Drazice OKC 250 NTR/HP, OKC 300 NTR/HP, OKC 400 NTR/HP, OKC 750 NTR/HP, OKC 1000 NTR/HP Operating And Installation Manual

...Page 1

OPERATING and

INSTALLATION MANUAL

INDIRECT WATER HEATER

OKC 250 NTR/HP

OKC 300 NTR/HP

OKC 400 NTR/HP

OKC 500 NTR/HP

OKC 750 NTR/HP

OKC 1000 NTR/HP

Družstevní závody Dražice-strojírna s.r.o.

(Works Cooperative - Dražice – Machine Plant, Ltd.)

Dražice 69, 294 71 Benátky nad Jizerou

tel.: +420 / 326 370 911

fax: +420 / 326 370 980

e-mail: export@dzd.cz

Page 2

- 2 -

CONTENTS

1 TECHNICAL SPECIFICATION OF PRODUCT ................................................................................................. 4

1.1 FUNCTION DESCRIPTION .................................................................................................................. 4

1.2 DESIGN AND GENERAL HEATER DIMENSIONS .................................................................................. 4

1.2.1 PRODUCT DESCRIPTION ............................................................................................................ 4

1.2.2 TECHNICAL DATA ...................................................................................................................... 5

2 OPERATION AND FITTING INSTRUCTIONS .............................................................................................. 12

2.1 PUTTING THE HEATER INTO OPERATION ........................................................................................ 12

2.2 CONNECTING A HEATER TO A HOT WATER DISTRIBUTION ............................................................ 12

2.3 PLUMBING FIXTURE ........................................................................................................................ 13

2.4 CONNECTING A HEATER TO A HEATING SYSTEM ............................................................................ 14

2.5 HEATER CLEANING AND ANODE ROD EXCHANGE .......................................................................... 15

2.6 SPARE PARTS .................................................................................................................................. 15

3 IMPORTANT NOTICES ............................................................................................................................. 15

3.1 IMPORTANT NOTICES ..................................................................................................................... 15

3.2 INSTALLATION REGULATIONS ......................................................................................................... 16

3.3 DISPOSAL OF PACKAGING MATERIAL AND FUNCTIONLESS PRODUCT............................................ 16

Page 3

- 3 -

Meaning of pictograms used in Manual

Important information for heater users.

Recommendations of manufacturer, observance of which will ensure trouble-free

operation and long service life of the product.

CAUTION!

Important notice to be observed.

READ CAREFULLY THE BELOW INSTRUCTIONS PRIOR TO THE INSTALLATION THE

HEATER!

Dear Customer,

The Works Cooperative of Dražice – Machine Plant, Ltd., would like to

thank you for your decision to use a product of our brand. With this

guide, we will introduce you to the use, construction, maintenance and

other information on electrical water heaters.

The manufacturer reserves the right for engineering modification of the product. The product is designed

for permanent contact with drinkable water.

It is recommended to use the product in indoor environment with air temperatures from +2°C to 45°C

and a relative humidity up to 80%.

Product’s reliability and safety is proven by tests implemented by the Engineering Test Institute in Brno.

Page 4

- 4 -

1 TECHNICAL SPECIFICATION OF PRODUCT

1.1 FUNCTION DESCRIPTION

Indirect stationary heater OKC 250 (300, 400, 500, 750, 1000) NTR / HP is designed for water heating in

conjunction with a heat pump. Reheat can be carried out by the electric heater TJ 6 / 4“.

1.2 DESIGN AND GENERAL HEATER DIMENSIONS

1.2.1 PRODUCT DESCRIPTION

The heater vessel is welded from a steel plate and as a whole is protected by enamel resistant to hot water.

Magnesium anode is added in the vessel as an additional protection against corrosion, which regulates the

electric potential of the inside of the vessel and thus reduces the effects of corrosion. Inside the vessel

there is a welded heat exchanger made of steel pipe with enamelled outer coating, and connections of hot

and cold water, circulation and thermostat tank.

The pipe heat exchanger is only intended for the heating circuit.

