Page 1

E

NCORE

S

ERIES

TM

61000 System

INSTALLATION GUIDE

DRANETZ - BMI

1000 New Durham Road

Edison, New Jersey 08818-4019

Page 2

WARNING

Death, serious injury, or fire hazard could result from improper connection of this instrument. Read and

understand this manual before connecting this instrument. Follow all installation and operating

instructio ns while using this instrument.

Connection of this instrument must be performed in compliance with the National Electrical Code (ANSI/

NFPA 70-2005) of USA and any additional safety requirements applicable to your installation.

Installation, operation, and maintenance of this instrument must be performed by qualified personnel

only. The National Electrical Code defines a qualified person as “one who has the skills and knowledge

related to the construction and operation of the electrical equipment and installations, and who has

received safety training on the hazards involved.”

Qualified personnel who work on or near exposed energized electrical conductors must follow applicable

safety related work practices and procedures including appropriate personal protective equipment in

compliance with the Standard for Electrical Safet y Re quirements for Employee Workplaces (ANSI/ NFPA

70E-2004) of USA and any additional workplace safety requirements applicable to your installation.

Published by Dranetz-BMI

1000 New Durham Road

Edison, NJ 08818-4019 USA

Telephone: 1-800-372-6832 or 732-287-3680

Fax: 732-248-1834

Web site: www.dranetz-bmi.com

Copyright ©2006 Dranetz-BMI

All rights reserved.

No part of this book may be reproduced, stored in a

retrieval system, or transcribed in any form or by any

means—electronic, mechanical, photocopying, recording,

or otherwise—without prior written permission from the

publisher, Dranetz-BMI, Edison, NJ 08818-4019.

Printed in the United States of America.

P/N UG-61000 Rev. B

ii

Page 3

ADVERTENCIA

U

na conexión incorrecta de este instrumento puede producir la muerte, lesiones graves y riesgo de incendio. Lea y

entienda este manual antes de conectar. Observe todas las instrucciones de instalación y operación durante el uso de

este instrumento.

La conexión de este instrumento a un sistema eléctrico se debe realizar en conformidad con el Código Eléctrico

Nacional (ANSI/NFPA 70-2005) de los E.E.U.U., ad emás de cualquier otra norma de seguridad correspon di ent e a su

establecimiento.

La instalación, operación y mantenimiento de este instrumento debe ser realizada por personal calificado solamente.

El Código Eléctrico Nacional define a una persona calificada como "una que esté familiarizada con la construcción y

operación del equipo y con los riesgos involucrados."

El personal cualificado que trabaja encendido o acerca a los conductor es eléctricos energizad os expuestos debe seg uir

prácticas y procedimientos relacionados seguridad aplicable del trabajo incluyendo el equipo protector personal

apropiado en conformidad con el estándar para los requisitos de seguridad eléctricos para los lugares de trabajo del

empleado (ANS I/NFPA 70E-2004) de los E.E.U.U. y cualqu ier requisito de seguridad adicional del lugar de traba j o

aplicable a su instalación.

AVERTISSEMENT

Si l'instrument est mal connecté, la mort, des blessures graves, ou un danger d'incendie peuvent s'en suivre. Lisez

attentivement ce manuel avant de connecter l'instrume nt. Lorsque vous utilisez l'instrument, suivez toutes les

instructions d'installation et de service.

Cet instrument doit être connecté conformément au National Electrical Code (ANSI/NFPA 70-2005) des Etats-Unis

et à toutes les exigences de sécurité applicables à votre installation.

Cet instrument doit être installé, ut ilisé et entretenu uniquement par un personnel quali fi é . Sel on le National

Electrical Code, une personne est qualifiée si "elle connaît bien la co nstruction et l'utilisation de l'équipement, ainsi

que les dangers que cela implique".

Le personnel qualifié qui travaillent dessus ou s'approchent des conducteurs électriques activés exposés doit suivre

des pratiques en matière et des procédures reliées pa r sûreté applicable de trav ail comprenant le matériel de protection

personnel approprié conformémen t à la norme pour des conditions de sûreté électriques pour les lieux de travail des

employés (ANSI/NFPA 70E-2004) des Etats-Unis et toutes les conditions de sûreté additionnelles de li eu de travail

applicables à votre installation.

WARNUNG

Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer verursachen. Bevor Sie dieses

Instrument anschließen, müssen Sie die Anleitung lesen und verstanden haben. Bei der Verwendung dieses

Instruments müssen alle Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen Bestimmungen für Elektrizität

(ANSI/NFPA 70-2005) der Vereinigten Staaten, sowie allen weiteren, in Ihrem Fall anwendbaren

Sicherheitsbestimmungen, vorgenommen werden.

Installation, B etrieb und Wartung dieses Instruments dür fen nur von Fachpersonal durc hgeführt werden. In dem

nationalen Bestimmungen für Elektrizität wird ein Fachmann als eine Person bezeichnet, welche "mit der Bauweise

und dem Betrieb des Gerätes sowie den dazugehörigen Gefahren vertraut ist."

Qualifiziertes Personal, das an bearbeiten oder herausgestellte angezogene elektrische Leiter sich nähern,

muß anwendbare Sicherheit bezogener Arbeit Praxis und Verfahren einschließlich passende persönliche

schützende Ausrüstung gemäß dem Standard für elektrische Sicherheitsauflagen für AngestelltArbeitsplätze (AN SI/NFPA 70E-2004) der Vereinigten Staaten und alle zusätzlichen

Arbeitsplatzsicherheitsauflagen folgen, die auf Ihre Installation anwendbar sind.

iii

Page 4

Safety Summary

Definitions

Symbols

Definiciones

WARNING statements inform the user that certain conditions or practices could result

in loss of life or physical harm.

CAUTION statements identify conditions or practices that could harm the 61000, its

data, other equipment, or property.

NOTE statements call attention to specific information.

The following International Electrotechnical Commission (IEC) symbols are marked

on the top and rear pa nel in the immediate vicinity of the refe ren ced terminal or device:

!

Las ADVERTENCIAS informan al usuario de ciertas condiciones o prácticas que

podrían producir lesiones mortales o daño físico.

Las PRECAUCIONES identifican condici ones o prác tica s que podrí an dañar la 61000,

sus datos, otros equipos o propiedad.

Caution, refer to accompanying documents (this manual).

Direct current (DC) operation of the terminal or device.

Power Switch

Símbolos

Las NOTAS llaman la atención hacia la información específica.

Los siguientes símbolos de la Comisión Internacional Electrotécnica (IEC) aparecen

marcados en el panel superior y el posterior inmediatos al terminal o dispositivo en

referencia:

!

Precaución, consulte los documentos adjuntos (este manual).

Operación de corriente continua (CC) del terminal o dispositivo.

Interruptor de encendido

Continued on next page

iv

Page 5

Safety Summary,

Continued

Définitions

Symboles

Definitionen

Les messages d’AVERTISSEMENT préviennent l’utilisateur que certaines conditions

ou pratiques pourraient entraîner la mort ou des lésions corporelles.

Les messages de MISE EN GARDE signalent des condi ti ons ou pratiques susceptibles

d’endommager “61000”, ses données, d’autres équipements ou biens matériels.

Les messages NOTA attirent l’attention sur certains renseignements spécifiques.

Les symboles suivants de la Commission éle ctrotechniq ue intern ationale (CEI ) figurent

sur le panneau arrière supérieur situé à proximité du terminal ou de l’unité cité:

!

WARNUNGEN informieren den Benutzer darüber, daß bestimmte Bedingungen oder

Vorgehensweisen körperliche oder tödliche Verletzungen zur Folge haben können.

VORSICHTSHINWEISE kennzeichnen Bedingungen oder Vorgehensweisen, die zu

einer Beschädigung von 61000, seiner Daten oder anderer Geräte bzw. von Eigentum

führen können.

Mise en garde, consultez les documents d’accompagnement (ce manual).

Fonctionnement du terminal ou de l’unité en courant continu (CC).

Interrupteur de tension

Symbole

HINWEISE machen auf bestimmte Informationen aufmerksam.

Die folgenden Symbole der Internationalen Elektrotechnischen Kommission

(International Electrotechnical Commission; IEC) befinden sich auf der Abdeck- und

Seitenplatte unmittelbar am betreffenden Terminal oder Gerät.

!

Vorsichtshinweis, siehe Begleitdokumente (dieses Handbuch).

Gleichstrombetrieb im Terminal oder Gerät.

Netzschalter

Continued on next page

v

Page 6

Safety Summary,

Continued

Safety

precautions

The following safety precautions must be followed whenever any type of voltage or

current connection is being made to the 61000.

• Wear proper Personal Protective Equipment, including safety glasses and insulated

gloves when making connections to power circuits.

• Hands, shoes and floor must be dry when making any connection to a power line.

• Before each use, inspect all cables for breaks or cracks in the insulation. Replace

immediately if defective.

• Set the 61000 power switch to Off.

Before connecting to electric circuits to be monitored, open their related circuit

breakers or disconnects. DO NOT install any connection of the 61000 to live power

lines.

• Pods should be connected first to the 61000, then connect to the circuit to be

monitored.

• If the equipment is used in a ma nner not specified in this user’s guide, th e pro tec tion

provided by the equipment may be impaired.

These safety precautions are repeated where appropriate throughout this manual.

vi

Page 7

Statements and Notices

Statement of

warranty

Statement of

reliability

Notice regarding

FCC compliance

All products of Dranet z-BMI are warranted to th e original pu rchaser against defective

material and workmanship for a period of one year from the date of delivery. DranetzBMI will repair or replace , at its opti on, all defec tive equ ipment that is returne d, freig ht

prepaid, during th e warrant y period. There wil l be no char ge for repair provided t here is

no evidence that the equi pment ha s been mishand led or ab used. Thi s warr anty s hall not

apply to any defects resulting from improper or inadequate maintenance, buyersupplied hardware/software interfacing, unauthorized modification or misuse of the

equipment, operation outside of environmental specifications, or improper site

preparation or maintenance.

The information in this m anual has be en reviewed and is believ ed to be entirely

reliable, however, no responsibility is assumed for any inaccuracies. All material is for

informational purposes only and is subject to change without prior notice.

This device has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable prote cti on against harmful interfere nce when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential are a is likel y to cause harmfu l inter feren ce in which cas e the

user will be required to correct the interference at his/her own expense.

Notice regarding

proprietary

rights

This publication contains information proprietary to Dranetz-BMI. By accepting and

using this manual, you agree that the information contained herein will be used solely

for the purpose of operating equipment of Dranetz-BMI.

