AV-S Ventilator

User Manual

This manual contains information for software upgrade v.1.87.01

DATASHEET

USER

AV-S Ventilator User Manual

Software Version 1.87.01

Addendum to the User Manual

Keep this Datasheet with the User Instruction Manual for AV-S at all times

Introduction

AVS software V. 1.87.01 introduces a new

user interface. However, if you are familiar

with the AV-S, please note that the basic

operation and calibration procedures remain

as per v.1.86.

Modifications to the User Interface

Setting up the Ventilator for use

1. Introduction Screen

1.1 Start-up

At start-up, the introduction screen

allows the user to select one of three

default settings:

SITE DEFAULTS

ADULT DEFAULTS

PEDIATRIC DEFAULTS

NOTE

a) The user must select one of the

above default groups before the

ventilator will switch to standby in that

default mode

b) SITE DEFAULT is editable in

standby mode (see section 1.2, below)

c) Settings can be saved via the

service menu to create a new site

default

1.2 Default Settings

1.2.1 Selection

The user can select ADULT, or

PEDIATRIC, or SITE, and view the

default parameter settings.

The options will remain, even after the

ventilator is turned off.

1.2.2 Site Default Settings

Adjust the parameter values from within

the Service menu (SITE DEFAULTS)

Press to confirm the new settings for

site defaults.

1.3 Calibrate Touchscreen

The introduction screen allows the

user to calibrate the screen

2. Parameter Display Identification

2.1 Active Parameters

Active parameters that can be set for use

in the current mode are displayed as:

White Text on Blue

2.2 Inactive Parameters

Inactive parameters that can be set for

any non-current mode are displayed as:

White Text on Blue Label

White values on Black

2.3 Measured Parameters

Yellow values on Black

2.4 T+PS INIT (target and pressure support

initial value)

The initial pressure value can be changed

so that when entering either PRESSURE

or PSV modes the TARGET value or

PSUPP value are pre-selected.

NOTE

Changing either of these limits in their

active modes will maintain the value when

changing between PSV, PRESSURE, and

STANDBY modes.

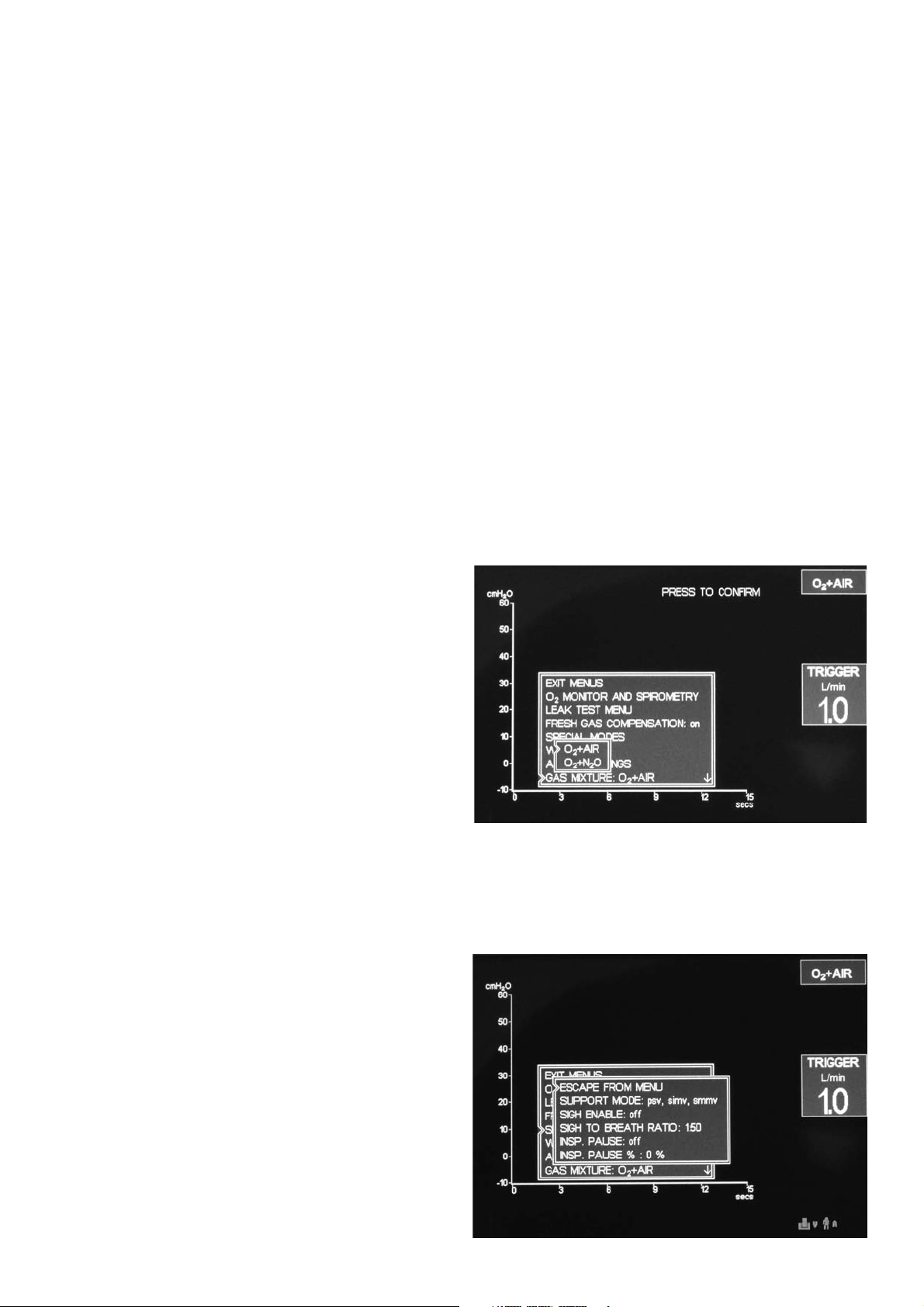

3. Gas Mixture

The Gas Mixture window is an active

touch-selectable area (in any mode), with

a drop down menu.

Gas Mixture is also available through the

menu structure.

Selection of the required mixture is in the

normal way with the scroll wheel.

Using the Ventilator - description of

modes and functions

4. Modes

4.1 Access to Support Modes

Access is available in Standby mode

(depending on the support mode options

on the ventilator).

Support Mode

a) PSV

b) SIMV

c) SMMV

d) SIGH ENABLE

SIGH TO BREATH RATIO

e) INSP PAUSE

INSP PAUSE %

WARNING

Modes a, b, and c are only available

when Spirometry is enabled.

2

4.2 Standby Mode

a) Standby mode at ventilator start-up:

The last used Volume mode settings will

be displayed

b) Standby mode selected while the

ventilator is in use:

The screen will display the previous

ventilation mode, highlighted in yellow,

within the relevant box. The last used

parameters will also be displayed.

4.3 Spontaneous Mode

a) Spontaneous mode at ventilator start-

up:

Default values will be displayed in white

on a black background if the ventilator

has just been powered ON.

b) Spontaneous mode selected while the

ventilator is in use:

The last used ventilation mode

(underlined) will be displayed, with the

last used set values in white on a black

background

4.4 Sigh

Sigh is settable from 1:n, where n has a

range of 10 to 100.

The Sigh menu can also be accessed by

touching the icon area of the screen.

NOTE

1:10 is one sigh to ten normal breaths.

4.5 Inspiratory Pause

Inspiratory pause can be varied in the

menu from 0 - 60%.

The inspiratory pause menu can also be

accessed by touching the icon area of

the screen.

WARNING

This can affect the maximum Tidal

Volume.

3

5. Apnoea Alarm Mute - Spontaneous

mode only

NOTE

The occurrence of another alarm event

will override this feature

In spontaneous mode the mute button

acts both to silence an existing apnoea

alarm and inhibit new apnoea alarms for

a given period (provided that no other

alarm events are present) .

This time period is selectable (choose

from 15, 30, 60, 120, or 180 seconds)

through the alarm settings menu, or

accessed by touching the alarm area of

the screen.

To adjust the default setting, use the SITE

DEFAULT menu option.

6. Touchscreen Access to Mode

Configuration Options

Touch the screen in the area containing

the green icons to access mode

configuration options (including INSP

PAUSE, SIGH, and APNOEA ALARM

mute/inhibit).

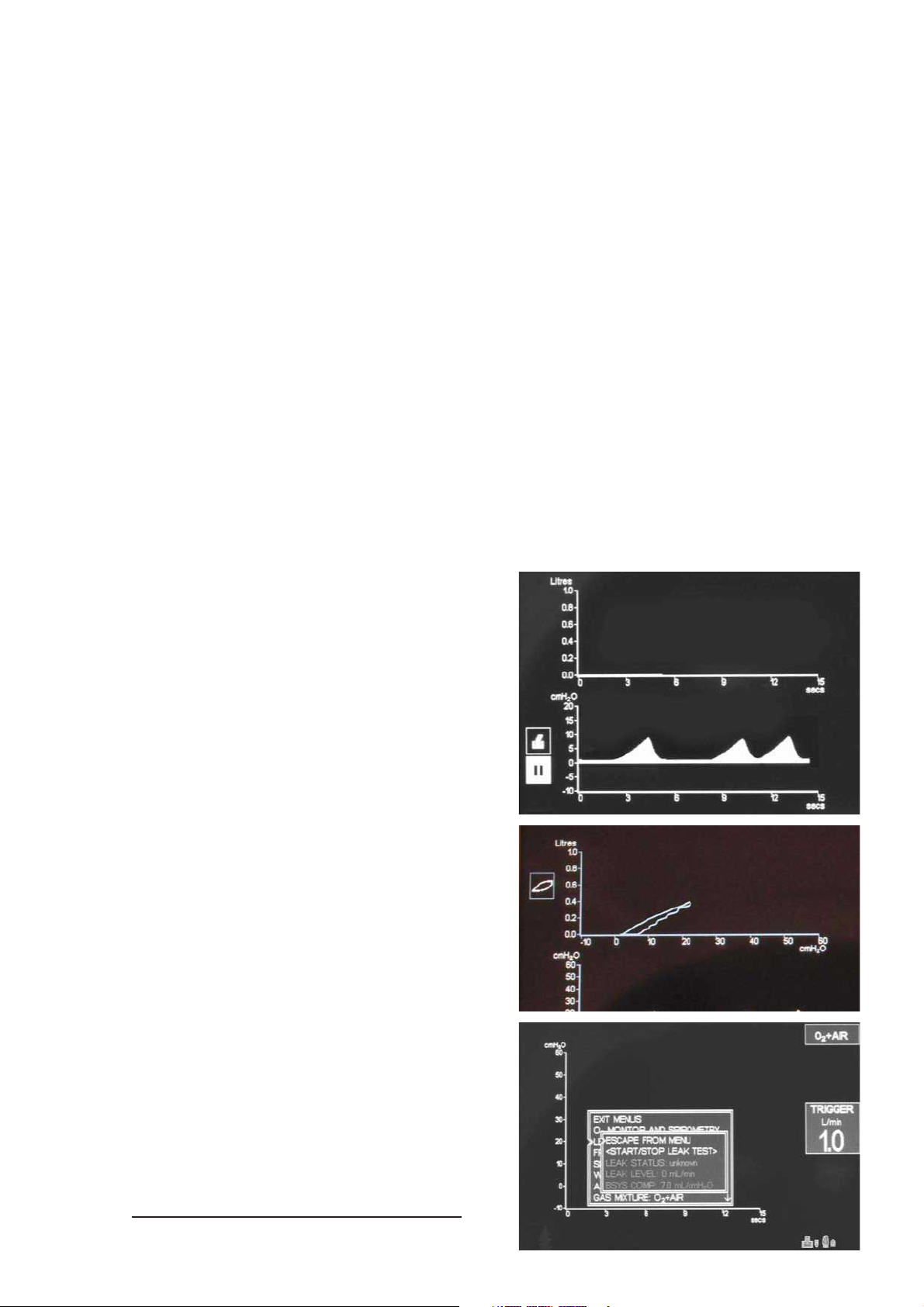

7. Waveform Pause and Print

Waveform pause and print icons are

located to the left hand side of the

waveform displays.

