Page 1

www.dragino.com

Version

Description

Date

1.0

Release

2018-Dec-4

1.1

Add steps of install STM320x; Add ST-Link Upload firmware method

2018-Dec-27

1.2

Add trouble shooting for UART upload, Add change log for firmware v1.4

2019-Jan-23

1.2.1

More detail description for 8 channel mode and trouble shooting for using in

US915/AU915

2019-Feb-21

1.2.2

Modify trouble shooting for upload via Flashloader

2019-Mar-13

1.2.3

Add ISP Mode / Flash mode different/

Add working flow diagram (Chapter 2.1 how it works)

Add FAQ for how to configure the Keys

2019-Apr-1

1.5.0

Upgrade to v1.5 version firmware

Add ultrasonic sensor support and description.

Add downlink description

Change decoder for v1.5

Add working flow chart

Add Mydevices support

2019-Apr-19

1.5.1

Improve Interrupt feature, change interrupt example to use door sensor

1.5.2

Various minor text and format edits.

2019-Jun-10

1.6.0

Update to firmware v1.6 version, add 3ADC mode

2019-Aug-7

1.6.1

Trouble shooting for AT Command input

Add support for 3 * DS18B20 (MOD4)

2019-Sep-18

LSN50 LoRa Sensor Node User Manual

Document Version: 1.6.1

Image Version: v1.6

LSN50 LoRa Sensor Node User Manual 1 / 60

Page 2

www.dragino.com

1. Introduction 4

1.1 What is LSN50 LoRa Sensor Node 4

1.2 Specifications 5

1.3 Features 6

1.4 Applications 6

1.5 Pin Definitions 7

1.6 Hardware Change log 8

1.7 Hole Option 9

2. Use LSN50 with LoRaWAN firmware 10

2.1 How it works 10

2.2 Quick guide to connect to LoRaWAN server (OTAA) 11

2.3 Working Mode & Uplink Payload 14

2.3.1 MOD=1 (Default Mode) 14

2.3.2 MOD=2 (Distance Mode) 15

2.3.3 MOD=3 (3 ADC + I2C) 16

2.3.4 MOD=4 (3 x DS18B20) 17

2.3.5 Decode payload in The Things Network 18

2.4 Payload Explanation and Sensor Interface 21

2.4.1 Battery Info 21

2.4.2 Temperature (DS18B20) 21

2.4.3 Digital Input 21

2.4.4 Analogue Digital Converter (ADC) 22

2.4.5 Digital Interrupt 23

2.4.6 I2C Interface (SHT20) 25

2.4.7 Distance Reading 26

2.4.8 Ultrasonic Sensor 26

2.4.9 +5V Output 27

2.5 Downlink Payload 28

2.6 Show Data in Mydevices IoT Server 29

2.7 Firmware Change Log 32

2.8 Battery Analysis 34

2.8.1 Battery Type 34

2.8.2 Power consumption Analyze 34

2.8.3 Battery Note 35

2.8.4 Replace the battery 35

3. Using the AT Commands 36

3.1 Access AT Commands 36

3.2 Common AT Command Sequence 38

3.2.1 Multi-channel ABP mode (Use with SX1301/LG308) 38

3.2.2 Single-channel ABP mode (Use with LG01/LG02) 38

4. Upload Firmware 39

4.1 Upload Firmware via Serial Port 39

4.2 Upload Firmware via ST-Link V2 42

5. Developer Guide 44

5.1 Source Code 44

5.2 Compile Source Code 44

LSN50 LoRa Sensor Node User Manual 2 / 60

Page 3

www.dragino.com

5.2.1 Set up Keil Compile Environment 44

5.2.2 Install STM32L0 Series Device 48

5.2.3 Compile Source Code 50

6. FAQ 52

6.1 Why there is 433/868/915 version? 52

6.2 What is the frequency range of LT LoRa part? 52

6.3 How to change the LoRa Frequency Bands/Region? 52

6.4 Can I use Private LoRa protocol? 52

6.5 How to set up LSN50 to work in 8 channel mode 53

6.6 How to set up LSN50 to work with Single Channel Gateway such as

LG01/LG02? 55

6.7 How to configure the EUI keys in LSN50? 56

7. Trouble Shooting 57

7.1 Connection problem when uploading firmware. 57

7.2 Why I can’t join TTN in US915 / AU915 bands? 57

7.3 AT Command input doesn’t work 58

8. Order Info 59

9. Packing Info 59

10. Support 60

11. References 60

LSN50 LoRa Sensor Node User Manual 3 / 60

Page 4

www.dragino.com

1. Introduction

1.1 What is LSN50 LoRa Sensor Node

LSN50 is a Long Range LoRaWAN Sensor Node. It is designed for outdoor data logging and

powered by Li/SOCl2 battery for long term use and secure data transmission. It is designed

to facilitate developers to quickly deploy industrial level LoRa and IoT solutions. It helps

users to turn the idea into a practical application and make the Internet of Things a reality. It

is easy to program, create and connect your things everywhere.

It is based on SX1276/SX1278 allows the user to send data and reach extremely long ranges

at low data-rates. It provides ultra-long range spread spectrum communication and high

interference immunity whilst minimizing current consumption. It targets professional

wireless sensor network applications such as irrigation systems, smart metering, smart cities,

smartphone detection, building automation, and so on.

LSN50 uses STM32l0x chip from ST, STML0x is the ultra-low-power STM32L072xx

microcontrollers incorporate the connectivity power of the universal serial bus (USB 2.0

crystal-less) with the high-performance ARM® Cortex®-M0+ 32-bit RISC core operating at a

32 MHz frequency, a memory protection unit (MPU), high-speed embedded memories (192

Kbytes of Flash program memory, 6 Kbytes of data EEPROM and 20 Kbytes of RAM) plus an

extensive range of enhanced I/Os and peripherals.

LSN50 is an open source product, it is based on the STM32Cube HAL drivers and lots of

libraries can be found in ST site for rapid development.

LSN50 LoRa Sensor Node User Manual 4 / 60

Page 5

www.dragino.com

1.2 Specifications

Micro Controller:

● STM32L072CZT6 MCU

● MCU: STM32L072CZT6

● Flash: 192KB

● RAM: 20KB

● EEPROM: 6KB

● Clock Speed: 32Mhz

Common DC Characteristics:

● Supply Voltage: 2.1v ~ 3.6v

● Operating Temperature: -40 ~ 85°C

● I/O pins: Refer to STM32L072 datasheet

LoRa Spec:

● Frequency Range,

○ Band 1 (HF): 862 ~ 1020 Mhz

or

○ Band 2 (LF): 410 ~ 528 Mhz

● 168 dB maximum link budget.

● +20 dBm - 100 mW constant RF output vs.

● +14 dBm high efficiency PA.

● Programmable bit rate up to 300 kbps.

● High sensitivity: down to -148 dBm.

● Bullet-proof front end: IIP3 = -12.5 dBm.

● Excellent blocking immunity.

● Low RX current of 10.3 mA, 200 nA register retention.

● Fully integrated synthesizer with a resolution of 61 Hz.

● FSK, GFSK, MSK, GMSK, LoRaTM and OOK modulation.

● Built-in bit synchronizer for clock recovery.

● Preamble detection.

● 127 dB Dynamic Range RSSI.

● Automatic RF Sense and CAD with ultra-fast AFC.

● Packet engine up to 256 bytes with CRC.

● LoRaWAN 1.0.2 Specification

Battery:

● Li/SOCI2 un-chargeable battery

● Capacity: 4000mAh

● Self Discharge: <1% / Year @ 25°C

● Max continuously current: 130mA

● Max boost current: 2A, 1 second

Power Consumption

● STOP Mode: 2.7uA @ 3.3v

● LoRa Transmit Mode: 125mA @ 20dBm 44mA @ 14dBm

LSN50 LoRa Sensor Node User Manual 5 / 60

Page 6

www.dragino.com

1.3 Features

● LoRaWAN 1.0.2 Class A,Class C

● STM32L072CZT6 MCU

● SX1276/78 Wireless Chip

● Pre-load bootloader on USART1/USART2

● MDK-ARM Version 5.24a IDE

● I2C, LPUSART1, USB, SPI2

● 3x12bit ADC, 1x12bit DAC

● 20xDigital I/Os

● LoRa™ Modem

● Preamble detection

● Baud rate configurable

● CN470/EU433/KR920/US915/IN865

● EU868/AS923/AU915

● Open source hardware / software

● Available Band:433/868/915/920 Mhz

● IP66 Waterproof Enclosure

● Ultra Low Power consumption

● AT Commands to change parameters

● 4000mAh Battery for long term use

1.4 Applications

● Smart Buildings & Home Automation

● Logistics and Supply Chain Management

● Smart Metering

● Smart Agriculture

● Smart Cities

● Smart Factory

LSN50 LoRa Sensor Node User Manual 6 / 60

Page 7

www.dragino.com

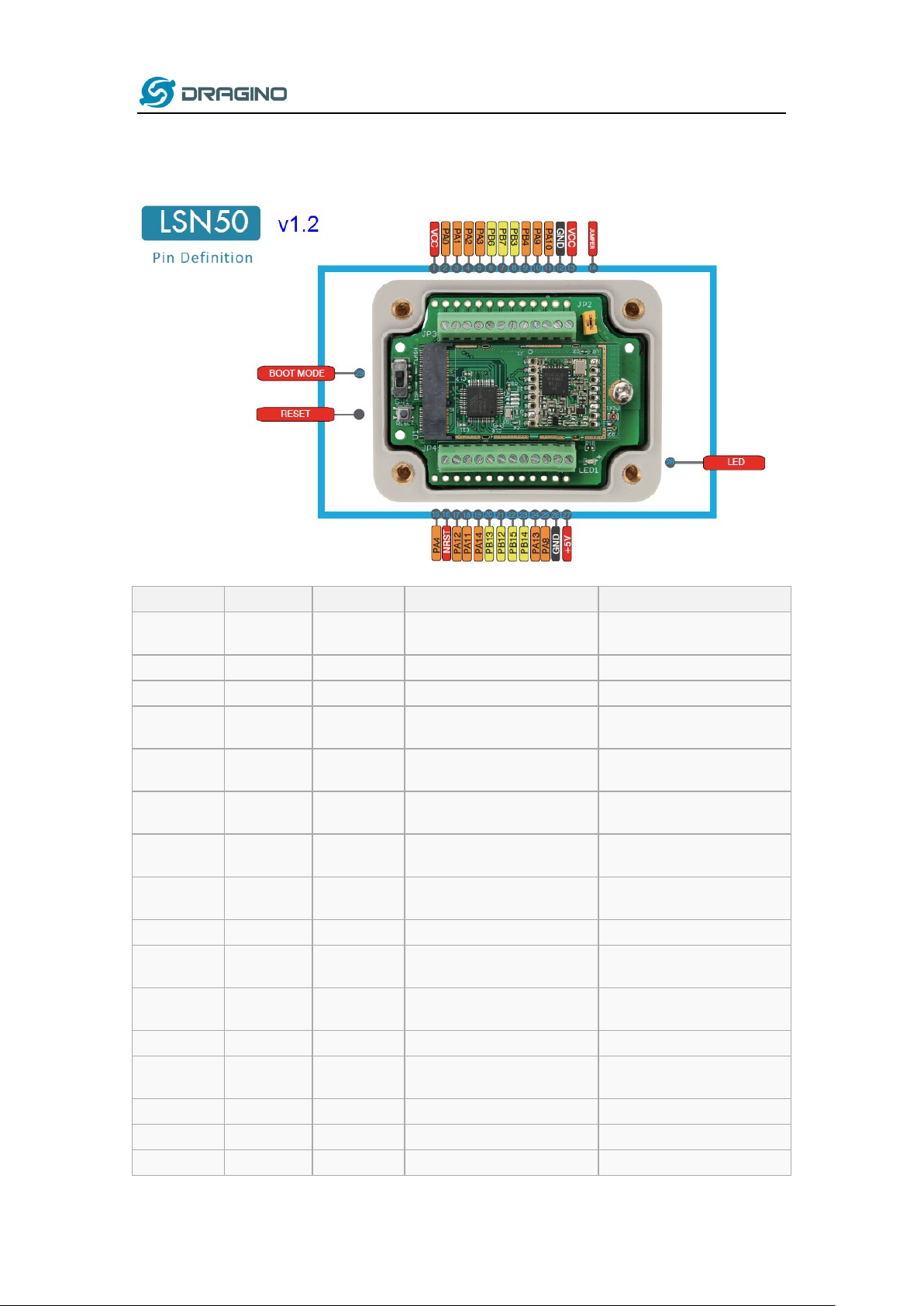

Pin No.

Signal

Direction

Function

Remark

1

VCC(2.9V)

OUTPUT

VCC

Directly connect to main

power for board

2

PA0

In/Out

Directly from STM32 chip

Used as ADC in LSN50 image

3

PA1

In/Out

Directly from STM32 chip

4

PA2

In/Out

Directly from STM32 chip, 10k

pull up to VCC

Used as UART_TXD in LSN50

image

5

PA3

In/Out

Directly from STM32 chip, 10k

pull up to VCC

Used as UART_RXD in LSN50

image

6

PB6

In/Out

Directly from STM32 chip, 10k

pull up to VCC

7

PB7

In/Out

Directly from STM32 chip, 10k

pull up to VCC

8

PB3

In/Out

Directly from STM32 chip, 10k

pull up to VCC

9

PB4

In/Out

Directly from STM32 chip

10

PA9

In/Out

Directly from STM32 chip, 10k

pull up to VCC

11

PA10

In/Out

Directly from STM32 chip, 10k

pull up to VCC

12

GND Ground

13

VCC(2.9V)

OUTPUT

VCC

Directly connect to main

power for board

14

Jumper

Power on/off jumper

15

PA4

In/Out

Directly from STM32 chip

16

NRST

In

Reset MCU

1.5 Pin Definitions

LSN50 LoRa Sensor Node User Manual 7 / 60

Page 8

www.dragino.com

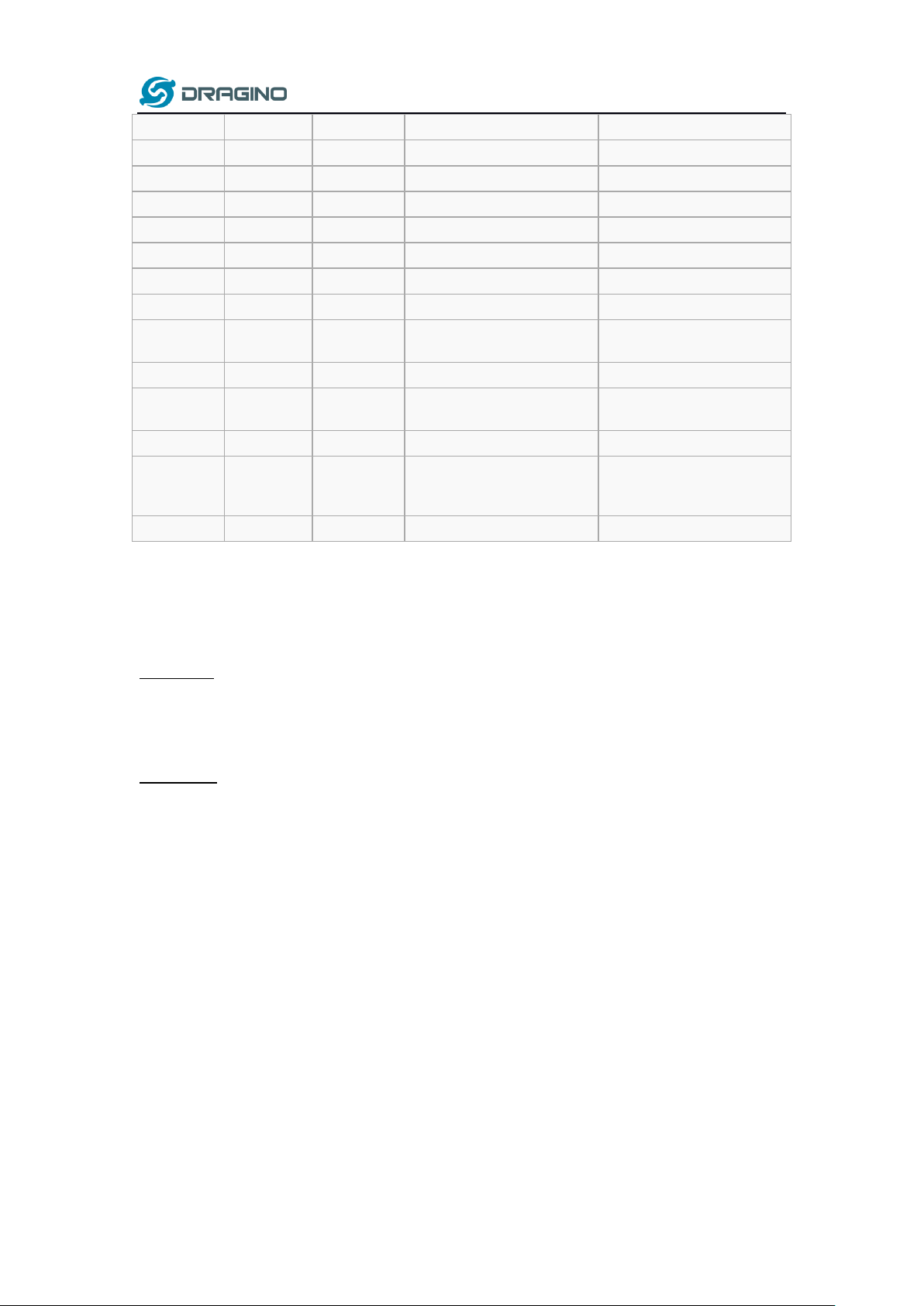

17

PA12

In/Out

Directly from STM32 chip

18

PA11

In/Out

Directly from STM32 chip

19

PA14

In/Out

Directly from STM32 chip

20

PB13

In/Out

Directly from STM32 chip

21

PB12

In/Out

Directly from STM32 chip

22

PB15

In/Out

Directly from STM32 chip

23

PB14

In/Out

Directly from STM32 chip

24

PA13

In/Out

Directly from STM32 chip

25

PA8

In/Out

Directly from STM32 chip

Default use to turn on/off LED1

in LSN50 image

26

GND Ground

27

+5V

Out

5v output power

Controlled by PB5(Low to

Enable, High to Disable)

28

LED1

Controlled by PA8

Blink on transmit

29

BOOT MODE

Configure device in working

mode or ISP program mode

Flash: Normal Working mode

and send AT Commands

ISP: UART Program Mode

30

NRST

In

Reset MCU

1.6 Hardware Change log

LSN50 v1.2:

● Add LED. Turn on for every LoRa transmit

● Add pin PA4, PB13, NRST

● Add 5V Output, on/off control by PB5(Low to Enable, High to Disable)

LSN50 v1.3:

● Add P-MOS to control 5V output

LSN50 LoRa Sensor Node User Manual 8 / 60

Page 9

www.dragino.com

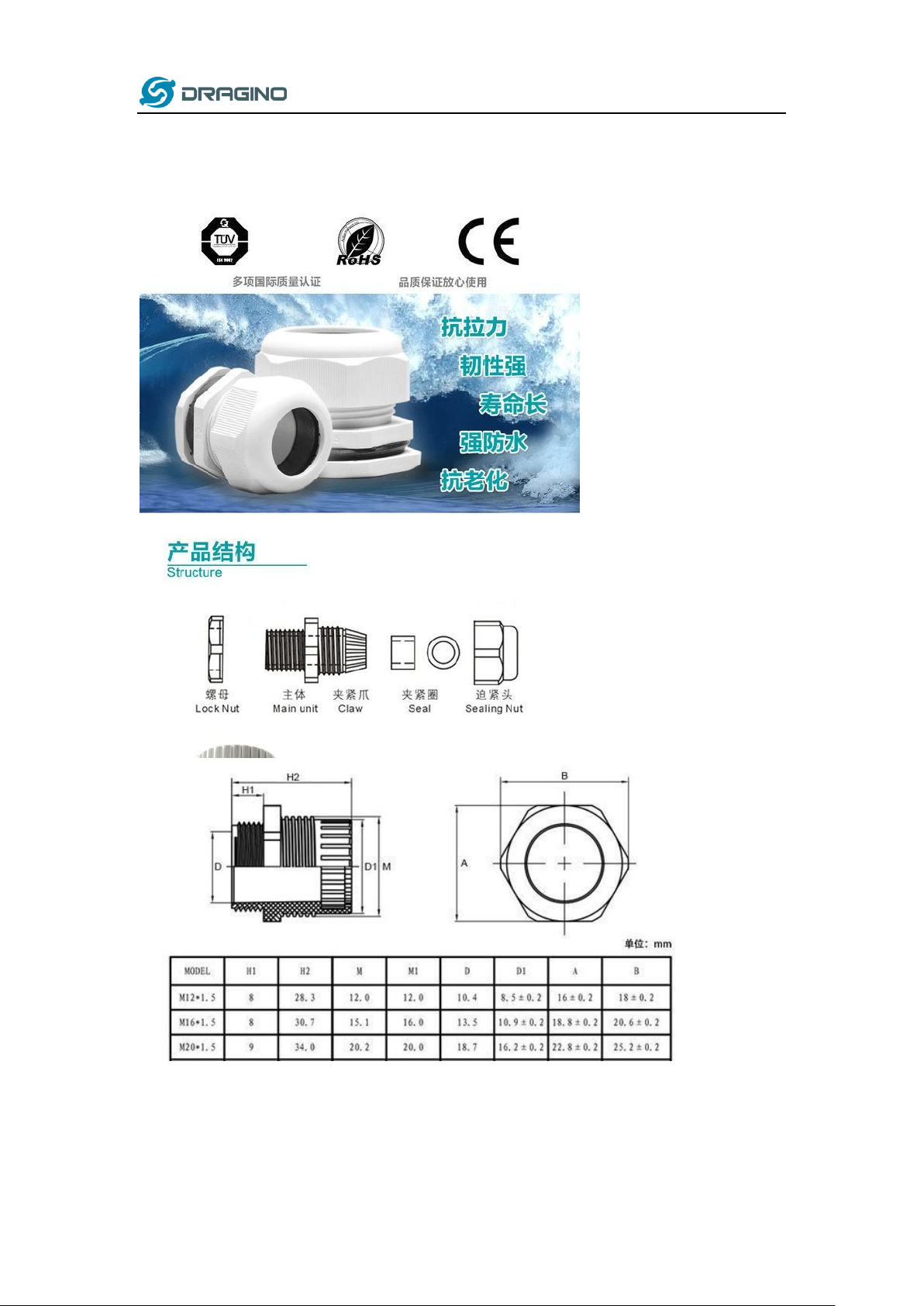

1.7 Hole Option

The LSN50 provides different hole size options for different size sensor cable. The options

provided are M12, M16 and M20. The definition is as below:

LSN50 LoRa Sensor Node User Manual 9 / 60

Page 10

www.dragino.com

2. Use LSN50 with LoRaWAN firmware

2.1 How it works

The LSN50 is pre-loaded with a firmware and is configured as LoRaWAN OTAA Class A mode

by default. It has OTAA keys to join LoRaWAN network. To connect a local LoRaWAN

network, you just need to input the OTAA keys in the LoRaWAN IoT server and power on the

LSN50. It will automatically join the network via OTAA.

The diagram below shows the working flow in default firmware (Ver 1.6):

In case you can’t set the OTAA keys in the LoRaWAN OTAA server, and you have to use the

keys from the server, you can use AT Commands to set the keys in the LSN50.

LSN50 LoRa Sensor Node User Manual 10 / 60

Page 11

www.dragino.com

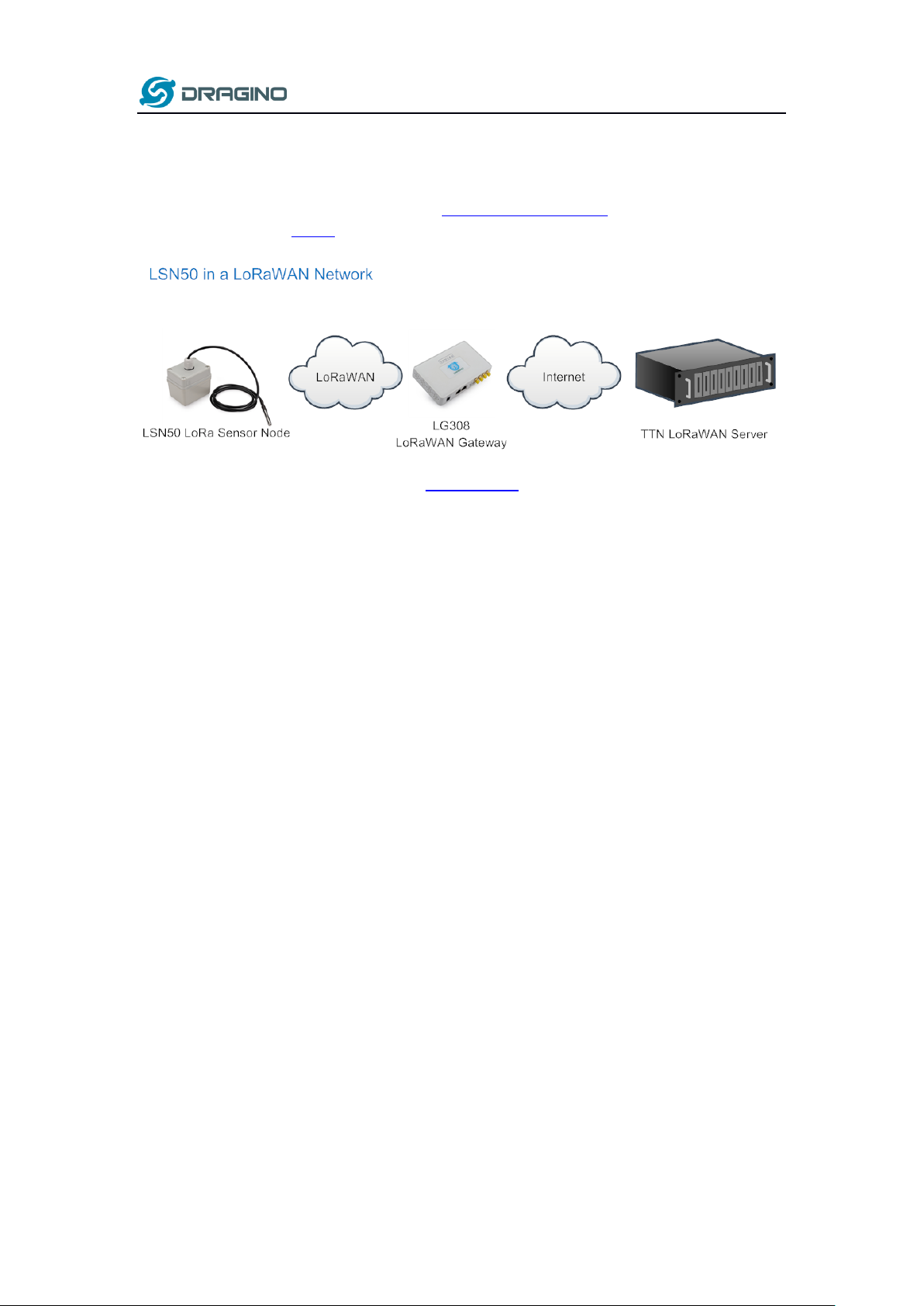

2.2 Quick guide to connect to LoRaWAN server (OTAA)

Following is an example for how to join the TTN LoRaWAN Network. Below is the network

structure; we use the LG308 as a LoRaWAN gateway in this example.

The LG308 is already set to connected to TTN network , so what we need to now is configure

the TTN server.

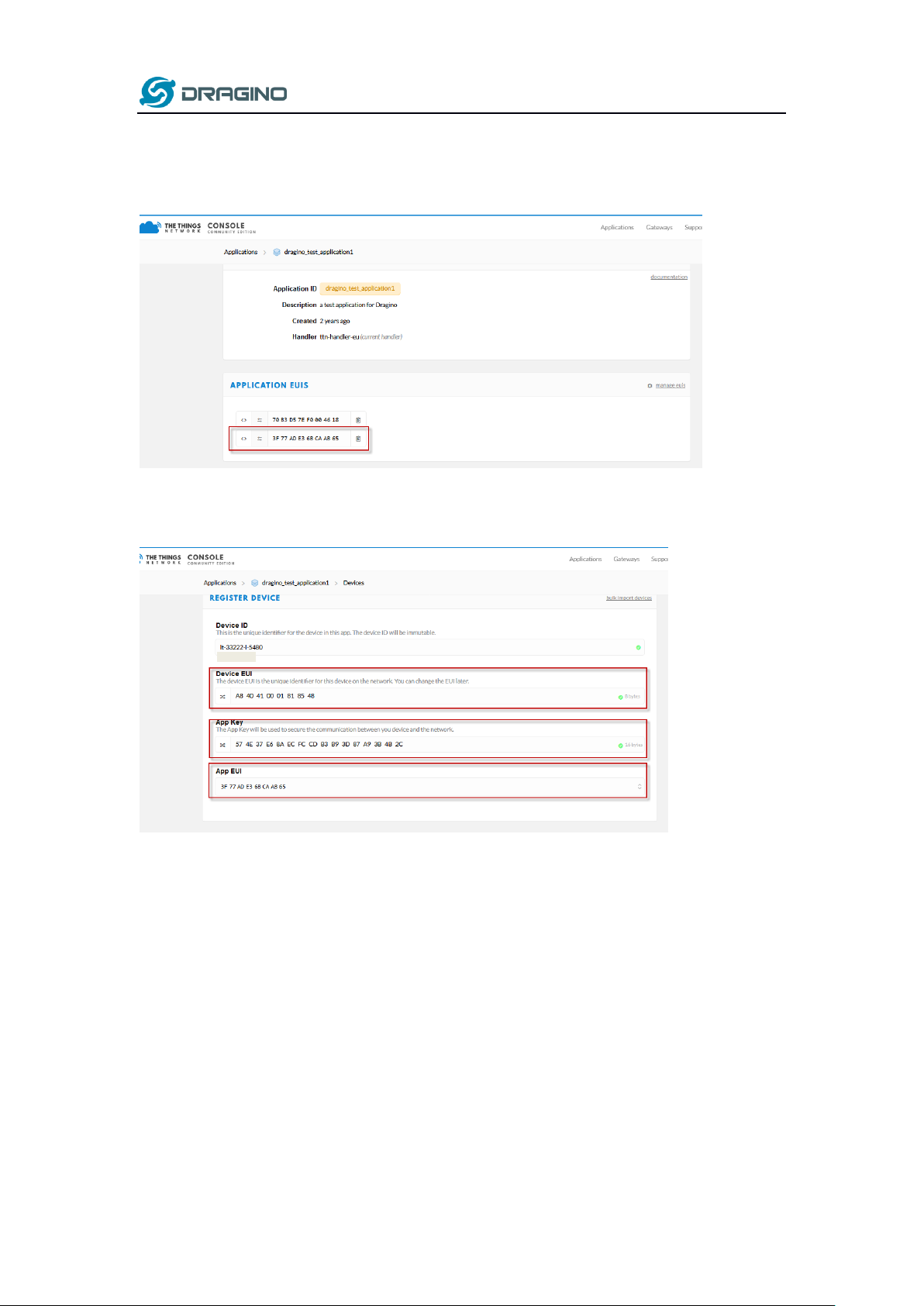

Step 1: Create a device in TTN with the OTAA keys from LSN50.