Continued on next page

vii

Page 8

Statements and Notices,

Continued

Copyright

Trademarks

This publication is protected under the Copyright laws of the United States, Title 17 et

seq. No part of this p ublica tion may be rep roduced , tr ansmit ted, t ranscr ibed, s tored in a

retrieval system, or translated into any langua ge or computer language, in any form, by

any means, electronic, mechanical, magnetic, optical, chemical, manual, or otherwise,

without the prior written consent of Dranetz-BMI, 1000 New Durham Road, Edison,

New Jersey 08818.

Copyright ©2006 Dranetz-B MI

All Rights Reserved. Printed in the United States of America.

Encore Series Software, DataNode, Scope Mode, NodeLink and PQView are registered

trademar ks of Dranetz- BMI.

viii

Page 9

Table of Contents

Safety Summary .................................................................................................................... iv

Statements and Notices.......................................................................................................... vii

CHAPTER 1 - Introduction

About the 61000.................................................................................................................... 1-1

Unpacking the 61000.................................................................................. ......... .................. 1-3

61000 Accessories................................................................................................................. 1-4

Physical Description.............................................................................................................. 1-5

CHAPTER 2 - Controls, Indicators, and Connectors

External Components ............................................................................................................ 2-1

Connecting to DC Power Source........................................................................................... 2-4

Communications Interface..................................................................................................... 2-7

Input Module Connectors...................................................................................................... 2-9

Connecting Voltage Measurement Cables ............................................................................ 2-15

Connecting Current Probes.................................................................................................... 2-18

Connecting Voltage/Current Input Pods................................................................................ 2-22

Connecting Digital Input Connectors.................................................................................... 2-24

CHAPTER 3 - Circuit Diagrams for Power Monitoring

Connecting Power to the Voltage/Current Connections........................................................ 3-1

Single Phase........................................................................................................................... 3-6

Split Phase............................................................................................................................. 3-7

3 Phase, Four Wire Wye........................................................................................................ 3-8

3 Phase Delta............................................................................ ............................................. 3-9

3 Phase 2-Watt Delta............................................................................................................. 3-10

2 1/2 Element without Voltage Channel B............................................................................ 3-11

2 1/2 Element without Voltage Channel C............................................................................ 3-12

CHAPTER 4 - Operational Description

Input Settings......................................................................................................................... 4-1

Data Collection...................................................................................................................... 4-3

Memory Functions................................................................................................................. 4-4

Section A -External Communications Interface .......................................................................... 4-5

Remote Computer Operation................................................................................................. 4-5

Connection Setup via Modem............................................................................................... 4-6

Connection Setup via Com 1 RS232..................................................................................... 4-7

Connection Setup via GPS Antenna...................................................................................... 4-8

ix

Page 10

Table of Contents,

Section B -Local Operation.......................................................................................................... 4-9

Stand Alone Unit................................................................................................................... 4-9

Basic Operation ..................................................................................................................... 4-10

APPENDIX A - Optional Accessories

Introduction ........................................................................................................................... A-1

Hardware Accessories List.................................................................................................... A-2

Enclosure Hardware Options................................................................................................. A-5

Software Accessories............................................................................................................. A-7

APPENDIX B - Technical Specifications

General Specifications..................................................... ...................................................... B-1

Interfaces ............................................................................................................................... B-2

Measurement Parameters....................................................................................................... B-3

APPENDIX C - Connecting an External DC Power Supply

Introduction ........................................................................................................................... C-1

Connecting the DC Input Cable............................................................................................. C-2

Continued

APPENDIX D - 61000 System Firmware Upgrade

Firmware Upgrade Instructions............................................................................................. D-1

x

Page 11

Dranetz-BMI Encore SeriesTM 61000 System

xi

Page 12

Page 13

About the 61000; Unpacking the 61000; Standard Accessories; Physical Description

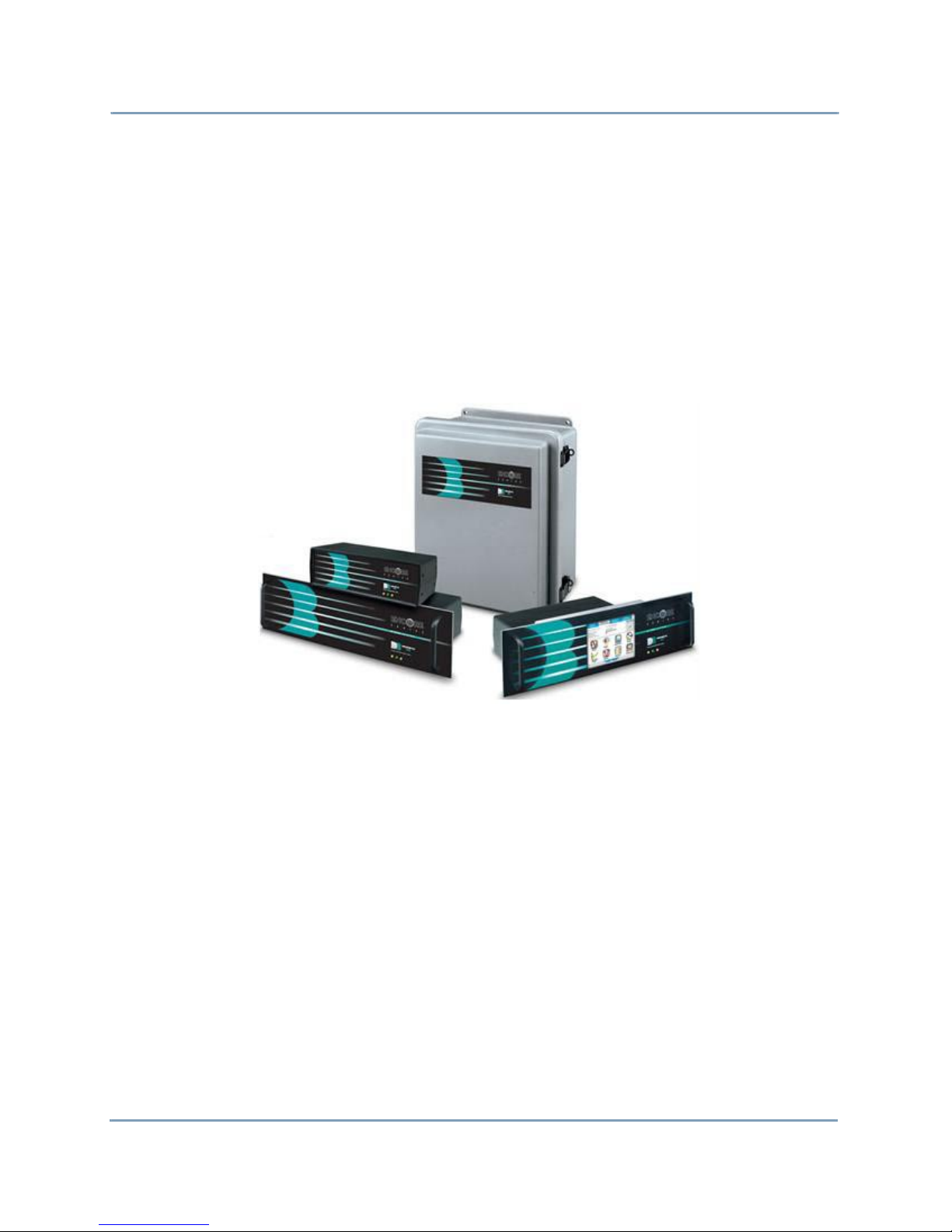

About the 61000

61000

description

The Encore Series

world-class data acquisition products developed by Dranetz-BMI - the DataNode

family of products for the Signature System

integration of power measurement capabilities coupled with an innovative modular

design set the 61000 apart as a truly revolutionary product. The modular concept

applies to both the hardware configuration and firmware architecture allowing the unit

to be a multi-purpose instrument. 61000 works from being a diagnostic tool to

providing preventive and predictive information as an embedded solution. The

instrument is designed to operate either locally as a stand-alone unit with the optional

LCD panel installed or via r emote comput er using the Encore Series

is compliant with IEEE1159, IEC61000-4-30 Class A, EN50160 standards, and more.

It can be installed in a permanent or semi-permanent installation.

C

HAPTER

Introduction

TM

61000 System hereinafter referred to as 61000 encompasses two

®

and the PowerXplorer® PX5. This

TM

Software. 61000

1

Interface to

61000

Data

communication

61000 can operate locally as a stand-alone unit and/or remotely as a data acquisition

module connected to t he Encore Series Software:

Local operation with optional user interface

As a stand-alone unit, the 61000 can be outfitted with optional liquid crystal display

(LCD) as user interface. Th e optio nal touch s creen d ispla y can be mounted on the f ront

panel of the instrument (rack mount) or as a separate unit (remote display), depending

on user-selected enclosure or packaging. The LCD panel provides immediate

accessibility to monitoring all measurement parameters and instrument setup and

configurations.

Remote computer operation

The 61000 can operate as a data acquisition module connected to the Encore Series

Software. This software provides a centralized connection point for remote devices,

turning the computer into a self-contained web server. Encore Series Software permits

remote communications with th e 61000, with t he conve ntion al Inter net br owser a s user

interface. Remote operation includes instrument setup and configurations and

monitoring real-time parameters, disturbance and trend data.

61000 can communicate data to the Encore Series Software via Ethernet (wired,

wireless or fiber-optic based), RS485, USB, and land/cellular modem via RS232. The

physical modem is an external option and is not included as part of the standard

product. This extends greater flexibility in the choice of communications interface for

remote operation.

Continued on next page

1-1

Page 14

About the 61000, continued

Input/Output

modules

Virtual analyzer

platform

61000 provides dedicated processing power via the separate and independent

connection for each input/output module installed. This modular and configurable

design shatters the traditional 8-channel (4 voltage, 4 current) instrument format.

Choose from the voltage, current, and data acquisition modules to build from one to

four instruments in a single, compact, cost-effect ive format. The available modules are :

• AC Voltage Modules - 4 channels using either terminal block, safety jack, or 25-pin

connector to external voltage pod

• AC Current Modules - 4 channels for clamp-on CTs or 25-pin connector to external

CT pod

• Digital Input/Output Modules - 8 channels

• Transducer Input Modules - 4 channels

NOTE: The Modules are factory- inst alled . They cann ot be inst alle d in the fie ld and are

not user accessible.

See Chapter 2 Controls, Indicators and Connectors for more information on the input

modules. Chapter 3 Circuit Diagrams for Power Monitoring contains wiring diagrams

for when power measurements are to be made.

