230V 228mm / 305mm / 340mm

BANDSAW

98446 / 84714 / 84715

Please note that model number 84714 is illustrated throughout this instruction booklet.

These instructions accompanying the product are the original instructions. This document is part of the product,

keep it for the life of the product passing it on to any subsequent holder of the product. Read all these instructions

before assembling, operating or maintaining this product.

This manual has been compiled by Draper Tools describing the purpose for which the product has been designed,

and contains all the necessary information to ensure its correct and safe use. By following all the general safety

instructions contained in this manual, it will ensure both product and operator safety, together with longer life of the

product itself.

AlI photographs and drawings in this manual are supplied by Draper Tools to help illustrate the operation of the

product.

Whilst every effort has been made to ensure the accuracy of information contained in this manual, the Draper Tools

policy of continuous improvement determines the right to make modifications without prior warning.

1. TITLE PAGE

1.1 INTRODUCTION

USER MANUAL FOR: 230V 228mm / 305mm / 340mm Bandsaw

Stock Nos: 98446 / 84714 / 84715

Part Nos: BS228/300D / BS305 / BS340/1100D

1.2 REVISION HISTORY

Date first published: July 2020.

Revised: August 2021.

As our user manuals are continually updated, users should make sure that they use

the very latest version.

Downloads are available from: http://drapertools.com/manuals

Draper Tools Limited

Hursley Road

Chandler’s Ford

Eastleigh

Hampshire

SO53 1YF

UK

Website: drapertools.com

Product help line: +44 (0) 23 8049 4344

General Fax: +44 (0) 23 8026 0784

1.3 UNDERSTANDING THIS MANUAL’S SAFETY CONTENT

WARNING! – Information that draws attention to the risk of injury or death.

CAUTION! – Information that draws attention to the risk of damage to the product or surroundings.

1.4 COPYRIGHT © NOTICE

Copyright © Draper Tools Limited.

Permission is granted to reproduce this publication for personal and educational use only.

Commercial copying, redistribution, hiring or lending is prohibited.

No part of this publication may be stored in a retrieval system or transmitted in any other form or

means without written permission from Draper Tools Limited.

In all cases this copyright notice must remain intact.

– 2 –

2. CONTENTS

2.1 CONTENTS

1. TITLE PAGE

1.1 INTRODUCTION ................................................................................................................. 2

1.2 REVISION HISTORY ........................................................................................................... 2

1.3 UNDERSTANDING THIS MANUAL’S SAFETY CONTENT ................................................ 2

1.4 COPYRIGHT © NOTICE ..................................................................................................... 2

2. CONTENTS

2.1 CONTENTS ......................................................................................................................... 3

3. WARRANTY

3.1 WARRANTY ........................................................................................................................ 5

4. INTRODUCTION

4.1 SCOPE ................................................................................................................................ 6

4.2 SPECIFICATION ................................................................................................................. 6

4.3 HANDLING AND STORAGE ............................................................................................... 6

5. HEALTH AND SAFETY INFORMATION

5.1 GENERAL SAFETY INSTRUCTIONS FOR POWER TOOL USE ....................................... 7

5.2 SPECIFIC SAFETY INSTRUCTION FOR BANDSAW USE ................................................ 8

5.3 RESIDUAL RISK ................................................................................................................. 9

5.4 CONNECTION TO THE POWER SUPPLY ....................................................................... 10

6. TECHNICAL DESCRIPTION

6.1 IDENTIFICATION ...............................................................................................................11

7. UNPACKING AND CHECKING

7.1 PACKAGING ...................................................................................................................... 12

7.2 WHAT’S IN THE BOX ........................................................................................................ 12

8. PREPARING THE BANDSAW

8.1 INSTALLING THE TABLE .................................................................................................. 13

8.2 LEVELLING THE TABLE ................................................................................................... 13

8.3 RIP FENCE RAIL ............................................................................................................... 13

8.4 RIP FENCE ........................................................................................................................ 14

8.5 DUST EXTRACTION OUTLET .......................................................................................... 14

8.6 DUST TRAY ....................................................................................................................... 14

9. OPERATING THE BANDSAW

9.1 NO-VOLT ON/OFF SWITCH ............................................................................................. 15

9.2 LED WORKLIGHT ............................................................................................................. 15

9.3 TILTING THE TABLE ......................................................................................................... 15

9.4 UPPER AND LOWER DOORS .......................................................................................... 16

9.5 BLADE GUARD SLIDE ADJUSTMENT ............................................................................. 16

9.6 TENSIONING THE BLADE ............................................................................................... 17

9.7 CHANGING AND SETTING THE NEW BLADE ................................................................ 17

9.8 TRACKING THE BLADE ................................................................................................... 18

9.9 ADJUSTING THE UPPER BLADE GUIDE ASSEMBLY .................................................... 18

9.10 IF REQUIRED TO ADJUST THE LOWER BLADE GUIDES ........................................... 19

9.11 MITRE GUIDE ................................................................................................................. 19

9.12 SETTING THE BLADE SPEED ....................................................................................... 19

– 3 –

2. CONTENTS

10. TIPS ON USING YOUR BANDSAW

10.1 USEFUL TIPS .................................................................................................................. 20

11. TROUBLESHOOTING

11.1 TROUBLESHOOTING GUIDE......................................................................................... 21

12. MAINTENANCE

12.1 SLIDE ADJUSTMENT ..................................................................................................... 22

13. EXPLANATION OF SYMBOLS

13.1 EXPLANATION OF SYMBOLS ....................................................................................... 23

14. DISPOSAL

14.1 DISPOSAL ....................................................................................................................... 23

– 4 –

3. WARRANTY

3.1 WARRANTY

Draper tools have been carefully tested and inspected before shipment and are guaranteed to be

free from defective materials and workmanship.

