Page 1

L

CONTROLS

OUTPUT CONTROL

The output control is located on the front of the brake

control unit at the top left side.

The output control establishes the maximum amount of

power available to the trailer brakes.

As the setting is moved to the left more power will be

available to the brakes when the brake pedal is

pressed or the manual control is used.

The output control would be adjusted when trailer load

changes, when different trailers are used or to adjust

for a change in road conditions.

SYNC CONTROL

The sync control is located on the left side of the brake

control unit, forward of the mounting bracket. The sync

control adjusts brake aggressiveness or the time it takes

to reach the full output set by the output control when the

brake pedal is pressed.

The sync adjustment has no effect on the manual control.

The brakes become more aggressive as the switch is

moved toward the front of the tow vehicle.

The sync control would be adjusted for individual driver

preference or changing road conditions.

MANUAL CONTROL

The manual control is located on the front of the brake

control unit at the right side.

The manual control only applies the trailer brakes and

would be used in situations when it is desirable to reduce

speed slowly.

When the manual control is pushed to the left the control

begins to apply the trailer brakes. The further to the left it

is pushed the harder the brakes are applied until the

maximum set by the output control is reached.

The manual control activates the tow vehicle and trailer

stoplights and the output indicator on the control unit.

OUTPUT INDICATOR

The red indicator light on the front of the control unit will

glow when brakes are applied either by the brake pedal

or the manual control (with or without a trailer attached).

The indicator will start dim and glow brighter as output

increases.

The indicator light will also help confirm proper installation.

SET UP

1. With a trailer connected, set the sync control half

way between + and -. Starting with the output

control in the lowest position (all the way right) roll

forward slowly and stop. If no trailer braking is felt

adjust the output control slightly to the left. Repeat

this process until firm trailer brakes are felt. If the

trailer brakes lock-up or jerk adjust the output

back to the right slightly.

2. Move the sync control back (toward the driver) to

about 1/4 of the distance between + and -.

3. Test drive making several stops. Adjust the sync

control until stops are smooth and firm. Slight

adjustment of the output control may also be

desirable.

Setting the brake control too aggressively

could cause brake pulsing when towing

with hazard flashers on. If such settings

are necessary, a pulse preventor can be

used.

4. Have someone watch the stoplights while the

manual control is activated to make sure the stoplights on both the tow vehicle and trailer are working.

Note: If any problems occur during set up refer to

the Trouble shooting section of these instructions.

USAGE TIPS

Light pressure on the brake pedal will activate the

trailer’s brakes with little or no effect on the tow vehicle’s brakes. This is useful for gradual slowing on

steep downhill grades or before stops.

INSTRUCTIONS FOR THE INSTALLATION

AND OPERATION OF

ELECTRONIC TRAILER BRAKE CONTROL FOR

2 AND 4 BRAKE SYSTEMS

IMP0RTANT: READ AND

FOLLOW THESE

INSTRUCTIONS CAREFULLY. KEEP THESE

INSTRUCTIONS IN YOUR

TOW VEHICLE FOR

FUTURE REFERENCE.

THIS PACKAGE INCLUDES:

(1) Brake Control Unit

(1) Mounting Bracket

(4) Mounting Screws

(1) Wire Tap Connector

(1) Warranty Card

TOOLS REQUIRED:

Assorted end wrenches

Drill with 1/8” bit

Wire connector crimp tool

Probe type circuit tester

Wire cutter/stripper

Screwdriver

MATERIAL REQUIRED:

12 Ga. or larger wire

20 Amp auto-reset circuit breaker

Assorted ring terminals

& butt connectors

4” cable ties (6-10)

Periodic adjustment of the Sync and Output controls may be necessary to correct for changing road

conditions, trailer loading, brake wear and/or driver

preference.

On some vehicles, operating the brake control’s manual

control will not disengage “Cruise Control.”

TROUBLE SHOOTING GUIDE

PROBLEM LIGHT POSSIBLE CAUSES SOLUTION

TRAILER BRAKING IS DELAYED ON INCORRECT SYNC ADJUSTMENT ADJUST TO MORE AGGRESSIVE POSITION

TRAILER BRAKES COME ON TOO FAST ON INCORRECT SYNC ADJUSTMENT ADJUST TO LESS AGGRESSIVE POSITION

TRAILER BRAKES ARE WEAK ON INCORRECT OUTPUT ADJUSTMENT ADJUST FOR MORE OUTPUT

TRAILER BRAKES COME ON TOO HARD ON INCORRECT OUTPUT ADJUSTMENT ADJUST FOR LESS OUTPUT

NO TRAILER BRAKES - PEDAL OR MANUAL OFF NO POWER TO UNIT THRU BLACK “BATTERY +” WlRE CHECK CONNECTIONS AT: BATTERY,

OPERATION CIRCUIT BREAKER, BRAKE CONTROL

OUTPUT ADJUSTED TOO LOW RE-ADJUST (SEE SET UP)

NO TRAILER BRAKES - PEDAL OR MANUAL ON NO CONNECTION TO TRAILER BRAKES THRU BLUE CHECK TRAILER CONNECTOR CONTACTS

OPERATION (BRIGHT) “BRAKE” WIRE CHECK WIRE CONNECTIONS (SEE WIRlNG)

TRAILER OR TRAILER BRAKES NOT GROUNDED CHECK TRAILER AND BRAKE GROUNDS

NO TRAILER BRAKES USING BRAKE PEDAL OFF NO CONNECTION AT STOPLIGHT SWITCH THRU RED CHECK STOPLIGHT CONNECTION

MANUAL OPERATION WORKS (PEDAL) “STOPLIGHT” WIRE (SEE WIRlNG STEP 8)

ON

(MANUAL)

TRAILER BRAKES LOCKED ON WHEN RED “STOPLIGHT” WlRE CONNECTED TO WRONG CHECK CONNECTION (SEE WIRlNG STEP 8)

CONNECTED TO CONTROL ON SIDE OF STOPLIGHT SWITCH OR TO BATTERY +

BREAK-AWAY SWITCH ACTIVATED CHECK SWITCH AND CORRECT

TRAILER BRAKES SEEM TO BE WORKING DIM OR FAULTY WHITE “GROUND” WIRE CONNECTION CHECK CONNECTIONS

FLICKERS

WEAK OR INCONSISTANT TRAILER BRAKES DIM OR SHORT IN BLUE “BRAKE” WlRE CIRCUIT LOCATE SHORT & CORRECT

FLICKERS SHORT IN TRAILER BRAKE CIRCUIT LOCATE SHORT & REPAIR

BRAKE CONTROL OVERHEATS, SMELLS DIM BLACK “BATTERY +” WIRE & WHITE “GROUND” BRAKE CONTROL UNIT DESTROYED

HOT, LOW OR NO BRAKE OUTPUT WIRE CONNECTIONS REVERSED CORRECT WIRING & REPLACE UNIT

TOWING PRODUCTS 47774

Anchor Court West

Plymouth, MI 48170

© TOWING PRODUCTS 2003

PRINTED IN CHINA

05100-037 1 of 3 rev. 1/21/03

Note: A standard voltmeter will not show true output voltage.

05100-037 1/21/03 English 3/6/03 2:00 PM Page 1

OUTPUT

CONTROL

More Output

Less Output

OUTPUT

INDICATORSYNC CONTROL

+ SYNC -

More Aggressive Braking

Less Aggressive Braking

ACTIVATOR

OUTPUT

ACTIVATOR

OUTPUT

Push to Apply

Trailer Brakes

MANUAL

CONTRO

+

SYNC–

Page 2

12 Volt Tow Vehicle Battery

BATT

AUX

20A Auto-Reset

Circuit Breaker

(Not Supplied)

This Electronic Brake Control is for Use

on 12-Volt Negative Ground Systems Only

IMPORTANT: DO NOT

REVERSE BLACK AND

WHITE WIRE CONNECTIONS!