Ensure that a compatible printer is

connected, and switched On (see section

5.1.8).

To print the waveform information, press

the pause icon. The print icon will be

displayed. Press the icon to print.

Press the pause icon to unfreeze the

waveform.

8. Waveform Freeze Loop

The FREEZE LOOP icon is located at the

left hand side of the top waveform.

9. Leak Test

a) Select LEAK TEST through the Menu

in Standby Mode.

b) With the bag/vent switch in VENT

position, this checks for a leak using an

occluded breathing system

The leak test procedure is given in

section 5.1.12 in the user manual.

4

Modifications to Operational Envelope

(sections 4.5 and 4.6 in user manual)

Flow Range: 2 – 70 Litres per min.

Volume Range: 20 ml – 1.6 Litres (tidal)

2 – 50 Litres per min (minute vol.)

Rate 4 – 100 bpm

I:E Ratio 1:0.2 – 1:8.0 (normal)

1:2.0 – 1:8.0 (effective in support modes)

Inspiratory Time 0.3 – 10 seconds (normal)

0.3 – 5 seconds (effective in support modes)

ExpiratoryTime 0.3 – 10 seconds

(effective dependent on Inspiratory time)

Additional information on Sigh and Inspiratory Pause

(section 3.7.2.4)

Inspiratory Pause

Inspiratory Pause has a range of 0 to 60% of the inspiratory time.

Sigh

This function must be enabled in the mode menu but is only

operational in volume ventilation.

The sigh ratio is 1 to n (1:n) with n giving a range of 10 – 100 breaths

between sighs.

5

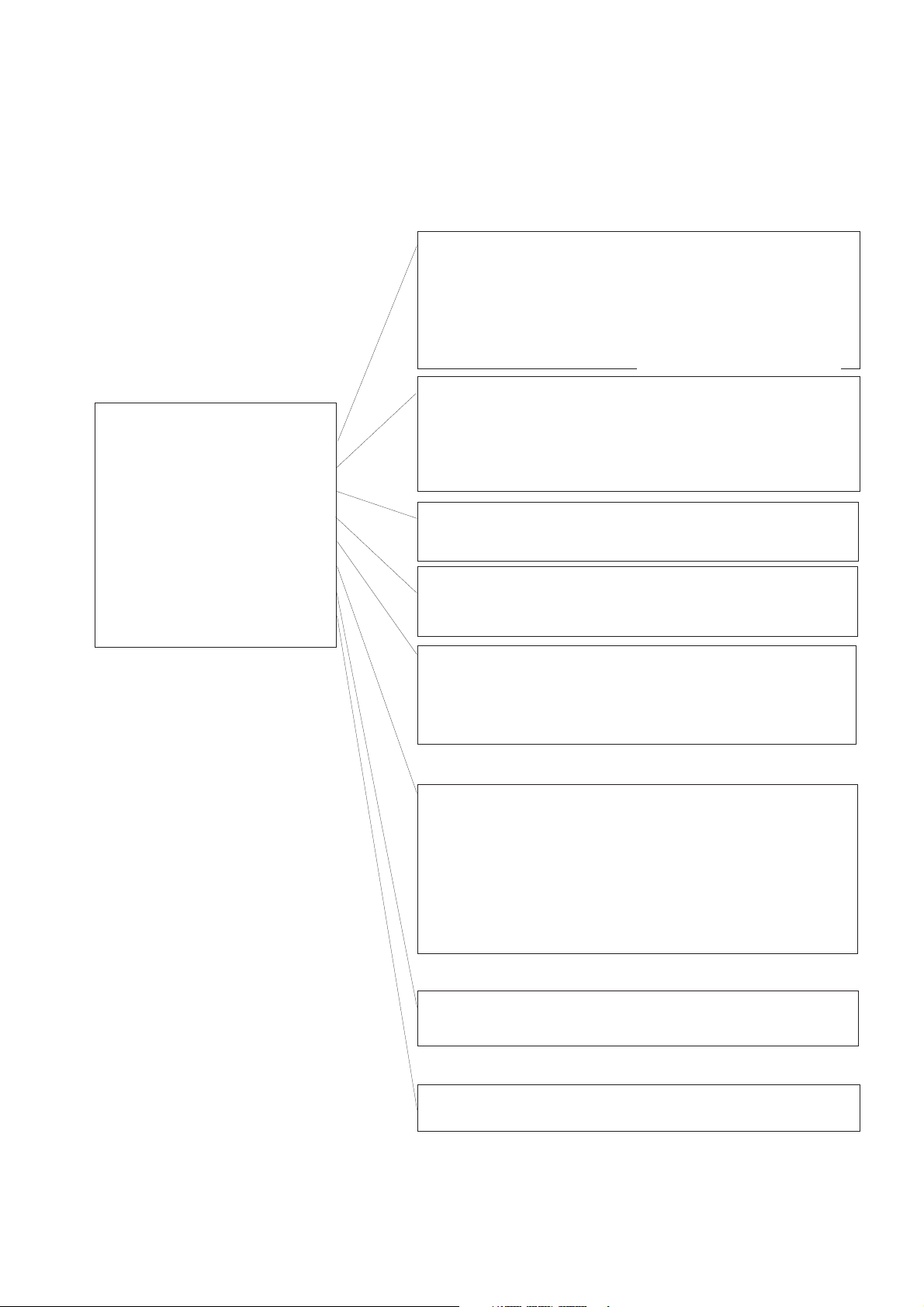

EXIT MENUS

O2 MONITOR & SPIROMETRY

LEAK TEST

FRESH GAS COMPENSATION:ON

MODES

WAVEFORM

ALARM SETTINGS

GAS MIXTURE: O2+AIR

SERVICE MENU

O2 Monitor & Spirometry

ESCAPE FROM MENU

O2 MONITOR: on

CALIBRATION: 100%

HIGH ALARM SET: 105

LOW ALARM SET: 18

SPIROMETER: on

SPIRO CALIBRATION: 0 L/min

off / on (Toggle option

21 / 100% (Toggle option)

19 -105 (Integer)

18 - 99 (Integer)

off / on (Toggle option)

0 L/min / 10 L/min (Toggle option)

off/on (Toggle option)

Fresh Gas Compensation

ON / OFF

Special Modes

See next page

Waveform

ESCAPE FROM MENU

SECOND WAVEFORM: off

Second waveform pick list

off

vol. vs time

vol. vs press.

Alarm settings

ALARM MENU

ESCAPE FROM MENU

ALARM MODE : default

HIGH TIDAL VOLUME: off

VM MIN: 3 L

VM MAX: 9 L

VT MIN: 300 mL

VT MAX: 900 mL

APNOEA ALARM LIMIT: 15 secs

ALARM VOLUME: 50%

default / user (Toggle option)

off / on (Toggle option)

0.0 - 7.4 (Integer)

0.1 - 7.5 (Integer)

10 - 1600 (Integer)

20 - 2400 (Integer)

0.3 - 3.5 (Integer)

50 - 100% (Integer)

Gas mixture: O2+Air

O2+AIR

O2+N2O

Leak Test

ESCAPE FROM MENU

<START/STOP LEAK TEST>

LEAK STATUS: unknown

LEAK LEVEL: 0 mL/min

BSYS COMP 7.0 mL/cmH2O

Service

See page 62

Menu Structure

Main Menu

6

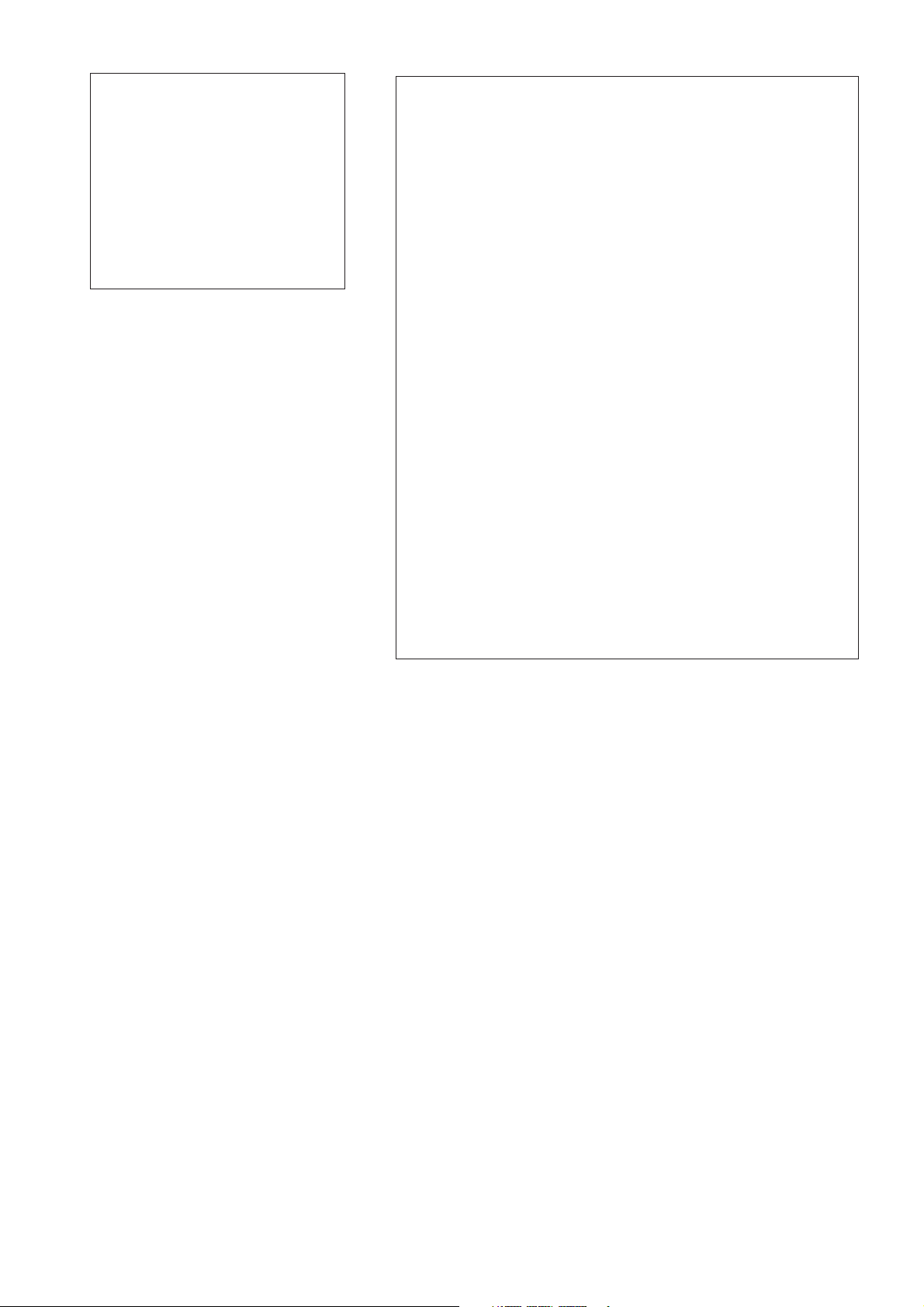

The SPECIAL MODES menu is context sensitive, with the contents

dependent on current mode.

In STANDBY the SPECIAL MODES menu is:

ESCAPE FROM MENU

SUPPORT MODE: SIMV, SMMV, PSV

(1)

VOLUME TYPE: Tidal

SIGH ENABLE:

(2)

SIGH TO BREATH RATIO:

INSP. PAUSE% : 0%

APPLY: SITE DEFAULT

In SPONT mode and VOLUME mode, and SIMV/ SMMV, the SPECIAL

MODES menu is:

ESCAPE FROM MENU

VOLUME TYPE: Tidal

SIGH ENABLE:

(2)

SIGH TO BREATH RATIO:

INSP. PAUSE% : 0%

In PRESSURE mode and PSV modes the SPECIAL MODES menu is:

ESCAPE FROM MENU

SIGH ENABLE:

(2)

SIGH TO BREATH RATIO:

INSP. PAUSE% : 0%

Notes

(1) Support mode depends on configuration options.

