Page 1

Wireless communication

ISA100 Wireless

TM

Technical Manual

Wireless communication

Page 2

This page has been left blank intentionally.

2 Technical Manual | Wireless communication

Page 3

Contents

TM

Wireless communicationISA100 Wireless

Contents

1 Introduction .............................................................................................. 5

1.1 Target group ................................................................................... 5

1.2 General safety statements.............................................................. 5

1.3 Meaning of the warning notes......................................................... 5

1.4 Typographical conventions............................................................. 5

1.5 Brand names .................................................................................. 6

2 Wireless data transmission in industrial settings................................. 7

3 ISA100 Wireless

TM

basics ....................................................................... 9

3.1 Network components and participants............................................ 10

3.1.1 System manager .............................................................. 11

3.1.2 Backbone.......................................................................... 11

3.1.3 Access points (AP) ........................................................... 11

3.1.4 Field devices..................................................................... 12

3.1.5 Hop points ........................................................................ 13

3.2 Network topologies ......................................................................... 14

3.2.1 Star topology .................................................................... 14

3.2.2 Mesh topology .................................................................. 15

3.2.3 Comparison of star topology and mesh topology ............. 16

3.3 Network performance and network configuration ........................... 16

3.3.1 Signal quality .................................................................... 16

3.3.2 Network coverage............................................................. 18

3.3.3 Sub-networks.................................................................... 19

3.3.4 Sky mesh.......................................................................... 20

3.3.5 Network configuration with retrofitted field devices .......... 20

3.3.6 Network configuration for small networks......................... 21

3.3.7 Network configuration with long backbone lines............... 22

3.3.8 Network configuration with a 4–20 mA control unit .......... 24

4 ISA100 Wireless

TM

data transmission basics........................................ 25

4.1 Frequency band and bandwidth ..................................................... 25

4.2 Data integrity................................................................................... 26

4.2.1 Frequency hopping........................................................... 26

4.2.2 Hopping patterns .............................................................. 26

4.2.3 Standard hopping pattern................................................. 27

4.2.4 Duo-Cast .......................................................................... 28

4.2.5 Time-Division-Multiple-Access (TDMA)............................ 28

4.2.6 Clear channel assessment (CCA) .................................... 28

4.2.7 Automatic-Repeat-reQuest (ARQ).................................... 28

4.2.8 Blacklisting........................................................................ 29

4.2.9 Adaptive hopping.............................................................. 29

4.2.10 Path diversity .................................................................... 29

4.2.11 Types of routing ................................................................30

4.3 Data structure ................................................................................. 30

4.3.1 Data fields......................................................................... 31

4.3.2 User application process (UAP) ....................................... 32

4.3.3 Object identifiers............................................................... 33

Technical Manual | Wireless communication 3

Page 4

Contents

4.3.4 Attribute classes ............................................................... 34

4.3.5 Data format (without PROFIsafe

®

communication).......... 35

4.4 Traffic.............................................................................................. 35

4.4.1 Data query ........................................................................ 36

4.4.2 Sampling rate and stale limit ............................................ 36

4.4.3 Network and energy management with ISA100 wireless

communication ................................................................. 38

4.4.4 Device performance information....................................... 39

5 Transmission basics for PROFIsafe

5.1 Black channel principle ................................................................... 40

5.2 Data integrity for PROFIsafe

5.2.1 PROFIsafe

®

network constraints...................................... 42

®

communication ......................... 40

®

communication ............................... 41

5.3 Data structure ................................................................................. 42

5.3.1 Data fields......................................................................... 42

5.3.2 Data format for PROFIsafe

5.4 Traffic for PROFIsafe

®

communication .......................................... 43

®

communication ................... 43

6 Network integration (provisioning) of gas warning devices................ 45

6.1 Network integration parameters...................................................... 45

6.1.1 Modbus parameters.......................................................... 45

6.1.2 PROFIsafe

®

traffic............................................................ 45

6.2 Out Of Band Provisioning (OOB, Yokogawa gateway only)........... 46

6.3 Over the air provisioning (OTA)...................................................... 48

7 Troubleshooting....................................................................................... 49

7.1 Errors during network integration.................................................... 49

7.2 Errors during operation ................................................................... 49

7.2.1 Status byte of a transmitted value .................................... 49

7.2.2 DIAG_STATUS attribute byte........................................... 51

8 Recommended network components..................................................... 53

8.1 Network components recommended without restrictions ............... 53

8.1.1 System manager .............................................................. 53

8.1.2 Access points ................................................................... 53

8.1.3 Other components............................................................ 53

8.2 Network components recommended with restrictions .................... 53

8.2.1 System manager .............................................................. 53

9 Glossary.................................................................................................... 54

9.1 Glossary on parameter and object names...................................... 55

4 Technical Manual | Wireless communication

Page 5

1 Introduction

This document supplements the instructions for use for gas warning devices:

– Dräger Polytron

– GasSecure GS01 / GasSecure GS01-EA

– Polytron Repeater ISA100

– Polytron 6700 IR WL

This document contains additional information on the ISA100 Wireless

1.1 Target group

This document is intended for technicians with training in PLC programming,

trained electricians or persons who have received instruction from a trained

electrician. These persons must also be familiar with the applicable standards.

1.2 General safety statements

Before using this product, carefully read the associated instructions for use. This

document does not replace the instructions for use.

®

6100 EC WL

Introduction

TM

interface.

1.3 Meaning of the warning notes

The following warning notes are used in this document to notify users of possible

dangers. The meanings of the warning notes are defined as follows:

Alert icon Signal word Consequences in case of nonob-

servance

WARNING Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION Indicates a potentially hazardous situation

which, if not avoided, could result in injury.

It may also be used to alert against unsafe

practices.

NOTICE Indicates a potentially hazardous situation

which, if not avoided, could result in damage to the product or environment.

1.4 Typographical conventions

Text Text marked in bold denotes labeling on the device and on-screen

messages.

► This triangle labels possible methods of avoiding the hazards men-

tioned in warning notices.

> The greater-than sign denotes the navigational path in a menu.

This symbol denotes information that make using the product easier.

Technical Manual | Wireless communication 5

Page 6

Introduction

1.5 Brand names

–HART® is a registered trademark of the HART Communication Foundation.

–PROFIBUS

e. V.

– FOUNDATION

– ISA100 Wireless

Automation (ISA).

– Bluetooth

– WirelessHART

Communication Foundation.

–PROFIsafe

®

is a registered trademark of the PROFIBUS Nutzerorganisation

TM

®

is a registered trademark of Bluetooth SIG, Inc.

®

®

is a registered trademark of Siemens Aktiengesellschaft.

is a registered trademark of the Fieldbus Foundation.

TM

is a registered trademark of the International Society of

(WHART) is a registered trademark of the HART

6 Technical Manual | Wireless communication

Page 7

Wireless data transmission in industrial settings

2

3

1

P6 P6

2 Wireless data transmission in industrial settings

There are a number of different protocols and types of network for wireless data

transmission, which will be described in this manual in conjunction with Dräger

products. The following diagram shows the application areas for various protocols.

Other protocols (WPAN, for example) are not considered in this context.

40934

Fig. 1 Wireless data transmission protocols

1WFAN

2WLAN

3

Bluetooth

®

or infrared

WLAN and WFAN

In a WFAN (Wireless Field (or Factory) Area Network), industrial field devices

communicate with one another or with a control center. The control center controls

and monitors the field devices. When communicating via WFAN, protocols such as

ISA100 Wireless

TM

and WirelessHART® (WHART) are used.

WLAN (Wireless Local Area Network) is a local, usually private wireless network.

The WLAN infrastructure of an industrial plant is used for mobile end devices and

video transmission (stationary cameras).

Technical Manual | Wireless communication 7

Page 8

Wireless data transmission in industrial settings

Main application areas

There are 3 main areas of application for wireless networks:

– Plant safety

Transmitters monitor safety-critical areas and send wireless measured values.

ISA100 Wireless

TM

allows for SIL 2-compliant failsafe communication through

the transport of PROFIsafe

– Monitoring field devices

The status of field devices is monitored (e.g. temperature, sensor status of a gas

warning device).

– Process monitoring and process control

Wireless data transmission allows for detailed process monitoring and process

control without expensive cable routing costs.

These areas of application must be able to tolerate latencies of 100 ms.

Advantages of a wireless network

Wireless networks offer many advantages compared to wired networks.

– Wireless networks can be made operational more quickly and installing the

infrastructure creates less costs.

– Wireless networks can be expanded with greater ease and at less cost. Adding

new field devices and putting them into operation, as well as removing them, is

easier.

– The parameters of field devices as well as diagnostics and maintenance can be

configured centrally.

– Errors do not occur when wiring field devices (e.g. cable break, wiring problems

in the field device).

– Wireless networks can be employed in places a wired network would be

impossible, expensive, or difficult to implement (e.g. on rotating platforms).

– Temporary installations that are dismantled after a certain time also profit from

wireless networking. Temporary installations no longer need arduous and

expensive cabling.

®

messages.

Furthermore, a wired network’s infrastructure can be expanded wirelessly (creating

redundancy).

8 Technical Manual | Wireless communication

Page 9

3 ISA100 WirelessTM basics

ISA100.11a is a wireless networking protocol internationally recognized as IEC

Standard 62734 and developed by the International Society of Automation (ISA). It

is based on the ISO/OSI reference model and allows for reliable, secure data

transmission for control- and regulation-related applications, process monitoring

and alerts.

ISA100 Wireless

data transmission even over long distances with low power consumption.

As with most fieldbus systems, a ISA100 Wireless

any field devices required due to standardization. All field devices in the network

can interact with one another independent of manufacturer.

ISA100 Wireless

system management, gateway requirements and security specifications.

Failsafe communication

ISA100 Wireless

between controller and field device. This secure data transfer method is performed

via tunneling. Tunneling facilitates the use of different communication protocols via

the ISA100 Wireless

PROFIsafe

outside the ISA100 Wireless

TM

is comparable to a fieldbus system in that it allows for reliable

TM

defines basic functions and requirements for field devices,

TM

allows for failsafe communication (e.g. SIL 2-compliant)

TM

®

communication protocol. This communication protocol is transmitted

infrastructure. Failsafe communication is done via the

TM

infrastructure via PROFINET.