Should the tool develop a fault, please return the complete tool to your nearest distributor or

contact

Draper Tools Limited, Chandler’s Ford, Eastleigh, Hampshire, SO53 1YF. England.

Telephone Sales Desk: (023) 8049 4333 or Product Help Line (023) 8049 4344.

A proof of purchase must be provided with the tool.

If upon inspection it is found that the fault occurring is due to defective materials or workmanship,

repairs will be carried out free of charge. This warranty period covering parts is 24 months and

labour is 12 months from the date of purchase except where tools are hired out when the warranty

period is 90 days from the date of purchase. This warranty does not apply to any consumable

parts, any type of battery or normal wear and tear, nor does it cover any damage caused by

misuse, careless or unsafe handling, alterations, accidents, or repairs attempted or made by any

personnel other than the authorised Draper warranty repair agent.

Note: If the tool is found not to be within the terms of warranty, repairs and carriage charges will

be quoted and made accordingly.

This warranty applies in lieu of any other warranty expressed or implied and variations of its terms

are not authorised.

Your Draper warranty is not effective unless you can produce upon request a dated receipt or

invoice to verify your proof of purchase within the warranty period.

Please note that this warranty is an additional benefit and does not affect your statutory rights.

Draper Tools Limited.

– 5 –

4. INTRODUCTION

4.1 SCOPE

This machine is designed to cut wood, wood derived materials and plastics by means of a

revolving endless saw band which is carried on two band wheels. The work piece is manual fed on

to the saw band.

4.2 SPECIFICATION

STOCK NOS. ............................................................................................... 98446 / 84714 / 84715

PART NOS. ............................................................................. BS228/300D / BS305 / BS340/1100D

MOTORS:

RATED VOLTAGES .......................................................................................................... 230V~

RATED FREQUENCIES .....................................................................................................50HZ

RATED INPUTS .......................................................................................300W / 750W / 1100W

SPEEDS (NO LOAD) .................................................................................................. 1400RPM

MAXIMUM THROAT CAPACITIES .......................................................... 228MM / 305MM / 340MM

CUTTING DEPTHS ......................................................................... 90MM / 165MM / 225MM AT 90°

MAXIMUM CAPACITIES UNDER GUIDES ............................................ 125MM / 172MM / 205MM

TABLE SIZES ..................................300 X 300 MM / 390 X 480 MM / 545 X 515 MM (TILT TO 45°)

BLADE SPEEDS ........................................................................... 98446 – 10.6M/SEC (635M/MIN)

............................................. 84714 / 84715 – 6.16M/SEC & 13.33M/SEC (370M/MIN & 800M/MIN)

BANDSAW BLADE LENGTHS .......................................................... 1575MM / 2240MM / 2560MM

SOUND PRESSURE LEVELS .......................................................................................... 83.7dB(A)

SOUND POWER LEVELS ................................................................................................ 70.7dB(A)

WEIGHTS (NETT) ............................................................................................. 19KG / 57KG / 74KG

4.3 HANDLING AND STORAGE

– Care must be taken when handling this product.

• Dropping this power tool could have an effect on its accuracy and could also result in

personal injury. This product is not a toy and must be respected.

– Environmental conditions can have a detrimental effect on this product if neglected.

• Exposure to damp air can gradually corrode components.

• If the product is unprotected from dust and debris, components will become clogged.

• If not cleaned and maintained correctly or regularly, the machine will not perform at its best.

– 6 –

5. HEALTH AND SAFETY INFORMATION

5.1 GENERAL SAFETY INSTRUCTIONS FOR POWER TOOL USE

When using any type of power tool there are steps that should be taken to make sure that you,

as the user, remain safe.

Common sense and a respect for the tool will help reduce the risk of injury.

Read the instruction manual fully. Do not attempt any operation until you have read and

understood this manual.

Most important you must know how to safely start and stop this machine, especially in an

emergency.

Keep the work area tidy and clean. Attempting to clear clutter from around the machine during

use will reduce your concentration. Mess on the floor creates a trip hazard. Any liquid spilt on the

floor could result in you slipping.

Find a suitable location. If the machine is bench mounted the location should provide good

natural light or artificial lighting as a replacement. Avoid damp and dust locations as it will have a

negative effect on the machine’s performance. If the machine is portable do not expose the tool to

rain. In all cases do not operate power tools near any flammable materials.

Keep bystanders away. Children, onlookers and passers by must be restricted from entering the

work area for their own protection. The barrier must extend a suitable distance from the tool user.

Unplug and house all power tools that are not in use. A power tool should never be left unattended

while connected to the power supply. They must be housed in a suitable location, away locked up

and from children. This includes battery chargers.

Do not overload or misuse the tool. All tools are designed for a purpose and are limited to what

they are capable of doing. Do not attempt to use a power tool (or adapt it in any way) for an

application it is not designed for. Select a tool appropriate for the size of the job. Overloading a tool

will result in tool failure and user injury. This covers the use of accessories.

Dress properly. Loose clothing, long hair and jewellery are all dangerous because they can

become entangled in moving machinery. This can also result in parts of body being pulled into the

machine. Clothing should be close fitted, with any long hair tired back and jewellery and neck ties

removed. Footwear must be fully enclosed and have a non-slip sole.