The SUPPORT MODE option will be missing from the SPECIAL

MODE menu if:

a) Options are not enabled

b) ‘’SPIROMETRY: off’’ is displayed.

The support mode sub menu can include:

none / PSV / SIMV / SMMV

(2) The options here are: 0 - 60%

(3) The options here are:

on - off

1:10 to 1:100

Note

1:10 indicates 1 breath with sigh, then 10 breaths without sigh

(2) The TRIGGER values are L/min with SPIROMETRY enabled, or

cmH

2O when SPIROMETRY disabled.

Spirometry enabled Spirometry disabled

0.7 L/min 0.5 cmH

2O

0.8 L/min 0.6 cmH

2O

0.9 L/min 0.7 cmH

2O

1.0 L/min 0.8 cmH

2O

1.5 L/min 0.9 cmH

2O

2.0 L/min 1.0 cmH

2O

2.5 L/min 1.2 cmH

2O

3.0 L/min 1.5 cmH

2O

3.5 L/min 1.7 cmH

2O

4.0 L/min 2.0 cmH

2O

SPECIAL MODES MENU

ESCAPE FROM MENU

SUPPORT MODE: SIMV, SMMV, PSV

VOLUME TYPE: Tidal

SIGH ENABLE:

SIGH TO BREATH RATIO:

INSP. PAUSE% : 0%

APPLY: SITE DEFAULT

7

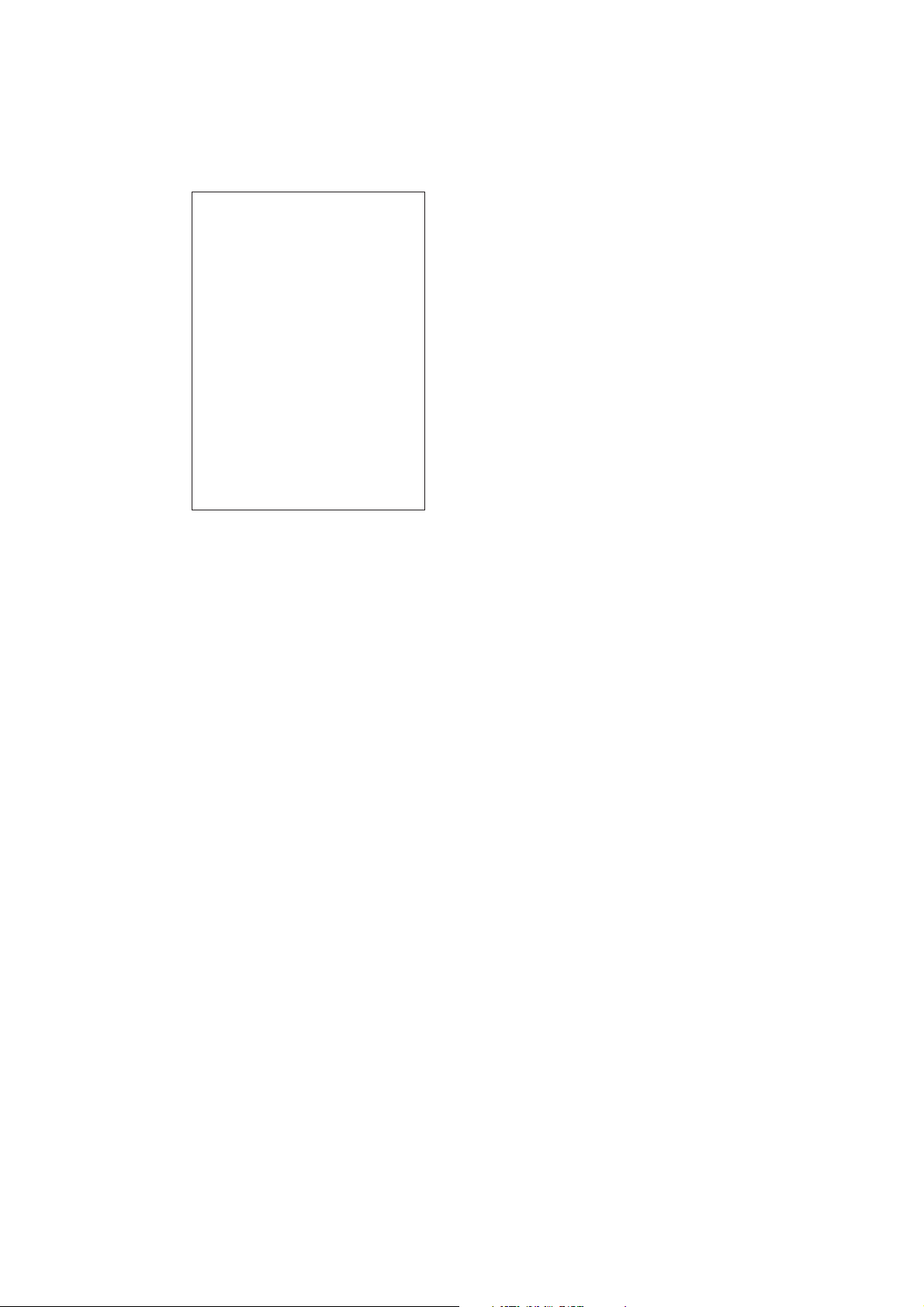

UPGRADE MENU

ESCAPE FROM MENU

I/O HARDWARE: 2

I/O FIRMWARE: vx.xx [Build xx]

MAIN FIRMWARE: vx.xx [Build xx]

REGISTRATION KEY: unknown

UPGRADE FIRMWARE: unavailable

ADD NEW FEATURE: unavailable

DISPLAY HISTORY

ESCAPE FROM MENU

MANUFACTURER DATE : 03/03/05

TOTAL HOURS RUN: 100

LAST SERVICE DATE: 13/08/04

HOURS SINCE SERVICE: 100

DRIVE VALVE CYCLES: 1253

PATIENT VALVE CYCLES: 822

CUTOFF VALVE CYCLES: 72

Service

ESCAPE FROM MENU

LANGUAGE: ENGLISH

PATIENT LOG MENU

SITE DEFAULTS

SERIAL MODE: none

ABSORBER SWITCH; ON

CLOCK MENU

UPGRADE MENU

AMBIENT PRESSURE: 988 mBar

DISPLAY HISTORY

*SERVICE PIN: 0

*ENGINEER MENU

CLOCK MENU

ESCAPE FROM MENU

YEAR: 2005

MONTH: 3

DATE: 16

HOUR: 9

MINUTE: 57

UPDATE CLOCK

DAYLIGHT SAVING: off

PATIENT LOG MENU

ESCAPE FROM MENU

PRINT PATIENT DATA

LOGGING: off

LOG STATUS: disabled

CLEAR LOG DATA

LOGGING WINDOW: 10 min

Clock pick list (integer)

2005 - 2099 (integer)

1 - 12 (integer)

1 -31 (integer)

0 - 23 (integer)

0 - 59 (integer)

off / on (toggle

option)

*NOTE

Sub-menus for Service PIN and

Engineer Menu are not accessible

by users.

SERVICE MENU

SITE DEFAULTS

ESCAPE FROM MENU

SAVE TO SITE

VIEW: SITE DEFAULTS

VOLUME TYPE : tidal

Vt SET: 550 ml

Vm SET: 5.5 Litres

T+PS INIT: 10 cmH2O

SET BPM : 10

I : E : 1:1.0

PEEP : OFF

LIMIT : 38 cmH2O

TRIGGER : 10 L/min

APNOEA ALARM LIMIT : 15 Sec

BACK LIGHT LEVEL : 50 %

Doc No. AVS 0408DS (U)

September 2008

DRE, Inc. 1800 Williamson Court Louisville, KY 40223 USA

Tel: (502) 244-4444

Fax: (502) 244-0369

Web: www.dremed.com

IMPORTANT

(i)

Servicing and Repairs

In order to ensure the full operational life of this

ventilator, servicing by an engineer trained by

the manufacturer should be undertaken

periodically.

The ventilator must be serviced to the following

schedule:

(a) Six monthly service - inspection and

function testing.

(b) Annual / two year / four year service -

inspection and function testing, and

component replacement.

Details of these operations are given in the

Service Manual for the AV-S, available only for

engineers trained by the manufacturer.

For any enquiry regarding the servicing or

repair of this product, contact DRE, Inc.

Technical Support

DRE, Inc.

1800 Williamson Court

Louisville, KY 40223

USA

Tel: (502) 244-4444

Fax: (502) 244-0369

Web: www.dremed.com

Always give as much of the following

information as possible:

1. Type of equipment

2. Product name

3. Serial number

4. Approximate date of purchase

5. Apparent fault

FOREWORD

(ii)

Parameter / Device Relevant Standard

Pressure Measuring ISO 8835-2

Pressure Limitation Device EN 60601-2-13:2006 - 51.101.1

Exhaled Volume Monitor EN 60601-2-13:2006 - 51.101.4

Breathing System Integrity Alarm System EN 60601-2-13:2006 - 51.101.5

Continuing Pressure Alarm EN 60601-2-13:2006 - 51.101.6

Oxygen Monitor ISO 7767

Carbon Dioxide Monitor ISO 9918

Breathing Circuit ISO 8835-2

Agent Monitor ISO 11196

Gas Scavenging ISO 8835-3

For information on installing and connection of any of these systems or devices, please refer to the relevant manufacturer’s instructions.

This manual has been produced to provide

authorized personnel with information on the

function, routine performance and

maintenance checks applicable to the AV-S

Anesthesia Ventilator.

Information contained in this manual is

correct at the date of publication.

The policy of the manufacturer is one of

continued improvement to its products.

Because of this policy, the manufacturer

reserves the right to make any changes

which may affect instructions in this manual,

without giving prior notice.

Personnel must make themselves familiar

with the contents of this manual and the

machine’s function before using the

apparatus.

The Importance of

Patient Monitoring

WARNING

Anesthetic systems have the capability to

deliver mixtures of gases and vapours to the

patient which could cause injury or death

unless controlled by a qualified anesthetist.

There can be considerable variation in the

effect of anesthetic drugs on individual

patients so that the setting and observation of

control levels on the anesthesia systems

does not in itself ensure total patient safety.

Anesthesia system monitors and patient

monitors are very desirable aids for the

anesthetist but are not true clinical monitors

as the condition of the patient is also

dependent on his respiration and the

functioning of his cardio-vascular system.

IT IS ESSENTIAL THAT THESE ELEMENTS

ARE MONITORED FREQUENTLY AND

REGULARLY AND THAT ANY OBSERVATIONS

ARE GIVEN PRECEDENCE OVER MACHINE

CONTROL PARAMETERS IN JUDGING THE

STATE OF A CLINICAL PROCEDURE.

Before using any monitoring system or

device, the user must check that it conforms

to the relevant standard, as listed in the table

below.

CONTENTS

(iii)

Page No.