At the heart of the 61000 is the virtual analyzer platform or ‘instruments within an

instrument’ configuration. The virtual analyzer allows the instrument to distinguish

data operations in mul tiple modules. The user can confi gure up t o four vi rtual a nalyzers

per 61000 instrument.

This guide

The 61000 firmware architecture is based on the concept of separating the various

stages of acquisition, characterization, communications and visualization with clearly

defined interfaces that decouple one from the other. The instrument can monitor power

quality phenomena for troubleshooting and/or compliance purposes. It can record

inrush conditions, carry out long-term statistical studies to establish performance

baselines, and perfor m field-based equipment t esting and eval uation for commissionin g

and maintenance. The firmware inte grates intuit ive instrument setup procedures for

each module analyzer to ensure the capture of all relevant data for additional post

process analysis, report writing, and data archiving using other compatible DranetzBMI software applications such as PQView

®

.

This guide is only part of a complet e document set designed to provide comprehensive

information about the 61000. It primarily contains instructions on how to set up the

basic 61000 hardware for operation. It describes the input module interface and the

wiring configurati ons pos sible fo r volt age/c urr ent c onnect ion. It al so des cri bes t he dat a

communication ports availa ble in the backp lane of the ins trument. An overview on how

to set up the 61000 either as a stand-alone unit or as a data acquisition module

connected to the Encore Series Software is included in this guide.

For operational description using the local LCD panel, refer to the 61000 Optional

User Interface Guide (check with Dranetz-BMI for availability).

For operational description using remote communications via Encore Series Software,

refer to the Encore Series Software User’s Guide.

1-2

Page 15

Unpacking the 61000

Chapter 1/ Introduction

Unpacking

Shipping

damage

inspection

For maximum protection against possible shipping damage, the 61000 has been sealed

in a two-piece, plastic suspension pack, enclosed within a durable shipping carton.

After opening the carton, inspect the contents for possible shipping damage and check

the carton inventory.

Unpack the 61000 from the carton as follows:

Step Action

1 Remove any remaining literature inside the top of the carton.

2 Carefully remove the 61000 from its shipping carton.

3 Remove all accessories inside the carton. Check that the standard (see

page 1-4) and optional accessories (see Appendix A) you ordered are

included.

Visually inspect the 61000 for possible shipping damage. If any damage exists, first

notify and file an insurance claim with your carrier or underwriter or both. Then noti fy

Dranetz-BMI Customer Service Department of your intentions to return the unit. DO

NOT return the 61000 without prior instructions from Dranetz-BMI Customer Service

Department. Dranetz-BMI Customer Service Department can be reached at (732) 2873680 or 1-800-372-6832.

Repacking for

return shipment

Return notice

If the unit must be return ed to Dranetz -BMI for servi ce or repai r , wrap the unit sec urely

in heavy packaging mater ial and place in a well padded box or crate to p revent damag e.

Do not return the 61000 in an unpadded box. Dranetz-BMI will not be responsible for

damage incurred during transit due to inadequate packing on your part.

Notify Dranetz-BMI Customer Service of your intention of returning the unit. Do not

return the unit without prior instructions from Dranetz-BMI. Dranetz-B MI Customer

Service Department can be reached at (732) 287-3680 or 1-800-372-6832.

1-3

Page 16

61000 Accessories

61000 Accessories

Standard

accessories

Optional

accessories

Technical

specifications

External dc

power source

Encore Series

61000 firmware

upgrade

Calibration

The standard accessory included with the 61000 is the Encore Series 61000 System

User’s Guide, P/N UG-61000.

Refer to Appendix A for the list of hardware and software optional accessories

available for use with 61000. The unit mainframe can be custom-built with optional

input module connecto rs, co mmunica tion port c onne ctors , GPS ant enna co nnec tor, and

a 12V dc power input jack.

Specifications for the 61000 measured parameters, computed parameters, voltage

modules, current probes, and pod accessories are listed in Appendix B.

To connect to an external dc power source, refer to Appendix C.

Refer to Appendix D for instructions on how to upload the latest available firmware

version to the Encore Series 61000 System mainframe.

The recommended calibration interval for this unit is once every 12 months.

We recommend that you return the unit to the factory for calibration. If you decide to

do so, first contact the Dranetz-BMI Customer Service Department to obtain an

Authoriz ation Number.

Telephone: (732) 287-3680 or 1-800-372-6832

FAX: (732) 248-9240

Fill out the Repair /Servi ce Ord er for m enclos ed in the shippi ng car ton and ship i t alon g

with the unit to the Dranetz-BMI Repair Department. (If this form is missing, ask the

Dranetz-BMI Customer Service Department for a replacement.)

1-4

Page 17

Physical Description0

Chapter 1/ Introduction

Dimensions

Optional display

panel

Connector panel

External dc

power source

The 61000 in the desktop e ncl os ure without the optional LCD panel is a self -contained

instrument weighing 4 pounds and measu ring 11.25” width x 3.5” height x 7 3/4 depth.

When used with the LCD panel installed in 19” rack, the instrument weighs 5 pounds

and has an 8” depth.

The optional user interf ace is a 1/4 VGA LCD panel with touch screen menus for l oca l

operation and configuration.

The backplane panel consists of industrial grade, voltage/current/pod connectors,

communication port connectors, dc input power connector, and power switch. See

Chapter 2 Controls, Indicators and Connectors for description.

To connect to an external dc power source, refer to Appendix C.

1-5

Page 18

This page intentionally left blank.

1-6

Page 19

Controls, Indicators, and Connectors

External Components; Connecting to AC Power Source; Communications Interface;

Input/Output Module Connectors; Connecting Voltage Measurement Cables;

Connecting Current Probes; Connecting Voltage/Current Input Pods; Connecting

Digital Input Connectors

External Components

C

HAPTER

2

Description

Front panel

External components refer to operator related external controls, indicators and

connectors.

The 61000 front panel display may look different depending on the enclosure options

specified.