Each LSN50 is shipped with a sticker with the default device EUI as below:

LSN50 LoRa Sensor Node User Manual 11 / 60

Page 12

www.dragino.com

You can enter this key in the LoRaWAN Server portal. Below is TTN screen shot:

Add APP EUI in the application

Add APP KEY and DEV EUI

LSN50 LoRa Sensor Node User Manual 12 / 60

Page 13

www.dragino.com

Step 2: Power on LSN50

Put a Jumper on JP2 to power on the device.

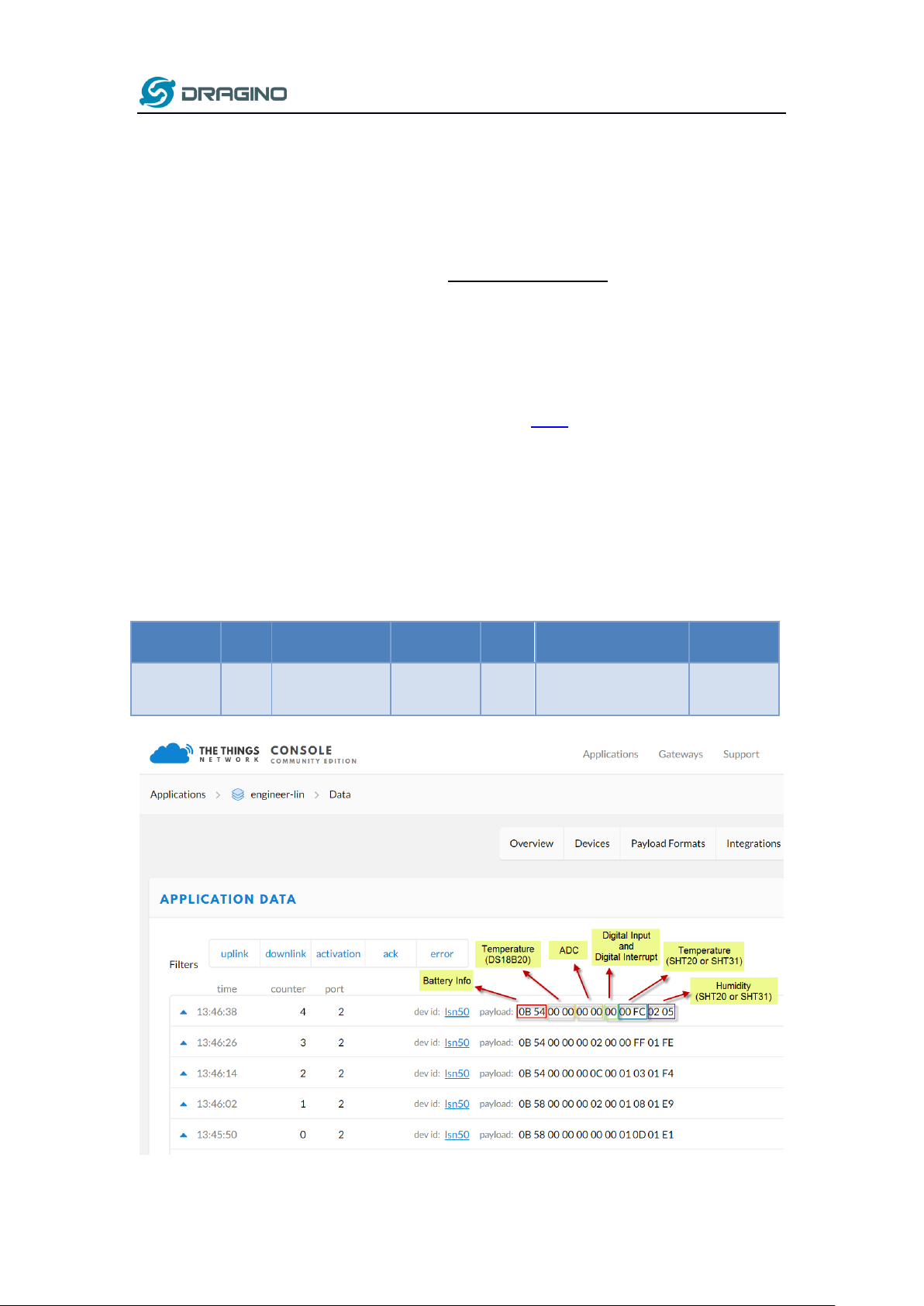

Step 3: The LSN50 will auto join to the TTN network. After join success, it will start to upload

messages to TTN and you can see the messages in the panel.

LSN50 LoRa Sensor Node User Manual 13 / 60

Page 14

www.dragino.com

Size(bytes

)

2 2 1 2 2

2

Value

BAT

Temperature

(DS18B20)

Digital in &

Digital

Interrupt

ADC

Temperature

(SHT20 or SHT31 or

Ultrasonic Sensor)

Humidity

(SHT20)

2.3 Working Mode & Uplink Payload

LSN50 has different working mode for the connections of different type of sensors. This

section describes these modes. Use can use the AT Command AT+MOD to set LSN50 to

different working modes.

For example:

AT+MOD=2 // will set the LSN50 to work in MOD=2 distance mode which target to measure

distance via Ultrasonic Sensor.

NOTE:

1. Some working modes has payload more than 12 bytes, The US915/AU915/AS923

frequency bands’ definition has maximum 11 bytes in DR0. Server sides will see NULL

payload while LSn50 transmit in DR0 with 12 bytes payload.

2. All modes share the same Payload Explanation from HERE.

3. By default, the device will send an uplink message every 10 minutes.

2.3.1 MOD=1 (Default Mode)

In this mode , uplink payload includes in total 11 bytes. Uplink packets use FPORT=2.

LSN50 LoRa Sensor Node User Manual 14 / 60

Page 15

www.dragino.com

Size(bytes)

2 2 1 2 2

2

Value

BAT

Temperature

(DS18B20)

Digital in &

Digital

Interrupt

ADC

Distance measure by:

1) LIDAR-Lite V3HP

Or

2) Ultrasonic Sensor

Humidity

(SHT20)

2.3.2 MOD=2 (Distance Mode)

This mode is target to measure the distance. The payload of this mode is totally 11

bytes. The 8th and 9th bytes is for the distance.

Connection of LIDAR-Lite V3HP:

LSN50 LoRa Sensor Node User Manual 15 / 60

Page 16

www.dragino.com

Size(bytes)

2 2 2 1 2

2

1

Value

ADC1

(Pin PA0)

ADC2

(PA1)

ADC3

(PA4)

Digital in &

Digital

Interrupt

Temperature

(SHT20 or

SHT31)

Humidity

(SHT20 or

SHT31)

BAT

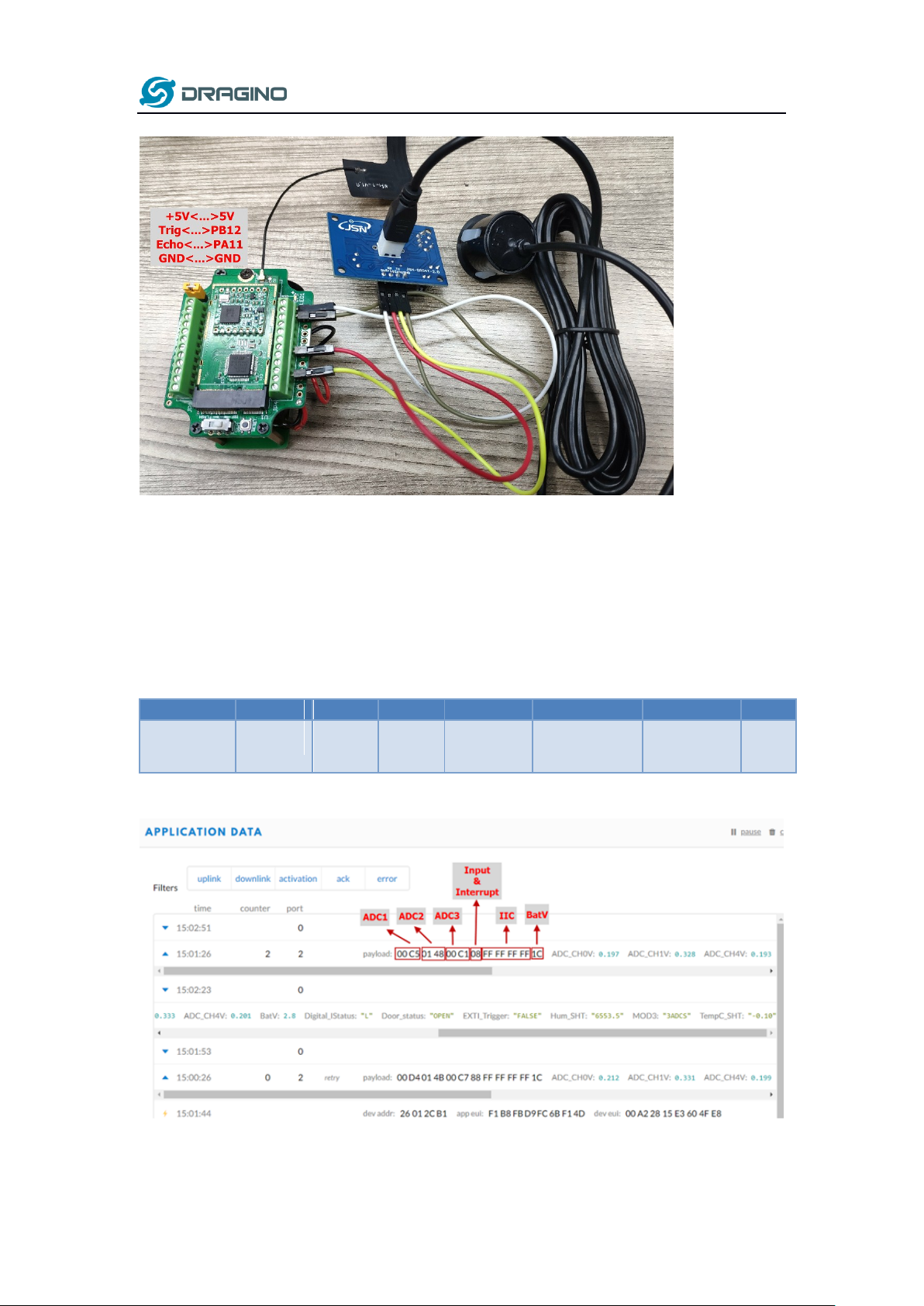

Connection to Ultrasonic Sensor:

While connecting to Ultrasonic sensor, the sleep current will jump to 250uA. It is

recommend to use external power source for ultrasonic sensor.