USER RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. DESCRIPTION

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Ventilation Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.1 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 14

3.5 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.1 Touchscreen Operation and Navigator wheel / push-button . . . . . . . . . . . . 15

3.5.2 User Adjustable Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5.3 Operational capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5.4 Output Compensation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Interface with Integra AV-S and A200SP . . . . . . . . . . . . . . . . . . . . . . 20

3.7 Ventilation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.1 Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.2 Volume Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.3 Pressure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.4 Spontaneous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.7.5 Advanced Spontaneous Breathing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.7.5.1 SIMV (Synchronised Intermittent Mandatory Ventilation) . . . . . . . . . . . . . 26

3.7.5.2 SMMV (Synchronised Mandatory Minute Ventilation) . . . . . . . . . . . . 27

3.7.5.3 PSV (Pressure Supported Ventilation) . . . . . . . . . . . . . . . . . . . . . . 28

3.7.5.4 PEEP ( Positive End Expiratory Pressure) . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.8 On-screen Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.9 Spirometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.10 Display Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.11 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.12 Oxygen Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.12.1 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.12.2 The Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.12.3 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.12.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.12.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.12.6 Alarm Mute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4. SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Oxygen Monitor . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CONTENTS

(iv)

5. PRE-OPERATION PROCEDURES

5.1 Ventilator Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.1 Mounting the Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.2 Electrical Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.3 Ventilator Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.4 Breathing System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.5 Bellows Drive Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1.6 Anesthetic Gas Scavenging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1.7 Remote Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1.8 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1.9 Breathing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1.10 Spirometer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1.11 Pressure Monitor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.12 Leak Test / Compliance value Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.1.13 Bellows Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2 Pre-use Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2.1 Daily Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2.1.1 Alarm System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2.1.2 Ventilator Internal Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2.1.3 Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.2.2 Weekly Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3 Oxygen Monitor Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.1 Installation . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.3 Sensor Low Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.3.4 Setting the High and Low O

6. MAINTENANCE

6.1 Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.1 Outside Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.2 Bellows Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.3 Spirometer Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.4 Oxygen Monitor Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.5 Patient Connector Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.3 Sterilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 Oxygen Monitor Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7. APPENDIX

1. Back-up Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2. Menu System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3. Ventilator Spirometry System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4. Disposal after use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5. Approved Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Statements in this manual preceded by the

following words are of special significance:

WARNING means there is a

possibility of injury to the

user or others.

CAUTION means there is a possibility

of damage to the apparatus

or other property.

NOTE indicates points of

particular interest for more

efficient and convenient

operation.

Always take particular notice of the

warnings, cautions and notes provided

throughout this manual.

USER RESPONSIBILITY

1

This anesthesia ventilator has been built to

conform with the specification and operating

procedures stated in this manual and/or

accompanying labels and notices when

checked, assembled, operated, maintained

and serviced in accordance with these

instructions.

To ensure the safety of this device it must be

checked and serviced to at least the

minimum standards laid out in this manual.

A defective, or suspected defective, product

must not under any circumstances be used.

The user must accept responsibility for any

malfunction which results from noncompliance with the servicing requirements

detailed in this manual.

Additionally, the user must accept

responsibility for any malfunction which may

result from misuse of any kind or noncompliance with other requirements detailed

in this manual.

Worn, broken, distorted, contaminated or

missing components must be replaced

immediately. Should such a repair become

necessary it is recommended that a request

for service advice be made to DRE, Inc.

This device and any of its constituent parts

must be repaired only in accordance with

written instructions issued by the

manufacturer and must not be altered or

modified in any way without the written

approval of the manufacturer. The user of

this equipment shall have the sole

responsibility for any malfunction which

results from improper use, maintenance,

repair, damage or alteration by anyone other

than the manufacturer.

USA and Canada:

Federal Law restricts the sale and use of this

device to, or on the order of, a licensed

practitioner.

1. WARNINGS AND CAUTIONS

2

The following WARNINGS and CAUTIONS

must be read and understood before using

this ventilator.

WARNINGS

General Information

1. Personnel must make themselves

familiar with the contents of this

manual and the machine’s function

before using the ventilator.

Before Using the Ventilator

2. Before the AV-S ventilator is used

clinically for the first time a Calibration

Check and Output Check must be

successfully completed.

Calibration and output checks must be

carried out by a DRE-trained

technician, following the procedure in

Appendix 6 in the AV-S Service Manual.

3. Before the ventilator is used clinically

for the first time, verify that the hospital

engineering department has carried out

an earth continuity test.

If the integrity of the protective

conductor is in doubt, the ventilator

must not be used.

Before the ventilator is used clinically

for the first time, the commissioning

engineer must confirm that the

air/oxygen selection is set correctly for

the drive gas that is to be used.

The use of any other gas will cause

inaccurate operation and may damage

the ventilator, resulting in potential

injury to the patient.

8. The driving gas is discharged through

the opening in the back of the ventilator

control unit.

The discharged gas may contaminate

the environment, and should therefore

be extracted using a gas scavenging

system.

9. The bellows can only support

approximately 1 kPa (10 cmH

differential positive pressure, above

which it may be dislodged from the

mounting ring, resulting in dangerous

malfunction of the ventilator.

Do not connect a positive end

expiratory pressure (PEEP) valve or

other restrictive device to the exhaust

port on the bellows base.

This would increase the pressure inside

the bellows and the bellows could

detach from the base, causing serious

malfunction.

2O)

4. Excessive electronic noise caused by

other poorly regulated devices, such as

an electrocautery unit, may adversely

interfere with the proper functioning of

the ventilator.

To avoid this problem, do not connect

the ventilator’s power cord into the

same electrical wall outlet or adaptor

strip into which an electrocautery unit

is connected.

5. If used with a mains extension cord, the

unit may be subject to electro-magnetic

interference.

6. The driving gas supply must be clean

and dry to prevent ventilator

malfunction.

7. This ventilator is designed to be driven

by oxygen or medical air only. The

drive gas is set during manufacture

and the ventilator is calibrated for that

gas.

10. Breathing System

The breathing system which conveys

gases from the anesthetic machine to

the patient, and disposes of expired

gases, must conform to the

requirements of ISO 8835-2.

Because breathing systems require

frequent cleaning and disinfection they

are not a permanent part of the

anesthetic ventilator and therefore

cannot be directly under the control of

the anesthetic ventilator manufacturer.

However, we strongly recommend that

only breathing systems which have

been approved and authorized by the

manufacturer for use with AV-S should

be employed.

Do not use conductive breathing

system hoses.

When mechanical ventilation is

employed the patient breathing system

must be connected directly to a

pressure relief valve to prevent the

possibility of barotrauma.

WARNINGS AND CAUTIONS

3

11. The spirometer sensors are mounted

within the A200SP absorber. Do not fit a

spirometer sensor to any other

location.

The device will not measure exhaled

volumes in any other position.

12. The operation of each alarm function

should be verified daily.

Periodically check the alarms at

clinically suitable intervals. If the

audible alarm or the visual indicator of

any alarm function fails to activate

during any alarm condition or fails to

reset after the alarm has been cleared,

refer the unit to an authorized service

technician.

13. Before using the ventilator check that

all connections are correct, and verify

that there are no leaks.

Patient circuit disconnects are a hazard

to the patient. Extreme care should be

taken to prevent such occurrences.

It is recommended that Safelock

fittings are used throughout the

breathing circuit.

Any problem arising from an

improperly functioning scavenging

system is solely the user’s

responsibility.

Do not use a scavenging system that

restricts drive gas flow when negative

pressure is exerted on it.

18. When the ventilator is connected to a

patient, it is recommended that a

qualified practitioner is in attendance

at all times to react to an alarm or other

indication of a problem.

19. In compliance with good anesthesia

practice, an alternative means of

ventilation must be available whenever

the ventilator is in use.

20. It is recommended that the patient

oxygen concentration should be

monitored continuously.

21. If the drive gas supply pressure drops

below a nominal 241 kPa (35 psi), the

LOW DRIVE GAS SUPPLY alarm will

activate both audibly and visually.

Patient minute volume may be reduced

due to lowered flow rates

14. Check that the cable between the

control unit and remote display screen

unit is connected before use.

Always use a cable type recommended

by the manufacturer.

Using the Ventilator

15. The AV-S ventilator is not intended for

use in intensive care applications.

16. This apparatus must not be used with,

or in close proximity to, flammable

anesthetic agents.

There is a possible fire or explosion

hazard.

17. Anesthesia apparatus must be

connected to an anesthetic gas

scavenging system (AGSS) to dispose

of waste gas and prevent possible

health hazards to operating room staff.

This requirement must be observed

during test procedures as well as

during use with a patient.

The scavenging transfer and receiver

system must conform to ISO 8835-3.

22. An audible alarm indicates an

anomalous condition and should never

go unheeded.

23. The characteristics of the breathing

circuit connected between the

ventilator and the patient can modify or

change patient ventilation.

To assist the maintenance of the

delivered patient tidal volume, the

ventilator control system software

includes:

A) a compliance compensation

algorithm,

B) a fresh gas compensation

algorithm.

However, patient ventilation must be

monitored independently from the

ventilator.

It is the responsibility of the user to

monitor patient ventilation.

24. Care must be taken to ensure that the

flow sensors are connected correctly

to the inspiratory and expiratory ports

of the absorber.

WARNINGS AND CAUTIONS

4

25. The Vent Inop (ventilator inoperative)

alarm indicates that one of the

following conditions has occurred:

a) The drive gas solenoid has failed.

b) The flow control valve has failed.

c) Internal electronic fault.

d) Internal electrical fault.

e) Software error.

Note that if a ventilator error is

detected, ‘Ventilator Inoperative’ will be

displayed on the front control panel

display.

26. The High and Low Airway Pressure

Alarms are important for patient care.

It is important that the sensor is

properly located in the expiratory limb

of the circuit - refer to section 5.1.10.

27. The patient must be continuously

attended and monitored when

Advanced Breathing Modes are in use.

User Maintenance

28. User maintenance is restricted to

cleaning the outside surfaces of

the ventilator, see section 6.

Other procedures detailed in this

manual must be carried out by

trained technicians.

Service and repair operations must

only be carried out by an engineer

trained by the manufacturer.

The warranty for this product is

void if the product is not

maintained in accordance with the

service schedule detailed in

section 6.1, and the procedures

published in the Service Manual for

this product.

Control Unit

29. Opening the control unit by

unauthorized personnel automatically

voids all warranties and specifications.

Prevention of tampering with the

control unit is exclusively the user’s

responsibility. If the control unit seal is

broken, the manufacturer assumes no

liability for any malfunction or failure of

the ventilator.

30. For continued protection against fire

hazards, any replacement fuses must

be the identical type and rating as the

original components. Replacement

must be carried out by trained

technician.

See section 4 for fuse rating.

31. If the internal battery is fully

discharged, the ventilator will not

function in the event of mains power

failure. The battery must be recharged

before the ventilator is used clinically,

otherwise backup cannot be

guaranteed.

See Appendix for battery maintenance.

See also CAUTION No. 7.

Used or defective batteries must be

disposed of according to hospital,

local, state, and federal regulations.

32. No oil, grease or other flammable

lubricant or sealant must be used on

any part of the ventilator in close

proximity to medical gas distribution

components.

There is a risk of fire or explosion.

33. Exterior panels must not be removed

by unauthorized personnel and the

apparatus must not be operated with

such panels missing.

There is a possible electric shock

hazard.

Bellows Assembly

34. The valve seat on the patient gas

exhalation diaphragm valve in the base

of the bellows assembly must be

cleaned regularly. Note that the bellows

assembly is built into the A200SP

Absorber - please refer to User Manual

for this product.

Failure to keep the valve seat clean

could result in the diaphragm sticking,

thus preventing exhalation.

Great care must be taken not to

damage the precision surface of the

valve seat on the patient gas exhalation

diaphragm valve in the base of the

bellows assembly.

Never use any hard object or abrasive

detergent to clean it; use only a soft

cloth.

If the valve seat is damaged, the valve

will leak and may cause serious

ventilator malfunction.

10. Circuit compliance is not activated until

Fresh Gas Compensation is switched

OFF.

NOTES

1. The term ‘cycle’ is used to designate the

transition to the exhalation phase.

2. The term ‘trigger’ is used to indicate the

transition to the inhalation phase.

WARNINGS AND CAUTIONS

5

CAUTIONS

1. Do not sterilize the ventilator control unit.

The patient block assembly must be

removed from the control unit before

sterilization ( see section 6.2.5).

All other internal components are not

compatible with sterilization techniques

and damage may result.

2. For ventilator components which require

sterilization, peak sterilization

temperatures should not exceed 134oC

(275oF) to prevent possible damage.

(See section 6).

3. Care must be taken not to let any liquid

run into the control unit; serious damage

may result.