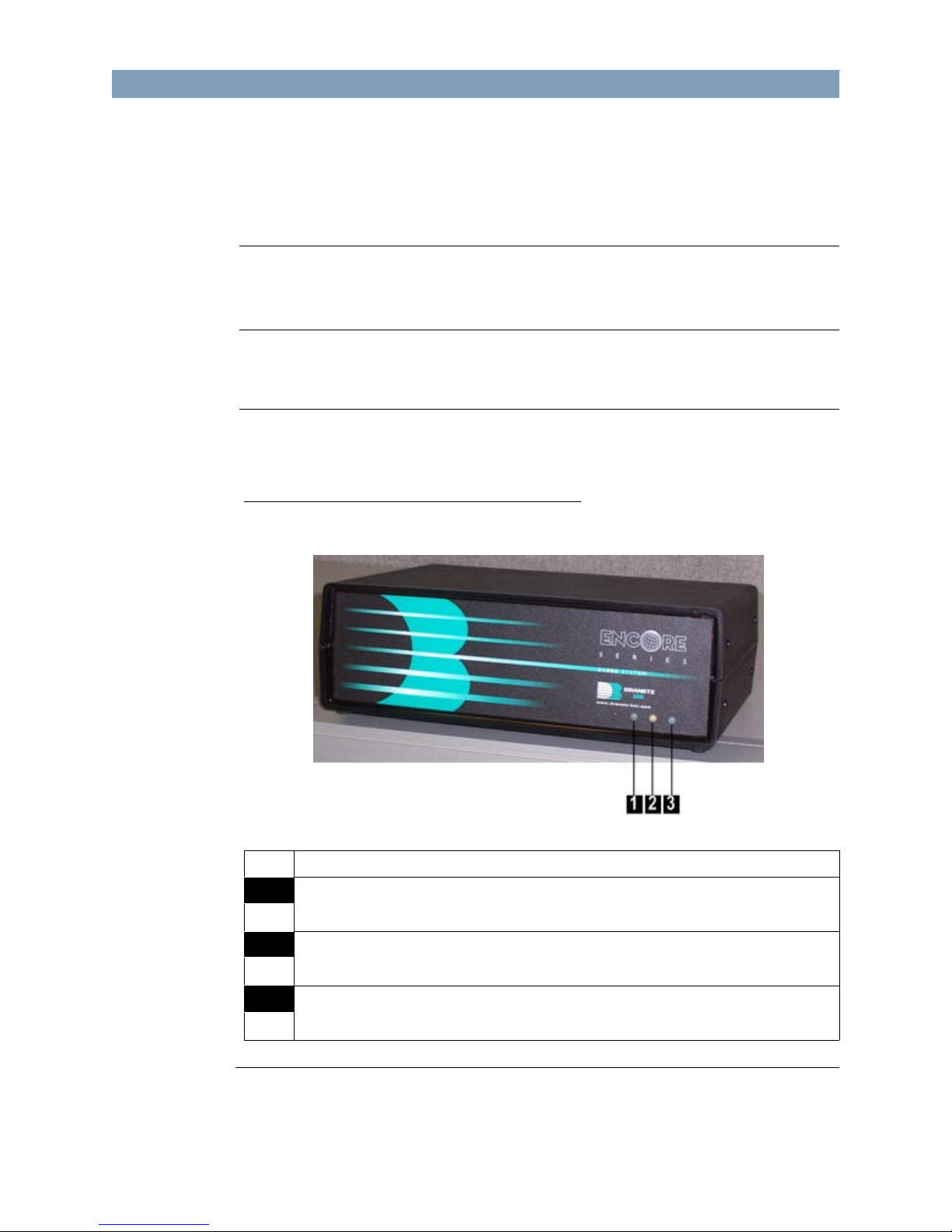

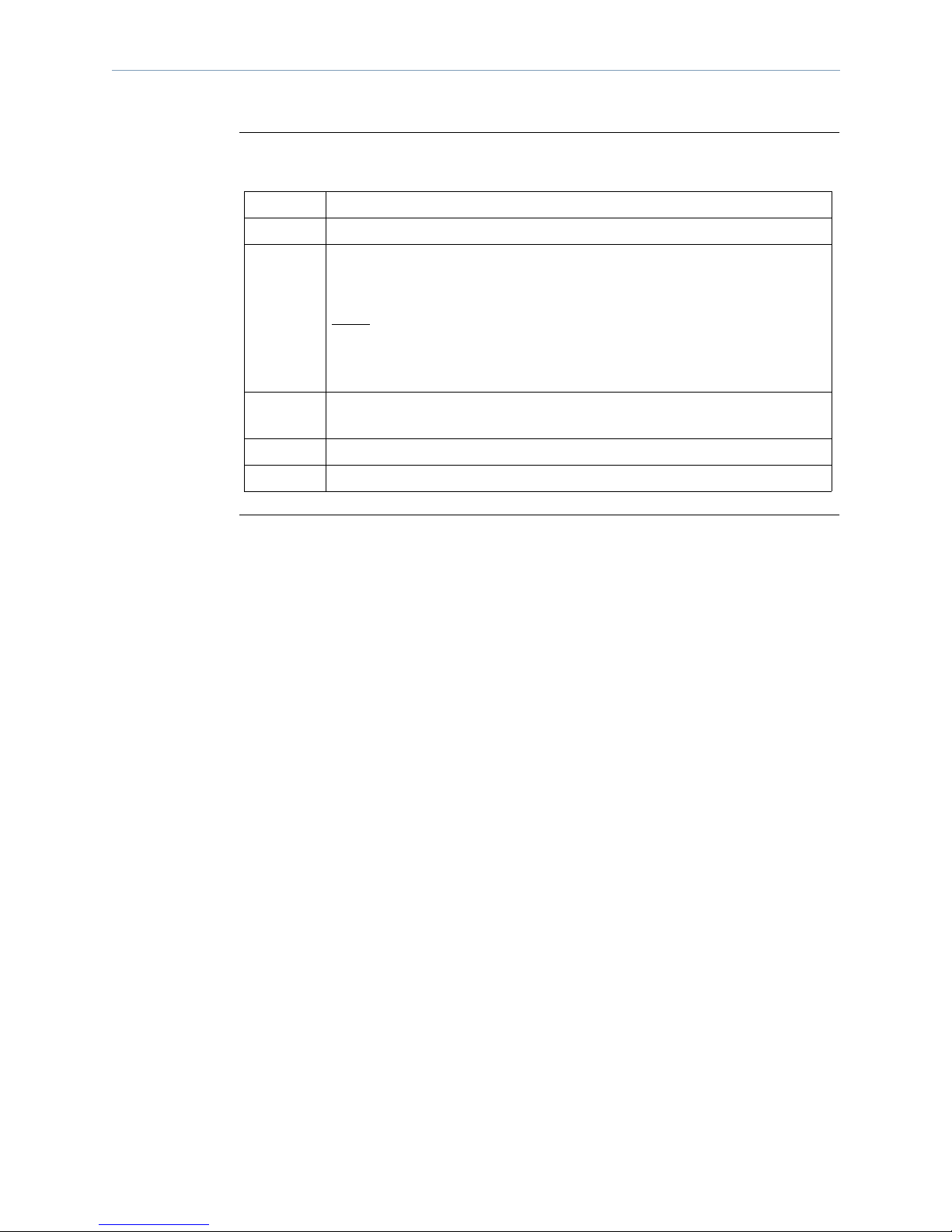

Front panel without the local LCD User Interface

See below for description of the 61000 front display without the LCD user interface.

SF-201

Part Function

1 Sta tus Indicator. LED will l ig ht steadily when abnormal condition is dete ct ed.

The unit is operating normally when light is off.

2 Monitoring On. LED will light if monitoring is on. Monitoring status is off

when light is off.

3 Power Indi ca tor. LED will blink when the unit power switch is turned on. The

number of blinks correspond to the number of modules installed.

Continued on next page

2-1

Page 20

External Components, continued

Front panel

(continued)

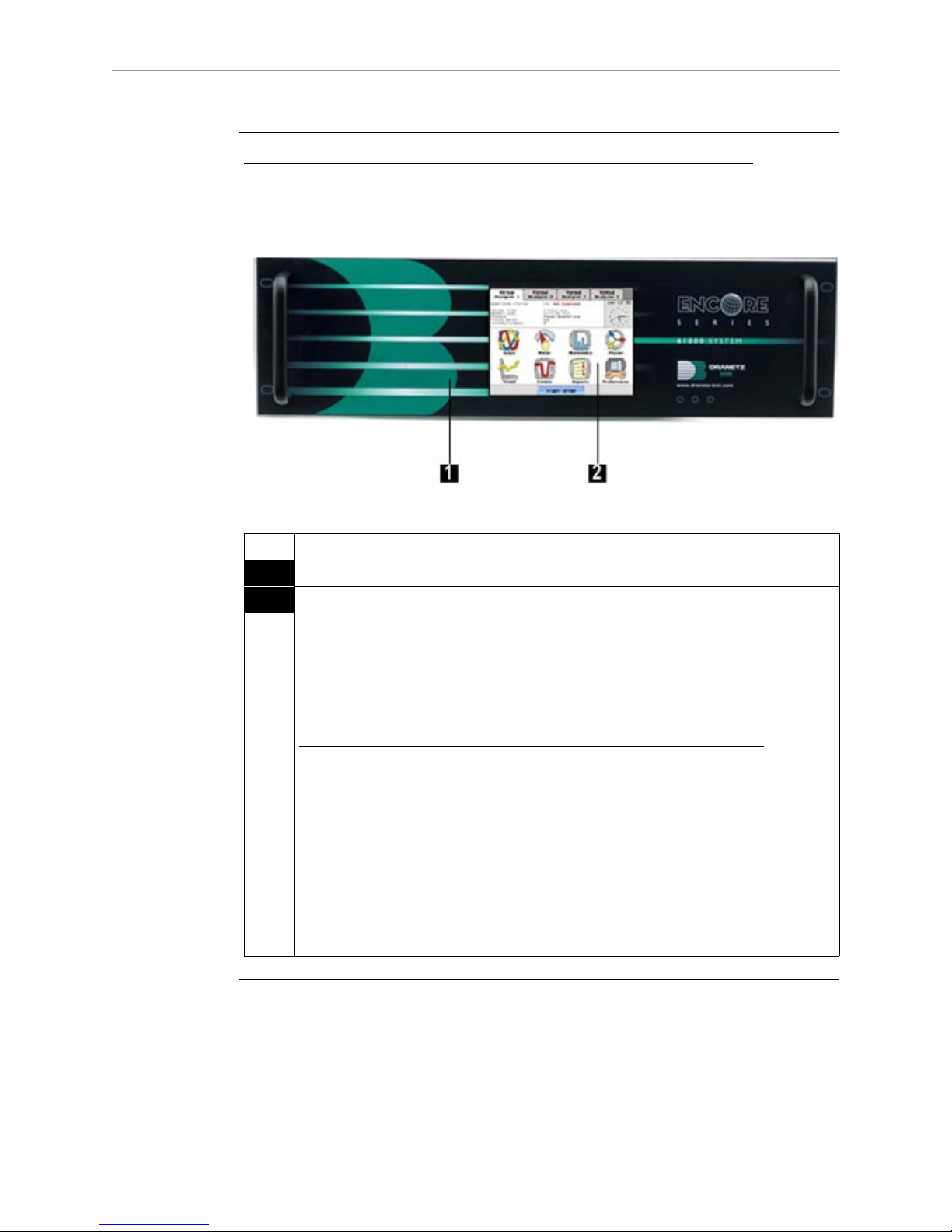

Front panel with the optional LCD User Interface in Rack Mount Eclosure

The front view primarily shows the color touch screen LCD. See below for descr ip ti on

of the 61000 front display with the LCD panel installed.

SF-202

Part Function

1 LCD Rack Mount Protective Enclosure with rack handles

2 Liquid Crystal Display (LCD). Provides 3.75 x 4.75 inches display consisting

of 1/4 VGA size screen of text and graphic information. The color LCD is

equipped with touch screen technology, operable using the finger and/or

stylus. Touch screen display permits menu sel ection, alphanumeric data entry,

and has a compact fluorescent (CCFL) backlighting that is on for low light

level viewing.

2-2

The following are some basic care instructions for the LCD monitor

:

• Use and store the unit within the specified temperature and humidi ty range.

The LCD screen may be adversely affec ted by exposure to high temperat ure

or humidity. Condensation or moisture produced by sudden temperature

changes may also damage the LCD screen. Clean any moisture from su rface

immediately.

• Be careful when cleaning or removing stains on the LCD surface. Gently

wipe the surface with a soft cloth or cotton pad. Isopropyl alcohol may be

used, but make sure that all solvent residue is removed.

• Do not apply exces si ve f orce to the LCD surface. The LCD screen contains

sensitive electronic components that may be damaged due to strong impact.

Page 21

Chapter 2/ Controls, Indicators, and Connectors

r

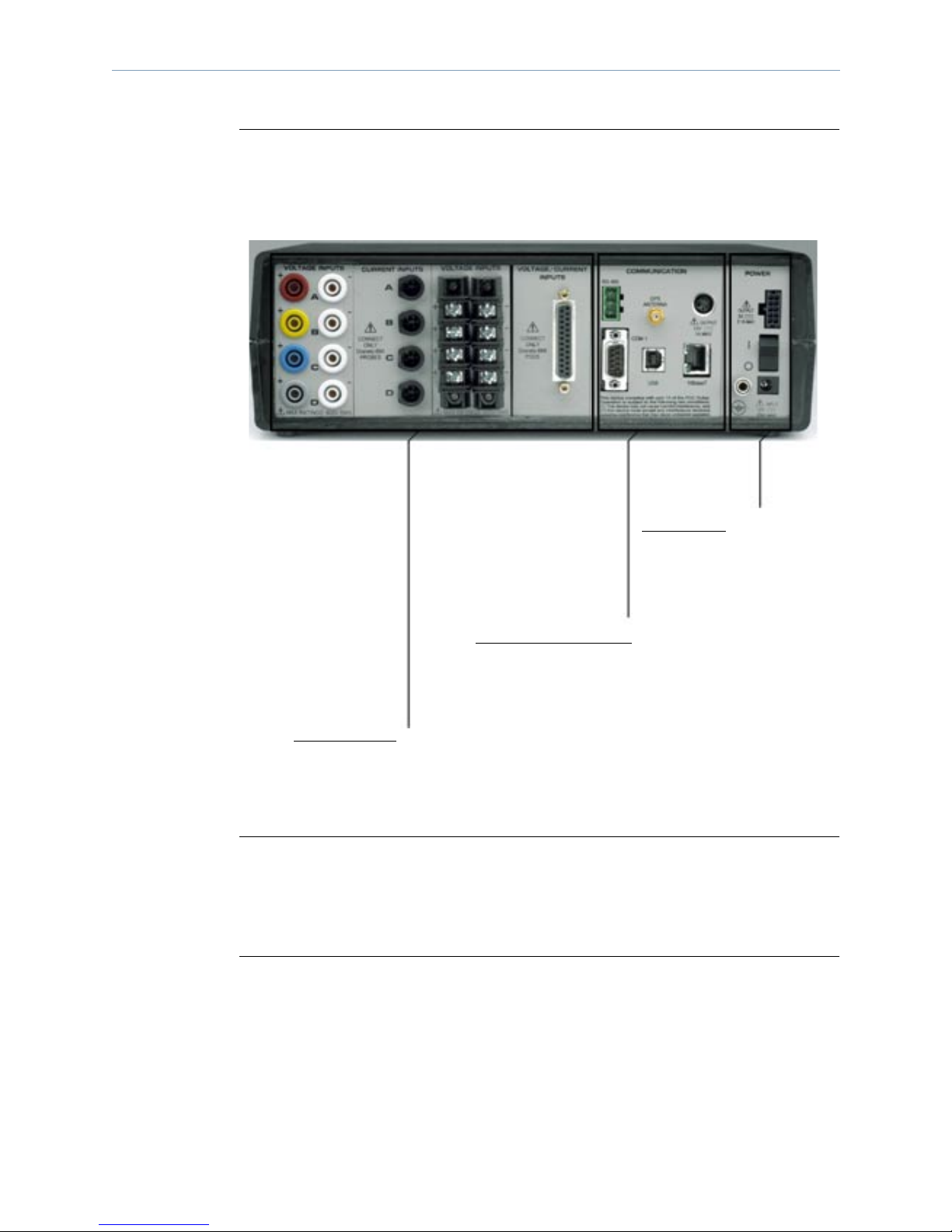

Rear panel

The rear panel consists of the input/output module connectors, communication ports,

and power switch. See below for description of a typical 61000 rear panel. Exact

configuration is dependent on the optional input/output modules ordered.

