Page 1

PowerGuide® 4400

USER’S GUIDE

DRANETZ

1000 New Durham Road

Edison, New Jersey 08818-4019

www. .com

information@itm.com1.800.561.8187

Page 2

WARNING

Death, serious injury, or fire hazard could result from improper connection of this instrument. Read and

understand this manual before connecting this instrument. Follow all installation and operating

instructions while using this instrument.

Connection of this instrument must be performed in compliance with the National Electrical Code (ANSI/

NFPA 70-2005) of USA and any additional safety requirements applicable to your installation.

Installation, operation, and maintenance of this instrument must be performed by qualified personnel

only. The National Electrical Code defines a qualified person as “one who has the skills and knowledge

related to the construction and operation of the electrical equipment and installations, and who has

received safety training on the hazards involved.”

Qualified personnel who work on or near exposed energized electrical conductors must follow applicable

safety related work practices and procedures including appropriate personal protective equipment in

compliance with the Standard for Electrical Safety Requirements for Employee Workplaces (ANSI/NFPA

70E-2004) of USA and any additional workplace safety requirements applicable to your installation.

Published by Dranetz

1000 New Durham Road

Edison, NJ 08818-4019 USA

Telephone: 1-800-372-6832 or 732-287-3680

Fax: 732-248-1834

Web site: www.dranetz

Copyright © 2003, 2004, 2005 Dranetz

All rights reserved.

No part of this book may be reproduced, stored in a

retrieval system, or transcribed in any form or by any

means—electronic, mechanical, photocopying, recording,

or otherwise—without prior written permission from the

publisher, Dranetz

Printed in the United States of America.

P/N UG-4400 Rev.

ii

.com

, Edison, NJ 08818-4019.

J

www. .com

information@itm.com1.800.561.8187

Page 3

ADVERTENCIA

U

na conexión incorrecta de este instrumento puede producir la muerte, lesiones graves y riesgo de incendio. Lea y

entienda este manual antes de conectar. Observe todas las instrucciones de instalación y operación durante el uso de

este instrumento.

La conexión de este instrumento a un sistema eléctrico se debe realizar en conformidad con el Código Eléctrico

Nacional (ANSI/NFPA 70-2005) de los E.E.U.U., además de cualquier otra norma de seguridad correspondiente a su

establecimiento.

La instalación, operación y mantenimiento de este instrumento debe ser realizada por personal calificado solamente.

El Código Eléctrico Nacional define a una persona calificada como "una que esté familiarizada con la construcción y

operación del equipo y con los riesgos involucrados."

El personal cualificado que trabaja encendido o acerca a los conductores eléctricos energizados expuestos debe seguir

prácticas y procedimientos relacionados seguridad aplicable del trabajo incluyendo el equipo protector personal

apropiado en conformidad con el estándar para los requisitos de seguridad eléctricos para los lugares de trabajo del

empleado (ANSI/NFPA 70E-2004) de los E.E.U.U. y cualquier requisito de seguridad adicional del lugar de trabajo

aplicable a su instalación.

AVERTISSEMENT

Si l'instrument est mal connecté, la mort, des blessures graves, ou un danger d'incendie peuvent s'en suivre. Lisez

attentivement ce manuel avant de connecter l'instrument. Lorsque vous utilisez l'instrument, suivez toutes les

instructions d'installation et de service.

Cet instrument doit être connecté conformément au National Electrical Code (ANSI/NFPA 70-2005) des Etats-Unis

et à toutes les exigences de sécurité applicables à votre installation.

Cet instrument doit être installé, utilisé et entretenu uniquement par un personnel qualifié. Selon le National

Electrical Code, une personne est qualifiée si "elle connaît bien la construction et l'utilisation de l'équipement, ainsi

que les dangers que cela implique".

Le personnel qualifié qui travaillent dessus ou s'approchent des conducteurs électriques activés exposés doit suivre

des pratiques en matière et des procédures reliées par sûreté applicable de travail comprenant le matériel de protection

personnel approprié conformément à la norme pour des conditions de sûreté électriques pour les lieux de travail des

employés (ANSI/NFPA 70E-2004) des Etats-Unis et toutes les conditions de sûreté additionnelles de lieu de travail

applicables à votre installation.

WARNUNG

Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer verursachen. Bevor Sie dieses

Instrument anschließen, müssen Sie die Anleitung lesen und verstanden haben. Bei der Verwendung dieses

Instruments müssen alle Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen Bestimmungen für Elektrizität

(ANSI/NFPA 70-2005) der Vereinigten Staaten, sowie allen weiteren, in Ihrem Fall anwendbaren

Sicherheitsbestimmungen, vorgenommen werden.

Installation, Betrieb und Wartung dieses Instruments dürfen nur von Fachpersonal durchgeführt werden. In dem

nationalen Bestimmungen für Elektrizität wird ein Fachmann als eine Person bezeichnet, welche "mit der Bauweise

und dem Betrieb des Gerätes sowie den dazugehörigen Gefahren vertraut ist."

Qualifiziertes Personal, das an bearbeiten oder herausgestellte angezogene elektrische Leiter sich nähern,

muß anwendbare Sicherheit bezogener Arbeit Praxis und Verfahren einschließlich passende persönliche

schützende Ausrüstung gemäß dem Standard für elektrische Sicherheitsauflagen für AngestelltArbeitsplätze (ANSI/NFPA 70E-2004) der Vereinigten Staaten und alle zusätzlichen

Arbeitsplatzsicherheitsauflagen folgen, die auf Ihre Installation anwendbar sind.

www. .com

iii

information@itm.com1.800.561.8187

Page 4

Safety Summary

Definitions

Symbols

Definiciones

WARNING statements inform the user that certain conditions or practices could result

in loss of life or physical harm.

CAUTION statements identify conditions or practices that could harm the 4400, its

data, other equipment, or property.

NOTE statements call attention to specific information.

The following International Electrotechnical Commission (IEC) symbols are marked

on the top and rear panel in the immediate vicinity of the referenced terminal or device:

!

Las ADVERTENCIAS informan al usuario de ciertas condiciones o prácticas que

podrían producir lesiones mortales o daño físico.

Las PRECAUCIONES identifican condiciones o prácticas que podrían dañar la 4400,

sus datos, otros equipos o propiedad.

Caution, refer to accompanying documents (this manual).

Direct current (DC) operation of the terminal or device.

Power Switch

Símbolos

Las NOTAS llaman la atención hacia la información específica.

Los siguientes símbolos de la Comisión Internacional Electrotécnica (IEC) aparecen

marcados en el panel superior y el posterior inmediatos al terminal o dispositivo en

referencia:

!

Precaución, consulte los documentos adjuntos (este manual).

Operación de corriente continua (CC) del terminal o dispositivo.

Interruptor de encendido

Continued on next page

iv

www. .com

information@itm.com1.800.561.8187

Page 5

Safety Summary, Continued

Définitions

Symboles

Definitionen

Les messages d’AVERTISSEMENT préviennent l’utilisateur que certaines conditions

ou pratiques pourraient entraîner la mort ou des lésions corporelles.

Les messages de MISE EN GARDE signalent des conditions ou pratiques susceptibles

d’endommager “4400”, ses données, d’autres équipements ou biens matériels.

Les messages NOTA attirent l’attention sur certains renseignements spécifiques.

Les symboles suivants de la Commission électrotechnique internationale (CEI) figurent

sur le panneau arrière supérieur situé à proximité du terminal ou de l’unité cité:

!

WARNUNGEN informieren den Benutzer darüber, daß bestimmte Bedingungen oder

Vorgehensweisen körperliche oder tödliche Verletzungen zur Folge haben können.

VORSICHTSHINWEISE kennzeichnen Bedingungen oder Vorgehensweisen, die zu

einer Beschädigung von 4400, seiner Daten oder anderer Geräte bzw. von Eigentum

führen können.

Mise en garde, consultez les documents d’accompagnement (ce manual).

Fonctionnement du terminal ou de l’unité en courant continu (CC).

Interrupteur de tension

Symbole

HINWEISE machen auf bestimmte Informationen aufmerksam.

Die folgenden Symbole der Internationalen Elektrotechnischen Kommission

(International Electrotechnical Commission; IEC) befinden sich auf der Abdeck- und

Seitenplatte unmittelbar am betreffenden Terminal oder Gerät.

!

Vorsichtshinweis, siehe Begleitdokumente (dieses Handbuch).

Gleichstrombetrieb im Terminal oder Gerät.

Netzschalter

Continued on next page

v

www. .com

information@itm.com1.800.561.8187

Page 6

Safety Summary, Continued

Safety

precautions

The following safety precautions must be followed whenever any type of voltage or

current connection is being made to the 4400.

• Wear proper Personal Protective Equipment, including safety glasses and insulated

gloves when making connections to power circuits.

• Hands, shoes and floor must be dry when making any connection to a power line.

• Before each use, inspect all cables for breaks or cracks in the insulation. Replace

immediately if defective.

• Set the 4400 power switch to Off.

• Before connecting to electric circuits to be monitored, open their related circuit

breakers or disconnects. DO NOT install any connection of the 4400 to live power

lines.

• Connections must be made to the 4400 first, then connect to the circuit to be

monitored.

These safety precautions are repeated where appropriate throughout this manual.

vi

www. .com

information@itm.com1.800.561.8187

Page 7

Statements and Notices

Statement of

warranty

Statement of

reliability

Notice regarding

FCC compliance

All products of Dranetz

material and workmanship for a period of one year from the date of delivery. Dranetz

will repair or replace, at its option, all defective equipment that is returned, freight

prepaid, during the warranty period. There will be no charge for repair provided there is

no evidence that the equipment has been mishandled or abused. This warranty shall not

apply to any defects resulting from improper or inadequate maintenance, buyersupplied hardware/software interfacing, unauthorized modification or misuse of the

equipment, operation outside of environmental specifications, or improper site

preparation or maintenance.

The information in this manual has been reviewed and is believed to be entirely

reliable, however, no responsibility is assumed for any inaccuracies. All material is for

informational purposes only and is subject to change without prior notice.

This device has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense.

are warranted to the original purchaser against defective

Notice regarding

proprietary

rights

This publication contains information proprietary to Dranetz

using this manual, you agree that the information contained herein will be used solely

for the purpose of operating equipment of Dranetz

.

. By accepting and

Continued on next page

www. .com

vii

information@itm.com1.800.561.8187

Page 8

Statements and Notices, Continued

Copyright

Trademarks

This publication is protected under the Copyright laws of the United States, Title 17 et

seq. No part of this publication may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language or computer language, in any form, by

any means, electronic, mechanical, magnetic, optical, chemical, manual, or otherwise,

without the prior written consent of Dranetz, 1000 New Durham Road, Edison,

New Jersey 08818.

