Page 1

Part Description Qty

C

Center punch

H

Drill motor

C

Center punch

H

Drill motor

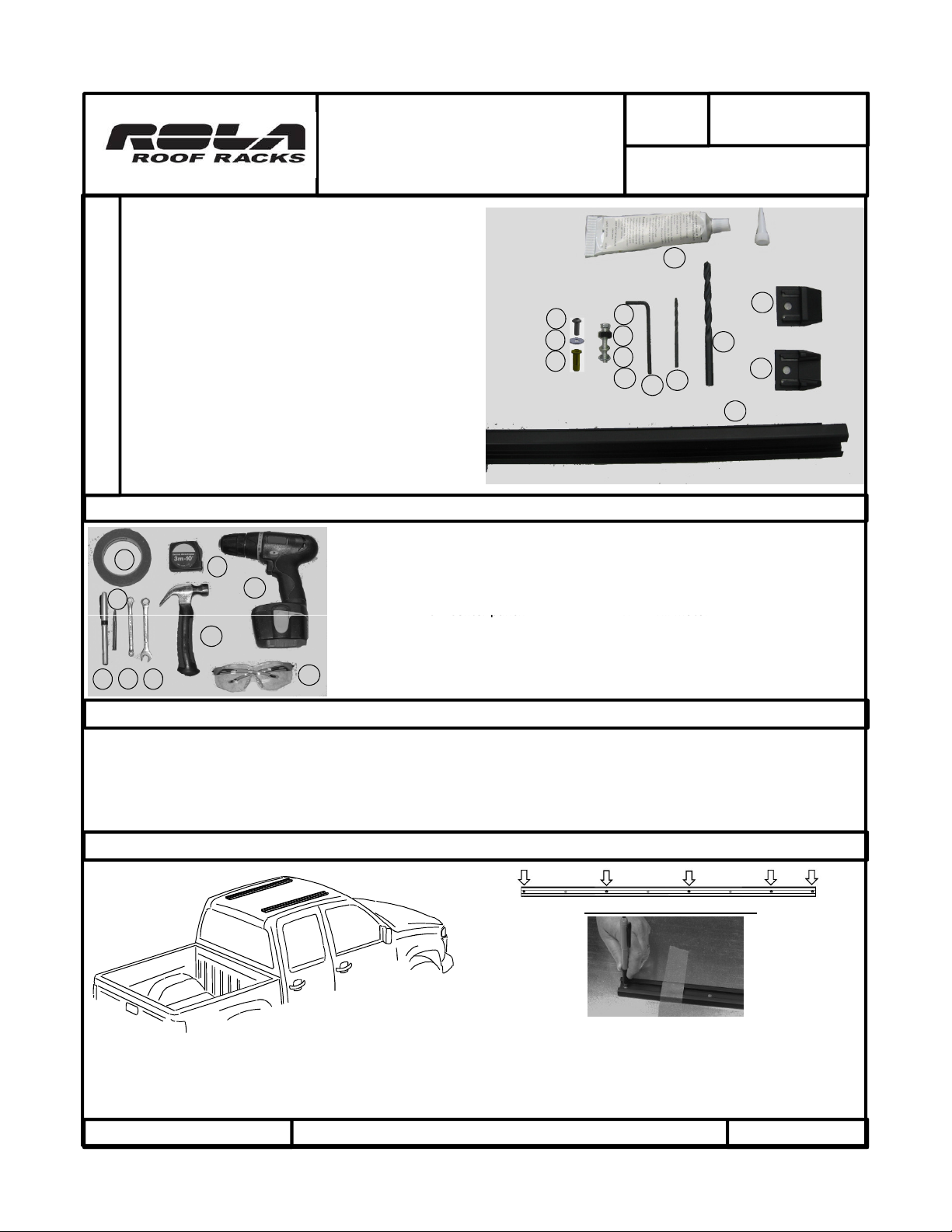

A Button head bolt M5 x 20mm 10

B Nylon washer 10

C Plus Nut Insert M5 10

D Hex bolt M5 x 30mm 1

E Hex Nut M6 1

F Washer M5 1

G Star Washer M5 10

H 3mm (.125”) Drill Bit 1

I .290 Dia. (“L”) Drill bit 1

KIT COMPONENTS

J Hex Key- 3mm 1

K Silicone sealant 1

L Track and Isolator pad 2

M Track End Cap- closed (Front) 2

N Track End Cap- open (Rear) 2

Tools required to install

A

F

C

Direct Mount Track Rail System TR42

PART No.

