Page 1

Technical Service Manual

Fabius GS

Inhalation Anesthesia Machine

Emergency Care • Perioperative Care • Critical Care • Perinatal Care • Home Care

Revision 3.0

5330.500

9036095

Because you care

Page 2

Page 3

Contents

General

1 Notes 3

1.1 Symbols and Definitions ......................................................................................................... 4

Function Description

1 General Information about the Fabius GS 7

2 Function diagram of Fabius GS 12

3 Battery backup 14

4 Fabius GS piping diagram 14

5 Function description of gas box 15

6 SORC (Sensitive Oxygen Ratio Controller) 16

7 Cosy 2 breathing system 18

7.1 Ventilation mode ................................................................................................................... 22

7.2 Function description: Manual ventilation .............................................................................. 23

7.3 Function description: Spontaneous breathing ...................................................................... 27

7.4 Function description: Volume/pressure control ventilation mode ......................................... 31

7.5 Cosy 2 absorber ................................................................................................................... 35

8 Ventilator 35

8.1 Safety valve .......................................................................................................................... 38

8.2 Auxiliary air valve ................................................................................................................. 38

9 Pneumatics 39

9.1 PEEP/Pmax valve control .................................................................................................... 39

9.2 APL bypass valve control ..................................................................................................... 40

All rights reserved. Copyright reserved.

K5330500IECIVZ.fm 10.11.05

I

Page 4

Contents

10 Electrical block diagram 41

11 Function description: Control PCB 41

12 Control panel assembly 42

13 FiO2 Measurement 44

14 Respiratory Flow Measurement 45

15 Gas flow rate measurement 46

16 Anesthetic vaporizer(s) 47

17 Leak test 49

17.1 System leak test ................................................................................................................... 49

17.2 Patient leak test .................................................................................................................... 49

Annex

Parts catalog

Technical Information

All rights reserved. Copyright reserved.

K5330500IECIVZ.fm 10.11.05

II

Page 5

General

1

Page 6

2

Page 7

Fabius GS General

1Notes This Technical Documentation conforms to the IEC 60601-1 standard.

Read each step in every procedure thoroughly before beginning any test.

Always use the proper tools and specified test equipment. If you deviate from

the instructions and/or recommendations in this Technical Documentation,

the equipment may operate improperly or unsafely, or the equipment could

be damaged.

Use only original Dräger parts and supplies.

The maintenance procedures described in this Technical Documentation may

be performed by qualified service personnel only. These maintenance

procedures do not replace inspections and servicing by the manufacturer.

The information in this manual is confidential and may not be disclosed to

third parties without the prior written consent of the manufacturer.

Strictly follow the Instructions for Use manual / Operating

Instructions! This Technical Documentation does not replace the

Instructions for Use manual / Operating Instructions. Any use of the

product requires full understanding and strict observation of the

product-specific Instructions for Use manual/ Operating Instructions.

Reference is hereby made to the observance of the relevant safety

provisions, for example in Germany, the Medical Product Law (MPG), the

Medical Device Operator Ordinance (MPBetreibV), the Pressure Container

Ordinance (Druckbehälterverordnung), the Technical Rules for Pressurized

Gases (Technische Regeln Druckgase), or the Occupational Health and

Safety Provisions (Unfallverhütungsvorschriften).

Unless otherwise stated, reference is made to laws, regulations or

standards (as amended) applicable in the Federal Republic of Germany.

Follow the laws and regulations applicable in your country.

Observe protection mark DIN 34. Copyright reserved.

Version 2.0_ Released_Printed on_10.11.05_K5330500_General.fm

5330.500

3

Page 8

General Fabius GS

1.1 Symbols and

Definitions

This symbol indicates a warning.

This symbol indicates tips and useful information.

This symbol is used to alert against unsafe practices when handling

electrostatic sensitive devices (ESD).

Definitions according to German standard DIN 31051:

Inspection = examination of actual condition

Maintenance = measures to maintain specified condition

Repair = measures to restore specified condition

Servicing = inspection, maintenance, and repair

Version 2.0_ Released_Printed on_10.11.05_K5330500_General.fm

Observe protection mark DIN 34. Copyright reserved.

4

5330.500

Page 9

Function Description

5

Page 10

6

Page 11

Fabius GS Function description

1 General Information

about the Fabius GS

The Fabius GS comprises the following assemblies:

– Display and Control Panel

– Flowmeter assembly

– Gas box: Gas Inlet Assembly and related items

– Breathing system

– Pneumatic assembly

– Ventilator

– Vaporizers

– Trolley

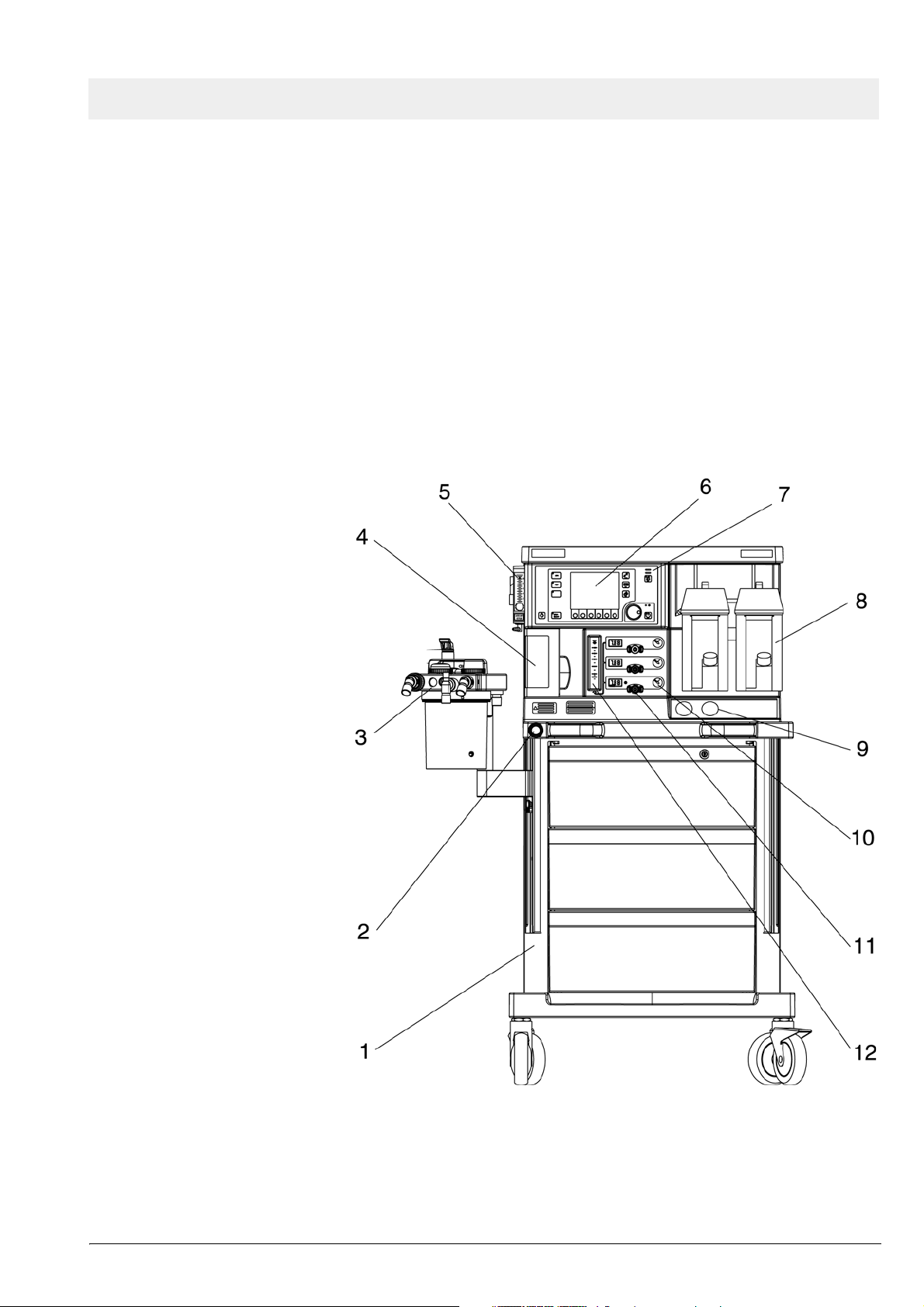

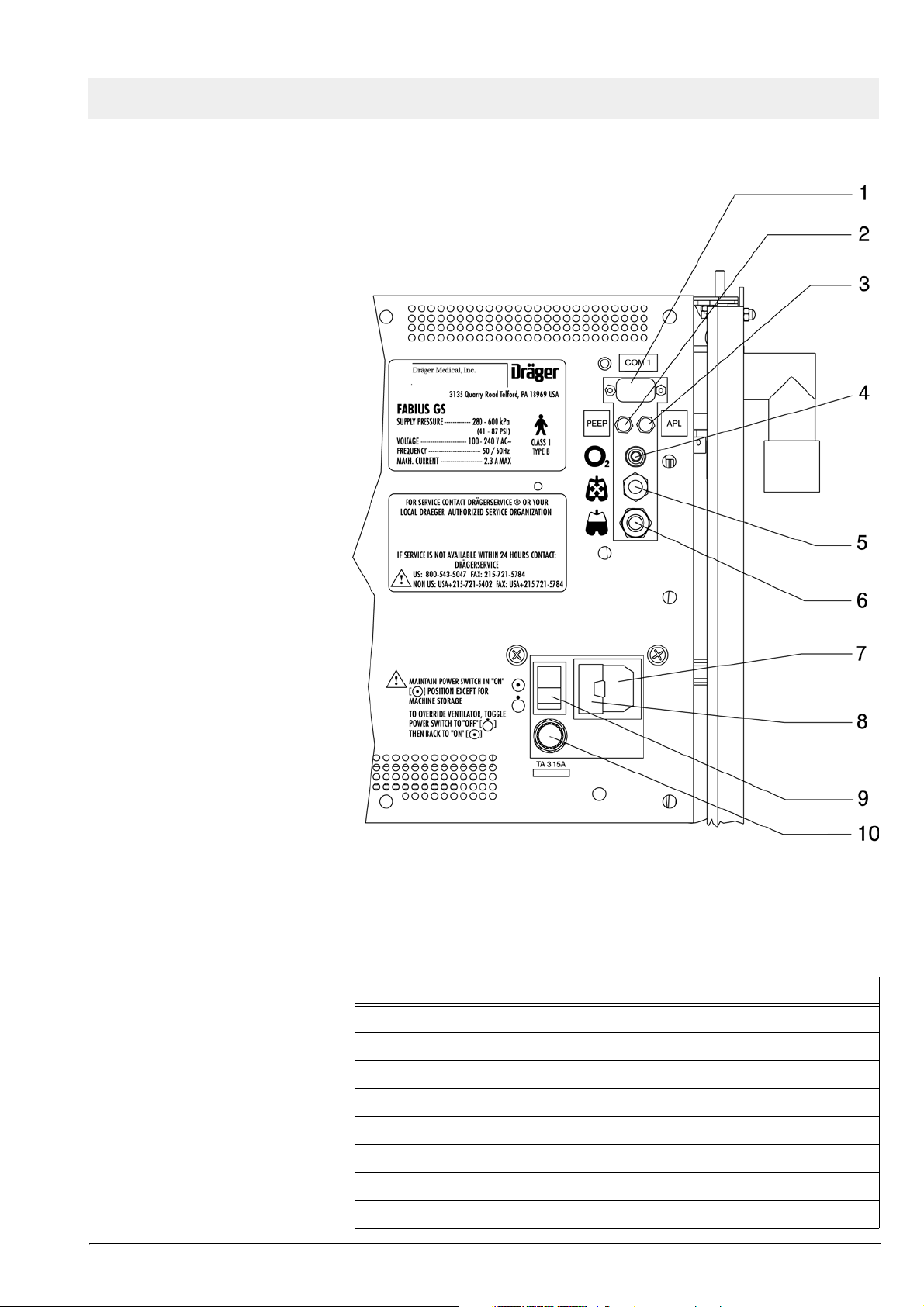

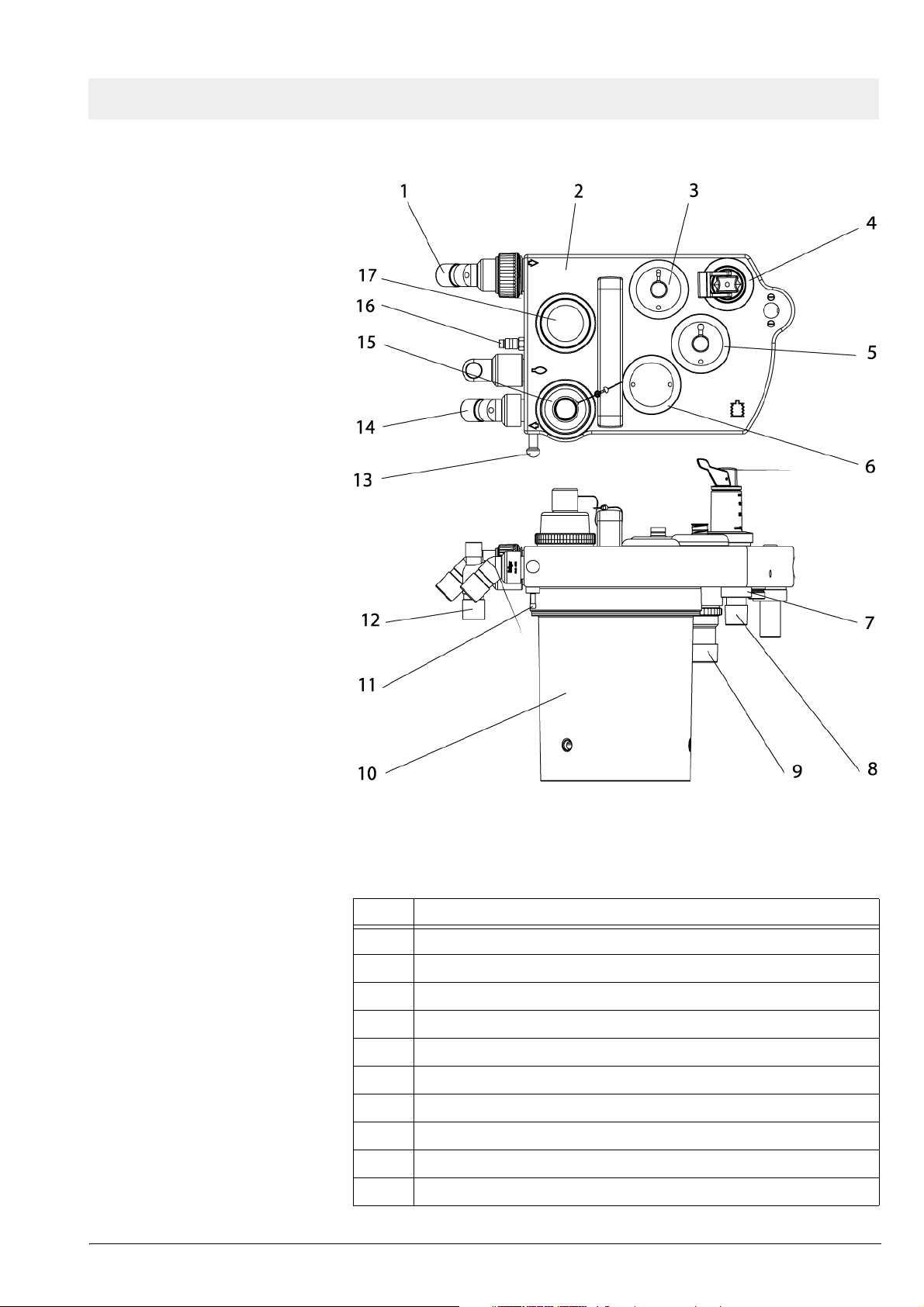

Monitoring, electrical connections and gas connections as shown in Figure 1,

Figure 2, Figure 3, and Figure 4.