4. The exhalation valve located in the

bellows base assembly and the pediatric

bellows adaptor must be cleaned and

sterilized separately. Note that the bellows

assembly is built into the A200SP

Absorber - please refer to User Manual for

this product.

5. Always check for correct fitment, and carry

out a full function test before clinical use, if

the bellows has been removed and

refitted for any reason. Note that the

bellows assembly is built into the A200SP

Absorber - please refer to User Manual for

this product.

6. Always check for correct fitment, and carry

out a full function test before clinical use, if

the bellows has been removed and

refitted for any reason. See section 6.

7. Damage may occur to the battery if it is

allowed to remain in a discharged state.

Check the battery frequently if the

ventilator is in storage (see Appendix 1).

8. Fresh gas compensation is disabled if :

a) The spirometry system is turned OFF

through the menu system, or

b) The spirometry system is not functioning

correctly.

9. Fresh gas mixture compensation is disabled

if :

a) The spirometry system is turned OFF

through the menu system, or

b) The spirometry system is not functioning

correctly.

c) The O2 monitor is switched OFF.

6

WARNINGS AND CAUTIONS - Oxygen Monitor

Oxygen Monitor

Note that the sensor for the oxygen

monitor is built into the A200SP

Absorber - for additional information,

please refer to the A200SP User

Manual.

WARNINGS

1. We recommend calibration of the

oxygen monitor every time the system

is turned on, as a safety precaution.

2. Do not attempt to open the fuel cell.

The sensor contains small quantities

of :

a) electrolyte, classified as a harmful

irritant which is potentially hazardous,

and

b) lead.

Used or defective cells must be

disposed of according to hospital,

local, state, and federal regulations.

CAUTIONS

1. Do not sterilize any oxygen monitor

component.

2. Do not autoclave or expose the sensor to

high temperatures.

3. If the sensor shows signs of being affected

by condensation, dry the sensor with soft

tissue.

Do not use heat to dry the sensor.

NOTES

1. The O2 SENSOR FAULT alarm indicates

that one of the following conditions has

occurred.

a) Internal electrical fault

b) Software/electronics fault

c) Oxygen sensor fault.

2. The concentration read-out may, in

certain conditions of excess pressure,

show a value above 100%.

To accommodate these conditions it is

possible to set the high alarm value up to

105% (see section 5).

3. ALWAYS check the integrity of the

sensor assembly before use.

4. Once exhausted, the sensor must be

disposed of according to hospital,

local, state and federal regulations.

5. The sensor measures oxygen partial

pressure, and its output will rise and

fall due to pressure change.

An increase in pressure of 10% at the

sensor inlet will produce a 10%

increase in sensor output.

6. The oxygen sensor is not suitable for

sterilization.

If contamination is suspected, fit a new

sensor (see section 6.4) and dispose of

the contaminated unit according to

hospital, local, state and federal

regulations.

3. To maintain maximum sensor life:

i) always switch off the anesthetic

machine after use, to ensure that the basal

flow ceases.

ii) disconnect the breathing circuit after

use.

4. The accuracy of flow and volume

measurements may be reduced if the

oxygen monitor is not in use.

5. Fresh gas mixture compensation is disabled

if the oxygen monitor is switched OFF.

2. PURPOSE

7

The AV-S Ventilator is a software controlled,

multi-mode ventilator, designed for

mechanical ventilation of adult and

pediatric patients under general

anesthesia.

In addition, in spontaneous mode, it can be

used to monitor spontaneously breathing

patients

It is designed for use in closed-circuit

anesthesia.

Indications for use of the device:

The AV-S Ventilator is intended to provide

continuous mechanical ventilatory support

during anesthesia. The ventilator is a

restricted medical device intended for use by

qualified trained personnel under the

direction of a physician. Specifically the

ventilator is applicable for adult and

pediatric patients.

The ventilator is intended for use by health

care providers, i.e. Physicians, Nurses and

Technicians with patients during general

anesthesia.

The AV-S ventilator is not intended for use in

intensive care applications.

Oxygen Monitor

The Oxygen Monitor is intended to

continuously measure and display the

concentration of oxygen in breathing gas

mixtures used in anesthesia, and is

intended for adult and pediatric patients.

The oxygen monitor is an integral part of the

ventilator.

The oxygen monitor is intended for use by

health care providers, i.e. Physicians,

Nurses and Technicians for use with patients

during general anesthesia.

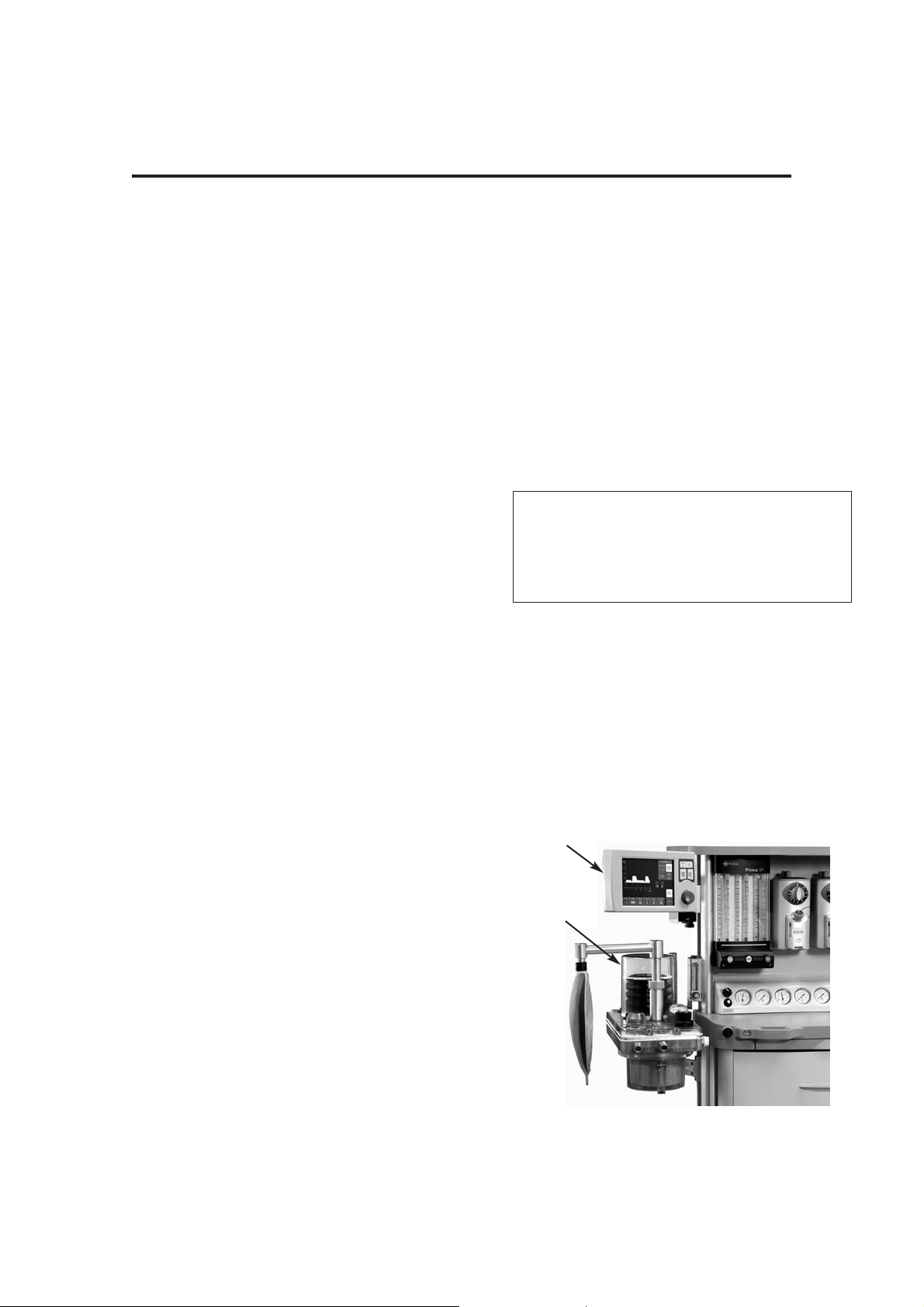

3. DESCRIPTION

8

1

2

Spontaneous Mode Patient Support

SIMV - Synchronised Intermittent Mandatory Ventilation

SMMV - Synchronised Mandatory Minute Ventilation

PSV - Pressure Supported Ventilation

PEEP - Positive End Expiratory Pressure

3.1 General Description

The AV-S Ventilator is a pneumatically driven, software

controlled, multi-mode ventilator.

The ventilator is a time-cycled, volume/pressure

controlled, and pressure limited.

The ventilator has compliance compensation and a

user selectable option of an inspiratory pause fixed at

25% of the inspiratory time.

In addition, fresh gas compensation and user

selectable gas mixture compensation is a standard

feature.

Ventilation Modes

Volume Mode - continuous mandatory ventilation

Pressure Mode - pressure controlled ventilation

Spontaneous, with advanced patient support -

SIMV, SMMV, PSV, PEEP

Patient Monitoring

Airway pressure, measured from the expiratory limb of

the breathing circuit.

Tidal Volume and Minute Volume measurement is

provided by a dual spirometry system

An integral oxygen monitor system measures oxygen

concentration in the breathing circuit inspiratory limb.

The print function provides a permanent record of

function activity for up to eight hours during a

procedure, or can be used to record waveforms.

Screen

210 mm (8.4 inch) high definition, colour TFT screen,

with single/dual waveform display.

Mounting:

Remote, arm-mounted as illustrated (1) or optional

combined control unit / screen (see section 5.1.1).

Bellows unit

The bellows unit (2) is built into the A200SP absorber.

A pediatric bellows assembly is available as an

option

Drive gas supply

The drive gas supply can be oxygen or air.

The supply must be at 310 to 689 kPa (45 to 100 psi).

Note that the drive gas is specified by the customer,

and set during manufacture. Conversion from one

drive gas to another must only be carried out by an

authorized service engineer trained by the

manufacturer.

