Page 1

300VMF+

Commercial Video Modulator

(For use in NTSC systems)

INSTRUCTION MANUAL

is a registered trademark of the R.L. Drake Company

© Copyright 2013 R. L. Drake Holdings, LLC Printed in Taiwan.

Rev: 20130322

10037xx

Page 2

2 Caution Statements

IMPORTANT SAFEGUARDS

This symbol is intended to alert the user to the presence of non-insulated

“dangerous voltage” within the product’s enclosure, that may be of suffi cient

magnitude to constitute a risk of electric shock to persons.

ing and maintenance (servicing) instructions in the literature accompanying

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

CAUTION: Do not attempt to service this product yourself as opening or removing covers may

ATTENTION: POUR PREVENIR LES CHOCS ELECTRIQUES, NE PAS UTILISER CETTE

VERT.

This symbol is intended to alert the user to the presence of important operatthe appliance.

CAUTION

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE

CAUTION

TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK)

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED PERSONNEL.

DO NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE.

expose you to dangerous voltage or other hazards. Refer all servicing to qualifi ed

service personnel.

FICHE POLARISEE AVEC UN PROLONGATEUR, UNE PRISE DE COURANT

OU UNE AUTRE SORTIE DE COURANT, SAUF SI LES LAMES PEUVENT

ETRE INSEREES A FOND SANS EN LAISSER AUCUNE PARTIE A DECOU-

IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any ventilation openings. Install in accordance with the manufacturer's instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (includ-

ing amplifi ers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding type plug has two blades and a third grounding prong. The

wide blade or the third prong are provided for your safety. If the provided plug does not fi t into your outlet, con-

sult an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11. Only use attachments/accessories specifi ed by the manufacturer.

12. Use only with the cart, stand, tripod, bracket, or table specifi ed by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when moving the cart/apparatus combination to avoid injury from

tip-over.

13. Unplug the apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualifi ed service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have

fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not operate normally, or

has been dropped.

Page 3

Table of Contents/Description/Specifi cations 3

TABLE OF CONTENTS

2 Caution Statements 5 Rear Panel Connections and Internal Jumper

2 Important Safety Instructions 6 Installation

3 Table of Contents / General Description 7 Frequency Allocation Charts

3 Specifi cations 8 Service / If You Need To Call For Help

4 Front Panel Controls, Indicators, and 9 Warranty

Connections

DESCRIPTION

The DRACOM 300VMF+ Video Modulator is a vestigial sideband heterodyne audio/video modulator that provides a

modulated visual and aural RF carrier output on any single EIA standard channel from channel 2 through channel 78 plus

channels 95 to 99. This range covers 54 through 552 MHz. Consult factory for custom channels. All aeronautical channels are offset positive with a tolerance of ±5 kHz as required by FCC rules. The 300VMF+ is designed to accept video

and audio baseband signals from a satellite receiver, TV camera, video tape recorder, TV demodulator or similar equipment. The heterodyne conversion system, in conjunction with the use of a SAW fi lter, insures optimum vestigial selectivity

for adjacent channel headends. The modulator accepts standard (sync negative) polarity video at a 0.7 -1.5 Vpp level. All

level controls are located on the front panel for ease of operation.

SPECIFICATIONS

RF

Frequency Range:

Channels Available:

FCC Frequency

Offsets:

Output Level:

Output Impedence:

Output Test:

A/V Ratio:

Frequency Stability,

Visual:

Aural Intercarrier

Frequency:

Spurious Outputs:

In-Channel C/N:

Broadband Noise:

54 - 552 MHz.

Factory-ordered for a single channel:

EIA CATV channels 2 to 78 and 95 to 99.

All aeronautical channels offset positive

with a tolerance of ±5 kHz.

+55 dBmV, (typically adjustable from +43

to +55 dBmV).

75 OHMS, return loss of 14 dB, nominal.

-30 dB, ±3 dB (referenced to

RF OUTPUT level).

Audio Carrier -20 to -12 dB referenced to

video carrier, adjustable.

Within ±10 kHz of assigned channel

frequency; ±5 kHz on FCC

offset channels.

4.5 MHz, ±5 kHz.

-60 dBc minimum, measured at -15 dB A/V

ratio and with modulator output level of

+55 dBmV.

Better than 60 dB.

-95 dBc @ ±30 MHz or

greater spacings. (Specifi ed levels are

referenced to the video carrier and

measured in a 4 MHz bandwidth).