Wear personal protective equipment (PPE). Dust, noise, vibration and swarf can all be

dangerous if not suitably protected against. If the work involving the power tool creates dust or

fumes wear a dust mask. Vibration to the hand, caused by operating some tools for longer periods

must be protected against. Wear vibration reducing gloves and allow long breaks between uses.

Protect against dust and swarf by wearing approved safety goggles or a face shield. These are

some of the more common hazards and preventions however, always find out what hazards are

associated with the machine/work process and wear the most suitable protective equipment

available.

Do not breathe contaminated air. If the work creates dust or fumes connect the machine

(if possible) to an extraction system either locally or remotely. Working outdoors can also help if

possible.

Move the machine as instructed. If the machine is hand held, do not carry it by the power supply

cable. If the product is heavy, employ a second or third person to help move it safely or use a

mechanical device. Always refer to the instructions for the correct method.

Do not overreach. Extending your body too far can result in a loss of balance and you falling.

This could be from a height or onto a machine and will result in injury.

Maintain your tools correctly. A well maintained tool will do the job safely. Replace any damaged

or missing parts immediately with original parts from the manufacturer. As applicable keep blades

sharp moving parts clean, oiled or greased handles clean and emergency devices working.

– 7 –

5. HEALTH AND SAFETY INFORMATION

Wait for the machine to stop. Unless the machine is fitted with a safety brake, some parts may

continue to move due to momentum. Wait for all parts to stop, then unplug it from the power supply

before making any adjustments, carrying out maintenance operations or just finishing using the

tool.

Remove and check setting tools. Some machinery requires the use of additional tools or keys to

set, load or adjust the power tool. Before starting the power tool always check to make certain they

have been removed and are safely away from the machine.

Prevent unintentional starting. Before plugging any machine in to the power supply, make sure

the switch is in the OFF position. If the machine is portable, do not hold the machine near the

switch and take care when putting the machine down, that nothing can operate the switch.

Carefully select an extension lead. Some machines are not suitable for use with extension

leads. If the tool is designed for use outdoors, use an extension lead also suitable for that

environment. When using an extended lead, select one capable of handling the current (amps)

drawn by the machine in use. Fully extend the lead regardless of the distance between the power

supply and the tool. Excess current (amps) and a coiled extension lead will both cause the cable to

heat up and can result in fire.

Concentrate and stay alert. Distractions are likely to cause an accident. Never operate a power

tool if you are under the influence of drugs (prescription or otherwise), including alcohol or if you

are feeling tired. Being disorientated will result in an accident.

Have this tool repaired by a qualified person. This tool is designed to conform to the relevant

international and local standards and as such should be maintained and repaired by someone

qualified, using only original parts supplied by the manufacturer. This will ensure the tool remains

safe to use.

5.2 SPECIFIC SAFETY INSTRUCTION FOR BANDSAW USE

Do not use saw bands which are damaged or deformed.

Replace table insert when worn.

Connect bandsaws to a dust collecting device when sawing wood.

Do not operate the machine when the door or guard protecting the saw band is open.

Take care; the selection of the saw band and the speed depends on the material to be cut.

Do not clean the saw band whilst it is in motion.

Wear suitable personal protective equipment, when necessary; this could include:

Hearing protection to reduce the risk of Induced hearing loss.

Respiratory [breathing] protection to reduce the risk of inhalation of harmful dust;

Gloves for handling the saw band and rough material.

Always keep hands and fingers away from the saw band, especially when coming to the end of

a cut.

Use a push stick or piece of scrap wood to do the pushing and guiding when sawing small pieces

which require the fingers to be close to the saw band.

Switch the machine off and let the blade come to a stop before removing scrap pieces from

the table.

Make all adjustments and set up with the power off and plug removed from power supply.

This includes tilting the table, adjusting the saw band guards, guide, tension and tracking.

Guards must be in place and securely fastened when performing any operation.

Securely lock all adjustable parts so they cannot move during operation. This will prevent

distraction from the operation.

– 8 –

When sawing curves, make relief cuts to allow removal of scrap material. This will help prevent

undue twisting or binding of the saw blade. The relief cuts are made before starting the curved

saw cut.

Hold material firmly and feed into the band at a moderate speed.

Be sure to use the correct band size and type for the application.

Do not saw any material that does not have a flat surface, unless a suitable support is used.

Permanently fix the bandsaw to a bench or stand before performing cutting operations.

Use in a well ventilated area to minimise airborne dust. Use of a suitable extraction device and

PPE equipment is required.

Before freeing any jammed material turn switch off, disconnect from power supply and wait for all

moving parts to stop.

Before starting to cut, watch and listen to the saw while it runs. If it makes an unfamiliar noise or

vibrates excessively, stop immediately. Turn the saw off and disconnect from the power supply.

Do not attempt to use the saw until the problem has been identified and rectified.

Repair or servicing required on this product should be carried out by a qualified service agent.

When servicing use only identical replacement parts.

When straight cutting against the fence use a push stick;

During transportation the saw band guard should be fully down and close to the table;

When bevel-cutting with the table inclined, place the guide on the lower half of the table;

When cutting round timber use a suitable holding device to prevent twisting of the workpiece;

Lifting and transportation must be carried out using the indicated points only;

Do not use guarding for handling or transportation.

Move the adjustable guard as to the workpiece as practicable;

Use the correct adjustment of the saw band guards.