Figure 1 Front view of Fabius GS anesthesia system, for legend see Table

1

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

7

Page 12

Function description Fabius GS

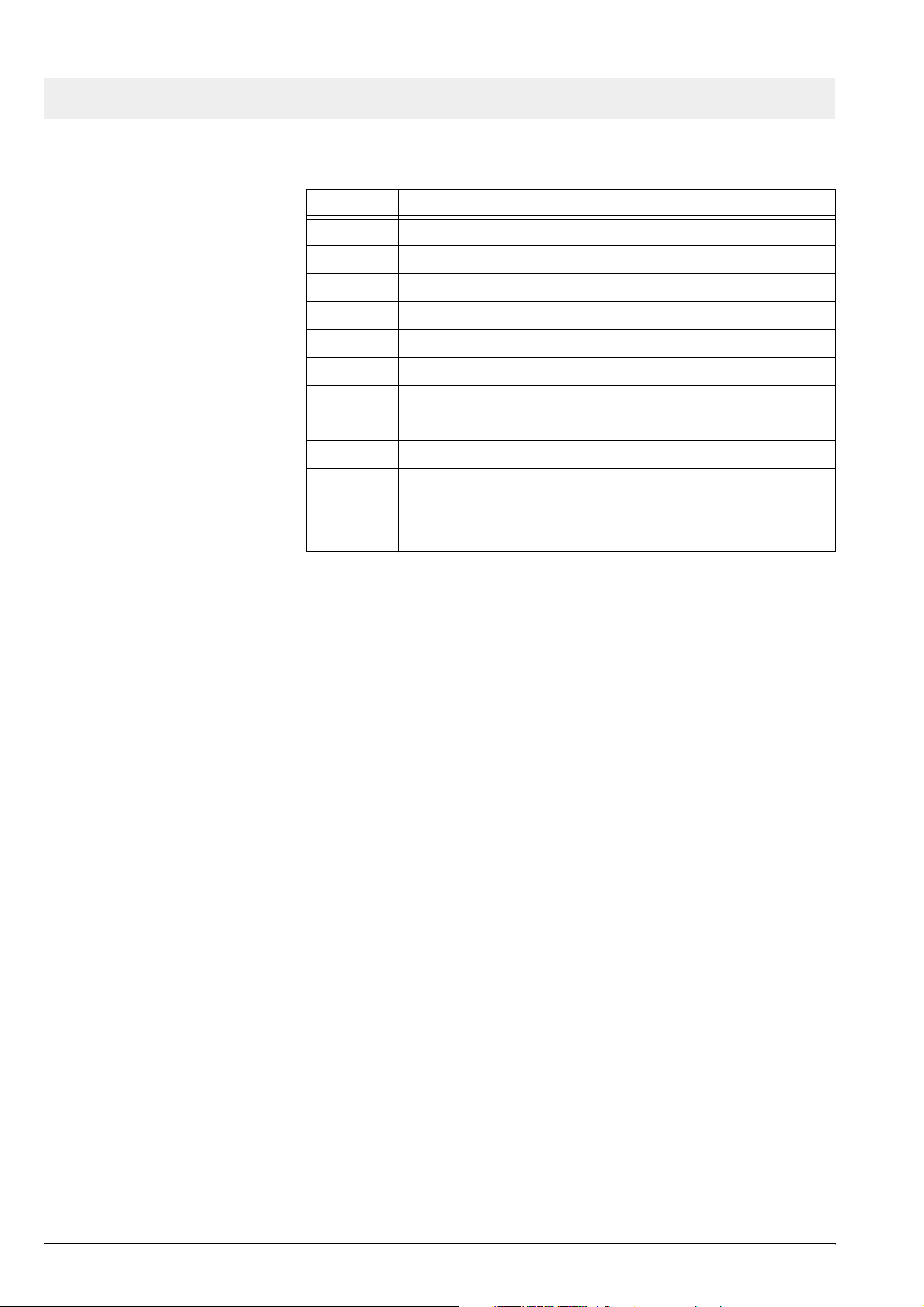

Table 1 Legend to Figure 1

No. Name

1 Trolley

2 O2 flush

3 Cosy 2 breathing system

4 Ventilator

5 Oxygen flowmeter (auxiliary)

6 Display

7 Control panel

8 Vaporizers

9 Cylinder Pressure Gauges

10 Pipeline Pressure Gauges

11 Flow Control Valves

12 Total fresh gas flowmeter

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

8

5330.500

Page 13

Fabius GS Function description

Figure 2 Rear view showing interface panel and power entry, for legend

see Ta b l e 2

Table 2 Legend to Figure 2

No. Name

1 Serial communication ports (only one is shown)

2 Tube connection for PEEP valve

3 Tube connection for APL bypass valve

4 O2 sensor connection

5 Airway pressure connection

6 Spirolog sensor connection

7 Power entry

8 Cover for power fuses (2x 2.5 A)

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

9

Page 14

Function description Fabius GS

No. Name

9 ON/OFF switch

10 Battery fuse

10

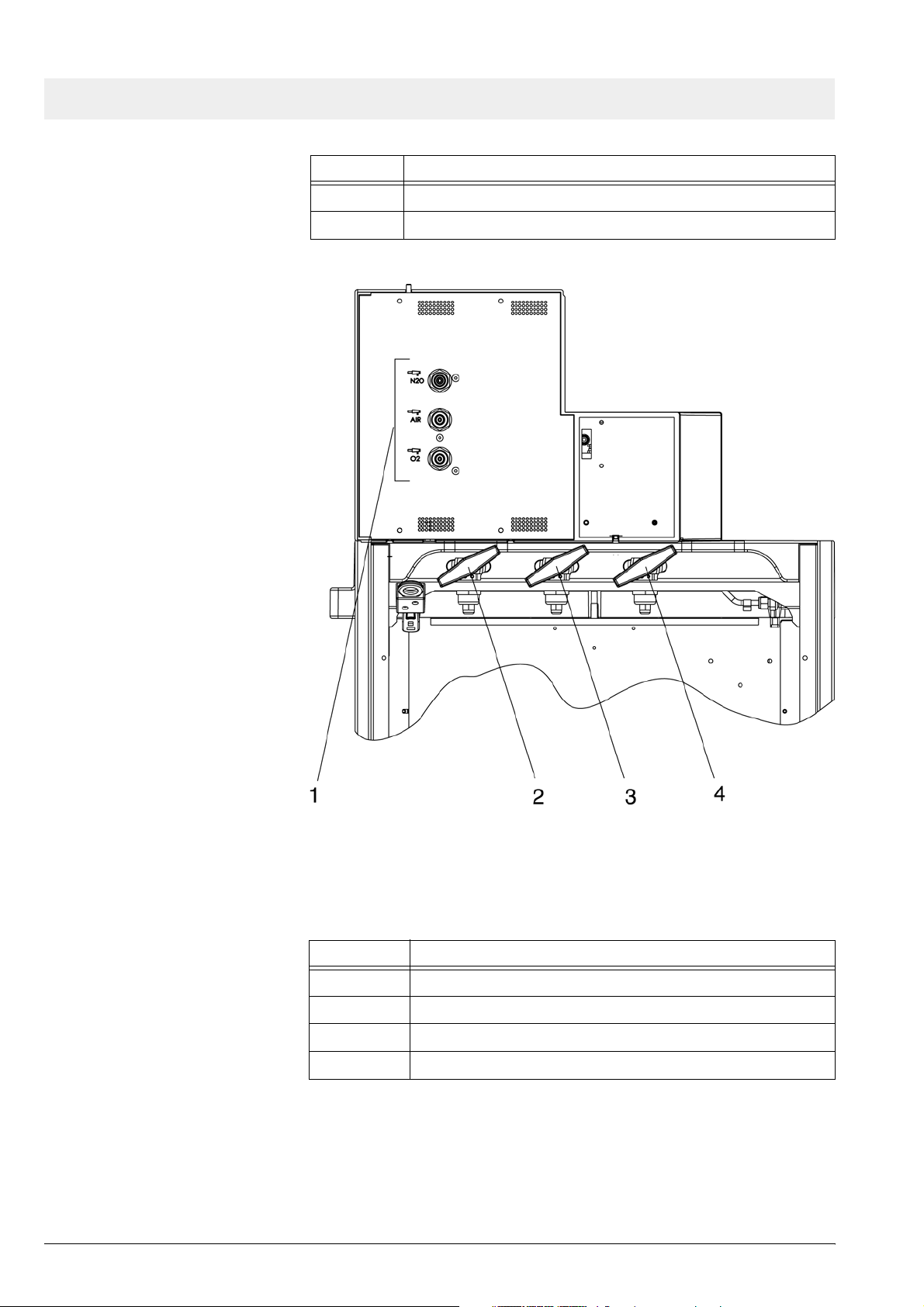

Figure 3 Rear view showing gas pipeline and PIN index cylinder connec-

tions, for legend see Ta b l e 3

Table 3 Legend to Figure 3

No. Name

1 Pipeline tube connections

2 N2O or AIR PIN index cylinder connections

3 O2 PIN index cylinder connection

4 O2 PIN index cylinder connection

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 15