VIDEO

Input level for 87.5%

Modulation:

Input Impedance:

Frequency Response:

Video S/N:

L/C Delay:

Differential Gain:

Differential Phase:

AUDIO

Input Level for

25 kHz Peak Deviation:

Input Impedance:

Pre-emphasis:

Frequency Response:

4.5 MHz Intercarrier Stability:

Total Harmonic Distortion:

Hum and Noise:

GENERAL

Modulator Power

Requirement:

Auxiliary AC Outlet:

Total AC Power Input:

Operating Temperature

Range:

Size:

Weight:

Connectors:

1 Vp-p ±3 dB, manual gain adjust with

front panel control.

75 Ohms, return loss of 18 dB

minimum.

Flat ±2 dB from 30 Hz to 4.2 MHz.

60 dB, luminance weighted.

Within 50 nSec of 0 nSec L/C delay

(complies with FCC rules, 76.605).

Less than ±5% (10 to 90% APL).

Less than ±5 degrees (10 to 90% APL).

175 mV rms minimum. Manual gain

adjustment with front panel control.

10K Ohms, unbalanced.

75 mSec.(fl at by moving internal jumper)

40 Hz to 15 kHz, ±1.5 dB, referenced to

75 mSec pre-emphasis curve.

Within ±5 kHz, 00 C to +500 C.

1.5% maximum.

-60 dB minimum, referenced

to 25 kHz peak deviation.

115 VAC ±10%, 60Hz, 10 Watts.

Nominal 120 VAC, 600 Watts, maximum.

Nominal 120 VAC 60 Hz,

610 Watts, maximum.

0 C to +50 C, ambient.

19” W x 1.75” H x 4.0” D.

3.6 lbs.

Video input, Audio input, RF output, and

Monitor output are all type F.

Page 4

4 Front Panel Description

F1 F2 F3 F4 F5 F6 F7

F1 - POWER Indicator

Lights when the unit is connected to a source of AC

power.

F2 - OUTPUT TEST Connector

Provides a reduced level sample of the RF output signal.

The level at this connector is approximately 30 dB lower in

level than the RF OUTPUT signal. It is used to monitor

the active signal without affecting the level or quality of the

RF output signal.

F3 - CHANNEL Designation

The label indicates the fi xed channel output for your

particular model. The 300VMF+ is capable of fi xed

channel output (factory tuned) within the following

ranges: Channel 2 through 78 and 95 through 99.

F4 - RF OUTPUT LEVEL

This screwdriver adjustment permits decreasing the RF

output level a minimum of 12 dB below its specifi ed

output level as the control is rotated counterclockwise.

The maximum output level of +55 dBmV is set with the

adjustment approximately fully clockwise.

NOTE: If an output level of less than +43 dBmV is

required, add an attenuator of the appropriate value at

the modulator output.

Example: For an output level of +35 dBmV, add a 12 dB

attenuator pad to the modulator output and set the

output level to +47 dBmV.

F5 - A/V RATIO Control

This screwdriver adjustment varies the level of the aural

carrier over a range from 12 to 20 dB below the visual

carrier. The aural carrier should normally be adjusted to

approximately 15 dB below the visual carrier (normal

operation). Clockwise rotation increases the aural carrier

level and thus decreases the A/V ratio.

F6 - AUDIO LEVEL Control

The setting of this screwdriver adjustment determines the

peak aural carrier deviation. Clockwise rotation

increases the carrier deviation. After installing the unit,

and with an audio source connected, adjust the AUDIO

LEVEL control for 25 kHz deviation. If an audio

modulation meter is not available, use a TV set and

adjust for equal volume as compared to a known off-air

broadcast. Monitor for a few minutes to assure that

maximum volume of the audio source program does not

cause an over-modulation condition.

F7 - VIDEO LEVEL Control

The setting of this screwdriver adjustment determines the

video modulation level. Clockwise rotation increases the

modulation depth. After installing the unit, and with a

nominal 1 Volt P-P video source connected, adjust the

VIDEO LEVEL control for the correct percentage of

modulation (87.5%). If test equipment is not available for

such measurements, then adjust for proper picture

contrast when viewed on a TV set (compare with known

off-air broadcast picture quality).

Page 5

Rear Panel Description and Internal Jumper 5

R1 R2 R3 R4 R5

R1 - VIDEO INPUT Connector

This is the baseband video input to the IF circuits. This

input accepts baseband through 4.2 MHz video at levels

from 0.7 Vp-p to 1.5 Vp-p

.