ISA100 WirelessTM basics

TM

network can be expanded with

Advantages of ISA100 Wireless

TM

There are different wireless network protocols. Among others, the ISA100

Wireless

– Transfer of other communication standards (e.g. PROFIsafe

TM

protocol has the following advantages over other protocols:

®

, HART®)

– Bandwidth for safety-relevant data can be reserved. This reserved bandwidth

ensures the rapid transmission of safety-relevant data at any time to the control

center. The transmission of safety-relevant data is not affected by other data

traffic.

– Response times of a ISA100 Wireless

TM

network are variable and shorter than

those of other protocols.

Technical Manual | Wireless communication 9

Page 10

ISA100 WirelessTM basics

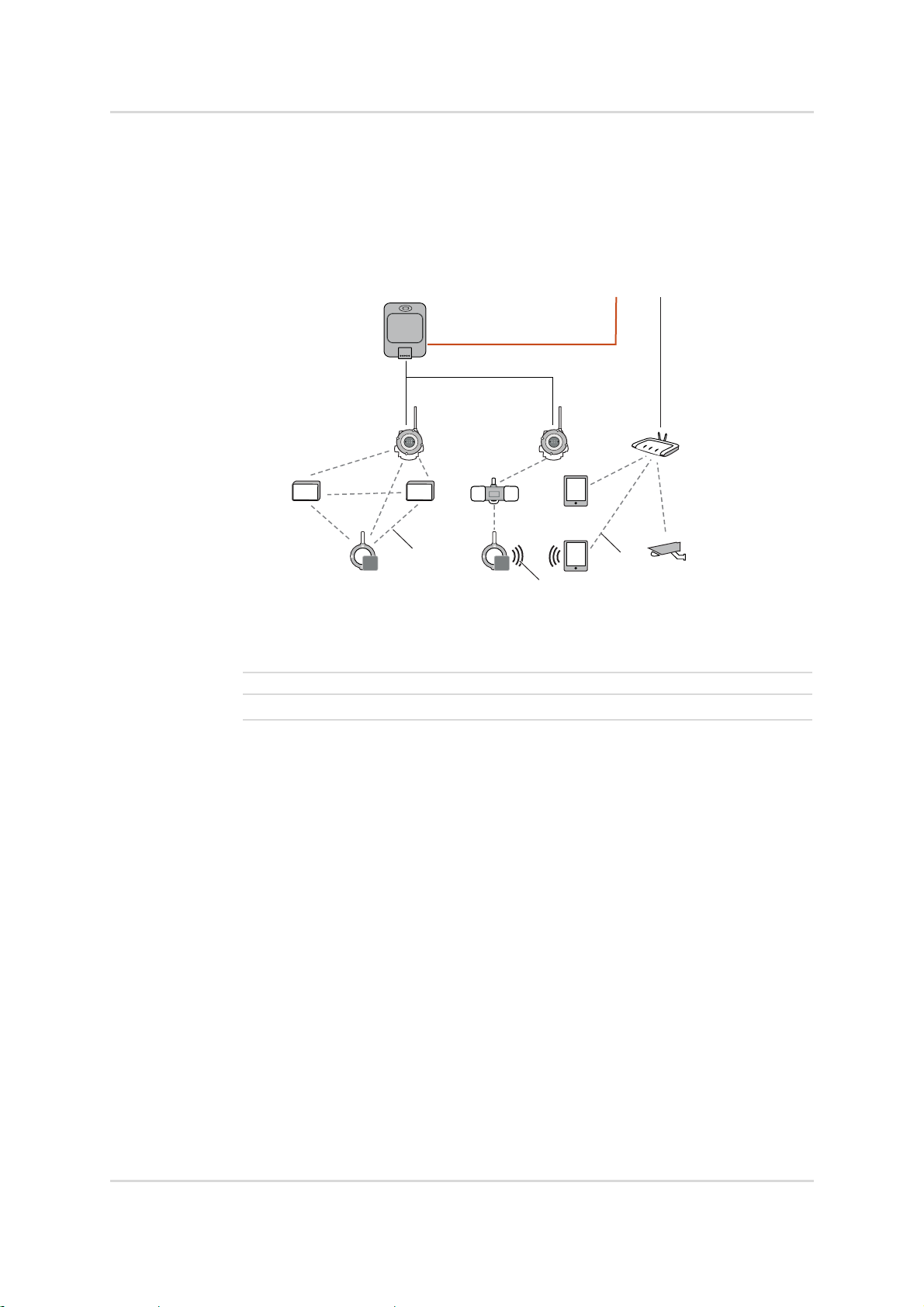

3.1 Network components and participants

4

18

5

6

7

6

10

14

15

16

13

11

12

P6

Fig. 2 Example topology of a wireless network

3

5

P6

8

1

9

17

38243

2

1 Control center

2 Control unit for wired field devices

3 Control unit

4 System manager

5 Access point in the function as a backbone router

6 Access point

7 Access point in the function as a field device access point

8Hop point

9 Retrofitted field device

10 I/O field device

11 GasSecure GS01

12

Dräger Polytron

®

6100 EC WL

13 Backbone

14 Ethernet or fiber-optics

15 Wireless data transmission from an access point to the backbone

16 Wireless data transmission between field devices and to the backbone

17 Wired analog or digital communication

18

Wired Modbus communication or PROFIsafe

®

communication via PROFI-

BUS/PROFINET

10 Technical Manual | Wireless communication

Page 11

3.1.1 System manager

The system manager monitors and manages the following system functions,

among others:

– Security management

– System performance, system latencies, redundancy

– System time

– Field device management (e.g. address allocation and routing tables)

Wireless gateway and system manager are the same thing for the purposes of this

manual. In detailed descriptions, system managers and gateways must be

considered separately from one another.

Controllers are connected to the system manager (e.g. Dräger REGARD

with Modbus Master module). Control units process the system manager’s data and

trigger alerts or countermeasures.

If PROFIsafe

F-host (failsafe host) must be used as a controller , which communicates with Fslaves (FailSafe field devices). In this case, the system manager only forwards the

messages and does not interfere with PROFIsafe

®

is used for communication purposes (e.g. for SIL 2 applications), an

ISA100 WirelessTM basics

®

communication.

®

7000

3.1.2 Backbone

The backbone is the wired part of the network, which connects the backbone router

(BBR) to the system manager. The connection is established via fiber-optic cable

(FOC) or Ethernet.

3.1.3 Access points (AP)

An access point is the transition from the wireless to the wired parts of the network.

Access points transmit the information from their end devices via cable to the

system manager. APs can be compared to the base station of a mobile landline

phone. In both cases, a wireless network is established for a multitude of mobile

end devices.

An AP performs different roles depending on the position in which it is located in the

network.

3.1.3.1 Backbone router (BBR)

If an access point is wired directly to the backbone, the access point is referred to

as the backbone router. Several backbone routers can be connected to the

backbone.

Field devices and field device access points communicate wirelessly with the

backbone router via the sub-network, which is established by the backbone router.

Technical Manual | Wireless communication 11

Page 12

ISA100 WirelessTM basics

Additional access points can be wired to the backbone router.

Risk of confusion

Backbone routers are connected to the backbone via cables. Repeaters or field

devices with routing functionalities are often also referred to as routers. However,

these "routers" are not connected to the backbone via cables and only forward the

signals.

Backbone routers as part of the system manager

Backbone routers can also be part of the system manager.

3.1.3.2 Field device access points (FDAP)

Field device access points are access points that communicate wirelessly with the

backbone. Communication to the backbone is done either via access points or

directly over the backbone router.

Dräger-approved devices are listed in the appendix.

3.1.4 Field devices

Field devices may also be called terminal devices or clients. They log on to the AP

and exchange information. Field devices are also called I/O devices because they

receive (input) and send (output) data.

There are field devices that communicate with the control center via cable in

addition to communicating wirelessly. These field devices are retrofitted with an

ISA100 Wireless

TM

antenna. They additionally communicate via wire with another

interface (a 4–20 mA interface, for example).

Field devices can be mobile field devices (tablets, smartphones, laptops), stationary

field devices or slow-moving stationary field devices. Mobile field devices often

communicate with an additional system manager or gateway via a different protocol

(non-ISA100 Wireless

TM

Due to their being integral elements of the network infrastructure, access points or

field device access points are not called field devices.

3.1.4.1 Routing functionalities

Some field devices can also act as a router in addition to their normal functionality.

Field devices with this function activated create hop points in the network.

These devices are often connected to a power line due to the extra energy

requirements involved in router operation.

Field devices with routing functionalities are also available without measuring

functions. They are then only integrated into the network as routers. The Polytron

Repeater ISA100 is a router without measuring function.

).

®

12 Technical Manual | Wireless communication

Page 13

3.1.4.2 Power supply

P6 P6

P6

1

1

2

ISA100 WirelessTM basics

Power is supplied to field devices via batteries or the power grid. ISA100

Wireless

TM

allows for every type of power supply.

If battery operation is not possible, field devices are connected to an external power

supply. An external power supply may be necessary if the routing functionality is

active and there is a lot of wireless communication.

When operating in explosion-hazard areas, an upstream safety barrier must be

installed for external power supplies.

