Page 1

Fitting Instructions

APE (Anchor Point Extended)

Cross Bar Kits for Track & Direct

Mounting Systems

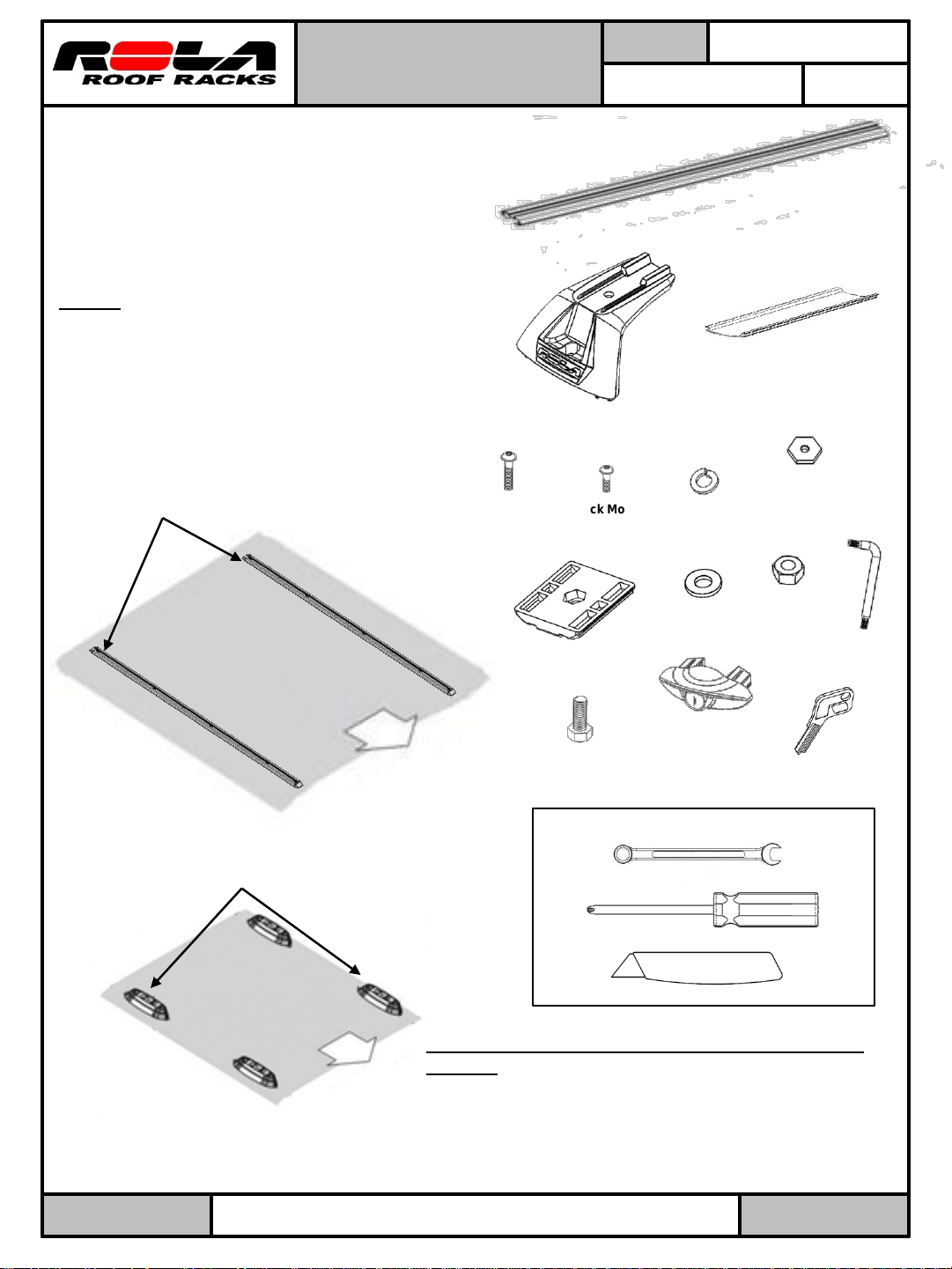

Note: Prior to Assembly

Prior to assembling your cross bar kit check

that the kit contains all the parts you will need

to fit the cross bars. Refer to parts lists for

guidance.

Please read these instructions before assembly.