Copyright © 2003, 2004, 2005 Dranetz

All Rights Reserved. Printed in the United States of America.

PowerGuide, Scope Mode, NodeLink and DranView are registered trademarks of

Dranetz

.

viii

www. .com

information@itm.com1.800.561.8187

Page 9

Table of Contents

Safety Summary .................................................................................................................... iv

Statements and Notices.......................................................................................................... vii

CHAPTER 1 - Getting Started

Overview ............................................................................................................................... 1-1

Unpacking the 4400............................................................................................................... 1-3

Standard Accessories............................................................................................................. 1-4

4400 Controls, Indicators, and Connectors ........................................................................... 1-5

Top and Side Views ........................................................................................................ 1-6

Front View ...................................................................................................................... 1-7

Bottom View................................................................................................................... 1-8

Rear View ....................................................................................................................... 1-9

Upgrading Firmware from a Data Card................................................................................. 1-10

4400 Features......................................................................................................................... 1-12

Basic Operation ..................................................................................................................... 1-14

Power-on Sequence......................................................................................................... 1-15

Home Screen Icons ......................................................................................................... 1-16

CHAPTER 2 - Voltage Measurement Cable and Current Probe Connections

Overview ............................................................................................................................... 2-1

Connecting Voltage Measurement Cables ............................................................................ 2-4

Connecting Current Probes.................................................................................................... 2-9

CHAPTER 3 - View Real Time Data

Overview ............................................................................................................................... 3-1

Section A -Scope Mode ............................................................................................................... 3-2

Overview ............................................................................................................................... 3-2

Turning Channels On/Off...................................................................................................... 3-3

Checking Input Range ........................................................................................................... 3-4

Section B -Meter Mode................................................................................................................ 3-5

Overview ............................................................................................................................... 3-5

Standard Meter Tab ............................................................................................................... 3-6

Distortion Meter Tab ............................................................................................................. 3-8

Section C -Harmonics .................................................................................................................. 3-10

Overview ............................................................................................................................... 3-10

Harmonic Graph .................................................................................................................... 3-11

Harmonic Detail .................................................................................................................... 3-12

Harmonic Options.................................................................................................................. 3-13

Harmonic List........................................................................................................................ 3-15

Section D -Voltage and Current Phasor....................................................................................... 3-16

Overview ............................................................................................................................... 3-16

Phasor Screen ........................................................................................................................ 3-17

Phasor Rotation...................................................................................................................... 3-18

Phasor Parameter/Channel Selection..................................................................................... 3-20

www. .com

ix

information@itm.com1.800.561.8187

Page 10

Table of Contents, Continued

CHAPTER 4 - Instrument Settings

Overview ............................................................................................................................... 4-1

Access Instrument Settings Menu ......................................................................................... 4-2

Time and Date Settings..........................................................................................................4-3

Select Language..................................................................................................................... 4-5

Set Display Preferences......................................................................................................... 4-6

Touch Screen Calibration ...................................................................................................... 4-7

Turn Threshold Beeper On/Off ............................................................................................. 4-9

Communications.................................................................................................................... 4-10

Data Card............................................................................................................................... 4-12

Reset to Factory Configurations............................................................................................ 4-14

CHAPTER 5 - Start Menu

Overview ............................................................................................................................... 5-1

Section A -Automatic Setup......................................................................................................... 5-3

Section B -Wizard Setup.............................................................................................................. 5-5

Overview ............................................................................................................................... 5-5

Current Probe Selection.........................................................................................................5-7

Scale Factor Setup ................................................................................................................. 5-9

Circuit Type Selection........................................................................................................... 5-11

Nominal Values ..................................................................................................................... 5-13

Mode of Operation................................................................................................................. 5-16

Monitoring Mode................................................................................................................... 5-17

Advanced Options ................................................................................................................. 5-18

Site Name/Memory Card....................................................................................................... 5-19

Section C -Monitor Same Circuit.................................................................................................5-23

Overview ............................................................................................................................... 5-23

Turning Monitoring On/Off................................................................................................... 5-24

Monitoring at a Specified Time and Date ............................................................................. 5-27

Modify Trigger Parameters and Intervals.............................................................................. 5-32

Section D -Load Setup Template from Card................................................................................ 5-33

Section E -Load Data from Card..................................................................................................5-34

Overview ............................................................................................................................... 5-34

Loading Data from Card........................................................................................................ 5-34

Card Error Messages ............................................................................................................. 5-35

CHAPTER 6 - Advanced Setup Options

Overview ............................................................................................................................... 6-1

Advanced Options Menu....................................................................................................... 6-2

Transient Limit ...................................................................................................................... 6-3

x

www. .com

information@itm.com1.800.561.8187

Page 11

Table of Contents, Continued

RMS Variation Limit............................................................................................................. 6-8

Waveform Capture ................................................................................................................ 6-13

Characterizer Options............................................................................................................ 6-14

Journal Limit.......................................................................................................................... 6-15

Journal Interval for Timed Readings..................................................................................... 6-18

EN50160 Power Quality (for strict EN50160 monitoring only) ........................................... 6-20

CHAPTER 7 - View Event Data

Overview ............................................................................................................................... 7-1

Section A -Events......................................................................................................................... 7-4

Overview ............................................................................................................................... 7-4

Event Data Display................................................................................................................ 7-5

Event Activity Graph............................................................................................................. 7-6

Event List............................................................................................................................... 7-7

Event Detail ........................................................................................................................... 7-9

Event Options ........................................................................................................................ 7-12

Section B -Trend .......................................................................................................................... 7-15

Overview ............................................................................................................................... 7-15

Trend Display ........................................................................................................................ 7-16

Trend Setup............................................................................................................................ 7-17

CHAPTER 8 - Reports

Overview ............................................................................................................................... 8-1

Section A -EN50160 .................................................................................................................... 8-2

Overview ............................................................................................................................... 8-2

EN50160 Measurement Parameters ...................................................................................... 8-3

EN50160 Compliance Limits ................................................................................................ 8-5

Compliance Statistical Bar Chart .......................................................................................... 8-8

Compliance History............................................................................................................... 8-11

Event Satistics........................................................................................................................ 8-13

Min/Max Table for Power Frequency and RMS Voltage ..................................................... 8-15

Section B -Status Report in Annunciator Panel ........................................................................... 8-16

Overview ............................................................................................................................... 8-16

Panel Setup Options............................................................................................................... 8-17

Panel Operation ..................................................................................................................... 8-19

CHAPTER 9 - Downloading Events

Overview ............................................................................................................................... 9-1

External Communication Interface........................................................................................ 9-2

Downloading Events via NodeLink ...................................................................................... 9-10

Viewing Events via DranView.............................................................................................. 9-11

DranView with HASP ........................................................................................................... 9-12

www. .com

xi

information@itm.com1.800.561.8187

Page 12

Table of Contents, Continued

APPENDIX A - Optional Accessories

Overview ............................................................................................................................... A-1

Hardware Accessories List & Descriptions........................................................................... A-2

Software Accessories List ..................................................................................................... A-8

APPENDIX B - Technical Specifications

Overview ............................................................................................................................... B-1

General................................................................................................................................... B-2

Interfaces ............................................................................................................................... B-3

Measured Parameters............................................................................................................. B-4

Computed Parameters............................................................................................................ B-5

Parameter Settings in Each Monitoring Mode ...................................................................... B-9

TR2500 Current Probe........................................................................................................... B-11

TR2510 Current Probe........................................................................................................... B-12

APPENDIX C - Battery Specifications and Replacement Procedure

Overview ............................................................................................................................... C-1

Battery Specifications............................................................................................................ C-2

Battery Safety Precautions..................................................................................................... C-3

External Battery Charger....................................................................................................... C-4

Battery Pack Replacement..................................................................................................... C-6

APPENDIX D - User Replaceable Parts List

APPENDIX E - Common Circuit Connections

Overview ............................................................................................................................... E-1

Verifying Voltage and Current Connections......................................................................... E-5

Single Phase........................................................................................................................... E-7

Split Phase ............................................................................................................................. E-8

3 Phase, Four Wire Wye........................................................................................................ E-9

3 Phase (Floating or Grounded) Delta................................................................................... E-10

3 Phase 2-Watt Delta ............................................................................................................. E-11

Generic Circuit ...................................................................................................................... E-12

2 1/2 Element Without Voltage Channel B........................................................................... E-13

2 1/2 Element Without Voltage Channel C........................................................................... E-14

Connecting to a Potential Transformer (PT) ......................................................................... E-15

Connecting to a Current Transformer (CT)........................................................................... E-17

Connecting to an Isolated Current Transformer (ISO).......................................................... E-18

APPENDIX F - Event Classification

APPENDIX G - 4400 Menu Structure

xii

www. .com

information@itm.com1.800.561.8187

Page 13

Dranetz PowerGuide® 4400

www. .com

xiii

information@itm.com1.800.561.8187

Page 14

xiv

www. .com

information@itm.com1.800.561.8187

Page 15

Overview

CHAPTER 1

Getting Started

PowerGuide

4400 description

4400 Firmware

The Dranetz

quality meter/monitor. This cutting-edge power quality instrument is designed with a

color liquid crystal display (LCD) 1/4 VGA, using touch screen technology. It can

monitor, record and display data on four voltage channels and four current channels

simultaneously.

The 4400 is designed to meet both the IEEE 1159 and IEC 61000-4-30 Class A

standards for accuracy and measurement requirements. It can also monitor EN50160

compliance based on the EN (European) Standards. The statistical package called

Quality of Supply (QOS) is built into the 4400, with monitoring and setup protocols set

to determine voltage measurement compliance required for EN50160 monitoring.

European standard EN50160 requires that measurement parameters must be within a

specified percentage for 95% of the time.

The firmware for the 4400 is contained on internal FLASH memory. It has an operating

system capable of performing multiple applications. When an updated version of the

firmware is released, the user can upgrade the internal program by putting the latest

4400 firmware program card in the appropriate slot of the mainframe. See page 1-10

for instructions on how to upgrade the 4400 firmware from a data card.

The 4400 firmware can monitor power quality phenomena for troubleshooting and/or

compliance purposes. It can record inrush conditions, carry out long-term statistical

studies to establish performance baselines, and perform field-based equipment testing

and evaluation for commissioning and maintenance. The firmware integrates an

intuitive instrument setup procedure to ensure the capture of all relevant data for

additional post process analysis, report writing, and data archiving using other

compatible Dranetz software applications such as NodeLink

PowerGuide

®

4400 is a portable, hand-held, eight-channel power

®

and DranView®.

This manual

This manual contains instructions for operating the Dranetz

www. .com

PowerGuide 4400.

