Page 1

OPERATING AND

INSTALLATION MANUAL

WATER HEATER WITH HEAT PUMP

AQUA HP

Družstevní závody Dražice-strojírna s.r.o.

(Works Cooperative - Dražice - Machine Plant, Ltd.)

Dražice 69, 294 71 Benátky nad Jizerou

tel.: +420 / 326 370 911

fax: +420 / 326 370 980

e-mail: export@dzd.cz

Page 2

- 2 -

CONTENTS

INTRODUCTION ..................................................................................................................................... 5

1.1 INFORMATION PRIOR TO THE INSTALLATION ............................................................................ 5

1.2 SAFETY INFORMATION ............................................................................................................... 5

SPECIFICATIONS ..................................................................................................................................... 7

2.1 COMPONENTS ............................................................................................................................ 7

2.2 HEAT PUMP PRINCIPLE ............................................................................................................... 8

2.3 TECHNICAL PARAMETERS ........................................................................................................... 9

TRANSPORT ......................................................................................................................................... 10

INSTALLATION ..................................................................................................................................... 10

4.1 SAFETY AND CONTROL DEVICE ................................................................................................. 10

4.1.1 LOW-PRESSURE/HIGH-PRESSURE FUSE ............................................................................ 10

4.1.2 THERMAL FUSE ................................................................................................................. 10

4.1.3 TEMPERATURE SENSOR .................................................................................................... 11

4.1.4 CORROSION PROTECTION ................................................................................................ 11

4.1.5 EXPANSION TANK * .......................................................................................................... 11

4.1.6 SAFETY SYSTEM * .............................................................................................................. 11

4.1.7 PRESSURE CONTROL VALVE* ............................................................................................ 11

4.2 LOCATION ................................................................................................................................. 12

4.3 INSTALLING AIR INTAKE/EXHAUST ........................................................................................... 13

4.3.1 INSTALLATION WITHOUT AIR PIPING ............................................................................... 13

4.3.2 INSTALLATION WITH AIR PIPING ...................................................................................... 14

4.4 PLUMBING FIXTURE .................................................................................................................. 16

4.5 CONDENSATE ............................................................................................................................ 17

4.6 WIRING DIAGRAM .................................................................................................................... 18

4.7 ELECTRICAL INSTALLATION DIAGRAM ...................................................................................... 18

CONTROL AND PROGRAMMING ......................................................................................................... 19

5.1 CONTROL PANEL ....................................................................................................................... 19

5.2 FUNCTION OF THE KEYS ........................................................................................................... 19

5.3 DISPLAY ..................................................................................................................................... 20

5.3.1 DISPLAY DESCRIPTION ...................................................................................................... 20

5.3.2 SYMBOLS ........................................................................................................................... 20

5.3.3 SYMBOLS IN THE APPLIANCE'S OPERATION ..................................................................... 21

5.4 PUTTING INTO OPERATION ...................................................................................................... 21

Page 3

- 3 -

5.5 OPERATING MODES .................................................................................................................. 22

5.5.1 ECO MODE ........................................................................................................................ 22

5.5.2 AUTO MODE ..................................................................................................................... 23

5.5.3 BOOST MODE.................................................................................................................... 23

5.5.4 TCC MODE ......................................................................................................................... 23

5.5.5 LAT MODE ......................................................................................................................... 24

5.6 ADDITIONAL FUNCTIONS .......................................................................................................... 24

5.6.1 DISINFECTION MODE ........................................................................................................ 24

5.6.2 HOLIDAY MODE ................................................................................................................ 24

5.7 MENU ........................................................................................................................................ 24

5.8 CHANGING THE MODE ............................................................................................................. 25

PROPER OPERATION TEST ................................................................................................................... 25

DESCRIPTION OF PARAMETERS ........................................................................................................... 25

ERROR MESSAGES TABLE .................................................................................................................... 27

TEMPERATURE SENSOR PARAMETERS ................................................................................................ 28

TROUBLESHOOTING ............................................................................................................................ 29

MAINTENANCE OF THE APPLIANCE ..................................................................................................... 30

11.1 GENERAL MAINTENANCE ......................................................................................................... 31

11.2 DRAINING WATER FROM THE TANK ......................................................................................... 31

11.3 MAGNESIUM ANODE ................................................................................................................ 31

11.4 CLEANING OF PRESSURE CONTROL VALVE............................................................................... 32

11.5 CONDENSATE DRAIN ................................................................................................................ 32

11.6 CLEANING THE VENTILATION CIRCUIT ..................................................................................... 32

11.7 THERMAL FUSE ......................................................................................................................... 32

* not included in the delivery

Page 4

- 4 -

CAREFULLY READ THIS MANUAL BEFORE INSTALLING THE WATER HEATER!

Dear Customer,

The Works Cooperative of Dražice - Machine Plant, Ltd., would like

to thank you for your decision to use a product of our brand.

The product is not intended to be controlled by

a) people (including children) with reduced physical, sensual or mental capacities, or

b) people with insufficient knowledge and experiences unless supervised by responsible person,

or unless properly instructed by such responsible person.

Meaning of pictograms used in the Manual

Important information for heater users.

Abiding by the recommendations of the manufacturer serves to ensure trouble-free operation

and the long service life of the product.

Caution!

Important notice to be observed.

Page 5

- 5 -

INTRODUCTION

Water heater with an AQUA HP air-water heat pump certainly fulfils all your expectations, and will

comfortably serve you and achieve maximum energy savings for many years. The manufacturer devotes a lot

of time, energy and financial resources to the development of innovations that will promote energy savings

achieved by using the product. Your choice proved correct sentiment and concern about energy

consumption, therefore, a matter that affects the environment. The manufacturer has been committed

to constantly come up with innovative and effective products so that the rational use of energy could actively

contribute to environmental protection and natural resources of the planet. This manual, the purpose of

which is to inform, warn and advise in connection with the use and maintenance of this appliance, should be

retained.

