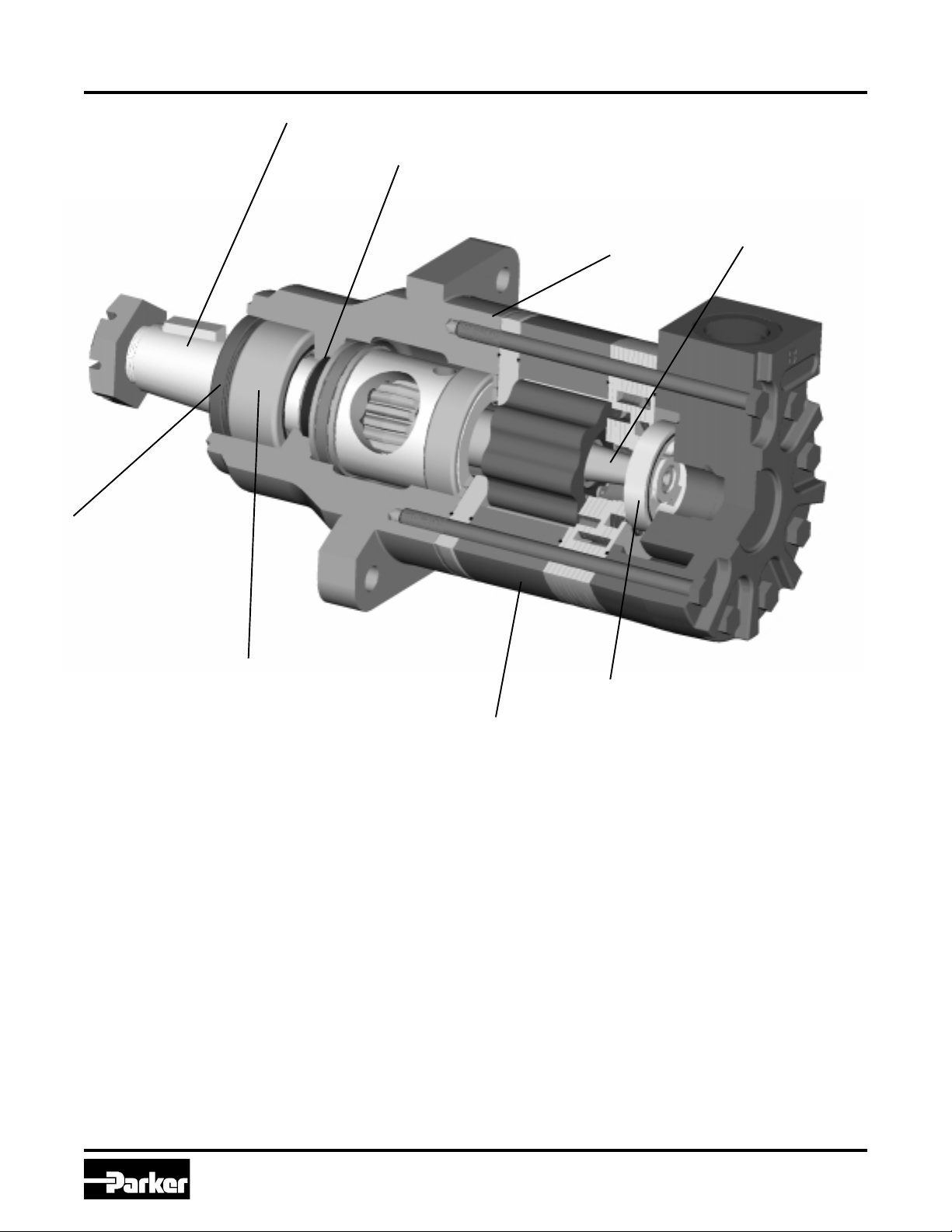

Torqmotor Design Features

COUPLING SHAFT

Low Speed High Torque, Hydraulic Motors

TK Series

HIGH PRESSURE SEAL

HOUSING

HEA VY DUTY

DRIVE LINK

TOOTH SPLINE

DIRT & W ATER SEAL

HEA VY DUTY

BEARING

HIGH SPEED COMMUT AT OR

MA TCHED ROTOR SET

TK Series features include:

• The roller vane rotor set design offers low-friction and wear compensation which maximizes the useful performance

life of the motor.

• Zero leak commutation valve provides greater, more consistent volumetric efficiency.

• Heavy duty spline geometry.

• Flow thru lubrication provides cooling extending motor life.