On the side of the heater there is a cleaning and inspection aperture ending with a flange of 110 mm

diameter, the pitch of eight M8 bolts is 150 mm. The heater is equipped with a G 1 ½ " aperture for

screwing an additional heater. This option is used, if the heater is connected into the system with a heat

pump, for water reheating at the top of the heater to the desired temperature. The tank is insulated by 50

or 60 mm of polyurethane foam not containing CFCs and the casing of the heater is made of plastic.

Page 5

- 5 -

1.2.2 TECHNICAL DATA

Table 1

Typ

OKC 250

NTR/HP

OKC 300

NTR/HP

OKC 400

NTR/HP

OKC 500

NTR/HP

OKC 750

NTR/HP

OKC 1000

NTR/HP

Capacity

l

245

295

356

440

727

945

Height

mm

1541

1580

1591

1921

2050

2083

Diameter

mm

584

670

700

700

990

1090

Maximum weight without

water

kg

119

138

172

203

263

335

Maximum operating

pressure in the tank

MPa 1 1 1 1 1 1

Maximum operating

overpressure in the

exchanger

MPa 1 1 1 1 1 1

Maximum heating water

temperature

°C

110

110

110

110

110

110

Maximum temperature of

HSW (Hot Service Water)

°C

90

90

90

90

90

90

Exchanger heat surface

m2

2,5

3,2 5 6,2

7,0

9,0

Exchanger volume

l

16

24

35

43

49

64

Page 6

- 6 -

OKC 250 NTR/HP

Figure 1

Page 7

- 7 -

OKC 300 NTR/HP

Figure 2

Page 8

- 8 -

OKC 400-500 NTR/HP

Figure 3

Page 9

- 9 -

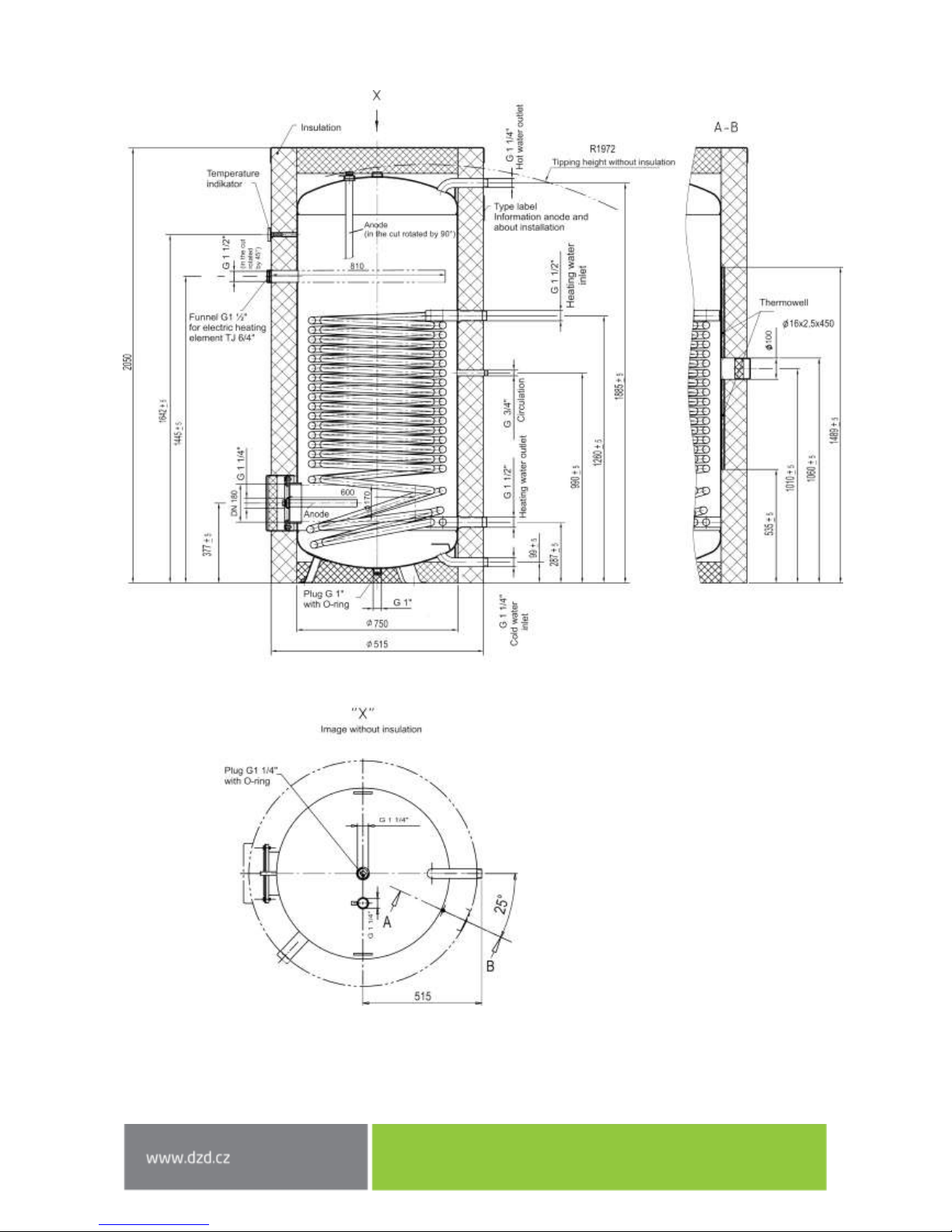

OKC 750 NTR/HP

Figure 4

Page 10

- 10 -

OKC 1000 NTR/HP

Figure 5

Page 11

- 11 -

Page 12

- 12 -

2 OPERATION AND FITTING INSTRUCTIONS

2.1 PUTTING THE HEATER INTO OPERATION

After connecting the heater to the water distribution system, hot water heating system, respectively

electrical power system and after checking the safety valve (following the instructions attached to the

valve) the heater can be put into operation.

Procedure:

a) Check the plumbing and electrical installation, including the connection to hot-water heating system.

Check proper placement of operating and safety thermostat sensors. The sensors must be inserted all

the way in; first the operating and then the safety thermostat.

b) Open the hot water valve on the combination faucet;

c) Open the cold water inlet valve to the heater.

d) When the water starts to flow through the hot water valve, the filling of the heater is finished and the

valve needs to be closed.

e) Should a leak (of the flange lid) occur, we recommend tightening the screws of the flange lid.

f) When heating the water with thermal energy from hot water heating system, turn off the electricity

and open the valves at the inlet and outlet of heating water or bleed the exchanger. When commencing