1.1 INFORMATION PRIOR TO THE INSTALLATION

The electrical installation must comply with the valid national legislation applicable to electrical

installations.

AQUA HP will work only after adding the correct dose of coolant.

The maximum recommended pressure of water supplied into the hydraulic circuit is 0.3 MPa,

and the minimum pressure is 0.1 MPa.

Power is AC 230 V, 50 Hz and the power cord must be connected to a grounded receptacle.

If the power cord is damaged, it must be replaced by the manufacturer or a trained service

technician in order to prevent any risk.

AQUA HP shall only be operated if the water heater is filled with water.

Heating other than potable water is not allowed.

1.2 SAFETY INFORMATION

The appliance can be used by children from 8 years of age, persons with physical, sensory

or mental disability or people without experience or knowledge, as long as those people were

briefed on the operation of this device in a secure manner, and are familiar with the related

dangers.

The appliance cannot be played with by children.

Cleaning and maintenance must not be performed by children without proper supervision

Page 6

- 6 -

During installation:

• The installation of the water heater with heat pump must be performed by a qualified installer

who has been properly trained and qualified to this activity.

• The appliance must not be installed in locations where there is a risk of damage from impact, shock

or explosion.

• Do not unpack the appliance from the package until it is located at the installation site and is ready

for installation.

• Before connecting the appliance to the power, make sure that all hydraulic connections

are watertight.

Maintenance of the appliance:

• Maintenance of the appliance must be performed by a service technician with the exception

of regular and continuous cleaning that should be performed by the user him/herself.

• During maintenance, the appliance equipment must be disconnected from service.

• The manufacturer recommends regular annual inspection of the appliance by a qualified technician.

• Cleaning and maintenance must not be performed by children without proper supervision.

High pressure and temperature:

• The principle of operation of this appliance is associated with high temperature and high pressure.

Contacting the appliance must be done carefully so as to avoid the risk of burns and injuries

by protruding parts.

Coolant

• The coolant used in the cooling circuit is R134a, CFC free, non-flammable and without harmful effects

on the ozone layer.

• However, in accordance with the law, the liquid from the appliance must not be discharged freely

into the environment.

• The liquid in the appliance may only be handled by a qualified technician.

Information for customer

• The installer must inform users about the operation of the appliance, its dangers and responsibilities

of the user.