2.3.3 MOD=3 (3 ADC + I2C)

This mode has total 12 bytes. Include 3 x ADC + 1x I2C

LSN50 LoRa Sensor Node User Manual 16 / 60

Page 17

www.dragino.com

Size(bytes)

2 2 2 1 2

2

Value

BAT

Temperature1

(DS18B20)

(PB3)

ADC

Digital in &

Digital

Interrupt

Temperature2

(DS18B20)

(PA9)

Temperature3

(DS18B20)

(PA10)

2.3.4 MOD=4 (3 x DS18B20)

This mode is supported in firmware version since v1.6.1

Hardware connection is as below, (Note: R3 & R4 should change from 10k to 4.7k to

support DS18B20, Software set to AT+MOD=4)

This mode has total 11 bytes. As shown below:

LSN50 LoRa Sensor Node User Manual 17 / 60

Page 18

www.dragino.com

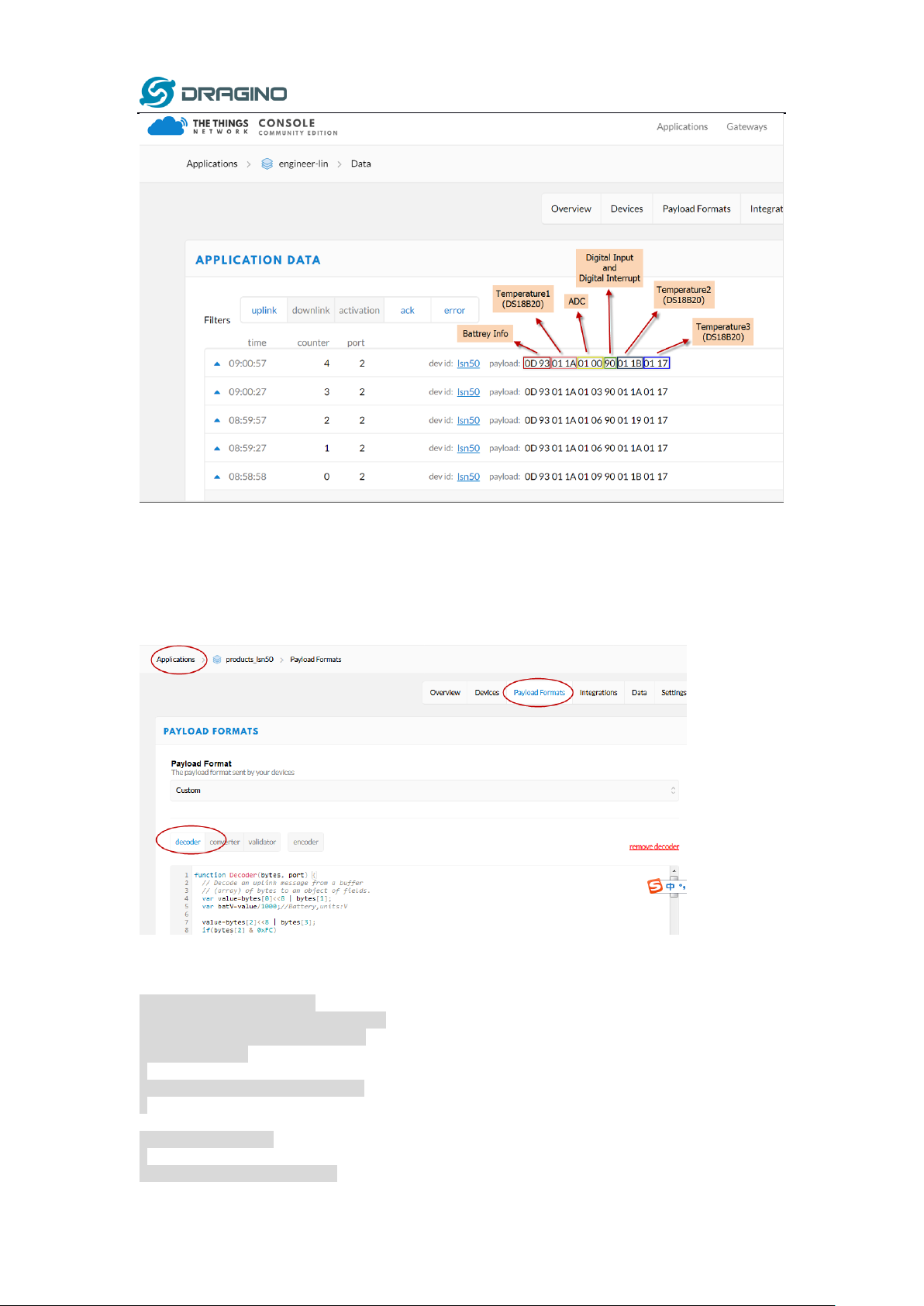

2.3.5 Decode payload in The Things Network

While using TTN network, you can add the payload format to decode the payload.

The payload decoding function is as follows:

function Decoder(bytes, port) {

// Decode an uplink message from a buffer

// (array) of bytes to an object of fields.

if(bytes[6] & 0x10)

{

var mod4="3DS18B20"; //work mode

}

else if(bytes[6] & 0x08)

{

var mod3="3ADC"; //work mode

LSN50 LoRa Sensor Node User Manual 18 / 60

Page 19

www.dragino.com

}

else if(bytes[6] & 0x04)

{

var mod2="Distance"; //work mode

}

else if(!(bytes[6] & 0x04))

{

var mod1="IIC"; //work mode

}

if(mod3=="3ADC")

{

var adc_ch0=(bytes[0]<<8 | bytes[1])/1000;//PA0,ADC Channel 0,units:V

var adc_ch1=(bytes[2]<<8 | bytes[3])/1000;//PA1,ADC Channel 1,units:V

var adc_ch4=(bytes[4]<<8 | bytes[5])/1000;//PA4,ADC Channel 4,units:V

var switch_=(bytes[6] & 0x80)? "CLOSE":"OPEN";//PB14,GPIO_MODE_IT_FALLING

var digital_IS=(bytes[6] & 0x02)? "H":"L";//PA12,Digital Input Status

var exti_trigger=(bytes[6] & 0x01)? "TRUE":"FALSE";//PB14,GPIO_MODE_IT_FALLING

value=bytes[7]<<8 | bytes[8];

if(bytes[7] & 0x80)

{value |= 0xFFFF0000;}

var temp_SHT=(value/10).toFixed(2);//SHT20,temperature,units:℃

value=bytes[9]<<8 | bytes[10];

var hum_SHT=(value/10).toFixed(1);//SHT20,Humidity,units:%

var batV= bytes[11]/10;//Battery,units:V

}

else if((mod1=="IIC")||(mod2=="Distance")||(mod4=="3DS18B20"))

{

var value=bytes[0]<<8 | bytes[1];

batV=value/1000;//Battery,units:V

value=bytes[2]<<8 | bytes[3];

if(bytes[2] & 0x80)

{value |= 0xFFFF0000;}

var tempc1=(value/10).toFixed(2);//DS18B20,PB3,units:℃

adc_ch0=(bytes[4]<<8 | bytes[5])/1000;//PA0,ADC Channel 0,units:V

switch_=(bytes[6] & 0x80)? "CLOSE":"OPEN";//PB14,GPIO_MODE_IT_FALLING

digital_IS=(bytes[6] & 0x02)? "H":"L";//PA12,Digital Input Status

exti_trigger=(bytes[6] & 0x01)? "TRUE":"FALSE";//PB14,GPIO_MODE_IT_FALLING

if(mod1=="IIC")

{

value=bytes[7]<<8 | bytes[8];

if(bytes[7] & 0x80)

{value |= 0xFFFF0000;}

temp_SHT=(value/10).toFixed(2);//SHT20,temperature,units:℃

value=bytes[9]<<8 | bytes[10];

LSN50 LoRa Sensor Node User Manual 19 / 60

Page 20

www.dragino.com

hum_SHT=(value/10).toFixed(1);//SHT20,Humidity,units:%

}

else if(mod2=="Distance")

{

value=bytes[7]<<8 | bytes[8];

var distance=(value/10) .toFixed(1); // Distance,units:cm

}

else if(mod4=="3DS18B20")

{

value=bytes[7]<<8 | bytes[8];

if(bytes[7] & 0x80)

{value |= 0xFFFF0000;}

var tempc2=(value/10).toFixed(2);//DS18B20,PB3,units:℃

value=bytes[9]<<8 | bytes[10];

if(bytes[9] & 0x80)

{value |= 0xFFFF0000;}

var tempc3=(value/10).toFixed(2);//DS18B20,PB3,units:℃

}

}

return {

BatV:batV,

TempC1:tempc1,

TempC2:tempc2,

TempC3:tempc3,

ADC_CH0V:adc_ch0,

ADC_CH1V:adc_ch1,

ADC_CH4V:adc_ch4,

Digital_IStatus:digital_IS,

EXTI_Trigger:exti_trigger,

Door_status:switch_,

MOD1:mod1,

MOD2:mod2,

MOD3:mod3,

MOD4:mod4,

Distance: distance,

TempC_SHT:temp_SHT,

Hum_SHT:hum_SHT

};

}

LSN50 LoRa Sensor Node User Manual 20 / 60

Page 21

www.dragino.com

2.4 Payload Explanation and Sensor Interface

2.4.1 Battery Info

Check the battery voltage for LSN50.

Ex1: 0x0B45 = 2885mV

Ex2: 0x0B49 = 2889mV

2.4.2 Temperature (DS18B20)

If there is a DS18B20 connected to PB3 pin. The temperature will be uploaded in the payload.

More DS18B20 can check the 3 DS18B20 mode

Connection

Example:

If payload is: 0105H: (0105 & FC00 == 0), temp = 0105H /10 = 26.1 degree

If payload is: FF3FH : (FF3F & FC00 == 1) , temp = (FF3FH - 65536)/10 = -19.3 degrees.

2.4.3 Digital Input

The digital input for pin PA12,

● When PA12 is high, the bit2 of payload byte 6 is 1.

● When PA12 is low, the bit2 of payload byte 6 is 0.