SF-203

Power Input

See Connecting to DC Powe

Source, page 2-4 on how to

power the unit on/off

Important

Communications Ports

See Communications Interface, page 2-7

for a description of the 61000 data ports

Input Modules

See Input Module Connectors, page 2-9

for a detailed description of the input

module connectors

Dranetz-BMI recommends that you leave adequate working space for rear panel

connections to the 61000. This rear clearance space is necessary for proper installation

of the measurement cables, pr obes and pods as wel l as extern al communic ations device

for the 61000.

2-3

Page 22

Connecting to AC Power Source

Connecting to AC Power Source

Power

specifications

The 61000 AC adapter can be connected to a 90-265V ac power input source

(dependent on model version) or directly to a 12V dc external power source. Refer to

Appendix C for information about connecting to an external dc power source. For

connection to voltages outside of the specified 90-265V ac, a Phase Power Adapter is

required. Phase Power Adapter is an optional accessory available at Dranetz-BMI.

Refer to Appendix A Optional Accessories for ordering information.

CAUTION Always set the power switch to the off position befor e connecting or disconnecting

the input power cable.

Operation of the 61000 from an ac voltage source other than the rated voltage

input stated on the unit nameplate can cause damage to the unit.

PRECAUCION Siempre fije el inter ruptor de encendido en la posic ión apagada antes de conect ar

o desconectar el cable de energía de entrada.

La operación del 61000 desde una fuen te de volt aje de ca que no sea la e ntrada d e

voltaje nominal indicada en la placa de identificación de la unidad puede causar

daños a la unidad.

MISE EN

GARDE

Mettez toujours l’interrupteur dans la position ouverte avant de connecter ou de

déconnecter le câble d’alimentation primaire.

Mettez toujours l’interrupteur dans la position ouverte avant de connecter ou de

déconnecter le câble d’alimentation primaire.

VORSICHT Vor dem Einstecken bzw. Ausstecken des Eingangsnetzkabels den Netzschalter

immer in die Aus-Stellung bringen.

Der Betrieb des 61000 von einer Wechselspannungsquelle, die nicht dem auf der

Namensplatte der Einheit aufgeführten Nennspannungseingang entspricht, kann

zur Beschädigung der Einheit führen.

2-4

Page 23

Chapter 2/ Controls, Indicators, and Connectors

Power input/

switch diagram

The power switch panel includes LED indicators, the On/Off power button, and power

input decal and connector. See input power diagram and description below.

1

2

3

4

SF-204

Part Function

1 Power Indicator. LED will blink when power is turned on. The number of

blinks correspond to the number of modules installed.

2 On/Off Power Button. Push for on, push for off.

NOTE: The on/off po wer switch shuts the unit down, but al l ows the battery to

continue to charge even with the switch in the Off position.

3 Power input decal and connector. The decal provides information about input

power rating. Plug in the AC Adapter output cable into the input connector.

AC input power source is specified as follows:

• Voltage range, 90-265V ac.

• Frequency, 50/60Hz.

• Power Consumption, 10W.

See page 2-6 for the procedure on how to connect to an ac power source.

4 Ground LUG. Connect with suitable wire to earth ground conductor or

connection.

2-5

Page 24

Connecting to AC Power Source, continued

Connecting to

an AC power

source

Follow these steps to connect to an ac power source.

Step Action

1 Set the power switch to Off.

2 Verify the operating voltage range for your 61000, as marked on the

power input decal.

Note:

For source voltages outside the range of the unit, a Phase Power

Adapter is available as an optional accessory. It converts the selected

source voltage to the output voltage needed to operate the unit. Refer to

Appendix A Optional Accessories for information.

3 Connect the appropriate power cord for the voltage rating of the unit.

Make connection to the instrument first.

4 Connect power cord to the power source.

5 Turn power switch to On.

2-6

Page 25

Communications Interface

Chapter 2/ Controls, Indicators, and Connectors

Communications

options

The 61000 can communicate to a compute r via Ethernet networ k, RS232, RS485, USB,

or land/cellular modem. This remote communication network enables the 61000 to act

as a DataNode for the Encore Series Software, or as a stand-alone monitor.

Computer

requirem ents

The computer used must be equipped with the same communication interface as the

61000. For example, if the instr ument is using Ethernet , the comput er must li kewise be

using Ethernet.

The computer must be loaded wit h the Encore Seri es Software package, which conve rts

the computer into a web server and enables it to browse data and information col le ct ed

by the 61000.

WARNING To avoid the risk of electric shock, do not remove communications instrument

until all power is de-energized to all power and measurement circuits.

ADVERTENCIA

Para evitar el riesgo de descargas eléctricas, no retire el instrumento de

comunicaciones hasta desconectar todo suministro de energía hacia todos los

circuitos de energía y medición.

AVERTISSEMENT

Pour éviter le risque de choc électrique, ne retirez pas le instrument de

communications avant que tous les circuits d’alimentation et de mesure aient été

mis hors tension.

WARNUNG Zur Vermeidung eines elektrischen Schlags die Kommunikationsplatte erst

instrument, wenn die Stromzufuhr zu allen Strom- und Meßschaltungen

unterbrochen wurde.

Remote

operation guide

Remote operation setup and instructions for 61000 are contained in the Encore Series

Software User’s Guide.

2-7

Page 26

Communications Interface, continued

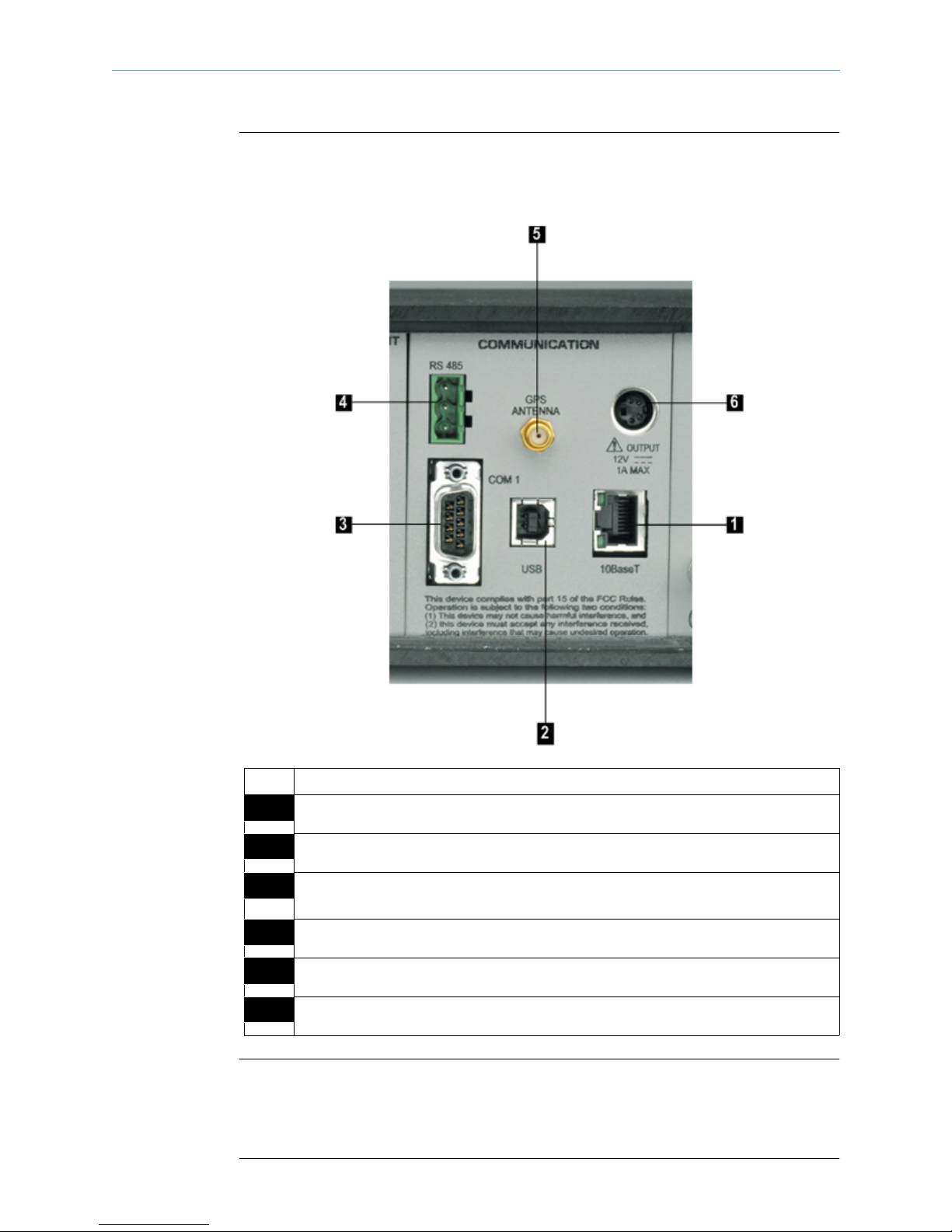

Communication

port diagram

The communications panel below shows the location of data ports available in

61000.The communications panel diagram and description as shown below appears in

the rear panel of the instrument.

