Page 1

PENCIL

POWER DRILL

TAPE MEASURE

LEVEL

MALLET

HARDWARE

(by others)

LightBloc FlexShade

®

Overview - LightBloc FlexShade Components

INSTRUCTIONS

INSTALL ATI O N & OPERATION

TOOLS

REQUIRED

Clutch

Endcap

Endcap

Cover

Motor

Endcap

Motor

Gudgeon assembly

Retainer clip

Idler endcap

fastens to ceiling,

face or jamb

Endcap

Covers

Channel

Liner

Fabric

Retainer

Side channel - Includes ¾" x 1"

adjustable mounting angles

(Mounting angles provided for

"Inside" or "Jamb"mount installations.

For "Face Mount" applications,

Top/Back Cover

(STANDARD)

Fabric grommet

Stays

Shade

fabric

Slat bar

Sill channel see details

Roller

SILL CHANNEL

Inside Mount

3

1

/8" H x ¾" D

Channel

locator

Fabric guide

Face/bottom

cover

(STANDARD)

Side channel

Face Mount

2¾" H x ¾" D

CRANK ASSEMBLY

Crank

Handle

Crank Endcap

& Assembly

Read and understand all warnings (Page 2 of this document) before beginning installation.

Contents

Overview LightBloc FlexShade Components .................................................1

Please Read Warnings and Safety Information ..................................................2

Please Read Field Adjustments, Cleaning and Maintenance ............................2

Section 1 Preparation for Installation .............................................................3

Section 2 Side Channels ..................................................................................4

Section 3 Check Shade Fabric ........................................................................4

Section 4 Bead Chain Limits and Safety Device Installation

(for Units with Clutch or Spring Roller Operation) ...................... 5

CAUTION

Section 5 Check Shade Operation

(for Units with Clutch or Spring Roller Operation) ...................... 5

Section 6 Electrical Connections

(for Motorized Units) ....................................................................... 6

Section 7 Wiring Diagrams

(for Motorized Units) ....................................................................... 6

Section 8 Limit Switch Adjustments

(for Motorized Units) ....................................................................... 7

Section 9 Dimensions - LightBloc FlexShade ................................................8

If you have any difficulties installing or servicing your

LightBloc FlexShade, call your dealer or Draper, Inc.

Draper, Inc. | 411 S. Pearl St. Spiceland, IN 47385

draperinc.com | 765.987.7999 | 800.238.7999

© 2018 All Rights Reserved | FORM: LBFS_Inst_18

Page 2

LightBloc FlexShade

®

page 2 of 8

Important Safety Information Important Safety Information

Improper installation and use of the LightBloc FlexShade® can result in serious injury or death. Primarily, injuries can occur when the shade falls

due to imprecise installation, mishandling of the shade during installation or installation on an insufficient wall or ceiling structure. Please use

extreme care.

1.

Please read the following installation guidelines thoroughly and follow them

carefully. Failure to do so may cause product to fall or otherwise fail, and

could result in serious injur y.

2.

Installation and calibration of the shade should only be performed by an

authorized, qualified, and experienced professional.

3.

Do not affix the unit to wall or ceilings that have inadequate strength to

permanently hold the unit during use. It is the owner’s and installer’s responsibility

to confirm the wall or ceiling to which the unit attaches is sufficient to

permanently hold the weight and stress loads of the unit at all times. Draper, Inc.,

is not responsible for improper installation, application, testing or workmanship

related to the product at place of installation.

4.

It is the installer’s responsibility to make sure appropriate fasteners are used for

mounting.

5.

All brackets, fascia, head boxes, pockets, wall clips, and other hardware must be

installed level. shade must be level and square.

6.

Never leave the area while operating the shade during installation, maintenance,

or normal operation, unless it is secure and safe.

7.

Before testing or operation, carefully inspect the entire area and path of the shade

and areas underneath the shade to be sure no persons or objects are in the area.

WARNING

8.

During testing or operation, carefully watch the surrounding area for any potential

safety concerns including nearby persons or objects.