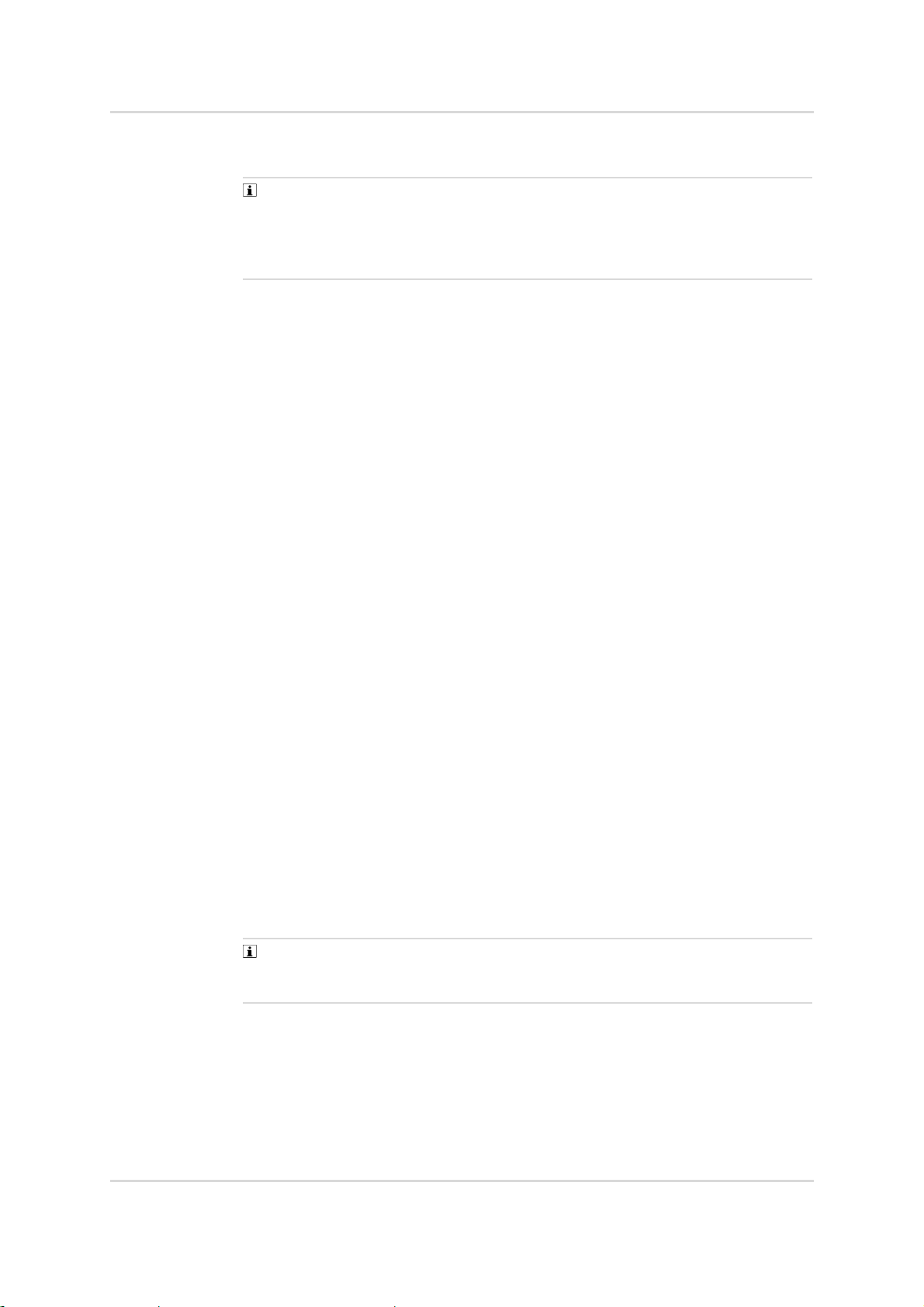

3.1.5 Hop points

Routers or field devices with a router function form a hop point in the sub-network.

Hop points expand a network and ensure redundant transmission routes. Signals

are forwarded without processing and no separate sub-network is established.

Data transmissions via hop points to the system manager are slower than direct

data transmissions to access points. Latencies (wait times) at the hop points can

delay communication.

The communication paths via hop points are prevented ex-factory for some

system managers. But, the function can be activated.

Restrictions for installations with short response times

Series-connected hop points can delay the response time. If response times are a

critical factor, there must be a limited number of hops (wireless interfaces) from the

field device to the access point. Fig. 3 shows a sub-network with only one (1) or two

(2) hops allowed.

Fig. 3 Hop points in a sub-network

1 First hop point after the sub-network access point

One further hop point is possible.

2 Second hop point after the sub-network access point

Another hop point could cause too much of a delay in the response time.

System managers from Yokogawa support a maximum of 4 hops (wireless

interfaces) between a field device and the backbone router (as at September 2020).

38255

Technical Manual | Wireless communication 13

Page 14

ISA100 WirelessTM basics

1 2

3.1.5.1 Routers

Routers are also called repeaters. Routers increase the size of the network and

cancel out weak spots. They form a hop point in the sub-network. Incoming data is

forwarded without processing.

Routers do not establish their own sub-networks.

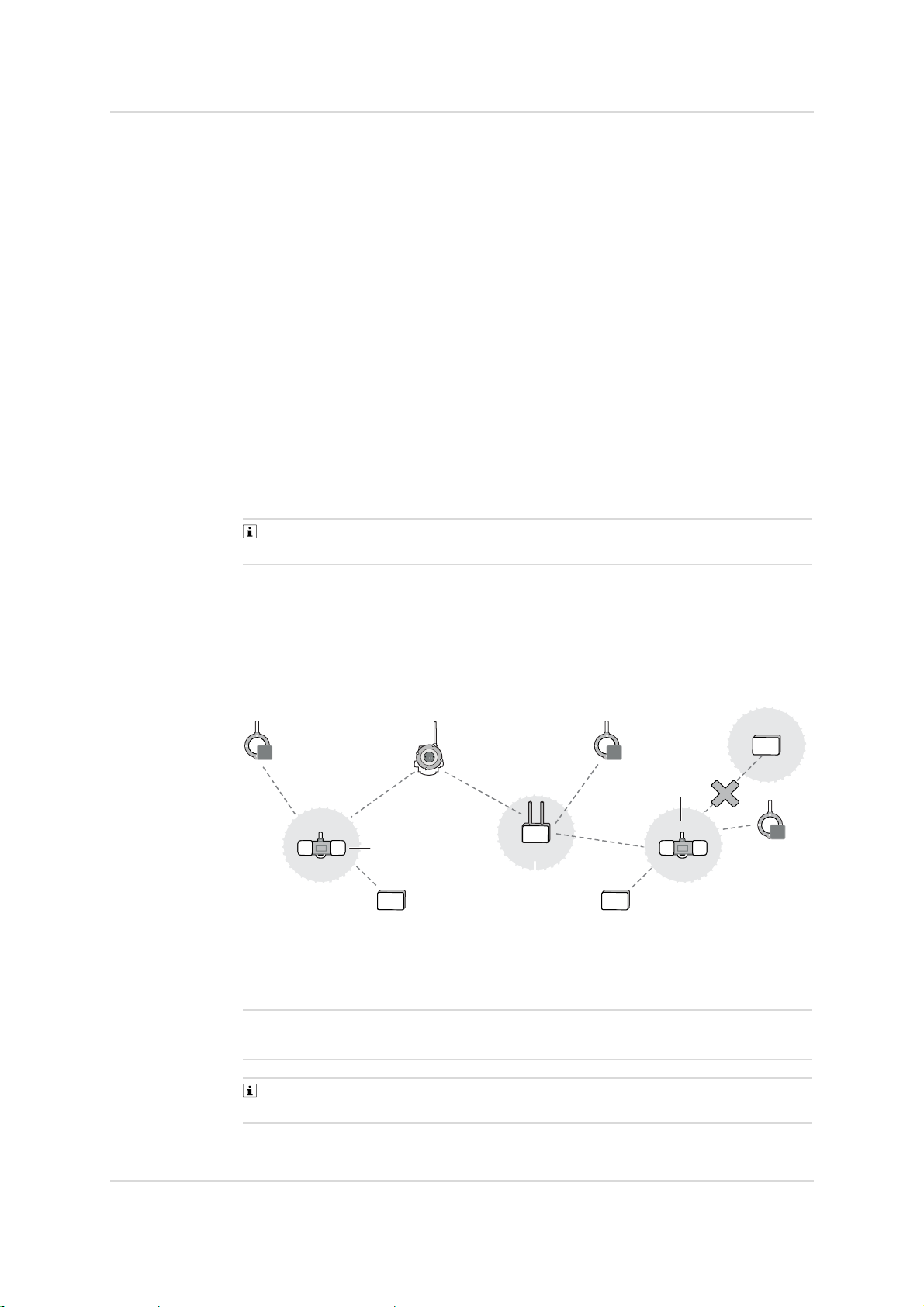

3.2 Network topologies

There are 3 network topologies for ISA100 networks.

– Star topology

– Mesh topology

– Partial mesh topology

3.2.1 Star topology

In a star topology, field devices communicate with one or more access points. The

field devices can only exchange information via access points, not directly with one

another. Multiple access points are often employed to make the network more failsafe.