9

DESCRIPTION

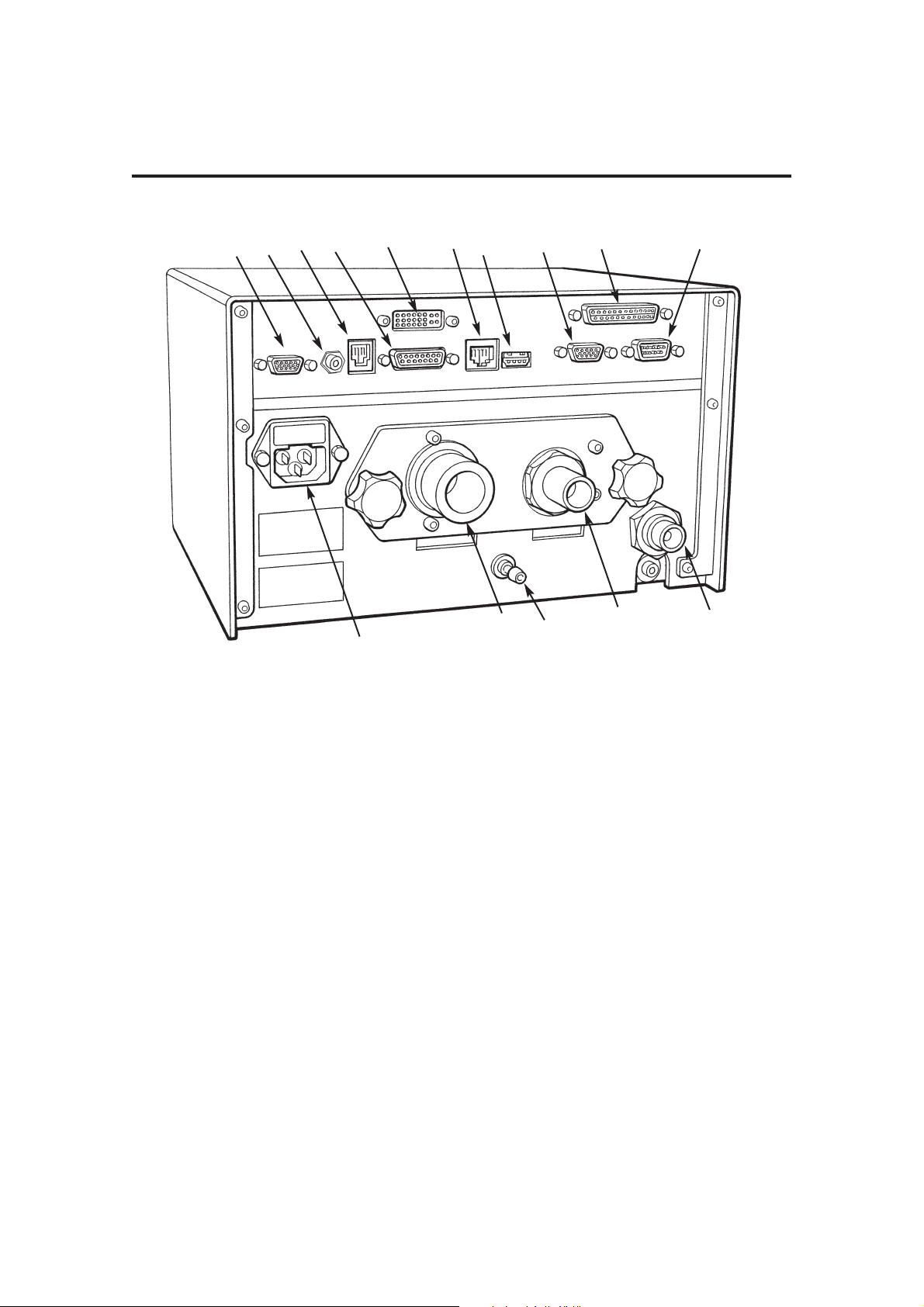

2

7

3

13 14

15

12

1110

9

8

6

5

4

1

Control Unit

Rear Panel

Gas Connections

1. Ventilator drive gas inlet

- connect to anesthetic machine

auxiliary gas outlet

2. Bellows Drive Gas Output

- connect to bellows via A200SP

absorber - see section 5.1.5

3. Outlet - Exhaust Valve

- connect to scavenge system - see

section 5.1.6

Electrical Connection

4. Electrical mains input and fuse unit

Interface and Parameter inputs

5. A200SP Absorber Bag/Vent

switch interface, and

Spirometer connector

6. Integra AV-S Interface

connector - (primary on/off

switch)

7. Pressure Monitor Port

8. Input socket - Oxygen monitor

sensor

Data and Printer Ports

9. Data Output

10. Output to remote display

11. Ethernet

12. USB

13. VGA

14. Printer port

15. RS232 (manufacturer’s use only)

NOTE

USB port is for access only by engineers

trained by the manufacturer.

All other data ports are read only.

For further information, please contact

your distributor’s service department, or

the manufacturer.

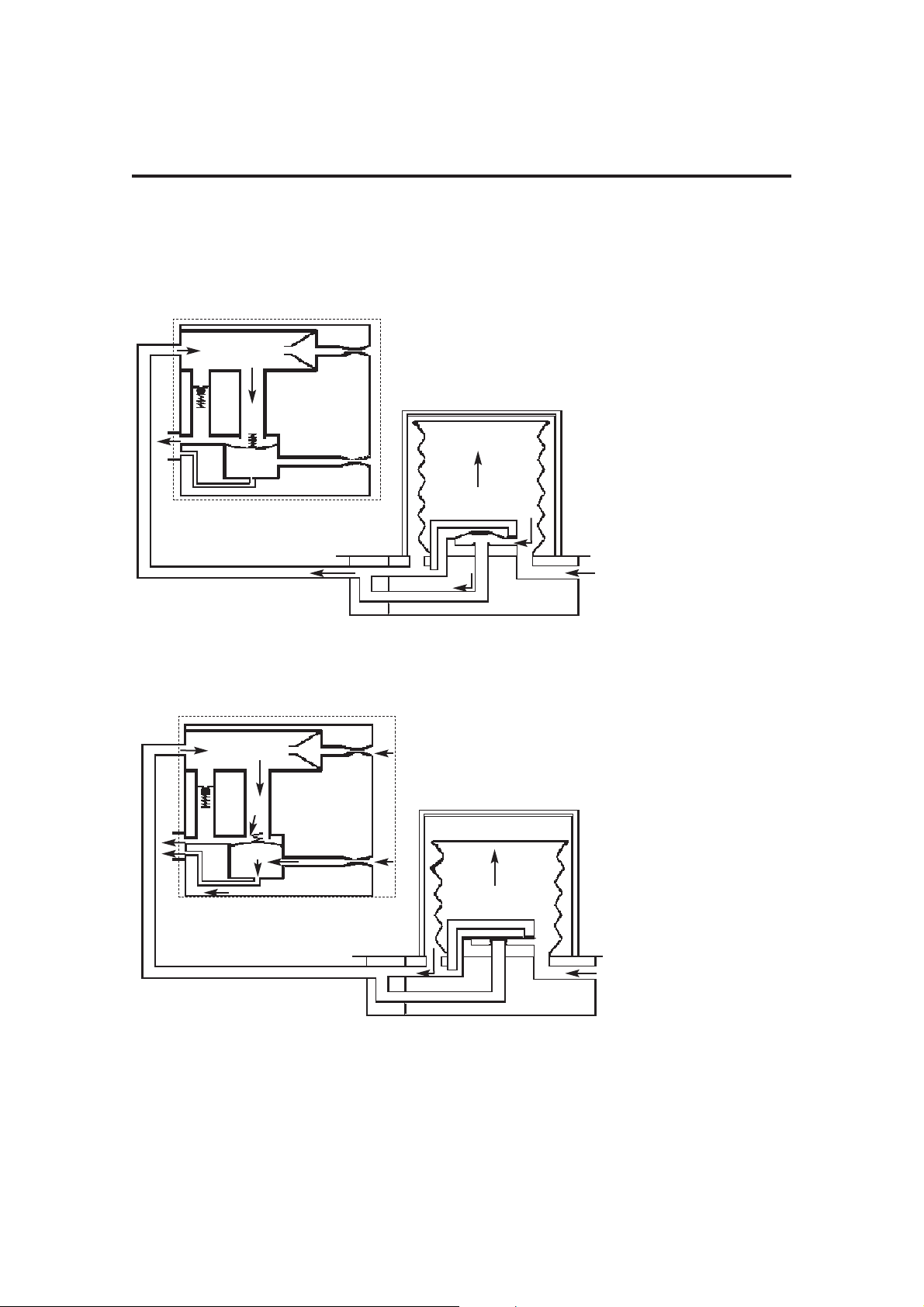

3.2 Ventilation Cycle

This section provides a simplified description of the ventilation cycle.

1. Inspiratory Phase

The drive gas proportional

valve (1) in the control unit

opens.

Drive gas is delivered to the

bellows housing (2).

The patient proportional

valve (3) opens, and gas

flows through the bleed

valve. The back pressure

ensures that the exhaust

valve (4) is kept closed.

Drive gas pressure builds

up above the bellows (5),

which starts to move down.

The diaphragm (6) in the

bellows assembly base is

held closed, and patient gas

is forced out of the bellows

base (7) into the breathing

system.

2. Beginning of

Expiratory Phase

The drive gas proportional

valve (1) closes.

The patient proportional

valve (3) closes.

The exhaust valve (4) opens.

Patient gas returns to the

bellows (5).

As the bellows rises,

redundant drive gas is

pushed out through the

exhaust valve.

DESCRIPTION

10

1

4

4

6

7

5

5

2

3

3

1

3

1

4

DESCRIPTION

3. End of

Expiratory Phase

With the bellows at the top

of its housing fresh gas

continues to flow.

To prevent a high pressure

build up the exhalation

diaphragm (6) lifts and

allows gas to exit through

the exhaust valve (4).

4. PEEP

Positive End

Expiratory

Pressure

(user selectable)

The patient proportional

valve (3) applies PEEP

pressure plus 20 cmH2O to

the exhaust valve, which

remains closed at this stage.

As fresh gas flows in the

patient circuit, any pressure

increase above PEEP

pressure in the bellows (5)

will cause gas to bleed past

the exhaust valve (4).

If there is a fall in pressure in

the breathing circuit, the

continuous flow from the

drive gas proportional valve

(1) helps maintain the set

PEEP pressure.

11

6

4

5

5

12

DESCRIPTION

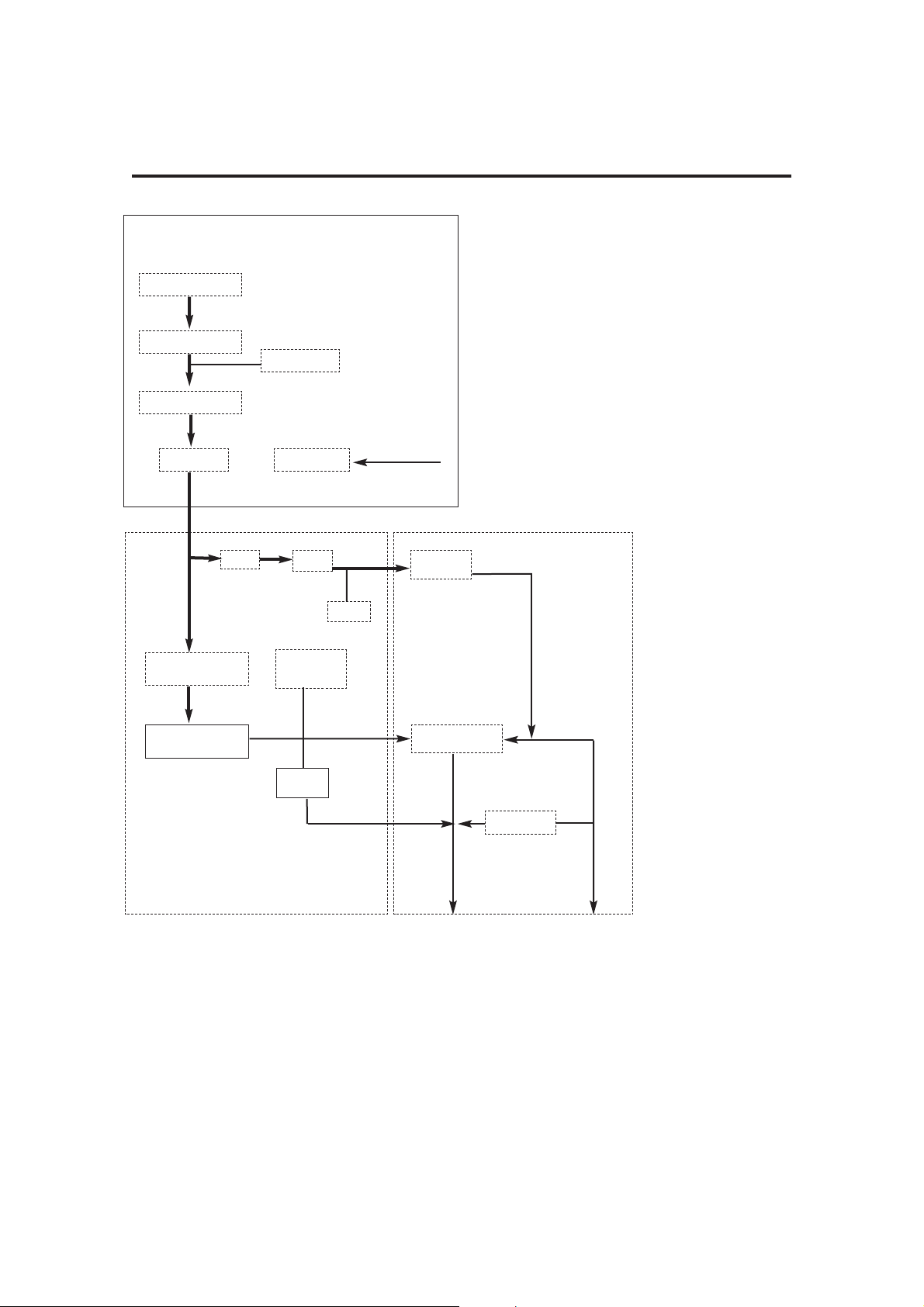

A

Pneumatic Flow

Diagram

C

1817

5

8

14

9

12

6

16

13

15

11

7

1

2

10

4

3

B

0 - 80 cmH2O

100 cmH

2O

0 - 90 cmH2O

241 kPa (35 psi)

3 to 7 bar

3.3 Pneumatic System

3.3.1 System Operation

Refer to the pneumatic system diagram on the previous page.

