Page 1

HAND HELD

BRAKE PIPE

FLARING TOOL

Version 1 – January 2023

EN

Original Instructions

4.75mm DIN

23313 – BPF/HAND/DIN INSTRUCTIONS FOR USE

Read this manual in full before using this product and retain it for future use. Always use the latest version of the manual.

Please visit drapertools.com/manuals for the latest version.

1. Intended Use

This product is designed to are brake pipes of 4.75mm

according to DIN Convex standards. Any other application

beyond the conditions established for use will be

considered misuse. Draper Tools accepts no responsibility

for improper use of this product.

Important: Ensure that you are familiar with the various

types of ares and their applications before using this

product. ALWAY S consult the vehicle manufacturer’s

instructions before use.

2. What’s in the Box?

Before assembling the product, lay the contents out and

check them against the parts listed below. If any part is

damaged or missing, do not attempt to use the product;

please contact the Draper Helpline.

A. 1 × Flaring tool

A1. Die

A2. Locking screws

B. 1 × Double-ended punch

B1. 4.75mm DIN punch

B2. Stop punch

C. 1 × Punch grease

(A1)

(A)

3. Operating Instructions

1. Partly screw the stop punch (B2) into the aring tool so

that the nut is no more than 5mm from the die (A1).

(A1)

(B2)

1 Fig.

2. Ensure that the tube nut is installed onto the brake pipe,

then insert the brake pipe into the open end of the die

and hand-tighten the locking screws (A2) just enough to

grip the pipe.

(A2)

(A2)

(C)

(B2)

(B)

(B1)

Helpline: +44 (0) 23 8049 4344 Sales Desk: +44 (0) 23 8049 4333 General Enquiries: +44 (0) 23 8026 6355 Website: drapertools.com Email: sales@drapertools.com

Draper Tools Limited, Hursley Road, Chandler’s Ford, Eastleigh, Hampshire, SO53 1YF, UK 0123

2 Fig.

Important: DO NOT overtighten the locking screws at

this stage as the stop punch may damage the pipe.

Page 2

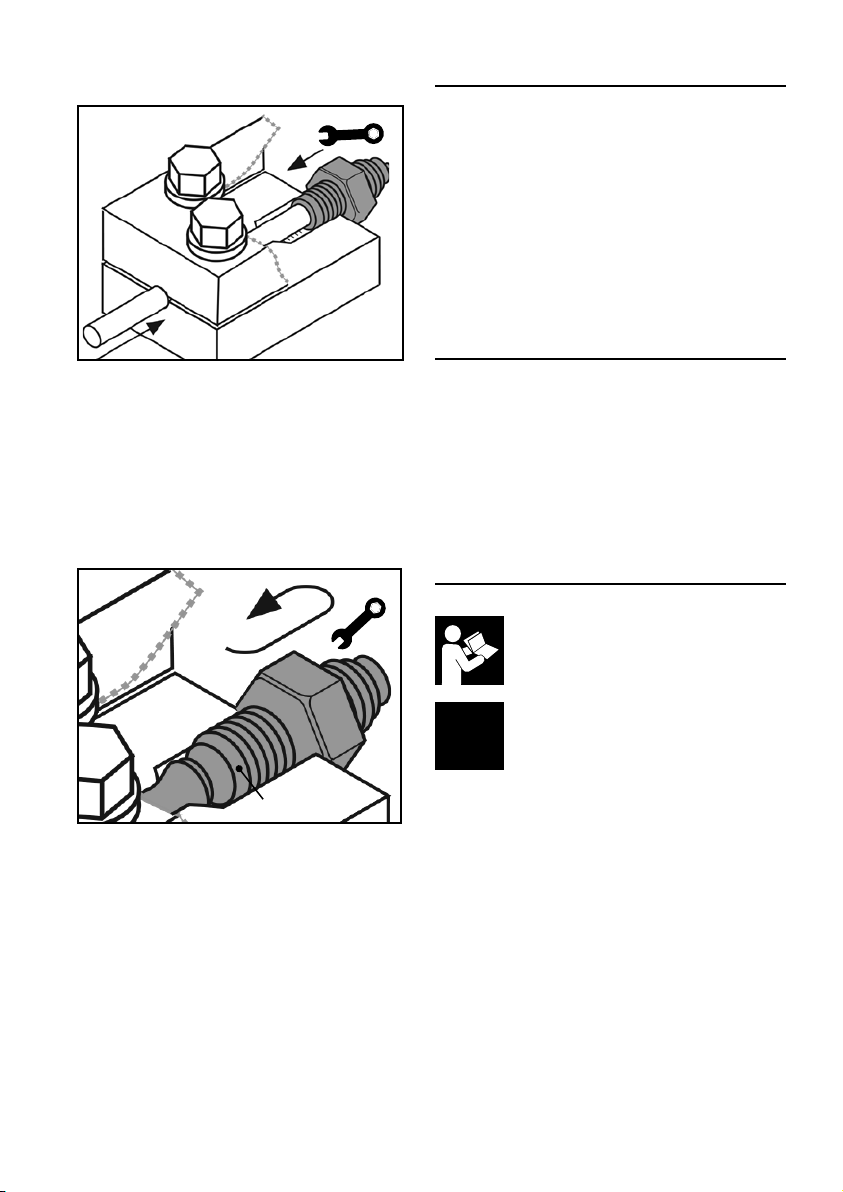

3. Use a 16mm spanner (not supplied) to screw the stop

punch fully into the die until tight.

3 Fig.

4. Use a 10mm spanner (not supplied) to fully tighten the

locking screws and secure the pipe.

Important: If the locking screws are not suciently

tight, the pipe will move during the aring process and

damage the are.

5. Unscrew the stop punch from the die.

6. Fully screw the 4.75mm DIN punch (B1) into the die until

it is tight.

4. Preparing the Brake Pipe

Important: A LWAYS ensure that the brake pipe is correctly

prepared before aring.

• The end of the pipe MUST be cut square.

• The outside edge of the pipe must be champfered by

approximately 0.25mm at 45°.

• The bore of the pipe must be deburred.

• If the pipe is plastic-coated, remove at least 6mm from

the end of the pipe to be ared, ensuring that the pipe is

not scored and that no metal is removed while doing so.

Important: DO NOT use an abrasive cloth on the end of the

brake pipe to be ared.

5. Maintenance and Storage

• Clean the product of dust or debris before and after

each use.

• Replace any punch that shows sign of damage or

excessive wear.

• Before storing the product, wipe it thoroughly with a

lightly oiled cloth to prevent corrosion of the exposed

metal parts.

• Store the product in a clean and dry environment, out of

reach of children.

6. Explanation of Symbols

(B1)

4 Fig.

7. Remove the punch from the die, then loosen the locking

screws and remove the pipe from the tool.

4.75mm

DIN

Read the instruction manual

Flaring output size

Loading...

Loading...