• Full interchangeability with other motors which are designed according to industry standards.

• Compatible with most hydraulic systems with regard to pressure, torque and speed.

• A unique high-pressure shaft seal that eliminates the need for case drains.

• Up to 73 horsepower output.

• Heavy duty roller bearings for high side loads.

Hydraulics

4

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

Introduction

Low Speed High Torque, Hydraulic Motors

TK Series

This service manual has one purpose: to guide you in

maintaining, troubleshooting, and servicing the TK

T orqmotor (low-speed, high-torque hydraulic motor).

Material in this manual is organized so you can work on

the T orqmotor and get results without wasting time or

being confused. T o get these results, you should read

this entire manual before you begin any work on the

Torqmotor.

This manual also contains troubleshooting information

and checklist. If you must service the Torqmotor, the

checklist will help you to determine where the problem

may be.

The three-column format of the Disassembly and

Inspection, and Assembly sections will make it easier

for you to conduct major work on the Torqmotor. Column

1 gives a brief key for each procedure. Column 2

explains in detail the procedure you should follow.

Column 3 illustrates this procedure with photographs.

Read all material carefully and pay special attention to

the notes, cautions, and warnings.

A page with the T orqmotor exploded assembly view is

provided several places in this manual. The component

part names and item numbers assigned on this exploded assembly view correspond with names and item

numbers (in parentheses) used in the disassembly and

assembly procedures set forth in this manual.

Service part list charts are also provided in this manual

with the part names and exploded view item numbers

cross referenced to Parker service part numbers.

Service parts are available through the Original Equipment Manufacturer or Parker approved TK Distributors.

As you gain experience in servicing the T orqmotor , you

may find that some information in this manual could be

clearer or more complete. If so, let us know about it. Do

not try to second guess the manual. If you are stuck,

contact us. Servicing the T orqmotor should be a safe and

productive procedure, in order for the unit to deliver the

reliable, long-life operation engineered into it.

Hydraulics

5

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

Troubleshooting Guide

NOTE: Before troubleshooting any system problem, check service literature published by the equipment and/or

component manufacturers. Follow their instructions, if given, for checking any component other than the T orqmotor

unit.

Low Speed High Torque, Hydraulic Motors

TK Series

Preparation

Make your troubleshooting easier by preparing as

follows:

• work in a clean, well-lighted place;

• have proper tools and materials nearby;

• have an adequate supply of clean petroleum-based

solvent.

WARNING: SINCE SOL VENTS ARE FLAMMABLE, BE

EXTREMEL Y CAREFUL WHEN USING ANY SOLVENT, EVEN A SMALL EXPLOSION OR FIRE COULD

CAUSE INJURY OR DEA TH.

WARNING: WEAR EYE PROTECTION AND BE SURE

TO COMPL Y WITH OSHA AND OTHER MAXIMUM AIR

PRESSURE REQUIREMENTS.

Preliminary Checks

Hydraulic systems are often trouble-free. Hence, the

problem an operator complains of could be cause by

something other than the hydraulic components.

Thus, once you have determined that a problem exists,

start with the easy-to-check items, such as:

• parts damaged from impact that were not properly

repaired, or that should have been replaced; and

• improper replacement parts used in previous

servicing

• mechanical linkage problems such as binding,

broken, or loose parts or slipping belts

Hydraulic Components

If you think the problem is caused by a hydraulic

component, start by checking the easy-to-reach items.

Check all hoses and lines for cracks, hardening, or

other signs of wear . Reroute any usable hoses that are

kinked, severely bent, or that rest against hot engine

parts. Look for leaks, especially at couplings and

fittings. Replace any hoses or lines that don’t meet

system flow and pressure ratings.

Next, go to the reservoir and filter or filters. Check fluid

level and look for air bubbles. Check the filter(s). A filter

with a maximum 50 micron filtration is recommended for

the T orqmotor system.

Visually check other components to see if they are

loosely mounted, show signs of leaks, or other damage

or wear.

Excessive heat in a hydraulic system can create

problems that can easily be overlooked. Every system

has its limitation for the maximum amount of temperature. After the temperature is attained and passed, the

following can occur:

• oil seal leaks

• loss of efficiency such as speed and torque

• pump loss of efficiency

• pump failure

• hoses become hard and brittle

• hose failure

A normal temperature range means an efficient hydraulic system. Consult the manuals published by equipment and/or component manufacturers for maximum

allowable temperature and hydraulic tests that may be

necessary to run on the performance of the hydraulic

components. The Torqmotor is not recommended for

hydraulic systems with maximum temperatures above

200°F (93.3°C).