9.

After installation, the entire system should be carefully tested to ensure safe and

normal operation. Extreme care should be taken during testing to remain clear of

moving par ts to avoid possible injury.

10.

Operation of shade should be performed only by authorized and qualified

personnel, who have been trained in the safe and effective operation of the shade

& understand its safety features.

11.

The safety features of the shade should never be disabled, bypassed or

overridden. The system should not be operated until all safety features are

properly and completely installed, calibrated and tested.

12.

Shade may need to comply with local, state or district rules and regulations, in

particular when installed in schools. All applicable rules and regulations should

be reviewed before installation and use.

13.

Failure to precisely follow installation guidelines invalidates all warranties.

14.

Custom products/installations may not be reflected in this manual. Call Draper,

Inc., if you have questions regarding your installation.

Before Beginning Installation

1.

Look for any job site conditions that could inter fere with installation or operation

of the system.

2.

Read carefully and be sure to understand all installation instructions and all

related operations manuals. These instructions are intended to serve as a guide

for the installer and owner. They should be followed closely and combined with

the expertise of experienced qualified installers. Draper, Inc., is not responsible

for improper installation, application, testing or workmanship related to the

product at place of installation. Please retain all instructions for future use.

3.

Open cartons lengthwise.

4.

Locate and lay out all pieces.

5.

Inspect all boxes to make sure you have received the proper shade and parts.

Controls may be shipped separately, or in same carton as shade.

6.

If you have any difficulties with installing, servicing or operating your shade, call

your dealer or Draper, Inc., 765-987-7999.