Page 7

- 7 -

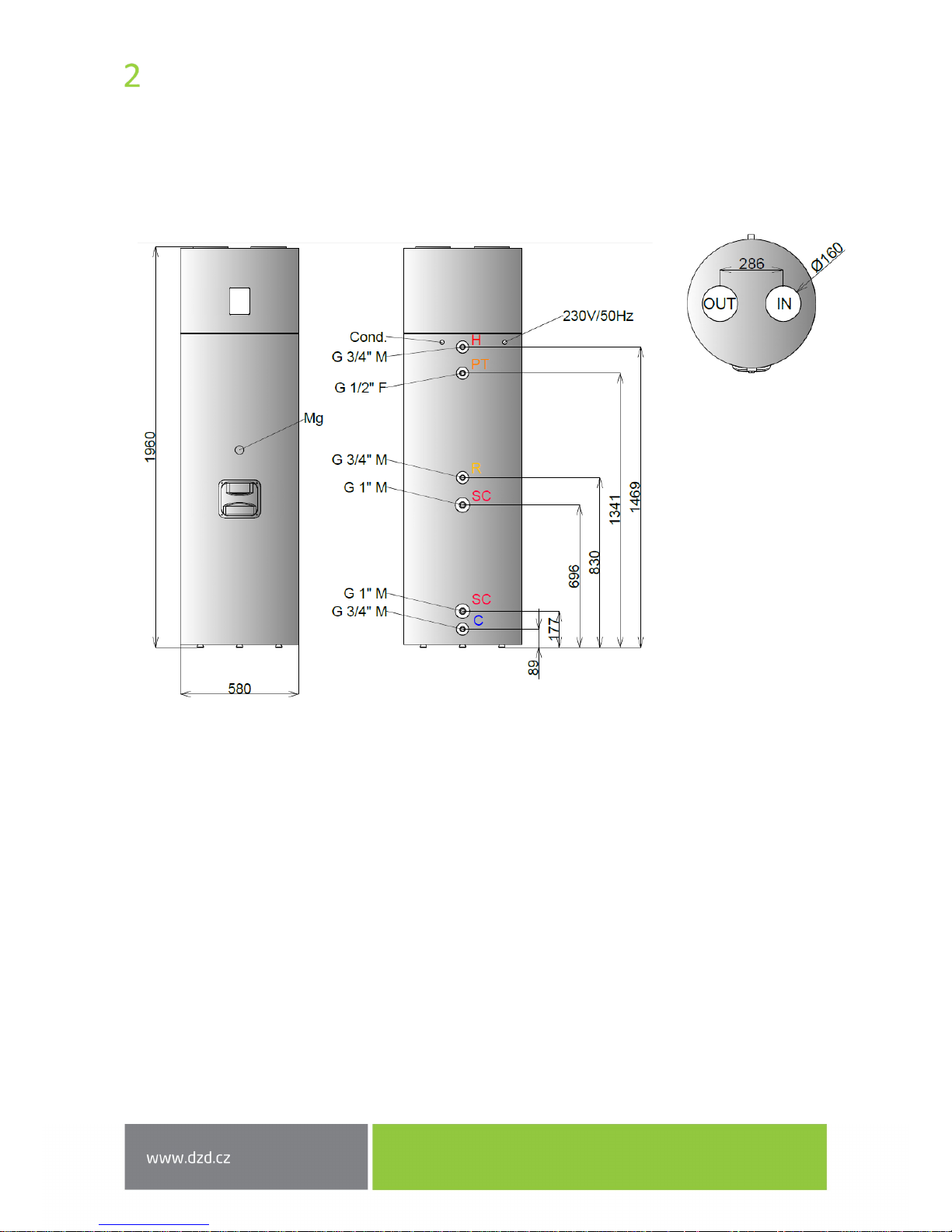

SPECIFICATIONS

2.1 COMPONENTS

AQUA HP 250 I/IX

Page 8

- 8 -

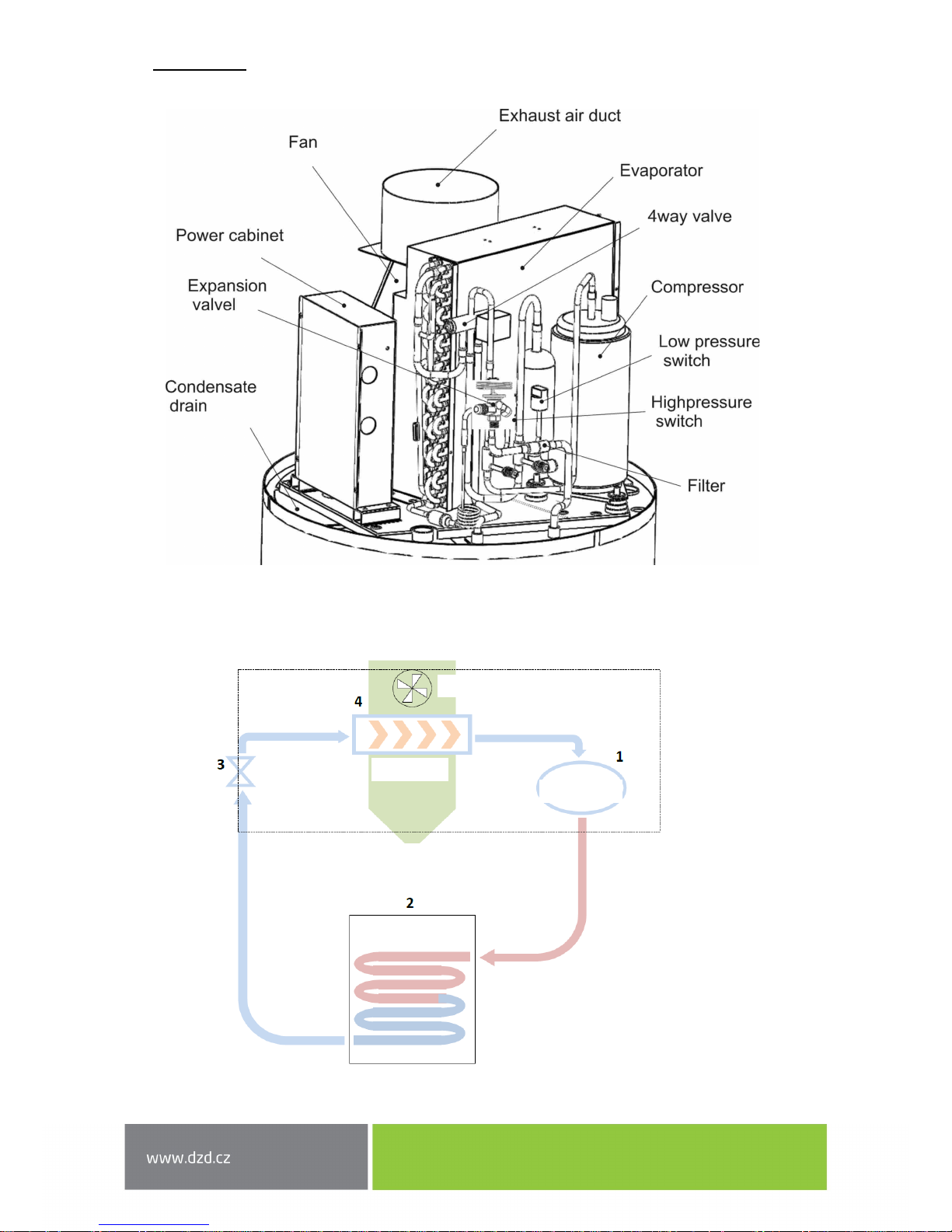

The cooling circuit located in the upper part is responsible for the transfer of heat from the ambient air

into the water.

2.2 HEAT PUMP PRINCIPLE

Fan

Compresor

Expansion

valve

Evaporator

Ambient air exhaust

(exhaust duct)

Capacitor

HOT WATER RECEPTACLE

Page 9

- 9 -

1. The coolant R134a is compressed in a highly efficient compressor that increases its pressure

and temperature.

2. In a capacitor that is not in direct contact with water, the thermal energy contained in the coolant

is transferred to the water in the hot water storage tank.

3. Condensed liquid flows from the expansion valve that is responsible for a drop in its pressure.

4. The fluid absorbs thermal energy from the air flowing through the evaporator with the help of a fan.

R134a is a HFC coolant, and therefore does not damage the ozone layer. It is characterized

by excellent chemical and thermal stability, low toxicity, is not flammable and is compatible

with most materials.