1-1

information@itm.com1.800.561.8187

Page 16

Overview, continued

In this chapter

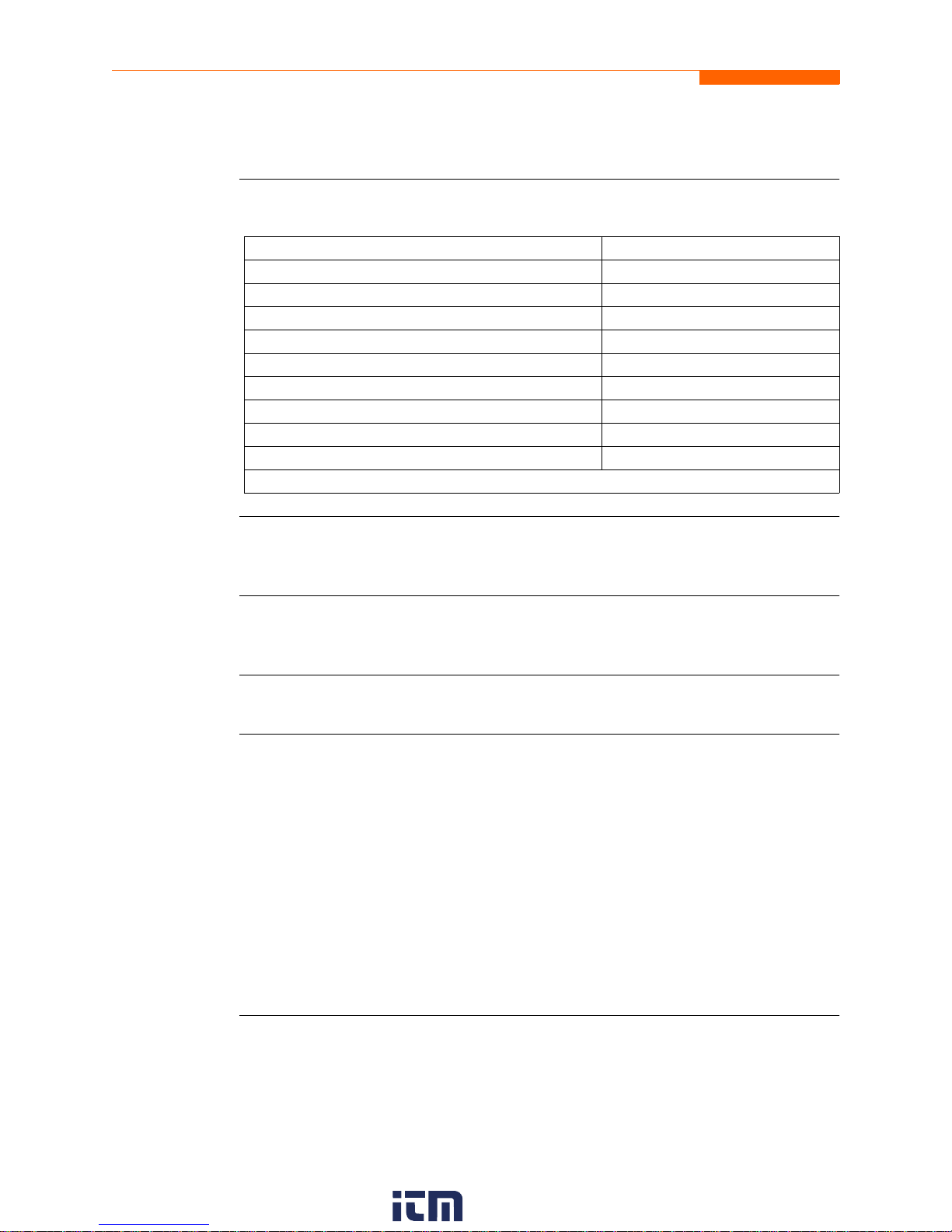

The following topics are covered in this chapter.

Topic See Page

Unpacking the 4400 1-3

Standard Accessories 1-4

4400 Controls, Indicators and Connectors 1-5

Upgrading Firmware from a Data Card 1-10

4400 Features 1-12

Basic Operation 1-14

1-2

www. .com

information@itm.com1.800.561.8187

Page 17

Unpacking the 4400

CH 1/ Getting Started

Introduction

Unpacking

Shipping

damage

inspection

For maximum protection against possible shipping damage, the 4400 has been sealed in

a two-piece, plastic suspension pack, enclosed within a durable shipping carton. After

opening the carton, inspect the contents for possible shipping damage and check the

carton inventory.

Unpack the 4400 from the carton as follows:

Step Action

1 Remove any remaining literature inside the top of the carton.

2 Carefully remove the 4400 from its shipping carton.

3 Remove all accessories inside the carton. Check that all of the standard

accessories (see page 1-4) are included.

Visually inspect the 4400 for possible shipping damage. If any damage exists, first

notify and file an insurance claim with your carrier or underwriter or both. Then notify

Dranetz

NOT return the 4400 without prior instructions from Dranet

Department. Dranetz

3680 or 1-800-372-6832.

Customer Service Department of your intentions to return the unit. DO

z Customer Service

Customer Service Department can be reached at (732) 287-

Repacking for

return shipment

Return notice

If the unit must be returned to Dranetz

in heavy packaging material and place in a well padded box or crate to prevent damage.

Do not return the 4400 in an unpacked box. Dranetz

damage incurred during transit due to inadequate packing on your part.

Notify Dranetz

return the unit without prior instructions from Dranetz

Service Department can be reached at (732) 287-3680 or 1-800-372-6832.

Customer Service of your intention of returning the unit. Do not

for service or repair, wrap the unit securely

will not be responsible for

. Dranetz Customer

www. .com

1-3

information@itm.com1.800.561.8187

Page 18

St andard Accesso ries

Standard Accessories

Standard

accessories

Optional

accessories

Batteries

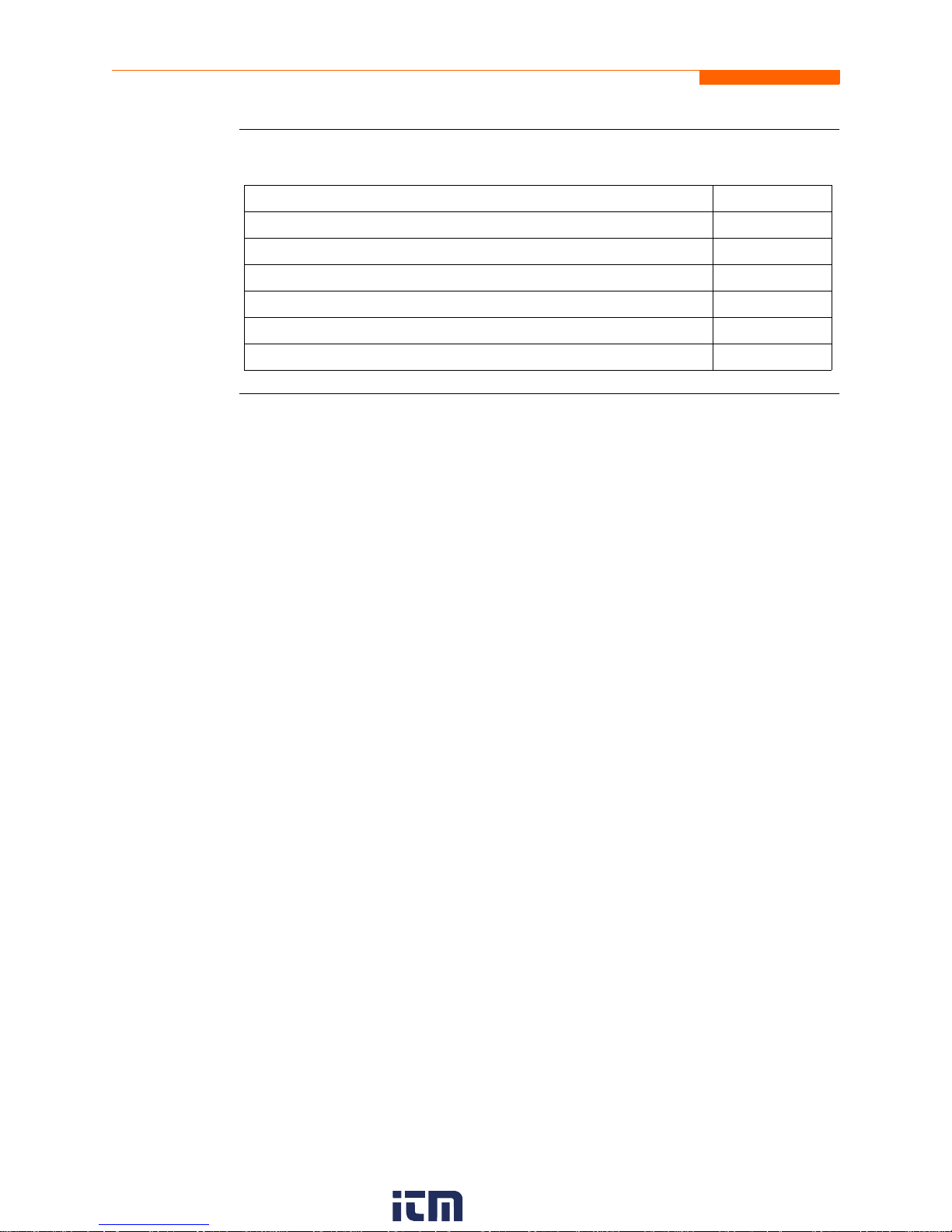

The following table lists the 4400's standard accessories.

Description Part Number

Cable Set 116042-G3

Easel 116038-G1

AC Adapter 117029-G1

*US Power Cord USSTDCORD (900744)

*European Power Cord EUROSTDCORD (115369-G2)

*United Kingdom Power Cord UKSTDCORD (115368-G2)

*Australian Power Cord AUSTDCORD (901347)

Notice: Charge Battery 899117

PowerGuide 4400 User’s Guide UG-4400

*User specified, one standard only.

Refer to Appendix A for the list of hardware and software optional accessories

available for use with 4400.

Refer to Appendix C for the description and replacement of the batteries contained in

4400.

Replaceable

parts

Calibration

Refer to Appendix D for the user replaceable parts.

The recommended calibration interval for this unit is once every 12 months.

We recommend that you return the unit to the factory for calibration. If you decide to

do so, first contact the Dranetz

Authorization Number.

Telephone: (732) 287-3680 or 1-800-372-6832

FAX: (732) 248-9240

Fill out the Repair/Service Order form enclosed in the shipping carton and ship it along

with the unit to the Dranetz Repair Department. (If this form is missing, ask the

Dranetz

Customer Service Department for a replacement.)