Fig. 4 Star topology and communication channels

1 Primary communication channel

2 Secondary communication channel

40935

14 Technical Manual | Wireless communication

Page 15

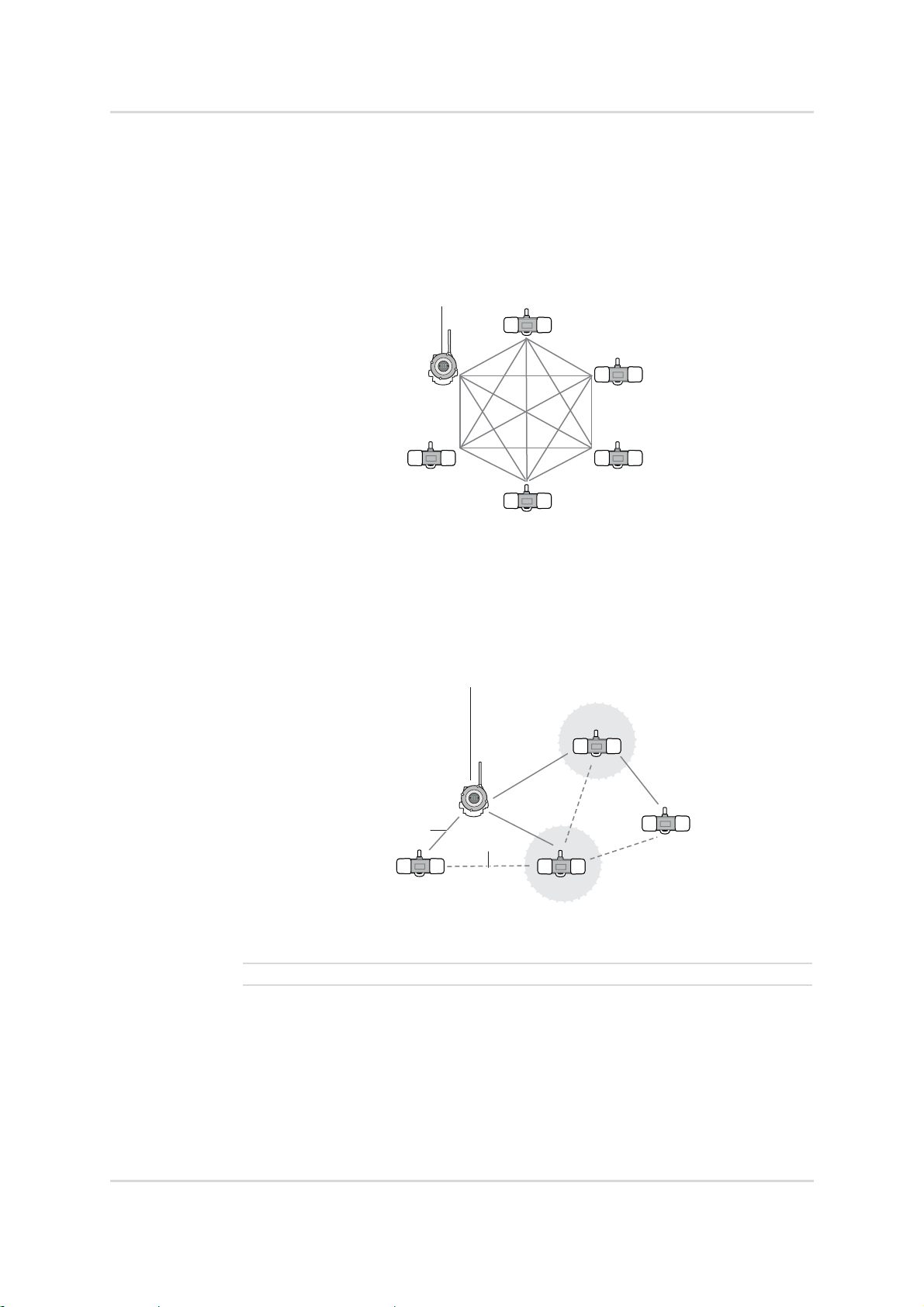

3.2.2 Mesh topology

In a mesh topology, all network participants that are within range communicate with

one another. Field devices, routers and access points can be network participants.

In a mesh network, the data transmission is redundant. If communication over a

field device or a repeater is interrupted, the data is transmitted via other network

participants.

Fig. 5 Mesh topology

ISA100 WirelessTM basics

4093640937

3.2.2.1 Partial mesh topology

The mesh topology and star topology can be mixed. This combination is called a

partial mesh topology or star-mesh topology. In this topology, a core network, in

which all network participants are interconnected, is expanded with network

participants that are no longer connected with all network participants.

Fig. 6 Partial mesh topology

1 Preferred communication channel

2 Redundant communication channel

1

2

Technical Manual | Wireless communication 15

Page 16

ISA100 WirelessTM basics

3.2.3 Comparison of star topology and mesh topology

Network cards are best compared by using the most important criteria for networks:

Reliability and latency.

Reliability

In a mesh network, network participants exchange information with each other (IoT

approach). If one network participant fails, communication is still possible. If a

network participant fails in a star topology, communication can fail.

Latencies

The latency of star topologies is usually less than that of meshed ones due to the

field devices being directly connected to an access point.

3.3 Network performance and network configuration

The wireless connection between field devices and the access point depends

greatly on the surroundings. The connection is best when there is an unobstructed

line of sight between the two. Oftentimes, however, there is no line of sight (due to

intervening pipes or walls, for example). If the line of sight is obstructed, routers or

the reflective properties of the obstacles themselves are used.

3.3.1 Signal quality

The signal quality of wireless transmissions depends on the signal strength (RSSI)

and the signal integrity (PER or TxFail rate). The RSQI range is another indicator of

signal quality.

PER or TxFail rate

This value represents the error rate during data transmission from the field device

to the backbone. This value is displayed as a percentage. The lower the value, the

better the integrity of data transmission. High values show poor data transmission

integrity. Poor data integrity can be caused by unfavorable communication paths or

interferences (other wireless technologies or obstacles, for example).

The expression and the limit values of this error rate depend on the manufacturer of

the system manager. The error rate can be expressed either as PER (packet error

rate) or as a TxFail rate.

RSSI

RSSI (received signal strength indication) shows the received signal strength

between the field device and the access point. RSSI is expressed in dBm (decibelmilliwatts). The received signal strength is always shown as a negative number.

The closer the value is to zero, the better the wireless connection.

RSQI

RSQI (received signal qualitiy indication) shows the received signal strength

between the field device and the access point. RSQI is a calculated value. Higher

values indicate better data transmission than lower values. Four quality classes are

defined in the standard ISA-100.11a (see table below).

16 Technical Manual | Wireless communication

Page 17

ISA100 WirelessTM basics

P6 P6

Signal quality values and their meaning

The interpretation of the value ranges can be adjusted in some system managers.

The following table provides an example of the ranges for the purpose of

orientation.

Indicator Value range Meaning

PER / TxFail rate 0 to 15 % Good

15 to 100 % High

RSSI -75 to -25 dBm Good

-85 to -75 dBm Acceptable

-100 to -85 dBm Poor

RSQI 196 to 255 Excellent

128 to 195 Good

64 to 127 Acceptable

0 to 63 Poor

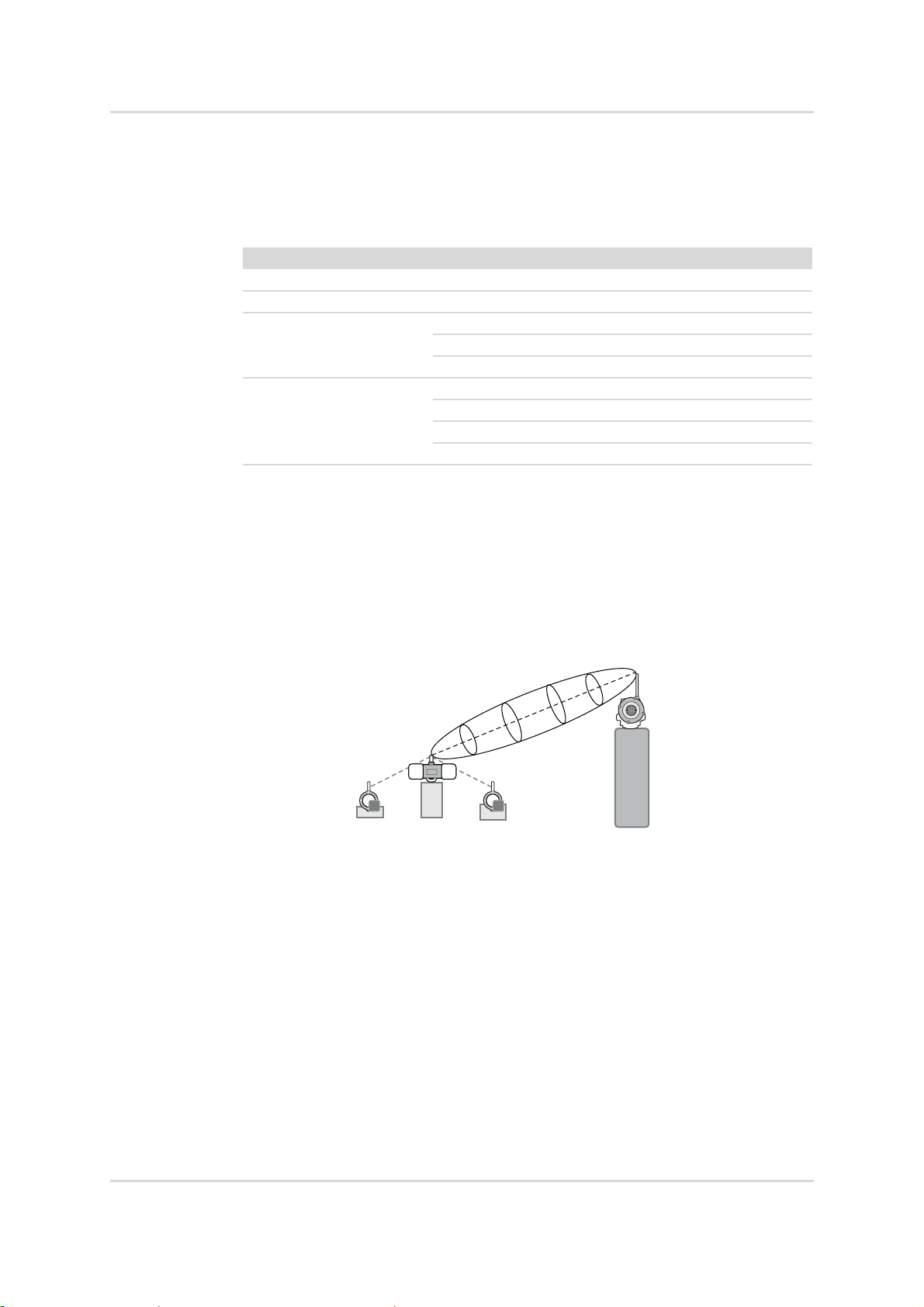

Fresnel zone

Signal quality can be disrupted by obstacles even if transmitter and receiver have

line of sight. Disruption due to obstacles occurs when obstacles are located in the

Fresnel zone. The Fresnel zone is an elliptical area formed around the line of sight,

whose diameter increases with the transmission range. It is therefore

recommended to install antennas as high up as possible to ensure longer distances

are covered.

Fig. 7 Line of sight between field device and access point with an elliptical

Fresnel zone

38862

Technical Manual | Wireless communication 17

Page 18

ISA100 WirelessTM basics

1

2

3

P6

Reflections

Metallic objects and structures can reflect radio waves. If line of sight is obstructed,

this effect can be utilized.