59853

For use on sheet metal surfaces

For use with ROLA APE and APX cross bar kits

K

A

B

C

D

E

F

G

H

J

M

I

N

L

Tools required:

A Masking tape F Tape measure

H

B Fine tip marker G Hammer

G

D

B

E

I

D 8mm wrench I Safety glasses

E 10mm wrench

Precaution Warnings before beginning

Use of ROLA track systems with Plus Nuts is intended for sheet

metal installations.

Install requires drilling and permanent installation of tracks.

Caution- never exceed the load rating for your

vehicle (contact manufacturer for details), or that

of your cross bar system which ever is lower.

Installation requires some tools and skill. If concerned please

have professionally installed.

Placement of Track Rails onto Vehicle surface (Crew Cab Truck shown)

Using a fine tip marker mark every other hole in track. Insure to mark the

Align Tracks parallel to each other and equal distance

from rear.

Hint: pre-installing your ROLA cross bars on the tracks

will insure good placement.

59853N Rev B 4-15-13

holes on each end of the tracks.

DO NOT mark or drill every hole as it is not required.

Hint: Use masking tape to hold the tracks well in place while marking.

Isolator pad can be removed while marking.

Then use a center punch to set the drill position.

Printed in China

Mark every other hole in track

Page 1 of 2

Page 2

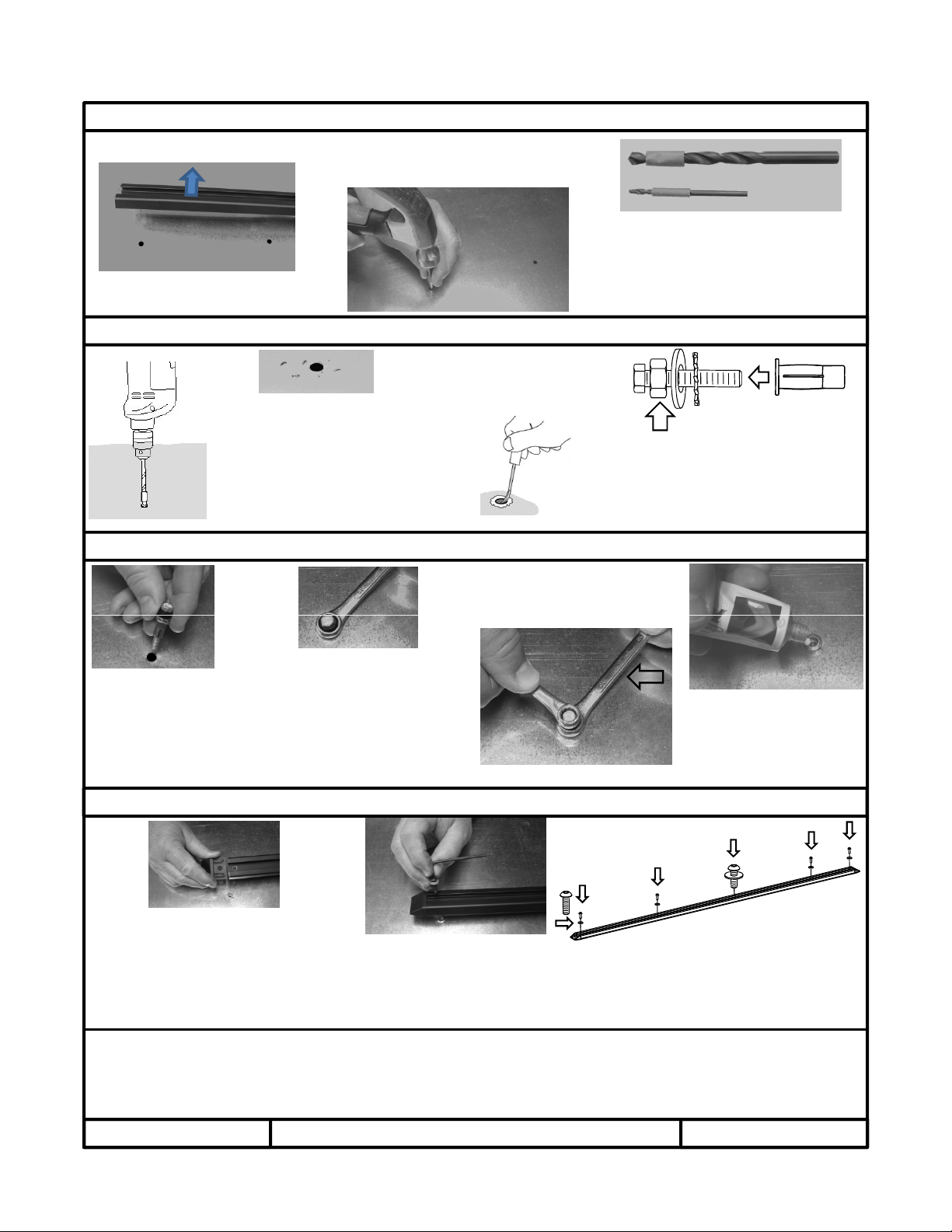

Preparing sheet metal surface for mounting

nut & washer assembly.