A) Gas inlet manifold block

The AV-S Ventilator is designed to operate on a 310 - 689 kPa (45 -100 psi)

drive gas supply (oxygen or air - to customer’s requirement).

1. DISS Connector

The gas source is connected to the DRIVE GAS SUPPLY fitting on the

rear of the ventilator control unit.

The gas supply should be capable of a flow rate of 80 L/min while

maintaining a minimum pressure in excess of 310 kPa (45 psi).

2. Filter

The drive gas is filtered with a 40-micron Input Gas Filter which protects

the pneumatic components from incoming particulate matter.

3. The Low Supply Pressure Detector

The pressure switch is set at a predetermined level to detect a loss or

reduction of the input gas source pressure.

When the pressure falls below 235 kPa (35 psi ± 1 psi), the LOW

SUPPLY PRESSURE indicator will be displayed and the high priority

audible alarm will activate.

4. Input Pressure Regulator

Regulates the input drive gas to 260 kPa ± 21 kPa (38 psi ± 3 psi).

5. Cut-off Valve

The valve isolates the the gas supply :

a) when the ventilator is switched off

b) when a fault condition occurs.

6. Airway Pressure Sensor

Connected to expiratory limb of breathing circuit.

B) Pneumatic Control Manifold Block

7. Drive Gas Proportional Valve

8. Drive Gas Flow Sensor

9. Drive Gas Pressure Sensor

10. Low Pressure Regulator

11. Patient Proportional Valve

12. PEEP pressure sensor

13. Restrictor

The restrictor allows a flow of up to 2 L/min (<2 L/min bleeding)

C) Exhaust Manifold Block

14. Check Valve

15. Diaphragm Valve

16. Pressure Relief valve - Set to 100 cmH

2O

17. Exhaust Port ( to AGSS)

18. Bellows drive gas outlet (to bellows assembly)

DESCRIPTION

13

3.4 Electrical System

Mains Supply

The mains supply inlet is designed for

connection to the following mains voltage

supplies:

100 to 120 VAC, 50 to 60 Hz

200 to 240 VAC, 50 to 60 Hz

Note that the ventilator adjusts automatically to

the supply voltage range.

The connector is a standard IEC type.

Back-up Battery

In the event of mains electrical failure, the backup battery cuts in automatically.

Standard battery:

A fully charged battery will power the ventilator

for approximately 30 minutes.

High-power battery (option):

A fully charged battery will power the ventilator

for approximately one hour.

See Appendix for battery care procedures.

DESCRIPTION

14

DESCRIPTION

3.5 Control Panel

3.5.1 Touchscreen and Navigator Wheel / Push Button

3.5.1.1 Control Panel

1. On/Off control

Switch On: Short internal test sequence

Switch Off: Power down sequence with progress indicator

2. Status indicators for electrical power (mains/battery supply)

Yellow indicator - illuminated whenever power is applied to the unit and internal battery is being

charged

Green indicator - illuminates when the unit is switched on

3. Menu switch

The menu function provides access to user and service pages, including alarm settings.

4. Alarm mute switch

30 second or 120 second alarm silence, depending on alarm status.

Note also that some alarms are not mutable (see 3.11).

5. Navigator Wheel and Press Button

Turn the wheel to select a function or parameter, or to alter the value of an active parameter.

Press to confirm the setting.

6. Active Tabs

Touch the screen at the appropriate tab area to activate the required function/parameter.

15

VmSET

mL

600

VmMEAS

Litres

3.6

SET

BPM

10

SET

I:E

2

PEEP

cmH2O

OFF

LIMIT

cmH2O

38

VOLUME

CONTROL

SPONT

MODE

STANDBY

%O2 105

21 18

PRESSURE

CONTROL

cm H2O

secs

AV-S

1

4

3

5

6

2

Gas Mixture

O

2 + air

.

.

IO

o

o

16

DESCRIPTION

3.5.1.2 Selecting Functions and Parameters

The functions/parameters shown on the screen can be

activated as follows:

a) touch the screen at the appropriate tab area.

b) rotate the navigator wheel and press it when the

indicator arrow is on the required parameter tab

Note that parameters default to factory-set values when

the ventilator is switched on and no further user

selection is made.

3.5.2 User Adjustable Parameters

Variable parameters can be altered by rotating

the navigator wheel.

When the required value is displayed, press

the active tab or

the wheel to confirm the

setting.

Tidal Volume Range 20-1600 ml

Rate 4-100 bpm

I:E Ratio 1:0.3 to 1:8

PEEP 4-20 cmH2O

Can be set to OFF

Pressure Limit

Volume mode: 10-80 cmH2O

Pressure mode: 10-50 cmH2O

Alarm limits (user adjustable alarms only - see 3.11)

3.5.3 Operational Capability

Tidal Volume, Rate, and I:E ratio settings are

all limited by a maximum inspiratory flow of

75 L/min, and a minimum flow of 2 L/min.

DESCRIPTION

17

0.1

0.2

0.4

0.3

0.6

0.5

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0 10 20 30 40 50 60 70 80

1:6 1:5 1:4 1:3 1:2 1:1 1:0.3

Rate (bpm)

Tidal

Volume

(litres)

(Vt)

I:E Ratio

The ventilator is capable of operating at the volumes and rates below

each I:E ratio curve.

Example

1. Select required volume: Vt = 1.0 L

2. Select rate = 20 bpm

In this example, the point of intersection X on the graph shows that an I:E ratio can be set

from 1:0.3 to 1:4, as these curves are all above the intersection point.

Similarly, a ratio of 1:5 cannot

be set, as this is below the intersection point.

X

3.5.4 Output Compensation

Functions

WARNING

The AV-S automatically compensates for

fresh gas (spirometry On), fresh gas mixture

(spirometry and oxygen monitor On), and

altitude.

However, the actual tidal volume delivered to

the patient may be different to the ventilation

parameters set by the user, due to:

A) an extreme compliance condition,

B) a substantial system leak,

C) patient circuit pressure effects, or

D) extreme fresh gas flows

In addition, high fresh gas flows will lead to an

increased Vt being delivered to the patient.

The patient must

be monitored independently

from the ventilator.

It is the responsibility of the user to monitor

the patient for adequate ventilation.

Fresh Gas Compensation

Adjusts delivered volume up to 60%

An alarm is triggered if the measured

volume varies by 50% from the set volume.

This function is user adjustable

NOTE

Fresh gas compensation is disabled if :

a) The spirometry system is turned OFF through

the menu system, or

b) The spirometry system is not functioning

correctly.

Fresh Gas Mixture Compensation

- models with Spirometry

The spirometry system compensates for fresh

gas mixture - the user must access the menu

system and select the gas mixture that will be

used for each clinical procedure.

NOTE

Fresh gas mixture compensation is disabled if :

a) The spirometry system is turned OFF through

the menu system, or

b) The spirometry system is not functioning

correctly.

If the O2 monitor is switched OFF, a 40% / 60%

mixture of O2/N2O is assumed.

DESCRIPTION

18

Compliance compensation

The ventilator will apply compliance

compensation to account for compliance

loss in the breathing system in cases where:

i) Fresh gas compensation is disabled, or

ii) Spirometry is unavailable or disabled

IMPORTANT

For correct operation the value of the

breathing system compliance must be

established first, by completing the ventilator

leak-test as part of the Pre-operation

Procedure.

Refer to section 5.1.12, noting that breathing

system compliance is displayed as

‘Bsys.comp’

If the leak test is not carried out, the default

value will be used.

NOTE

In compliance compensation mode any fresh

gas used will be in addition to the set tidal

volume.

Altitude Compensation

This function monitors ambient pressure,

and adjusts the delivered volume

accordingly

NOTE Altitude compensation is automatically

applied during calibration of the oxygen monitor see section 5.3.2.

19

DESCRIPTION

A

B

20

DESCRIPTION

D

C

3.6 Interface to Integra AV-S and A200SP Absorber

The AV-S is designed to interface with the Integra AV-S

Anesthetia Machine and the A200SP Absorber.

3.6.1 Integra AV-S Interface

The interface cable links the socket (A) on the control panel to a

socket on the rear panel of the anesthetic machine.

a) Turn the anesthetic machine Gas Delivery Switch to ON.

The ventilator will power-up.

b) While the anesthetic machine power is ON, the Ventilator

can be turned OFF and ON, using the ventilator On/Off

switch, as described in section 3.5.1.

c) Turn the anesthetic machine Gas Delivery Switch to OFF.

The ventilator will power-down.

3.6.2 A200SP Absorber Interface

The interface cable links the socket (B) on the control panel to a

socket (C) at the rear of the absorber.

a) The A200SP is fitted with a sensor that detects the

position of the absorber bag/vent control (D). The sensor

signal cabling is routed internally to connector (C), and a

second cable runs to the the rear of the AV-S control unit.

b) Operation of the Bag/Vent control will trigger automatic

Mode switching on the AV-S ventilator, as follows:

i) Ventilator in Volume or Pressure mode

Switching the absorber Bag/Vent control from Vent

to Bag

- the ventilator will change from Volume Mode, or

Pressure Mode, into Spontaneous Mode.

ii) Ventilator in Spontaneous Mode

Switching the absorber Bag/Vent control from Bag

to Vent

Note that the mode switching operation is dependant on the

original selection process used to reach Spontaneous Mode:

A) If the ventilator was previously in Volume, or

Pressure, or Special Mode, and Spontaneous Mode was

automatically selected by the operation of the bag/vent

control (from Vent to Bag, as described above):

- the ventilator will now revert to that previous mode.

B) If the ventilator was in Standby Mode, and

Spontaneous Mode was selected on-screen:

- the ventilator will revert to Volume Mode.

NOTE

a) operation of the absorber Bag/Vent control will have no effect

on the ventilator unless the above conditions are met.

b) This function can be enabled/disabled through the on-screen

Service sub-menu (see appendix).

DESCRIPTION

21

Volume Mode Parameters

Tidal volume 20 - 1600 mL

Rate 4 -100 bpm

I:E ratio 1:0.3 - 1:8

PEEP 'Off' or adjustable 4 -20 cmH

2O

Inspiratory pressure limit 10 to 100 cmH

2O

Inspiratory pause 25%

(does not affect I:E ratio)

Sigh Approximately 1.5 x Set Vt is

delivered once, twice, three times

or four times every 50 breaths

(user selects frequency)

VmSET

mL

600

VmMEAS

Litres

3.6

SET

BPM

10

SET

I:E

2

PEEP

cmH2O

OFF

LIMIT

cmH2O

38

VOLUME

CONTROL

SPONT

MODE

STANDBY

%O2 105

21 18

PRESSURE

CONTROL

Gas Mixture

O2 + air

3.7 Ventilation Modes

3.7.1 Standby Mode

Allows parameters to be set.

Some patient alarms are active:

High airway pressure

(at 80 cmH

High/Low Oxygen

Negative pressure

Incorrect Rate/Ratio

Continuous high pressure

2O)

3.7.2 Volume Mode

The ventilator delivers a mandatory set

volume of gas at preset, fixed breath

intervals.

The Patient is making no respiratory

effort.

3.7.2.1 Fresh Gas Compensation

The delivered volume is adjusted by up

to 60%.

