Page 1

CONTROLS

The Output Control establishes the maximum amount of

power available to the trailer brakes.

As the Output Control is rotated up more power will be

available to the brakes when the brake pedal is pressed or

the manual control is used.

The Output Control would be adjusted during initial setup,

when trailer load changes, when different trailers are used

or to adjust for a change in road conditions.

The Output setting is shown on the digital display when a

trailer is connected and the brake pedal is pressed or the

Manual Control is actuated.

The Output setting is shown as 0 through 10 with 0 being

the minimum and

SYNC CONTROL

The Sync Control is located on the left side of the Brake

Control Unit, forward of the mounting bracket.

The Sync Control adjusts trailer brake aggressiveness.

The trailer brakes become more aggressive as the switch is

moved toward the front of the tow vehicle.

To view the Sync setting on the display, press the brake

10 the maximum.

pedal (trailer must be connected) and move the SyncControl slightly. The display will change to the Sync mode.

The Sync setting is shown as

least aggressive and

10 through 90 with 10 being the

90 being the most aggressive.

The Sync adjustment has no effect on the manual control.

The Sync Control would be adjusted for individual driver

preference or changing road conditions.

MANUAL CONTROL

The Manual Control is located on the front of the

Brake Control Unit at the right side.

The Manual Control only applies the trailer brakes and used

during initial setup and in situations to reduce speed slowly.

When the Manual Control is pushed to the left, the control

begins to apply the trailer brakes. The further to the left it is

pushed the harder the brakes are applied until the maximum

set by the Output Control is reached.

The Output setting will be shown on the display and can be

adjusted when using the Manual Control.

The Manual Control activates the tow vehicle and trailer stoplights.