Parts table

Remote

operation guide

SF-205

Part Function

1 10/100BaseT (RJ45). Allows connection via Ethernet cable.

2 USB. Not activate d at this time; future option.

3 COM 1. RS232 serial port for land/cellular modem connection. Allows

administrative set up of the 61000 for IP addressing, etc.

4 RS485 serial port. Can be used for multi-drop serial connections.

5 Optional GPS Antenna. Allows use of optional cable to active antenna.

6 Power Connector for External GM28/29 Modem.

See Chapter 4 External Communications for a discussion of the external

communications device and software applications necessary for remote computer

operation of 61000.

2-8

Page 27

Input/Output Module Connectors

Chapter 2/ Controls, Indicators, and Connectors

Input/Output

module types

Users can choose different types of analog and digital input/output modules that can be

installed on the rear panel of 61000. The modules must be selected at time of order. In case

users want additional modules installe d, the unit must be return ed to the factory. The input/

output modules allow a variety of voltage and current measurement cables, probe types, or

pods to connect to the instrument for voltage, current, and/or digital signal monitoring.

The voltage and current connectors are designed in modular configuration, with the

following analog input module measurement point interface:

• AC/DC Voltage Module with safety connectors (Model 61MVB)

• AC/DC Voltage Module with terminal block connectors (Model 61MVS)

• AC/DC Current Module with connectors for external CTs (Model 61MAC)

• AC/DC Module for Voltage or Current Pod (Model 61MZP)

The eight-channel digi tal inp ut module Mo del 61MDIN allo ws users to mon itor on/o ff ty pe

digital signals, such as breaker or switch signal positions. Digital inputs can be configured

to provide demand interval synchronization, pulse counting, KYZ metering, or to provide

start/stop monitoring control.

Digital output module allows certain events to result in change of state of a relay contact.

See Appendix A for specifications of Dranetz-BMI digital output module Models

61MDOH and 61MDOL.

Transducer input module Models 61MXVS and 61MXAS can record and trigger on

analog signal levels in either the 0-24V and 4-20mA range respectively.

Input channels

WARNING

Input channels for the modules installed on the rear connector panel are labelled ±A, ±B,

±C, and ±D. You must turn on any input channel to be used for monitoring. If a channel is

not turned on, no data will be collected for it.

Death, serious injury, or fire hazard could result from improper connection of this

instrument. Read and understand this manual before connecting this instrument. Follow

all installation and opera ti ng instructions while using this instrument.

Connection of this instrument must be performed in compliance with the National

Electrical Code (ANSI/NFPA 70-2005) and any additional safety requirements applicable

to your installat i on.

Installation, operation, and maintenance of this instrument must be performed by

qualified personnel only. The National Electrical Code defines a qualified person as “o ne

who has the skills and knowledge related to the construction and operation of the electrical

equipment and installations, and who has received safety training on the hazards

involved.”

Qualified personnel who work on or near exposed energized electrical conductors must

follow applicable safety related work practices and procedures including appropriate

personal protective equipment in compliance with the Standard for Electrical Safety

Requirements for Employee Workplaces (ANSI/NFPA 70E-2004) of USA and any

additional workplace safet y requirements applicable to your installation.

Continued on next page

2-9

Page 28

Input/Output Module Connectors, continued

ADVERTENCIA

Una conexión incorrecta de este instrumento puede producir la muerte, lesiones

graves y riesgo de incendio. Lea y enti enda este manual antes de conectar. Observe

todas las instrucciones de instalación y operación durante el uso de este

instrumento.

La conexión de este instrumento a un sistema eléctrico se debe realizar en

conformidad con el Código Eléctrico Nacional (ANSI/NFPA 70-2005) de los

E.E.U.U., además de cualquier otra norma de seguridad correspondiente a su

establecimiento.

La instalación, operación y mantenimiento de este instrumento debe ser realizada

por personal calificado solamente. El Código Eléctrico Nacional define a una

persona calificada como "una que esté familiarizada con la construcción y

operación del equipo y con los riesgos involucrados."

El personal cualificado que trabaja encendido o acerca a los conductores

eléctricos energizados expuestos debe seguir prácticas y procedimientos

relacionados seguridad aplicable del trabajo incluyendo el equipo protector

personal apropiado en conformidad con el estándar para los requisitos de

seguridad eléctricos para los lugares de trabajo del empleado (ANSI/NFPA 70E-

2004) de los E.E.U.U. y cualquier requisito de seguridad adicional del lugar de

trabajo aplicable a su instalación.

AVERTISSEMENT

Si l'instrument est mal connecté, la mort, des blessures graves, ou un danger

d'incendie peuvent s'en suivre. Lisez attentivement ce manuel avant de connecter

l'instrument. Lorsque vous utilisez l'instrument, suivez toutes les instructions

d'installation et de service.

Cet instrument doit être connecté conformément au National Electrical Code

(ANSI/NFPA 70-2005) des Etats-Unis et à toutes les exigences de sécurité

applicables à votre installation.

Cet instrument doit être inst allé, util isé et entre tenu uniquement par un perso nnel

qualifié. Selon le National Electrical Code, une personne est qualifiée si "elle

connaît bien la construction et l'utilisation de l'équipement, ainsi que les dangers

que cela implique".

Le personnel qualifié qui travaillent dessus ou s'approchent des conducteurs

électriques activés exposés doit suivre des pratiques en matière et des procédures

reliées par sûreté applicable de travail comprenant le matériel de protection

personnel approprié conformément à la norme pour des conditions de sûreté

électriques pour les lieux de travail des employés (ANSI/NFPA 70E-2004) des

Etats-Unis et toutes les conditions de sûreté additionnelles de lieu de travail

applicables à votre installation.

2-10

Continued on next page

Page 29

Chapter 2/ Controls, Indicators, and Connectors

WARNUNG Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer

verursachen. Bevor Sie dieses Instrument anschließen, müssen Sie die Anleitung

lesen und verstanden haben. Bei der Verwendung dieses Instruments müssen alle

Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen

Bestimmungen für Elektrizität (ANSI/NFPA 70-2005) der Vereinigten Staaten,

sowie allen weiteren, in Ihrem Fall anwendbaren Sicherheitsbestimmungen,

vorgenommen werden.

Installation, Betrieb und Wartung dieses Instruments dürfen nur von

Fachpersonal durchgeführt werden. In dem nationalen Bestimmungen für

Elektrizität wird ein Fachmann als eine Person bezeichnet, welche "mit der

Bauweise und dem Betrieb des Gerätes sowie den dazugehörigen Gefahren

vertraut ist."

Qualifiziertes Personal, das an bearbeiten oder herausgestellte angezogene

elektrische Leiter sich nähern, muß anwendbare Sicherheit bezogener Arbeit

Praxis und Verfahren einschl ie ßli ch passende persönliche schützende Ausrüstung

gemäß dem Standard für elektrische Sicherheitsauflagen für AngestelltArbeitsplätze (ANSI/NFPA 70E-2004) der Vereinigten Staaten und alle

zusätzlichen Arbeitsplatzsicherheitsauflagen folgen, die auf Ihre Installation

anwendbar sind.

Safety

precautions

The following safety precautions must be followed whenever any type of voltage or

current connection is being made to the 61000.

• Wear proper Personal Protective Equipment, including safety glasses and insulated

gloves when making connections to power circuits.

• Hands, shoes and floor must be dry when making any connection to a power line.

• Before each use, inspect all cables for breaks or cracks in the insulation. Replace

immediately if defective.

• Set the 61000 power switch to Off.

Before connecting to electric circuits to be monitored, open their related circuit

breakers or disconnects. DO NOT install any connection of the 61000 to live power

lines.

• Pods should be connected first to the 61000, then connect to the circuit to be

monitored.

• If the equipment is used in a ma nner not specified in this user’s guide, th e pro tec tion

provided by the equipment may be impaired.

2-11

Page 30

Input/Output Module Connectors, continued

Module

connectors

diagram

The 61000 can accommodate up to four input/output modules with different types of

connectors. The modules installed on the rear panel are customized based on user

specifications. The following pages describe how the optional voltage and current

measurement cables, probes and pod accessories can connect to the 61000 for circuit

monitoring.

The photo below shows the 61000 rear panel with four analog input modules installed.

Digital input/out put mod ules a re al so av ail able (see Appendi x A Op tional Acces sorie s)

but are not shown in photo.

1.1

1.3

1

1.2

2.1

3.1

1.4

2.2

3.3

3

SF-206

3.2

4.1

3.4

Parts table

1.5

1.7

1.6

1.8

2.3

2.4

3.5

3.7

3.6

3.8

2 4

Part Function

1 AC Voltage Module with Safety Jack Connectors (Model No. 61MVB)

1.1 CH A, + Differential Voltage Input Connector; color red

1.2 CH A, - Differential Voltage Input Connector; color white

1.3 CH B, + Differential Voltage Input Connector; color yellow

1.4 CH B, - Differential Voltage Input Connector; color white

1.5 CH C, + Differential Voltage Input Connector; color blue

1.6 CH C, - Differential Voltage Input Connector; color white

1.7 CH D, + Differential Voltage Input Connector; color grey

1.8 CH D, - Differential Voltage Input Connector; color white

2-12

Continued on next page

Page 31

Parts

(continued)

Chapter 2/ Controls, Indicators, and Connectors

Part Function

2 AC Current Module with Connectors for External CTs (Model No. 61MAC)

2.1 CH A, PROBE, Current Input Connector

2.2 CH B, PROBE, Current Input Connector

2.3 CH C, PROBE, Current Input Connector

2.4 CH D, PROBE, Current Input Connector

3 AC Voltage Module with Terminal Block Connectors (Model No. 61MVS)

3.1 CH A, + Differential Voltage Input Connector

3.2 CH A, - Differential Voltage Input Connector

3.3 CH B, + Differential Voltage Input Connector

3.4 CH B, - Differential Voltage Input Connector

3.5 CH C, + Differential Voltage Input Connector

3.6 CH C, - Differential Voltage Input Connector

3.7 CH D, + Differential Voltage Input Connector

3.8 CH D, - Differential Voltage Input Connector

Measurement

cables, probes

and pods

4 AC Voltage/Current Module with 25-PIN DConnector (Model No. 61MZP)

4.1 25-PIN DConnector

Digital Input Module (Model Nos. 61MDIN) and Digital Output Module (Model No.

61MDOUT) are also available as input/output module options. See page 2-24 for

information on digital input connections.

The input modules and the cables, probes and pods that connect to it are optional

accessories listed in Appendix A Optional Accessories.