Remove rails after marking

Hint- lightly center punch to hole

locations before drilling pilot holes.

Hint- it’s not advisable to drill

through the rails.

Installing Track Rails to mounting surface

Drill 3mm pilot hole first, then drill

.290” dia. holes. Blow or vacuum

any debris away.

Do not drill deeper than ¼”- use a

drill stop or tape to insure proper

depth. Wear safety glasses when

drilling!

Attaching and tightening hardware

Seal edges of drilled

holes with automotive

touch up paint.

Once the Plus nut inserts are

installed remove the hex bolt,

Important- Use drill stops or wrap

masking tape around the drill bits

to insure drilling no deeper than

¼” below sheet metal

Plus Nut

M6 hex nut

Assemble M6 hex nut, M5 x 30mm

bolt, steel flat washer, star

washer, & Plus nut as shown .

Holding the M6 hex nut firmly with

Install Plus Nut

inserts into drilled

holes.

Use new star washer

to install each Plus

a 10mm wrench, tighten the hex

bolt (item D) with a 8mm wrench

until the Plus nut insert collapses

(there will be a noticeable force

increase).

Hold

Apply a small amount of

silicone into the Plus nut

insert to seal the threads

Nut.

Installing Track Rails to mounting surface

Position isolator pad, front and rear end

caps on mounting surface and align

holes. Note: rear end caps allow cross

bars to slide on and off rails.

Install bolts and nylon washers into rails

and through track and into Plus nuts.

ROLA carries a variety of cross bar styles and lengths to attach to our rails. Cross Bars are sold with mounting hardware.

Any weight carried on the vehicle will adversely affect its handling particularly in cornering or in a cross wind and the vehicle should

therefore be driven with increased caution. Check the function of all doors and sunroof before driving.

For lost key replacement or other service items call customer service: 1-800-632-3290 or visit: www.rolaproducts.com

Please have lock core number or part numbers available.

59853N Rev B 4-15-13

Page 2 of 2Printed in China

Page 3

Système de rails pour montage direct TR42

C

Pointeau

H

Perceuse

C

Pointeau

H

Perceuse

Pour utilisation sur surface de tôle

Pour utilisation avec les ensembles de

Pièce Description Qté

A Boulon à tête ronde bolt M5 x 20mm 10

B Rondelle en nylon 10

C Douille Plusnut M5 10

D Boulon hexagonal M5 x 30mm 1

E Écrou hexagonal M6 1

F Rondelle M5 1

G Rondelle en étoile M5 10

H Foret 3 mm (0,125”) 1

I Foret (“L”) 0,290” (dia.) 1

J Clé hexagonale - 3 mm 1

K Scellant au silicone 1

L Rail et coussinet d'isolateur 2

COMPOSANTS DE L'ENSEMBLE

M Capuchon de rail - Fermé (avant) 2

N Capuchon de rail - Ouvert (arrière) 2

Outils nécessaires à l'installation

A

C

F

H

NoPIÈCE

traverses ROLA APE et APX

K

A

B

C

A Ruban-cache F Ruban à mesurer

B Marqueur à pointe fine G Marteau

D

E

F

G

J

Outils requis :

H

59853

M

I

N

L

G

D

B

E

I

D Clé 8 mm I Lunettes de protection

E Clé 10 mm

Mises en garde avant de commencer

L'utilisation du système de rails ROLA avec douilles Plusnut est

destiné aux installations sur toit en tôle.

L'installation nécessite le perçage et la pose permanente de rails.

L'installation nécessite aussi certains outils et habiletés. En cas

Attention : Ne jamais dépasser la capacité de

charge la moins élevée, soit celle du véhicule

(consulter le fabricant pour des détails), soit celle

de votre système de traverses de toit.

de doutes, faire appel à un installateur qualifié.

Positionnement des rails sur la surface du véhicule (camionnette à cabine double illustrée)

Faire une marque à tous les deux trous dans le rail

Utiliser un marqueur à pointe fine pour marquer un emplacement à tous les

Aligner les rails pour qu'elles soient parallèles et à

distance égale de l'arrière.

