Digestion Furnace Operating Instructions

DW-KDN-08D

Drawell International Technology Limited

Shanghai Drawell Scientific Instrument Co.,Ltd

Add :Suite 1506,Lane581 XiuChuan Rd.,PuDong New Area,Shanghai,China

Tel/ Fax: 0086 21 50966080

Web : www.drawell.com.cn

Email : sales01@drawell.com.cn

1

CONTENTS

Security warning ......................................................................................... 3

Introduction ................................................................................................. 5

1.Features .............................................................................................. 5

2.Technical Parameters ......................................................................... 5

Method of connection of digester furnace .................................................. 6

Digestion furnace temperature control ....................................................... 6

1.Temperature control instrument button description: ......................... 6

2.Temperature setting: .......................................................................... 7

Method of operation .................................................................................... 7

Precautions .................................................................................................. 8

List of attachments ...................................................................................... 9

2

Respected customers:

Thank you for choosing our company's products. In order to obtain satisfactory results, please

read the product manual carefully before starting the machine. If you have any questions, please

contact us in time. We will serve you wholeheartedly!

The instruction manual of this product is completed by the company's technicians, and we

strive to make the content of this manual clear, popular and understandable, if you feel the

intention is not expressed, and also ask the experts to find the question in the course of use or to

give the message, please give the message, and we express our heartfelt thanks for it.

Shanghai Drawell Scientific Instruments Co., Ltd.

Tel:0086 21 50966080

Security warning

Danger!!! May constitute property damage or personnel injury, please use as required!

SPECIAL POWER SOURCE GND

FLAMMABLE AND EXPLOSIVE

No RENOVATION

a. Please use the power supply and voltage conforming to the requirements of this product.

b. The voltage of this device is AC220V/50HZ.

c. The product must be grounded reliably and away from the electromagnetic interference

source.

d. The product should use an independent power socket, and confirm that the plug and socket

are well grounded.

e. It is not allowed to unplug or plug in the power switch without turning off the power

switch in operation.

3

f. The repair shall not be carried out without authorization, and the company must be

instructed by the professional to repair it.

g. The working environment requires no dust, inflammable and explosive gas.

h. The working environment temperature is 10 --45 degrees, relative humidity is less than

80%.

i. The instrument must be installed in a place without direct sunlight.

j. The reagent and other solutions are corrosive, and should be equipped with protective

equipment and safe operation during operation.

4

Introduction

1.Features

a. The heating body (module) adopts the infrared quartz tube, which can withstand strong acid and

alkali, and prevent explosion and long life.

b. The heat area of the digestive tube is large, the temperature difference is small, the sample

digestion is good, and the thermal efficiency is high.

c. Temperature control adopts a new generation of digital display temperature control device.

d. Beautiful appearance, light structure and easy to use.

2.Technical Parameters

a. Determination quantity: 8 / batch;

b. Measurement of sample size: the solid is less than 5g, and the liquid is less than 20ml/;

c. Capacity of digestive tube: 300ml standard;

d. Determination range :240mgN;

e. Temperature control range:at room temperature to 550 ℃;

f. Heating rate: 30 degrees /min;

g. Temperature control accuracy:±1℃

h. Power consumption: digester (8 holes 2000W);

i. Power source: 220 (V) + / -10%, 50~60HZ;

j. Appearance size: 435*270*225 (mm);

k. Weight: 8.6kg;

In accordance with the principle of the kjeldahl method, the apparatus is widely used in the

digestion of food, feed, food, dairy products, beverage, soil, water, medicine, sediment and

chemical. Test precision, safe and reliable, easy to operate, the harmful gas such as SO2 of

digestive tube overflow at the same time, through the digestive sewage collection on the furnace

tube through the suction filter pump from the water into the sewer, and effectively restrain the

harmful gas to escape.

5

Method of connection of digester furnace

Extraction tee A side with A rubber hose connection with faucet, B side with A rubber hose

connected to the exhaust gas absorption nozzle, C termination rubber hose into the sewer, B end

connection rubber hose shoulds not be too long, digest sewage water flow should be properly (3-4

l/min), to ensure that the suction tee suction, exhaust gas and water together in the sewage (besides

the icon on the mating method is adopted, my company is also equipped with A high matches

connection method: adopt vacuum pumps, filters, and exhaust gas absorption equipment through

rubber hose connection. The filter contains 500-1000ml of lye, which is neutralized by harmful

gases such as SO2, which can be used to filter the harmful substances of adsorption particles.