Customer Service Department to obtain an

1-4

www. .com

information@itm.com1.800.561.8187

Page 19

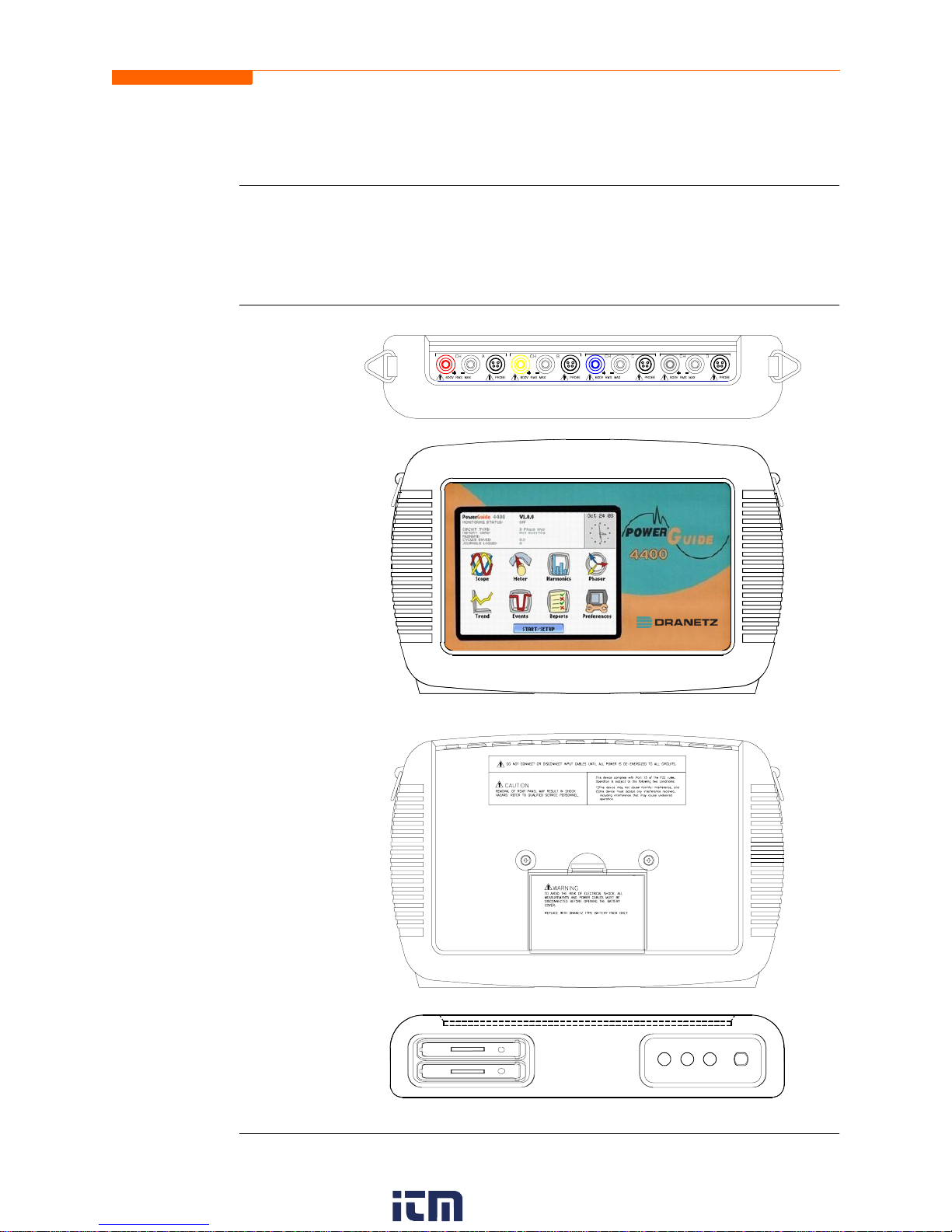

4400 Controls, Indicators, and Connectors

CH 1/ Getting Started

Dimensions

4400 is a self-contained, portable instrument weighing less than 4 pounds and

measuring 8" (20.3 cm) deep by 12" (30.5 cm) wide by 2.5" (6.4 cm) high. This section

identifies and describes the controls, indicators, and connectors on all panels of the

4400 shown with rubber boot installed.

Top View

Front View

Rear View

Bottom View

SLOT 1

SLOT 2

1-5

www. .com

information@itm.com1.800.561.8187

Page 20

4400 Controls, Indicators, and Connectors, continued

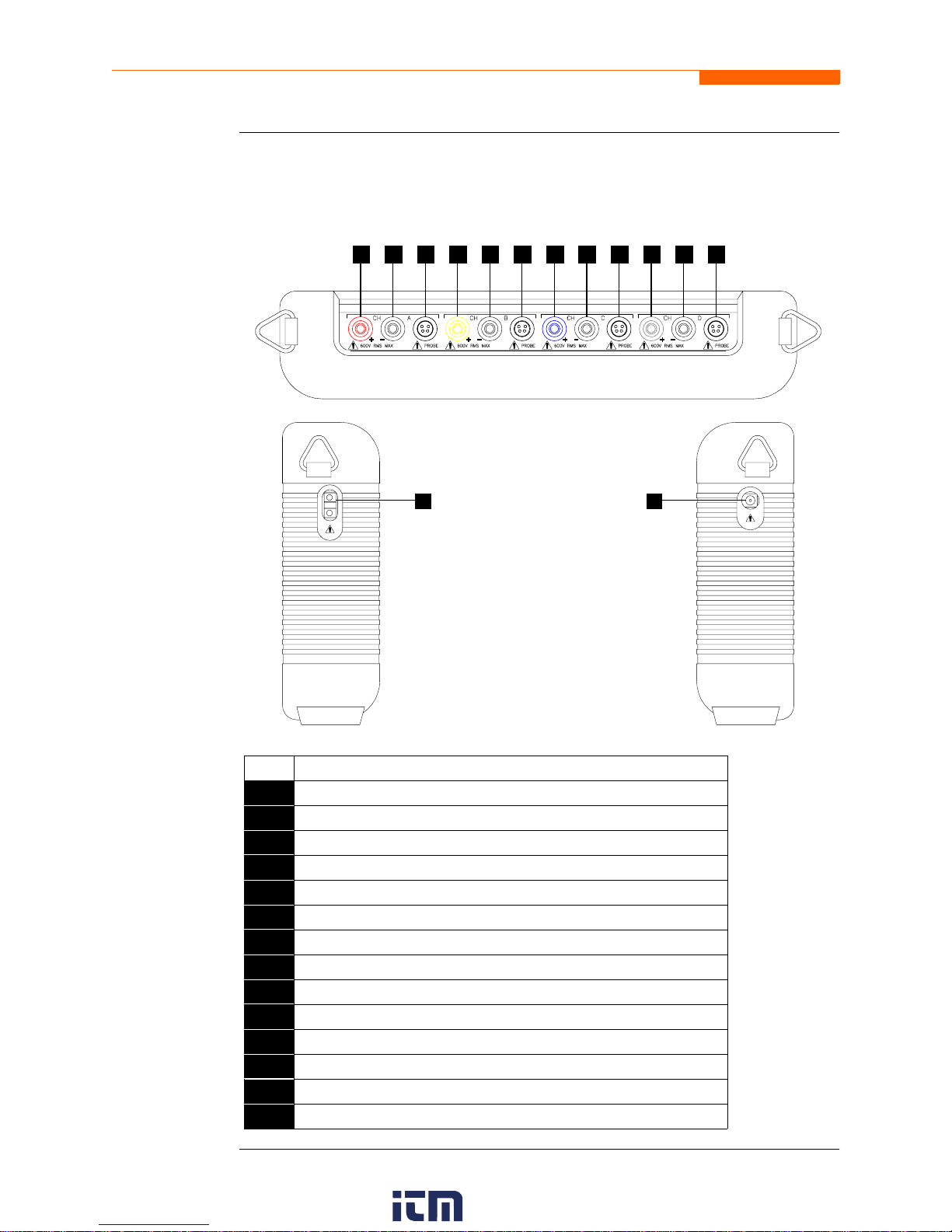

Top and Side

views

The top (circuit connection) view features the input voltage and current connectors.

The left side contains the optical interface port. The right side contains the AC adapter

input connector. Both sides have rings for attaching the supplied carrying strap. See

below for descriptions of the top and side connectors.