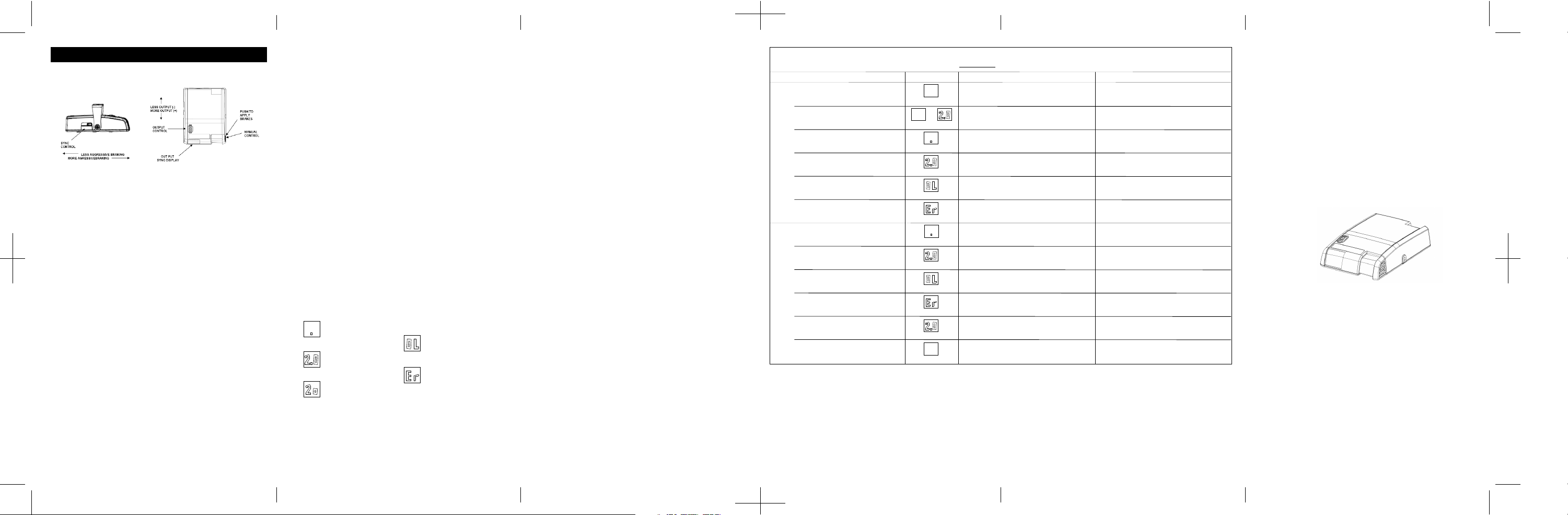

SINGLE DECIMAL

CONTROL ACTIVATED

NO TRAILER CONNECTED

LEVEL

OUTPUT DISPLAY

CONTROL ACTIVATED

TRAILER CONNECTED

LEVEL

SYNC DISPLAY

BRAKE PEDAL PUSHED

SYNC CONTROL ACTIVATED

TRAILER CONNECTED

LEVEL

OVER LOAD DISPLAY

SHORTED OR OVER LOADED

BRAKE CIRCUIT

SEE TROUBLE SHOOTING GUIDE

LEVEL

ERROR DISPLAY

INTERNAL CONTROL ERROR

SEE TROUBLE SHOOTING GUIDE

LEVEL

DISPLAY MODES

DIGITAL DISPLAY

The Digital display shows the Output setting when the

control is activated. It is used to setup and monitor the

Brake Control and can be used when trouble shooting.

SETUP

Preliminary Adjustments:

With the trailer connected press and hold the brake pedal,

the Display will show the Output setting.

Adjust to 2.0 by turning the control up or down as needed.

While still holding the brake pedal move the Sync Control

slightly, the Display will change to the Sync setting.

Adjust to 40 by sliding the Sync Control ahead or back as

necessary.

TEST DRIVE

In an open area, such as a large parking lot, drive forward

and apply the trailer brakes using the Manual Control.

If the trailer brakes are weak adjust the Output Control up.

If the trailer brakes jerk or lockup adjust the Output Control

down.

Repeat this step until firm braking is felt with out jerking or

lockup.

Once the Output is set, drive forward and press the brake

pedal, the tow vehicle and trailer should make a smooth

stop.

If the stop seems slow and more aggressive braking is

desired, move the Sync Control rearward while holding the

brake pedal.

If the stop seems too aggressive adjust the Sync Control

rearward while holding the brake pedal.

After making a Sync adjustment the Display will show the

setting until the brake pedal is released.

Make several stops at various speeds and adjust the Sync

until stops are smooth and firm. Slight adjustment of the

Output Control may also be desirable.

NOTE: If any problems occur during Setup refer to the

Trouble Shooting section of these instructions.

TROUBLE SHOOTING GUIDE

TEST WITHOUT TRAILER FIRST

CONDITION DISPLAY PROBABLE CAUSES POSSIBLE SOLUTION

DECIMAL POINT DOES NOT LIGHT

WHEN BRAKE PEDAL OR MANUAL

CONTROL IS USED

DECIMAL POINT DOES NOT LIGHT

WHEN BRAKE PEDAL IS PUSHED

DOES LIGHT WITH MANUAL

DECIMAL ON ALL THE TIME

DISPLAY SHOWS OUTPUT

SETTING

DISPLAY SHOWS OL WHEN

ACTIVATED

DISPLAY SHOWS Er

NO TRAILER BRAKES, PEDAL

OR MANUAL

NO TRAILER BRAKES, PEDAL

OR MANUAL

NO TRAILER BRAKES, PEDAL

OR MANUAL

NO TRAILER BRAKES, PEDAL

OR MANUAL

WEAK OR NO TRAILER BRAKES MISWIRED TRAILER CONNECTOR

TRAILER BRAKES ON ALL THE

TIME

LEVEL

BLANK

LEVEL LEVEL

PEDAL MANUAL

LEVEL

DECIMAL ONLY

LEVEL

OUTPUT SETTING

LEVEL

FLASHING OL

LEVEL

ERROR

LEVEL

DECIMAL ONLY

LEVEL

OUTPUT SETTING

LEVEL

FLASHING OL

LEVEL

ERROR

LEVEL

OUTPUT SETTING

LEVEL

BLANK

USAGE TIPS

Light pressure on the brake pedal will activate the trailer's

brakes with no effect on the tow vehicle's brakes. This is

useful for gradual slowing on steep grades or before stops.

Periodic adjustment of the Sync and Output controls may

be necessary to correct for changing road conditions, trailer

loading, brake wear, and/or driver preference.

On some vehicles, operating the Brake Control's Manual

control will not disengage "Cruise Control."