2.3 TECHNICAL PARAMETERS

Unit 250 I

Type of appliance

Water heater with heat pump

Hot water volume L 250

Weight without water

kg

83

Material of upper part

-

Stainless steel

Tank shell material - Steel sheet

Insulation - Polyurethane foam 50 mm

Mg anode

-

1”

Maximum service temperature

°C

80

Maximum service pressure

MPa (bar)

7

Test pressure

MPa (bar)

10

Heat loss

kWh/ annum

0,99

Tubular heat exchanger (diameter / length)

m

- / -

Exchanger power output 1)

kW

-

IP Protection

-

IPX1

Supply voltage - 1/N/PE ~ 230V/50Hz

Input (medium / maximum)

W

400 / 700

Output of the electrical heating element

W

1500

Heat pump output W 1800

Fan input

W

65

Maximum service current

A

3.2 + 6.8 (with backup electrical heating)

Recommended breaker

-

16A (sensitivity 30 mA)

Max temperature of hot water for heat pump

°C

55

Max temperature of hot water for heating element

°C

65

Coolant

-/kg

R 134a / 1.2

Load profile

-

XL

COP 2)

-

3.24

Heating time 2)

HH:mm

6:48

Volume of usable water 40 °C 2)

l

314

Energy efficiency class 2) - A+

Energy efficiency 2) % 138

Annual energy consumption 2)

kWh . a-1

1251

Ambient temperature limit values

°C

-5 / 40

Acoustic pressure level

dB(A)

51

Airflow

m3/h

450

Maximum length of air technical manifold

m

10

Page 10

- 10 -

a) Temperature of heating water (90/80 °C); hot water temperature (10/60 °C)

b) Temperature of heating water (70/60 °C); hot water temperature (10/60 °C)

2) A20/W10-54, according to EN16147 and applicable regulation No. 812/2013

TRANSPORT

The appliance must be transported to the installation site in the original packaging and must be

transferred in an upright position. When handling the appliance, proceed with maximum

caution to avoid the collision that could damage any part of the appliance. Make sure that the

transport belts or straps do not cause material damage. For transportation, always use suitable

means of transport (pallet truck, forklift, etc.).

The packaging contains the following information symbols:

INSTALLATION

4.1 SAFETY AND CONTROL DEVICE

4.1.1 Low-pressure/high-pressure fuse

In preparation for operation outside the recommended operating pressures defined by the manufacturer,

the appliance switches off and the electronic panel displays an error.

4.1.2 Thermal fuse

Thermal fuse is factory set by the manufacturer, and ensures that the water temperature in the hot water

tank does not exceed the maximum value. If the temperature exceeds this value, the fuse shuts off backup

electric heating. Turning on is performed manually by a service technician after analyzing the reasons

for the switching off.

Fragile, handle with extreme caution

Make sure that the arrow always

points upwards

Keep the packaging dry

Do not stack the packaging

Page 11

- 11 -

4.1.3 Temperature sensor

Temperature sensor measures the water temperature in the hot water tank to control the entire system.

4.1.4 Corrosion protection

In addition, the top part shell of the hot water heater is corrosion resistant (it is made of stainless steel)

and the hot water tank is enamelled and also contains magnesium anode which needs to be checked

regularly, as recommended by the installer or service technician.

4.1.5 Expansion tank *

Expansion tank is a device whose purpose is to compensate for the increase and decrease in water volume

due to temperature fluctuations.

Installing the expansion tank is recommended to save water. The recommendation of installing

an expansion tank is the responsibility of the installer.

It is generally installed on a cold water pipe.

4.1.6 Safety system *

The safety system allows for protection against any non-standard situations: cooling water heater, reverse

flow of warm water back into the water main, emptying the hot water heating tank and pressurisation.

The safety valve should be calibrated to the opening pressure of 0.6 MPa. To discharge water from the hot

water tank it is necessary to close the inlet valve and open the drain valve. The drain pipe of the safety valve

should be drained into sewers by transparent hose, since water may drip or even drain off the valve.

The safety valve must be regularly opened to remove impurities and to control its patency. The drain pipe

must be installed in an area protected from frost.

4.1.7 Pressure control valve*

Pressure control valve must be installed in case of high pressure on cold water connection in order to ensure

the proper operation of the safety valve. The connection may be provided with a pressure gauge to check

the pressure.

* Parts that are not delivered by the manufacturer. Their delivery and installation must be performed

by the installer.

Page 12

- 12 -

4.2 LOCATION

When placing the appliance to the installation site, keep in mind possible future service calls. To avoid having

to leave too much space behind the tank, the magnesium anode is disposed on the front side of the hot water

storage tank.

Make sure that the following minimum space is available around the appliance:

Adjust the levelling legs of the appliance. Acceptable is the tilt angle 1° rearward.

If the appliance is tilted in a different direction

than backwards, condensates are going to be

settled in the appliance.

Page 13

- 13 -

4.3 INSTALLING AIR INTAKE/EXHAUST

Since AQUA HP absorbs heat during operation, it is good to route cooled air (intake/exhaust)

to unheated spaces. The appliance will cool the room in which it is located and if it is installed

in heated rooms, cooled air should be routed to other rooms or outside.

4.3.1 Installation without air piping

The AQUA HP appliance should be installed in a location that is not too heated and can be used

for dehumidification and cooling these areas (e.g. laundry rooms, basements, etc.). The distance between

the top of the unit and the ceiling should not be less than 600 mm. If the distance between the unit

and the ceiling is less than 600 mm, it is necessary to install two elbows, as shown in the figure.

Page 14

- 14 -

4.3.2 Installation with air piping

If you use piping for airflow into spaces that do not require heating, you can:

Use the outside air

Using outdoor air, the unit can be placed either in heated or unheated room.

Use air from an adjacent room

The unit can also be placed in a heated room, but airflow should be directed to an unheated room. Keep in

mind that because of the air flow, cooling of an unheated room might affect adjacent heated rooms.

UNHEATED AREA

Min 50 m

3

HEATED OR UNHEATED

AREA

Page 15

- 15 -

Use air from an adjacent room and outside air

To supply air to the appliance, branched pipe can be used. In summer, you can use hot air from the outside

and in winter you can use the air from the unheated area.