R2 - AUDIO INPUT Connector

This is an unbalanced audio input to the IF circuits. This

input accepts 40 Hz through 15 kHz audio at a nominal

level of 250 mV RMS (approximately -10 dBu).

If a separate BTSC stereo encoder, such as the Drake

MMTS20, is to be used with this modulator, this jack can

input 40 Hz through over 50 kHz with fl at response if

internal jumper J8 is set to fl at - see below)

R3 - RF OUTPUT

This is the modulator output.

INTERNAL JUMPER SETTING - AUDIO RESPONSE

Internal jumper J8 may be used to disable the 75 uSec

pre-emphasis (normal setting). Flat response may be

chosen if an external BTSC stereo signal is to be input to

the modulator through the audio input jack. To access this

jumper, disconnect the unit from AC power. Remove the

three screws holding the top cover of the chassis in place.

Remove top cover. J8 is a three pin header with J8

printed on the PCB. After setting this jumper, reinstall the

cover before returning power to the unit.

R4 - AC OUTLET Receptacle

This is a power receptacle for other equipment and is

rated at 600 W maximum; 120 V, 5 Amp. This receptacle

is unfused and unswitched.

R5 - LINE CORD

This is a three-wire power cable. When the cable is

connected to a properly wired AC power line outlet, this

cable grounds the instrument cabinet. Connect to a

115 VAC ±10%, 60 Hz source. Do not defeat the safety

purpose of the attached line cord plug.

NORMAL RESPONSE of 75 uSec = Jumper in the 1-2

position (shorting pins 1 and 2 of the J8 header). Use this

setting for normal mono audio input. This is the factory

default setting.

FLAT RESPONSE = Jumper in the 2-3 position (shorting

pins 2 and 3 of header J8). Change to this setting when

an external BTSC stereo encoder is used with the

300VMF+.