5.3 RESIDUAL RISK

Important: Although the safety instructions and operating manuals for our tools contain extensive

instructions of safe working with power tools, every power tool involves a certain residual risk

which can not be completely excluded by safety mechanisms. Power tools must therefore always

be operated with caution!

– 9 –

5. HEALTH AND SAFETY INFORMATION

5.4 CONNECTION TO THE POWER SUPPLY

Caution: Risk of electric shock. Do not open.

This appliance is supplied with an approved plug and cable for your safety. The value of the fuse

fitted is marked on the pin face of the plug. Should the fuse need replacing, ensure the substitute

is of the correct rating, approved to BS1362 and ASTA or BS Kite marked.

ASTA

BSI

The fuse cover is removable with a small plain slot screwdriver. Ensure the fuse cover is replaced

before attempting to connect the plug to an electrical outlet. If the cover is missing, a replacement

must be obtained or the plug replaced with a suitable type.

If a replacement plug is to be fitted this must be carried out by a qualified electrician.

The damaged or incomplete plug, when cut from the cable shall be disabled to prevent connection

to a live electrical outlet.

This appliance is Class I † and is designed for connection to a power supply matching that detailed

on the rating label and compatible with the plug fitted.

If an extension lead is required, use an approved and compatible lead rated for this appliance.

Follow all the instructions supplied with the extension lead.

†Earthed: This product requires an earth connection to protect against electric shock from

accessible conductive parts in the event of a failure of the basic insulation.

IMPORTANT

If using an extension lead, follow the instructions that came with your lead regarding

maximum load while cable is wound. If in doubt, ensure that the entire cable is unwound.

Using a coiled extension lead will generate heat which could melt the lead and cause a fire.

– 10 –

6. TECHNICAL DESCRIPTION

6.1 IDENTIFICATION

(1)

(2)

(13)

(15)

(3)

(5)

(4)

(24)

(7)

(22)

(12)

(23)

(30)

(14)

(27)

(6)

(21)

(16)

(10)

(25)

(20)

(19)

(28)

(29)

(26)

(8)

(9)

(11)

(18)

(17)

(1) Upper door

(2) Lower door

(3) Fine tensioner setting knob

(4) Upper saw band wheel

(5) Blade tension viewing window

(6) Blade guard adjustment

(7) Blade guard

(8) Upper blade guide

(9) Saw band

(10) Table

(11) Rip fence

(12) Rip fence rail

(13) No-volt switch

(14) Lower saw band wheel

(15) Drive belt

(16) Saw band tracking knob

(17) Cradle/Table tilt [bevel] adjustment

(18) Motor

(19) Base

(20) Dust extraction port

(21) Mitre guide

(22) Table insert

(23) Lower blade guide

(24) Upper door lock

(25) Lower door lock

(26) Flexible worklight

(27) Dust tray

(28) Blade tension lever

(29) Tool holder

(30) Drive belt tensioning knob

– 11 –

7. UNPACKING AND CHECKING

7.1 PACKAGING

Carefully remove the product from the packaging and examine it for any sign of damage that may

have happened during shipping. Lay the contents out and check them against the parts shown

below. If any part is damaged or missing, please contact the Draper Help Line (the telephone

number appears on the Title page) and do not attempt to use the product.

The packaging material should be retained at least during the warranty period, in case the

machine needs to be returned for repair.

Warning!

– Some of the packaging materials used may be harmful to children. Do not leave any of these

materials in the reach of children.

– If any of the packaging is to be thrown away, make sure they are disposed of correctly,

according to local regulations.

7.2 WHAT’S IN THE BOX

As well as the bandsaw, there are several parts not fitted or attached to it.

Note: For details of our full range of accessories and consumables, please visit drapertools.com

(31)

(32)

(33)

(31) 4 x plastic wing bolts

(32) Push stick

(33) Open-ended spanner

(34) 4 x Hex. keys

(35) 4 x M7x12mm pan head screws

(36) 4 x 8.5mm washers

(35)

(34)

(36)

– 12 –

8. PREPARING THE BANDSAW

Note: Remove the plug from the socket before

carrying out adjustment, servicing or maintenance.