Pipes used for air flow is not part of the appliance, and its installation is a matter of the installer;

if necessary, follow the recommendations of the manufacturer.

The pipe diameter must be 160 mm. Pipe length should not exceed 8 meters.

UNHEATED AREA

Min 50 m

3

HEATED OR UNHEATED

AREA

Page 16

- 16 -

4.4 PLUMBING FIXTURE

EXPLANATORY NOTES

[1] Shutoff valve

[2] Pressure control valve (3 bar/0.3 MPa)

[3] Return valve

[4] Safety valve (6 bar/0.6 MPa)

[5] Sink drain

[6] Expansion receptacle

[7] Drain valve

[8] Circulation pump

[9] Thermostatic mixing valve

[A] Cold water connection

[B] Hot water outlet

[C] Circulation

Page 17

- 17 -

Safety valve has to be installed on the cold water inlet into the appliance. The safety device must

comply with EN 1487: 002, maximum pressure of 6 bar (0.6 MPa). No closing armature may be

mounted between the safety valve and the tank or check valve that could disable the safety

valve.

The safety valve must be connected via a line whose diameter is smaller than the connecting

dimension. The drain must be connected to a sewage siphon or, if this is not possible, raised

to a distance of at least 20 mm from the pavement to enable visual inspection.

Pressure control valve set to 3 bar (0.3 MPa) must be installed in case of high pressure

on the cold water connection.

The manufacturer is not liable for any damages related to failure to observe these

recommendations and warnings.

Water you use may contain contaminants or substances damaging the appliance and even

harmful to your health. Make sure that you use water with a level of quality equivalent to the

consumption in your household. The following table lists some of the parameters that must

be chemically treated if exceeded.

4.5 CONDENSATE

During operation, condensation may occur. The condensate flows into a drip tray and is discharged through

a hole on the back side. The person performing the installation must connect the condensate hose supplied

by the manufacturer and direct the condensate into a drainage system or a sewer siphon.

The condensate hose must not be bent or compressed, and must be installed so as to best

ensure proper drainage of the condensate.

Hardness (ºdH) pH Treatment

3.0 to 20.0 6.5 to 8.5 No

3.0 to 20.0 <6.5 or >8.5 Yes

<3.0 or >20.0 -------------- Yes

Page 18

- 18 -

R1 - Backup electrical heating HP - High pressure switch LP - Low pressure switch

M - Compressor TB - Thermal fuse F1 - Compressor fuse (10 A)

F2 - Main fuse (10 A) S1 - Water temperature sensor S2 - Ambient sensor

S3 - Evaporator temperature sensor Fan – Ventilator V4V - 4-way valve

4.6 WIRING DIAGRAM

Water heater with heat pump can be connected to power only when the tank is filled with water.

Water heater with heat pump is supplied with a cable for connecting to a prepared grounded receptacle

(1/N/PE 230 V/50 Hz).

Wiring installation must conform to the standards applicable in the country or territory where the heater

with heat pump is installed.

The installation involves:

• Bipolar circuit breaker and Cu-cable with 3 x 2.5 mm

2

cross-section or greater

• Protective current device 30 mA

If the power cord is damaged, it must be replaced by the manufacturer or a trained service technician with

similar qualification.

4.7 ELECTRICAL INSTALLATION DIAGRAM

Page 19

- 19 -

CONTROL AND PROGRAMMING

5.1 CONTROL PANEL

The Eco control panel of the appliance is simple and intuitive. It allows you to configure several operating

parameters according to the operating mode selected by the user.

It includes six control keys (ON/OFF / CANCEL MENU, ▲ COMP, E-HEATER and OK DISINFECT and OK / LOCK)

that enable checking the operation of the appliance, monitoring the parameters and their change.

5.2 FUNCTION OF THE KEYS

Key Function Description

ON/OFF

CANCEL

ON/OFF Switch Turning the controller on and off

(CANCEL) Termination

Function of exiting to the end menu, sub-menu or cancel

function

OK /

(OK) Confirmation Confirming the parameters in the menus or submenus

(LOCK) Locked / Unlocked Locking or unlocking the keypad

MENU MENU Entering the menu

COMP Compressor ON/OFF

Pressing the key allows you to turn the compressor on and

off

E-HEATER

ON/OFF

Electrical resistance

Pressing the key allows you to enable and disable the

electrical resistance

▲

▼

Changing values

Allows you to adjust the parameter value (in menu

context)

Movement across the

menus/submenus

Function to browse menus and submenus (inside the

menu)

DISINFECT

(DISINFECTION) AntiLegionella

Press this button and the system automatically creates a

thermal shock in water to neutralize the bacteria

(Legionella)

Page 20

- 20 -

ECO

5.3 DISPLAY

5.3.1 Display description

5.3.2 Symbols

Symbol

Description

Appliance in ECO service mode

Appliance in AUTO service mode

Appliance in BOOST service mode

Timer clock control ON

Low ambient temperature protection ON

Compressor ON

Fan ON

Electrical backup ON

4-V

4-way valve ON

Keypad enabled

Keypad disabled

Disinfection function ON

Defrost function ON

Holiday mode ON

Error alert

AUTO

BOOST

TCC

LAT

45 ºC

12/10/1210:25

Er01

- S1 -

LAT

ECO BOOSTAUTO TCC

Page 21

- 21 -

OFF

5.3.3 Symbols in the appliance's operation

Symbol Description

(ON) Compressor ON

(OK) Compressor ON and setting point achieved

(TA) Electrical backup ON due to S1 < P08 and/or P07 < Temp. S3 (Auto

mode)

(TA) Electrical backup ON due to compressor ON to more than T05

(Auto mode)

(MA) Electrical backup ON manually

(ON) Electrical backup ON

(OK) Electrical backup ON and setting point achieved

(ON) Fan ON

(OFF) Fan OFF

(ON) Disinfection ON

(ON) Defrost function ON

(ON) Holiday mode ON

Error alert

5.4 PUTTING INTO OPERATION

Before activation, check the entire installation, whether everything is according to the recommendations

and make sure everything is in accordance with these instructions; only then you can connect the device

to the power outlet.