Fig. 8 Alternate communication paths via reflective objects

1 Preferred communication path (Primary-Path)

2 Alternate communication path via reflection ensured.

3 Obstructed, direct communication path (Line-Of-Sight)

38868

3.3.2 Network coverage

It can occur that network coverage is weaker in some areas. Weak spots such as

these are usually due to structural conditions. The routers (repeaters) and field

devices with hop point functionality are used to balance weak spots in network

coverage.

Remote antennas are another possible way to alleviate weak spots. The antenna is

positioned in a spot with good network coverage. The antenna is then connected

via cable with the gas warning device. The gas warning device can then be installed

in the area where it is required without negatively affecting communication.

Site survey (Site-Survey)

To determine the network coverage at the installation area of the gas warning

device, a site survey (measurement and analysis of the site) can be conducted in

advance.

The site survey generally involves the creation of a heat map. The heat map is a

presentation of the site, which marks the quality of the network coverage in color.

18 Technical Manual | Wireless communication

Page 19

Network size and range

The range depends on the sources of interference (e.g. building development),

infrastructure used and thus differs from location to location. The following table

shows the typical ranges for three sample environments.

Environment Example Range [m]

Free field

No sources of interference

Environment with few

sources of interference

Environment with many

sources of interference

3.3.3 Sub-networks

Sub-networks are smaller networks which together form the main network. Subnetworks are established by access points.

ISA100 Wireless

theoretically contain up to 2

practice for various reasons (e.g. flexibility for extensions and stability), addresses

still need to be assigned to the field devices at the sub-network level. Every field

device is assigned a 16 bit address on the sub-network level. On the main network

level, the 16 bit address is increased to 128 bits.

ISA100 WirelessTM basics

Fuel depot 500

Refinery (few buildings

200

and plants)

Oil platform 50

TM

allows for many sub-networks. Every sub-network can

16

field devices. While this possibility is not utilized in

For data transmission between sub-networks, the data packets are sent to the

backbone router. The BBR forwards the data packets to the target sub-network.

Communication between sub-networks is not yet provided for gas detection

applications. These applications send sub-network data packets only to the

backbone. Exchanging data between sub-networks is not yet implemented.

P6

P6

P6P6

40972

Fig. 9 Sub-networks are established by various network participants.

Technical Manual | Wireless communication 19

Page 20

ISA100 WirelessTM basics

3.3.4 Sky mesh

Field device access points are installed above field devices and establish their own

sub-networks. FDAPs then communicate wirelessly with the access point or the

backbone router. The field devices can utilize the reflective properties of the

surrounding objects for communications to the FDAP. The FDAP itself

communicates via line of sight with the access point.

The line of sight’s Fresnel zone should not be obstructed by structures (cranes or

masts, for example).

38326

P6P6

Fig. 10 Sub-networks are established by access points at a higher altitude.

3.3.5 Network configuration with retrofitted field devices

Field devices not actually designed for wireless communication can be retrofitted

with antennas. The antenna contains a ISA100 Wireless

integrated into the network as a wireless field device.

The ISA100 Wireless

device’s signals to the ISA100 Wireless

TM

module is connected to a converter that converts the field

TM

protocol. The field device’s signals can

be digital signals (RS485 Modbus, HART) or analog 4–20 mA signals. The

universal commands are supported bidirectionally for digital signals. Analog 4–

20 mA signals have to follow the NAMUR NE43 recommendation.

Some converters come equipped with built-in batteries for supplying connected

field devices with power.

TM

module. This module is

P6P6

20 Technical Manual | Wireless communication

Page 21

ISA100 WirelessTM basics

1

2

3

P8

Fig. 11 Retrofitted gas warning device (Dräger Polytron® 8xx0)

1

Antenna with ISA100 Wireless

2 Converter for digital or analog communication

3 Retrofitted field device that originally only communicates by wire

The following components from Yokogawa have been tested and approved by

Dräger as suitable field devices for retrofitting purposes (as at September 2020).

– FN110 Field Wireless Communication Module

ISA100 Wireless

TM

module (antenna)

– FN310 Field Wireless Multi-Protocol Module

Converter for digital communication (HART7 and RS485 Modbus)

– FN510 Field Wireless Multi-Function Module

Converter for analog communication (4–20 mA)

TM

module

42275

3.3.6 Network configuration for small networks

For small networks, solutions are available that combine access point and system

manager in one component. This solution saves steps during network configuration,

but is less effective than conventional installations.

2

1

P6

Fig. 12 Small network with system manager and backbone router in one

component

1

Antenna with ISA100 Wireless

TM

module that combines system manager and

backbone router

2 Interface adapter

3 Control unit

3

42273

Technical Manual | Wireless communication 21

Page 22

ISA100 WirelessTM basics

The following components from Yokogawa have been tested and approved by

Dräger for small networks (as at September 2020).

– FN110 Field Wireless Communication Module

ISA100 Wireless

TM

module (antenna)

– LN90 Interface Adapter

Interface adapter between the FN110 and the control unit

FN110 field wireless communication module

An FN110 consists of an antenna and an ISA100 Wireless

TM

connected to an interface adapter (LN90) which establishes the connection to a

controller via Modbus RTU.

The FN110 can only establish 1 sub-network. Field devices in this sub-network can

only be configured in star topology. Depending on the network’s refresh rate, 10 to

20 field devices can be integrated. SIL2 communication is not possible.

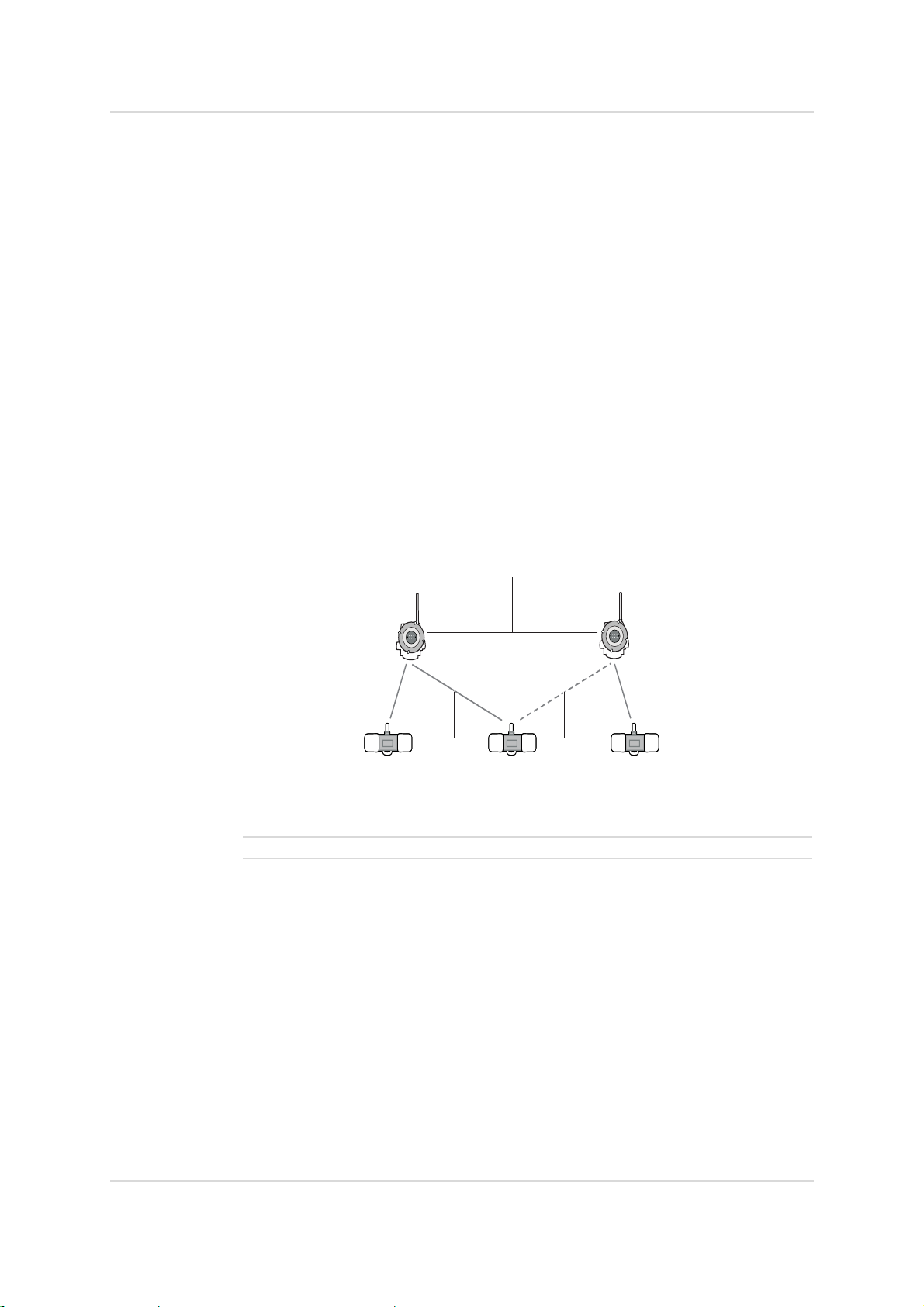

3.3.7 Network configuration with long backbone lines

The use of Ethernet cables limits the length of backbone lines to approx. 100 m. If

backbone lines need to cover long distances, the Ethernet lines can be expanded

with other transmission technologies.

– Fiber-optic cables (FOC)

To use fiber-optic cables, a converter between the backbone and the system

manager must be installed. The converter converts the signals of the fiber-optic

cable to signals for Ethernet cables (conversion between 100BASE-TX and

100BASE-FX).

– Copper cables for DSL transmission

To be able to use DSL, modems must be installed at the transfer point from the

Ethernet to the copper cables.

module. The FN110 is

Long backbone with fiber-optic cable

1

2 3

Fig. 13 Long backbone with fiber-optic cable

1 Backbone as fiber-optic cable (100BASE-FX)

2Converter

3 Backbone as Ethernet cable (100BASE-TX)

42274

22 Technical Manual | Wireless communication

Page 23

ISA100 WirelessTM basics

1

2

1

2

3

The following components from Yokogawa have been tested and approved by

Dräger for conversion between fiber-optic and Ethernet cables (as at September

2020).