Conseil : Pré-installer les traverses de toit ROLA sur

les rails permettra un positionnement correct.

59853N Rev B 4-15-13

deux trous dans le rail. S'assurer de marquer les trous à chaque extrémité des

rails.

S'ABSTENIR de marquer ou percer tous les trous car cela n'est pas nécessaire.

Conseil : Utiliser du ruban-cache pour maintenir les rails bien en place pendant

le marquage. Le coussinet d'isolateur peut être retiré pendant le marquage.

Utiliser ensuite un pointeau pour déterminer la position de perçage.

Imprimé en Chine

Page 1 de 2

Page 4

Préparation de la surface de tôle pour le montage

rondelle.

Enlever les rails après le marquage.

Conseil : Marquer légèrement au

pointeau l'emplacement des trous

avant de percer les trous de guidage.

Conseil : Il n'est pas recommandé

de percer à travers les rails.

Installation des rails sur la surface de montage

Percer d'abord un trou de guidage 3mm, puis

percer un trou de 0,290 po (diam.). Souffler ou

aspirer les débris.

Ne pas percer plus profondément que ¼ po;

utiliser des butées de perçage ou du rubancache autour des forets pour obtenir la

profondeur appropriée. Toujours porter des

lunettes de protection lors du perçage!

Fixation et serrage de la visserie

Important : Utiliser des butées de

perçage ou enrouler du ruban-cache

autour des forets de façon à limiter

la profondeur des trous à ¼ po

maximum sous la tôle.

Sceller le pourtour des

trous percés avec de la

peinture de retouche

pour carrosserie.

Assembler l'écrou hexagonal M6, le

boulon M5 x 30 mm, la rondelle plate

en acier, la rondelle en étoile et la

douille Plusnut, comme illustré.

Une fois les douilles Plusnut

posées, retirer l'assemblage

boulon hexagonal, écrou et

Plusnut

Écrou hexagonal M6

Poser les douilles

Plusnut dans les trous

percés.

Utiliser une nouvelle

rondelle en étoile

pour chaque douille

Plusnut.

hexagonal M6 à l'aide d'une clé

10 mm, serrer le boulon hexagonal

(article D) à l'aide d'une clé 8 mm

jusqu'à ce que la douille Plusnut se

comprime (on percevra une

augmentation de la résistance).

Tenir

Appliquer une petite

quantité de silicone dans

les douilles Plusnut pour

étancher le filetage.

Installation des rails sur la surface de montage

Positionner le coussinet d'isolateur ainsi que

les capuchons d'extrémité avant et arrière sur

En immobilisant fermement l'écrou

la surface de montage et aligner les trous.

Nota : Les capuchons d'extrémité arrière

permettent de faire glisser les traverses pour

les introduire ou les retirer.

ROLA offre une variété de styles et longueurs de traverses de toit à fixer sur nos rails. Les traverses sont vendues avec la visserie.

Toute charge transportée par le véhicule affectera la conduite, notamment par effet de dérive ou par vent de côté, de sorte qu'il convient

de redoubler de prudence. Vérifier le fonctionnement de toutes les portières et du toit ouvrant avant la conduite.

Pour le remplacement de clés ou obtenir d'autres pièces de rechange, contacter le service à la clientèle : 1-800-632-3290 ou visiter :

www.rolaproducts.com

Veiller à tenir le numéro de l'âme de la serrure ou le numéro de pièce à portée de la main.

Poser des boulons et des rondelles en nylon dans

les chemins de rail et les douilles Plusnut.

59853N Rev B 4-15-13

Page 2 de 2Imprimé en Chine

Page 5

Sistema de rieles para montaje directo TR42

C

Perforador central

H

Motor de taladro

C

Perforador central

H

Motor de taladro

Para uso sobre superficies de metal laminado

Use con kits de travesaños APE y APX de ROLA

Parte Descripción Cant.

A Tornillos de cabeza de botón, M5 x 20mm 10

B Arandela de nylon 10

C Insertos Plus Nut, M5 10

D Tuerca hexagonal, M5 x 30mm 1

E Tuerca hexagonal, M6 1

F Arandela, M5 1

G Arandela de estrella, M5 10

H Broca de taladro, 3mm (1.25") 1

I Broca de taladro, .290” diá. (“L”) 1

J Llave hexagonal, 3mm 1

K Sellante de silicona 1

COMPONENTES DEL KIT

L Almohadilla del riel y aislante 2

M Tapa lateral del riel- cerrada (frente) 2

N Tapa lateral del riel- abierta (trasera) 2

Herramientas necesarias para instalar

A

C

F

H

PARTE No.