Page 6

6 Installation

CONNECTIONS AND CONTROLS

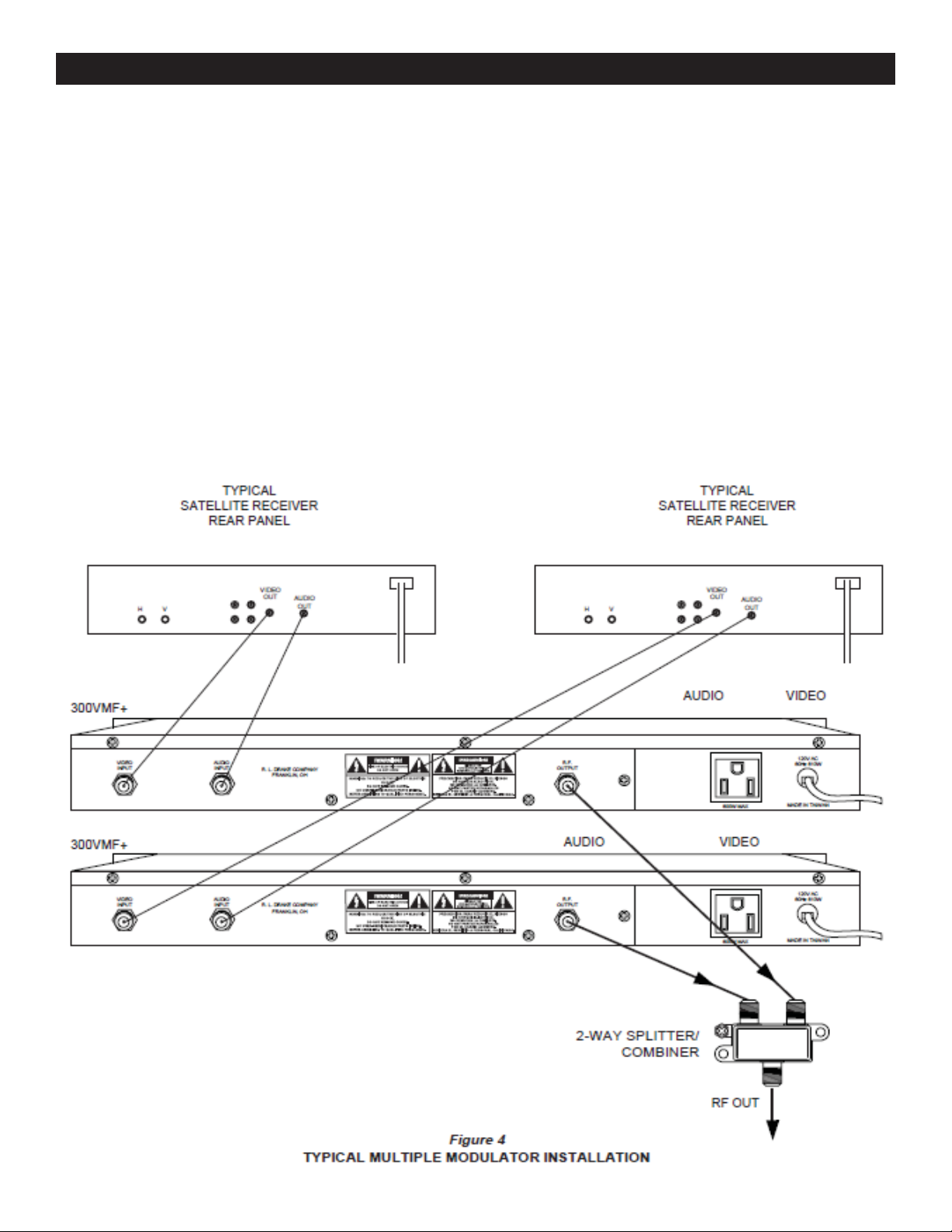

All connections to and from the 300VMF+ are made through

the rear panel. Figure 4 shows a typical two channel

installation using a typical satellite receiver as a signal

source. Additional channels can be added by using

additional 300VMF+ modulators and either multi-port

combiners or combinations of two-port combiners.

INSTALLATION NOTES

Level adjustment provides optimum performance in

multichannel installations. The modulator outputs should be

checked periodically with a spectrum analyzer to maintain a

±1 dB variation of adjacent channel carriers. Aural/Visual

(A/V) ratios should be held to -15 dB or less.

The ‘RF Output Level’ and ‘A/V Ratio’ controls are used

respectively to make these adjustments. If an output level

of less than +43 dBmV is required, add an attenuator of the

appropriate value to the modulator output.

Example: For an output level of +35 dBmV, add a 12 dB

attenuator pad to the modulator output and set the output

level.

RACK MOUNTING

Adequate ventilation is very important in multichannel

installations. Units should be spaced apart by at least one

panel height wherever possible, and some air movement is

advisable in enclosed rack cabinets. Excessive heat will

shorten component life and modulator performance will be

degraded without proper cooling.

Page 7

Frequency Allocation Charts 7

Table 1 CHANNEL ASSIGNMENTS

Page 8

8 Service / If You Need To Call For Help

SERVICE INFORMATION

You may contact the R.L. DRAKE HOLDINGS, LLC

Service Department for additional information or assistance by calling:

+1 (937) 746-6990

Monday through Friday

8:00 A.M. to 4:00 P.M. EST, except on holidays.

You may also contact the R.L. DRAKE HOLDINGS, LLC

Service Department by E-mail at the following address:

servicehelp@rldrake.com

or by Telefax:

+1 (937) 806-1510.

IF YOU NEED TO CALL FOR HELP

Call our Customer Service/Technical Support line a

+1 (937) 746-6990 between 8:00 A.M. and 4:00 P.M.

Eastern Time, weekdays. Please have the unit’s serial

number available. We will also need to know the specifi cs

of any other equipment connected to the unit.

When calling, please have the unit up and running, near

the phone if possible. Our technician(s) will likely ask

certain questions to aid in diagnosis of the problem. Also,

have a voltmeter handy, if possible.

R.L. DRAKE also provides technical assistance by e-mail:

servicehelp@rldrake.com

Should you want to return your unit for service, package

the unit carefully using the original carton or other

suitable container.

Write your return address clearly on the shipping carton

and on an enclosed cover letter describing the service

required, symptoms or problems. Also include your

daytime telephone number and a copy of your proof of

purchase.

The unit will be serviced under the terms of the

R.L. DRAKE HOLDINGS, LLC Limited Warranty and

returned to you.

Red is an overnight service.

Send the unit in a way that it can be traced if we can’t

verify receipt of shipment. We suggest UPS or insured

postal shipment.

If the unit is still under the original owner’s warranty,

R.L. DRAKE will pay the cost of the return shipment to

you. Our return shipping policy is that we will return it

UPS Brown if received Brown or by US Mail, it will be

returned Blue if received Blue or Red—or it will be

returned however you prefer if you furnish the return cost

for the method you select.

or by Telefax:

+1 (937) 806-1510.