Once the appliance is connected, you need to wait a few seconds until the data are loaded, and the controller

starts.

ON

OK

TA

TC

MA

ON

OK

ON

ON

ON

ON

Page 22

- 22 -

ver

12/10/1210:25

Ver 0.M.X .X

45 ºC

12/10/1210:25

ON ON

ECO

45 ºC

12/10/1210:25

ECO

AUTO

BOOST

Then you can start the device by following these instructions:

Note 1: LED on the display indicates the status of the appliance. If it blinks, it means that the device has no

operating instructions set up. If the LED is lit and not flashing, the system works according to the given

instructions.

Note 2: Restart the unit by switching off and repeated switching on by pressing the ON/OFF button.

5.5 OPERATING MODES

AQUA HP is programmed to run in three operating modes - ECO, AUTO and BOOST that are summarized

in the following table:

User can change the operating mode at will, all they need is to simultaneously press the MENU + OK/LOCK

keys for 3 seconds. Upon entry, use the COMP ▲ and E-HEATER ▼ keys to move in the menu and submenus.

To confirm the values/parameters press the OK/LOCK key. To exit the menu, press the CANCEL key.

5.5.1 ECO Mode

In the ECO operation mode, the device operates only as a heat pump heating water in a hot water tank.

It is thus possible to achieve greater efficiency and savings for user.

Every time the user deems it necessary, they can turn on a supporting heating element in this mode manually

by pressing the (E-HEATER) key. This device automatically changes the operating mode to BOOST

and indicates this status on the display (including the heating element indication). If the heating element

is turned off manually, the appliance returns to the ECO mode.

Mode Symbol Function

ECO

Regular mode as heat pump

AUTO

Optimised management of heat pump or electrical heating

element run

BOOST

Run of both the heat pump and the electrical heating element

Controller when turned on

The system is turned off (OFF)

Press the ON/OFF switch

Press the COMP key to

start the system

ECO

ECO

Page 23

- 23 -

AUTO

5.5.2 AUTO Mode

In the AUTO mode, the unit works as a heat pump with the support of the heating element, and the operation

of the heating element is optimised in order to maintain the COP of the appliance.

The heating element starts whenever:

• is enabled by the user manually (by pressing E-HEATER).

• LP contact opens (low ambient temperature, lack of coolant, leak in the cooling circuit, etc.).

• compressor running time exceeds the T05 parameter*

• water temperature is below P08*

* The parameter is adjustable (ON/OFF)

5.5.3 Boost Mode

In the BOOST mode, the unit works as a heat pump with the support of the heating element, and the run

of the heating element isn't optimised. This mode allows users to achieve sufficiently hot water in a shorter

period of time.

5.5.4 TCC Mode

The TCC function provides the ability to achieve higher water temperatures at a time when an alternative

source of electric energy (photovoltaic system, etc.) is available.

You just need to connect the control connector

between the photovoltaic inverter and the appliance's

control panel. This connection to the panel must be

made potential-free (no voltage). The voltage on this

contact causes irreversible damage to the appliance.

If the contact is K1, it activates the TCC function, and

all sources of heat (both the heat pump and the

heating element) work according to the new

programmed operating parameters.

Note: When the contact K1 is opened, the device

operates according to the preset operating mode (Eco,

Auto or Boost) and the corresponding parameters.

Contact K1 can be thus used for the tariff control, i.e.

to switch according to the "night current". For this

purpose, connect potential-free either the timer or

the contact controlled according to the HDO signal.

BOOST

TCC

Page 24

- 24 -

5.5.5 LAT Mode

LAT mode starts automatically at a low temperature of the input air in order to protect the compressor. When

this mode is activated, the compressor shuts down and only electric heating activates. When the intake air

temperature rises, the device returns to the previously selected mode.

5.6 ADDITIONAL FUNCTIONS

5.6.1 Disinfection Mode

The AQUA HP controller includes a Disinfection (Anti-Legionella) function consisting of a water heating cycle

up to 65 °C for a time sufficient to prevent formation of bacteria inside the tank.

The disinfection function can be set automatically or manually. In the automatic mode, user can set

the function to every week or every month. Unless the automatic mode is activated, user must be activated

manually by pressing Disinfect.

At the end of this function, the system returns to the operating mode set before the activation

of this function.

5.6.2 Holiday Mode

To activate the Holiday function, it is necessary to enter the menu and set the number of days of the holiday

and the appliance automatically enters the standby mode and stays there until the last day of the holiday.

The last day of the holiday the appliance activates the disinfection function to eliminate any formation of

bacteria that could emerge in the hot water tank during the periods of user's absence.

Once the holiday is over and the disinfection programme terminates, the appliance returns to the selected

mode (ECO, AUTO or BOOST).

Note: If you set the appliance to enter into the holiday mode, but switch it OFF and ON using the ON/OFF

switch, the function will not be active. After returning from a holiday, user must not forget to turn on the

appliance and cancel the entered holiday days (value = 0). If user fails to do so, the appliance returns to the

default mode until the expiration of the specified number of the holiday days.

5.7 MENU

Every time the parameters need to be modified or new ones set during the operation of the device, user

must enter the menu.

To access the menu, it is necessary to press the MENU button for 3 seconds. Upon the entry, use the COMP

▲ and E-HEATER ▼ keys to navigate the menu and submenus. To confirm the values/parameters press

the OK/LOCK key. To exit the menu, press the CANCEL key.