Fabius GS Function description

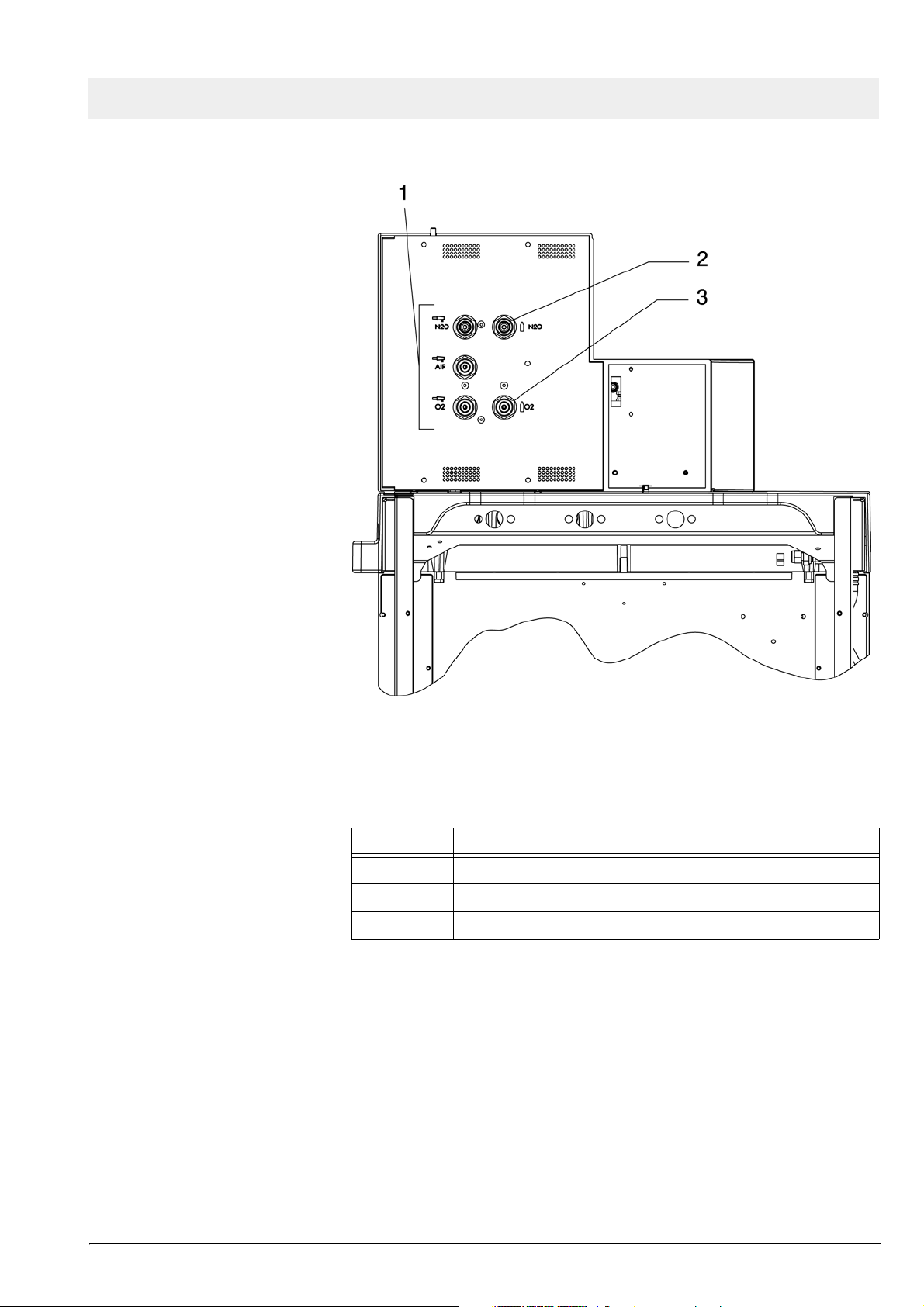

Figure 4 Rear view showing gas pipeline and cylinder connections (units

without PIN index cylinder connections), for legend see Table 4

Table 4 Legend to Figure 4

No. Name

1 Pipeline tube connections

2 N2O cylinder connection

3 O2 cylinder connection

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

11

Page 16

Function description Fabius GS

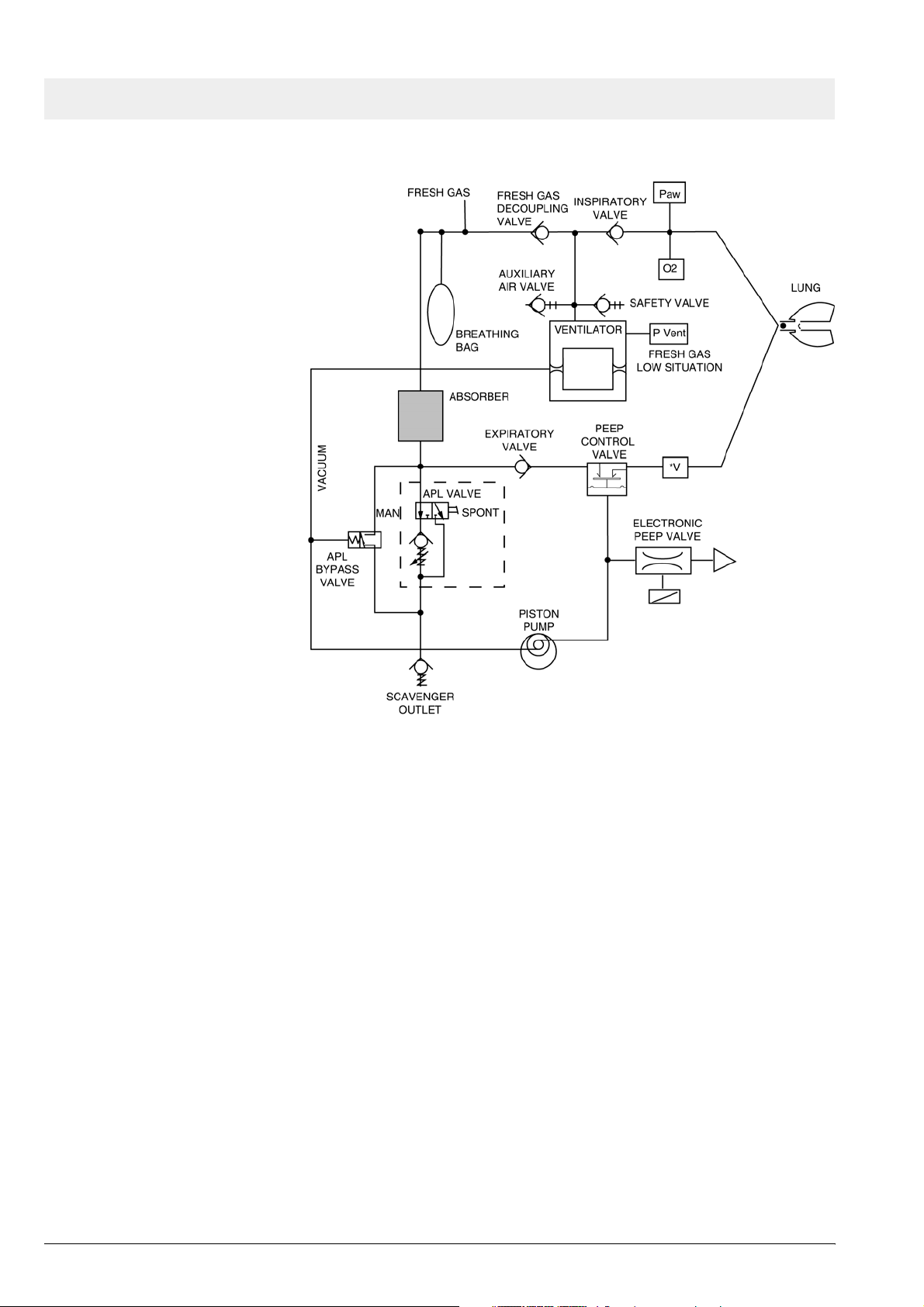

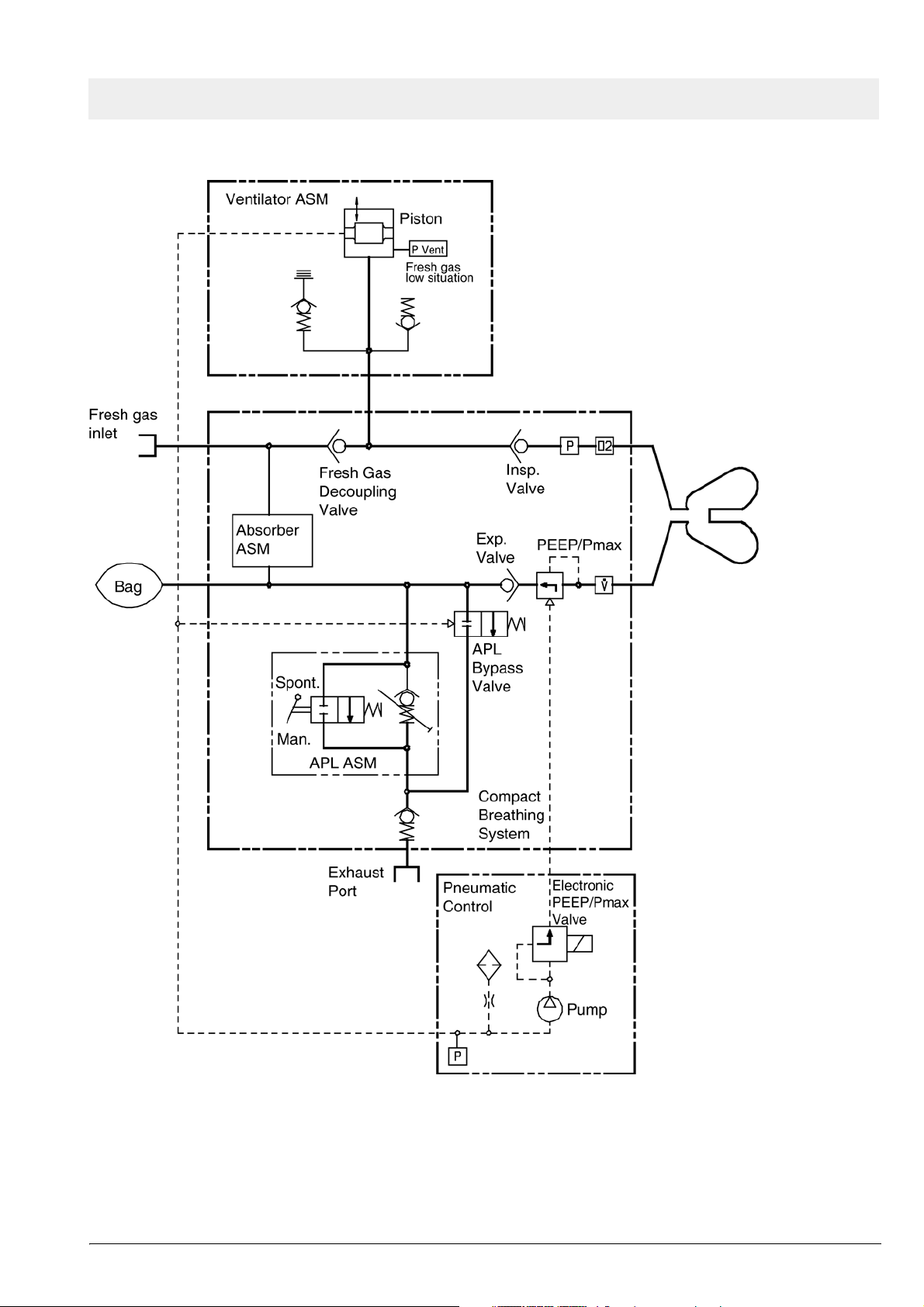

2 Function diagram of

Fabius GS

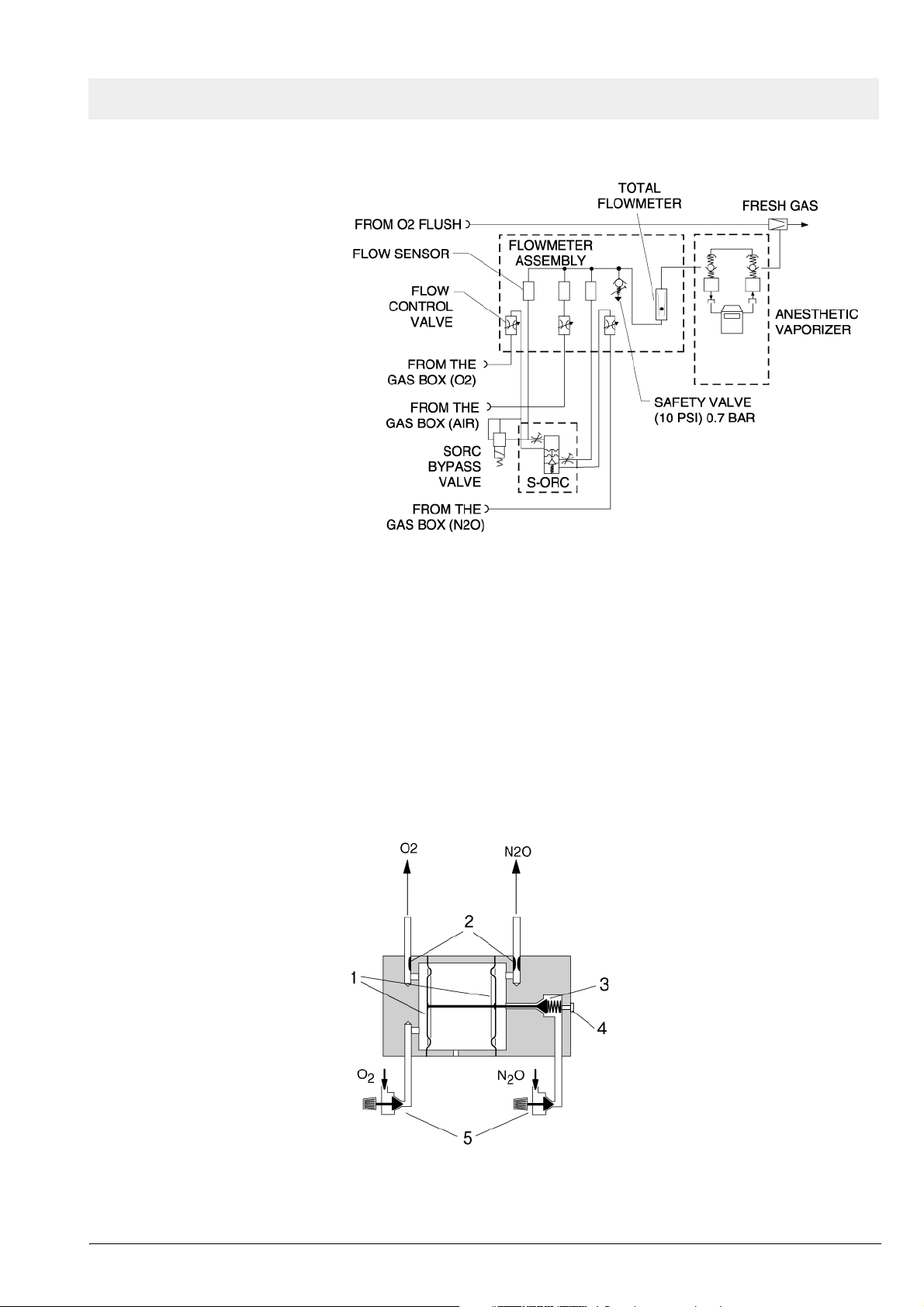

Figure 5 Function diagram of Fabius GS - Cosy 2 breathing system

12

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 17

Fabius GS Function description

Figure 6 Function diagram of Fabius GS - Cosy 2.5 (2.6) breathing system

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

13

Page 18

Function description Fabius GS

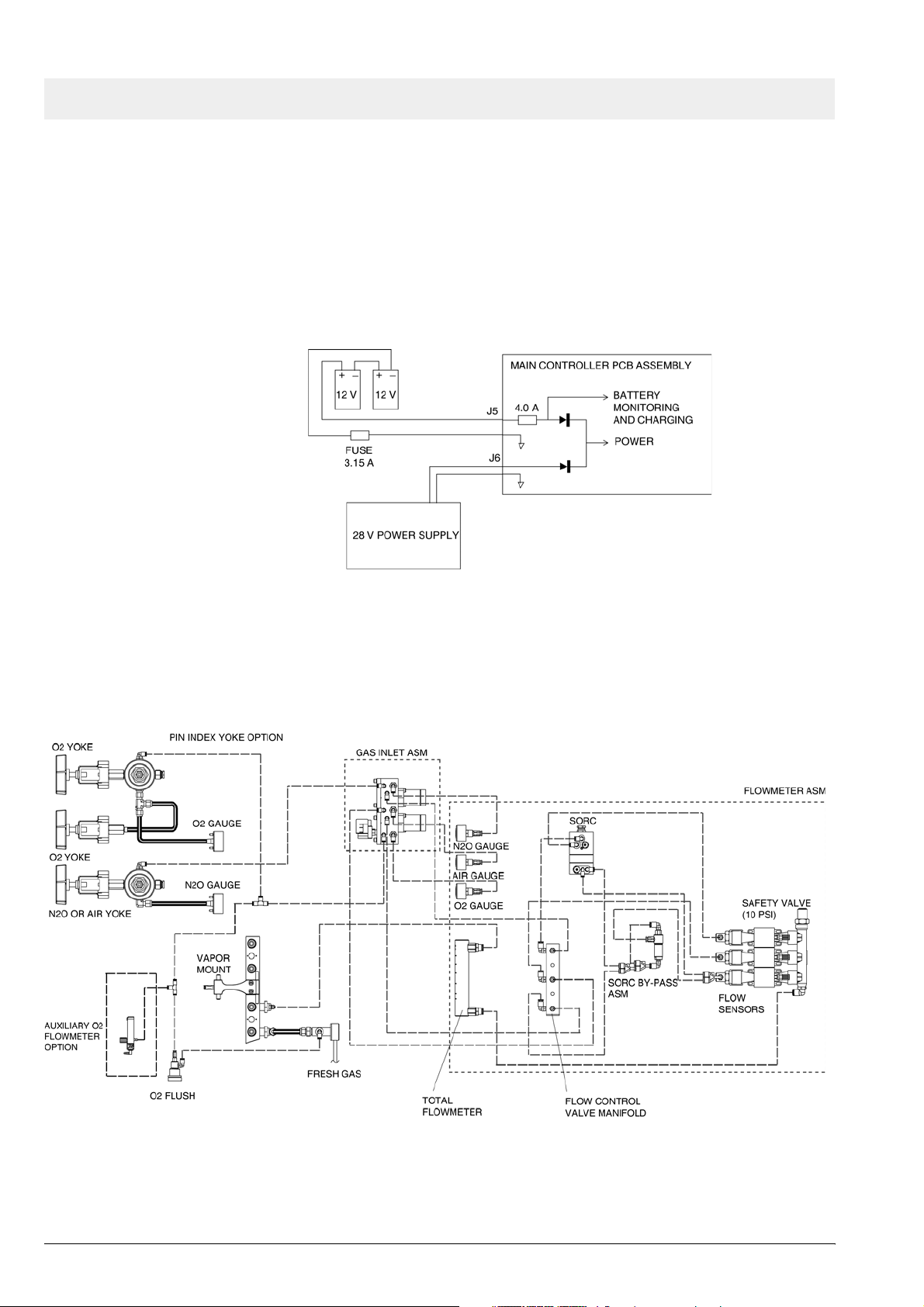

3 Battery backup Fabius GS backup power is provided by two series-connected 12 V recharge-

able batteries. These batteries remain on charge as long as the machine is

plugged into an active AC outlet. Should power supply fail while the machine

is in operation, the batteries will allow the machine to continue operating for a

minimum of 45 minutes, provided that the batteries are fully charged.

The batteries are accessible by opening the ventilator compartment. The

3.15A battery fuse is located at the back of the control box.

4 Fabius GS piping