Voltage Measurement Cables (for Voltage Input Module with safety jack connectors Model No. 61MVB): Volta ge measure ment cable s ar e sto red i n a cabl e pouc h as part of

the measurement cable set, P/N 116042-G3. Each cable set consists of a cable and

alligator clip. Each alligator clip has an insulate d safety grip. R ed alligator clips are

used for connection to the line connection (+) of voltage channels A, B, C, and D.

Black alligator clips ar e used for the neutral or return li ne connecti on (-). See page 2-15

for more information voltage cable connections.

Current Probes (for Current Input Module - Model No. 61MAC)

: A variety of current

cables and probes are available for connecting Channels A, B, C, and D to the current

input jack. Typical current probes are illustrated on page 2-19.

Continued on next page

2-13

Page 32

Input/Output Module Connectors, continued

Measurement

cables, probes

and pods

(continued)

Voltage/Current Pods (for Voltage/Current Input Module - Model No. 61MZP)

:

Connects to the Series 5500 Voltage/Current input module via the 25-PIN interface

cable connector on the rea r panel of the instr ument. See page 2-2 2 for more informati on

on voltage/current input pod connection.

The next pages describe the possible voltage and current assembly connections to the

input connectors in the rear panel of 61000.

NOTE: VOLTAGE AND CURRENT PROBES ARE NOT SHOWN

CONNECTED TO THE SPECIFIC INPUT MODULES IN THE CONNECTION

DIAGRAMS PROVIDED BECAUSE THE ACTUAL VOLTAGE CABLE AND

CURRENT PROBES USED ARE DEPENDENT ON THE TYPE OF INPUT

MODULES AND OPTIONAL ACCESSORIES PURCHASED.

See Chapter 3 Circuit Diagrams for Power Monitoring for the wiring connection

diagrams to set up the instrument for monitoring.

2-14

Page 33

Chapter 2/ Controls, Indicators, and Connectors

Connecting Voltage Measurement Cables

Measurement

cable set

Optional fused

voltage adapter

Description

: Voltage measurement cables or customer-supplied wiring are used as

connectors for Voltage input modules with safety jack or terminal block connectors,

respectively. Each cable set consists of a cable and alligator clip.

Voltage Rating

: Direct connection of all voltage measurement cables are rated at 600

Vrms max. For measur ing vol tages gr eate r than 600 Vrms, potential transfo rmers (PT s)

must be used. Any customer-supplied wiring should be UL-listed for 600 Vrms

minimum.

Contents

: The voltage measurement cables are shown on page 2-16. A cable set

consists of eight, 6-foot channel measurement cable assemblies (probes), each with a

detachable, alligator jaw, safety clip assembly (maximum jaw opening, 3/4 in (20

mm)). The safety clip assemblie s are red (+) and black (-) for each of the four channe ls.

One cable each of red (channel A), yellow (channel B), blue (channel C), and grey

(channel D), and four each of white are provided.

A pouch for storage of the cables and the AC ada pt er/ ba ttery charger is included in the

contents of the measurement cable set, but is not shown in the figure.

There are two optional fuse accessory kits available for use with the measurement

cables. One kit (P/N FVA-1) contains one fused voltage adapter and one measurement

connecting Red cable 50 cm i n lengt h. The othe r kit ( P/N FVA-4) contains four volta ge

adapters and four measurement connecting cables 50 cm in length (one Red, one

Yellow, one Blue, and one Grey).

The single fuse voltage adapter kit is used for one single voltage measurement input.

While the four fuse voltage adapter kit is used for a three phase and neutral voltage

measurement inputs. If these fuse kits are not used, i t i s recommended that the user use

terminal strips to fused circuits, preferably with local disconnects.

Continued on next page

2-15

Page 34

Connecting Voltage Measurement Cables, continued

Measurement

cable set wi th

optional fuse

diagram

WARNING

WARNING

WARNING

NOTE: 2 FT CABLE

INCLUDED WITH

FUSE VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

OPTIONAL

FUSE

VOLTAGE

ADAPTER

A+ B+ C+ D+ A- B- C- D-

To AC Voltage Module with safety jack

SF-207

or terminal block connectors

To avoid the risk of electric shock or burns, always connect the safety (or earth)

ground before making any other connections.

To reduce the risk of fire, electrical shock, or physical injury it is strongly

recommended to fuse the voltage measurement inputs.

Fuses must be located as close to the load as possible to maximize protection.

For continued protection against risk of fire or shock hazard replace only with

same type and rating of recommended fuse.

Use only fast blow type fuse which is rated 600V. Recommended fuse type is

Littelfuse, part number KLKD0.30 rated 600V AC/DC, 0.3A fast blow.

WARNING

Do not replace fuse again if failure is repeated. Repeated failure indicates a

defective condition that will not clear with replacement of the fuse. Refer

condition to a qualified technician.

2-16

Page 35

Chapter 2/ Controls, Indicators, and Connectors

Contact Dranetz-BMI Customer Service for more information on the fused voltage

adapter. Refer to Dranetz-BMI Information Sheet titled Model FVA - Fuse Voltage

Adapter, P/N 899107 .

Voltage input

connectors

There are two categorie s of voltage conn ectors in Voltage Input Modules: one for single

phase voltage connections, designated VOLTAGE INPUTS, CH D; the other for three

phase connections, designated VOLTAGE INPUTS CH A, CH B, CH C. See the

voltage cable connections diagram below.

In general, the single phase channel D cable is used to measure the neutral to ground

voltage. In this type connection it is referenced as channel D. This cable also can be

used for any single phase connection. See Chapter 3 Circuit Diagrams for Power

Monitoring for the various circuit connections using this cable.

2-17

Page 36

Connecting Current Probes

Connecting Current Probes

T ype s of curr ent

cables

T ype s of curr ent

probes

Safety

precautions

Several Dranetz-BMI current probes can be used with the Current Input Module Model No. 61MAC of the 61000. The following are two types of current cables

available for connecting to the current input channels A, B, C, and D.

• CT Series Adapter Assembly.

• Four Channel Current Probe Cable Assembly (for TR25xx probes).

A variety of current measurement probes and transformers are available that can be

connected to these cables in a number of ways.

For instance:

• TR25xx clamp-on current probes that provide a broad range of current

measurements.

• Multiple probes and adapter cables that are currently used with Dranetz-BMI

equipment i.e. Flex Core models and Hall-effect probe models.

Typical current probes are illustrated on page 2-19. A diagram showing current

connection to a single phase circuit for general hookup is also provided on page 2-21.

The following safety precautions apply to current probe connections.

• DO NOT attempt to measure current in any circuit in which the circuit to ground

voltage exceeds the insulation rating of the current probe (600 Vrms max).

• Make sure the jaws of the current probe are tightly closed. Keep mating surfaces

clean and free from foreign matter.

2-18

Page 37

Typical current

probes

Chapter 2/ Controls, Indicators, and Connectors

NOTE: The TR2500 can perform all current measurements except high frequency

transient detection. Current probes TR2500 can be used interchangeably with

TR2500A, TR2510 with TR2510A, and TR2520 with TR2520A.

Refer to Appendix A for descriptions and part numbers of probes and adapter cables.

Refer to Appendix B for specifications of current connections.

To any Current CH A, B, C, D of Model No. 61MA C

4300 TO LEMFLEX

CURRENT PROBE

ADAPTER CABLE

116310-G1

SF-210

2-19

Page 38

Connecting Current Probes, continued

Example

WARNING

ADVERTENCIA

AVERTISSEMENT

The diagram on page 2-21 shows how to connect a cur rent probe for curr ent monitoring

of a single phase line. The channel to be monitored can be any chann el so designated by

the operator.

DO NOT USE non-insulated current probe cores around a non-insulated wire.

Probes of this type are designed for use around insulated wires only. Use only

completely insulated probe cores with no exposed conductive areas of the core

around non-insulated wires.

NO UTILIZAR transformadores de corriente sin material aislante al rededor de

conductores sin material aislante. Los Transformadores de corriente de este tipo

están diseñados para ser utilizados solamente con conductores con aislamiento

eléctrico. Utilizar transformadores de corriente completamente aislados

alrededor de conductores sin aislamiento.

N'EMPLOYEZ PAS les noyaux courants non-isolés de sonde autour d'un fil nonisolé. Des sondes de ce type sont concues pour l'usage autour des fils isolés

seulement. L'utilisatio n seul ement a compl ét ement iso lé des noy aux de s onde s ans

des secteurs conducteurs exposés du noyau autour des fils non-isolés.

WARNUNG

Probe

positioning

VERWENDEN Sie keine Stromzangen mit nicht isolierten Ferritkernen bei

Messungen an nicht isolierten Leitungen. Stromzangen dieses Typs sind nur für

Messungen an isolierten Leitern geeignet. Bitte verwenden Sie zur Messung an

nicht isolierten Leitungen Stromzangen mit vollständig isoliertem Kernmaterial.

An arrow marking on the handle is a guide to ensure that you position the probe with

the arrow pointing towards the load when monitoring the line conductor. Correct

positioning of the probe is necessary for correct power measurements, where in-phase

voltage and curre nt measure ments are neces sary. A positive watts r eading i ndicates that

the probe is pointed towards the load, and a negative reading indicates that the probe is

pointed towards the source.

Continued on next page

2-20

Page 39

Chapter 2/ Controls, Indicators, and Connectors

Single phase

current probe

connection

example

The following diagram shows how to connect a current probe to channel A for current

monitoring of a single phase line.

The current probe may be connected to the return line if desired to measure the return

current when checking for load current leakage, loop current relationships, etc. If

measuring power, position the probe with the arrow pointing towards the load.

7703-21

SF-211

To Voltage CH D To Current CH A

Note The connection example shown above is not recommended without a voltage probe

connected to ensure that the measurements are synchronized to the external source. If

the configuration shown is used, an internal frequency reference must be entered.

2-21

Page 40

Connecting Volt age/C urren t Input Pods

Connecting Voltage/Current Input Pods

Pod types

Pod assembly

diagram

Two Series 5500 input pod types, voltage and current, can connect alternatively to the

same Voltage/Current Input Module Model No. 61MZP with 25-PIN interface cable

connector. The inputs are attenua te d t o low voltage signals that can be measured by the

61000.

Photos of Model 5536 voltage pod and Model 5537 current pod are shown below. See

pod assembly labels on page 2-23.

3

1

SF-212

2-22

3

2

SF-213

Continued on next page

Page 41

Pod assembly

parts

Chapter 2/ Controls, Indicators, and Connectors

Part Function

Example:

Voltage pod

connection

1 Voltage Module. Accepts four 5-600 V

(AC or DC), ±1000 Vpk channels A,

rms

B, C voltage, plus neutral and ground. Neutral to ground voltage range: 0.5 20 Vrms (AC or DC).