Damage to the brake control

unit will occur!

IMPORTANT: Read and

follow all warnings and cautions

printed on tow vehicle battery.

SPECIAL INSTRUCTIONS:

For Ford E and F Series Trucks and Vans,

1989-1991 with Anti-Lock Brakes

Do NOT Connect to stoplight switch on these vehicles

Turn signal harness connector under

dash near steering column. Splice red

stoplight wire to light green wire using

the wire tap connector supplied

Light

Green Wire

Trailer

Connector

Brake Control

Battery (+) Black

Stoplight Red

Ground (–) White

Brake Blue

Wire Tap

(Supplied)

Use 12 gauge

or larger wire

Butt Connectors

(Not Supplied)

Stoplight

Switch

Connect to cold side (“On” only when brake

pedal is depressed), see wiring Step 8.

IMPORTANT: For 1989-1991

Ford E and F Series vehicles with

anti-lock brakes see Step 8 and

special instructions above.

wire and crimp type ring terminals connect the

“BATT” side of the circuit breaker to the positive

battery terminal.

3. Feed two, different colored, 12 GA or larger

stranded wires from the brake control location to

the tow vehicle battery area.

4. Connect one of the wires (noting the color) to the

“AUX” side of the circuit breaker with a ring terminal.

5. Connect the other wire to the negative battery

cable with a ring terminal.

6. Attach the control’s black “BATTERY +” wire to the

wire connected to the “AUX” terminal of the circuit

breaker using a butt connector. Make sure that the

connection is made to the correct wire (color).

7. Connect the control’s white “GROUND -” wire to

the wire leading to the negative side of the battery

with another butt connector.

WARNING: A brake control that is not properly

grounded may operate intermittently or not at all.

Make sure all connections are solid.

8. For tow vehicles other than 1989-91 Ford E and F

series trucks and vans:

Determine which side of the stoplight switch is the

cold side. To determine the cold side probe the

terminals of the switch with a test light until one is

found that is only on when the brake pedal is

depressed.

Using the wire tap provided, splice the brake control’s

red “STOPLIGHT” wire to the wire attached to the cold

side of the stoplight switch as determined above.

For 1989-91 Ford E and F series trucks and vans

with anti-lock brakes:

Find the crescent shaped connector located on the

steering column (turn signal harness). The connector

has two rows of wires, one row has four wires (inside

row) the other has seven. The wire needed is the light

green wire, second from the left in the row of seven

(see wiring diagram).

Using the wire tap provided, splice the brake control’s

red “STOPLIGHT” wire to the light green wire.

10. Secure all loose wires with cable ties so that they will

not be damaged and reconnect battery. See vehicle’s

owners manual for special reconnection instructions.

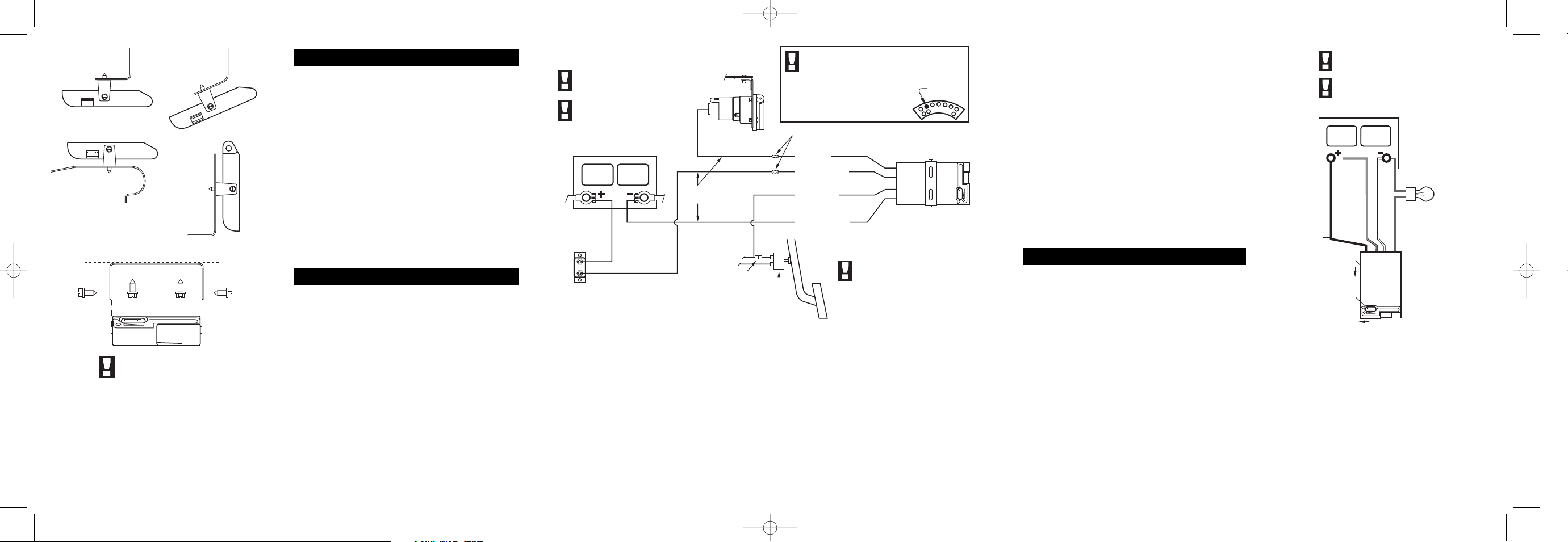

BENCH TEST INSTRUCTIONS

1. Wire as shown at right. Set Output control to maximum and the Sync control to minimum.

2. Test brake pedal activation:

While watching the test bulb, hold the red wire on the

positive (+) battery terminal.

The bulb should start dim and slowly get brighter.

The red output indicator on the brake control should

glow brightly.

Disconnect the red wire.

Adjust the Sync control to maximum (+).

While watching the test bulb, hold the red wire on the

positive (+) battery terminal.

The bulb should light brightly with no delay.

With the red wire still on the battery terminal, slide the

output control back and forth. The test bulb should

change from bright to dim with the movement of the

output control. Disconnect the red wire.

3. Test manual activation:

Set the output control to maximum.

While watching the test bulb, slowly activate the

manual control.

The test bulb should start dim and get brighter as

the manual control is pushed.

While holding the manual control all the way on,

slide the output control back and forth.

The test bulb should change from bright to dim with

the movement of the output control.

4. If the brake control does not function as described

above, return it for service or replacement.