Digestion furnace temperature control

D-type digital digestion oven, using a new generation of digital temperature controller to

control the digester heating, can display the target temperature and the actual temperature value,

the user can change the heating temperature according to actual needs.

1.Temperature control instrument button description:

a. "PV" display window: shows the current temperature value;

b. "SV" display window: display the new parameter value after setting the

value and the self-defined value;

c. " " mode menu key: set the temperature value / enter the instrument to view, set parameters,

temperature control

6

confirm and modify the parameters have been set.

d. "AT" self-adjusting indicator: The instrument activates self-adjusting function keys;

e. "OUT" master output indication: light during heating;

f. "ALM" signal indicator;

g. " " " " Addition and Subtraction Key: When setting parameters, it is used to increase or

decrease the value.

2.Temperature setting:

Press “ ” key, when “SP” appears in “PV” window, press “ ” and “ ” to increase or

decrease according to the required temperature value. When the value of “ ” display window

reaches the required temperature value, ie After the setting is completed, press " " to confirm.

Method of operation

a. Put the digestive tube containing samples in vitro digestion rack, will waste gas in the in

vitro digestion absorption equipment rack (hands holding a waste gas absorption bottle, to absorb

the gas bottle seal on the digestive tube, cover can.)

b. According to the above diagram, connect the tap water and the pumping pump, and pay

attention to the proper water flow (3/4l /min). First pick good extraction tee (the suction filter

pump), adjust flow after connected to the gas absorption tube (besides using standard, our

company also with another high matches: vacuum pumps, filters, and exhaust gas absorption

equipment connection. This method can neutralize the harmful gases such as SO2, which is easier

to operate.

c. Connect the power cord in the fitting, open the main switch of the ship type power supply,

the temperature instrument is bright, and the first infrared quartz tube is energized to start the work;

Press the power switch 1, and the second infrared quartz tube begins to heat; Press the power

switch 2 the third infrared quartz tube begins to heat.

d. According to the instrument instructions and set the temperature in two stages: first of all,

first set to a temperature of 200 degrees, after reaching the temperature continue to heat the 20-30

min, and then reset the temperature continue heating 30 to 60 min after 450 degrees, then the

sample will gradually stop boiling, and then began to change color, when the sample color

becomes completely transparent blue-green liquid continue heating 10-20 min, after digestion to

complete at this time.(such as moisture content is exorbitant, heating of the digestive wall with

black objects, to extend the heating time until the color of the sample becomes transparent

blue-green liquid)

Generally, the time required is 60-90min from the boot to the sample, which is determined

according to the sample (the higher the nitrogen content, the longer the digestion time).

e. After the digestion is completed, it will be moved to the test tube cooling rack together

with the tube digester and exhaust gas absorption device.

7

Precautions

a. The first answer extraction tee (suction filter pump) guarantee extraction tee three interface

flow state of the suction filter pump) and figure B side hole must be kept with A, C and inner hole,

to ensure that the digestive tube exhaust gas can be siphoned off, if there is A gas leak is more, you

can check here for the suction filter pump is normal, can rotate B side to adjust its position.

b. When installing exhaust gas absorption bottle, pay attention to the sealing ring of the

sealing ring and the digestive pipe joint to prevent the waste gas from overflowing. (when taking

the exhaust gas absorption bottle, first pour the bottle to one side and then take it off the whole, so

as to avoid the pressure to bring the digestive tube together with the accident.)

c. Since the location of the alimentary canal digestion process, the surrounding and the

temperature of the center position is a bit poor, so some sample color change first appeared in the

process of digestion, these all belong to normal phenomenon, at the same time in order to ensure

the digest completely, may be extended appropriately digestion time or increase the heating

temperature.

d. After the digestion is completed, the water source cannot be closed during the cooling

phase, otherwise there will be residual waste gas overflow.