diagram

Figure 7 Battery backup arrangement

Figure 8 Fabius GS piping diagram

14

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 19

Fabius GS Function description

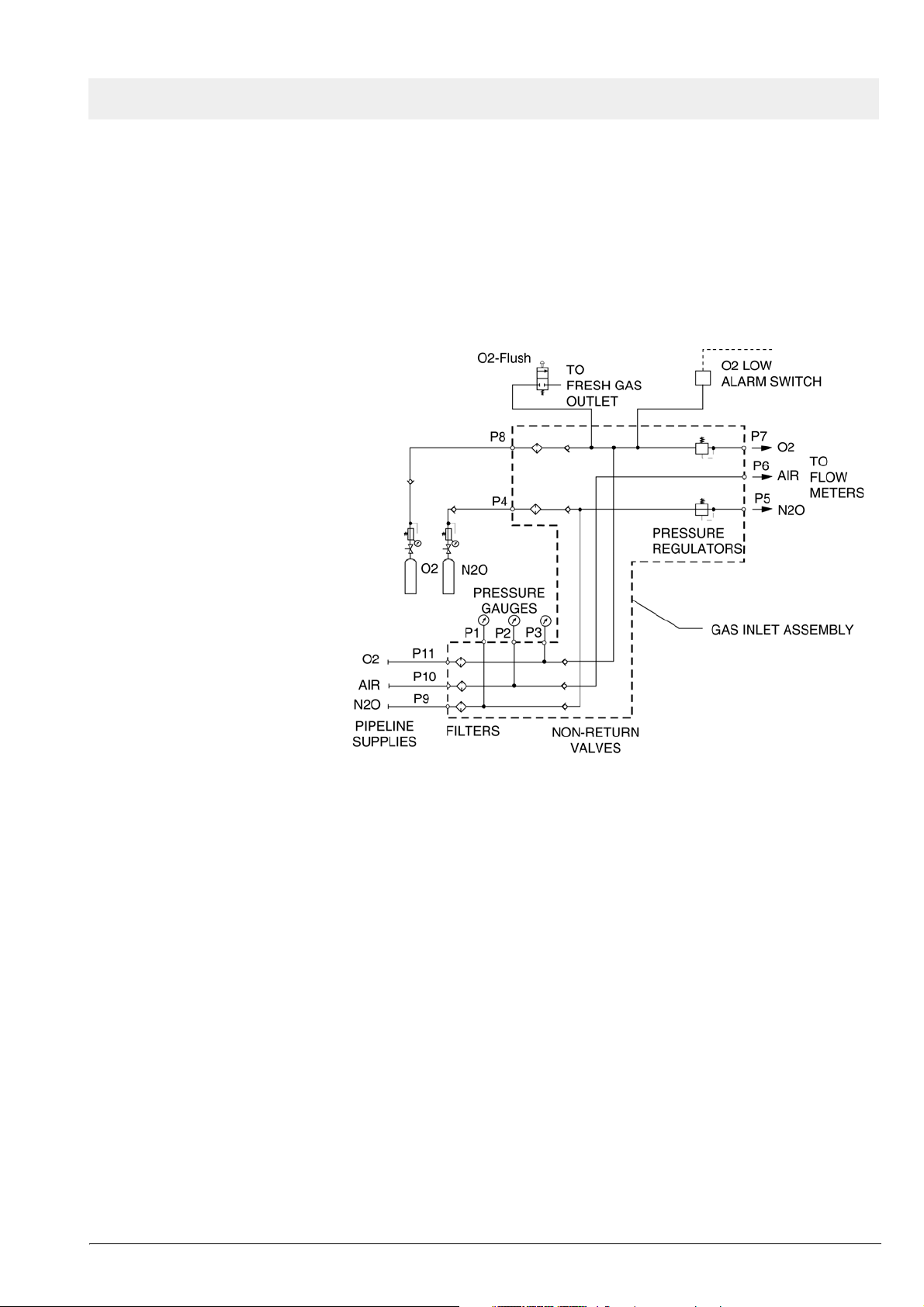

5 Function descrip-

tion of gas box

The supply gases flow through the filters and non-return valves in the gas

inlet assembly. Pipeline supply pressures are indicated on pipeline pressure

gauges located on the flowmeter assembly. Cylinder pressure gauges are

located on the trolley assembly. The pressures of O2 and N2O delivered to

the flowmeter assembly are set by regulators on the gas inlet assembly.

Should the O2 supply fail or if its pressure decrease below a certain limit, the

O2 low alarm switch signals an alarm.

Figure 9 Gas box function diagram, part 1

If the O2 flush button is pressed, oxygen is delivered to the fresh-gas outlet.

The fresh-gas ejector prevents the fresh gas from flowing back into the anesthetic vaporizer. This avoids an increase in the anesthetic gas concentration.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

15

Page 20

Function description Fabius GS

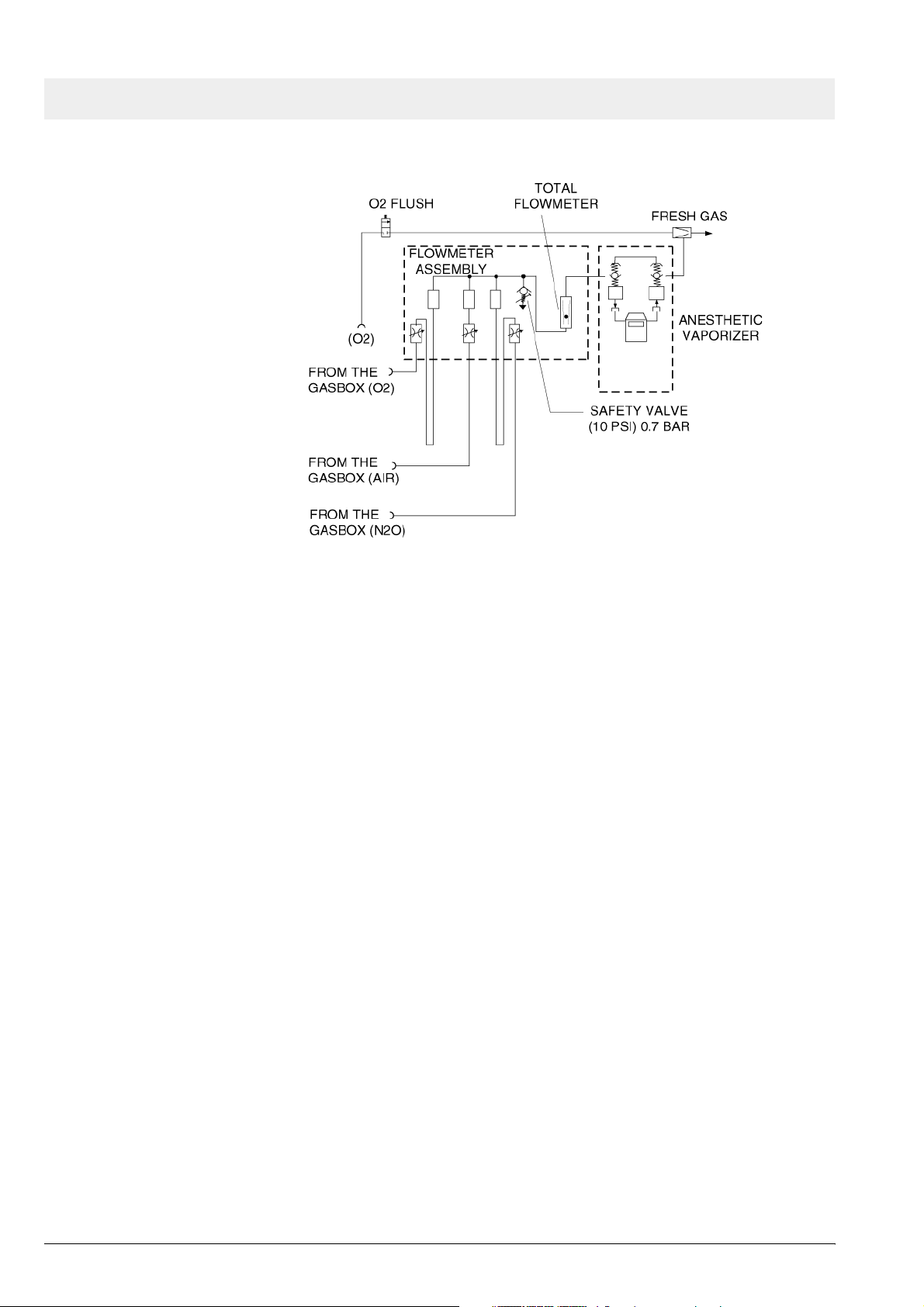

6 SORC (Sensitive

Oxygen Ratio Controller)

Figure 10 Gas box function diagram, part 2

The SORC is a control element that functions like an N2O shut-off device and

ensures a vital O2 concentration in the fresh gas. In the event of an O2 shortage, the SORC limits the N2O flow such that the O2 concentration in the

fresh gas does not decrease below 21 vol.%.