Many of the products that are sent to us for repair are in

perfect working order when we receive them. For these

units, there is a standard checkout fee that you will be

charged. Please perform whatever steps are applicable

from the installation sections of the Owner’s Manual

before calling or writing—this could save unnecessary

phone charges. Please do not return the unit without

contacting R.L. DRAKE fi rst: it is preferred to help

troubleshoot the problem over the phone (or by mail) fi rst,

saving you both time and money.

Inside the carton, enclose a note with your name,

address, daytime phone number, and a description of the

unit’s problem.

The unit must be sent to the following address:

Service Department R.L.

DRAKE HOLDINGS. LLC

710 Pleasant Valley Drive

Springboro, OH 45066 U.S.A.

Be sure to include your street address which will be

needed for UPS return.

UPS Surface (Brown Label) takes 7-10 days to reach us depending on your location.

Blue takes 2-3 days.

If the unit is out of warranty, use one of the following

methods for return shipment:

1) You designate billing to American ExPress, VISA,

MasterCard or Discover card;

2) You prepay the service charges with a personal check,

or

3) You specify some other method of return and payment.

When calling, the technician can estimate the repair

charges for you over the phone. This is another good

reason to call before sending a unit in for repair.

Typically, equipment is repaired in fi ve to ten working

days after it arrives at DRAKE if we have all the facts. If

we must call you, it may take longer. R.L. DRAKE HOLDINGS, LLC is not responsible for damage caused by

lightning, non-professional

alterations, “acts of God”, shipping damage, poor

storage/handling, etc. DRAKE will make note of any

shipping damage upon receipt.

You will need to send proof of purchase to receive

warranty service. Typically, a copy of the invoice from a

DRAKE dealer will suffi ce. The warranty is for the

original owner only and is not transferable.

Page 9

WARRANTY 9

One Year Limited Warranty

R.L. DRAKE HOLDINGS LLC warrants to the original purchaser this product shall be free from defects in material

or workmanship for one (1) year from the date of original purchase.

During the warranty period R.L. DRAKE HOLDINGS LLC or an authorized Drake service facility will provide,

free of charge, both parts and labor necessary to correct defects in material and workmanship. At its option, R.L.

DRAKE HOLDINGS LLC may replace a defective unit.

To obtain such a warranty service, the original purchaser must:

1. Retain invoice or original proof of purchase to establish the start of the warranty period.

2. Notify R.L. DRAKE HOLDINGS LLC or the nearest authorized service facility, as soon as possible after

discovery of a possible defect, of:

a) the model and serial number,

b) the identity of the seller and the approximate date of purchase; and

c) A detailed description of the problem, including details on the electrical connection to associated

equipment and the list of such equipment.

3. Deliver the product to R.L. DRAKE HOLDINGS LLC or the nearest authorized service facility, or ship

the same in its original container or equivalent, fully insured and shipping charges prepaid.

Correct maintenance, repair, and use are important to obtain proper performance from this product. Therefore

carefully read the Instruction Manual. This warranty does not apply to any defect that R.L. DRAKE HOLDINGS

LLC determines is due to:

1. Improper maintenance or repair, including the installation of parts or accessories that do not conform

to the quality and specifi cations of the original parts.

2. Misuse, abuse, neglect or improper installation.

3. Accidental or intentional damage.

All implied warranties, if any, including warranties of merchantability and fi tness for a particular purpose, terminate

one (1) years from the date of the original purchase.

The foregoing constitutes R.L. DRAKE HOLDINGS LLC’S entire obligation with respect to this product, and the

original purchaser shall have no other remedy and no claim for incidental or consequential damages, losses or

expenses. Some states do not allow limitations on how long an implied warranty lasts or do not allow the exclusions

or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you.

This warranty gives you specifi c legal rights and you may also have other rights which vary from state to state.

This warranty shall be construed under the laws of Ohio.

For Service, contact:

R.L. DRAKE HOLDINGS LLC

710 Pleasant Valley Drive

Springboro, Ohio 45066. USA

Customer Service and Parts Telephone: +1 (937) 746-6990

Telefax: +1 (937) 806-1510

Web Site: http://www.rldrake.com

Page 10

[THIS PAGE IS INTENTIONALLY LEFT BLANK]

Page 11

[THIS PAGE IS INTENTIONALLY LEFT BLANK]

Page 12

R.L. Drake Holdings, LLC

710 Pleasant Valley Drive

Springboro, OH 45066

(937) 746-4556

www.rldrake.com

Loading...

Loading...