8

List of attachments

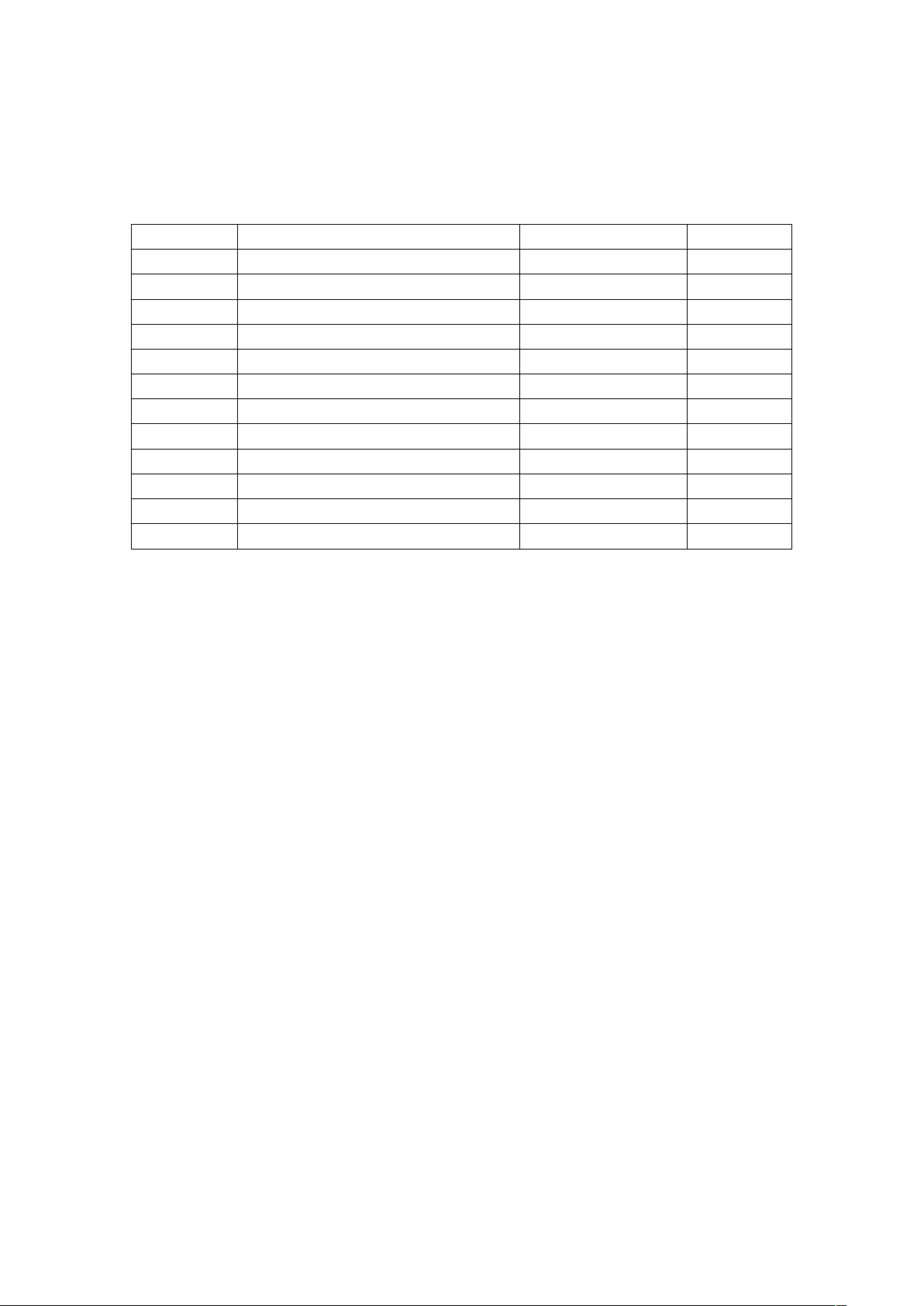

NO. Designation Specifications Quantity

1 Digester Host 1

2 Digestive tube stent 8 holes 1

3 Digestive tube cooling rack 8 holes 1

4 Digestive tube Φ40*300mm 8

5 Exhaust absorption Φ50*280mm 2

6 Exhaust gas absorption bottle seal Φ55*28mm 8

7 Extraction tee Teflon 1

8 Power cable AC 220 1

9 Y type tee PC tube 1

10 Fuse tube 10A 2

11 6*11 Rubber tube Meter 4

12 Certification Sheet 1

9

Drawell International Technology Limited

Shanghai Drawell Scientific Instrument Co.,Ltd

Add :Suite 1506,Lane581 XiuChuan Rd.,PuDong New Area,Shanghai,China

Tel/ Fax: 0086 21 50966080

Web : www.drawell.com.cn

Email : sales01@drawell.com.cn

Loading...

Loading...