If the O2 flow control valve is closed or if the O2 flow is lower than or equal to

200 mL/min, the SORC interrupts the N2O flow.

N2O can be added as of an O2 flow of approx. 300 mL/min. In this case, the

SORC also prevents O2 concentrations below 21 vol.%.

The SORC bypass allows O2 to bypass the restrictor in the SORC when O2

flows above 10 L/min are needed.

16

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 21

Fabius GS Function description

Figure 11 SORC function diagram, part 1

The O2 and N2O flows are adjusted with the flow control valves.

Restrictors located at the outlets of the SORC generate back-pressures.

These back-pressures exert a force on the control diaphragms of the SORC.

The O2 back-pressure opens the SORC. The N2O back-pressure closes the

SORC. The pressure ratio at the control diaphragm affects the N2O flow.

The resistors and the spring force are dimensioned such that a minimum concentration of 21 vol.% of O2 is always ensured. The maximum O2 flow is

approx. 12 L/min.

Figure 12 SORC function diagram, part 2, for legend see Tab le 5

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

17

Page 22

Function description Fabius GS

Table 5 Legend to Figure 12

No. Name

1 Control diaphragms

2 Restrictors

3 N2O non-return valve

4 Operating-point adjusting screw

5 Flow control valves

7 Cosy 2 breathing

system

The Cosy 2 breathing system allows three modes of patient ventilation:

– Manual ventilation and spontaneous breathing

– Volume controlled ventilation

– Pressure controlled ventilation

The APL valve (adjustable pressure limiting valve), lever type, has a selector

switch which can be used to toggle between “MAN” and “SPONT”.

On APL valves with control knob, switching from “IPPV/SPONT” to “MAN” is

carried out by turning the knob.

In the “MAN” position, the breathing system is closed to atmosphere. This

position is used for manual ventilation of the patient. The APL valve opening

pressure can be adjusted from 5 to 70 cmH2O (mbar).

In the “SPONT” position the APL valve is open to atmosphere. This position

is used for spontaneous breathing.

Using the control box and the PEEP Pmax valve, the pressure limit (Pmax)

can also be adjusted during volume control from 15 cmH2O (mbar) to

70 cmH2O (mbar) via the membrane keypad.

18

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 23

Fabius GS Function description

Figure 13 Cosy 2 breathing system, for legend see Tabl e 6

Table 6 Legend to Figure 13

No. Name

1 Expiratory connection

2 Flow sensor (Spirolog) (not shown)

3 PEEP/Pmax valve

4 MAN/SPONT APL valve

5 APL Bypass valve

6 Fresh-gas decoupling valve

7 Fresh-gas port

8 Ventilator port

9 Anesthetic gas scavenging port

10 Absorber

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

19

Page 24

Function description Fabius GS

No. Name

11 Pressure sensor connection

12 Breathing bag terminal and standby holder for Y-piece

13 Breathing bag hook

14 Inspiratory connection

15 Inspiratory valve and O2 sensor connection

16 Anesthesia monitor return line (only for systems outside the USA)

17 Expiratory valve

20

Figure 14 Cosy 2.5 (2.6) breathing system, for legend see Table 7

Table 7 Legend to Figure 14

No. Name

1 Expiratory connection

2 Flow sensor (Spirolog) (not shown)

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 25

Fabius GS Function description

No. Name

3 PEEP/Pmax valve

4 Anesthesia monitor return line (only for systems outside the USA)

5 MAN/SPONT APL valve

6 APL Bypass valve

7 Fresh-gas decoupling valve

8 Fresh-gas port

9 Ventilator port

10 Anesthetic gas scavenging port

11 Absorber

12 Pressure sensor connection

13 Breathing bag terminal and standby holder for Y-piece

14 Breathing bag hook

15 Inspiratory connection

16 Inspiratory valve and O2 sensor connection

17 Expiratory valve

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

21

Page 26

Function description Fabius GS

7.1 Ventilation mode

Figure 15 Functional diagram of the ventilation mode, for legend see Table

8

Table 8 Legend to Figure 15, Figure 16, Figure 17, Figure 18, Figure

19, Figure 20, Figure 21, Figure 22, Figure 23, Figure 24, Fig-

ure 25, Figure 26, Figure 27

No. Name

1 Breathing bag

2 Fresh gas inlet

3 Fresh-gas decoupling

4 Ventilator

5 Inhalation valve

6 Pressure sensor

7 Oxygen sensor

8 Inspiratory tube

9Y-piece

10 Lung

22

11 Expiratory tube

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 27

Fabius GS Function description

No. Name

12 Flow sensor

13 PEEP/Pmax valve

14 Expiratory valve

15 APL bypass valve

16 APL valve

17 Exhaust valve

18 Absorber

7.2 Function description: Manual ventilation

Manual ventilation: General

Manual ventilation: Inspiration

During manual ventilation, the APL valve is set to the “MAN” position. The

safety valve of the ventilator is activated. The piston of the ventilator is in the

upper end position in order to reduce the volume of the ventilator.

The position numbers mentioned in this chapter refer to Figure 16 and Figure

17.

During inspiration, expiratory valve 14 remains closed. When the operator

compresses the breathing bag 1 the gas mixture (expiratory gas and fresh

gas 2) flows through the fresh-gas decoupling valve 3, the inspiratory valve 5,

the O2 sensor 7, the inspiratory hose 8, and the Y-piece 9 into the patient’s

lung 10. The pressure sensor 6 measures the airway pressure. The ventilation pressure is limited by the APL valve 16. Any excess amount of the gas

mixture flows through the APL valve and the non-return valve 17 to the anesthetic gas scavenging system.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

23

Page 28

Function description Fabius GS

Figure 16 Manual ventilation (inspiration) - Cosy 2 breathing system; for

legend see Tab l e 8

24

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 29

Fabius GS Function description

Manual ventilation: Expiration – Cosy 2 breathing

system

Figure 17 Manual ventilation (inspiration) - Cosy 2.5 (2.6) breathing sys-

tem; for legend see Table 8

During expiration, the inspiratory valve remains closed thus preventing the

expiratory gas from flowing back into the inspiratory branch.

The position numbers mentioned in this chapter refer to Figure 18.

After releasing the breathing bag 1, the expiratory gas from the lung 10 flows

through the expiratory hose 11, the flow sensor 12, the PEEP/Pmax valve 13,

the expiratory valve 14, and through the absorber 18 into the breathing bag.

At the same time, new fresh gas 2 flows into the breathing bag.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

25

Page 30

Function description Fabius GS

Manual ventilation: Expiration – Cosy 2.5 (2.6)

breathing system

Figure 18 Manual ventilation (expiration) - Cosy 2 breathing system; for leg-

end see Table 8

During expiration, the inspiratory valve remains closed thus preventing the

expiratory gas from flowing back into the inspiratory branch.

The position numbers mentioned in this chapter refer to Figure 19.

After releasing the breathing bag 1, the expiratory gas from the lung 10 flows

through the expiratory hose 11, the flow sensor 12, the PEEP/Pmax valve 13,

the expiratory valve 14, into the breathing bag and through the absorber 18.

At the same time, new fresh gas 2 flows into the breathing bag.

26

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 31

Fabius GS Function description

7.3 Function description: Spontaneous

breathing

Spontaneous breathing:

General

Spontaneous breathing:

Inspiration

Figure 19 Manual ventilation (expiration) - Cosy 2.5 (2.6) breathing system;

for legend see Tab l e 8

A prerequisite for spontaneous breathing is that the patient is supplied with a

sufficient amount of fresh gas. The APL valve selector must be set to the

“SPONT” position. No gas pressure builds up in the compact breathing system.

During inspiration, the expiratory valve remains closed thus preventing

rebreathing of expiratory gas containing CO2.

The position numbers mentioned in this chapter refer to Figure 20 and Figure

21.

The patient inhales the gas mixture (expiratory gas and fresh gas 2) from the

breathing bag 1. The gas mixture flows through the fresh-gas decoupling

valve 3, the inspiratory valve 5, the O2 sensor 7, the inspiratory hose 8, and

through the Y-piece 9 into the lung 10. The pressure sensor 6 measures the

airway pressure.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

27

Page 32

Function description Fabius GS

Figure 20 Spontaneous (inspiration) - Cosy 2 breathing system; for legend

see Tab l e 8

28

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 33

Fabius GS Function description

Spontaneous breathing:

Expiration – Cosy 2

breathing system

Figure 21 Spontaneous (inspiration) - Cosy 2.5 (2.6); breathing system; for

legend see Table 8

During expiration, the inspiratory valve remains closed thus preventing the

expiratory gas from flowing back into the inspiratory branch.

The position numbers mentioned in this chapter refer to Figure 22.

The APL valve 16 is open, irrespective of its pressure setting.

The expiratory gas flows from the lung 10 through the expiratory hose 11, the

flow sensor 12, the PEEP control valve 13, the expiratory valve 14, and

through the absorber 18 into the breathing bag 1. At the same time, new fresh

gas 2 flows into the breathing bag.

When the breathing bag is full, any excess gas mixture flows through the

non-return valve 17 into the anesthetic gas scavenging system.

The CO2 is scrubbed from the expiratory gas by the soda lime contained in

the absorber. The fresh gas replaces the anesthetic and the oxygen taken up

by the patient.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

29

Page 34

Function description Fabius GS

Spontaneous breathing:

Expiration – Cosy 2.5 (2.6)

breathing system

Figure 22 Spontaneous (expiration) - Cosy 2 breathing system; for legend

see Tab l e 8

During expiration, the inspiratory valve remains closed thus preventing the

expiratory gas from flowing back into the inspiratory branch.

The position numbers mentioned in this chapter refer to Figure 23.

The APL valve 16 is open, irrespective of its pressure setting.

The expiratory gas flows from the lung 10 through the expiratory hose 11, the

flow sensor 12, the PEEP control valve 13, the expiratory valve 14, the

breathing bag 1 and through the absorber 18. At the same time, new fresh

gas 2 flows into the breathing bag.

When the breathing bag is full, any excess gas mixture flows through the

non-return valve 17 into the anesthetic gas scavenging system.

30

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 35

Fabius GS Function description

7.4 Function description: Volume/pressure control

ventilation mode

Volume control ventilation

mode: General

Volume/pressure control

ventilation mode: Inspiration

Figure 23 Spontaneous (expiration) - Cosy 2.5 (2.6); breathing system; for

legend see Table 8

A prerequisite for volume control ventilation is that the patient is supplied with

a sufficient amount of fresh gas.

The APL bypass valve opens in volume ventilation mode, allowing excess

gas to be vented to the scavenging system regardless of the MAN/SPONT

valve setting.