1 2 3 5 6 7 8 9 10 11 124

13 14

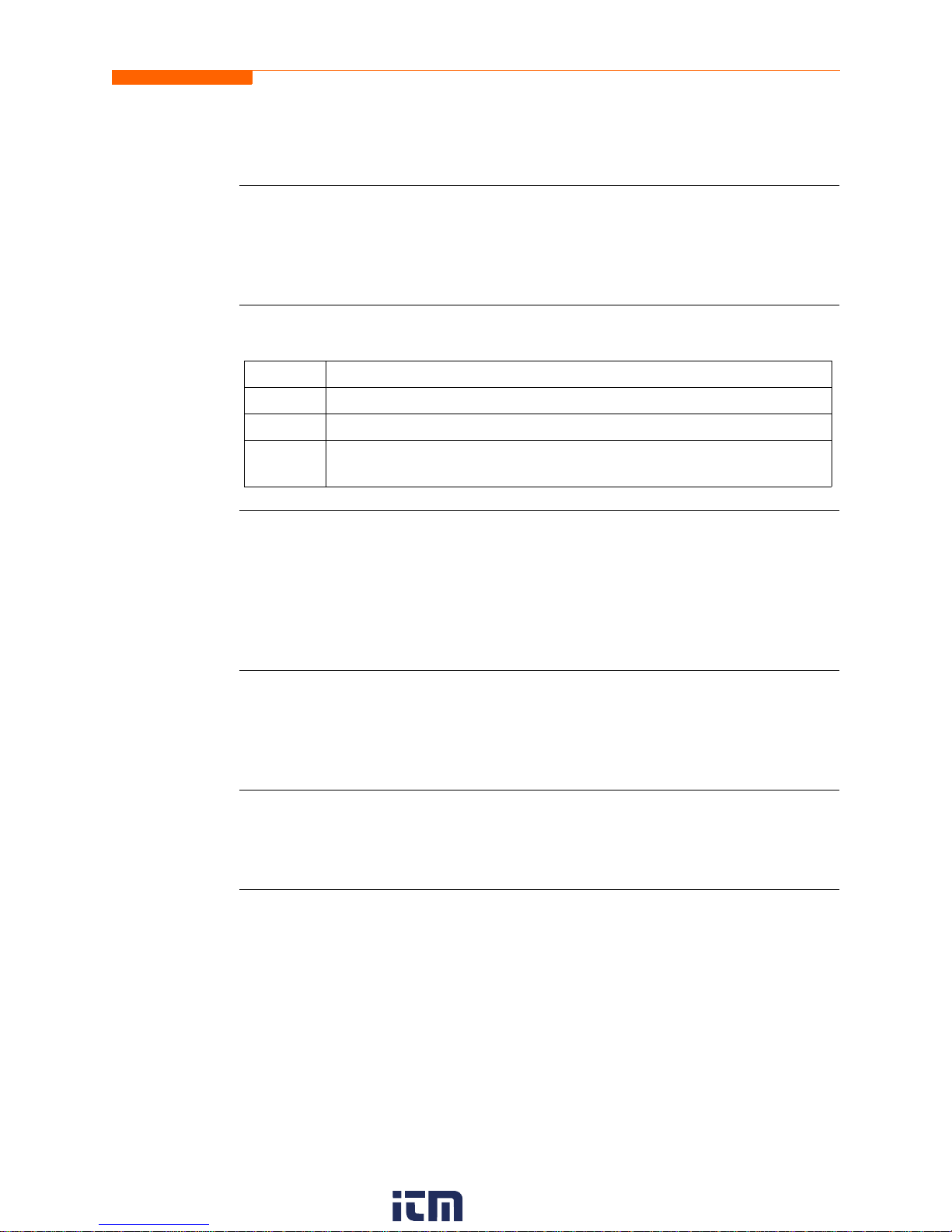

Parts table

1-6

Part Function

1 CH A, + Differential Voltage Input Connector; color red.

2 CH A, - Differential Voltage Input Connector; color white.

3 CH A, PROBE, Current Input Connector.

4 CH B, + Differential Voltage Input Connector; color yellow.

5 CH B, - Differential Voltage Input Connector; color white.

6 CH B, PROBE, Current Input Connector.

7 CH C, + Differential Voltage Input Connector; color blue.

8 CH C, - Differential Voltage Input Connector; color white.

9 CH C, PROBE, Current Input Connector.

10 CH D, + Differential Voltage Input Connector; color grey.

11 CH D, - Differential Voltage Input Connector; color white.

12 CH D, PROBE, Current Input Connector.

13 Optical Serial Data Port

14 AC Adapter/Battery Charger Input Connector.

www. .com

information@itm.com1.800.561.8187

Page 21

CH 1/ Getting Started

Front view

The front view primarily shows the color touch screen LCD. See below for descriptions

of the 4400 front panel.

21

Parts table

Part Function

1 Mainframe Protective Rubber Boot Enclosure

2 Liquid Crystal Display (LCD). Provides 3.75 x 4.75 inches display

consisting of 1/4 VGA size screen of text and graphic information. The

color LCD is equipped with touch screen technology, operable using the

finger and/or PDA stylus. Touch screen display permits menu selection,

alphanumeric data entry, and has a compact fluorescent (CCFL)

backlighting that is always on for low light level viewing.

The following are some basic care instructions for the LCD monitor

• Use and store the unit within the specified temperature and humidity

range. The LCD screen may be adversely affected by exposure to high

temperature or humidity. Condensation or moisture produced by

sudden temperature changes may also damage the LCD screen. Clean

any moisture from surface immediately.

• Be careful when cleaning or removing stains on the LCD surface.

Gently wipe the surface with a soft cloth or cotton pad. Isopropyl

alcohol may be used, but make sure that all solvent residue is removed.

• Do not apply excessive force to the LCD surface. The LCD screen

contains sensitive electronic components that may be damaged due to

strong impact.

:

www. .com

1-7

information@itm.com1.800.561.8187

Page 22

4400 Controls, Indicators, and Connectors, continued

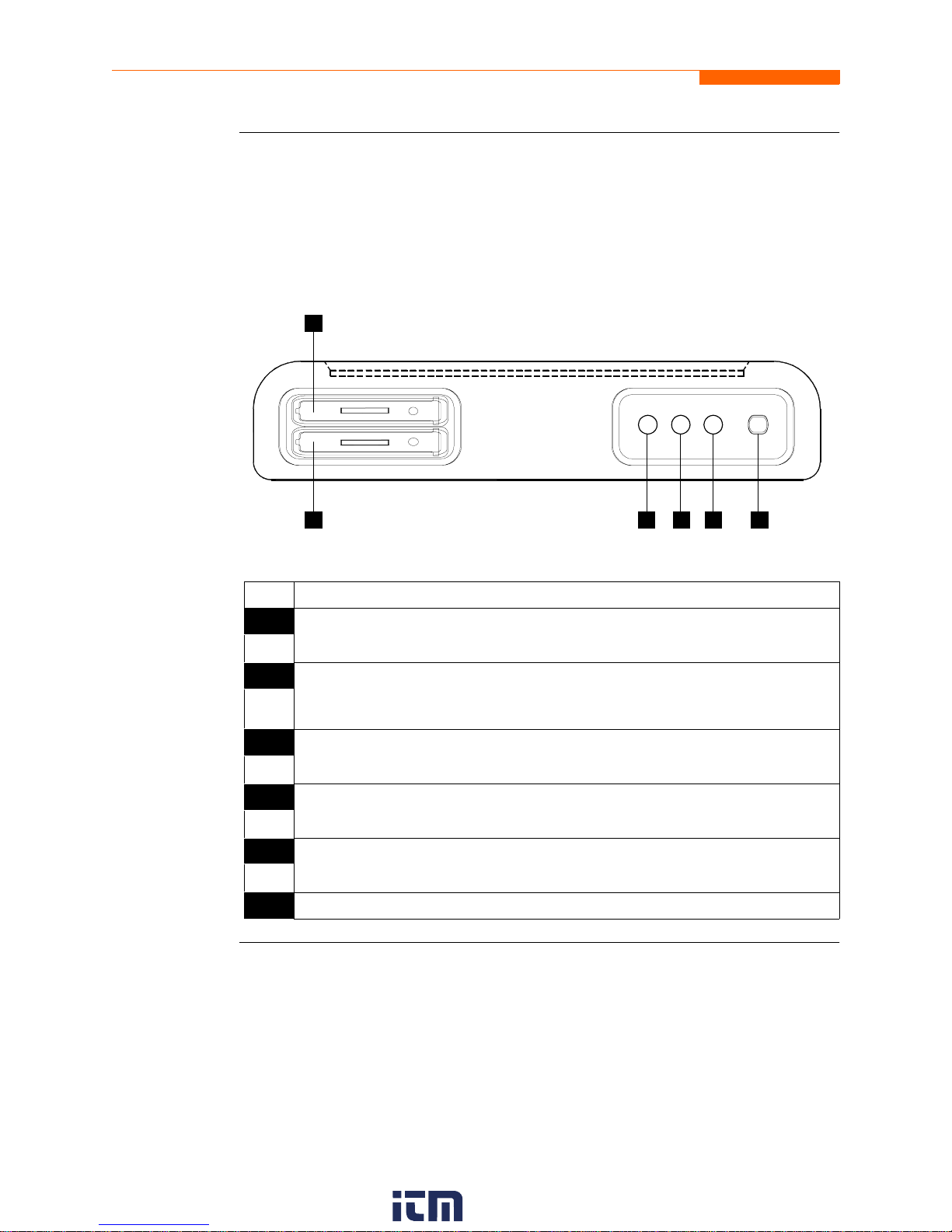

Bottom view

Parts table

The bottom view features two slots. Either slot can be used to hold the data card.

NOTE: Use only one card slot (one data card) at a time. The additional slot will be used

for future communications options.

The bottom also features LED indicators and the On/Off power button. See below for

descriptions of the slots, indicators, and button.

1

SLOT 1

SLOT 2

2 3 5 64

Part Function

1 Slot 1. Holds and connects data card to internal circuitry. Data card works in

either Slot 1 or Slot 2. Eject data card by pushing data card release.

2 Slot 2. Holds and connects data card to internal circuitry. Data card works in

either Slot 1 or Slot 2. Eject data card by pushing data card release.

NOTE: This additional slot will be used for future options.

3 Battery Charge Indicator. LED will light steadily while battery is fast

charging and blink when fully charged.

4 Status Indicator. LED will light steadily when abnormal condition is detected.

The unit is operating normally when light is off.

5 Power Indicator. LED will blink in a heartbeat fashion (once per second) when

the unit is operating normally.

6 On/Off Power Button. Push for on, push for off.

1-8

www. .com

information@itm.com1.800.561.8187

Page 23

CH 1/ Getting Started

Rear view

The rear view shows the battery compartment and the easel studs to mount the unit to

desired angular position for use on a flat surface or to hang from a panel.

www. .com

1-9

information@itm.com1.800.561.8187

Page 24

Upgrading Firmware from a Data Card

Upgrading Firmware from a Data Card

PX5 firmware

web upgrade

Copy 4400

firmware

program in data

card

Users can upgrade the 4400 internal program by downloading the latest

firmware update release from the web and installing it into the 4400 internal

memory. Refer to the instructions below on how to upgrade the 4400 firmware.

Firmware upgrades for the 4400 can be downloaded from the Dranetz

website. Log on to www.dranetz

firmware update releases.

The procedure below specifies how to download the latest 4400 firmware from the web

and copy it into a data card.

Step Action

1 Locate the latest version of the firmware upgrade (in data file format

“hostcode.bin”) from the Dranetz website www.dranetz.com.

Dranetz

regarding 4400 firmware upgrade releases.

2 Format the Compact Flash data card using the Memory Card options in

4400. The card must be formatted before it can be written to. Refer to

Chapter 5 Start Menu - Site Name/Memory Card on page 5-21 for

instructions on how to format data card.

regularly posts the latest information and instructions

.com for the latest information on 4400

NOTE: All data and setups stored in card will be lost when you format

the data card. Copy any files that you want to save to a computer first

before formatting card.

3 Insert the Compact Flash data card into the appropriate slot in the

computer. If the computer does not accommodate a Compact Flash card

in its native format, use a compatible PC card adapter to be able to read/

write data into the card.

4 Download and copy the latest version of the 4400 firmware upgrade

program (data file “hostcode.bin”) from the Dranetz

data card.

Refer to page 1-11 for instructions on how to install the data card

containing the latest firmware upgrade to the 4400.

website to the

1-10

www. .com

information@itm.com1.800.561.8187

Page 25

CH 1/ Getting Started

Install data card

to 4400

The procedure below specifies how to install the data card containing the latest

firmware upgrade to the 4400.

Step Action

1 Make sure that the unit is off. If not, press the 4400 On/Off power button

to turn unit off.

2 Remove the data card from its protective holder and check that the plug

end of card is clean and free of any obstruction.