operation, flush the heater until the cloudiness in the water is gone.

g) Make sure to fill in properly the warranty certificate.

2.2 CONNECTING A HEATER TO A HOT WATER DISTRIBUTION

Figure 6

Page 13

- 13 -

The heater’s cold water inlet must be fitted with a T-fitting with a discharge valve for any

discharge of water from the heater

Each individually lockable heater must also be equipped at the hot water inlet with a test

cock, check valve, safety valve and level gauge.

2.3 PLUMBING FIXTURE

Power water connects to pipes with 3/4” thread in the bottom part of the heater. Blue - cold

water supply, red – hot water outlet. For potential disconnection of the heater, the service

water inlets and outlets must be provided with screw coupling Js 3/4”. Safety valve is

mounted on the cold water inlet identified with a blue ring.

Each hot service water pressure heater must have a membrane spring loaded with a safety

valve. Nominal clearance of safety valves is defined in the Standard. The heaters are not

equipped with a safety valve. The safety valve must be easily accessible, as close to the

heater as possible. The input pipes must have at least the same clearance as the safety valve.

The safety valve is placed high enough to secure dripping water drain by gravity. We

recommend mounting the safety valve onto a branch pipe. This allows easier exchange

without having to drain the water from the heater. Safety valves with fixed pressure settings

from the manufacturer are used for the assembly. Starting pressure of a safety valve must be

identical to the maximum allowed heater pressure, and at least 20% higher than the

maximum pressure in the water main (Table 3). If the water main pressure exceeds such

value, a reduction valve must be added to the system. No stop valves can be put between

the heater and the safety valve. During the assembly, follow the guide provided by the safety

equipment manufacturer.

It is necessary to check the safety valve each time before putting it into operation. It is

checked by manually moving of the membrane from the seat, turning the make-and-break

device button always to the right. After being turned, the button must click back into a

notch. Proper function of the make-and-break device results in water draining through the

safety valve outlet pipe. In common operation, such a check needs to be implemented at

least once a month, and after each heater shutdown for more than 5 days. Water may be

dripping off the drain pipe of the safety valve; the pipe must be open into the air, pointed

down; environment temperatures must not drop below zero.