Hydraulics

6

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

Troubleshooting Checklist

Low Speed High Torque, Hydraulic Motors

TK Series

Trouble Cause Remedy

Oil Leakage Check & replace damaged

Significant loss of

speed under load

1 .Hose fittings loose, worn or

damaged.

2.Oil seal rings (5) deteriorated by

excess heat.

3.Special bolt (1)

loose or its sealing area

deteriorated by corrosion.

4.Internal shaft seal (18) worn or

damaged.

5.Worn coupling shaft (14) and

internal seal (18).

1.Lack of sufficient oil supply

fittings or “O” Rings. Torque to

manufacturers specifications.

Replace oil seal rings by disassembling

T orqmotor unit.

(a ) Loosen then tighten single bolt to

torque specification.

(b ) Replace bolt.

Replace seal. Disassembly of T orqmotor unit

necessary.

Replace coupling shaft and seal by

disassembling T orqmotor unit.

(a ) Check for faulty relief valve and

adjust or replace as required.

(b ) Check for and repair worn pump.

(c) Check for and use correct oil for

temperature of operation.

Low mechanical

efficiency or undue

high pressure

required to operate

T orqmotor unit

2.High internal motor leakage

3.Severely worn or damaged

internal splines.

4.Excessive heat.

1 .Line blockage

2.Internal interference

3.Lack of pumping pressure

4.Excessive binding or loading in

system external to T orqmotor

unit.

Replace worn rotor set by disassembling

T orqmotor unit.

Replace rotor set, drive link and coupling

shaft by disassembling T orqmotor unit.

Locate excessive heat source (usually a

restriction) in the system and correct the

condition.

Locate blockage source and repair or

replace.

Disassemble T orqmotor unit, identify and

remedy cause and repair, replacing parts as

necessary.

Check for and repair worn pump.

Locate source and eliminate cause.

CAUTION: If the hydraulic system fluid becomes overheated [in excess of 200°F (93.3°C)], seals in the system

can shrink, harden or crack, thus losing their sealing ability .

7

Hydraulics

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

T ools and Materials Required for Servicing

• Clean, petroleum-based solvent

• Emery paper

• Vise with soft jaws

• Air pressure source

• Arbor press

• Screw driver

• Masking tape

• Breaker bar

• T orque wrench-ft. lbs. (N m)