NOTE: If plug end of card is dirty, clean with static-free, dry, low pressure

air to remove any foreign material causing obstruction of the plug holes.

3 At the bottom of the unit, position the data card with the label facing up

and the plug end facing the top slot (Data Card Slot 1). Make sure that

there are no other cards in the unit except for the data card.

4 Insert the card fully into the top slot (Data Card Slot 1) until resistance is

felt, then press firmly until the card engagement is felt.

NOTE: Do not force the card further into the slot if no card engagement is

felt. Remove card and check if there is foreign object on or in the plug end

of the card. Remove any obstruction. Reinsert program card and repeat

card engagement. If card cannot be engaged, STOP all further action and

call Dranetz

Technical Support at 1-800-372-6832 for assistance.

5 Turn the unit on by pushing the on/off button. The loader should display

“Booting from program card”. If not, call Dranetz

for assistance.

6 The instrument will prompt the user to verify whether or not to upgrade

the firmware. Press Yes and the upgrade procedure will commence. Do

not turn the power off nor remove the data card while firmware upgrade is

in progress.

7 If no errors were detected, a window displaying “Installation Complete”

will pop up. Remove the data card from the unit.

Technical Support

www. .com

1-11

information@itm.com1.800.561.8187

Page 26

4400 Features

4400 Features

Touch screen

function

Scope mode

Meter mode

Harmonics

All 4400 functions described below are operable using a color LCD touch screen

technology. Users may use a finger and/or a PDA stylus to apply pressure to the LCD

screen to result in touch screen recognition. The touch screen display is also workable

with lineman gloves on. Touch screen buttons will appear in reverse-video to show

visual feedback of contact along with audible feedback. In order to reduce power

consumption, the backlight of the LCD screen times-out after a specified

programmable time of no user activity. The backlight reactivates by touching any part

of the screen.

Scope mode functions as an oscilloscope, displaying real-time waveforms of voltage

and current for up to eight channels simultaneously, with one second update rate. The

colors of waveform display are user programmable. Scope mode also provides a textual

display of rms values, division for axis values, and frequency.

Meter mode functions as a true rms voltmeter and a true rms clamp-on ammeter.

Voltage and current measurements, along with other calculated parameters, are

displayed on the Meter mode screens in both textual and graphical format.

Harmonics display the amplitude and phase of each harmonic to the 63rd harmonic in

both graphical and textual format.

Phasor diagram

Flicker

Event

The phasor screen displays a graph that indicates phase relations between voltage and

current based upon the angles at the fundamental frequency, as determined by Fourier

analysis. Phasor diagram displays voltage and current phasors for all channels.

Functioning as a phase angle meter, the unit can display system imbalance conditions

and provides such information in textual form also. The phase angle display can also

verify if monitoring connections have been made correctly. Animated phasor demo

rotations demonstrating resistive, inductive and capacitive loads can be displayed.

Flicker is a phenomenon due primarily to rapid small fluctuations of the voltage. Loads

that exhibit continuous, rapid variations in the load current, particularly the reactive

component, can cause voltage variations often referred to as flicker. Flicker is

characterized by modulation at a frequency typically less than 25 Hz. Modulating

signal magnitudes as low as 0.5% of the fundamental for frequencies between 5-10 Hz

can result in perceptible light flicker.

An event occurs when a programmed threshold limit is crossed. An event consists of

the pre-trigger cycle(s), trigger cycle(s), and post-trigger cycle(s).

Continued on next page

1-12

www. .com

information@itm.com1.800.561.8187

Page 27

CH 1/ Getting Started

Monitoring

capacity

Automatic

setup, Wizard

setup, or

Advanced setup

Tre nd

The 4400 can monitor the following power configurations:

• Single Phase • 3 Phase 2-Watt Meter Delta

• Split Phase • Generic

• 3 Phase Delta • 2 1/2 Element without V

• 3 Phase Wye • 2 1/2 Element without V

While monitoring any of the above configurations, the 4400 can also be connected to

monitor neutral to ground voltage and neutral or ground current.

Setup is a configuration of parameter thresholds that control the data recorded by the

4400. Users may perform instrument setup in three ways: via Automatic Setup which

utilizes auto-configured settings and allows users to proceed directly with data

monitoring; via Wizard Setup which follows a step-by-step sequence where users go

through a series of circuit setup screens; or via Advanced setup which allows users to

modify trigger parameters and intervals or tweak threshold settings under the Advanced

Options.

Users can generate plots for all journalled data combined with min/max recordings of

that parameter. Most journal parameters have multiple channels to plot.

B

C

Reports

Data Card

Users have two options on how to view QOS compliance reports.

EN50160 displays statistical reports on QOS compliance based on an analysis of the

voltage as per requirements of the EN50160 standard. Compliance data is presented in

bar charts, statistical tables, and graphs. Statistical data is calculated on the required

parameters specified in EN50160 over one week interval to produce a PASS/FAIL

decision of QOS compliance.

Status presents a report summary for Standard PQ, EN50160, and Motor Quality

parameters via the annunciator panel. The panel is color coded such that green indicates

the parameter is within limits, yellow means it is moderately out of limits, red signifies

it is severely out of limits. Unlike the EN50160 which reports on QOS compliance on a

weekly basis, Status monitors compliance continuously. There is also the option to

view a parameter in more detail i.e. display its data plot, threshold values, or edit

parameter/channel settings.

4400 supports the use of Compact Flash data cards with AT LEAST 32MB storage

capacity. The user replaceable data card is used as primary storage for data. Data

monitoring CANNOT proceed without the data card. The 4400 is designed to

accommodate the Compact Flash card in its native format, and does not require the use

of a PC card adapter. However, a PC card adapter can be used to read the data into a

laptop or other computer with a PC card slot.

www. .com

1-13

information@itm.com1.800.561.8187

Page 28

Basic Operation

Basic Operation

Introduction

Battery pack

The normal power source for the 4400 is its internal battery pack. The AC Adapter/

Battery Charger is used to charge the battery. Always charge the battery fully before

use. The 4400 will always operate on the charger and is designed to do so, regardless of

the state of charge of the battery.

Type :

Sealed, rechargeable NiMH (Nickel Metal Hydride) cells.

Length of operation

than two (2) hours with the backlight on. When the backlight is turned off, the unit can

operate for more than three (3) hours. For information on how to turn backlight on or

off, see Chapter 4 Instrument Settings - Set Display Preferences on page 4-6.

Charging

Charger to the 4400. A screen warning will appear during operation when battery

charge is low. A depleted battery pack can be recharged in six (6) hours whether the

unit is on or off. The Battery Charge Indicator glows steadily while charging, and

flashes when fully charged.

NOTE: The Battery Charge Indicator functions whenever the AC Adapter/Battery

Charger is properly connected.

: The battery pack can be charged by connecting the AC Adapter/Battery

: The 4400 can operate on a fully charged battery pack for more

AC power

source

The 4400 can be operated from a 50/60 Hz 120/230V AC power source with or without

the battery pack installed.

Connect the AC Adapter output cable to the Input Connector on the right side of the

4400. Connect the AC Adapter power cord to an appropriate outlet.

Refer to Appendix C for the specifications and replacement of the batteries contained

in 4400.

1-14

www. .com

information@itm.com1.800.561.8187

Page 29

CH 1/ Getting Started

Power on

sequence

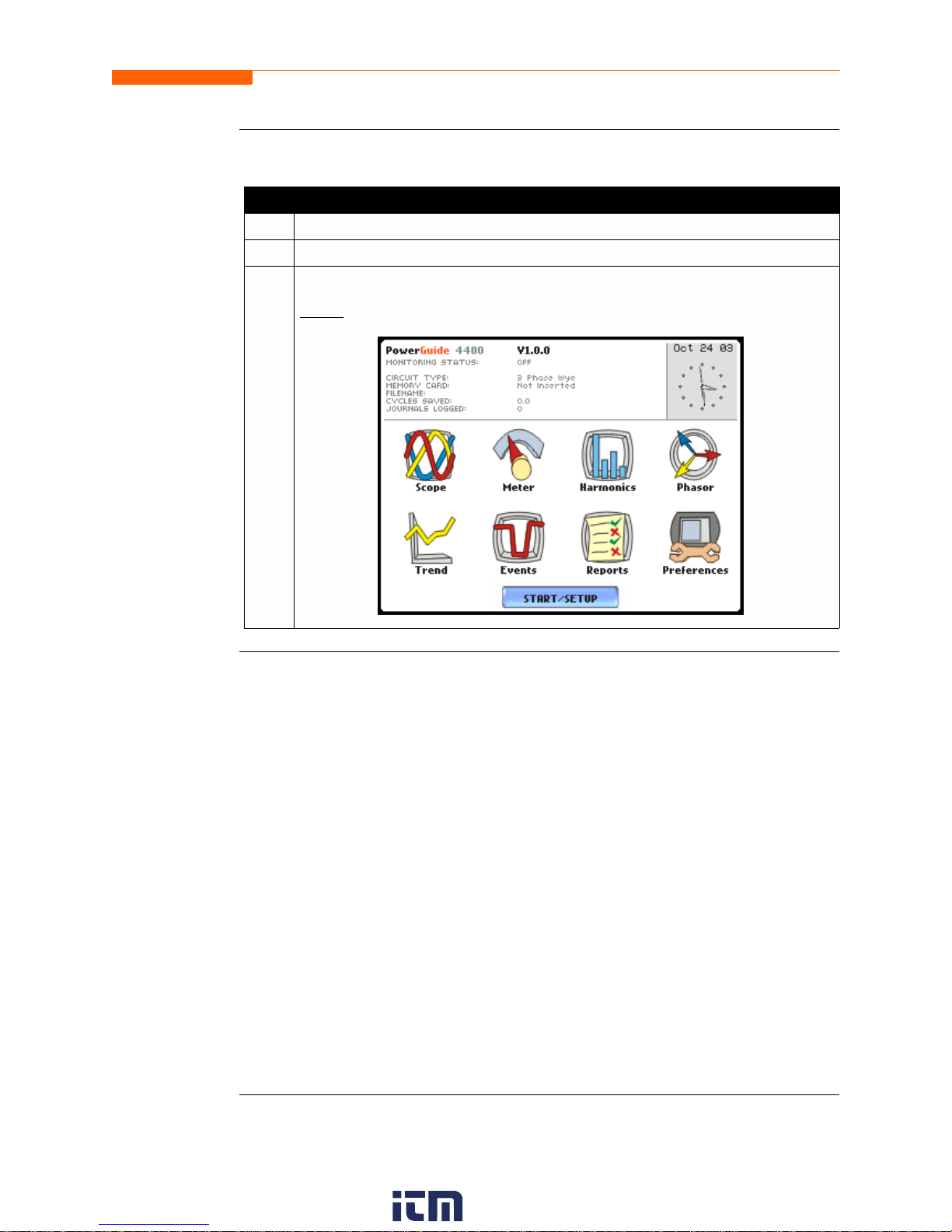

Follow these steps to turn on the 4400 and display the Home screen.