When draining the heater, use a recommended drain valve. First, close water input into the

heater. Find necessary pressure values in the following table. For proper safety valve

operation, a backflow valve must be mounted on the inlet pipes, preventing spontaneous

heater draining and hot water penetrating back into the water main. We recommend that

the hot water distribution from the heater was as short as possible to minimise heat losses.

Page 14

- 14 -

Required pressures – Table 33. We recommend that the hot water distribution from the heater was as

short as possible to minimise heat losses.

Heaters must be provided with a discharge valve

mounted on the cold service water inlet to the

heater for potential disassembly or repair. When

assembling the security equipment, follow

Standards.

SAFETY VALVE

STARTING

PRESSURE

[MPa]

ADMISSIBLE

OPERATING

OVER-

PRESSURE OF

WATER

HEATER [MPa]

MAXIMUM

PRESSURE IN

COLD WATER

PIPES [MPa]

0.6

0.6

up to 0.48

0.7

0.7

up to 0.56

1

1

up to 0.8

Table 3

2.4 CONNECTING A HEATER TO A HEATING SYSTEM

The heater is placed on the ground, next to the heating source, or in its vicinity. The heating circuit is

connected to marked inputs and outputs of the heater exchanger; the deaerating valve is mounted in the

highest place. It is necessary to install a filter into the circuit in order to protect the pumps, the three-way

valve, and backflow flaps, and the exchanger from sedimentation. It is recommended to flush the heating

circuit before the assembly. All wiring connections must be properly insulated from heat. If the system

works with priority heating of HSW using a three-way valve, always follow the installation instructions of

the three-way valve’s manufacturer.

An example of a group heater connection for steady hot water consumption from all tanks using

Tichelmann’s method

OV – Heating water

SV – Cold water

C - Circulation

TUV – Hot service water

1 – back pressure valve

2 - Pump

Figure 7

Page 15

- 15 -

2.5 HEATER CLEANING AND ANODE ROD EXCHANGE

Repetitive water heating causes limestone sediment on both the enamelled tank walls and chiefly the

flange lid. The sedimentation depends on the hardness of water heated, its temperature, and amount of

hot water consumed.

We recommend checking and cleaning the tank from scale and eventual replacement of

the anode rod after two years of operation.

The anode life is theoretically calculated for two years of operation; however, it changes with water

hardness and chemical composition in the place of use. Based on such an inspection, the next term of

anode rod exchange may be determined. Have the company in charge of service affairs clean and exchange

the anode. When discharging water from the heater, the combination faucet hot water valve must be open

in order to avoid creating underpressure that would prevent water discharge.

To prevent the occurrence of bacteria (e.g. Legionella pneumophila) within stack heating it

is recommended, if absolutely necessary, to increase the temperature of hot service water

(HSW) periodically for a transitional period of time to at least 70°C. It is also possible to

make use of another way of disinfecting HSW.

2.6 SPARE PARTS

- Magnesium anode

- contact thermometer

When ordering spare parts, give part name, type, and type number from the heater label.

3 IMPORTANT NOTICES

3.1 IMPORTANT NOTICES

Without a proof issued by a professional company about performed electrical and

plumbing fixture the warranty shall be void.

It is necessary to check the protective magnesium anode periodically and replace it if

necessary.

No stop valves can be put between the heater and the safety valve.

All outlets of hot water must be equipped with combination faucets.

Before the first filling of water heater it is recommended to tighten the nuts of the flange

joint of the tank..

Page 16

- 16 -

3.2 INSTALLATION REGULATIONS

Both the electric and water installation must follow and meet the requirements and

regulations relevant in the country of use!

3.3 DISPOSAL OF PACKAGING MATERIAL AND FUNCTIONLESS

PRODUCT

A service fee for providing return and recovery of packaging material has

been paid for the packaging in which the water heater was delivered. The

service fee was paid pursuant to Act No 477/2001 Coll., as amended, at EKOKOM a.s. The client number of the company is F06020274. Take the water

boiler packages to a waste disposal place determined by the town. When the

operation terminates, disassemble and transport the discarded and

unserviceable heater to a waste recycling centre (collecting yard), or contact

the manufacturer.

3-2014

Loading...

Loading...