LAT

Page 25

- 25 -

5.8 CHANGING THE MODE

ECO is set as the default mode for the operation of the device. If at any time the user wants to edit

the operation mode they can proceed as follows:

Unlock the keypad and hold the MENU key down for 3 seconds. Use the COMP ▲ and E-HEATER ▼ keys to

browse the menu and select F03 to enter the submenu and select the operation mode.

Note: To change the operating mode, you do not need to restart the appliance.

PROPER OPERATION TEST

To check whether your device works properly, run it and wait about 20 - 30 minutes and then check

the following:

• The air temperature at the evaporator outlet should be lower by 3-4 °C compared to the air

temperature at the inlet.

DESCRIPTION OF PARAMETERS

Code Type Description Min Max Setting

F01 Language

Portuguese

English

French

German

Italian

Spanish

Czech

English

F02 Clock Date and time

F03 Mode

Eco mode

Boost

Auto

Eco

F04 Holiday Holiday mode 1 99 0

F05 Disinfection

Disinfection function inactive

Disinfection function active once a week

Disinfection function active once a month

--- --- Monthly

F06

Parameters

P01 - required temperature, compressor 5 55 53°C

H01 - P01 parameter hysteresis 2 10 4°C

P02 - required temperature, final el. heating 1 60 53°C

H02 - P02 parameter hysteresis 2 10 4°C

P01TCC - required temperature, compressor 5 55 55°C

Page 26

- 26 -

F06

Parameters

(continued)

H01TCC - P01TCC parameter hysteresis 2 10 4°C

P02TCC - required temperature, final el. heating 1 65 60°C

H02PV - P02 parameter hysteresis 2 20 10°C

P03 - defrost start -15 10 -8°C

P04 - defrost finish 0 25 16°C

P05 - safe temperature 70 80 70°C

P06 - Anti-Legionella disinfection temperature 60 69 65°C

P07 - min evaporator temperature for final el.

heating activation

-15 20 -5°C

P07 - setting ON OFF ON

P08 - min water temperature for final el. heating

activation

1 40 30°C

P08 - setting ON OFF ON

P09 - air temperature for defrost 0 15 10°C

P10 - minimum air temperature -10 10 -5°C

H10 - P10 parameter hysteresis 2 10 5°C

T01 - delay before compressor startup 1 20 2 min

T02 - min running time before defrost 1 10 1 min

T03- max defrost time 2 15 8 min

T04 - compressor startup delay after defrost 1 10 1 min

T05- max compressor runtime 6 15 10 h

T06- defrost start time delay 30 360 60 s

T07 - startup delay after low pressure error 2 20 10 min

T08 - time interval between defrost cycles 10 120 40 min

T09 - prodleva před vyhlášením LAT 2 20 5 min

T10- min defrost time 2 10 4 min

F07 INFO List of control parameters

F08 Level

Installation technician 0022

Manufacturer ****

F09 Output test

CO - contact N.O., compressor

RE - contact N.O., final el. heating

VE - contact N.O., fan

V4V - contact N.O., 4-way valve

F10 Errors

Elist - list of error messages

Ereset - deletion of error messages

F11 Reset Restoring default settings

F12 System Compressor runtime hours

Page 27

- 27 -

ERROR MESSAGES TABLE

Symbol Description Trouble / Check

Er01 – S1

Error - temperature

sensor 1

• Damaged temperature sensor - Measure the internal resistance

of the sensor which is about 10 KΩ at the temperature of 25 °C.

• The sensor is disconnected from the controller - Make sure the

connector is properly connected to the electronic board and that

the connecting terminals are properly secured.

Er02 – S2

Error - temperature

sensor 2

Er03 – S3

Error - temperature

sensor 3

Er04 – TA

Water temperature

error

• The water temperature in the water tank is too high - check for

possible damage on the electronic board, such as a damaged

relay.

• The temperature sensor is short-circuited - Measure the internal

resistance of the sensor which is about 10 KΩ at the temperature

of 25 °C.

Er05 – S1 Probe 1 short circuit

• Measure the internal resistance of the sensor which is about 10

KΩ at the temperature of 25 °C, check for the correct connection

of the connector to the electronic board and the connecting

terminals for good condition.

Er06 – S2 Probe 2 short circuit

Er07 – S3 Probe 3 short circuit

Er08 – DF

Too many defrost

cycles in short period of

time

• Measure the internal resistance of the sensor which is about 10

KΩ at the temperature of 25 °C, check for the correct connection

of the connector to the electronic board and the connecting

terminals for good condition.

• Low ambient temperatures

• Lack of R134a

• Leakage in the circuit of the fluid

LINK

ERROR

Connection failure

between the display

and the supply board

• The connection cable between the display and the control panel Make sure the cable is in good condition and that the cables are

properly engaged (on the display and the control panel).

Page 28

- 28 -

Temperature (°C)

TEMPERATURE SENSOR PARAMETERS

Dependence of sensor's resistance on temperature

Resistance of sensor (kΩ)

Page 29

- 29 -

TROUBLESHOOTING

Trouble Potential cause What to do

Failure in the electronic

board

Power failure

Check the power supply.

Check corresponding circuit breaker.

Damaged or disconnected cable

Check the integrity (intactness) of the

electronic circuit board.

Low water temperature

or lack of hot water

Low temperature programmed

as a set point

Adjust the temperature set point.

53 °C as default factory setting.

Error activation

Check the presence of an error on the

electronic board and see the error

table.

Damaged or disconnected cable

Check the device connection to the

plug. Check corresponding circuit

breaker.

Check the integrity of cables.

Make sure the electrical cord is

connected to the power board.

Holiday mode ON Switch off the Holiday mode.

Appliance or compressor OFF See "5.4 System startup".

Use a large amount of hot water

For rapid heating of water, change the

device mode to "BOOST".