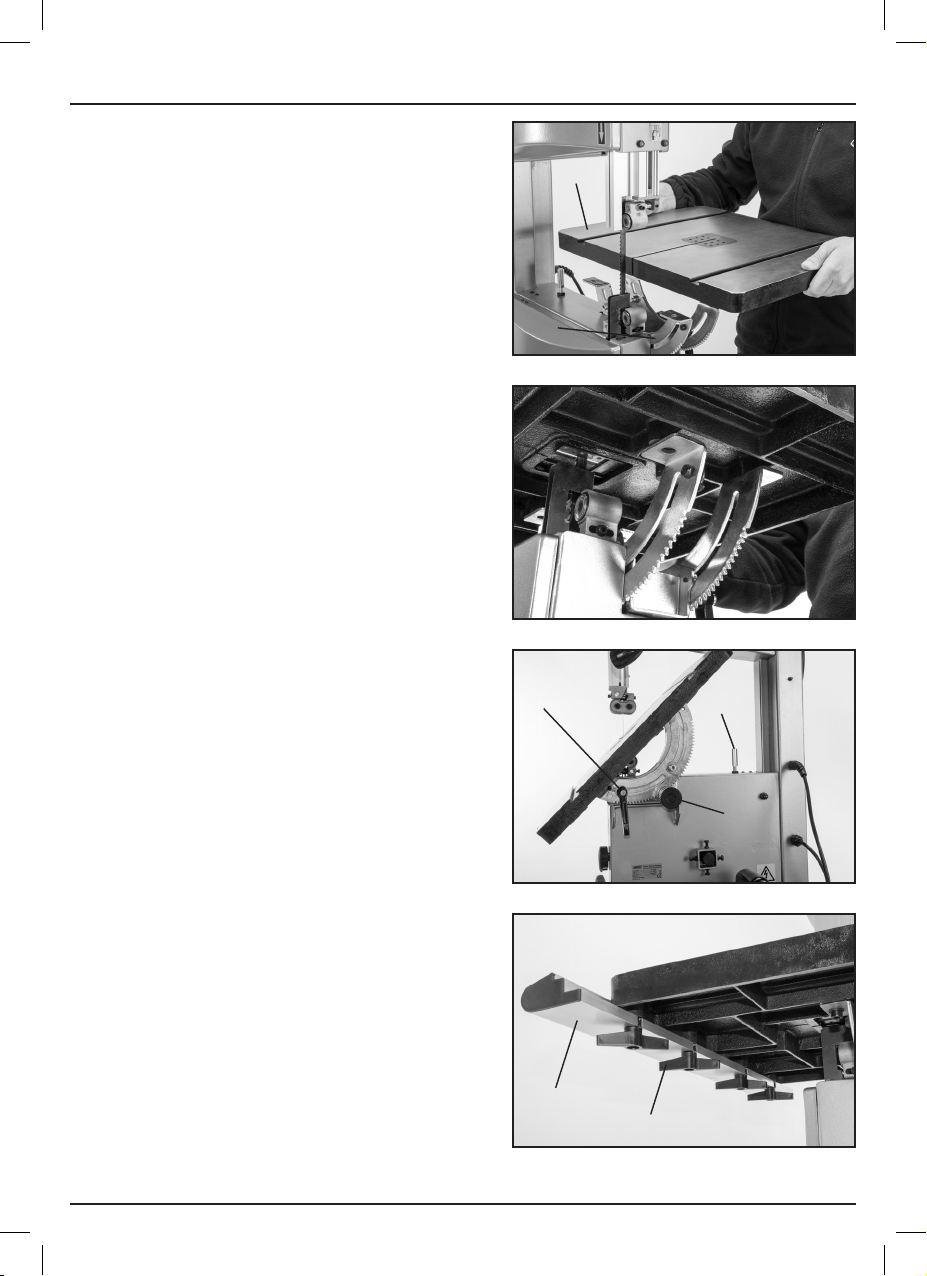

8.1 INSTALLING THE TABLE – FIG. 1

Pull the table (10) onto the cradle/table tilt

adjustment (17) ensure the holes on the underside

are lined up, using the pan head screws (35) and

washers (36) secure the table in place.

(10)

8.2 LEVELLING THE TABLE –

FIGS. 2 – 3

The saw table can be tilted up to 45°. To tilt,

loosen the wing nut (17.1) on the cradle. A stop

on the underside of the table rests on the lower

wheel housing (17.3) when the table is at 90°

with the blade.

Loosen the lock nut (17.2) and turn the bolt in

or out, as required, to change angle against the

saw band.

Use a spirit level to check the table is square.

8.3 RIP FENCE RAIL – FIG. 4

Place the rip fence rail (12) on the front edge of

the table and tighten in place with the four plastic

wing bolts (31).

(17)

FIG. 1

FIG. 2

(17.1)

FIG. 3

(17.3)

(17.2)

– 13 –

(12)

(31)