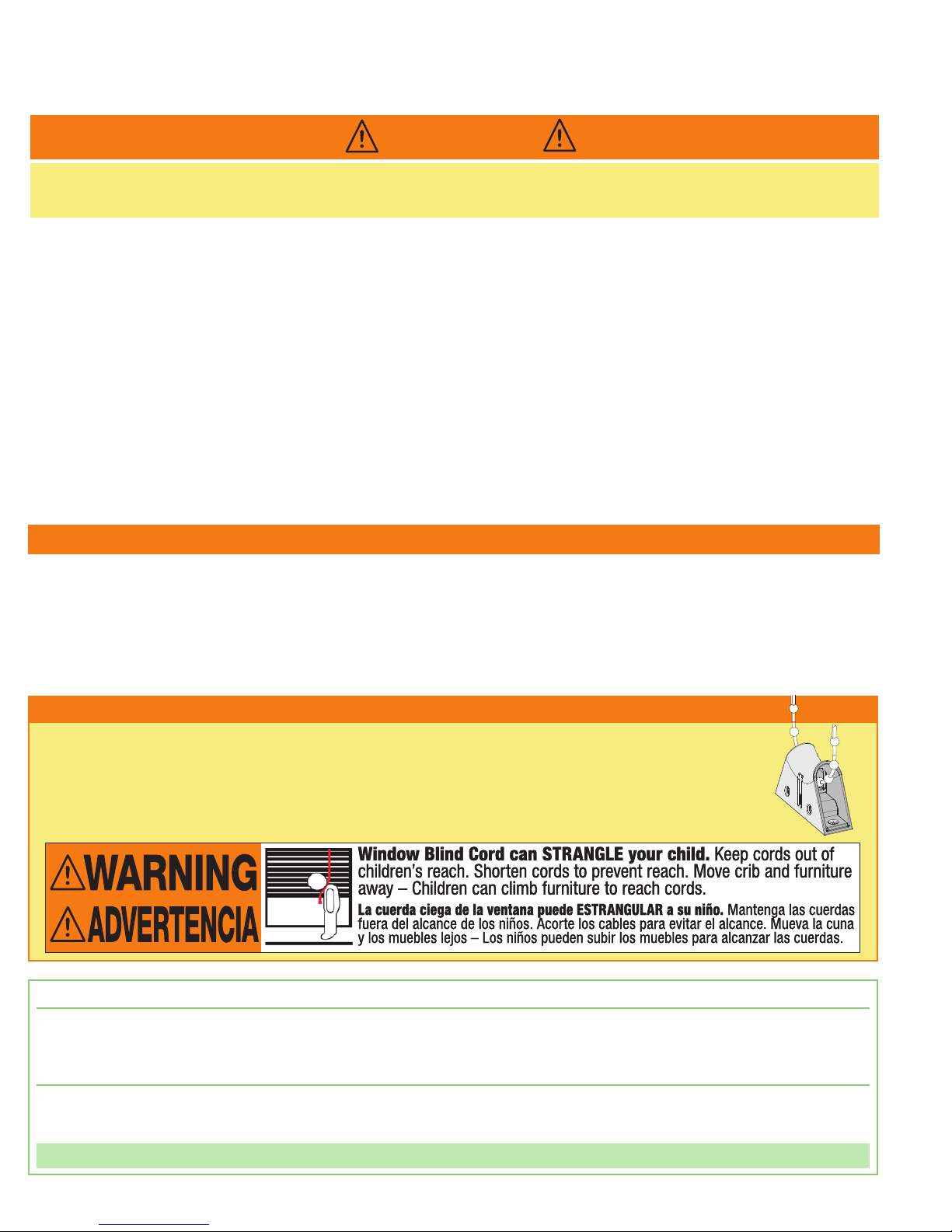

Child Safety Information

ANSI/WCMA A100.1-2018 standard (developed by the Window Coverings Manufacturer’s Association and the Consumer Product Safety

Commission) was established on December 15, 2018, to eliminate strangulation hazards for small children from hanging cords and chain loops.

When a Draper dealer specifies that custom shades comply with ANSI/WCMA A100.1-2018, Draper provides a pre-installed Spring-Loaded Chain

Tension Device (shown at right) for clutch-operated units. A warning label is attached to the kit and approved mechanical fasteners are included.

When properly installed, the tension device prevents the creation of a hazardous loop by maintaining tension on the bead chain. If not installed

properly, the shade is par tially inoperable. A warning label (shown below) is also added to the shade roller.

For more information, please see Draper's ANSI/WCMA A100.1-2018 compliance page: www.draperinc.com/windowshades/wcmacompliance.aspx

Field Adjustments

Each Draper Solar Control Shade is tested to ensure proper operation. Even with this testing, some field adjustments may be needed for telescoping.

If the shade is telescoping, place a piece of high quality gaffer tape about 1" wide on the exposed roller (where the fabric will cover it) on the side that the

fabric will be drawn toward. For example: if the fabric is tracking to the left, place the tape on the right side.

Cleaning and Maintenance

Window covering products manufactured by Draper, when properly installed, should require no operational maintenance or lubrication.

Most of Draper’s standard fabrics may be cleaned at the window by vacuuming with a soft brush attachment. They also may be cleaned by using a sponge

or soft cloth and mild solution of warm soapy water. A mild dishwashing liquid is recommended. A clean dry cloth is recommended for the metal finish.

Please Note:

Exceptions are Flocké and Phifer SW7000 fabrics, which must be cleaned with a dry art sponge.

Page 3

Endcap

20lb Clutch

Clutch

Endcap

2

3

Insert

Spear

Idler

Endcap

Top

End

Back

1

1

/2"

1

1

/2"

3

/

4"

3

/

4"

5

/

8

5

/

8

LightBloc FlexShade

Section 1 - Preparation for Installation

®

page 3 of 8

Caution: Before mounting shades, verify measurements on package label with shade.

Please Note: Installer is responsible for selecting mounting hardware appropriate for site conditions.

1.

FOR ALL: Open cartons lengthwise. Remove all pieces from carton. If shade has a detachable crank handle, remove universal

joint and shaft/bracket assembly by removing 2 screws from bottom of endcap (Fig. 1). Save universal joint & screws.