The safety valve of the ventilator makes sure that no pressures greater than

75 cmH2O (mbar) build up in the system.

During ventilation, the pressure limit (Pmax) can adjusted at the user interface.

During inspiration, the PEEP Pmax valve remains closed. The control pressure present at the PEEP Pmax valve varies with the set pressure limit

(Pmax).

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

31

Page 36

Function description Fabius GS

The position numbers mentioned in this chapter refer to Figure 24 and Figure

25.

The pressure generated by the piston 4 of the ventilator closes the fresh-gas

decoupling valve 3. The gas mixture (expiratory gas and fresh gas 2) flows

through the inspiratory valve 5, the O2 sensor 7, the inspiratory hose 8, and

the Y-piece 9 into the lung 10. The pressure sensor 6 measures the airway

pressure. The ventilation pressure cannot exceed the pressure limit (Pmax)

set on the control box because the PEEP/Pmax valve 13 opens. The fresh

gas fills the breathing bag 1.

Any excess fresh-gas flows through the open APL valve 15, and the nonreturn valve 17 into the anesthetic gas scavenging system.

32

Figure 24 Volume control ventilation (inspiration) - Cosy 2 breathing sys-

tem; for legend see Tab l e 8

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 37

Fabius GS Function description

Volume/pressure control

ventilation mode: Expiration

Figure 25 Volume control ventilation (inspiration) - Cosy 2.5 (2.6); breathing

system; for legend see Table 8

During expiration, the inspiratory valve remains closed thus preventing

rebreathing into the inspiratory branch.

The position numbers mentioned in this chapter refer to Figure 26 and Figure

27.

The expiratory gas from the lung 10 flows through the expiratory hose 11, the

flow sensor 12, the PEEP/Pmax valve 13, the expiratory valve 14, and the

absorber 18 back into the breathing bag 1 mixing with fresh gas 2 also flow-

ing into the breathing bag.

The ventilator’s piston 4 moves back drawing the gas mixture needed for the

next inspiration into the piston space.

Any excess fresh-gas flows through the open APL valve 15, and the nonreturn valve 17 into the anesthetic gas scavenging system.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

33

Page 38

Function description Fabius GS

Figure 26 Volume control ventilation (expiration) - Cosy 2 breathing sys-

tem; for legend see Tab l e 8

34

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 39

Fabius GS Function description

Figure 27 Volume control ventilation (expiration) - Cosy 2.5 (2.6); breathing

system; for legend see Table 8

7.5 Cosy 2 absorber The absorber canister is filled with fresh soda lime. The CO2 is scrubbed

from the expiratory gas by the soda lime.

Expired soda lime changes its color. The soda lime must be replaced when

two thirds of the soda lime in the absorber canister is discolored.

8 Ventilator The ventilator is located in a swing-out compartment at the left side of the

Fabius GS. The ventilator is connected to the Cosy 2 via a tube. Fresh gas is

delivered to the patient by a piston that is driven by a motor and ball-screw

arrangement. A sight window on the compartment allows the operator to verify movement of the piston.

Two diaphragms (upper and lower) form a bag-type rolling seal that surrounds the piston. The pneumatic assembly generates a vacuum between

the seal and the cylinder, to ensure proper operation of the upper seal during

piston movement.

During inspiration the ventilator delivers fresh gas at a given volume, pressure and frequency. These parameters are set at the control panel. Refer to

the Operator’s Manual for details on ventilator settings, displays and controls.

During expiration, the bag-type rolling seal fills with expired gas from the

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

patient and with fresh gas stored in the breathing bag.

5330.500

35

Page 40

Function description Fabius GS

The ventilator motor is controlled by the Control PCB. A light barrier on the

ventilator signals the Control PCB when the piston reaches its lower limit. An

incremental encoder on the motor shaft determines the number of revolutions

and provides piston travel information to the control PCB.

The ventilator pressure is monitored by a Paw pressure sensor on the Control

PCB. When the auxiliary air valve on the patient system opens, a fresh-gas

low alarm is generated if it has been enabled in the service mode.

The ventilator pressure sensor is the same type as the one used for measuring airway pressure. The ventilator pressure is picked up at the ventilator

cover. This sensor allows the software to detect a fresh-gas low situation.

The threshold value used by the software for this condition is listed in the

table below. In normal use the primary cause for this condition is an insufficient amount of reserve gas in the breathing bag. The operator is alerted

when this condition exists, with a medium priority “FRESH GAS LOW” alarm.

This alarm can be disabled in service mode.

Table 9 Threshold

Software version Threshold

US units with SW >1.20 -8 mbar (cmH20)

US units with SW 1.20 -3 mbar (cmH20)

Non-US units with SW d1.20 -3 mbar (cmH20)

Non-US units with >SW 1.20 -8 mbar (cmH20)

36

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 41

Fabius GS Function description

Figure 28 Ventilator (piston shown in ‘down’ position), for legend see Tab le

10

Table 10 Legend to Figure 28

No. Name

1 Cylinder

2 Safety valve

3 Auxiliary air valve

4 Ventilator pressure sensor line

5 Vacuum line to the pneumatic assembly

6 Upper diaphragm

7Piston

8 Lower diaphragm

9 Motor/ballscrew assembly

10 Incremental encoder

11 Light barrier

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

37

Page 42

Function description Fabius GS

The top of the ventilator assembly (patient system) contains two valves:

8.1 Safety valve If the pressure limit control fails, the ventilator's safety valve limits the gas

pressure. This valve is set to open at approximately 75 cmH2O (mbar).

Figure 29 Sectional view of the safety valve, for legend see Tab l e 11

Table 11 Legend to Figure 29

No. Name

1Screw

2Spring

3 Washer

4 Valve disc

8.2 Auxiliary air valve The auxiliary air valve allows the patient to spontaneously breathe ambient

air should the medical gas supply and/or Fabius GS fail. The opening pressure of this valve is listed in the table below.

Table 12 Threshold

Software version Threshold

US units with SW >1.20 -8 mbar (cmH20)

US units with SW 1.20 -3 mbar (cmH20)

38

Non-US units with SW d1.20 -3 mbar (cmH20)

Non-US units with >SW 1.20 -8 mbar (cmH20)

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 43

Fabius GS Function description

Figure 30 Sectional view of the auxiliary air valve, for legend see Table 13

Table 13 Legend to Figure 30

No. Name

1 Threaded ring

2 Valve seat

3 Valve disc

4 Valve cross with spring

9Pneumatics The pneumatic assembly provides pressure for the PEEP valve control, and

also provides vacuum for the ventilator bag-type rolling seals and the APL

bypass valve control.

9.1 PEEP/Pmax valve

control

When the Fabius GS is operating in the automatic mode, the pump on the

pneumatic assembly is running, and the electronic PEEP valve is actuated by

the Control PCB. The current supplied to the coil of the electronic PEEP valve

is proportional to the set PEEP value, and controls the position of the diaphragm within the electronic PEEP valve. This then determines the control

pressure applied to the proportional PEEP valve in the breathing system,

which maintains the desired amount of PEEP during patient expiration. The

V1 reservoir smooths out pressure variations caused by the pump. See Fig-

ure 31.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

39

Page 44

Function description Fabius GS

9.2 APL bypass valve

control

Figure 31 Pneumatic control system schematic

When the Fabius GS is operating in the automatic mode, the pneumatic

assembly provides a vacuum signal to hold open the APL bypass valve in the

breathing system. The V2 reservoir and filter provide noise damping, and the

variable restrictor is used to set the vacuum level in the range of –150 to –240

cmH2O (mbar).

When the machine is operating in the Manual mode, the pump on the pneumatic assembly (and the ventilator) is stopped, and the spring-loaded APL

bypass valve in the breathing system closes, directing exhaled gas through

the APL valve.

40

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 45

Fabius GS Function description

10 Electrical block dia-

gram

11 Function descrip-

tion: Control PCB

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

Figure 32 Electrical block diagram

The Control PCB contains the following functions:

– Motor control and monitoring

– Measurement of O2 and flow parameters

– Provision of one or two serial interfaces

– Evaluation of the O2 low signal

– Measurement and display of fresh-gas parameters

– PEEP valve control

– Pump control

– Front panel display control

– Evaluation of keypad and rotary encoder

– The required supply voltages are supplied by the power supply unit.

41

Page 46

Function description Fabius GS

Figure 33 Controller functional block diagram

12 Control panel

assembly

The control panel consists of a 320 x 240 pixel graphical display, a table lamp

with six LEDs, a membrane keypad, rotary encoder and speaker.

Data and power for the display comes from the Control PCB via a 20-conductor ribbon cable. The keypad interface is connected to the Control PCB by a

30-conductor ribbon cable. A block diagram of the control panel assembly is

shown in the following illustration.

42

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 47

Fabius GS Function description

Figure 34 Control panel block diagram

Figure 35 Fabius GS control panel (“Standby” screen shown), for legend

see Table 14

Table 14 Legend to Figure 35

Item Function

1 Selects volume control ventilation mode.

Refer to Instructions for Use manual

2 Selects pressure control ventilation mode.

Refer to Instructions for Use manual

3 Reserved for future functions (Pressure Support)

4 Reserved for future functions (SIMV)

5 Controls table lamp: Off/On

6 Places the ventilator in MAN/SPONT mode

Refer to Instructions for Use manual

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

43

Page 48

Function description Fabius GS

Item Function

7 Soft keys: activate the corresponding function that appears on

screen above the key

8 For setting alarm limits

Refer to Instructions for Use manual

9 Setup key: activates sub-screens for monitoring functions.

Refer to Instructions for Use manual

10 Home key: returns display to main screen shown before standby

11 Rotary encoder: moves the cursor on the screen; confirms selec-

tion when pressed

12 Alarm Status indicators:

Flashing Red: Warning; Flashing Yellow: Caution; Solid Yellow:

Note

13 Alarm Silence key: silences all active alarms for two minutes

14 Power ON indicator: lighted when machine is plugged into an

active AC outlet

15 Switches the unit back to standby mode.

13 FiO2 Measurement The O2 sensor measures the O2 concentration in the respiratory gas (FiO2).

The O2 sensor contains a capsule with alkaline electrolyte, a lead anode, two

gold cathodes, and a Teflon membrane. The spatial separation of the two

gold cathodes allows to carry out a voltage comparison.

The O2 sensor is an electrochemical cell that generates a voltage from the

ion current.

44

Figure 36 O2 sensor, for legend see Table 15

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 49

Fabius GS Function description

Table 15 Legend to Figure 36

No. Name

1 Teflon membrane

2 Gold cathode A

3 Lead anode

4 Temperature compensation resistors

5 Alkaline electrolyte

6 Gold cathode B

The O2 to be measured diffuses through the Teflon membrane, undergoes a

chemical reaction at the gold cathodes (negative) and produces lead oxide

and water at the lead anode (positive). During this chemical process, a voltage is generated that is proportional to the O2 partial pressure.