FIG. 4

8. PREPARING THE BANDSAW

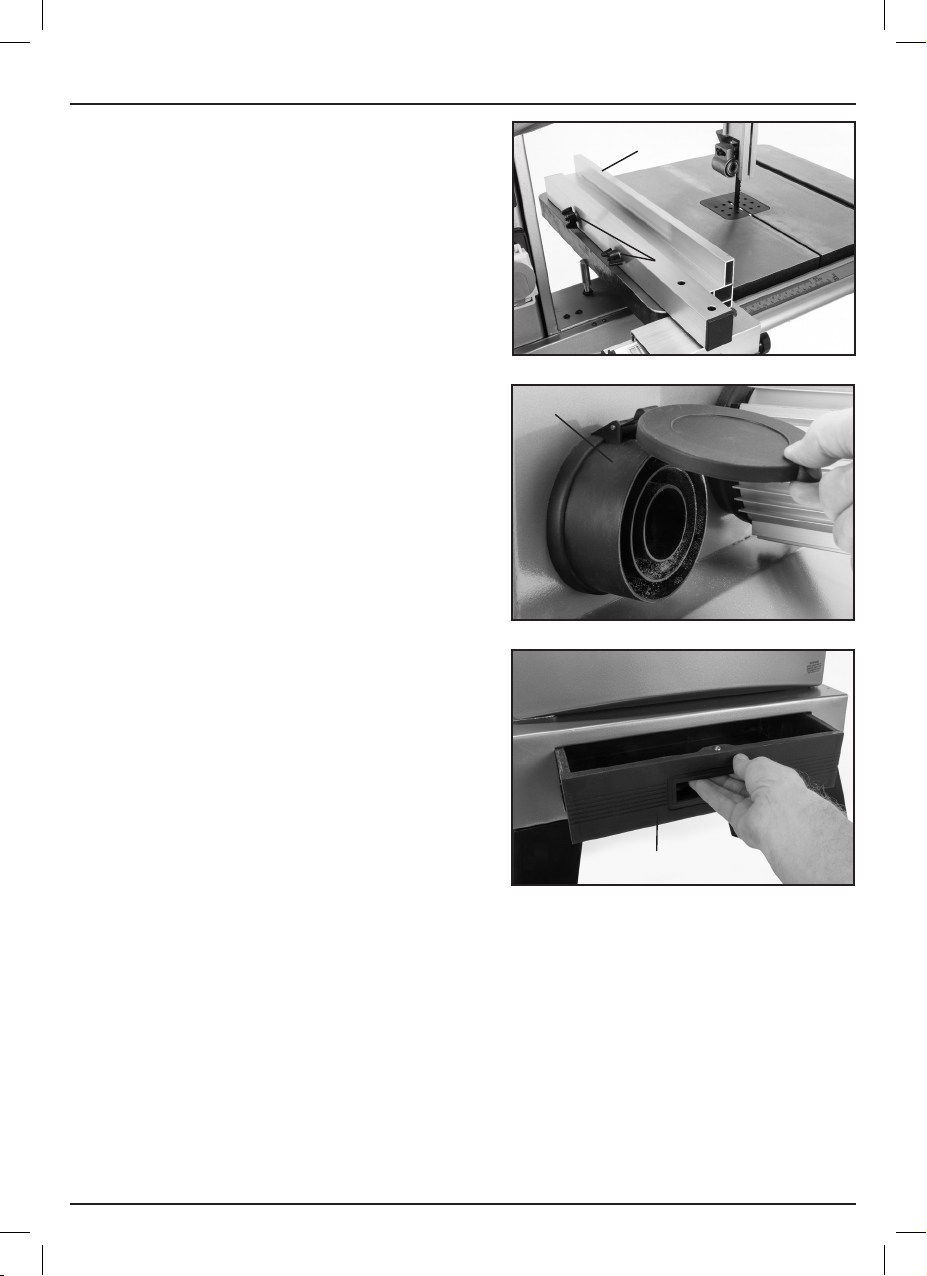

8.4 RIP FENCE – FIG. 5

Attach the rip fence (11) to the rip fence rail as

shown to secure the fence.

When the rip fence is against the blade in its

vertical configuration ensure the scale reads ‘0’

through the window. If not loosen wing bolts (31)

and adjust accordingly.

The rip fence can be set up for left and right

handed cuts and the wing nuts (11.1) can be

loosened to change the rip fence into a horizontal

configuration for thin cuts.

8.5 DUST EXTRACTION OUTLET –

FIG. 6

Note: Inhalation of dust particles can be

detrimental to your health. The dust outlet (20)

must be connected with a dust extraction machine.

Note: Due to the outlet diameter, a size adaptation

may be necessary. All wood dust [including dust

from composites like chipboards and fibre boards

etc.] is hazardous to health; it can affect the nose,

the respiratory system and the skin for example

MDF [medium density fibreboard] which can

contain formaldehyde [a known carcinogen].

In addition to the above measures a correctly fitted

dust mask, suitable for the activity and in

accordance to the relevant standard, must be

worn. For work activities involving exposure to fine

wood dust a mask rated to at least FFP2 should

be used.

(11)

(11.1)

FIG. 5

(20)

FIG. 6

8.6 DUST TRAY – FIG. 7

Insert the dust tray (27) into the slot in the base of

the saw.

– 14 –

(27)

FIG. 7

9. OPERATING THE BANDSAW

Note: Removing the plug from the socket before

carrying out adjustment, servicing or maintenance.

9.1 NO-VOLT ON/OFF SWITCH –

FIG. 8

The bandsaw is fitted with a no-volt switch (13).

To switch the bandsaw on, push the green button

marked ‘I’.

To switch the bandsaw off, push the red button

marked ‘0’.

In the event of a power failure the bandsaw will

have to be manually re-started.

9.2 LED WORKLIGHT – FIG. 9

The flexible light is switched on by depressing the

switch (26.1).

FIG. 8

(13)

9.3 TILTING THE TABLE – FIG. 10

Using the bevel indicator (17.4) as a guide the

angle of the table can be adjusted between 0°

and 45°.

To tilt, loosen the wing nut (17.1) and adjust by

turning (17.2) when set, secure.

Note: When greater accuracy is required,

make practice cuts on waste material and

adjust the table as necessary.

(26.1)

FIG. 9

(17.4)

(17.1)

(17.2)

FIG. 10

– 15 –

9. OPERATING THE BANDSAW

9.4 UPPER AND LOWER DOORS –

FIG. 11

To open doors turn the door locks (24) and

(25) clockwise to close push door shut and turn

locks anticlockwise.

Warning!

The bandsaw is fitted with a micro switches inside

the doors. This safety feature will de-activate the

machine when the doors are open.

(24)

9.5 BLADE GUARD SLIDE

ADJUSTMENT – FIG. 12

The blade guard (7) should be adjusted to within

3mm of the workpiece. Always adjust the blade

guide assembly to suit the workpiece before each

operation. Loosen the blade guard adjustment (6)

to raise or lower the guard. When complete, tighten

to secure.

FIG. 11

(21)

(6)

(7)

FIG. 12

– 16 –

9.6 TENSIONING THE BLADE –

FIGS. 13 – 14

The blade tension lever (28) allows the quick

release of the blade tension when changing

the blade.

To set the tension the lever should be moved

anti-clockwise to the tensioned position as shown.

Turning the fine tensioner setting knob (3)

clockwise will increase the tension, turning

anti-clockwise will lower the tension.

Note: Do not overtighten the blade. Too much

tension may cause blade breakage. Too little

tension may cause the blade to slip on the wheels.