This delivered volume will consist of the

volume delivered from the ventilator

bellows, plus the fresh gas flow from the

anesthetic machine fresh gas supply,

minus any compliance loss and minus

any leak.

This gives a total actual inspired tidal

volume.

An alarm is triggered if the measured

volume is 50% above or below the set

volume.

This function is user adjustable.

Compliance Compensation

Please refer to section 3.5.4

Altitude Compensation

This function monitors ambient

pressure, and adjusts the delivered

volume accordingly.

3.7.2.2 Select Volume Mode

Volume Mode selected from Standby Mode:

1. Press the screen tab: ‘VOLUME CONTROL’

Volume Mode selected from Pressure Mode:

1. Press the screen tab: ‘VOLUME CONTROL’

The ventilator continues to ventilate in

Pressure Mode.

2. The Volume Set display shows the previous

setting, or default setting.

3. A new Volume value can be set if required.

WARNING

Set appropriate values for the clinical procedure

in progress. Take note of all on-screen symbols

and display messages.

4. Press to confirm change of mode and new

setting.

NOTE

Pressure limit will default to the previous

Pressure Target value + 5 cmH

2O

5. At confirmation, the ventilator will switch to

Volume Mode.

NOTE

Volume Mode will commence at the beginning

of an exhalation phase.

3.7.2.3 Volume Type Selection

Use the menu to switch between Tidal

Volume and Minute Volume.

NOTE Minute Volume is derived from a rolling average

during a 30 second period.

3.7.2.4 Volume Mode Operating Functions

Inspiratory Pause function:

This function creates a plateau that equates

to 25% of the inspiratory time.

Select Inspiratory Pause

Press the Menu switch

Select Special Modes

Select Insp pause on/off

Exit menus

The symbol for Inspiratory Pause

will appear on the display:

Note that Inspiratory Pause function is cancelled

when Standby is selected

DESCRIPTION

22

Menu Switch

Turn the wheel

to scroll through

the menus.

Press to enter

sub-menu

EXIT MENUS

O2 MONITOR & SPIROMETRY

FRESH GAS COMPENSATION: ON

> SPECIAL MODES

WAVEFORM

ALARM SETTINGS

GAS MIXTURE: O2+AIR

USER SETTINGS

SERVICE MENU

Sigh function:

When the ventilator is in Volume Cycle mode

the "Sigh" option is available.

When selected, this option provides extra

volume for 1 to 4 breaths in 50 (the user can

select 1, 2, 3, or 4 breaths).

The extra volume will be approximately 50%

above the tidal volume set by the user.

Note that the High Volume Alarm is not

triggered when ‘Sigh’ is selected.

Select Sigh function:

Press the Menu switch

Select Special Modes

Select Sigh Enable on/off

Select Sigh to Breath Ratio

Rotate the wheel to select required value

Press wheel to confirm

Exit menus

The legend for Sigh will

appear on the display:

Note that sigh function is cancelled when Standby is

selected

Volume measurement:

Volumes are measured if the Spirometry

function is selected.

Automatic High or Low volume alarms are

triggered if the measured volume is 50%

above or below the set volume.

User adjustable option

If the maximum pressure limit is achieved,

the ventilator cycles to the expiratory phase.

SIGH

23

DESCRIPTION

DESCRIPTION

24

PRESS

CONTROL

AV-S

.

.

IO

o

o

3.7.3 Pressure Mode

3.7.3.1 Parameters

In pressure mode the ventilator delivers a flow of gas

to achieve a set pressure at fixed breath intervals.

The Patient is making no respiratory effort.

This is a common mode for the ventilation of small

pediatric patients.

Inspiratory pressure 10 - 70 cmH

2O

Rate 4 - 100 bpm

I:E ratio 1:0.3 - 1:8

PEEP 'Off' or adjustable: 4 - 20 cmH2O

Inspiratory decelerating flow is controlled by the

ventilator according to the pressure setting.

There is no Inspiratory Pause function in pressure

mode.

3.7.3.2 Selecting Pressure Mode

Pressure Mode selected from Standby Mode:

1. Select by touching the screen tab: ‘PRESS CONTROL’.

Pressure Mode selected from Volume Mode:

1. Select by touching the screen tab: ‘PRESS CONTROL’.

The ventilator continues to ventilate in Volume Mode.

2. The target pressure button flashes (the display shows

the previous setting of target pressure, or default setting).

3. The user can set a new Target Pressure if required.

WARNING

Set appropriate values for the clinical procedure in

progress. Take note of all on-screen symbols and

display messages.

4. Press to confirm change of mode and new target

pressure.

5. At confirmation of the new mode, the ventilator will switch

to Pressure Mode.

NOTE

Pressure Mode will commence at the beginning of an

exhalation phase.

3.7.3.3 Pressure Mode Operating Functions

Pressure mode defaults to a target pressure of 10

2O at switch on.

cmH

A high Inspiratory Flow is used to achieve and maintain

the target pressure.

The exhaust valve operates to prevent excess

pressure.

DESCRIPTION

25

3.7.4 Spontaneous Mode

3.7.4.1 Parameters

The ventilator monitors the following patient parameters:

Rate

I:E ratio

Pressure

Tidal volume

In spontaneous mode the waveform displays are active,

and inspiratory oxygen levels are measured

3.7.4.2 Spontaneous Mode Operating Functions

Selection during Ventilation

Move the absorber Bag/vent switch to ‘Bag’ - the ventilator will

switch from Pressure Mode or Volume Mode to Spontaneous

Mode (see 3.6.2 - Absorber Interface).

Functions

No mechanical ventilation

No Inspiratory Pause function

Patient Monitoring (Bag mode and Ventilator mode):

Airway pressures

FiO2,

Tidal volume,

Rate

I:E ratio,

Supply pressures

Advanced Ventilation Modes

Patient support modes are selectable from this mode see below, and section 3.7.5.

3.7.4.3 Patient Support Modes

The following support modes are selectable from the

'Special Modes' menu, and must be pre-selected from the

main menu, whilst in Standby.

SIMV - Synchronised Intermittent Mandatory Ventilation

SMMV - Synchronised Mandatory Minute Ventilation

PSV - Pressure Supported Ventilation

CAUTION

The required patient support mode must be pre-selected in

Standby Mode (select from main menu), before it can be

activated during the ventilation of a patient.

Please refer to sections 3.7.5.1, 3.7.5.2, 3.7.5.3.

Note that if the system fails to detect an absorber

bag/vent switch, a confirm message will be displayed.

26

DESCRIPTION

3.7.5 Advanced Spontaneous

Breathing Modes

3.7.5.1 SIMV

Synchronised Intermittent

Mandatory Ventilation

SIMV provides a minimum level of tidal

volume.

SIMV allows spontaneous breaths and a set

mandatory breath, synchronised with the

start of a patient breath

SIMV must be pre-selected in Standby

Mode

Select Standby

Select Menu

Select Special Modes

Select Support Mode

Select SIMV

Escape Menu

SIMV will be displayed on the main screen

when Spontaneous mode is selected or

triggered.

NOTE

1. The trigger window is pre-set to 60% of

the BPM cycle time.

2. The trigger is flow activated.

3. If Spirometry is disabled then SIMV is

not available

4. If the pressure limit and alarm are

activated the inspiratory phase is

terminated

Activate SIMV during Ventilation

NOTE

SIMV will not function unless already preselected in Standby Mode

1. Select ‘Special Mode’ on the display.

If the absorber Bag/Vent switch is not

detected, a message will appear:

‘SET ABSORBER TO VENT’

Press the navigator wheel / push

button to confirm.

2. Move the absorber Bag/vent switch to

‘Ventilator’.

3. Check that SIMV is functioning

correctly.

SIMV Default Settings

The ventilator will default to pre-set values

for Tidal volume (Vt), Rate, Inspiratory Time

and Trigger Level, after selecting 'SIMV'.

Note:

1. Vt can be adjusted before SIMV is

confirmed.

2. The trigger setting is adjustable

between 0.7 and 4.0 L/min.

PEEP

0 cmH2O

Pmax

A

SIMV - Spontaneously Breathing Patient

A = Cycle Time (set from BPM)

B = Trigger Window

C = Spontaneous Breath

D = Trigger

E = Mandatory breath at the set tidal volume (Vt)

Inspiratory flow in the Trigger Window (generated by the

patient’s spontaneous breath) results in a synchronised

mandatory breath at a preset volume and rate

SIMV - No breathing effort by Patient

A = Cycle Time (set from BPM)

B = Trigger Window

C = Flat Pressure Trace (no breathing effort)

D = Mandatory breath at the end of the Trigger Window at the set Vt

If the patient makes no effort to breathe during a cycle, a

mandatory breath, at the end of the trigger window, will still be

delivered at the preset volume and rate.

A

B

B

C

D

E

PEEP

0 cmH2O

Pmax

A A

B

B

C

D

27

DESCRIPTION

3.7.5.2 SMMV

Synchronised Mandatory

Minute Ventilation

SMMV provides a set level of minute

volume ventilation.

SMMV allows spontaneous breaths,

combined with a synchronised mandatory

breath, to achieve the set minute volume

SMMV must be pre-selected in Standby

Mode

Select Standby

Select Menu

Select Special Modes

Select Support Mode

Select SMMV

Escape Menu

SMMV will now be displayed on the main

screen when Spontaneous mode is

selected or triggered.

NOTE

1. The trigger window is pre-set to 60% of

the BPM cycle time.

2. The trigger is flow activated.

3. If the Spirometry is disabled then

SMMV is not available

4. If the pressure limit and alarm are

activated the inspiratory phase is

terminated.

Activate SMMV during Ventilation

NOTE

SMMV will not function unless already preselected in Standby Mode

1. Select ‘Special Mode’ on the display.

If the absorber Bag/Vent switch is not

detected, a message will appear:

‘SET ABSORBER TO VENT’

Press the navigator wheel / push

button to confirm.

2. Move the absorber Bag/vent switch to

‘Ventilator’.

3. Check that SMMV is functioning

correctly.

SMMV Default Settings

The ventilator will default to pre-set values

for minute volume (Vm), Rate, Inspiratory

Time and Trigger Level, after selecting

'SMMV'.

Note:

1. Vm can be adjusted before SMMV is

confirmed.

2. The trigger setting is adjustable

between 0.7 and 4.0 L/min.

PEEP

0 cmH2O

Pmax

A

SMMV - Spontaneously Breathing Patient

A = Cycle Time (set from BPM)

B = Trigger Window

C = Spontaneous Breath

D = Trigger

E = Mandatory Breath tidal volume.

This is equal to Vm/BPM, minus the volume spontaneously

breathed during the cycle (this maintains the set Vm)

Inspiratory flow in the Trigger Window (generated by the

patient’s spontaneous breath) results in a synchronised

mandatory breath, ensuring that the set minute volume is

achieved

A

B

B

C

D

E

PEEP

0 cmH2O

Pmax

A

SMMV - No breathing effort by Patient

A = Cycle Time (set from BPM)

B = Trigger Window

C = Flat Pressure Trace (no breathing effort)

D = Mandatory breath at the end of the Trigger Window (at the set Vm)

If the patient makes no effort to breathe during a cycle, a

mandatory breath, at the end of the trigger window, will still be

delivered at the preset volume and rate

A

B

B

C

D

DESCRIPTION

28

3.7.5.3 PSV

Pressure Supported

Ventilation

PSV assists each spontaneous breath to

achieve a preset pressure, thus reducing the

effort required to breathe.

Inspiratory flow (generated by the patient’s

spontaneous breath) results in synchronised

pressure support.

PSV must be pre-selected in Standby

mode

Select Standby Mode

Select Menu

Select Special Modes

Select Support Mode

Select PSV

Escape Menu

PSV will be displayed on the main screen

when Spontaneous mode is selected or

triggered.

Activate PSV during Ventilation

NOTE

PSV will not function unless already preselected in Standby Mode

1. Select ‘Special Mode’ on the display.