Step 1: Determine if you have a Direct or

Track mounting roof rack system. These

systems must be installed prior to installing

the cross bar kits. If it’s a Track Mounting

System (part numbers 59853, 59854, &

59855) follow steps 2 and 3. (Fig. 1) If it’s a

Direct Mounting System (part numbers

59753 & 59754) follow steps 4 and 5 (Fig. 2)

Track Systems part numbers

59853 – 59854 - 59855

Direct Mount

Bolt M6 x 24mm

Qty 4

PART No:

CARRYING CAPACITY:

Parts list

Cross Bars

End Support

Qty 4

Track Mount

Bolt M6 x 16mm

Qty 4

M8 Spring

59772, 59773,

59774

75Kgs/

165 Lbs

Qty 2

Under Cover

Qty 2

M6 Hex Nut

Brass

Qty 4

Washer

Qty 4

Vehicle’s roof

Fig. 1

Direct Systems part numbers

59753 – 59754

Vehicle’s roof

Fig. 2

Front of

vehicle

M8 Hex Nut

Qty 4

End Cap Key

Qty 4

Front of

vehicle

M8 Washer

Qty 4

Clamp Plate

Qty 4

Cross Bar End Caps

Qty 4

Bolt

M8 x 20mm

Qty 4

Tools required

13mm or adjustable wrench

Phillips screw driver

Scissors or Blade

Step 2: Installing Cross Bars on a Track Mounting

System.

A. Locate hardware bag labeled “Track Mount

Hardware”.

B. Assemble bolt M6x16 into End Support and thread

on M6 Hex nut brass onto bolt, (Fig. 3)

L Wrench

Qty 1

59772-3-4N REV 4-24-13

Printed in China

Pg 1 of 3

Page 2

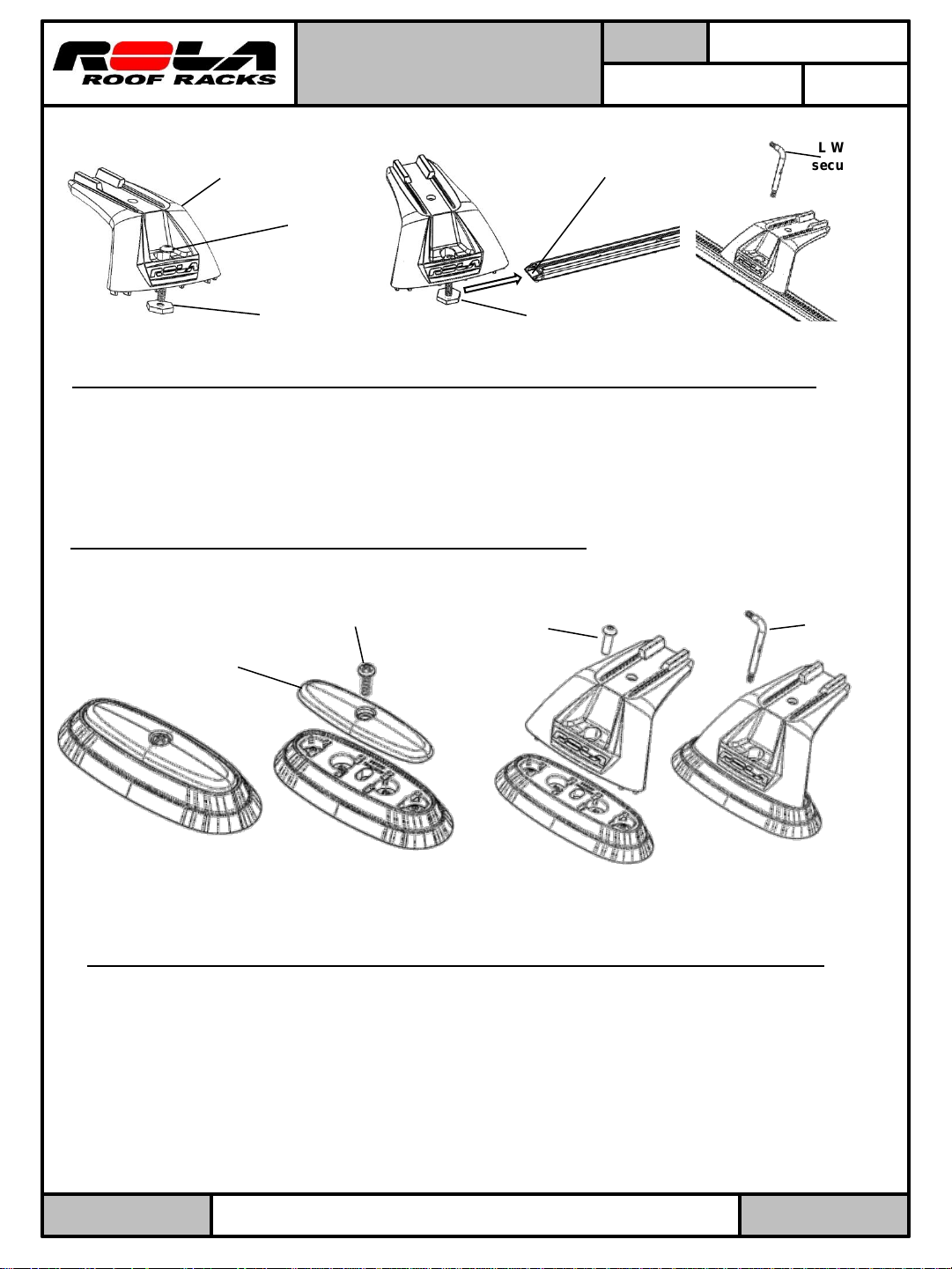

End Support

M6x16 Bolt

Fitting Instructions

APE (Anchor Point Extended)

Cross Bar Kits for Track & Direct

Mounting Systems

Open end of Track

PART No:

59772, 59773,

59774

CARRYING CAPACITY:

75Kgs/

165 Lbs

L Wrench-

security key

M6 Hex Nut

Brass

Fig. 3

To slide into position

do not thread nut past

end of bolt.