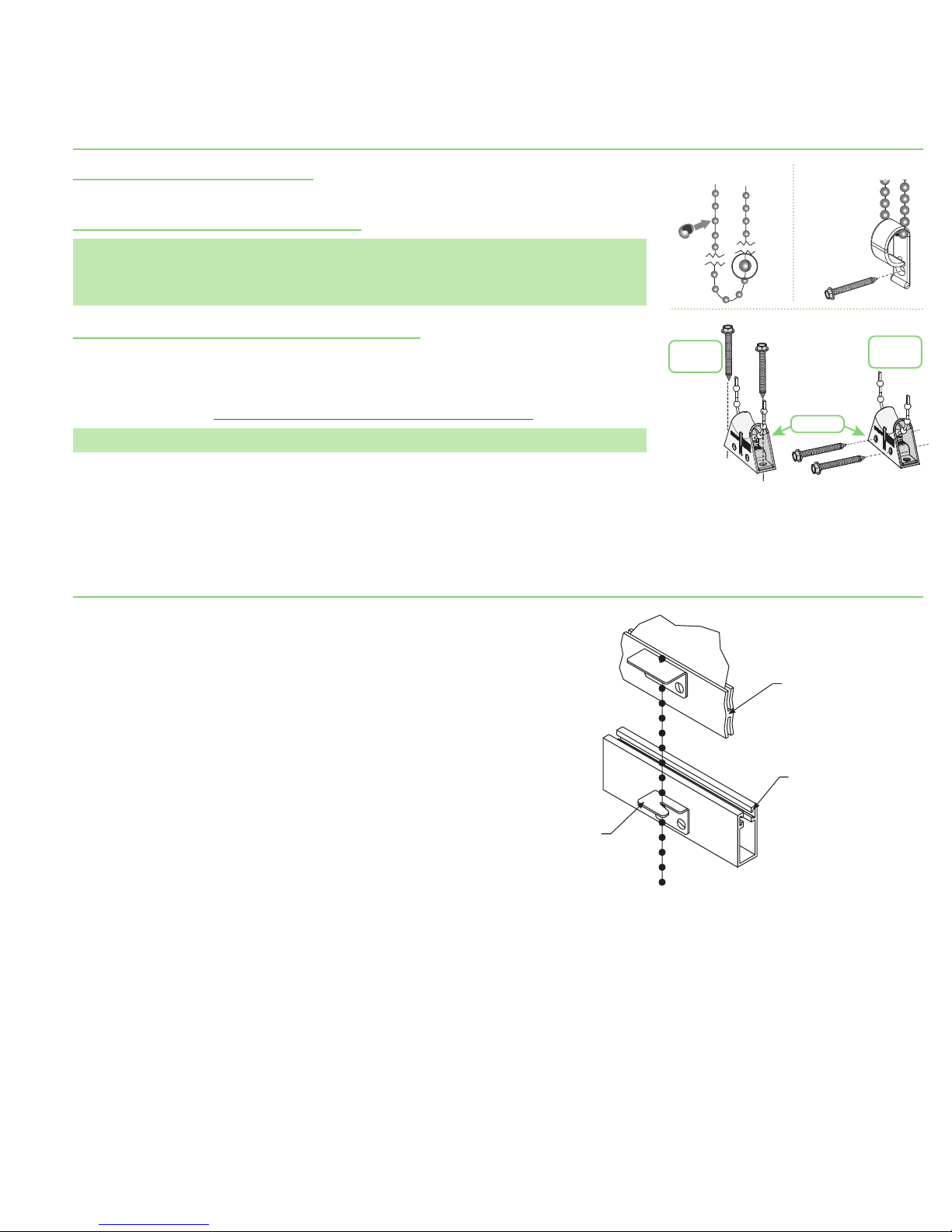

Figure 2

2.

FOR ALL: Remove face cover from

headbox by pulling down and out on

bottom edge of cover near endcaps. It

will snap off (Fig. 2). If this is a pocket

installation, remove screws at endcaps.

Bottom of cover box snaps down and

off at endcaps then slides out of slot in

cover box (Fig. 2).

Wall/Ceiling Pocket

3.