– Field Wireless Media Converter (YFGW610)

Long backbone with DSL transmission

Fig. 14 Long backbone with DSL modem

43001

1 Backbone as Ethernet cable (100BASE-TX)

2DSL modem

3

Backbone as copper cable (e.g. BFOU 2x2x1.5 mm

2

)

The following components from Phoenix Contact have been tested and approved

by Dräger for conversion between Ethernet and copper cables (as at September

2018).

– TC EXTENDER 2001 ETH-2S

– TC EXTENDER 6004 ETH-2S

Technical Manual | Wireless communication 23

Page 24

ISA100 WirelessTM basics

1

2 3

3.3.8 Network configuration with a 4–20 mA control unit

The signal output of the system manager is digital (Modbus, for example). To be

able to use analog 4–20 mA link cards of control units, a digital-to-analog converter

must be inserted in between.

Fig. 15 Network configuration with a 4–20 mA control unit

1 System manager with digital signal output

2 Digital-to-analog converter

3 Control unit with 4–20 mA link card

42284

The following Phoenix Contact component has been tested and approved by

Dräger for converting the system manager’s digital signals to an analog 4-20 mA

signal to the controller (as at September 2018).

– ILC 131 ELH / IB IL AO 2UI-PAC

24 Technical Manual | Wireless communication

Page 25

ISA100 WirelessTM data transmission basics

4 ISA100 WirelessTM data transmission basics

The requirements for data transmission via wireless network in industrial settings

differ greatly from those for WLAN networks. In WLAN networks, the loss or delay

of data packets usually "only" leads to user frustration. In an industrial network,

however, this can lead to processes being halted or to injuries or material damage.

To ensure secure data transmission, the frequency spectrum and communication

paths are continuously monitored.

Communication paths are the paths the data packets follow through the network.

Monitoring is done via the field devices’ performance data.

Various mechanisms are executed based on this performance data.

– Time-Division-Multiple-Access (TDMA) (deterministic transmission and time

diversity)

– Clear-Channel-Assessment (CCA) (collision avoidance)

– Path-Diversity, Graph-Routing (different communication paths)

– Automatic-Repeat-reQuest (ARQ) (data packet acknowledgment)

– Blacklisting, Adaptive-Hopping (frequency spectrum management)

Every mechanism contributes to the error-free transmission of data within a defined

time period.

For this, every mechanism fulfills at least one of the 3 data integrity requirements.

– Latency

Data must reach the recipient without undue delay.

– Convergence

Data must remain complete and unaltered on its way to the recipient.

– Deterministics

Data must reach the recipient within the predetermined time.

4.1 Frequency band and bandwidth

Radio channel and frequency

A radio channel is a frequency range for data transmission. The wider the

frequency range, the more data can be transmitted.

The distance between radio channels and the width of the frequency range

(bandwidth) are defined. These channel characteristics are also known as the

channel spacing.

ISA100 Wireless

The bandwidth of a radio channel is 2 MHz. The distance between 2 radio channels

(distance from center of one radio channel to center of the next radio channel) is

5MHz.

ISA100 Wireless

standard 802.15.4 (channels 11-26). This frequency band can be used world-wide

with no license needed.

TM

channel spacing

TM

uses the 2.4 GHz ISM frequency band according to IEEE

Technical Manual | Wireless communication 25

Page 26

ISA100 WirelessTM data transmission basics

25 MHz

22 MHz

11

12

13 14 15

16

17

18 19 20

21

22

23 24 25

26

2 MHz5 MHz

WLAN channel 11

WLAN channel 6

WLAN channel 1

2425 MHz 2450 MHz 2475 MHz

Spectrum

ISA100

Channels

ISA100 WirelessTM shares this frequency band with channels defined for WLAN

transmission. Channels 1, 6 and 11 partially overlap with the wireless channels of

the ISA100 Wireless

Wireless

TM

channel spacing are not overlapped.

TM

channel spacing. Channels 15, 20, 25 and 26 of the ISA100

Fig. 16 ISA100 Wireless

4.2 Data integrity

TM

channel spacing and frequency band with overlapping

44320

4.2.1 Frequency hopping

When frequency hopping, the field devices change the frequency. Poor

performance data may make a change of frequency necessary. If the is the case,

an ARQ is executed.

Frequency changes follow the predefined hopping scheme (Patterns). This

sequence is assigned during provisioning of the field device.

4.2.2 Hopping patterns

Hopping patterns determine on which channels transmission and reception take

place in a time slot. Duration and sequence are predetermined.

TM

defines 3 hopping patterns.

ISA100 Wireless

Slotted hopping

Data is transmitted once on every channel in a time slot. This way, a relatively large

amount of time passes before transmission and reception occurs again on a

channel.

Slotted hopping is suitable for regular data that is transmitted synchronously. It is

therefore not suitable for event-based transmissions (alarms, for example). Field

devices wait to transmit and receive data until their channel’s turn. The time window

for this is relatively small.

Slow hopping

Transmission and reception can occur on every channel for the duration of exactly

one time slot. Slow hopping is therefore better suited for event-based transmissions

that must be sent immediately. However, the energy consumption of a field device

is increased due to the device having to wait for incoming messages for a longer

time.

26 Technical Manual | Wireless communication

Page 27

ISA100 WirelessTM data transmission basics

time

Timeslot 1

Channel

12

11

13

14

15

16

Timeslot 2

Hybrid Hopping

Slotted Hopping Slow Hopping

11

12

13

14

Channel

15

16

Timeslot 1

Timeslot 2 Timeslot 1 Timeslot 2

time

Fig. 17 Comparison of slotted hopping and slow hopping

Hybrid hopping

Hybrid hopping combines the advantages of slotted and slow hopping. The

combination of slow and slotted hopping is configurable. This way, planned

transmissions can be performed in small time slots and unplanned transmissions

can be performed on another channel that has a longer time slot available.

For further information see: "Time-Division-Multiple-Access (TDMA)", page 28.

3892138923

Fig. 18 Hybrid hopping

4.2.3 Standard hopping pattern

ISA100 WirelessTM defines 5 standard hopping patterns. A standard hopping

pattern defines the channel sequence. Every field device must support the pattern.

A 19, 12, 20, 24, 16, 23, 18, 25, 14, 21, 11, 15, 22, 17, 23, 26 (optional)

B Reverse order of A

C 3, 15, 20, 25

D Reverse order of C

E 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26 (optional)

Technical Manual | Wireless communication 27

Page 28

ISA100 WirelessTM data transmission basics

4.2.4 Duo-Cast

Duo-Cast (dual transmission) is the option of sending data packets to access points

via 2 communication paths simultaneously. The access points must be

synchronized for this. When Duo-Cast is active, communication is only possible

with the synchronized access points. This creates a star topology. Other topologies

(mesh, partial mesh) are excluded.

Fig. 19 Communication between field devices is not possible with duo-cast.

38254

Duo-Cast is configured in the system manager during Provisioning. Some

system manager user interfaces allow for setting Duo-Cast and mesh topologies.

However, these settings cannot be downloaded to the system manager.

4.2.5 Time-Division-Multiple-Access (TDMA)

Time-Division-Multiple-Access defines the time slot in which messages can be sent

and received on certain channels. The time slot duration can be set variably. It can

be between 10 and 12 ms.

The variable duration enables the close timing of many short transmissions.

To send a number of status messages from different field devices as a bundle (from

a router/access point to the backbone), a time slot with a longer duration is suitable.

4.2.6 Clear channel assessment (CCA)

Clear channel assessment is performed by a field device before sending data

packets. The field device checks whether the channel is free. If the channel is not

free, the field device waits a set amount of time (generally several milliseconds)

before attempting to send the data packet again.

4.2.7 Automatic-Repeat-reQuest (ARQ)

Automatic repeat request enables sending unacknowledged data packets on

another radio channel and via a different communication path.

Each received data packet must be acknowledged by the receiving participant

within a set amount of time.

28 Technical Manual | Wireless communication

Page 29

ISA100 WirelessTM data transmission basics

Time slot 1

11

12

13

14

Channel

15

16

Fig. 20 Repeat transmission via another channel

4.2.8 Blacklisting

Blacklisting is the exclusion of channels by the system manager. The system

manager excludes channels based on performance data sent by the field devices.

Other radio technologies can be the source of poor performance data. Field devices

avoid these excluded channels during frequency hopping.

Manual blacklisting

Wireless channels can also be blocked manually in the system manager. When the

settings have been performed in the system manager, the system manager

distributes the information in the network. The network participants are updated.

ARQ

Time slot 2

38939

Time

4.2.9 Adaptive hopping

Adaptive-Hopping is very similar to Blacklisting. As with Blacklisting, the

performance data is used to decide whether an action is performed. An action in

this case is the switch to another channel. In contrast to Blacklisting, the field device

itself decides this. This enables the field device to adjust itself independently to the

frequency spectrum without depending on the system manager.

Adaptive hopping is activated by default.

4.2.10 Path diversity

Path diversity continuously adjusts redundant communication paths. This

adjustment is made based on the collected performance data.

Redundant paths are established by the network itself. Users do not have to take

action.

Routing and Forwarding contribute to path diversity.

Forwarding

Forwarding is oftentimes also called Routing. Forwarding, however, is the decisionmaking process of a network participant on which communication path the data

packets are forwarded over.

Technical Manual | Wireless communication 29

Page 30

ISA100 WirelessTM data transmission basics

Routing

Data packets take different communication paths. The routing is the way specified

by the system manager.

Routing is possible in different ways. For further information see: "Types of

routing", page 30.

4.2.11 Types of routing

Routings are predefined communication paths for data packets. The predefined

communication paths can be implemented in various ways.

Graph routing

In graph routing, all possible communication paths in the network are loaded onto

each participant in the form of a routing table. When a data packet is sent, the

sending participant writes the identification of the communication path in the

packet’s header. The next participant compares the identification with the routing

table and forwards the packet.

Source routing

In source routing, the entire communication path is integrated into the data packet.

Every network participant forwards the packet to the node specified in the data

packet itself.

4.3 Data structure

Object-oriented data model

The ISA100 Wireless

describe and distinguish components and tasks of the real world in objects. Objects

are an abstract representation of a specific device component or field device task.