Fig. 4

Fig. 5

Step 3: Installing Cross Bars to the vehicle with Track Mounting System. (Continued)

A. Place an End Support and the M6 Hex Nut Brass into the open end of the Track (Fig 4.)

Ensure that the Brass Nut is engaged in the channel. Position it along the rail with the

logo facing out. Turn the bolt approx 2-3 turns with the L Wrench security key (Fig 5).

Do not tighten yet, Repeat for the other 3 End Supports.

B. Go to step 6 to continue installing cross bar.

Step 4: Installing Cross Bars on a Direct Mounting System.

A. Locate hardware bag labeled “Direct Mount Hardware”.

M6- Bolt

Cover

Philips head

M6x24 Bolt

L wrench-

security key

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Step 5: Installing Cross Bars to the vehicle with Direct Mounting System. (Fig. 6)

A. Using a Philips head screw driver remove the top screw and cover from mounting

block. Covers will not be replaced while the cross bars are on the vehicle. Store

the Covers and Bolts for later replacement when cross bars are removed. (Fig. 7)

B. Place End Support on mounting block with the logo facing out. Install the M6x24

bolt through End Support and turn the bolt approx 2-3 turns with the L wrench

security key. (Fig. 8-9) Do not tighten yet, repeat for other 3 End Supports.

C. Go to step 6 to continue installing cross bar.

59772-3-4N REV 4-24-13

Printed in China

Pg 2 of 3

Page 3

Fitting Instructions

APE (Anchor Point Extended)

Cross Bar Kits for Track & Direct

Mounting Systems

Step 6: Fitting Cross Bars to the vehicle

A. Place the Cross Bar onto the End Supports

ensuring that the End Support Tabs are located

into the cutouts on the underside of the bar.

Ensure the Cross Bar marked “FRONT” is

placed on the front End Supports. Check that

the Cross Bar has equally distanced overhang

on either side of the End Supports. (Fig. 10)

B. Insert the M8 hex nut into the Clamp Plate.

Insert the Clamp Plate into the end of the Cross

Bar and align it so that the nut and the End

Support’s bolt hole align.

C. Secure the Cross Bar to the End Support by

screwing the M8 x 20mm bolt with Washer and

Spring Washer through the End Support hole

and into the Clamp Plate nut. (Fig. 11)

D. Using a 13mm or adjustable wrench fully

tighten the bolt on the underside of the

support. Now using the Security Key finish

tightening the M6x16 bolts to 5Nm (44 in/ lbs)

or to a firm hand tightness.

Step 7: Installing Under Cover strips

Mark on underside of bars with a pencil the length

of Under Cover strips needed.

Remove bars, measure length of under cover filler

strips to fill slot. Cut Under Cover pieces using

scissors or a blade. Slide inner most Under Cover

into position on the bars and re-assemble bars

onto vehicle. Add the outer Under Cover piece

once bars are attached. (Fig. 12)

End Cap

PART No:

CARRYING CAPACITY:

Cross Bar

Cross Bar shortened for

illustrative purposes

Tabs

Clamp Plate

Inner Under

Cover strip

Fig. 10

M8 Nut

Fig. 11

Caution sharp

edges

59772, 59773,

59774

75Kgs/

165 Lbs

M8 Washer

Spring Washer

M8 Bolt

Step 8: Install End Caps

Locking End Caps can now be installed into the ends

Slide to end

Fig. 12

Outer Under

Cover strip

of the cross bars. (Fig. 13) Remove keys and keep in

a safe place.

End Cap

To load accessories into the Cross Bar accessory

channel remove End Cap, cut Buffer Strips as needed.

Once accessories have been loaded, re-insert the End

Caps and lock. Additional Buffer Strips may be

purchased from ROLA if needed.

REGULARLY CHECK THE TIGHTNESS OF CROSS BAR & ATTACHMENTS.

Loads should be evenly distributed and secured.

Check the function of all doors and sunroof before driving.

Any weight carried on the vehicle will adversely affect its handling particularly in cornering or in a cross wind and the vehicle

should therefore be driven with increased caution.

For lost key replacement or other service items call customer service: 1-800-632-3290 or visit: www.rolaproducts.com.

Please have lock core number or part numbers available.

Only use NON-STRETCH tie down straps.

A number of accessories for carrying special loads are available.

59772-3-4N REV 4-24-13

Printed in China

Ensure bars are parallel and straps are tightened against

the side rails. Perform a check by tugging on the cross bars.

Fig. 13

Pg 3 of 3

Loading...

Loading...