Step Action

1 Connect ac adapter/battery charger plug into the right side of 4400.

2 Plug the ac adapter into an ac power source.

3 Press the 4400 On/Off power button to turn the unit on.

Result

: The Home screen will be displayed.

Home screen

features

MARK001b

Home screen is frequently referenced as the starting point for all major functionalities

of the 4400.

The date and time appear on the top right corner of the Home screen. Both can be

configured to appear in a different format. See page 4-3 for the procedure on how to set

and reformat time and date.

The unit name and model, 4400 program revision level, and status messages appear in

the upper portion of the Home screen. Pertinent information that appear in the status

message area are the monitoring status, circuit configuration, percentage of data card

used while monitoring, site/file name, number of event cycles saved, and number of

timed intervals saved.

MONITORING STATUS: OFF indicates that the instrument is not actively

monitoring data. The monitoring status message will change to ON, DONE or

ARMED, depending upon the state of data monitoring. See page 5-25 for the

procedure on how to turn monitoring on/off.

Home screen contains the icons used to access the various 4400 functions. See page

1-16 for the description of each icon found in Home screen.

www. .com

1-15

information@itm.com1.800.561.8187

Page 30

Basic Operation, continued

Home screen

icons

Home screen contains the following icons used to access various 4400 functions:

- Scope mode shows real-time voltage and current waveforms of the signals on

Scope

the measuring inputs. See Chapter 3 View Real Time Data - Section A Scope Mode.

- Meter mode displays voltage and current measurements, along with other

Meter

calculated parameters. See Chapter 3 View Real Time Data - Section B Meter Mode.

Harmonics

amplitude and phase of each voltage and current harmonic to the 63rd harmonic. See

Chapter 3 View Real Time Data - Section C Harmonics.

Phasor

upon the angles of the fundamental. See Chapter 3 View Real Time Data - Section D

Voltage and Current Phasor.

Preferences

feedback, language selection, communications, LCD display, and data card operation.

See Chapter 4 Instrument Settings.

Events

Events are classified according to IEEE 1159, IEC 61000-4-30 Class A, and EN50160

standards. Events are displayed only after monitoring has been turned on or upon

reading a stored file from the data card. See Chapter 7 View Event Data - Section A

Events.

- Harmonic screen displays a spectral graph and textual matrix featuring the

- Phasor diagrams indicate phase relations between voltage and current based

- Users can set instrument preferences like time and date, threshold alarm

- Events result in a contiguous collection of cycles that is recorded into memory.

- Trend allows users to view plots of journalled data along with min/max

Trend

measurements over the interval. See Chapter 7 View Event Data - Section B Trend.

Reports

EN50160 reports show graphs and statistical tables reflecting the compliance of

parameters specified according to EN50160 standard. Status shows a quick status

summary of Standard PQ, EN50160, and Motor Quality parameters using the

annunciator panel. The color coded panel indicates whether or not the parameter is

within limits. See Chapter 8 Reports.

Start/Setup

data monitoring or they can configure the instrument step-by-step using the Wizard

Setup. Users can also do Advanced setups to modify trigger parameters and intervals or

tweak threshold settings under the Advanced Setup Options. See Chapter 5 Start Menu

and Chapter 6 Advanced Setup Options.

- The 4400 allows users to view two types of reports on QOS compliance.

- Users have the option to use Automatic Setup and proceed directly with

1-16

www. .com

information@itm.com1.800.561.8187

Page 31

CHAPTER 2

Vo ltage M easu remen t Cable and C urrent Probe C o nnections

Overview

Introduction

In this chap ter

WARNING Death, serious injury, or fire haza rd coul d r esul t from improper conn ectio n of this

This section describes how to connect the 4400 to make basic single phase voltage

measurements. For multi-phase connection diagrams, refer to Appendix E.

The following topics are covered in this c

Topic See Page

Connecting Voltage Measurement Cables 2-4

Connecting Current Probes 2-9

instrument. Read and understand this manual before connecting this instrument.

Follow all installation and operating instructions while using this instrument.

Connection of this instrument must be performed in compliance with the National

Electrical Code (ANSI/NFPA 70-2005) and any additional safety requirements

applicable to your installation.

Installation, operatio n, and maintena nce of t his i nstrument must be performed by

qualified personnel only. The National Electrical Code defines a qualified person

as “one who has the skills and knowledge rela ted to the construction and

operation of the electrical equipment and installations, and who has received

safety training on the hazards involved.”

hapter.

Qualified pers onnel who wo rk on or near exposed energized electrica l conductors

must follow applicable safety related work practices and procedures including

appropriate personal protective equipment in compliance with the Standard for

Electrical Safety Requirements for Employee Workplaces (ANSI/NFPA 70E-2004)

of USA and any additional workplace safety requirements applicable to your

installation.

www. .com

Continued on next page

2-1

information@itm.com1.800.561.8187

Page 32

Overview, continued

ADVERTENCIA

AVERTISSEMENT

Una conexión incorrecta de este instrumento puede producir la muerte, lesiones

graves y riesgo de i ncendio. Lea y entienda es te manual ant es de conect ar. Observe

todas las instrucciones de instalación y operación durante el uso de este

instrumento.

La conexión de este instrumento debe ser hecha de acuerdo con las normas del

Código Eléctrico Nacional (ANSI/NFPA 70-2005) de EE. UU., además de

cualquier otra norma de seguridad correspondiente a su establecimiento.

La instalación, operación y mantenimiento de este inst rument o deb e ser realizada

por personal calificado solamente. El Código Eléctrico Nacional define a una

persona calificada como "una que esté familiarizada con la construcción y

operación del equipo y con los riesgos involucrados."

Si l'instrument est mal connecté, la mort, des blessures graves, ou un danger

d'incendie peuvent s'en suivre. Lisez attentivement ce manuel avant de connecter

l'instrument. Lorsque vous utilisez l'instrum ent, suivez toutes les instructions

d'install ation et de service.

Cet instrument doit être connecté conformément au National Electrical Code

(ANSI/NFPA 70-2005) des Etats-Unis et à toutes les exigences de sécurité

applicables à votre installation.

Cet instrument doit ê tr e i nstal lé, ut ilis é et e ntr et enu un iquement par un pe rsonnel

qualifié. Selon le National Electrical Code, une personne est qualifiée si "elle

connaît bien la construction et l'utilisation de l'équipement, ainsi que les dangers

que cela implique".

WARNUNG Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer

verursachen. Bevor Sie dieses Instrument anschließen, müssen Sie die Anleitung

lesen und verstanden habe n. Bei der Verwendung dieses Ins tr uments müs se n all e

Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen

Bestimmungen für Elektrizität (ANSI/NFPA 70-2005) der Vereinigten Staaten,

sowie allen weiteren, in Ihrem Fall anwendbaren Sicherheitsbestimmungen,

vorgenommen werden.

Installation, Betrieb und Wartung dieses Instruments dürfen nur von

Fachpersonal durchgeführt werden. In dem nationalen Bestimmungen für

Elektrizität wird ein Fachmann als eine Person bezeichnet, welche "mit der

Bauweise und dem Betrieb des Gerätes sowie den dazugehörigen Gefahren

vertraut ist."

2-2

www. .com

information@itm.com1.800.561.8187

Page 33

CH 2/ Voltage Measurement Cable and Current Probe Connections

Safety

precautions

The following safety precautions must be followed whenever any type of voltage or

current connection is being made to the 4400.

• Wear proper Personal Protective Equipment, including safety glasses and insulated

gloves when making connections to power circuits.

• Hands, shoes and floor must be dry when making any connection to a power line.

• Before each use, inspect all cab les for breaks or cracks in the insulation. Replace

immediately if defective.

• Press the 4400 On/Off power button to Off.

• Before connecting to electric circuits to be monitored, open their related circuit

breakers or disconnects. DO NOT install any connection of the 4400 to live power

lines.

• Connections must be made to the 4400 first, then connect to the circuit to be

monitored.

Continued on next page

www. .com

2-3

information@itm.com1.800.561.8187

Page 34

Connecting Voltage Measurement Cables

Connecting Voltage Measurement Cables

Measurement

cable set

Optional fu sed

voltage adapter

Description

stored in a cable pouch as part of the measurement cable set, P/N 116042-G3. Each

cable set consists of a cable and alligator clip.

Voltage Rating

Vrms max. For mea suring v o ltages g reater than 600 Vr ms, pote ntial t ransfor mers (PTs)

must be used.

Contents

to their actual use). A cable set consists of eight, 6-foot channel measurement cable

assemblies (probes), each with a detachable, alligator jaw, safety clip assembly

(maximum jaw opening, 3/4 in (20 mm)). The safety clip assemblies are red (+) and

black (-) for each of the four channels. One cable each of red (channel A), yellow

(channel B), blue (channel C), and grey (channel D), and four each of white are

provided.

A pouch for storage of the cables and the AC adapter/battery charger is included in the

contents of the measurement cable set, but is not shown in the figure.

There are two optional fuse accessory kits available for use with the measurement

cables. One kit (P/N FVA-1) contains one fused voltage adapter and one measurement

connecting Red cable 50 cm in length. The ot her kit (P/ N FVA-4) contai ns fo ur v olt age

adapters and four measurement connecting cables 50 cm in length (one Red, one

Yellow, one Blue, and one Grey).

: Voltage measurement cables are provided as standard accessories and are

: Direct connection of all voltage measurement cables are rated at 600

: The voltage measurement cables are shown on page 2-5 (positioned relative

2-4

The single fuse voltage adapter kit is used for one single voltage measurement input.

While the four fuse voltage a dapter kit is used for a three p hase and neutral voltage

measurement inputs.

Continued on next page

www. .com

information@itm.com1.800.561.8187

Page 35

Measurement

cable set w ith

optional fuse

diagram

CH 2/ Voltage Measurement Cable and Current Probe Connections

WARNING

WARNING

WARNING

WARNING

NOTE: 2 FT C A B LE

INC L U DE D W ITH

FUSE VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

PX5-11.vsd

To avoid the risk of electric shock or burns, always connect the safety (or earth)

ground before making any other connections.

To reduce the risk of fire, electrical sh ock, or physical injury it i s strongly

recommended to fuse the voltage measurement inputs.

Fuses must be located as close to the load as possible to maximize protection.

For continued protection against risk of fire or shock hazard replace only with

same type and rating of recommended fuse.