• Sockets: 1/2 or 9/16 inch thin wall, 1 inch

• Allen Sockets: 3/16, 3/8 inch

• Adjustable crescent wrench or hose fitting wrenches

• SAE 10W40 SE or SF oil

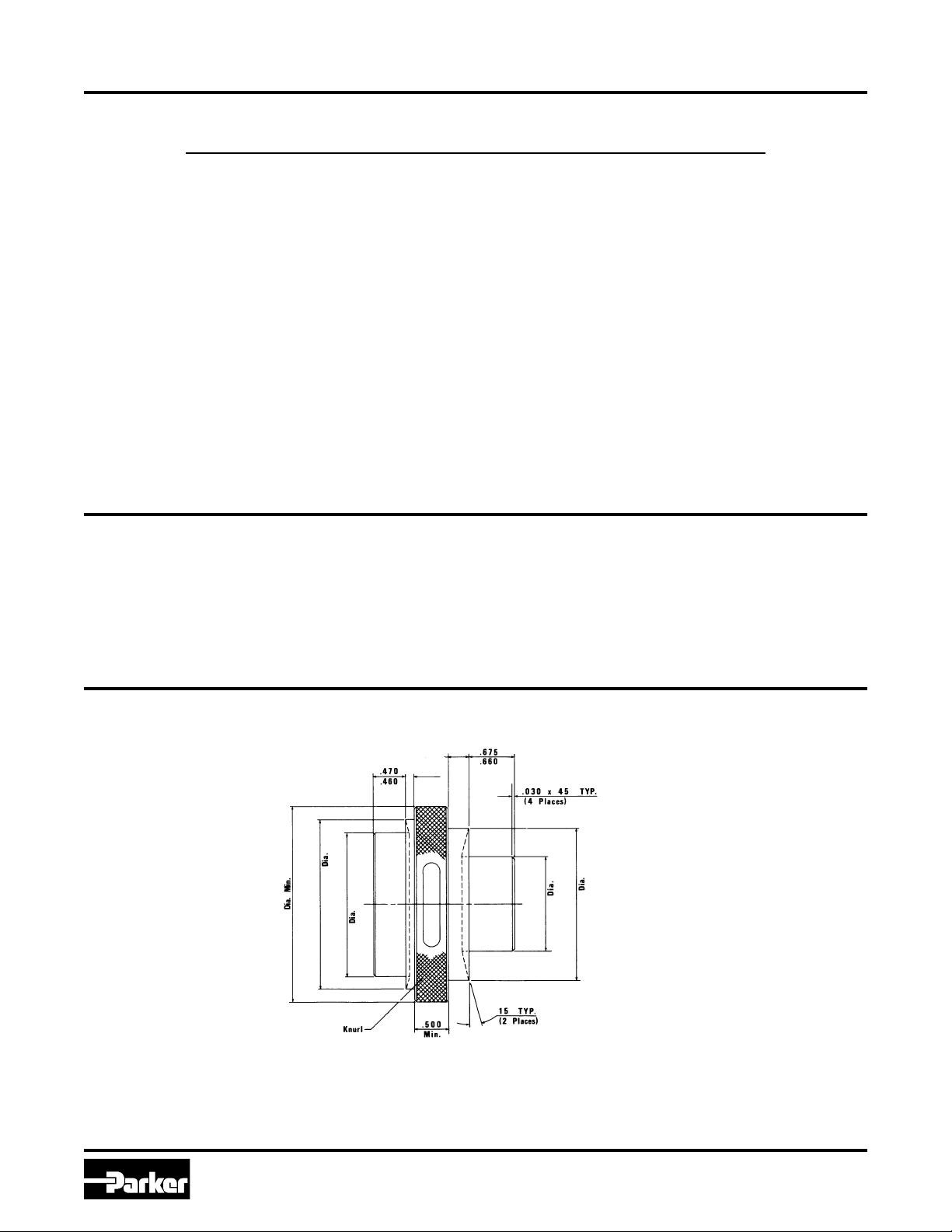

• Special bearing mandrel for TK T orqmotor (SEE FIGURE 1)

• Feeler gage .005 inch (.13 mm)

• TK Torqmotor requires blind hole bearing puller for a 1.750 inch dia. (44.45 mm) and 2.750 inch dia. (69.85 mm)

bearings.

• Clean corrosion resistant grease. Part #406018 is included in each seal kit. Recommended grease is Parker

Specification #045236 or Mobil Mobilith SHC® 460

Low Speed High Torque, Hydraulic Motors

TK Series

NOTE: The available service seal kits include the recommended grease as a grease pack #406018

CAUTION: Mixing greases that have different bases can be detrimental to bearing life.

Hydraulics

8

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

T echnical Information

INCHES mm INCHES mm

.020 .51 1.060 26.92

.021 .53 1.295 32.89

.029 .74 1.297 32.94

.030 .76 1.396 35.46

.111 2.81 1.398 35.51

.119 3.02 1.620 41.15

.152 3.86 1.622 41.20

.160 4.06 1.983 50.37

.296 7.52 1.985 50.42

.304 7.72 2.120 53.85

.460 11.68 2.122 53.90

.470 11.94 2.233 56.72

.500 12.70 2.235 56.77

.585 14.86 2.483 63.07

.595 15.11 2.485 63.12

.660 16.76 2.500 63.5

.675 17.15 2.88 73.2

1.058 26.87

Low Speed High Torque, Hydraulic Motors

TK Series

CONVERSIONS

Torque Chart

Part Name Item Number T orque

bolt 3/8 24 UNF 2A 1 45-55 ft. lbs. (60-76 N m)

nut 1-1/4 18 UNEF 2B 14 b 350-450 ft. lbs. (475-610 N m)

.420"

.410"

.150

.130

3.122

3.60

3.120

2.748

2.746

1.748

1.746

2.988

2.986

Hydraulics

(Fabricate if considered necessary)