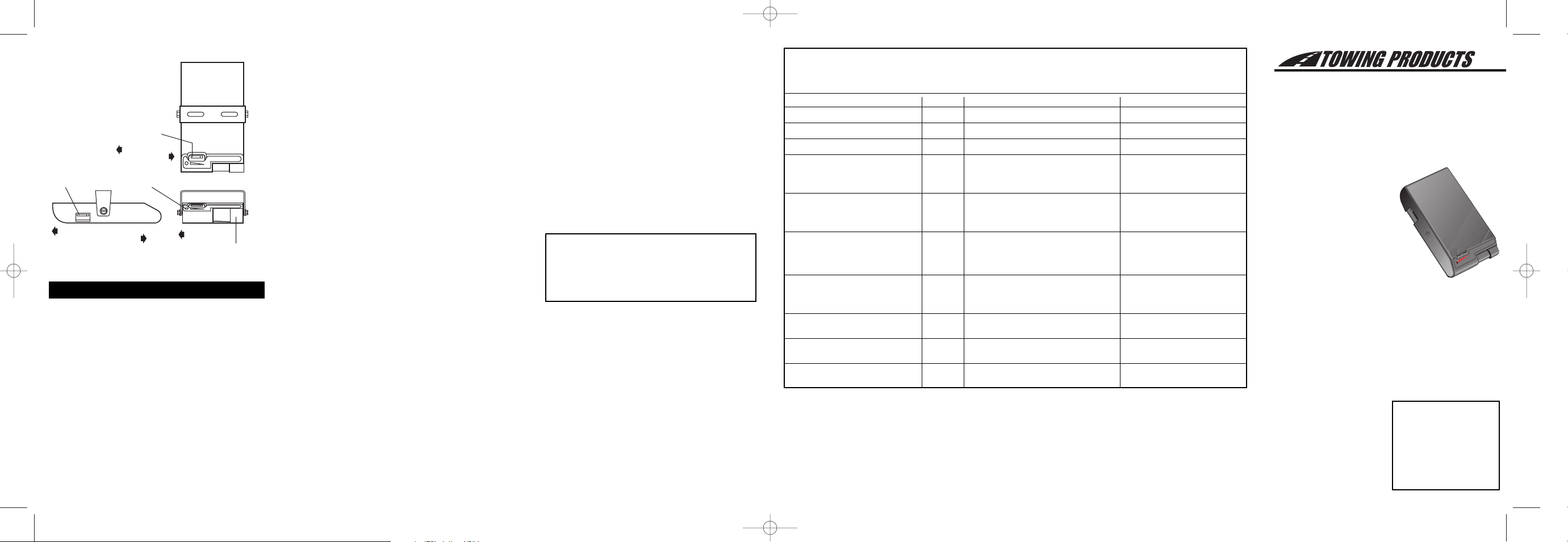

MOUNTING

1. Determine a suitable mounting location.

A) The unit must be mounted securely to a solid

surface.

B) The unit must be easily reached by the driver.

C) The area behind the mounting location must be

clear so nothing will be damaged when drilling.

2. Hold the mounting bracket in the position selected and

mark hole locations through the slots in the bracket.

3. Using a 1/8” dia. bit, drill holes in the marked locations.

4. With a screwdriver or a 1/4” nut driver, secure the

bracket in place using (2) self tapping screws (provided). Be careful not to strip the holes by over-tightening.

5. Mount the brake control unit in the bracket using the other

(2) self tapping screws as shown in the illustration.

WIRING

WARNING: Do not connect the black “BATTERY”

wire to the fuse panel or tie into accessory wiring.

Connecting to existing wiring may damage vehicle

wiring and cause trailer brake failure.

Do not reverse black “BATTERY” wire and white

“GROUND” wire connections. Even a momentary misconnection can damage the brake control unit.

FOR TOW VEHICLES EQUIPPED WITH

FACTORY TRAILER TOWING PACKAGES:

Wire per tow vehicle manufacturer’s instructions.

FOR TOW VEHICLES WITHOUT FACTORY

TRAILER TOWING PACKAGES:

1. Disconnect the tow vehicle’s negative (-) battery cable.

2. Mount a 20 Amp auto-reset circuit breaker (such as

Draw-Tite 18051) as close to the positive (+) battery

terminal as possible. Using 12 GA or larger stranded

05100-037 1/21/03 English 3/6/03 2:00 PM Page 2

+ SYNC -

UNDER DASH

+ SYNC -

TOP OF DASH

IMPORTANT:

Make sure area behind panel

is clear before drilling!

OUTPUT

VERTICAL

ACTIVATOR

Use bracket as template to mark hole locations.

Drill two 1/8" diameter holes and mount bracket

with screws provided.

Mount brake control to bracket using the remaining

two screws.

-

SYNC

+

ANY ANGLE

IMPORTANT: Read and

follow all warnings and cautions

printed on battery.

IMPORTANT: Make sure

White wire goes to

Black wire goes to

connection will damage the

brake control unit.

12 Volt Battery

Red

Wire

Only connect

red wire when

needed. See

instructions

below.

Black

Wire

Sync

Control

Minimum (–)

Output

Control

Maximum

– and

+. Improper

White Wire

Standard 1156

Automotive Bulb

Use a socket or

solder wires to bulb.

Blue Wire

Brake

Control

Manual

Control

Page 3

INSTRUCTIONS POUR L’INSTALLATION ET

L’OPÉRATION DU

CONTRÔLE ÉLETRONIQUE DE FREINAGE POUR

REMORQUES À SYSTEMES DE 2 ET 4 FREINS

IMPORTANT: LISEZ ET

SUIVEZ TOUTES LES

INSTRUCTIONS

FIDELMENT. GARDEZLES DANS VOTRE

VÉHICULE

REMORQUEUR POUR

RÉFÉRENCE

ULTÉRIEUR.

CE NÉCESSAIRE CONTIENT

(1) Dispositif de contrôle de

freinage

(1) Support de montage

(4) Vis pour le montage

(1) Connecteur volant

(1) Fiche de garantie

OUTILS REQUIS:

Ciés diverses

Perceuse avec foret de 1/8”

Pinces pour connecteurs électriques

Vérificateur de circuit

Pinces coupe-fils/à dénuder

Tournevis

MATÉRIEL REQUIS

Néc. de câblage pour contrôle

de freins ou:

Câblage de calibre 12

Disjoncteur à réenclenchement

automatique de 20 A

Cosses à sertir et manchons

connecteurs divers

Colliers de serrage de 4” (6-10)

TOWING PRODUCTS

47774 Anchor Court West

Plymouth, MI 48170

© TOWING PRODUCTS 2003

PRINTED IN CHINA

05100-037 2 of 3 rev. 1/21/03

SECTION 1 – MONTAGE

1. Choisissez un emplacement d’installation convenable.

A) Le dispositif doit être solidement fixe à une surface

solide.

B)Le chauffeur doit avoir un accéss facile au dispositif.

C)L’espace derrière l’emplacement doit être libre de

facon à ce que rien ne soit endommagé lors du

perÇage.

2. Tenez le support de montage dans la position choisie

et marquez l’emplacement des trous au travers des

trous oblongs dans le support.

3. Au moyen d’un foret de 1/8" de diamètre, percez les

trous dans les emplacements marqués.

4. Au moyen d’un tournevis ou d’un tourne-écrous de

1/4", fixez le support en place avec les deux vis auto

taraudeuses (fournies). Faites attention de ne pas

foirer les trous en serrrant trop.

5. Montez le contrôle de freins dans le support au moyen

des deux autres vis auto taraudeuses comme montré

dans l’illustration.

SECTION 2 - CÂBLAGE

AVERTISSEMENT: Ne pas brancher le fil noir

"BATTERY" àla boîte de fusibles ou connecter au

câblage auxiliare. Un branchement au câblage

existant pourrait endommager le câblage du

véhicule ou provoquer une panne des freins de la

remorque.

Ne pas inverser les connexions du fil noir

"BATTERY" et du fil blanc "GROUND". Une mauvais

branchemente même trés bref peut endommager le

dispositif de contrôle de freins.

POUR VÉHICULES REMORQUEURS ÉQUIPÉS D’UN

DISPOSITIF DE REMORQUAGE INSTALLÉ EN

USINE:

Posez les fils selon les directives du manufacturier

du véhicule.