NO POWER TO CONTROL, NO GROUND,

REVERSED BLACK AND WHITE WIRES,

CIRCUIT BREAKER BLOWN

NO CONNECTION OR INCORRECT

CONNECTION AT STOPLIGHT SWITCH,

BLOWN FUSE IN STOPLIGHT CIRCUIT

RED WIRE CONNECTED TO THE WRONG

SIDE OF THE STOPLIGHT SWITCH OR

TO WRONG SWITCH (CRUISE CONTROL)

BRAKE CONTROL UNIT MISWIRED

SHORT IN BLUE WIRE CIRCUIT

INTERNAL BRAKE CONTROL PROBLEM

NO CONNECTION BETWEEN BRAKE CONTROL AND

BRAKES - BLUE WIRE CIRCUIT

MISWIRED TRAILER CONNECTOR

SHORT OR OVERLOAD IN TRAILER BRAKES

INTERNAL BRAKE CONTROL PROBLEM

MISWIRED TRAILER CONNECTOR

CHECK AND REPAIR CONNECTIONS

REFER TO "WIRING" SECTION

CHECK AND REPAIR CONNECTIONS

REFER TO "WIRING" SECTION,

CHECK STOPLIGHT CIRCUIT

CHECK AND REPAIR CONNECTIONS

REFER TO "WIRING" SECTION

CHECK AND REPAIR CONNECTIONS

REFER TO "WIRING" SECTION

LOCATE AND CORRECT SHORT

RETURN UNIT TO DEALER FOR

EVALUATION

CONFIRM CONNECTION TO TRAILER

CONNECTOR, CONFIRM CONNECTOR

TERMINAL POSITIONS, CHECK TRAILER

CONFIRM TRAILER CONNECTOR

TERMINAL POSITIONS

TROUBLE SHOOT TRAILER BRAKE

CIRCUIT PER BRAKE MANUFACTURER'S

INSTRUCTIONS

RETURN UNIT TO DEALER FOR

EVALUATION

CHECK AND CORRECT CONNECTOR

WIRE POSITIONS

CHECK AND CORRECT CONNECTOR

WIRE POSITIONS

When Towing (in most applications) with Hazard Flashers on

the Digital Display will flash with the Hazard Flashers. If the

Brake Control is set aggressively pulsing may be felt in the

trailer brakes.

Installation of a Pulse Preventor will isolate the brake control from the flashers and eliminate the flash/pulse situation.

INSTRUCTIONS FOR THE INSTALLATION AND

OPERATION OF THE DRAW-TITE ACTIVATOR III &

REESE BRAKEMAN ELECTRONIC BRAKE CONTROL

ELECTRONIC TRAILER BRAKE CONTROL FOR 2, 4, 6 & 8

BRAKE SYSTEMS

IMPORTANT: READ AND FOLLOW THESE

INSTRUCTIONS CAREFULLY. KEEP INSTRUCTIONS

IN YOUR TOW VEHICLE FOR FUTURE REFERENCE.

THIS PACKAGE

INCLUDES:

(1) Brake Control Unit

(1) Mounting Bracket

(4) Mounting Screws

(1) Warranty Card

TOOLS REQUIRED:

Assorted end wrenches

Drill w/ 1/8" bit

Wire Cutter

Wire Crimp Tool

Electrical Circuit Tester

Screw Driver or 1/4" Nut Driver

ACCESSORIES REQUIRED:

Quick Connect Style Plug

30 Amp auto-reset circuit breaker

Electrical Terminals

Ring / Butt Connectors

Cable Ties

10 Gauge Wire or OEM Harness

CEQUENT TOWING PRODUCTS

47774 Anchor Court West

Plymouth, Mi 48170

Printed in Philippines

Cequent Towing Products 2007

05520-02 06/30/07

Page 2

UNDER DASH

ANY ANGLE

VERTICAL

IMPORTANT: MAKE SURE AREA BEHIND PANEL IS CLEAR

BEFORE DRILLING.

USE BRACKET AS TEMPLATE TO MARK HOLE LOCATIONS.

DRILL (2) 1/8" DIA. HOLES AND MOUNT BRACKET WITH

SCREWS PROVIDED.