To help in the correct tension setting the indicator

(that can be viewed through the blade tension

viewing window (5)) should be set to the correct

blade width that is being used.

9.7 CHANGING AND SETTING THE

NEW BLADE – FIGS. 15 – 16

To change the saw band, remove the rip fence

rail from the table. Slacken the blade tension with

the tensioner, open both doors and remove the

blade carefully.

Fit the new saw band carefully [with the teeth

facing down]. When the saw band is located

correctly through the guide and is sat centrally

on the upper and lower wheels, operate the

tensioner to re engage the tension. As the tension

has been released during this process, the tracking

should be checked and adjusted as per page 18.

The blade should run in the centre of the rubber

lined bandsaw wheels otherwise it may jump off.

Warning!

Select a blade suitable for the intended

material and use on this machine. Read the

safety instructions.

(3)

(28)

FIG. 13

(5)

FIG. 14

FIG. 15

– 17 –

FIG. 16

9. OPERATING THE BANDSAW

9.8 TRACKING THE BLADE –

FIGS. 17 – 18

Note: The blade tension must be correctly adjusted

before tracking the blade.

When fitting a new blade it may be necessary for

the blade tracking to be adjusted.

The blade should sit centrally or slightly to the front

of the rubber on the two wheels. To track the blade,

open the top & bottom doors, move the blade by

hand by rotating the upper saw band wheel (4).

If the blade starts moving towards the front edge

of the wheel, turn the saw band tracking knob (16)

clockwise.

There is a large wing nut (16.1) found behind the

tracking adjustment knob to lock the position

once set.

9.9 ADJUSTING THE UPPER BLADE

GUIDE ASSEMBLY – FIGS. 19 – 20

Loosen the hex screw (8.1) and adjust the guide

assembly forward or backwards so that the front of

the bearing is 2mm back from the deepest part of

the tooth.

Loosen the left hand nut (8.2) to adjust the rear

thrust bearing so that it is 0.5mm from the back

edge of the blade.

For thicker blades fine adjustments can be

achieved by using the hex key provided (34)

(not pictured) to loosen the bolt (8.3) behind

each of the side bearings.

Slide them left or right in the slot so that they are

0.5mm from the side of the blade.

FIG. 17

FIG. 18

(16)

(8.2)

(4)

(16.1)

(8.1)

– 18 –

FIG. 19

(8.3)

FIG. 20

9.10 IF REQUIRED TO ADJUST THE

LOWER BLADE GUIDES – FIG. 21

Use the hex key provided (34) to loosen the left

hand bolt (23.1) allowing the guide assembly to

move forwards or backwards so that the front edge

of the bearing is 2mm back from the deepest part

of the blade teeth.

Loosen the right hand bolt (23.2) to adjust the rear

thrust bearing so that it is 0.5mm from the back

edge of the blade.

Warning!

Do not start the bandsaw until all blade guides

have been correctly adjusted and all locking

screws and bolts are secured.

Note: Always reset the upper and lower blade

guides after changing to a different width of blade.

9.11 MITRE GUIDE – FIG. 22

Slide the mitre guide (21) into one of the T-slots on

the table (10). Loosening the handle (21.1) will

enable you to adjust the angle. There are stops for

90° and 45° each way. Pull out the silver pin at the

front of the mitre guide to move past the stop.

Ensure the handle is fully tightened before using

the guide.

9.12 SETTING THE BLADE SPEED –

FIGS. 23 – 24

To change the speed of the bandsaw, open the

lower door and turn the drive belt tensioning knob

(30) anticlockwise to slacken the drive belt.

Move the belt (15) over to the other pair of pulleys.

Re-tension the belt so that finger pressure deflects

it by approx. 10mm.

There are two speeds 800m/min for general

woodcutting, 370m/min for cutting hardwoods

and metals.

(23.1)

FIG. 21

FIG. 22

FIG. 23

(23.2)

(21.1)

(21)

(10)

(30)

– 19 –

(15)

FIG. 24

10. TIPS ON USING YOUR BANDSAW

10.1 USEFUL TIPS

For all cutting operations the upper blade guard should be adjusted to just clear the work being

cut (3mm). Not only does this provide the best operator safety, but it also brings the blade guides

closer to the work giving more accurate results and easier control.

Use both hands to feed the workpiece to the blade. The work must be held flat on the table at

all times to prevent binding of the blade. Use a steady even pressure just sufficient to keep the

blade cutting.

Always use a rip fence or mitre guide where possible to eliminate any sideways slip of the work.

This is most important when the table is tilted to an angle.

Always plan work ahead. The tradesman’s rule is “measure twice, cut once”. It is best to finish a

cut in one continuous operation, but frequently backtracking will be necessary. Turn off the motor

and allow the blade to come to a complete stop before backing the blade out of the cut.

Remember that the blade removes material during the cut. This gap created by the blade is called

the kerf and must be allowed for when cutting to exact sizes. Plan your cut so that the kerf is to the

scrap side of the line you wish to cut. If necessary, allow a little more for finish sanding.

Rip sawing

This term refers to the cutting of timber with the grain rather than at a right angle to the grain.

You can rip wood freehand to a previously drawn line, but best results are obtained by using the

rip fence. If the table is set at a level angle set the rip fence to the left hand side of the blade.

This allows you to use your right hand to hold the work firmly against the fence. The width of cut

indicator on right hand side of the blade if the width of the workpiece allows it.

With the fence on the downhill side of the table it will help support the work against slipping.