LSN50 LoRa Sensor Node User Manual 21 / 60

Page 22

www.dragino.com

1

0

~

7

0c

m

* Bouy on top, the oil sensor act as a 10K resistor.

* Bouy on bottom, it act as a 0ohm resistor,

To get the deep for the liquid, we can measure the

output resistance for oil sensor and calculate where

the bouy is so to calculate the height of oil.

Solder a 10K Resistor between

PA0 and VCC

Connect oil sensor to PA0 and

PB4

PB4 will be set to low(0v) at

every sampling

ADC Pin

2.4.4 Analogue Digital Converter (ADC)

The ADC monitors the voltage on the PA0 line, in mV.

Ex: 0x021F = 543mv,

Example1: Reading an Oil Sensor (Read a resistance value):

In the LSN50, we can use PB4 and PA0 pin to calculate the resistance for the oil sensor.

Steps:

1. Solder a 10K resistor between PA0 and VCC.

2. Screw oil sensor’s two pins to PA0 and PB4.

The equipment circuit is as below:

LSN50 LoRa Sensor Node User Manual 22 / 60

Page 23

www.dragino.com

According to above diagram:

(

So

is the reading of ADC. So if ADC=0x05DC=0.9 v and VCC (BAT) is 2.9v

The

4.5K ohm

Since the Bouy is linear resistance from 10 ~ 70cm.

The position of Bouy is

, from the bottom of Bouy

2.4.5 Digital Interrupt

Digital Interrupt refers to pin PB14, and there are different trigger methods. When there is a

trigger, the LSN50 will send a packet to the server.

Example to use with door sensor

(Requires firmware > 1.5.1)

The door sensor as shown at right. It is a two

wire magnetic contact switch used for detecting

the open/close status of doors or windows.

When the two pieces are close to each other, the

2 wire output will be short or open (depending

on the type), while if the two pieces are away

from each other, the 2 wire output will be the

opposite status. So we can use LSN50 interrupt

interface to detect the status for the door or

window.

Below is the installation example:

Fix one piece of the magnetic sensor to the door and connect the two pins to LSN50 as

follows:

● One pin to LSN50’s PB14 pin

● The other pin to LSN50’s VCC pin

Install the other piece to the door. Find a place where the two pieces will be close to each

other when the door is closed. For this particular magnetic sensor, when the door is closed,

the output will be short, and PB14 will be at the VCC voltage.

LSN50 LoRa Sensor Node User Manual 23 / 60

Page 24

www.dragino.com

The above photos shows the two parts of the magnetic switch fitted to a door.

The software by default uses the falling edge on the signal line as an interrupt. We need to

modify it to accept both the rising edge (0v --> VCC , door close) and the falling edge (VCC -->

0v , door open) as the interrupt.

The command is:

AT+INTMOD=1 //(more info about INMOD please refer AT Command Manual. )

Below shows some screen captures in TTN:

LSN50 LoRa Sensor Node User Manual 24 / 60

Page 25

www.dragino.com

2.4.6 I2C Interface (SHT20)

The PB6(SDA) and PB7(SCK) are I2C interface lines. You can use these to connect to an I2C

device and get the sensor data.

We have made an example to show how to use the I2C interface to connect to the SHT20

Temperature and Humidity Sensor. This is supported in the stock firmware since v1.5 with

AT+MOD=1 (default value).

Below is the connection to SHT20.

The device will be able to get the I2C sensor data now and upload to IoT Server.

Convert the read byte to decimal and divide it by ten.

Example:

Temperature: Read:0116(H) = 278(D) Value: 278 /10=27.8℃;

Humidity: Read:0248(H)=584(D) Value: 584 / 10=58.4, So 58.4%

If you want to use other I2C device, please refer the SHT20 part source code as reference.

LSN50 LoRa Sensor Node User Manual 25 / 60

Page 26

www.dragino.com

2.4.7 Distance Reading

Refer Ultrasonic Sensor section.

2.4.8 Ultrasonic Sensor

The LSN50 v1.5 firmware supports ultrasonic sensor (with AT+MOD=2) such as SEN0208

from DF-Robot. This Fundamental Principles of this sensor can be found at this link:

https://wiki.dfrobot.com/Weather__proof_Ultrasonic_Sensor_with_Separate_Probe_SKU___SEN0208

The LSN50 detects the pulse width of the sensor and converts it to mm output. The accuracy

will be within 1 centimeter. The usable range (the distance between the ultrasonic probe

and the measured object) is between 24cm and 600cm.

The picture below shows the connection:

Connect to the LSN50 and run AT+MOD=2 to switch to ultrasonic mode (ULT).

The ultrasonic sensor uses the 8th and 9th byte for the measurement value.

Example:

Distance: Read:0C2D(Hex) = 3117(D) Value: 3117 mm=311.7 cm

LSN50 LoRa Sensor Node User Manual 26 / 60

Page 27

www.dragino.com

You can see the serial output in ULT mode as below:

In TTN server:

2.4.9 +5V Output

Since v1.2 hardware version, a +5v output is added in the hardware. The +5V output will be

valid for every sampling.

LSN50 LoRa Sensor Node User Manual 27 / 60

Page 28

www.dragino.com

Downlink Control Type

FPort

Type Code

Downlink payload size(bytes)

TDC (Transmit Time Interval)

Any

01 4 RESET

Any

04 2 AT+CFM

Any

05 4 INTMOD

Any

06

4

2.5 Downlink Payload

By default, LSN50 prints the downlink payload to console port.

Examples

Set TDC

If the payload=0100003C, it means set the END Node’s TDC to 0x00003C=60(S), while type

code is 01.

Payload: 01 00 00 1E TDC=30S

Payload: 01 00 00 3C TDC=60S

Reset

If payload = 0x04FF, it will reset the LSN50

CFM

Downlink Payload: 05000001, Set AT+CFM=1 or 05000000 , set AT+CFM=0

INTMOD

Downlink Payload: 06000003, Set AT+INTMOD=3

LSN50 LoRa Sensor Node User Manual 28 / 60

Page 29

www.dragino.com

2.6 Show Data in Mydevices IoT Server

Mydevices provides a human friendly interface to show the sensor data, once we have data

in TTN, we can use Mydevices to connect to TTN and see the data in Mydevices. Below are

the steps:

Step 1: Be sure that your device is programmed and properly connected to the network at

this time.

Step 2: To configure the Application to forward data to Mydevices you will need to add

integration. To add the Mydevices integration, perform the following steps:

LSN50 LoRa Sensor Node User Manual 29 / 60

Page 30

www.dragino.com

Step 3: Create an account or log in Mydevices.

Step 4: Search the LSN50 and add DevEUI.

Use the LSN50 v1.6+ for the firmware version > v1.6

After added, the sensor data arrive TTN, it will also arrive and show in Mydevices.

Example for AT+MOD=1 plus SHT20 + DS18B20 sensor:

MOD=2

LSN50 LoRa Sensor Node User Manual 30 / 60

Page 31

MOD=3.

www.dragino.com

LSN50 LoRa Sensor Node User Manual 31 / 60

Page 32

www.dragino.com

2.7 Firmware Change Log

V1.6.1 Firmware (Not release):

Add 3 x DS18B20 mod

V1.6 Firmware:

Improve Interrupt feature.

Downlink to change AT+CFM. Downlink to change AT+INTMOD

Add 3ADC + I2C mode.

Fix power consumption bug in v1.5.

Fix SHT20, SHT31 reading bug.

V1.5 Firmware:

Add ultrasonic sensor support.

Add AT+MOD command to select difference sensors: (Ultrasonic, I2C) (See update AT

Command manual)

Add Downlink command to change TDC and reset the device.

Add AT+TXP command to be able manually set the exact TX Gain (See update AT

Command manual)

V1.4 Firmware:

Adjust payload, the default firmware include SHT20 and SHT31, If there is no SHT20,

SHT31, the related filed will show FF FF FF FF

Adjust 868 & 915 payload into 11 bytes, now 868 & 915 has same payload

Fix the 85 degree bug for DS18B20

Add new AT command which can adjust RX window time for LG01/LG02

Add AT command to print all parameters.

Any FPORT can accept downlink message and print.

v1.3 Firmware:

Add new AT Commands: AT+CHS & AT+CHE

Change AT+FDR command. This command will reset to factory except the keys

+5v power will only enable when read sensor data

Optimize OTAA join procedure. The first 50 joins will act as per LoRaWAN

request(request join every few seconds), if devices have not joined in network, the Join

Interval will extend to 30 minutes. If devices still not join at 200 tries, it will restart and

start to Join again.

Now print Device Model/Frequency bands/ Image Version/Dev EUI at start.

V1.2 Firmware:

Support Class C

After the configuration key can be stored in. No need to configure again even after

power off.

Add auto send feature after power on

Solve negative temperature issue.

Support Mydevices_LPP payload, user need to recompile firmware again.

V1.1 Firmware:

Support Battery Voltage(mV) ,the data of Oil Sensor ,the data of DS18B20, Digital I/0,

ADC_IN1(PA1),

LSN50 LoRa Sensor Node User Manual 32 / 60

Page 33

www.dragino.com

Proximity switch, I2C Device Example

V1.0 Firmware:

Support ADC monitoring (See how to in the case study of Oil Sensor) and DS18B20 (See

how to in the case study of DS18B20)

LSN50 LoRa Sensor Node User Manual 33 / 60

Page 34

www.dragino.com

2.8 Battery Analysis

2.8.1 Battery Type

The LSN50 battery is a combination of a 4000mAh Li/SOCI2 Battery and a Super Capacitor.

The battery is non-rechargeable battery type with a low discharge rate (<2% per year). This

type of battery is commonly used in IoT devices such as water meter.

The battery is designed to last for more than 5 years for the LSN50.

The battery related documents as below:

● Battery Dimension,

● Lithium-Thionyl Chloride Battery datasheet, Tech Spec

● Lithium-ion Battery-Capacitor datasheet, Tech Spec

2.8.2 Power consumption Analyze

In a minimum system with DS18B20 and Oil Sensor and default firmware, the power

consumption includes:

1. Deep Sleep (Stop mode) for STM32. ~ 5uA

2. Sampling current while reading DS18B20 and Oil Sensor

● Oil Sensor sampling time: 200us, current: 0.3mA

● DS18B20 sampling time: 750ms, current: 0.64mA

● Above power should add 8mA CPU power in working mode.

3. LoRaWAN transmit and receive time consumption. The LoRa TX / RX time and power

can be found in the LoRa calculator tool.