MOUNT BRAKE CONTROL TO BRACKET USING THE

REMAINING (2) SCREWS.

MOUNTING

1. Determine a suitable mounting location.

A) The unit must be mounted securely to a solid surface.

B) The unit must be easily reached by the driver.

C) The area behind the mounting location must be clear so

nothing will be damaged when drilling.

2. Hold the mounting bracket in the position selected and

mark hole locations through the slots in the bracket

3. Using a 1/8" dia. bit, drill holes in the marked locations.

4. With a screwdriver or a 1/4" nut driver, secure the bracket

in place using (2) self tapping screws (provided). Be careful

not to strip the holes by over-tightening.

5. Mount the brake control unit in the bracket using the

other (2) self tapping screws as shown in the illustration.

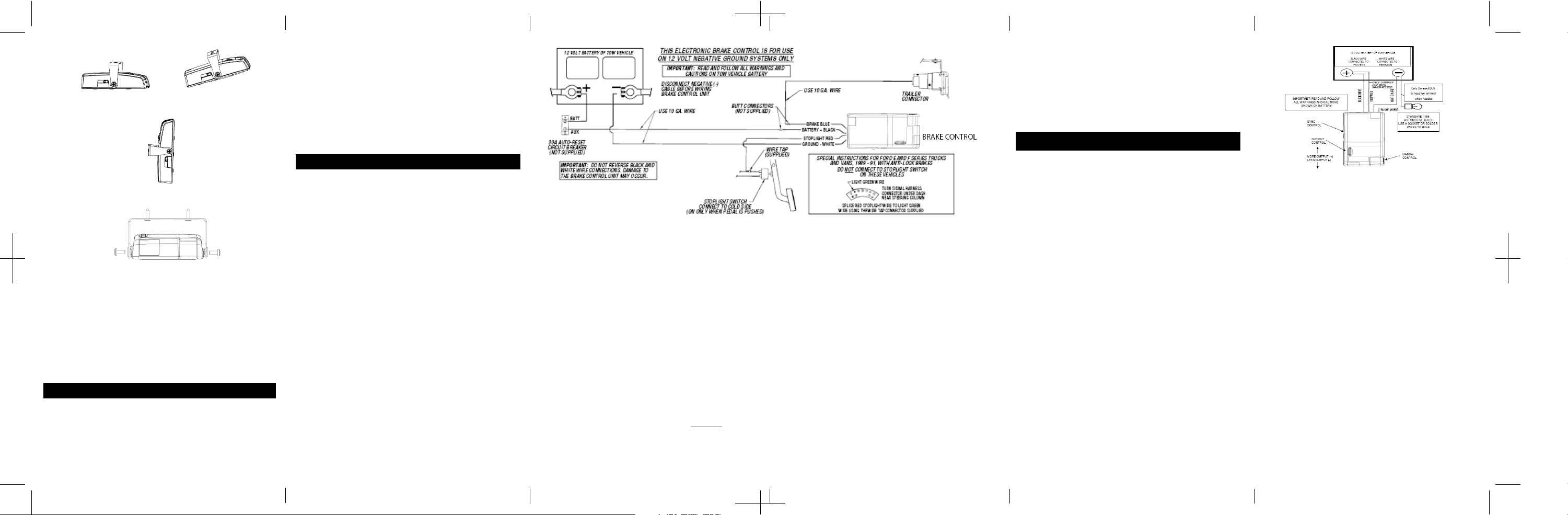

WIRING

WARNING: Do not connect the black "BATTERY" wire to

the fuse panel or tie into accessory wiring. Connecting

to existing wiring may damage vehicle wiring and

cause trailer brake failure.

FOR TOW VEHICLES EQUIPPED WITH FACTORY TRAILER

TOWING PACKAGES: Wire per tow vehicle

manufacturer's instructions.

NOTE: Make sure that the tow vehicle's Brake Control

Battery Feed circuit is capable of carrying enough

current to supply trailer brake requirements (check tow

vehicle manu- facturer's instructions and trailer brake

manufacturer's information). If the circuit does not meet

the trailer's requirements, wire directly to the battery per

through 7.

steps 1

FOR TOW VEHICLES WITHOUT FACTORY TRAILER

TOWING PACKAGES:

1. Disconnect the tow vehicle's negative (-) battery cable.

2. Mount a 30 Amp auto-reset circuit breaker as close to the

positive (+) battery terminal as possible. Using 10 Ga.

stranded wire and crimp type ring terminals connect the

"BATT" side of the circuit breaker to the positive battery terminal.