The following task is an example of an object: methane concentration monitoring.

The object must have at least one field for the current measured value data. For the

measured value, Dräger uses the Process value "PV" of the ISA100 Wireless

protocol.

ISA100 Wireless

contain optional standard objects or manufacturer-specific objects.

An example of a manufacturer-specific object is the object for the PROFIsafe

communication (Custom_(“SafeData”)). Observe the following information: "UAP,

objects, attributes and parameters using the example of the GS01 in the Yokogawa

YFGW 410 configurator (as at July 2018)", page 33.

TM

defines obligatory standard objects. In addition, devices can

TM

protocol is object-oriented. Object-oriented models

TM

®

30 Technical Manual | Wireless communication

Page 31

4.3.1 Data fields

ISA100 WirelessTM data transmission basics

Regardless of their status as either standard or manufacturer-specific objects,

objects always contain data fields for alarms, methods

1)

and attributes. Depending

on the command, these are either read, written, triggered, stopped or

acknowledged.

Methods

Methods are actions the corresponding device performs. Examples of methods are

sensor adjustments or firmware updates.

Attributes

Attributes are device values (sensor temperature, for example) or measured

values. ISA100 Wireless

TM

defines 5 classes of attributes (see "Attribute classes",

page 34).

Alarms

Alarms can be set in addition to attributes. They are provided via the "alert reporting

management object" (ARMO).

In order to be more flexible and to reduce complexity, Dräger gas warning devices

do not support the function via ARMO. Measured values are provided as process

values (PV). The user can edit the corresponding alarm values at the control unit.

Editing at the controller is more flexible than via the ISA100 Wireless

TM

protocol at

the gas warning device.

Parameters

The combination of object identifier and an object’s attribute, method or alarm is

called a parameter. The parameter for monitoring the methane concentration would

therefore be: AI_01("METHANE").PV.

AI stands for Analog Input

PV stands for Process Value

Failsafe parameters

For failsafe data transmission (e.g. via PROFIsafe

®

), manufacturer-specific objects

are available in addition to the standard objects. The parameters of the

manufacturer-specific objects are named as "SafeData" with the corresponding

attribute (Custom_00("SafeData").Attribut2(12), for example).

1) Also known as routines or operations.

Technical Manual | Wireless communication 31

Page 32

ISA100 WirelessTM data transmission basics

4.3.2 User application process (UAP)

A device’s objects can be found in the device software in the so-called User

Application Process (UAP). A device can have multiple UAPs. To ensure

compatibility with the system manager, Dräger gas warning devices only have one

UAP.

Every UAP contains a main object which indicates the status of the UAP. Aside from

the status, the main object also indicates the amount and types of the other objects

of the UAP. This main object is called the User Application Management Object

(UAPMO).

User application process n

User application process 1

UAPMO

UAP status

Objects

...

Object n

Object 1

Alarm

Method

Attribute

Fig. 21 UAP with UAPMO and corresponding objects

38824

32 Technical Manual | Wireless communication

Page 33

ISA100 WirelessTM data transmission basics

1

2

3

4

5

6

4.3.2.1 UAP and parameters in the Yokogawa YFGW 410 configurator

The following diagram uses the GS01 as an example to show the display of the

UAP, the corresponding objects, attributes and parameters in the configuration

screen of a system manager (Yokogawa YFGW410).

Here, the UAP with the corresponding UAPMO object and the other objects are

displayed.

38827

Fig. 22 UAP, objects, attributes and parameters using the example of the GS01 in

the Yokogawa YFGW 410 configurator (as at July 2018)

1 UAP with the UAPMO object, the gas concentration monitoring objects and a

Custom object named SafeData

2 Readable DIAG_Status attribute

3 Readable process value (PV) attribute for methane

4 Readable process value (PV) attribute for propane

5 Manufacturer-specific attributes

6 Readable parameters of the UAP02.

4.3.3 Object identifiers

In addition to their names, objects also have unique identifiers. Object identifiers are

16 bits long. They can be used for finding and uniquely identifying them in the

system manager.

UAPMO objects always have the identifier 1 (0x0001). Identifier 2 is reserved for

UDO objects (0x0002). UDO objects are upload/download objects. They are used

to transmit firmware updates.

Technical Manual | Wireless communication 33

Page 34

ISA100 WirelessTM data transmission basics

Dräger-specific object identifiers

In addition to UAPMO and UDO objects, gas warning devices also contain objects

with the following identifiers:

– 6 (0x0006) process value for methane

– 7 (0x0007) process value for propane

– 8 (0x0008) process value for EC sensor measuring gases (hydrogen sulfide, for

example)

4.3.4 Attribute classes

Constant

The values of these attributes must remain constant. If a device is disconnected

from the power supply, reset or rebooted, the values of these attributes must remain

unchanged (the serial number of a wireless node, for example).

Static

The values of these attributes rarely change. These values only change due to an

external trigger. A trigger can be a configuration tool, for example. The values of

these attributes should remain unchanged if a device is disconnected from the

power supply or rebooted (units or operating areas, for example).

Static-volatile

The values of these attributes can change when the device is disconnected from

the power supply or rebooted.

Dynamic

The values of these attributes can be changed by the field device itself. These

values do not have to remain unchanged when a device is disconnected from the

power supply or rebooted (process variables, timers or calculation results, for

example).

Non-bufferable

The values of these attributes may not be cached. These values must be queried

directly from the field device. These values may not be queried from the cache of a

network node (critical safety information, for example).

34 Technical Manual | Wireless communication

Page 35

ISA100 WirelessTM data transmission basics

4.3.5 Data format (without PROFIsafe® communication)

The DIAG_STATUS byte is 4 bytes long and contains information on device

performance and signal properties. The UAP parameters are 4+1 bytes long. Each

parameter includes a status byte that indicates the quality of the value.

Process Value 1, 5 bytes

PV

status

Byte

Process Value 2, 5 bytes

PV

status

Byte

PV

4 byte float

PV

4 byte float

DIAG_STATUS, 4 bytes

Diagnosis info

Not Safety Related

41774

Fig. 23 Example process value data format

4.4 Traffic

ISA100 WirelessTM defines 3 data transmission methods

– Unidirectional, buffered data

– Unidirectional, queued data

– Bidirectional, queued data

Dräger only uses 1:1 data transmission between field devices and the system

manager or F-host. This includes data transmissions via hop points. This data

transmission method is known as client-server service and uses bidirectional,

queued data.

UAP

UAPMO

DIAG_STATUS

AI METHANE

PV

AI PROPANE

PV

Technical Manual | Wireless communication 35

Page 36

ISA100 WirelessTM data transmission basics

UAP

DIAG_STATUS

UAPMO

AI METHANE

AI PROPANE

PV

PV

4.4.1 Data query

UAP data and field device performance are queried cyclically.

The UAP data contains the field device’s parameters (process value for methane

concentration, for example). Each of these parameters returns a value which

provides information on the attribute quality. This value is known as a status byte.

The field device performance contains information on the field device’s status and

signal properties. This data is transmitted in the DIAG_STATUS attribute.

For further information see: "Data format (without PROFIsafe

page 35.

®

communication)",

40915

Fig. 24 Parameter with status byte and DIAG_STATUS attribute during system

manager transmission

4.4.2 Sampling rate and stale limit

Sampling rate

The sampling rate (publication period) determines the time intervals at which uplink

transmissions are sent by the gas warning device.

Stale limit

The stale limit, together with the sampling rate, determines the time slot within

which uplink transmissions from the gas warning device must arrive at the system

manager. If no uplink transmissions arrive within the time slot, the gas warning

device will be marked as not available.

The following formula illustrates the relationship between sampling rate, time slot

and stale limit.

Time slot = stale limit x sampling rate

36 Technical Manual | Wireless communication

Page 37

ISA100 WirelessTM data transmission basics

Example: Sampling rate and stale limit

The following example illustrates the relationship between stale limit, sampling rate

and the time slot after which the gas warning device will be marked as unavailable.

In this example, the failure of the gas warning device or a poor wireless interface

will be recognized after a time slot of 60 seconds.

Stale limit = 30

Sampling rate = 2 seconds

43009

2 s

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1 3 5 7 9 11 1315171921 23 25 2729

OK

60 s

Fig. 25 Relationship between the sampling rate and stale limit

Stale limit

NOK

Technical Manual | Wireless communication 37

Page 38

ISA100 WirelessTM data transmission basics

GAS!

1

2

Auswerteeinheit

System-Manager

4.4.3 Network and energy management with ISA100 wireless

communication

The wireless communication takes place between the field device and the system

manager. Field devices must transmit new sampling rate and stale limit data within

the time slot defined in the system manager. If new data does not arrive within the

predefined time limit, the field device in the system manager and in the controller

will be marked as unavailable.

The number of available time slots for the uplink transmission, i.e. from field device

to system manager, is determined by the sampling rate. If there is no internal alarm

condition, not all uplink time slots will be used (see illustration below). This mode of

operation saves energy. If there is an internal alarm condition, all uplink time slots

will be used to ensure quick communication. The relationship between available

time slots and time slots used in the absence of an alarm condition is described as

the publication factor. The threshold value for the internal alarm condition and the

publication factor are determined in the field device.

49320

Fig. 26 Relationship between time slots and alarm conditions

Blue Time slots for uplink transmissions

1 Time slots are not used because no alarm condition is present.

2 The presence of an alarm condition means all time slots will be used.

38 Technical Manual | Wireless communication

Page 39

ISA100 WirelessTM data transmission basics

4.4.4 Device performance information

Energy life

The battery status gives an estimate of the remaining operating time of the field

device. This status is also displayed as "Days Left".

Unit: Values greater than 0 specify the remaining operating time in months. If the

remaining operating times are only days, values smaller than zero are displayed.

Listen rate

Duration for which the field device can have its receiver switched on.

Unit: seconds or hours

Transmit rate

Duration for which the field device can have its transmitter switched on.

Unit: data packets or minutes

Advertisement rate

Duration for which the field device can transmit Advertisements. Field devices that

support OTA send Advertisements. For further information see: "Over the air

provisioning (OTA)", page 48.