In a typical LoRaWAN data transmit. The energy profile is as below:

In the LoRaWAN protocol, the device will transfer in different LoRa Radio, and have different

energy profile in LoRa part. We can calculate the battery life in two cases:

1) Lower power LoRa radio. Device has a good signal to gateway

2) Higher power LoRa radio. Device has a poor signal to gateway

LSN50 LoRa Sensor Node User Manual 34 / 60

Page 35

www.dragino.com

Low Power Case:

● Radio Parameter: SF7, 125kHz, 20dbm

● Transmit interval: 15 minutes.

● Payload: 8 Bytes.

High Power Case:

● Radio Parameter: SF10, 125kHz, 20dbm

● Transmit interval: 15 minutes.

● Payload: 8 Bytes.

To simplify the calculation, we can:

● Combine oil sensor and DS18B20 sampling energy together to 751ms@8.64ma

● Combine the two RX windows together.

There is a power consumption tool for easy analysis. Below is the analysis result.

Note: Ignore the 18 year result, because the battery has a max 2% discharge per year.

2.8.3 Battery Note

The Li-SICO battery is designed for small current / long period application. It is not good to

use a high current, short period transmit method. The recommended minimum period for

use of this battery is 5 minutes. If you uses a shorter period time to transmit LoRa, then the

battery life may be decreased.

2.8.4 Replace the battery

You can change the battery in the LSN50. On the main board, there is a diode (D1) between

the battery and the main circuit. If you need to use a battery with less than 3.3v, please

LSN50 LoRa Sensor Node User Manual 35 / 60

Page 36

www.dragino.com

remove the D1 and shortcut the two pads of it so there won’t be voltage drop between

battery and main board.

3. Using the AT Commands

3.1 Access AT Commands

LSN50 supports AT Command set in the stock firmware. You can use a USB to TTL adapter to

connect to LSN50 for using AT command, as below.

In the PC, you need to set the serial baud rate to 9600 to access the serial console for LSN50.

LSN50 will output system info once power on as below:

LSN50 LoRa Sensor Node User Manual 36 / 60

Page 37

www.dragino.com

Below are the available commands, a more detailed AT Command manual can be found at

AT Command Manual

(http://www.dragino.com/downloads/index.php?dir=LSN50-

LoRaST/&file=DRAGINO_STM_AT_Commands_v1.3.pdf)

AT+<CMD>? : Help on <CMD>

AT+<CMD> : Run <CMD>

AT+<CMD>=<value> : Set the value

AT+<CMD>=? : Get the value

General Commands

AT : Attention

AT? : Short Help

ATZ : MCU Reset

AT+TDC : Application Data Transmission Interval

Keys, IDs and EUIs management

AT+APPEUI : Application EUI

AT+APPKEY : Application Key

AT+APPSKEY : Application Session Key

AT+DADDR : Device Address

AT+DEUI : Device EUI

AT+NWKID : Network ID (You can enter this command change only after

successful network connection)

AT+NWKSKEY : Network Session Key Joining and sending date on LoRa network

AT+CFM : Confirm Mode

AT+CFS : Confirm Status

AT+JOIN : Join LoRa? Network

AT+NJM : LoRa? Network Join Mode

AT+NJS : LoRa? Network Join Status

AT+RECV : Print Last Received Data in Raw Format

AT+RECVB : Print Last Received Data in Binary Format

AT+SEND : Send Text Data

AT+SENB : Send Hexadecimal Data

LoRa Network Management

AT+ADR : Adaptive Rate

AT+CLASS : LoRa Class(Currently only support class A

AT+DCS : Duty Cycle Setting

AT+DR : Data Rate (Can Only be Modified after ADR=0)

AT+FCD : Frame Counter Downlink

AT+FCU : Frame Counter Uplink

AT+JN1DL : Join Accept Delay1

AT+JN2DL : Join Accept Delay2

AT+PNM : Public Network Mode

AT+RX1DL : Receive Delay1

AT+RX2DL : Receive Delay2

AT+RX2DR : Rx2 Window Data Rate

AT+RX2FQ : Rx2 Window Frequency

AT+TXP : Transmit Power

Information

AT+RSSI : RSSI of the Last Received Packet

AT+SNR : SNR of the Last Received Packet

AT+VER : Image Version and Frequency Band

AT+FDR : Factory Data Reset

LSN50 LoRa Sensor Node User Manual 37 / 60

Page 38

www.dragino.com

AT+PORT : Application Port

AT+CHS : Get or Set Frequency (Unit: Hz) for Single Channel Mode

AT+CHE : Get or Set eight channels mode, Only for US915, AU915, CN470

3.2 Common AT Command Sequence

3.2.1 Multi-channel ABP mode (Use with SX1301/LG308)

If device has not joined network via OTAA:

AT+FDR

AT+NJM=0

ATZ

If device already joined network:

AT+NJM=0

ATZ

3.2.2 Single-channel ABP mode (Use with LG01/LG02)

See Sect 6.7

LSN50 LoRa Sensor Node User Manual 38 / 60

Page 39

www.dragino.com

4. Upload Firmware

Notes:

- Since image v1.3, the firmware will show version info during boot. If your device doesn’t

show version info, you may have a very old image version.

- Always run AT+FDR to reset parameters to factory default after an update image.

If the update is from image >= v1.3 to another image version >=v1.3, then the keys will

be kept after running AT+FDR.

Otherwise (e.g. from v1.2 to v1.3), AT+FDR may erase the keys.

4.1 Upload Firmware via Serial Port

The LSN50’s AT Command port can be used for firmware upgrade. The hardware connection

for upgrade firmware is as below:

Step1: Download flash loader.

Step2: Download the LSN50 Image files.

Step3: Open flashloader; choose the correct COM port to update

LSN50 LoRa Sensor Node User Manual 39 / 60

Page 40

www.dragino.com

Board detected

LSN50 LoRa Sensor Node User Manual 40 / 60

Page 41

www.dragino.com

Step4: Switch SW1 back to flash state and push the RESET button.

The LSN50 will then run the new firmware.

LSN50 LoRa Sensor Node User Manual 41 / 60

Page 42

www.dragino.com

4.2 Upload Firmware via ST-Link V2

You can use ST-LINK to upgrade firmware into LSN50. The hardware connection for upgrade

firmware is as below:

Connection:

● ST-LINK v2 GND <--> LSN50 GND

● ST-LINK v2 SWCLK <--> LSN50 PA14

● ST-LINK v2 SWDIO <--> LSN50 PA13

● ST-LINK v2 RST <-->LSN50 NRST.

Step1: Install ST-LINK driver first and then install ST-LINK Utility

Step2: Download the LSN50 Image files.

Step3: Open ST-LINK utility, file --> open file to select the image to be upgraded.

Step4: Click the “Program Verify” button on ST-LINK.

Step5: The led on the ST-LINK adapter will now blinking, and the ST-Link utility will pop up a

download window. Click the start button to download the image to LSN50.

LSN50 LoRa Sensor Node User Manual 42 / 60

Page 43

www.dragino.com

NOTE: If this step fails, ST-LINK can’t establish connection to LSN50, please try to swap

SWDIO & SWCLK pin. Some ST-LINK v2 devices are incorrectly marked.

LSN50 LoRa Sensor Node User Manual 43 / 60

Page 44

www.dragino.com

5. Developer Guide

5.1 Source Code

Software Source Code Download Link.

(https://github.com/dragino/LoRa_STM32/tree/master/STM32CubeExpansion_LRWAN)

Hardware Source Code Download Link

(https://github.com/dragino/Lora/tree/master/LSN50)

5.2 Compile Source Code

5.2.1 Set up Keil Compile Environment

Assuming you already have Keil uVision5 installed, the steps below show how to install the

MDK support and get a license.

1: Open the Webpage: http://www2.keil.com/stmicroelectronics-stm32/mdk

2: Download the Keil MDK:

3: Login with an account that has administration rights.

4: Right-click the µVision icon and select Run as Administrator… from the context menu.

LSN50 LoRa Sensor Node User Manual 44 / 60

Page 45

www.dragino.com

5: Open the dialog File — License Management… and select the Single-User License tab.

6: Click the button Get LIC via Internet..., then click the button OK to register the product.

This action opens the License Management page on the Keil web site.

LSN50 LoRa Sensor Node User Manual 45 / 60

Page 46

www.dragino.com

7: Enter the Product Serial Number 4PPFW-QBEHZ-M0D5M along with your contact

information and click the button Submit. An e-mail is sent back with the License ID Code (LIC)

within a few minutes.

(1)

(2)

(3)

LSN50 LoRa Sensor Node User Manual 46 / 60

Page 47

www.dragino.com

8: To activate the Software Product, enter the LIC in the field New License ID Code (LIC) of

the dialog License Management… and click Add LIC.

9: Finish

LSN50 LoRa Sensor Node User Manual 47 / 60

Page 48

www.dragino.com

5.2.2 Install STM32L0 Series Device

1: Open the webpage: http://www.keil.com/dd2/pack/eula-container;

2: Find the STMicroelectronics STM32L0 Series Device and download it.

3: Find the Software Pack and install it.

LSN50 LoRa Sensor Node User Manual 48 / 60

Page 49

www.dragino.com

4: Add the Device, then you can rebuild the project.

LSN50 LoRa Sensor Node User Manual 49 / 60

Page 50

www.dragino.com

Note: If you don’t add the Device, then Keil will report this error:

5.2.3 Compile Source Code

1. Download the source code from Software Source Code Download Link.

2. Use Keil to open the project file:

STM32CubeExpansion_LRWAN/Projects/Multi/Applications/LoRa/DRAGINOLRWAN(AT)/MDK-ARM/STM32L072CZ-Nucleo/Lora.uvprojx

3. In Keil, you can see what frequency band the code support.

LSN50 LoRa Sensor Node User Manual 50 / 60

Page 51

www.dragino.com

4. If you want to change frequency, modify the Preprocessor Symbols.

For example, change EU868 to US915

5. Compile and build

LSN50 LoRa Sensor Node User Manual 51 / 60

Page 52

www.dragino.com

Version

LoRa IC

Working Frequency

Best Tune

Frequency

Recommend Bands

433

SX1278

Band2(LF): 410 ~525 Mhz

433Mhz

CN470/EU433

868

SX1276

Band1(HF):862~1020 Mhz

868Mhz

EU868

915

SX1276

Band1(HF):862 ~1020 Mhz

915Mhz

AS923/AU915/

KR920/US915

6. FAQ

6.1 Why there is 433/868/915 version?

Different countries have different rules for the ISM band for LoRa. Although the LoRa chip

can support a wide range of Frequencies, we provide different versions of the hardware for

best tune of the LoRa hardware part.