FOR ALL: Remove roller assembly

from headbox.

Please Note: If unit is motorized with a crank override, skip this step. Roller

assembly and headbox assembly must be installed as a unit — the roller

assembly cannot be removed without completely disassembling headbox.)

FOR CRANK OR MOTORIZED UNITS: Remove black plastic retainer clip from

idler end of roller and retainer clips from motor studs. Save these clips to replace

when re-assembling. Lift idler out of bracket Depress spring-loaded pin by pressing

roller toward pin end endcap until clutch hooks are free from operator endcap.

Figure 3:

Idler End Operator End

Motorized

Idler

Endcap

Idler End

of Roller

Remove roller assembly from headbox.

FOR BEAD CHAIN CLUTCH UNITS: Lift up on clutch end so that clutch hooks

can disengage from operator endcap. Depress spring-loaded pin by pressing roller

toward pin end endcap until clutch hooks are free from operator endcap. Remove

roller assembly from headbox.

Please Note: It may be necessary to locate and drill a hole for conduit connector

Retainer Clip

Be sure retainer clip is installed.

(Conduit connector is not supplied) (Fig. 4).

CRANK ASSEMBLY

Crank

Handle

Crank Endcap

& Assembly

Figure 1

FOR ALL: Verify dimensions of opening and refer to order for overall dimensions

of unit. Determine location of headbox directly above and centered on opening.

It is critical that headbox is installed absolutely level (use shims and caulking if

needed). Install headbox assembly using appropriate fasteners through pre-drilled

Idler

Idler End

of Roller

Crank

holes in endcaps, then drill through cover for wall/ceiling mounting (Fig. 5).

Figure 4

Figure 5

Retainer Clip

Be sure retainer clip is installed.

Bead Chain Clutch

Idler

Endcap

Wall/Ceiling (face) or Jamb Mount

Existing Pocket

Retainer Clip

Idler End

of Roller

Page 4

Face Mount Jamb Mount

Plug Button

1" x

3

/4" angles

toward window

(standard)

LightBloc FlexShade

Section 2 - Side Channels

®

page 4 of 8

Figure 6

Fabric Guide

Figure 7

Section 3 - Check Shade Fabric

Bottom edge

of mounting

angle must

be mounted

flush with

bottom edge

of side

channel

Caution: For motorized units, make sure POWER IS OFF before making any

1.

FOR ALL: Install side channels (NOTE: Ensure side channels, headbox, and sill

channel are square).

A.

Install channel locater and fabric retainer in top of each side channel. Lightly

tap channel locater with a rubber mallet to en- sure it is fully seated in side

channel. Slide into place (Fig. 6).

B.

For face mount, side channel mounts on surface of wall or window mullion.

Fasteners go through side channels. Plug buttons should be used to cover

holes (access and mounting holes will be pre-drilled) (Fig. 7).

C.

For inside or jamb mount, attach mounting angles to side channels. Install side

channel with mounting angle toward window, if depth will allow, so it is not

visible (it can also be installed toward room). Bottom edge of mounting angle

must be mounted flush with bottom edge of side channel. Fasteners will go

through mounting flange (Fig. 7).

2.

FOR ALL: Install sill channel between

side channels using appropriate

fasteners (Fig. 8). On some large

LightBlocs, sill channel is replaced by

an angle.

Please Note: Be sure of a centered and

snug fit between side channels.

3.

FOR ALL: Re-install roller assembly

by generally reversing procedures in

Section 1.

FOR SPRING ASSISTED CLUTCH OPERATOR: Spring has been pretensioned

in factor y. Notch on spring roller should be positioned down. Rotate roller so that

spear end can be worked out of slot in spear endcap. Remove roller assembly

from headbox.

4.

FOR MOTORIZED UNITS: Complete electrical wiring according to national and

local codes.

Please Note: Opaque caulking around perimeter of cover, side channels, and sill

may be necessary for complete light block—especially for jamb mounts where

window openings are not square.

electrical connections. Use extreme caution when working with

electric motors.