NOTE: When passing wire through sheet metal always go

through an existing grommet, add a grommet or use

silicone rubber to insulate the wire from the hole

3. Feed one black and one white, 10 Ga. stranded wire from

the Brake Control location to the tow vehicle's battery area.

4. Connect the black wire to the "AUX" side of the circuit

breaker with a ring terminal.

5. Connect the white wire to the negative battery post with a

ring terminal.

6 Attach the Control's black "BATTERY +" wire to the wire

(black) connected to the "AUX" side of the circuit breaker

using a butt connector.

7. Connect the control's white "GROUND" wire to the wire

(white) leading from the negative battery terminal with

another butt connector.

IMPORTANT: A brake control that is not properly grounded

may operate intermittently or not at all. Recheck

sure that the white "GROUND -" wire is connected to the (-)

negative battery terminal and that the black "BATTERY +"

wire is attached to the (+) positive battery terminal.

to make

8. For tow vehicles other than 1989-91 Ford E and F

series trucks and vans:

Determine which side of the stoplight switch is the cold side.

To determine the cold side probe the terminals of the switch

with a test light until one is found that is only on when the

brake pedal is depressed.

Using the wire tap provided, splice the brake control's red

"STOPLIGHT" wire to the attached to the cold side of the

stoplight switch as determined above.

For 1989-91 Ford E and F series trucks and vans with

anti-lock brakes:

Find the crescent shaped connector located on the steering

column (turn signal harness). The connector has two rows of

wires, one row has four wires (inside row) the other has

seven.

The wire needed is the light green wire, second in from the

row of seven (see wiring diagram above).

Using the wire tap provided, splice the brake control's red

"STOPLIGHT" wire to the light green wire.

9. Secure all loose wires with cable ties so that they will not

be damaged and reconnect battery. See vehicle's owners

manual for special re-connectioninstructions.

10. Test Installation:

Without a trailer connected, push the brake pedal. A single .

(decimal point) should light up on the Display.

If the decimal point does not light or if OL or Er is shown go

to the Trouble Shooting section.

BENCH TEST INSTRUCTIONS

1. Wire as shown at right

Set the Output control to maximum (+) and set the Sync control

to minimum (-).

NOTE: If at any time during the bench test, the display shows

OL make sure that the blue "BRAKE" wire is not shorted to the

"-" battery terminal or the white "BATTERY -" wire.

If at any time, the display shows Er return the unit to your

Cequent dealer for further evaluation.

2. Test "Standby Condition"

Hold the red "STOPLIGHT" wire on the "+" battery terminal. The

display should show a single . (decimal point). This indicates

correct wiring and that the control is ready.

Disconnect the red "STOPLIGHT" wire from the battery

3. Test Brake Pedal Activation

Firmly ground the light bulb to the "-" terminal of the battery.

Re-attach the red "STOPLIGHT" wire to the "+" battery

terminal.

The display should step up to 10 and the bulb should start

out dim and slowly get brighter (unhook and re-attach the

red wire as many times as necessary to confirm this)

With the red wire still hooked up, slowly move the Output

Control down to (-). The display should count down to 0 and

the bulb should dim and go off.

Slowly move the Output Control back up to (+), the Display

should go back to 10 and the bulb should return to full

brightness.

Slowly move the Sync Control to maximum (+). The

display should change to Sync mode and count up to 9

Disconnect and reconnect the red wire. The bulb should

light brightly with no delay and the Display should read 10.

Disconnect the red wire.

4. Test Manual Activation

With the Output Control still set at maximum, slowly activate

the Manual Control button.

The bulb should start to dim and get brighter and the dis-

play should count up to 10 as the Manual Control is

pushed.

While holding the Manual Control all the way in, rotate

Output Control up and down. As the output changes the

the

bulb should go bright and dim and the display should

read 0 to

5. Defective Unit

If the Brake Control unit does not function as described,

return it for service or replacement.

10.

Loading...

Loading...