6.2 What is the frequency range of LT LoRa part?

Different LT version supports different frequency range, below is the table for the working

frequency and recommend bands for each model.

6.3 How to change the LoRa Frequency Bands/Region?

You can follow the instructions for how to upgrade image.

When downloading the images, choose the required image file for download.

6.4 Can I use Private LoRa protocol?

The stock firmware is based on LoRaWAN protocol. You can use a private LoRa protocol in

LSN50. This section describes an example for base LoRa transfer. It is a reference/demo and

we do not provide further software development support on this topic.

In this demo, we will show the communication between LoRa Shield and LSN50, both of

them using the basic LoRa library. LSN50 will send a message to a LoRa Shield and the LoRa

Shield will print it to the console.

LSN50 LoRa Sensor Node User Manual 52 / 60

Page 53

www.dragino.com

LoRa Shield + UNO:

Use the LoRa Library and upload the LoRa_Receive Sketch to Arduino.

Refs:

http://www.dragino.com/downloads/index.php?dir=LSN50-LoRaST/LoRa_Raw_Example/Arduino/&file=LoRa.zip

http://www.dragino.com/downloads/downloads/LSN50-LoRaST/LoRa_Raw_Example/Arduino/LoRaReceiver.ino

Open the serial monitor to Arduino. The device acts as a LoRa Receiver and listen on the

frequency 868.3Mhz by default.

LSN50:

Use the <LoRa RAW code> . The project file is in: MDK-ARM\STM32L072CZ-Nucleo\

Lora.uvprojx

Compile it and Upload it to LSN50, the LSN50 will transfer on the frequency 868.3Mhz.

In the Arduino Console, it will see the received packets as below.

6.5 How to set up LSN50 to work in 8 channel mode

By default, the frequency bands US915, AU915, CN470 work in 72 frequencies. Many

gateways are 8 channel gateways, and in this case, the OTAA join time and uplink schedule is

long and unpredictable while the end node is hopping in 72 frequencies.

You can configure the end node to work in 8 channel mode by using the AT+CHE command.

The 500kHz channels are always included for OTAA.

LSN50 LoRa Sensor Node User Manual 53 / 60

Page 54

www.dragino.com

CHE

US915 Uplink Channels(125KHz,4/5,Unit:MHz,CHS=0)

0

ENABLE Channel 0-63

1

902.3

902.5

902.7

902.9

903.1

903.3

903.5

903.7

Channel 0-7

2

903.9

904.1

904.3

904.5

904.7

904.9

905.1

905.3

Channel 8-15

3

905.5

905.7

905.9

906.1

906.3

906.5

906.7

906.9

Channel 16-23

4

907.1

907.3

907.5

907.7

907.9

908.1

908.3

908.5

Channel 24-31

5

908.7

908.9

909.1

909.3

909.5

909.7

909.9

910.1

Channel 32-39

6

910.3

910.5

910.7

910.9

911.1

911.3

911.5

911.7

Channel 40-47

7

911.9

912.1

912.3

912.5

912.7

912.9

913.1

913.3

Channel 48-55

8

913.5

913.7

913.9

914.1

914.3

914.5

914.7

914.9

Channel 56-63

Channels(500KHz,4/5,Unit:MHz,CHS=0)

903

904.6

906.2

907.8

909.4

911

912.6

914.2

Channel 64-71

CHE

AU915 Uplink Channels(125KHz,4/5,Unit:MHz,CHS=0)

0

ENABLE Channel 0-63

1

915.2

915.4

915.6

915.8

916

916.2

916.4

916.6

Channel 0-7

2

916.8

917

917.2

917.4

917.6

917.8

918

918.2

Channel 8-15

3

918.4

918.6

918.8

919

919.2

919.4

919.6

919.8

Channel 16-23

4

920

920.2

920.4

920.6

920.8

921

921.2

921.4

Channel 24-31

5

921.6

921.8

922

922.2

922.4

922.6

922.8

923

Channel 32-39

6

923.2

923.4

923.6

923.8

924

924.2

924.4

924.6

Channel 40-47

7

924.8

925

925.2

925.4

925.6

925.8

926

926.2

Channel 48-55

8

926.4

926.6

926.8

927

927.2

927.4

927.6

927.8

Channel 56-63

Channels(500KHz,4/5,Unit:MHz,CHS=0)

915.9

917.5

919.1

920.7

922.3

923.9

925.5

927.1

Channel 64-71

For example, in US915 band, the frequency table is as below. By default, the end node will

use all channels (0~71) for OTAA Join process. After the OTAA Join, the end node will use

these all channels (0~71) to send uplink packets.

When you use the TTN network, the US915 frequency bands use are:

● 903.9 - SF7BW125 to SF10BW125

● 904.1 - SF7BW125 to SF10BW125

● 904.3 - SF7BW125 to SF10BW125

● 904.5 - SF7BW125 to SF10BW125

● 904.7 - SF7BW125 to SF10BW125

● 904.9 - SF7BW125 to SF10BW125

● 905.1 - SF7BW125 to SF10BW125

● 905.3 - SF7BW125 to SF10BW125

● 904.6 - SF8BW500

Because the end node is now hopping in 72 frequency, it makes it difficult for the devices to

Join the TTN network and uplink data. To solve this issue, you can access the device via the

AT commands and run:

AT+CHE=2

ATZ

to set the end node to work in 8 channel mode. The device will work in Channel 8-15 & 6471 for OTAA, and channel 8-15 for Uplink.

The AU915 band is similar. Below are the AU915 Uplink Channels.

LSN50 LoRa Sensor Node User Manual 54 / 60

Page 55

www.dragino.com

6.6 How to set up LSN50 to work with Single Channel Gateway such as

LG01/LG02?

In this case, users need to set LSN50 to work in ABP mode and transmit in only one

frequency.

Assume we have a LG02 working in the frequency 868400000 now, below is the steps.

Step1: Log in TTN, Create an ABP device in the application and input the network session key

(NETSKEY), app session key (APPSKEY) from the device.

Note: You need to make sure the above three keys match in the device and in TTN. You can

change them either in TTN or in the Device to make them match. In TTN, NETSKEY and

APPSKEY can be configured in the setting page, but the Device Addr is generated by TTN.

You can also change the Device ADDR in TTN by using the The Things Network CLI.

LSN50 LoRa Sensor Node User Manual 55 / 60

Page 56

www.dragino.com

Step2: Run AT commands to make the LSN50 work in Single frequency and ABP mode.

Below are the AT commands:

AT+FDR Reset Parameters to Factory Default, Keys Reserve

AT+NJM=0 Set to ABP mode

AT+ADR=0 Set the Adaptive Data Rate Off

AT+DR=5 Set Data Rate (Set AT+DR=3 for 915 band)

AT+TDC=300000 Set transmit interval to 5 minutes

AT+CHS=868400000 Set transmit frequency to 868.4Mhz

AT+DADDR=26 01 1A F1 Set Device Address to 26 01 1A F1

ATZ Reset MCU

As shown below:

6.7 How to configure the EUI keys in LSN50?

The early version of LSN50 firmware doesn’t have pre-configured keys.

It is recommended that you update the image to the latest version before configure the keys.

Refer upgrade_image to update the firmware to the latest version.

Run AT commands to set the keys to desired keys; refer AT Command manual.

LSN50 LoRa Sensor Node User Manual 56 / 60

Page 57

www.dragino.com

7. Trouble Shooting

7.1 Connection problem when uploading firmware.

Issue: While using USB to TTL to upload firmware via UART interface. It works for several

times but most of times it fails.

Checklist:

1. Double check if follow up exactly the steps as manual.

2. Check if hardware works fine: a) check if AT command works, b) check if ISP / flash

switch works: PA12 will have different output level while set the ISP/Flash Switch in

different position. c) check if reset button works.

3. If you use Windows10 system. Please change the flash loader to run in Windows7

compatibility mode.

4. We have seen cases where the FT232 USB TTL adapter has a reliability issue with the PC

USB chipset (Intel). In this case, even though points 1 and 2 above work, it still has a

reliability issue for uploading. If this happens, change to a different PC or change the

USB to TTL adapter to solve the issue.

7.2 Why I can’t join TTN in US915 / AU915 bands?

It is due to channel mapping. Please see the Eight Channel Mode section above for details.

LSN50 LoRa Sensor Node User Manual 57 / 60

Page 58

www.dragino.com

7.3 AT Command input doesn’t work

In the case if user can see the console output but can’t type input to the device. Please check

if you already include the ENTER while sending out the command. Some serial tool doesn’t

send ENTER while press the send key, user need to add ENTER in their string.

LSN50 LoRa Sensor Node User Manual 58 / 60

Page 59

www.dragino.com

8. Order Info

Part Number: LSN50-XX-YY

XX: The default frequency band

● AS923: LoRaWAN AS923 band

● AU915: LoRaWAN AU915 band

● EU433: LoRaWAN EU433 band

● EU868: LoRaWAN EU868 band

● KR920: LoRaWAN KR920 band

● US915: LoRaWAN US915 band

● IN865: LoRaWAN IN865 band

● CN470: LoRaWAN CN470 band

YY:

● 12: With M12 waterproof cable hole

● 16: With M16 waterproof cable hole

● 20: With M20 waterproof cable hole

● NH: No Hole

9. Packing Info

Package Includes:

● LSN50 LoRa Sensor Node x 1

Dimension and weight:

● Device Size: 8 x 6.5 x 5 cm

● Device Weight: 137g

● Package Size / pcs : 9 x 7 x 6cm

● Weight / pcs : 160g

LSN50 LoRa Sensor Node User Manual 59 / 60

Page 60

www.dragino.com

10. Support

● Support is provided Monday to Friday, from 09:00 to 18:00 GMT+8. Due to different

timezones we cannot offer live support. However, your questions will be answered as

soon as possible in the before-mentioned schedule.

● Provide as much information as possible regarding your enquiry (product models,

accurately describe your problem and steps to replicate it etc) and send a mail to

support@dragino.com

11. References

● Product Page

(http://www.dragino.com/products/lora/item/128-lsn50.html)

● Data Sheet

(http://www.dragino.com/downloads/index.php?dir=datasheet/EN/&file=Datasheet_LoRaS

ensorNode.pdf)

● Image Download

(https://github.com/dragino/LoRa_STM32/tree/master/LSN50.hex)

● AT Command Manual

(http://www.dragino.com/downloads/index.php?dir=LSN50LoRaST/&file=DRAGINO_STM_AT_Commands_v1.3.pdf)

LSN50 LoRa Sensor Node User Manual 60 / 60

Loading...

Loading...