Figure 8

Inside Mount

3

1

/8" H x ¾" D

Face Mount

2¾" H x ¾" D

1.

With fabric and slat fully raised, pull slat bar forward, out of headbox and

in front of side channels.

2.

Activate operator (crank, spring roller, bead clutch, or electric) to

completely lower shade fabric. Repeat several times. With the shade

fabric hanging in front of side channels, check fabric hang. Shade fabric

should hang straight and equally spaced between outside edges of side

channels.

3.

If misalignment still occurs, correct by sticking a small (approximately 2")

piece of cloth tape directly to roller to affect direction the fabric runs. (For

example, fabric hanging too far left may be corrected by placing tape on

right end of roller beneath fabric. This, in effect, makes that end of the

roller larger, therefore taking up more fabric.)

Figure 9

Lip along bottom edge of headbox

Slat Bar

Side Channels

Channel Locator

Fabric Retainer

Light Seal

Fabric Guide

Fabric

Rivet

Stay Pocket

Steel Stay

Side Channel

¾" x 2 ¾"

Page 5

Slat Bar

Catch

Sill Channel

LightBloc FlexShade

®

Section 4 - Bead Chain Limits and Safety Device Installation

(for Units with Clutch or Spring Roller Operation)

page 5 of 8

Section 4.1 - Attaching Stop Balls

1.

Set upper and lower travel limits by installing stop balls to bead chain (crimp closed using pliers) (Fig. 7).

Section 4.2 - P-Clip Cord Tension Device

Attach

Stop Balls

Please Note: Draper Bead Chain Clutch Operated shades that do not comply with WMCA/ANSI Standard

A100.1-2012 come with a cord tension device pre-attached to bead chain (Fig. 8). This device

must be attached to wall, jamb or sill so that bead chain is held taut enough that children

cannot pull it away from wall or fit their head into loop.

Section 4.3 - Spring-Loaded Cord Tension Device

Draper LightBloc FlexShade complies with WMCA/ANSI Standard A100.1-2018, a Spring-Loaded Cord

Tension Device comes installed on bead chain (Fig. 9). An approved permanent warning label and approved

Sill

Mount

mechanical fasteners (wood screws) are included. Device is designed so that children cannot pull bead chain

away from wall or fit their head into loop. (See safety note on page 2).

For more information, visit www.draperinc.com/WindowShades/WCMAcompliance.asp.

Please Note: Over-tightening screws will damage Spring Loaded Tension Device.

Section 5 - Check Shade Operation (for Units with Clutch or Spring Roller Operation)

Attach bead chain to slat bar and catch to sill channel. To operate shade, pull

down, locking in place using the bead chain (Fi g . 11).

Figure 10

Crimp

Closed

with

Pliers

Figure 8Figure 7

Figure 9

Tensioner

Jamb

Mount

Page 6

Controls & System Overview

Controls & System Overview

Controls & System Overview

Data Cable Pin-Out - RJ45 ConnectorMOTOR Pin-Out - RJ9 Connector

LightBloc FlexShade

®

page 6 of 8

Section 6 - Electrical Connections (for Motorized Units)

Caution: For motorized units, make sure POWER IS OFF before making any electrical connections. Use extreme caution when working with electric motors.

Shade operates on 110-120v, 60 Hz. current. Shade ships with internal wiring complete and control switch(es) fully boxed, and standardly supplied with a 6’ cable

lead. Longer lead can be substituted by removing two screws in motor end of roller, removing lead, plugging new lead in, and replacing screws. Wire to connect

shade to switch(es) and switch(es) to power supply should be furnished by installer. Connections should be made in accordance with attached wiring diagram,

and wiring should comply with national and local electrical codes. Only RTS and 485 motors can be wired in parallel.

Please Note: All operating switches should be “off” before power is connected.

Please Note: For low voltage wiring requirements, Draper recommends consulting with a professional low voltage electrical contractor. It is very important that

shielded and stranded CAT 5 cable be used to prevent any electrical interference.