Figure 1

9

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

HY13-1518-M1/USA

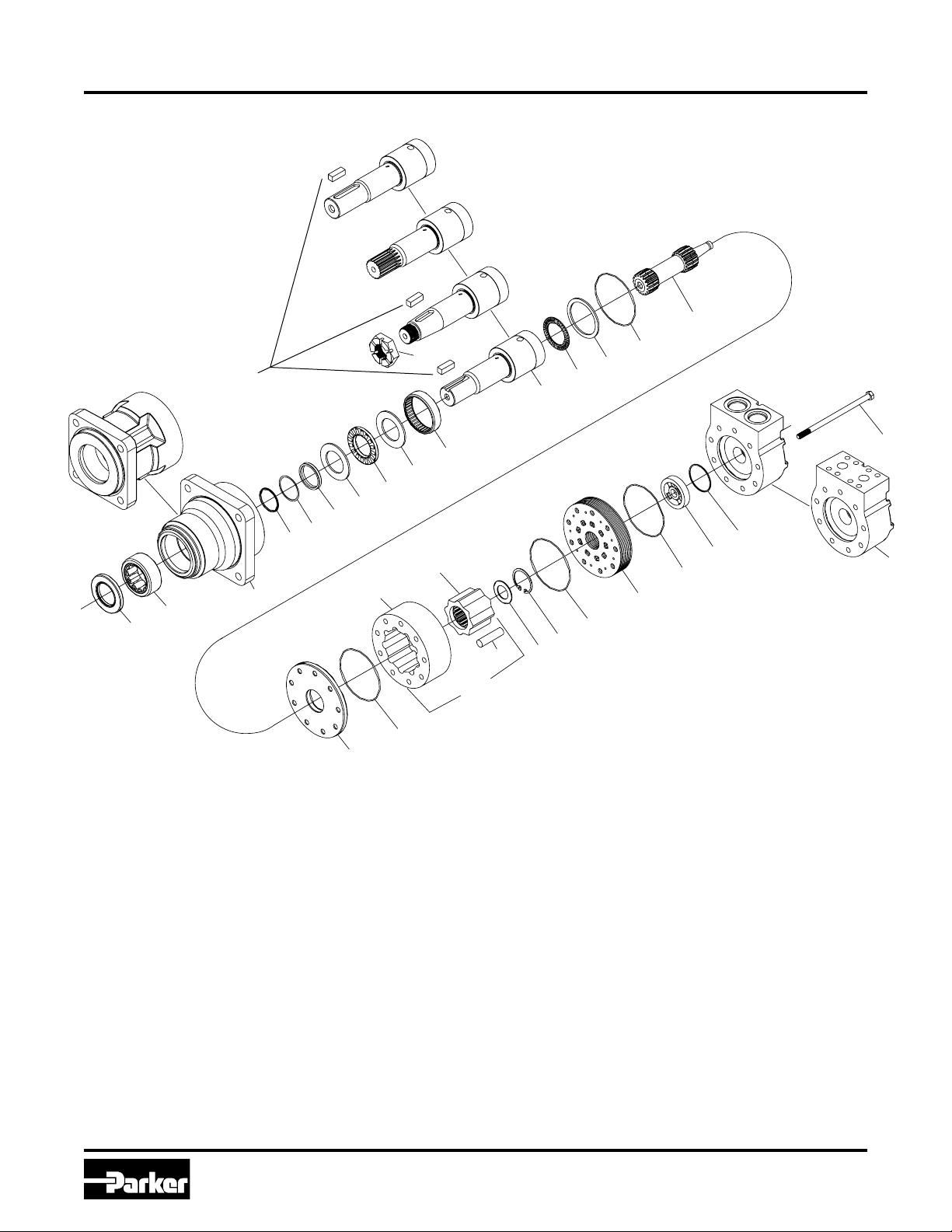

Exploded View

Typical Assembly

Low Speed High Torque, Hydraulic Motors

TK Series

11

23

22

14a

21

20

19

18

10

16

9b

17

14b

13

5

12

14

1

15

16

3

9a

4

5

2

6

5

7

8

9c

9

Matched

Set

5

Item No. Description

1 Special Bolt

2 Endcover

3 Seal Ring - Commutator

4 Commutator

5 Seal Ring

6 Manifold

7 Retaining Ring

8 Rotor Washer

9 Rotor Set

9a Rotor

9b Stator

9c Vane (9)

10 Wear Plate

11 Drive Link

12 Retaining Washer

13 Thrust Bearing

14 Coupling Shaft

14a Key

14b Nut

15 Radial Bearing

16 Thrust Washer

17 Thrust Bearing

18 Shaft Seal

19 Back Up Washer

20 Back Up Ring

21 Housing

22 Radial Bearing

23 Dirt & Water Seal

Note: See “Service Parts List Chart” page 11 for all part numbers.

10

Hydraulics

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

Loading...

Loading...