Hot water return into the cold

water circuit (safety device

installed incorrectly or

damaged)

Close the cold water inlet. Open the

hot water tap. Wait 10 minutes, and if

the water continues to flow, check the

function of the entire safety system.

Clean the safety device filter.

ECO mode selected and

ambient temperature very low

Change the device to the AUTO mode

to initialize the automatic control of

the system.

For rapid heating of water, change the

device mode to "BOOST".

Electrical heating OFF

Make sure that the backup electrical

heating is on.

Water is too hot or steam

generates

Problem with temperature

sensor

Check the errors displayed on the

screen.

Problem with thermal fuse

Check the correct function of the

thermal fuse.

Excessive use of electrical

heating as a backup (auto

mode)

Low ambient temperature

The operation of the device depends

on the conditions and the weather.

Low water temperature

The operation of the device depends

on the temperature of the inlet water.

Low voltage installation

Make sure that the installation is

powered by the voltage of the value

stated on the plate.

Page 30

- 30 -

Heat pump failure

Check the errors displayed on the

screen.

Evaporator blocked Clean the evaporator.

Fan blocked Check the fan status (dust, cable, ...).

Low hot water flow Hydraulic circuit blocked

Check the condition of the hydraulic

circuit.

Leaking safety valve

Absence or incorrect size of the

expansion tank (unless the leak

is continuous)

Installation or correct pressure in the

expansion receptacle.

High water pressure (unless the

leak is continuous)

Check the pressure control valve (if

installed).

Install a pressure control valve (if not

installed).

Power consumption is

abnormally high and

constant

Leak or blockage of the coolant

circuit.

Make sure the duct is not damaged.

Use a suitable device to check for

leaks in the circuit.

Adverse conditions of the

environment

Final electrical heating does

not work

Safety thermostat ON Check the status of the thermal fuse.

Faulty electrical heating Check the electrical heating.

Unpleasant odour

Absence of siphon or no water

in the siphon

Install and make sure there is water in

the siphon.

Condensate does not drain

Drain circuit clogged Clean the condenser circuit.

Drain pipe blocked Check the drain pipe.

Too fast magnesium anode

consumption

Magnesium anode wears in time. This wear is normal and prevents

corrosion in the tank. Wear rate varies depending on the water quality.

It is advisable to check the condition of the anode at least once every 2

years.

MAINTENANCE OF THE APPLIANCE

Prior to carrying out any maintenance work on the appliance, make sure that the appliance

is not powered.

Wait until the fan stops completely.

The liquid in the appliance may ONLY be handled by a qualified technician.

Although the coolant in the cooling circuit is ecological, it must not be discharged freely into the

environment.

Ecological disposal must be ensured.

Page 31

- 31 -

11.1 GENERAL MAINTENANCE

The coolant in the device can be handled ONLY by a qualified refrigeration technician with valid

authorisation.

Over the lifetime of the appliance, user must perform general maintenance and control of the appliance

depending on the place of installation:

• Surface cleaning of the appliance and the surrounding area with a wet cloth

• Visual inspection of the entire appliance in order to detect possible leakage and mechanical

damage to the appliance.

11.2 DRAINING WATER FROM THE TANK

Remember that the water in the hot water tank may have a high temperature, and therefore

a risk of scalding may be present.

Before emptying the hot water tank, allow temperature of hot water to drop to a level at which

scalding can no longer occur.

Once the water temperature is at a safe level at which scalding can no longer occur, proceed as follows:

• Disconnect the system from power.

• Close the inlet cold water valve and open the hot water tap.

• Open the drain valve of the system.

11.3 MAGNESIUM ANODE

The appliance is equipped with a magnesium anode that, together with the materials used in the receptacle,

ensures effective protection against corrosion.

The inner enamel surface of the tank ensures effective protection against corrosion which helps to maintain

water quality within the health parameters. However, the characteristics of water vary according

to the installation location (see Section 4.4 and warranty).

A the user's installation location the quality of water can be aggressive for the appliance. Therefore

a magnesium anode is supplied together with the device that wears over time and protects your appliance.

Wear of the anode depends on the characteristics of the water used. Checking the status of the anode

is so very important, especially in the early years of the installation:

To check the status of the anode, follow these steps:

• Disconnect the appliance from the electrical outlet.

• Shut off the water supply.

• Reduce the pressure (for example, open a hot water tap) and reduce the water level.

• Unscrew the anode using a suitable tool.

• Check the wear of the anode and replace it if necessary.

• If the diameter of the anode is less than 15 mm, it needs to be replaced.

Page 32

- 32 -

11.4 CLEANING OF PRESSURE CONTROL VALVE

For regular cleaning of the pressure control valve, proceed as follows:

• Shut off the water supply.

• Turn anti-clockwise until the spring is under tension.

• Remove the handle.

• Remove the filter and clean it.

11.5 CONDENSATE DRAIN

Remember within the routine maintenance and cleaning of the system to check the condensate drain system

and the drip tray. Clean the drip tray used because it may contain accumulated dust from outer space, which

can block the flow of condensate through the drainage holes. Make sure that the vents and the outlet pipes

of the condensate are clear.

11.6 CLEANING THE VENTILATION CIRCUIT

Make sure the suction filters are not clogged. Check them at least once a year.

Dust may settle on the evaporator. Also, clean it; eye on the evaporator fins.

Evaporator fins are very thin; there is a risk of injury.

Be careful not to damage the fins.

11.7 THERMAL FUSE

The thermal fuse is deactivated when any abnormal condition occurs in the system, so every time you want

to activate it, you must identify the problem that led to its shutdown.

If you are unable to determine what happened and the thermal fuse is still disabled, contact a service

technician to resolve the problem.

4-2-2019

Loading...

Loading...