2 Current Module. Accepts four 0.01-5 A

Measurement range allows 25 A

pk

.

and up to #12 AWG wires.

rms

3 Data cables. Enables connection of measurement pods to the 61000. Cable

length is 3” (0.9m).

The figure below shows a voltage pod connected to the Voltage input module with 25PIN interface cable connector.

SF-214

2-23

Page 42

Connecting Digital Input Connectors

Connecting Digital Input Connectors

Digital input

connections

Model No.

61MDIN is an eight channel, digital input module, providing users with

the capability to monitor on/off-type digital signals, such as breaker or switch position

indicators. The functionality of the inputs can be configured on a channel basis to also

provide demand interval synchronization, pulse counting, KYZ metering or to provide

start/stop monitoring control. Each channel can be individually labeled, is triggerable,

and the polarity set as N/O or N/C.

Photo below shows the digital input module without the external connector.

2-24

A logical one or HI condition is when the voltage level goes above 3.5 volts and a

logical zero or LO condition is when the voltage level goes below 1.0 volts. Maxi mu m

input signal level is 135Vac or 200Vdc. If the inputs are configured for AC instead of

DC signals, it is the rms value of the ac signal that is used to determine the state. This

will also slow the response time down, as the rms value is computed over 100msec

window for operation on 50 or 60Hz systems.

All logic transitions are to be time stamped to the millisecond and available for

simultaneous comparison by the user to data collected via other modules (V, I, other

Digital input, etc). An "event" can be either set to occur on the change of state (edgetriggered) or at a particular state, HI/LO (level-triggered). Such events can be used to

cross-trigger other modules and/or instruments to also record data.

The Meter screens will report the present state of the inputs. Trends and Events

timeplots will indicate the signal level at the either 1 or 0 state at the time of data

storage, as will waveform data. There is no min/max/average value, just the

instantaneous value.

Page 43

Circuit Diagrams for Power Monitoring

Connecting Power to the Voltage/Current Connections; Single Phase; Split Phase;

3 Phase, Four Wire Wye; 3 Phase Delta; 3 Phase 2-Watt Delta; 2 1/2 Element without

Voltage Channel B; 2 1/2 Element without Voltage Channel C

Connecting Power to the Voltage/Current Connections

C

HAPTER

3

Voltage and

current

connections

WARNING

This section contains diagrams of voltage and current connections that are required

when power measurements are to be made.

T

he 61000 should be handled with care. After unpacking the unit, verify that all items

ordered have been accounted for. Contact Dranetz-BMI Customer Service if any items

are missing or damaged.

Position the 61000 on a dry, flat surface or mount with proper brackets or in an

appropriate enclosure. Access to the power, measurement and communication

connections is necessary.

Refer to the illustrations in Chapter 2 Controls, Indicators and Connectors for location

of the various connectors on the rear panel of the unit.

Death, serious injury, or fire hazard could result from improper connection of this

instrument. Read and understand this manual before connecting this instrument.

Follow all installation and operating instructions while using this instrument.

Connection of this instrument must be performed in compliance with the National

Electrical Code (ANSI/NFPA 70-2005) and any additional safety requirements

applicable to your installation.

Installation, operation, and maintenance of this instrument must be performed by

qualified personnel only. The National Electrical Code defines a qualified person as

“one who has the skills and knowledge related to the construction and operation of the

electrical equipment and installations, and who has received safety training on the

hazards involved.”

Qualified personnel who work on or near exposed energized electrical conductors

must follow applicable safety related work practices and procedures including

appropriate personal protective equipment in compliance with the Standard for

Electrical Safety Requirements for Employee Workplaces (ANSI/NFPA 70E-2004) of

USA and any additional workplace safety requirements applicable to your

installation.

Continued on next page

3-1

Page 44

Connecting Power to the Voltag e/Curre nt Connections , continued

ADVERTENCIA

Una conexión incorrecta de este instrumento puede producir la muerte, lesiones

graves y riesgo de incendio. Lea y enti enda este manual antes de conectar. Observe

todas las instrucciones de instalación y operación durante el uso de este

instrumento.

La conexión de este instrumento a un sistema eléctrico se debe realizar en

conformidad con el Código Eléctrico Nacional (ANSI/NFPA 70-2005) de los

E.E.U.U., además de cualquier otra norma de seguridad correspondiente a su

establecimiento.

La instalación, operación y mantenimiento de este instrumento debe ser realizada

por personal calificado solamente. El Código Eléctrico Nacional define a una

persona calificada como "una que esté familiarizada con la construcción y

operación del equipo y con los riesgos involucrados."

El personal cualificado que trabaja encendido o acerca a los conductores

eléctricos energizados expuestos debe seguir prácticas y procedimientos

relacionados seguridad aplicable del trabajo incluyendo el equipo protector

personal apropiado en conformidad con el estándar para los requisitos de

seguridad eléctricos para los lugares de trabajo del empleado (ANSI/NFPA 70E-

2004) de los E.E.U.U. y cualquier requisito de seguridad adicional del lugar de

trabajo aplicable a su instalación.

AVERTISSEMENT

Si l'instrument est mal connecté, la mort, des blessures graves, ou un danger

d'incendie peuvent s'en suivre. Lisez attentivement ce manuel avant de connecter

l'instrument. Lorsque vous utilisez l'instrument, suivez toutes les instructions

d'installation et de service.

Cet instrument doit être connecté conformément au National Electrical Code

(ANSI/NFPA 70-2005) des Etats-Unis et à toutes les exigences de sécurité

applicables à votre installation.

Cet instrument doit être inst allé, util isé et entre tenu uniquement par un perso nnel

qualifié. Selon le National Electrical Code, une personne est qualifiée si "elle

connaît bien la construction et l'utilisation de l'équipement, ainsi que les dangers

que cela implique".

Le personnel qualifié qui travaillent dessus ou s'approchent des conducteurs

électriques activés exposés doit suivre des pratiques en matière et des procédures

reliées par sûreté applicable de travail comprenant le matériel de protection

personnel approprié conformément à la norme pour des conditions de sûreté

électriques pour les lieux de travail des employés (ANSI/NFPA 70E-2004) des

Etats-Unis et toutes les conditions de sûreté additionnelles de lieu de travail

applicables à votre installation.

3-2

Continued on next page

Page 45

Chapter 3/ Circuit Diagrams for Power Monitoring

WARNUNG Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer

verursachen. Bevor Sie dieses Instrument anschließen, müssen Sie die Anleitung

lesen und verstanden haben. Bei der Verwendung dieses Instruments müssen alle

Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen

Bestimmungen für Elektrizität (ANSI/NFPA 70-2005) der Vereinigten Staaten,

sowie allen weiteren, in Ihrem Fall anwendbaren Sicherheitsbestimmungen,

vorgenommen werden.

Installation, Betrieb und Wartung dieses Instruments dürfen nur von

Fachpersonal durchgeführt werden. In dem nationalen Bestimmungen für

Elektrizität wird ein Fachmann als eine Person bezeichnet, welche "mit der

Bauweise und dem Betrieb des Gerätes sowie den dazugehörigen Gefahren

vertraut ist."

Qualifiziertes Personal, das an bearbeiten oder herausgestellte angezogene

elektrische Leiter sich nähern, muß anwendbare Sicherheit bezogener Arbeit

Praxis und Verfahren einschl ie ßli ch passende persönliche schützende Ausrüstung

gemäß dem Standard für elektrische Sicherheitsauflagen für AngestelltArbeitsplätze (ANSI/NFPA 70E-2004) der Vereinigten Staaten und alle

zusätzlichen Arbeitsplatzsicherheitsauflagen folgen, die auf Ihre Installation

anwendbar sind.

Safety

precautions

The following safety precautions must be followed whenever any type of voltage or

current connection is being made to the 61000.

• Wear proper Personal Protective Equipment, including safety glasses and insulated

gloves when making connections to power circuits.

• Hands, shoes and floor must be dry when making any connection to a power line.

• Before each use, inspect all cables for breaks or cracks in the insulation. Replace

immediately if defective.

• Set the 61000 power switch to Off.

Before connecting to electric circuits to be monitored, open their related circuit

breakers or disconnects. DO NOT install any connection of the 61000 to live power

lines.

• Pods should be connected first to the 61000, then connect to the circuit to be

monitored.

• If the equipment is used in a ma nner not specified in this user’s guide, th e pro tec tion

provided by the equipment may be impaired.

3-3

Page 46

Connecting Power to the Voltag e/Curre nt Connections , continued

WARNING

WARNING

WARNING

WARNING

WARNING

T o reduce the risk of fire, el ectri c shock, or phy sic al inju ry, it is strongly recommended

that connections be made with al l circui ts de-en ergi zed and cur rent car rying conductor s

fused. If it is necessary to make connections on energized circuits, these must be

performed by Qualified Personnel ONLY with proper Personal Protective Equipment.

To avoid the risk of electric shock or burns, always connect the safety (or earth)

ground before making any other connections.

To reduce the risk of fire, electrical shock, or physical injury it is strongly

recommended to fuse the voltage measurement inputs.

Fuses must be located as close to the load as possible to maximize protection.

For continued protection against risk of fire or shock hazard replace only with

same type and rating of recommended fuse.

Use only fast blow type fuse which is rated 600V. Recommended fuse type is

Littelfuse, part number KLKD.300 rated 600V AC/DC, 0.3A fast blow.

Do not replace fuse again if failure is repeated. Repeated failure indicates a

defective condition that will not clear with replacement of the fuse. Refer

condition to a qualified technician.

3-4

Page 47

Chapter 3/ Circuit Diagrams for Power Monitoring

Connection

Guidelines

Refer to the appropriate connection diagram on pages 3-6 to 3-12 to connect

power to the voltage/current input connections.

• Make sure all circuits are de-energized before making connections.

• Connect the data cables. Plug the measurement cables into the appropriate

connectors on the rear panel of the 61000.

• Remove the terminal protective cover(s) from the Voltage Input Module(s).

• Route power wires in a safe manner in accordance with good practice and local

codes.

• Connect the ground wire first, before making any other connections.

• Connect power source to the Voltage and Current Input Modules. Attach pha se A, B,

and C voltage connections plus neutral, if applicable, to the screw terminals on the

Voltage Input Module(s). (5-600 Vrms, up to #12 AWG wire)

• Replace the terminal protective cover(s) on the front of the Voltage Input Module(s).

• Pass the CT secondary conductors (0.01-5 Arms and up to #12 AWG wire) through

current tubes located on the face of the input module. The arrows on the input

module point from source to load.