Unit: Advertisements or minutes

Technical Manual | Wireless communication 39

Page 40

Transmission basics for PROFIsafe® communication

P6

P6

P6

P6

5

3

1

2

4

5 Transmission basics for PROFIsafe®

communication

With PROFIsafe® communication, failsafe field devices (F-slave) and failsafe

controllers (F-host) communicate directly with each other. The infrastructure (e.g.

system manager) only forwards the data.

The PROFIsafe

Wireless

TM

follow the specifications described in this document (e.g. requirements from 4).

®

communication takes place in the black channel of the ISA100

communication. Communication via ISA100 WirelessTM continues to

38256

Fig. 27 PROFIsafe

®

communication between gas warning device (F-slave) and

controller (F-host)

1

2

3

Wireless standard communication via ISA100 Wireless

PROFIsafe

PROFIsafe

4 Field device (hop point) that forwards the tunneled message without

processing.

5

The PROFIsafe

Controller for interpreting the PROFIsafe

®

protocol allows for the use of a failsafe network for safety-oriented

applications according to the following standards:

– SIL 3 (IEC 61508 / IEC 62061)

– Safety category 4 (EN 954-1)

– PL "e" (ISO 13849-1)

5.1 Black channel principle

The black channel principle enables the exchange of system- and safety-relevant

data over the same network (Physical Layer). System-relevant data in this case can

be the sensor vitality or adjustment interval status, etc. Safety-relevant data

comprises error messages, alarm acknowledgments and pre- and main alarms.

TM

®

in black channel via ISA100 WirelessTM protocol

®

in black channel via PROFINET protocol

®

signals

protocol

40 Technical Manual | Wireless communication

Page 41

Transmission basics for PROFIsafe® communication

PROFIsafe PROFIsafe

ISA100 Wireless Standard

PROFINET

Safety-relevant data is only evaluated by the corresponding F-slave and the F-host.

All other network participants such as hop points, access points, or system

managers are considered transparent.

38376

Fig. 28 PROFIsafe

®

communication

5.2 Data integrity for PROFIsafe® communication

The following measures and parameters guarantee the integrity of the data

exchanged between F-host and F-slave in the black channel.

– Signal of life

Data packages must be sent sequentially. A sequential number counter in the Fhost and F-slave ensures this is the case.

– Watchdog

Received data packets must be acknowledged.

– Safe address

Transmitter and receiver must have a unique identifier.

– Time stamped security

A timeout counter always starts when the transmission of a data package

begins. The data package will only be accepted if it is received within a

predefined “WD_timeout” time limit. F-host and F-slave have their own counters

and a time stamp for uplink and downlink transmission.

– Cyclic redundancy check - CRC (cyclic block check)

Data completeness and consistency are checked.

In addition to completeness and consistency of the data, whether configuration

of the F-slave has changed is also verified. The CRC contains a parameter

which provides information about the configuration of the F-slave. This

parameter is transmitted to the F-host with the network integration of the F-slave

and synchronized during data exchange. If configuration of the F-slave changes,

the parameters specified during network integration and the transmitted

parameters are no longer identical. If the CRC parameters are not identical, an

SIL 2-compliant communication will no longer be possible.

Technical Manual | Wireless communication 41

Page 42

Transmission basics for PROFIsafe® communication

5.2.1 PROFIsafe® network constraints

– The maximum number of hop points connected in series must be observed for

short response times For further information see: "Hop points in a sub-network",

page 13.

– The IP addresses within a sub-network must be unique.

– If 2 sub-networks with the same IP address space are connected to one router,

that router must be a multi-port router.

5.3 Data structure

5.3.1 Data fields

In addition to the data fields for communication via ISA100 WirelessTM, further data

fields from the manufacturer-specific objects will be required for the PROFIsafe

communication.

Failsafe parameters

For failsafe data transmission (e.g. via PROFIsafe

are available in addition to the standard objects. The parameters of the

manufacturer-specific objects are named as "SafeData" with the corresponding

attribute (Custom_00("SafeData").Attribut2(12), for example).

®

), manufacturer-specific objects

®

42 Technical Manual | Wireless communication

Page 43

Transmission basics for PROFIsafe® communication

PROFIsafe

Empty

CRC

PROFI

status

PROFI

UAP

DIAG_STATUS

UAPMO

Custom SafeData

Attribute

Gas ReadingGas Reading

Uplink

PV

status

PV

4 byte float

Diagnosis info

Not Safety Related

Process Value, 5 bytes

DIAG_STATUS, 4 bytes

AI METHANE

PV

Downlink

PV

status

PV

4 byte float

PROFI

CRC

PROFIsafe, 9 bytes

PROFI

status

5.3.2 Data format for PROFIsafe® communication

In addition to standard data formats, manufacturer-specific custom parameters

(SafeData) are also transmitted during PROFIsafe

®

communication

41772

®

Fig. 29 Example PROFIsafe

process value data format

5.4 Traffic for PROFIsafe® communication

PROFIsafe® communication takes place between F-host and F-slave. F-slaves are

passive. They can only respond to messages from the F-host. When the F-host has

received the response, the next message is sent directly.

F-slaves must respond within a set time period. If there is no response within the

predefined time period, the F-slave is marked as unavailable in the control center.

Each message must be followed by a reply (one-to-one communication). The Fslave can only send data once a new message has been sent from the F-host.

Stale limit, sampling rate and publication factor for PROFIsafe

The settings for ISA100 WirelessTM communication for stale limit, sampling rate

(publication period) and publication factor are also valid during PROFIsafe

communication. For further information see: "ISA100 Wireless

basics", page 25.

®

®

TM

data transmission

Technical Manual | Wireless communication 43

Page 44

Transmission basics for PROFIsafe® communication

OK

? ? ?

NOK

?

?

? ?

GAS!

OK NOK NOK NOK

1

2

Auswerteeinheit

System-Manager

Uplink and downlink transmissions

Downlink transmission is the transmission of data from the F-host to the F-slave.

The F-slave responds with an uplink transmission.

Time slots for uplink and downlink transmissions

The sampling rates set in the system manager determine the available time slots for

the downlink transmission to the F-slave and the uplink transmission to the F-host.

The threshold value for the internal alarm status is set in the field device. If no alarm

condition is present, not all uplink time slots will be used. This mode of operation

saves energy. As the response to an F-host message is delayed until just before the

subsequent F-host message is expected, the field device is always prepared and

ready to immediately report an alarm.

If an alarm condition is present, the F-slave (field device) always reacts immediately

to the message from the F-host.

49316

Fig. 30 Relationship between transmissions and alarm conditions

Blue Time slots for downlink transmissions (direction F-slave) and uplink

transmissions (direction F-host)

1 Uplink time slots are not used because there is no alarm condition

present.

2 Because an alarm condition is present, the first available time slot is

used for uplink transmissions.

44 Technical Manual | Wireless communication

Page 45

Network integration (provisioning) of gas warning devices

6 Network integration (provisioning) of gas

warning devices

Gas warning devices can be integrated into networks in two ways.

– Network integration with a provisioning device "Out of band" (OOB)

In this case, a provisioning device reads out the gas warning device on-site and

sets values. The read-out data is then loaded into the system manager. A

provisioning device can be a handheld scanner or laptop with the corresponding

software, which communicates with the gas warning device via an infrared

interface, Bluetooth

– Wireless network integration "Over the air" (OTA)

In this case, the gas warning device joins an open (unsecured) provisioning subnetwork. The gas warning device is then transferred from this sub-network to the

operative sub-network.

During network integration, various settings and parameters are set for the gas

warning device and the device is integrated into the network. The settings are made

in the configuration software of the system manager. The configuration software is

called up in the browser of a computer (Microsoft Internet Explorer and Microsoft

Edge are currently suitable options).

®

, or wired adapter.

6.1 Network integration parameters

6.1.1 Modbus parameters

The parameters for the device status and process values are mapped to the

Modbus registers (16 bits) in the configuration software of the system manager.

Process values (PV) occupy 3 registers. The status byte of the process values

occupies the first 8 bits of the first register. The process value (32 bit floating point

number) is divided among the other two registers.

The device status in the DIAG_STATUS parameter is mapped to 2 registers.

Several gateways (e.g. Yokogawa) insert a status byte into the preceding register.

This gateway status byte is ignored as the content has already been provided by

the PV status byte.

6.1.2 PROFIsafe® traffic

PROFIsafe® parameters contain data for the parameterization and operation of

failsafe networks. The integrity of the data is verified by the receiver.

The following parameters are required for network integration.

– F-device address (safe address of the F-slave)

Unique address of a field device in the network for failsafe data transmission.

– F-host address (safe address of the host)

Unique address of the control unit in the network for failsafe data transmission.

– Watchdog timeout

The time [ms] that may elapse after sending a data packet is entered here (timestamped security).

–SIL

Contains the expected SIL.

Technical Manual | Wireless communication 45

Page 46

Network integration (provisioning) of gas warning devices

– iParameter CRC

The configuration of the F-slave defines the value of this parameter. The F-slave

parameter is stored in the F-host during network integration. For further

information see: "Data integrity for PROFIsafe

– With Dräger Polytron

Dräger PolySoft configuration software (Version 1.9.0 or later).

– With GasSecure GS01, possible values for this parameter can be found in

the GS01 and GS01-EA Safety Manual (Doc-ID 21440).

®

6100 EC WL, this parameter is read out using the

®

communication", page 41.

6.2 Out Of Band Provisioning (OOB, Yokogawa gateway

only)

A provisioning device is required for OOB. OOB communication devices include the

infrared adapter (e.g. Actisys ACT-IR224UN-LN96-LE), BLE (Bluetooth Low

Energy), and wired front ports (e.g. serial GS01 adapter). Various data and files are

required for the network integration of gas warning devices and provisioning

devices:

– Information on stale limit and sampling rate

– Capability file (CF file)

1)

for the gas warning device

These files contain information from the gas warning device. They can be

compared to drivers for devices connected to a computer.

– Provisioning file (.ypif file)

This file is created with the provisioning device that is connected to the field

device and contains the following information:

– Date and time of the provisioning file creation

–Join-Key

The join key is a 128-bit-long alphanumeric key which is synchronized during

network integration in the system manager.