Use only fast blow type fuse which is rated 600V. Recommended fuse type is

Littelfuse, part number KLKD0.30 rated 600V AC/DC, 0.3A fast blow.

Do not replace fuse again if failure is repeated. Repeated failure indicates a

defective condition that will not clear with replacement of the fuse. Refer

condition to a qualified technician.

Contact Dr anetz Customer Service for more informatio n on the fused voltage

adapter. Refer to Dranetz

Adapter, P/N 899107.

Information Sheet titled Model FVA - Fuse Voltage

www. .com

2-5

information@itm.com1.800.561.8187

Page 36

Connecting Voltage Measurement Cables, continued

Connection

guidelines

Example: Single

phase

connection

Follow these guidelines when making voltage connections.

• Refer to the measurement cable set figure for color coding of probes that connect to

input channel connectors A, B, C, and D.

• Each channel input has plus (+) and minus (-) differential inputs of 1 to 600 Vrms

max.

The following f igure sho ws a volta ge connecti on to a single phas e circuit for channel A.

2-6

PX5-12.vsd

Continued on next page

www. .com

information@itm.com1.800.561.8187

Page 37

CH 2/ Voltage Measurement Cable and Current Probe Connections

Example:

Neutral to

ground

connection

The following f igu re sho ws a v ol tage connec tion using ch annel D as a differential inp ut

for measuring neutral to ground voltage. Connections are identical for split phase and

wye configurations. One probe connects the source neutral line to the D+ input.

Another probe connects the ground to the D- input.

PX5-13.vsd

2-7

www. .com

information@itm.com1.800.561.8187

Page 38

Connecting Voltage Measurement Cables, continued

Safety

precautions

WARNING

ADVERTENCIA

AVERTISSEMENT

The following safety precautions apply to current probe connections in addition to

those safety precautions stated on page 2-3.

• DO NOT attempt to measure current in any circuit in which the circuit to ground

voltage exceeds the insulation rating of the current probe (600 Vrms max).

• Make sure the jaws of the current probe are tightly closed. Keep mating surfaces

clean and free from foreign matter.

DO NOT USE non-insulated current probe cores around a non-insulated wire.

Probes of this type are designed for use around insulated wires only. Use only

completely insulated probe cores with no exposed conductive areas of the core

around non-insulated wires.

NO UTILIZAR transformadores de corriente sin material aislante al rededor de

conductores sin material aislante. Los Transformadores de corriente de este tipo

están diseñados para ser utilizados solamente con conductores con aislamiento

eléctrico. Utilizar transformadores de corriente completamente aislados

alrededor de conductores sin aislamiento.

N'EMPLOYEZ PAS les noyaux courants non-isolés de sonde autour d'un fil nonisolé. Des sondes de ce type sont concues pour l'usage autour des fils isolés

seulement. L'utilisation seul ement a compl ét ement isolé des noy aux de sonde sans

des secteurs conducteurs exposés du noyau autour des fils non-isolés.

WARNUNG

VERWENDEN Sie keine Stromzangen mit nicht isolierten Ferritkernen bei

Messungen an nicht isolierten Leitungen. Stromzangen dieses Typs sind nur für

Messungen an isolierten Leitern geeignet. Bitte verwenden Sie zur Messung an

nicht isolierten Leitungen Stromzangen mit vollständig isoliertem Kernmaterial.

Continued on next page

2-8

www. .com

information@itm.com1.800.561.8187

Page 39

Connecting Current Probes

CH 2/ Voltage Measurement Cable and Current Probe Connections

Current probes

Severa l Dra net z

are illustrated on page 2-10. Refer to Appendix A for descriptions and part numbers of

probes and adapter cables. Refer to Appendix B for specifications of current probe

models TR2500 and TR2510.

NOTE: The TR2500 can perform all current measurements except high frequency

transient detection.

Probe positioning

position the probe with the arrow pointing towards the load when monitoring the line

conductor. Correct position of the probe is necessary for correct power measurements,

where in-phase voltage and current measurements are necessary. A positive watts

reading indicates that the probe is pointed towards the load. A negative reading

indicates that the probe is pointed towards the source.

current probes can be used with the 4400. Typical current probes

: An arrow marking on the handle is a guide to ensure that you

Continued on next page

www. .com

2-9

information@itm.com1.800.561.8187

Page 40

Connecting Current Probes, continued

Typical current

probes

NOTE: Current probes TR2500 can be used interchangeably with TR2500A, TR2510

with TR2510A, and TR2520 with TR2520A.

2-10

www. .com

4300 TO LEMFLEX

CURRENT PROBE

ADAPTER CABLE

116310-G1

PX5-14.vsd

Continued on next page

information@itm.com1.800.561.8187

Page 41

CH 2/ Voltage Measurement Cable and Current Probe Connections

Typical current

probes

(continued)

Actual photos of TR series probes and part numbers are shown below to aid users in

probe identification. Contact Dranetz

information on curren t probes, pri cing and availability.

P/N TR-2500

Customer Service Department for more

P/N TR-2510 P/N TR-2520

P/N TR-2500A P/N TR-2510A P/N TR-2520A

www. .com

Continued on next page

2-11

information@itm.com1.800.561.8187

Page 42

Connecting Current Probes, continued

Single phase

current probe

connection

example

The following figure shows how to connect a current probe to channel A for current

monitoring of a single phase line.

The current probe may be connected to the return line if desired to measure the return

current when checking for load current leakage, loop current relationships, etc. If

measuring power, position the probe with the arrow pointing towards the load.

PX5-15.vsd

NOTE: The conne ction shown abov e is not recommend ed without a v olta ge connecti on

to ensure frequency synchronization. If this configuration is used, then an internal

frequency reference must be entered. Refer to pages 5-14 to 5-16.

2-12

www. .com

information@itm.com1.800.561.8187

Page 43

Overview

CHAPTER 3

View Real Time Data

Introduction

Access to real

time data

The 4400 allows users to view power quality phenomena as it happens, when it

happens. The instrument is able to capture and process data in real time, and allows

users to view it in Scope mode, Meter mode, Harmonics, and Phasor display.

Icons for Scope mode, Meter mode, Harmonics, and Phasor display are available in the

Home screen. Follow these steps to display the Home screen.

Action... Result...

STEP 1: Press the 4400 On/Off

power button to turn the unit on.

The Home screen will be

displayed.

MARK001b

In this chapter

This chapter is divided into four sections.

Section Title See Page

A Scope Mode 3-2

B Meter Mode 3-5

C Harmonics 3-10

D Voltage and Current Phasor 3-15

www. .com

3-1

information@itm.com1.800.561.8187

Page 44

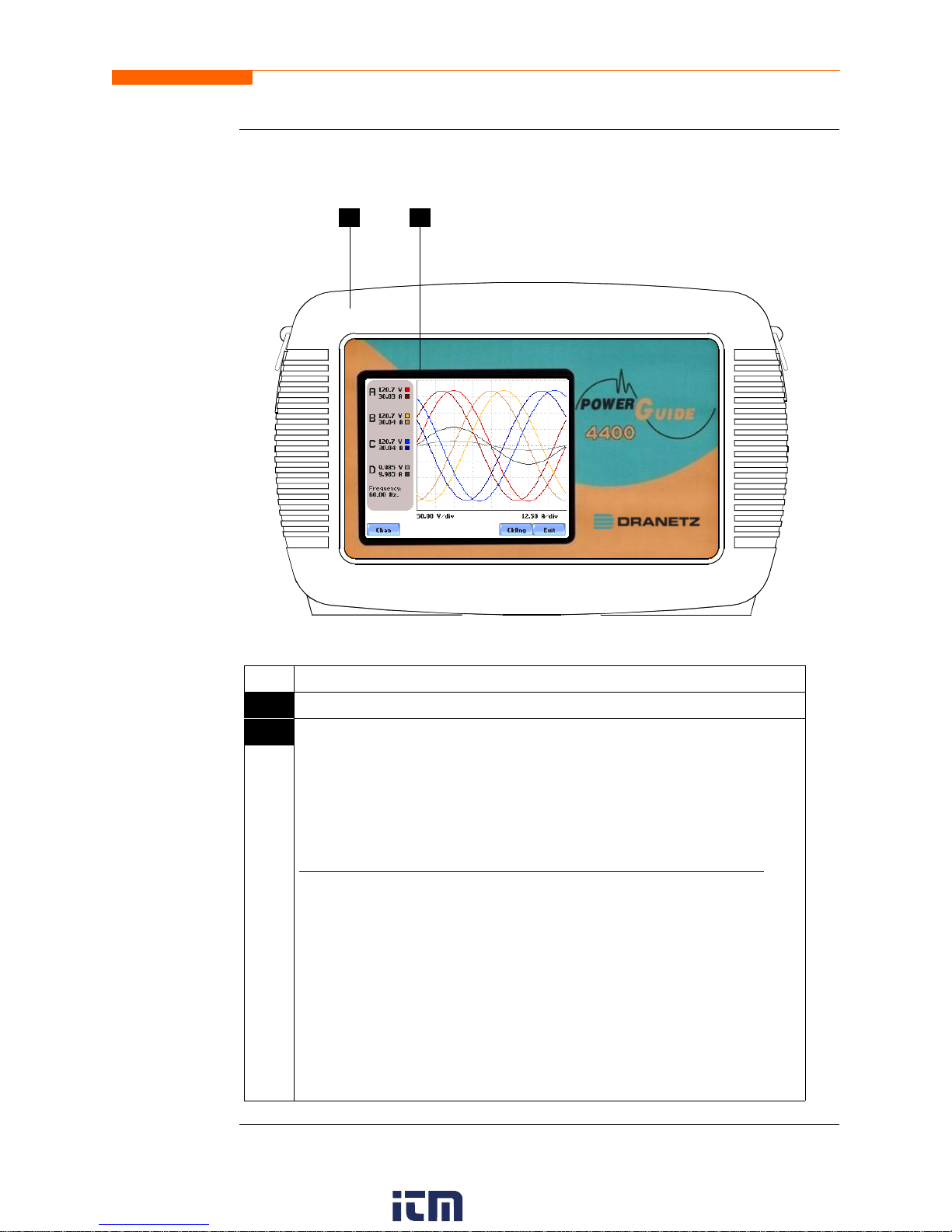

Overview

Overview

Section A

Scope Mode

Introduction

Scope mode

screen

Scope mode allows you to view real-time voltage and current waveforms for up to

eight channels simultaneously.

The Scope mode screen can be displayed by pressing the Scope key on the Home

screen.

Volts/Amps

channel labels

and RMS values

for displayed

waveforms

Frequency

Voltage scale

Turn channels on/off

(p. 3-3)

Show channels input

range (p. 3-4)

Display one cycle

of selected

waveforms which

are scaled relative