POUR LES VÉHICULES SANS DISPOSITIF DE

REMORQUAGE INSTALLÉ EN USINE:

1. Déterminez quel est le c

ô

t

é

mort de l’interrupteur

des feux d’arr

ê

t. Pour le trouver, faites un essai sur

les bornes de l’interrupteur au moyen d’une

lampe d’essai jusqu’

à

ce que vous trouviez une

borne qui allume seulement lorsqu’on appui sur la

pédale de frein. Marquez le câble mort.

Batterie 12-Volts Du Véhicule Remorqueur

BATT

AUX

Disjoncteur A

Réenclenchement

Automatique De

20 A (Non Fourni)

Ce Contrôle Electronique De Freins Ne Devra

Etre Utilisée Que Sur Des Systèmes De 12 Volts

Avec Mise A La Terre Négative Seulement

IMPORTANT: N'INVERSEZ PAS

LES CONNEXIONS DU CÂBLE NOIR

ET DU CÂBLE BLANC! Vous

endommageriez le dispositif de

contrôle de freins

IMPORTANT: lisez tous les avertissements

et prenez toutes les précautions imprimées

sur la batterie du véhicule remorqueur.

INSTRUCTIONS PARTICULIERES:

Pour les fourgonnettes et camions Ford de Séries

E et F 1989-1991 avec freins antiblocage:

NE CONNECTEZ PAS à l'interrupteur des feux d'arrêt

Connecteur du faisceau des clignotants sous le

tableau de bord près de la colonne de direction.

Epissez le câble rouge du feu d'arrêt au câble

vert pâle au moyen du connecteur volant fourni.

Fil vert

pâle

Connecteur

pour Remorque

Contrôle De Freins

Batterie (+), Noir

Feux d'arrêt, Rouge

Masse (-), Blanc

Frein, Bleu

Connecteur

Volant (Fourni)

Utilisez Câble De

Calibre 12 Ou Plus

Manchons Connecteurs

(Non Fournis)

Interrupteur

des feux d'arrêt

Branchez au côté "mort" (en marche

seulement si on appuie sur le pédale de

frein). Voir étape 9 du câbleage.

IMPORTANT: Pour les véhicules

Ford de Séries E et F de 1989-1991

avec freins antiblocage, voir étape 9,

iet les instructions particulières ci-dessus.

11. Fixez tous les câbles libres au moyen des colliers

de serrage de faÇon

à

ce qu’ils ne soient pas

endommagés. Rebranchez la batterie. Voir le

manuel de propriétaire du véhicule pour les

instructions particuli

è

res de rebranchement.

CONTRÔLE MANUEL

Le contrôle manuel est situédu côtédroit, sur le

devant du dispositif de contrôle de freins.

Le contrôle manuel applique seulement les freins de la

remorque et doit être utilisédans les situations où il

faut lentement r

é

duire la vitesse.

Lorsque le contrôle manuel est poussévers la gauche,

il commence àop

é

rer sur les freins de la remorque.

Plus il est pouss

é

vers la gauche, plus le freinage sera

ferme, jusqu’àatteindre la puissance maximum fixée

par le réglage du contrôle de sortie.

Le contrôle manuel actionne les feux d’arrêt du

v

é

hicule remorqueur et de la remorque ainsi que

l’indicateur de sortie du dispositif de contrôle.

INSTRUCTIONS POUR TESTS EN ATELIER

1. Posez les fils tel qu’indiqué à droite. Réglez le

contrôle de sortie à maximum et le contrôle "Sync" à

minimum.

2. Vérifiez l’activation de la pédale de frein.

Tout en surveillant la lampe d’essai, tenez le câble

rouge sur la borne positive (+) de la batterie

La lampe d’essai devrait s’allumer d’abord faiblement,

puis de plus en plus fortement.

Le voyant lumineux rouge de sortie du contrôle de

frein devrait briller.

Débranchez le câble rouge.

Ajustez le contrôle "Sync" au maximum (+).

Tout en surveillant la lampe d’essai, tenez le fil rouge

sur la borne positive (+) de la batterie.

La lampe d’essai devrait s’allumer fortement sans

délai.

Tout en maintenant le fil rouge sur la borne de la

batterie, faites aller et venir le controle de sortie.

La lampe d’essai devrait suivre le mouvement du

contrôle de sortie, passant d’éclairage fort à faible.

Débranchez le câble rouge.

3. Vérifiez l’activation manuelle:

Réglez le contrôle de sortie à maximum.

Tout en surveillant la lampe d’essai, activez lentement

le contrôle manuel.

La lampe d’essai devrait éclairer d’abord faiblement,

puis de plus en plus fort.

Tout en maintenant le contr

ô

le manuel en mode actif,

faites aller et venir le contr

ô

le de sortie.

La lampe d’essai devrait suivre le mouvement du

contrôle de sortie, passant d’éclairage fort à faible.

4. Si le contr

ô

le de freins ne fonctionne pas comme

expliqué ci-dessus, renvoyez-le pour réparation ou

faites-le remplacer.

Fig. 2

Fig. 2a

e

Fig. 4

05100-037 1/21/03 French 3/6/03 2:01 PM Page 1

+

SYNC–

IMPORTANT: Lisez tous les

avertissements et prenez toutes les

précautions imprimées sur la batterie.

IMPORTANT: Assurez-vous que le

câble Blanc va à (-) et que le câble noir

va à (+). Une mauvaise connexion

endommagera le contrôle de freins.

Batterie 12 V

Câble

Rouge

Connectez le

câble rouge

seulement

quand il y a

besion. Voir

les instructions

à gauche.

Câble

Noir

Contrôle

Sync

Minimum (–)

Contrôle

De Sortie

Maximum

Câble Blanc

Lampe standard d'auto

1156. Utilisez une douill

ou soudez le câbles à

la lampe

Câble Bleu

Contrôle

De Freins

Contrôle

Manuel

Page 4

GUIDE DE LOCALISATION DE LA PANNE

PROBLEME VOYANT CAUSES POSSIBLES SOLUTION

FREINAGE DIFFÉRÉ DE LA REMORQUE OUI MAUVAIS RÉGLAGE DU CONTRÔLE <<SYNC>>

AJUSTER EN POSITION PLUS AGRESSIVE

FREINAGE DE LA REMORQUE TROP RAPIDE OUI MAUVAIS RÉGLAGE DU CONTRÔLE <<SYNC>>

AJUSTER EN POSITION MOINS AGRESSIVE

FREINS DE LA REMORQUE TROP FAIBLES OUI MAUVAIS RÉGLAGE DU CONTRÔLE DE SORTIE AJUSTER POUR PUISSANCE ACCRUE

FREINS DE LA REMORQUE TROP RIGIDES OUI MAUVAIS RÉGLAGE DU CONTRÔLE DE SORTIE AJUSTER POUR PUISSANCE RÉDUITE

PAS DE FREINAGE DE LA REMORQUE PAR NON

PAS DE COURANT AU DISPOSITIF DE CONTRÔLE DE

VÉRIFIER CONNEXIONS À LA BATTERIE, AU DISJONC-

LA PÉDALE OU EN MODE MANUAL

FREINS EN PROVENANCE DU FIL NOIR + DE LA BATTERIE

TEUR, ET AU DISPOSITIF DE CONTRÔLE DE FREINS

R

ÉGLAGE DU CONTRÔLE DE SORTIE TROP BAS

REPRENDRE LES RÉGLAGES (VOIR RÉGLAGES)

PAS DE FREINAGE DE LA REMORQUE PAR OUI (VIF) PAS DE CONEXION AUX FREINS DE REMORQUE

VÉRIFIER CONTACTS DE CONNEXION DE REMORQUE

LA PÉDALE OU EN MODE MANUAL À TRAVERS LE CÂBLE BLEU <<BRAKE>>

VÉRIFIER CONNEXIONS DE CÂBLAGE (VOIR CÂBLAGE)