Please Note: Wiring diagram for standard right-hand motor placement with fabric from rear of roller, or left-hand motor placement with fabric from front of roller.

For left hand motor placement with fabric from rear of roller or right hand motor placement with fabric from front of roller, Red is “Up” and Black is

“Down.”

Please Note: All Motorized LightBloc FlexShade motors are equipped with M12 Connectors.

Section 7 - Wiring Diagrams (for Motorized Units)

Sonesse 120VAC Motors

120V

MOTOR

M12

Connector

W B R G

B

110-120V Line

NOTE: Test shade operation

If shade direction does not

correspond with the switch

orientation, turn power back

off and switch the red and black

wires from the motor to the switch.

Do not wire motors in parallel without

written permission from Draper.

Dashed Wiring

by Electrician

Control

Switch

Single Gang

Box (by others)

Sonesse RTS 120VAC Motors

RTS

MOTOR

120V

M12 Connector

Telis 1

RF Remote

B W G

STOP

Decora RTS

110-120V Line

Wireless Keypad

Dashed Wiring

by Electrician

Sonesse RS485 120VAC Motors

Bus Power

Supply

110V

LAN

BUS IN

110-120V Line

RS485

120VAC

Motor

B W G

DATA

CABLES

M12

Connectors

Outlet

Data Hub

RS485

120VAC

Motor

B W G

110-120V Line

BUS OUT

to next

DATA HUB

STOP

Wall Switch

Data Cable

with RJ45

Connector

Dashed Wiring

by Electrician

4 - GROUND - (BROWN)

3 - POWER + (BLUE)

2 - DATA - (ORANGE)

1 - DATA + (ORANGE/WHITE)

1 - DATA + (ORANGE/WHITE)

2 - DATA - (ORANGE)

3 - N/A (GREEN/WHITE)

4 - POWER + (BLUE)

5 - POWER - (BLUE/WHITE)

6 - N/A (GREEN)

7 - GROUND - (BROWN/WHITE)

8 - GROUND - (BROWN)

Page 7

Bottom View

ROOM SIDE

+

+

Bottom View

Programming

Button

Pen

BACK

BACK

LightBloc FlexShade

®

Section 8 - Limit Switch Adjustments (for Motorized Units)

Section 8.1 - Standard and Quiet Motors (All procedures shown are for Standard Roll. Inver t orientation for Reverse Roll)

Section 8.1.1- Push Button Limits

1.

Fully depress both limit switch push buttons, then

operate wall switch to ensure system works properly.

2.

Raise shade to desired “up” stop position.

3.

Set upper limit by depressing proper (back) push button.

4.

Lower shade to desired “down” stop position.

5.

Set lower limit by depressing proper (front) push button.

Section 8.1.2 - Screw-Type Limits

1.

Determine which direction of fabric travel corresponds

with arrows on motor.

2.

Operate shade to desired “down” stop position.

Set limit by turning proper socket toward “+”

Caution:

- All switches must be in “off”

position before adjusting limit

switches.

- Be prepared to shut off

manually while testing.

- Shade may be damaged by

running shade fabric down

too far to expose roller.

- If using a group control system,

each limit switch must be set

prior to connecting to system.

- Motor must be installed so limit

switches are pointed down.

to lower limit, and “-” to raise it.

3.

Operate shade to desired “up” stopping position. Set limit by turning proper screw

toward “-” to raise limit, and “+” to lower it.

Section 8.2 - Limit Adjustments (RS485 Motors)

For limit setting instructions on these motors, see instructions packaged

with RS485 Address/Limit Setting Tool (part# C156.241).

PUSH BUTTON LIMITS

ROOM SIDE

Front

Back

GLASS SIDE

Bottom View

SCREW-TYPE LIMITS

Front

Back

GLASS SIDE

+

+

Bottom View

Standard right-hand

motor configuration shown

Side View

Standard right-hand

motor configuration shown

Screws

Side View

page 7 of 8

Section 8.3 - Limit Switch Adjustments—RTS Motors

Section 8.3.1 - Programming Instructions

1.