K

A

B

C

Herramientas necesarias:

A Cinta de enmascarar F Cinta de medir

B Marcador de punta fina G Martillo

D

E

F

G

H

J

59853

M

I

N

L

G

D

B

E

I

D Llave, 8mm I Gafas de seguridad

E Llave, 10mm

Advertencias de precaución antes de comenzar

El sistema de rieles ROLA con Plus Nuts está diseñado para instalaciones en

metal laminado.

La instalación requiere la perforación y la instalación permanente de los

rieles.

La instalación requiere algunas herramientas y habilidades. Si tiene dudas,

haga que un profesional realice la instalación.

Precaución: Nunca exceda la capacidad de carga de su

vehículo (contacte al fabricante para obtener los

detalles), o la del sistema de travesaños, la que sea

menor.

Colocación de los rieles sobre la superficie del vehículo (se muestra el casco del vehículo)

Marque un orificio de por medio en el riel

Con un marcador de punta fina marque un orificio de por medio. Verifique

Alinee los rieles paralelos entre sí y a

igual distancia desde la parte posterior.

Sugerencia: La instalación previa de los

travesaños ROLA en los rieles garantizará

una buena colocación.

59853N Rev B 4-15-13

que marca los orificios en cada extremo de los rieles.

NO marque ni perfore todos los orificios, ya que no es necesario.

Sugerencia: Use cinta de enmascarar para sujetar los rieles bien en su lugar

mientras marca. La almohadilla aislante se puede extraer mientras marca.

Luego, use un perforador central para fijar la posición de perforación.

Impreso en China

Página 1 de 2

Page 6

Cómo preparar la superficie de metal laminado para el montaje

perno hexagonal, el ensamble

onducir.

Quite los rieles después de

marcar

Sugerencia: Perfore ligeramente los

puntos de los agujeros antes de

perforar los orificios pilotos.

Sugerencia: No es recomendable

perforar a través de los rieles.

Cómo instalar los rieles a la superficie de montaje

Taladre un orificio piloto de 3mm primero,

luego taladre agujeros de

.290". Sople o retire los residuos con

aspiradora.

No perfore a una profundidad superior a ¼ ".

Use un tope de taladro o cinta para asegurar

la profundidad adecuada. ¡Use gafas de

seguridad cuando perfore!

Cómo colocar los travesaños y apretar las piezas

Importante: Use topes de perforación o

enrolle cinta de enmascarar alrededor de

las brocas de perforación para asegurar

una profundidad no mayor de ¼ "por

debajo del metal laminado.

Selle los bordes de los

orificios perforados con

pintura automotriz para

retocar.

Ensamble la tuerca hexagonal M6,

el perno M5 x 30mm, la arandela de

acero plana, la arandela de estrella,

el Plus nut como se muestra.

Una vez que los insertos Plus

nut estén instalados retire el

Plus Nut

Tuerca hexagonal, M6

de tuerca y arandela.

Instale los insertos

Plus-nut dentro de

los orificios

perforados.

Use una arandela de

estrella nueva para

instalar cada Plus-nut

Sosteniendo la tuerca hexagonal

M6 firmemente con una llave de

10mm, apriete la tuerca hexagonal

(pieza D) con una llave de 8mm

hasta que el inserto del Plus nut

colapse (habrá un aumento de

fuerza notorio).

Sostenga

Aplique una pequeña

cantidad de silicona en el

inserto Plus nut para

sellar las roscas

Cómo instalar los rieles a la superficie de montaje

Posicione la almohadilla aislante, las tapas laterales

delantera y trasera sobre la superficie de montaje y

alinee los orificios. Nota: Las tapas traseras

permitirán que los travesaños se deslicen y se

salgan de los rieles.

ROLA vende una variedad de estilos de travesaños y longitudes para instalar con nuestros rieles. Los travesaños se venden con

accesorios de montaje.

Cualquier peso del vehículo afectará de manera adversa su manipulación especialmente en las esquinas o con el viento en contra, por lo

cual el vehículo se debe conducir con mayor precaución. Revise la función de todas las puertas y techo corredizo antes de c

Para el reemplazo de llaves perdidas u otras piezas de servicio llame a servicio al cliente: 1-800-632-3290 o visite:

www.rolaproducts.com

Tenga a mano el número de candado o números de partes.

Instale los pernos y las arandelas de nylon en

los rieles y a través del carril y dentro de los

Plus nuts.

59853N Rev B 4-15-13

Página 2 de 2Impreso en China

Loading...

Loading...