REMORQUE OU FREINS DE REMORQUE NE SONT

PAS MISES À LA MASSE

VÉRIFIER MISE À LA MASSE

PAS DE FREINAGE DE LA REMORQUE PAR

NON

PAS DE CONNEXION À L’INTERRUPTEUR DES FEUX

VÉRIFIER CONNEXION DE FEUX D’ARRET

LA PÉDALE DE FREINAGE EN MODE MANUEL (PÉDALE)

D’ARRET EN PROVENANCE DU CÂBLE ROUGE <<STOPLIGHT>>

(VOIR CÂBLAGE À L’ÉTAPE 9)

OUI

(MANUEL)

FREINS DE REMORQUE BARRÉS LORSQUE

CÂBLE ROUGE <<STOPLIGHT>> EST CONNECTÉ AU MAUVAIS

VÉRIFIER LA CONNEXION

CONNECTÉS AU CONTRÔLE OUI

CÔTÉ DE L’INTERRUPTOR DES FEUX D’ARRET OU DE LA BATTERIE

(VOIR CÂBLAGE À L’ÉTAPE 9)

INTERRUPTEUR DE D

ÉTACHEMENT ACTIVÉ

VÉRIFIER L’INTERRUPTOR ET CORRIGER

LES FREINS DE REMORQUE SEMBLENT OPÉRER

FAIBLE OU

CONNEXION DE MISE À LA TERRE (CÂBLE BLANC VÉRIFIER LES CONNEXIONS

VACILLANT

<<GROUND>>) DÉFECTUEUSE

FREINAGE DE REMORQUE FAIBLE OU INTERMITTENT FAIBLE OU

COURT-CIRCUIT DE LA CONNEXION DU CÂBLE BLEU <<BRAKE>> DE FREINAGE

REPÉRER ET RÉPARER LE COURT-CIRCUIT

VACILLANT

COURT-CIRCUIT DANS LE CIRCUIT DE FREINAGE DE LA REMORQUE

REPÉRER ET RÉPARER LE COURT-CIRCUIT

SURCHAUFFE DU CONTRÔLE DE FREINS, SENT LE

FAIBLE CONNEXIONS DE CÂBLE NOIR À LA BATTERIE ET

DISPOSITIF DE CONTRÔLE DE FREINS DÉTRUIT CORRIGER

CHAUFFÉ, PEU OU PAS DE PUISSANCE DE FREINAGE

DU CÂBLE BLANC DE MISE À LA TERRE INVERSÉES

LES CONNEXIONES ET REMPLACER LE DISPOSITIF

2. Débranchez le câble négatif (-) de la batterie du

véhicule remorqueur.

3. Installez un disjoncteur àréenclenchement

automatique de 20 A aussi près que possible de la

borne positive (+) de la batterie. Au moyen d’un

câble de calibre 12 ou plus et d’une cosse àsertir

fermée, branchez le côté"BATT" du disjoncteur àla

borne positive de la batterie.

4. Acheminez un câble blanc et un câble noir de calibre

12 ou plus àpartir de l’emplacement du côntrole de

frein jusqu’àl’emplacement de la batterie du véhicule

remorquer.

5. Branchez le câble noir au côté"AUX" du disjoncteur

au moyen d’une cosse àsertir fermée.

6. Branchez le câble blanc au câble négatif de la

batterie au moyen d’une cosse àsertir fermée.

7. Reliez le câble noir "BATTERY +" du côntrole au

câble (noir) branchéàla borne "AUX" du disjoncteur

au moyen d’un manchon connecteur.

8. Connectez le câble blanc "GROUND" du c

ô

ntrole de

frein au câble blanc provenant du câble négatif de la

batterie au moyend’un autre manchon connecteur.

IMPORTANT: un contr

ô

le de freins qui n’est pas

bien mis àla terre peut opérer par intermittences

ou pas du tout. Revérifiez afin de vous assurer que

le câble blanc "GROUND" est connect

éà

la borne

n

é

gative de la batterie et que le câble noir

"BATTERY +" est reli

é

au câble positif de la

batterie.

9. Pour tous le véhicules remorqueurs sauf les

fourgonnettes et les camions Ford, Séries E et F,

1989-91:

Au moyen du connecteur volant fourni, épissez le

câble rouge "STOPLIGHT" du contrôle de freins au

câble reliéau c

ôté

mort del’interrupteur des feux

d’arr

ê

t, tel que décrit a l’

é

tape 1. Allez àl’étape 10.

Pour les fourgonnettes et camions Ford S

é

rie E

et F de 1989-91 avec freins antiblocage: voir la

fig. 2a.

Rep

é

rez le connecteur en forme de croissant sur la

colonne de direction (faisceau de clignotants). II y a 2

rang

é

es de câbles dansce connecteur, une rangée

de 4 câbles (rangée intérieure) et l’autre en a 7. Vous

avez besoin du vert pâle qui est le deux i

è

me

à

partir

de la gauche dans la rang

é

e de 7 câbles (voir la

Fig. 2a).

Au moyen du connecteur volant fourni,

é

pissez le

câble rouge "STOPLIGHT" du c

ô

ntrole de freins au

câble vert pâle.

10. Branchez le câble bleu "BRAKE" du côntrole de

freins au câble de freins de remorque.

CONTRÔLE DE SORTIE

Le contrôle de sortie est situé sur le devant du dispositif

de contrôle de freins, du côté supérieur gauche.

Le contrôle de sortie définit la quantité maximum de

courant disponible pour les freins de la remorque.

Plus le réglage est déplacé vers la gauche, plus il y a de

courant disponible pour les freins lorsqu’on appuie sur la

pédale de freins ou que le contrôle manuel est utilisé.

II faudra ajuster le contrôle de sortie si le chargement de

la remorque augmente, lorsque différentes remorques

sont tirées ou selon les conditions routières.

CONTRÔLE <<SYNC>>

Le contrôle <<sync>> est du côté gauche du dispositif

de contrôle de freins, devant le support de montage. Le

contrôle <<sync>> ajuste l’agressivité du freinage, ou le

temps nécessaire pour atteindre toute la puissance fixée

par le réglage du contrôle de sortie lorsqu’on appuie sur

la pédale de freins.

L’ajustement <<sync>> n’a aucun effet sur le contrôle

manuel.

Les freins seront plus agressifs selon que I’interrupteur

est déplacé vers I’avant du véhicule remorqueur.

Le contrôle <<sync>> sera ajusté selon les préférences

de chaque chauffeur ou selon les conditions routières.

VOYANT DE SORTIE

Le voyant rouge sur le devant du dispositif de contrôle

s’allumera lorsque les freins seront appliqués soit en

utilisant la pédale de frein soit par le contrôle manuel

(avec ou sans remorque attachée). Le voyant sera de

plus en plus brillant au fur et àmesure que la

puissance déployée augmentera.

Le voyant pourra aussi confirmer que l’installation est

conforme.

RÉGLAGES

1. Avec une remorque attachée, fixez le contrôle

<<sync>> àmi-chemin entre + et -. Avec au départ

le contrôle de sortieàla plus faible demande

(conplètemente àdroite), avancez lentement et

arrêtez. Si aucun freinage de la remorque n’est

perÇu, déplacez le contrôle de sortie légèrement

vers la gauche. Répétez l’opération jusqu’àce qu’un

freinage ferme s’applique. Si les freins de la

remorque bloquent ou s’appliquent par à-coups,

ramenez le contrôle de sortie vers la droite

légèrement.

2. Ramenez le contrôle <<sync>> (vers le chauffeur)

sur environ le 1/4 du distance entre le + et -.