Connect power to one motor. Select a transmitter channel to assign motor. Hold UP & DOWN buttons until motor jogs, then release.

2.

Check motor direction. To reverse motor direction, hold MY/STOP button for 5 seconds until motor jogs. Check direction again.

Please Note: Failure to complete Step 2 before Step 3 can only be corrected with a motor reset (Section 8.3.6).

3.

Move motor to upper limit position. Hold MY/STOP & DOWN buttons until motor moves down, then release.

Stop shade at desired lower limit position using MY/STOP button (shade will not stop on its own).

UP and DOWN buttons can be used to adjust the lower limit position if needed.

4.

While motor is at lower limit, hold UP & MY/STOP buttons until motor moves up, then release.

The shade should move to upper limit and stop.

5.

Next, hold MY/STOP button for five seconds until motor jogs.

6.

Put motor into USER MODE by pressing small programming button (Fig. 13) on back of transmitter until motor jogs.

7.

Disconnect power to this motor and move to next motor in installation and start with step 1.

8.

Reconnect motor to power when all motors are programmed.

Section 8.3.2 - Setting an Intermediate Stop - Shade MUST BE in USER mode.

1.

Move shade to desired mid-point location and hold MY/STOP button until motor jogs.

2.

To test, press MY/STOP button when motor is standing still. Shade will move to that intermediate location.

3.

To delete an intermediate stop, go to intermediate stop and hold MY/STOP button until motor jogs.

Section 8.3.3 - Add a Channel - Shade MUST BE in USER mode.

1.

Select channel currently operating motor, then hold programming button until motor jogs.

2.

Select new channel to add to motor, then hold programming button until motor jogs.

3.

The motor should now work on both old and new channel.

Section 8.3.4 - Delete a Channel - Shade MUST BE in USER mode.

1.

Select channel operating motor that you want to keep, then hold programming button until motor jogs.

2

Select channel to remove, then hold programming button until motor jogs.

Motor should now only work on channel kept from Step 1.

Section 8.3.5 - Adjust Limits in User Mode

1.

Move motor to limit (upper or lower) to be changed. Shade must move to previously set limit and will stop automatically.

2.

Hold UP & DOWN buttons until motor jogs.

3.

Move motor to its new limit location and hold MY/STOP button until motor jogs.

Section 8.3.6 - Reset Motor

1.

Disconnect power for 5 seconds and reconnect to power for 15 seconds. Disconnect power for 5 seconds, then reconnect to power and leave connected.

Shade should roll down a few inches and stop.

2.

Hold programming button (Fig. 13) for 15 seconds. Motor will jog up and down once; pause and then jog a 2nd time.

Motor is now reset and ready to be programmed.

Figure 12

UP

STOP

DOWN

LED Lights

Channel

Selector

Figure 13

Pen

Programming

Button

Page 8

)

Top/Back Cover

(3

LightBloc FlexShade

®

Section 9 - Dimensions - LightBloc FlexShade

⁷₈

" (22.23mm)

Unit width = Cloth width + 2

Endcap Assembly

Stay

₈

" (60.33mm)

Face/Bottom Cover

⁷₈

" (22.23mm)

2"

⁵₁₆

"(100.01mm)

3

(50.8mm)

page 8 of 8

3

⁷₁₆

(87.32mm)

Light

Seal

Overall shade height

Cloth

"

₄

"

1

(44.45mm)

2

₄

(69.85mm

"

1

⁹₁₆

9.69mm)

1

₁₆

(30.16mm)

Slat

Bar

Weight

Bar

Liner

Side Channel

Sill

Channel

₄

"

"

Clear opening = Cloth width - 3

Cloth width

Side channel width = Cloth width + 2

₈

" (79.38mm)

₈

" (60.33mm)

1

⁹₁₆

" (39.69mm)

1

₁₆

" (30.16mm)

2

₄

" (69.85mm)

"

Loading...

Loading...