The width cut indicator shows the distance between the blade and the rip fence.

When cutting long pieces, consider making cuts from the waste edge up to the cut line, then the

waste will fall away in small sections as you make the cut. The workpiece may need additional

support to stop it from bending and causing the blade to bind, this can be achieved with a table at

the correct height or an assistant, provided that they have been trained in the use of the machine

and are aware of all safety implications.

Cross cutting

This term refers to cutting of timber at right angles to the grain. This type of cut can also be made

freehand but the mitre guide is used to ensure accurate results. The mitre guide can be adjusted

to a 45˚ angle to produce mitre cuts, or with the table tilted as well, compound mitre cuts.

Make sure the work is held firmly against the table and against the face of the mitre guide.

Be careful to keep your fingers away from the blade, particularly at the end of the cut.

Freehand sawing

The ease with which many different and varied shapes can be cut is one of the most important

features of the bandsaw. Select a blade suitable for cutting the smallest radius in the work you

have planned.

When freehand cutting always feed the work slowly so that the blade can follow the line you wish

to saw. Make sure not to drag the work off line forcing the blade sideways, or twisting it.

In many cases, it is helpful to rough cut about 6mm away from the line in difficult curves and

corners. In the case of very sharp curves which may be too tight for the blade, make relief cuts

onto the face of the curve so that these scraps will fall as the final radius is sawn.

– 20 –

11. TROUBLESHOOTING

11.1 TROUBLESHOOTING GUIDE

Warning!

For your own safety, turn the switch off and remove the plug from the power supply socket.

Problem Possible Cause Remedy

Breaking blades. Wrong tension.

Over working blade.

Wrong blade application.

Twisting blade.

Motor will not run. Defective cable or plug.

Defective motor.

Vibration.

Note: There will always be

some vibration when the saw

is running due to the motor

operation.

Blade runout. Blade guides not aligned. Check blade guide settings

Incorrect mounting of saw.

Unsuitable mounting surface.

Loose table.

Loose motor mounting.

Adjust blade tension.

Reduce feed rate.

Use narrow blades for cutting

thin material or sharp curves,

wide blades for thicker

material or straight cuts.

Avoid side pressure on blade

Replace defective parts.

Consult your service agent.

Any attempt to repair this

motor may be dangerous

unless the repair is carried

out by a qualified service

agent.

Refer to the mounting

instructions in this manual.

The heavier your work

bench is, the less vibration.

A plywood workbench is not

as good as solid timber.

Tighten table locking knob.

Adjust table if necessary.

Tighten mounting screws.

as per manual.

Note: Repairs should only be carried out by a qualified person.

– 21 –

12. MAINTENANCE

12.1 SLIDE ADJUSTMENT

Warning!

For your own safety turn switch off and remove plug from power supply before attempting any

adjustment or repairs.

Changing tyres

Eventually the rubber tyres on the bandsaw wheels will wear due to the constant contact of the

sharp teeth of the blade. Lift the edge of the tyre with a small screwdriver and the tyre can be

worked off the wheel easily. We recommend that the two tyres be changed at the same time.

(See Spare Parts Listing/Drawing).

Blade guides

Blade guides should be inspected regularly for wear or chipping. When replacing guides replace

all guides at the same time, both upper and lower. (See Spare Parts Listing/Drawing).

Bearings

All bearings used in the construction of your bandsaw and its motor are sealed and lubricated

for life.

Clean out

Remove the plug from the socket before carrying out adjustment, servicing or maintenance.

Accumulated dust and chips should be removed from inside the bandsaw frequently. Open the

front covers and use a brush or vacuum cleaner. At the end of every work session clean sawdust

away from the motor vents.

Regular inspection and cleaning reduces the necessity for maintenance operations and will keep

your tools in good working condition.

The motor must be correctly ventilated during the tools operation. For this reason avoid blocking

the air inlets.

If the replacement of the supply cord is necessary, this has to be done by the manufacturer or his

agent in order to avoid a safety hazard.

– 22 –

13. EXPLANATION OF SYMBOLS

13.1 EXPLANATION OF SYMBOLS

WEEE – Waste Electrical &

Electronic Equipment.

Do not dispose of Waste Electrical & Electronic

Equipment in with domestic rubbish.

Read the instruction manual.

Wear face mask and safety

glasses.

Keep hands away from blade.

Disable the machine before

attempting to maintain it.

14. DISPOSAL

14.1 DISPOSAL

– At the end of the machine’s working life, or when it can no longer be repaired, ensure that it is

disposed of according to national regulations.

– Contact your local authority for details of collection schemes in your area.

In all circumstances:

• Do not dispose of power tools with domestic waste.

• Do not incinerate.

• Do not dispose of WEEE* as unsorted municipal waste.

* Waste Electrical & Electronic Equipment.

– 23 –

CONTACTS

Draper Tools Limited, Hursley Road,

Chandler’s Ford, Eastleigh, Hampshire. SO53 1YF. U.K.

Help line: (023) 8049 4344

Sales desk: (023) 8049 4333

Internet: drapertools.com

E-mail: sales@drapertools.com

General enquiries: (023) 8026 6355

Service/Warranty Repair Agent:

For aftersales servicing or warranty repairs, please contact the

Draper Tools help line for details of an agent in your local area.

YOUR DRAPER STOCKIST

TAFW0821

©Published by Draper Tools Limited.

No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means,

electronic, mechanical photocopying, recording or otherwise without prior permission in writing from Draper Tools Ltd.

Loading...

Loading...