3. Faites un essai en faisant plusieurs arrêts. Ajustez

le contrôle <<sync>> jusqu’àce que les arrêts se

fassent fermement et en douceur. Un ajustement

minime du contrôle de sortie peut aussi être

souhaitable.

4. Demandez àquelqu’un de v

é

rifier que les feux

d’arrêt du v

é

hicule et de la remorque fonctionnent

bien lorsque le contrôle manuel est utilisé.

Note: si des problèmes surgissent pendant les

réglages, référez-vous àla section de Localisation

de la Panne de ces instructions.

TRUCS

Une pression légère sur la p

é

dale de frein n’aura que

peu ou pas d’effet sur les freins du véhicule

remorqueur. Ceci est utile pour ralentir graduellement

dans les pentes abruptes ou avant d’arrêter.

Fig. 1

Fig. 3

L’ajustement périodique des contrôles de sortie et <<sync>> peut être nécessaire pour s’adapter aux changement des conditions routières, de

chargements de la remorque, de l’usure des freins ou des préférences du chauffeur.

Sur certains véhicules, le contrôle manuel de freins ne désengagera pas le pilote automatique.

Note: Un voltmètre standard ne montera pas le véritable voltage à la sortie

SECTION 3 - CONTRÔLES

05100-037 1/21/03 French 3/6/03 2:01 PM Page 2

+ SYNC -

EN DESSOUS DU

TABLEAU DE BORD

+ SYNC -

EN DESSUS DU

TABLEAU DE BORD

VERTICAL

OUTPUT

IMPORTANT:

Avant de percer, assurez-vous

que l'espace derrière le panel

soit libre!

Utilisez le support en guise de modèle

pour marquer l'emplacement de trous.

Percez deux trous de 1/8" de diamètre

et montez le support avec les vis fournies.

Montez le contrôle de freins sur le support

au moyen des deux vis restantes.

-

SYNC

+

N'IMPORTE

QUEL ANGLE

CONTRÔLE

CONTRÔLE SYNC

+ SYNC -

Freinage plus agressif

Freinage moins agressif

DE SORTIE

Plus de Sortie

Moins de Sortie

VOYANT

DE SORTIE

OUTPUT

OUTPUT

Appuyez pour

faire marcher

les freins

CONTRÔLE

MANUEL

Page 5

INSTRUCCIONES PARA LA INSTALACION Y

OPERACION DEL

CONTROL DE FRENO ELECTRONICO PARA

REMOLQUES CON SISTEMAS DE 2 Y 4 FRENOS

IMPORTANTE: LEA Y

SIGA CUIDADOSAMENTE ESTAS

INSTRUCCIONES.

GUARDE ESTAS

INSTRUCCIONES EN SU

VEHICULO DE

REMOLQUE PARA REFERENCIA FUTURA.

ESTE PAQUETE INCLUYE:

(1) Unidad de Control de Freno

(1) Soporte de Montaje

(4) Tornillos de Montaje

(1) Conector para Conexion de Cable

(1) Tarjeta de Garantia

HERRAMIENTAS NECESARIAS:

Llaves de diferentes calibres

Taladro con mecha de 1/8" (3,175mm)

Herramienta para plegar conectores de cable

Probador de circuitos con probadores

Cortador/pelador de cables

Destornillador o dado de 1/4"

MATERIALES NECESARIOS:

Juego de Cables para Control

de Freno o:

Cable de calibre 12 o mayor

Cortacircuitos de tipo de

reposicion de 20 amperios

Varios conectores de anillo y

dobles (6-10) Amarres de cable

de 4" (101,6 mm)

TOWING PRODUCTS

47774 Anchor Court West

Plymouth, MI 48170

© TOWING PRODUCTS 2003

PRINTED IN CHINA

05100-037 3 of 3 rev. 1/21/03

SECCIÓN 1 – INSTALACIÓN

1. Encuentre un lugar apropiado para la instalación

A) La unidad debe ser instalada firmemente a una

supsuperficie sólida.

B) La unidad debe estar en un lugar de acceso fácil para

el conductor.

C) El área detrás del lugar de montaje debe estar libre

de objetos, de manera que nada se dañe al hacer los

huecos con el taladro.

2. Sostenga el soporte de montaje en la posición

deseada y marque la posición de los agujeros usando

los agujeros del soporte como guía.

3. Use una mecha de 1/8" (3,175 mm) de diámetro y

taladre los agujeros en los lugares previamente

marcados.

4. Con un destornillador o un dado de 1/4", asegure el

soporte en su lugar usando (2) tornillos autoroscantes

(se proveen). Tenga cuidado de no barrer la rosca al

apretar los tornillos.

5. Instale la unidad de control de freno en el soporte

usando los otros (2) tornillos autoroscantes, así como

se ilustra.

SECCIÓN 2 CABLEADO

ADVERTENCIA: No conecte el cable negro

"BATTERY" al panel de fusibles o al corriente del

cableado de accesorios. Al conectarlo al cableado

existente puede dañar el cableado del vehículo y

causar fallas en los frenos del remolque.

No intercambie las conexiones del cable negro

"BATTERY" y el blanco "GROUND" (TIERRA). La

más mínima conexión momentánea errada puede

dañar la unidad de control de freno.

EN VEHíCULOS QUE TIENEN EQUIPO DE

REMOLQUE DE FÁBRICA:

Haga el cableado de acuerdo a las instrucciones del

fabricante del vehículo de remolque.

EN VEHICULOS QUO NO TIENEN EQUIPO DE

REMOLQUE DE FÁBRICA:

1. Determine cuál lado (terminal) del interruptor de

la luz de freno es el lado muerto. Para determinar

el lado muerto, use una luzde prueba, conéctela

Batería de 12V del Vehículo de Remolque

BATT

AUX

Cortacircuitos de

tipo de reposición

de 20 amperios

(No se provee)

Este Control De Freno Electrónico Debe Ser

Usado Solamente En sistemas De 12 Voltios

Con Negativo A Tierra.

IMPORTANTE: ¡NO INTERCAMBIE

LAS CONEXIONES DE LOS

CABLES BLANCO Y NEGRO!

Esto dañará la unidad de control

de freno.

IMPORTANTE: Lea y siga todas las

fadvertencias y precauciones impresas

en la batería del vehículo de remolque.

INSTRUCCIONES ESPECIALES:

Para camionetas cerradas y camiones Ford (1989-

1991) de la serie E y F con frenos antibloqueantes

En estos vehículos NO CONECTE NADA al interruptor de la luz de freno

El conector que tiene forma de creciente debajo

de la comumna de dirrección (manojo de cables de

las diagonales). Usando el conector a corriente

que se provee, una el cable rojo de control de

freno "STOPLIGHT" (LUZ DE FRENO) al cable

de color verde claro.

Cable

Verde Claro

Conector

del Remolque

Control de Freno

Batería (+) Negro

Luz de Freno Rojo

Tierra (–) Blanco

Freno Azul

Conector a

corriente (Se provee)

Use cable de

calibre 12 o mayor

Conectores Dobles

(no se proveen)

Interruptor de

la luz de freno

Conecte el lado muerto (el que está prendido

solamente cuando el pedal de freno está

presionadso), vea el paso de cableado 9.

IMPORTANTE: Para vehículos Ford

(1989-1991) de la serie E y F con freno

antibloqueantes, vea el paso 9 y las

instrucciones especiales de ariba

lado muerto del interruptor de luz de freno, ya

determinado en el paso 1. Vaya al paso 10.

En camionetas cerradas y camiones Ford

(1989-91) de las series E y F con frenos

antibloqueantes: (Vea la Fig. 2a)

Busque el conector que tiene forma de creciente

debajo de la columna de dirección (manojo de

cables de las diagonales). El conector tiene dos

hileras de cables, una hilera tiene cuatro cables

(hilera interna) y la otra siete.

El cable que se busca es el de color verde claro,

es el segundo de izquierda a derecha en la hilera

de siete cables (vea la Fig.2a)

Usando el conector a corriente que se provee, una

el cable rojo "STOPLIGHT" (LUZ DE FRENO) del

control de freno al cable de color verde claro.

CONTROL DE SINCRONIZACIÓN

El control de sincronización se encuentra localizado en

el lado izquierdo de la unidad de control de freno,

delante del soporte de montaje. El control de

sincronización ajusta la agresividad del freno o el

tiempo que le toma al freno para alcanzar la ganancia

máxima establecida por el control de ganancia cuando

el pedal del freno es presionado.

El ajustar el control de sincronización no tiene efecto

sobre el control manual.

Los frenos se vuelven más agresivo a medida que el

interruptor es movido hacia el frente del vehículo de

remolque.

El control de sincronización deberá ser ajustado de

acuerdo a la preferencia del conductor o al cambio de

las condiciones de la carretera.

que las paradas sean suaves y firmes. Puede que

sea necesario también ajustar un poquito el control

de ganancia.

4. Pídale a alguien que observe las luces de freno

mientras el control manual está activado para así

asegurarse de que las luces de frenado estén

funcionando tanto en el vehículo remolcador como

en el remolque.

Nota: Si ocurren algunos problemas durante el

ajuste, vea la sección de localización de fallas de

éstas instrucciones.

RECOMENDACIONES DE USO

Presión leve en el pedal del freno activará los frenos

del remolque con poco o ningún efecto sobre los

frenos del vehículo de remolque. Esto es necesario

cuando se quiere disminuir la velocidad gradualmente

en una bajada inclinada o antes de paradas.

INSTRUCCIONES DE PRUEBA

EN MESA DE TRABAJO

1. Conecte los componentes así como se ilustra en la

derecha. Ajuste el control de Ganancia al máximo y el

control de Sincronización al minimo.

2. Pruebe la activación del pedal de freno.

Mientras observa el bombillo de prueba, sostenga el

cable rojo en el terminal positivo (+) de la batería.

El bombillo debe prender con una luz opaca y poco a

poco aumentar en brillantez.

El indicador de ganancia (rojo) que se encuentra en el

control de freno debe resplandecer de manera

brillante.

Desconecte el cable rojo.

Ajuste el control de Sincronización al máximo.

Mientras observa el bombillo de prueba, sostenga el

cable rojo en el terminal positivo (+) de la batería.

El bombillo debe prender de manera brillante

inmediatamente.

Con el cable rojo aún en el terminal de la batería,

ajuste el control de ganancia hacia adelante y hacia

atrás. El bombillo de prueba deberá cambiar de

3. Prueba de activación manual:

Ajuste el control de ganancia al máximo.

Mientras observa el bombillo de prueba, active

lentamente el control manual.

El bombillo de prueba debe prender con una luz

opaca y poco a poco aumentar en brillantez a

medida que el control manual es movido.

Mientras tiene el control manual ajustado al máximo,

deslice el control de ganancia hacia adelante y

hacia atrás.

El bombillo de prueba deberá cambiar de brillante a

opaco con el movimiento del control de ganancia.

4. Si la unidad de Control de Freno no funciona como

se ha descrito arriba, regrésela para ser reparada o

reemplazada.

Fig. 2

Fig. 2a

Fig. 4

05100-037 1/21/03 Spanish 3/6/03 2:03 PM Page 1

+

SYNC–

IMPORTANTE: Lea y siga todas

las advertencias y precauciones

impresas el la batería

IMPORTANTE: Asegúrese de que el

Blanco vaya conectado al (-) y de que

el Negro vaya al (+). Malas conexiones

dañarán la unidad de control de freno.

BATERÍA DE 12 VOLTIOS

Cable

Rojo

Conecte el

cable rojo

solo cuando

sea necessario

Vea las

instrucciones

en la izquierda

Cable

Negro

Control de

Sincronización

Minimo (–)

Control de

Ganancia

Máximo

Cable Blanco

Automotriz Común #1156.

Use un enchufe o suelde

los cables al bombillo

Cable Azul

Control

de Freno

Control

Manual

Page 6

GUÍA DE LOCALIZACIÓN DE FALLAS

PROBLEMA LUZ POSIBLES CAUSAS SOLUCIÓN

EL FRENADO DEL REMOLQUE ES LENTO ENCENDIDA AJUSTE INCORRECTO DE SINCRONIZACIÓN

ADJúSTELO A UNA POSICIÓN MÁS AGRESIVA

LOS FRENOS DEL REMOLQUE SE ACTIVAN MUY RÁPIDO

ENCENDIDA AJUSTE INCORRECTO DE SINCRONIZACIÓN

ADJúSTELO A UNA POSICIÓN MENOS AGRESIVA

EL FRENADO DEL REMOLQUE ES DÉBIL ENCENDIDA AJUSTE INCORRECTO DE GANANCIA INCREMENTE LA GANANCIA

EL FRENADO DEL REMOLQUE ES MUY FUERTE ENCENDIDA AJUSTE INCORRECTO DE GANANCIA DISMINUYA LA GANANCIA

EL REMOLQUE NO FRENA--AL USAR EL PEDAL APAGADA

LA UNIDAD NO ESTÁ RECIBIENDO VOLTAJE A TRAVÉS

REVISE LAS CONEXIONS EN: LA BATERÍA, EL

O EL CONTROL MANUAL

DEL CABLE NEGRO “BATTERY”

CORTACIRCIOTOS Y EL CONTROL DE FRENO

LA GANANCIA AJUSTADA A UN NIVEL MUY BAJO

REAJUSTE (VEA AJUSTE)

EL REMOLQUE NO FRENA--AL USAR EL PEDAL ENCENDIDA

NO HAY CONEXIÓN A LOS FRENOS DEL REMOLQUE A TRAVÉS DEL

REVISE LOS CONTACTOS DEL CONECTOR DEL REMOLQUE

O EL CONTROL MANUAL (BRILLANTE)

CABLE CABLE AZUL “BRAKE” (FRENO)

REVISE LAS CONEXIONES DE LOS CABLES (VEA EL CABLEDO

EL REMOLQUE O LOS FRENOS DEL REMOLQUE NO TIENEN

REVISE LAS CONEXIONES A TIERRA DEL REMOLQUE Y DE

CONEXIÓN A TIERA

LOS FRENOS

EL REMOLQUE NO FRENA AL USAR EL PEDAL DEL

APAGADA NO HAY LA CONEXIÓN ENTRE EL INTERRUPTOR DE

REVISE LA CONEXIÓN DE LA LUZ DE FRENO

FRENO, EL CONTROL MANUAL FUNCIONAE (PEDAL) LUCES D FRENO Y EL CABLE ROJO “STOPLIGHT”

(VEA CABLEADO PASO 9)

PRENDIDA

(MANUAL)

LOS FRENOS DEL REMOLQUE SE TRANCAN

EL CABLE ROJO “STOPLIGHT” ESTÁ CONECTADO AL LADO

REVISE LA CONEXIÓN (VEA CABLEADO PASO 9)

CUANDO SE CONECTAN AL CONTROL ENCENDIDA

EQUIVOCADO DEL INTERRUPTOR DE LUZ DE FRENO O A LA BATERÍA

EL INTERRUPTOR DE SEPARACIÓN ESTÁ ACTIVADO

REVISE EL INTERRUPTOR Y CORRIJA EL PROBLEMA

LOS FRENOS DEL REMOLQUE PARECE QUE

PÁLIDA O

MALA CONEXIÓN DEL CABLE BLANCO “GROUND” REVISE LAS CONEXIONES

ESTÁN FUNCIONANDO

INCONSTANTE

EL FRENADO DEL REMOLQUE ES DÉBIL O INCONSISTENTE

PÁLIDA O

HAY UN CORTO EN EL CIRCUITO DEL CABLE AZUL “BRAKE” (FRENO)

LOCALICE EL CORTO Y CORRÍJALO

INCONSTANTE

HAY UN CORTO EN EL CIRCUITO DEL FRENO DEL REMOLQUE

LOCALICE EL CORTO Y REPÁRELO

EL CONTROL DE FRENO SE RECALIENTA, HUELE A

PALIDA

LAS CONEXIONS DEL CABLE NEGRO “BATTERY +” Y EL

LA UNIDAD DE CONTROL DE FRENO SE HA DAÑADO, CORRIJA

QUEMADO, HAY POCA O NINGUN POTENCIA DE FRENADO

BLANCO (-) “GROUND” SE ENCUENTRAN INTERCAMBIADAS

EL PROBLEMA DEL CABLEADO Y REEMPLACE LA UNIDAD

a un terminal del interruptor y presione el pedal del

freno, repita este procedimiento en el otro terminal.

El lado muerto será aquel terminal en el cual la luz

se encienda cuando el pedal de freno esté

presionado.

2. Desconecte el terminal negativo (-) de la batería

del vehículo.

3. Instale un cortacircuitos de tipo de reposición de 20

amperios tan cerca como sea posible al terminal

positivo (+) de la batería. Use un cable de cordón de

calibre 12 o mayor y pliegue (2) terminales de anillo

al mismo. Use este cable para conectar el lado que

dice "BATT" del cortacircuitos al terminal positivo (+)

de la batería.

4. Conecte un cable de cordón negro y otro blanco, de

calibre 12 o mayor, desde el lugar de instalación del

control de freno hasta el área de la batería del

vehículo de remolque.

5. Conecte el cable negro al lado "AUX" del

cortacircuitos usando un terminal de anillo.

6. Conecte un terminal de anillo al cable blanco y

conéctelo al cable negativo de la batería.

7. Una el cable negro de control "BATTERY +" al

cable (negro) conectado al terminal "AUX" del

cortacircuitos, use un conector doble.

8. Conecte el cable de control blanco "GROUND"

(TIERRA) al cable (blanco) que va conectado al

lado negativo de la batería, use un conector

doble.

ADVERTENCIA: Un control de freno que no está

conectado a tierra adecuadamente puede que no

funcione o que funcione de manera intermitente.

Revise el cable blanco "GROUND" (TIERRA) y

asegúrese de que está conectado al cable negative

(-) de la batería y de que el cable negro "BATTERY

(+)" está conectado al cable positivo (+) de la

batería.

9.

En vehículos de remolque diferentes a las

camionetas cerradas o camiones Ford de las

series E y F de 1989-91:

Usando el conector a corriente que se provee, una el

cable rojo "STOPLIGHT" (LUZ DE FRENO) del

control de freno al cable que se encuentra unido al

10. Conecte el cable azul "BRAKE" (FRENO) al cable de

freno del remolque.

11. Para evitor daño o maltrato a los cables, asegure

todos los cables que se encuentren guindando

usando los amarres que se proveen. Reconecte la

batería.

Refiérase al manual de instrucciones de

vehículo para obtener las instrucciones

especiales de reconexión.

SECCIÓN 3 - CONTROLES

CONTROL DE GANANCIA

El control de ganancia se encuentra localizado en

la parte frontal de la unidad de control de freno, en la

parte superior izquierda.

La función del control de ganancia es la de establecer el

monto máximo de potencia disponible para los frenos

del remolque.

Si el control es movido hacia la izquierda, más potencia

estará disponible para los frenos cuando el pedal del

freno sea presionado o cuando el control manual sea

usado.

El control de ganancia deberá ser ajustado cuando el

peso de la carga varíe, cuando diferentes remolques

sean usados o cuando las condiciones de la carretera

cambien.

CONTROL MANUAL

El control manual se encuentra localizado al lado

derecho de la parte frontal de la unidad de control de

freno.

El control manual se aplica solamente a los frenos del

remolque y debería ser usado cuando se desee reducir

la velocidad lentamente.

Cuando el control manual es movido hacia la

izquierda, el control comienza a activar los frenos del

remolque. A medida que se mueva más hacia la

izquierda, los frenos serán aplicados de manera más

fuerte hasta que se llegue al nivel máximo establecido

por el control de ganancia.

El control manual activa las luces de freno del vehículo

de remolque, del remolque y el indicador de ganancia

que se encuentra en la unidad de control.

INDICDOR DE GANANCIA

La luz indicadora roja que se encuentra en el frente de

la unidad de control se encenderá cuando los frenos

sean aplicados ya sea usando el pedal del freno o el

control manual (con o sin el remolque unido al

vehículo). El indicador producirá un brillo opaco y

luego aumentará a medida que la ganancia aumente.

La luz indicadora también ayudará a confirmar que la

instalación ha sido hecha apropiadamente.

AJUSTE

1. Con el remolque conectado, ajuste el control de

sincronización en el medio de (+) y (-). Comenzando

con el control de ganancia en la posición más baja

(todo hacia la derecha) muévalo hacia adelante

lentmente y luego pare. Si no siente que los frenos

están siendo aplicados, ajuste el control de

ganancia un poquito hacia la izquierda. Repita este

procedimiento hasta que sienta que los frenos del

remolque están siendo aplicados firmemente. Si los

frenos del remolque se trancan o tironean, ajuste

otra vez la ganancia un poquito hacia la derecha.

2. Mueva el control de sincronización hacia atrás

(hacia el conductor) aproximadamente a π de la

distancia entre (+) y (-).

3. Realice un manejo de prueba haciendo varias

paradas. Ajuste el control de sincronización hasta

+ SYNC -

OUTPUT

OUTPUT

CONTROL DE

GANANCIA

Más Ganancia

Menos Ganancia

INDICADOR

DE GANANCIA

CONTROL DE

SINCRONIZACIÓN

CONTROL

MANUAL

Frenado Más Agresivo

Frenado Menos Agresivo

Presione para

Aplicar los Frenos

del Remolque

Fig. 1

Fig. 3

Ajuste periódico de los controles de Sincronización y Ganancia será necesario cuando las condiciones de la carretera veríen,

la carga del remolque varíe, los frenos empiecen a desgastarse y/o de acuerdo a la preferencia del conductor.

En algunos vehículos, el uso del control manual del control de freno no desactivará el "Control de Crucero".

Nota: Un voltímetro común no mostrará la verdadera salida de voltaje

brillante a opaco al momento que el control de

ganancia es movido. Desconecte el cable rojo.

05100-037 1/21/03 Spanish 3/6/03 2:03 PM Page 2

+ SYNC -

SYNC

DEBAJO DEL TABLERO

+ SYNC -

ENCIMA DEL TABLERO

+

VERTICAL

OUTPUT

IMPORTANTE:

¡Asegúrese de que el área detrás

del panel esté libre de objetos antes

Use el soporte como guía para marcar

la posición de los agujeros

Taladre dos agujeros de 1/8" (3,175 mm) de

diámetro e instale el soporte de montaje

usando los tornillos que se proveen.

Instale el control de freno al soporte usando

los dos tornillos restantes.

de taladrar!

-

A CUALQUIER

ANGULO

Loading...

Loading...