The internal resistance of the cell is determined by the surface of the gold

cathodes, the O2 diffusion velocity, and the distance between the gold cathodes and the lead anode. This resistance is approximately 700 ohms.

14 Respiratory Flow

Measurement

The chemical process is temperature-sensitive. Therefore, thermistors are

connected in parallel to the O2 sensor. These resistors and the internal resistor of the O2 sensor correct the measuring voltage. Since two cathodes are

used in the O2 sensor cell, two different voltages are generated. These voltages are compared with each other. If their difference exceeds a certain

value, the machine prompts the operator to check the cell.

If the O2 sensor fails, the control box will indicate an error on the graphics

display.

The flow sensor functions according to the constant temperature hot-wire

anemometer principle. Respiratory gas flows past a thin platinum wire. This

platinum wire (A) is located in a measuring tube and is electrically heated.

The platinum wire is held at a constant temperature. Gas flow removes heat

from the hot wire. The higher the gas flow rate, the greater the heat removal.

The amount of electrical current needed to maintain a constant platinum wire

temperature is thus proportional to the gas flow rate.

A second platinum wire (B) in the measuring tube is used to compensate for

interferences from different gases present in the respiratory gas. The heat

removed from the second platinum wire is measured during inspiration when

the gas flow is zero.

The different gases present in the respiratory gas have a different thermal

conductivity. The amount of heat removed from the second platinum wire is

thus an indicator of respiratory gas composition.

Internal calibration tables for O2/N2O mixtures, Air and 100% O2 are used to

linearize the measured flow.

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

5330.500

45

Page 50

Function description Fabius GS

Figure 37 Respiratory flow sensor, for legend see Table 16

Table 16 Legend to Figure 37

No. Name

“A” Platinum wire “A”

15 Gas flow rate mea-

surement

“B” Platinum wire “B”

The gas flow sensors operate on the principle of specific heat for individual

gases. In each sensor, as the gas flows through a heated chamber the gas

molecules carry away a certain amount of heat relative to the specific heat

index for that gas.

A known amount of electrical current is required to maintain the temperature

in the heated chamber. The higher the gas flow rate, the more heat is

removed from the chamber and more current is required to maintain the temperature in the chamber. This current is then scaled and displayed as liters

per minute flow rate for each gas.

46

Figure 38 Details of the flow sensor, for legend see Table 17

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 51

Fabius GS Function description

Table 17 Legend to Figure 38

No. Name

1 Tube connector

2 Electronic components

3 Electrical connection

4 Gas outlet port (to manifold)

5 Mounting pole

6 Heated chamber

7 Gas inlet assembly

16 Anesthetic vapor-

izer(s)

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

Figure 39 Gas flow through sensors, for legend see Table 18

Table 18 Legend to Figure 39

No. Name

1 from the oxygen flow control valve

2 from the Air flow control valve

3 from the N2O flow control valve

4 Fresh-gas flow to the total fresh-gas flowmeter

5 Fresh-gas manifold

Refer to separate technical documentation of the anesthetic vaporizer.

5330.500

47

Page 52

Function description Fabius GS

48

5330.500

Version 1.0_ Released_Printed on_10.11.05_F5330500_Function_Description.fm

All rights reserved. Copyright reserved.

Page 53

Fabius GS Function description

17 Leak test The leak test menu screen instructs the user how to begin the leak test.

After preparing the machine, the user initiates the test.

If the size of the leak is outside the tolerance range, an appropriate message

is displayed to tell the user that the system leak test has failed.

With sidestream monitoring, seal off the sampling tube from the Y-piece, otherwise there will be an additional leak rate of 150 to 200 mL/min.

17.1 System leak test 1. The leak test menu prompts the user to plug the Y-piece and to flip the

Man/Spont valve to “Man” (with the pressure set to 40 to 50 mbar).

2. The motor control then moves the piston upward. Then the user activates

the O2 flush to increase the system pressure to a value between 15 and

30 mbar.

3. The software monitors the airway pressure.

4. If the airway pressure is in range, the airway pressure is then allowed to

drop for 15 seconds or by 1.5 mbar. If no appreciable pressure drop

occurred in 15 seconds, the leak test is considered “passed”.

5. If the pressure has decreased significantly (up to 1.5 mbar), the piston will

move upward until the airway pressure has increased 2 mbar, or the piston has moved upward a specific volume of 160 mL, whichever comes

first.

6. The upward piston movement in mL, divided by the increase in airway

pressure yields the system compliance value. This compliance value is

used when calculating the system leak rate only. The system compliance

is calculated in the next step upon completion of the system leak test.

7. The total time that elapsed between the start of the piston movement and

the transition pressure drop by 1.5 mbar is the time base for the leak calculation.

17.2 Patient leak test The patient leak test is done in a similar way to the system leak test:

1. The PEEP/Pmax valve is used to close off the expiratory part of the pneumatic circuit. Only the patient circuit is tested.

2. The test begins by opening the PEEP valve and checking where the current piston position is.

3. If the piston is above the desired starting position the piston is servoed

downward.

4. If the piston is below the desired starting position the piston is servoed

upward.

5. Then the PEEP valve is closed and the piston is moved upward.

6. When the airway pressure has reached 30 mbar, the piston is paused at

that position and maintained there by the servo function.

7. Once the pressure has stabilized, the state changes to “waiting for leak.”

8. When the airway pressure and ventilator pressure have dropped 1 mbar

or the elapsed waiting time exceeds 20 seconds, the state changes to

calculation of the leak in mL and leak rate in mL/min.

9. The software detects that the completion state has gone to “pass” or “fail”

and will then display the leak test results on the leak test screen (or display an appropriate error message, if the completion state is one of the

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_10.11.05_F5330500_Leaktest.fm

error conditions).

5330.500

49

Page 54

Function description Fabius GS

The result of the “patient leak test” is displayed after each test.

The result of the “system leak test” is displayed only if the value is outside the

tolerance range.

Otherwise only OK will be displayed.

50

5330.500

Version 2.0_ Released_Printed on_10.11.05_F5330500_Leaktest.fm

All rights reserved. Copyright reserved.

Page 55

Annex

Parts catalog

Technical Information

51

Page 56

52

Page 57

Parts catalog

Fabius GS

Emergency Care - Perioperative Care - Critical Care - Perinatal Care - Home Care

Revision: 2005-09-14 09:18:30

5330.500

Because you care

Page 58

2

Page 59

Suction hoses

A

A

A

A

Parts catalog

Item

Part No. Description Qty.

No.

1 M35015

2 M33297

3 M33298

4 M33299

GS-SCAVANGER HOSE 0,5M 1.000 St

GS-SCAVANGER HOSE 1,5M 1.000 St

GS-SCAVANGER HOSE 3M

GS-SCAVANGER HOSE 5M 1.000 St

1.000

Qty.u

nit

St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

5330.500

Revision: 2005-09-14 09:18:30

3

Page 60

Plugs

A

A

Parts catalog

Item

Part No. Description Qty.

No.

1 G60580

2 G60495

GSS PROBE/STRAIGHT-TYPE1/ EN 1.000 St

GSS ANGLE PROBE / TYPE 1 / EN 1.000 St

Qty.u

nit

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

5330.500

Revision: 2005-09-14 09:18:30

4

Page 61

Plugs

A

Parts catalog

Item

Part No. Description Qty.

No.

3 G60440

NAESTH.WASTE GAS PROBE 45 1.000 St

Qty.u

nit

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

5330.500

Revision: 2005-09-14 09:18:30

5

Page 62

ventilator

Parts catalog

Item

Part No. Description Qty.

No.

2 2600650 DIAPHRAGM,CUP 1.000 St

5 8604319 patient assembly

10 2M08777 O-RING SEAL

1.000 St

1.000

Qty.u

nit

St

Remark

5330.500

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Revision: 2005-09-14 09:18:30

6

Page 63

absorber

A

A

A

Parts catalog

Item

Part No. Description Qty.

No.

1 M29320

2 M29999

3 M29994

BSORBER CICERO 1.000 St

BSORBER INSERT 1.000 St

BSORBER POT

1.000

Qty.u

nit

St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

5330.500

Revision: 2005-09-14 09:18:30

7

Page 64

Fabius GS

Assembly Description Part No.

Parts catalog

absorber

ABSORBER CICERO M29320

ABSORBER INSERT M29999

ABSORBER POT M29994

AGGS-System

AGS CONTAINER M33292

AGS-SYSTEM, BASIC UNIT M33300

FILTER M33294

AIR

AIR CONNECTING HOSE 3M (BLACK) M29241

AIR CONNETING HOSE 1,5M(BLACK) M29281

AIR-CONNECTING HOSE 1,5M M29279

AIR-CONNECTING HOSE 5M M29259

AIR-CONNECTING HOSE 5M (BLACK) M29261

AIR-HOSE NIST 1,5M DIN PROBE M34407

AIR-HOSE NIST 3M DIN PROBE M34408

AIR-HOSE NIST 5M DIN PROBE M34409

AIR-ZV-HOSE 1,5M NIST EN-COLOR 8602519

AIR-ZV-HOSE 3M NIST EN-COLOR 8602520

AIR-ZV-HOSE 5M NIST EN-COLOR 8602521

AIR/O2

02/AIR-CONNECTING HOSE 3M M29243

AIR/O2-ZV-HOSE 1,5M NIST EN-C. 8602525

AIR/O2-ZV-HOSE 3M NIST EN-COL. 8602526

AIR/O2-ZV-HOSE 5M NIST EN-COL. 8602527

O2/AIR-HOSE NIST 1,5MDIN PROBE M34410

O2/AIR-HOSE NIST 3M DIN PROBE M34411

O2/AIR-HOSE NIST 5M DIN PROBE M34412

O2-AIR CONNECT.HOSE 3M(BLACK) M29245

O2-AIR CONNECT.HOSE 5M (BLACK) M29265

O2-AIR CONNECTING HOSE 1,5M M29283

O2-AIR CONNECTING HOSE 5M M29263

O2-AIR-CONNECT.HOSE 1,5(BLACK) M29285

Basic Unit

AGS-SYSTEM, BASIC UNIT M33300

breathing system COSY2

Membrane Asm 8604406

5330.500

Revision: 2005-09

8

Page 65

Fabius GS

Assembly Description Part No.

Parts catalog

Central Air distributor

AIR-DISTRIBUTOR 1,5M M28963

AIR-DISTRIBUTOR 1,5M (BLACK) M29866

AIR-DISTRIBUTOR 1,5M DIN PROBE M34561

AIR-DISTRIBUTOR 3M M30709

AIR-DISTRIBUTOR 3M (BLACK) M30711

AIR-DISTRIBUTOR 3M DIN-PROBE M34562

AIR-DISTRIBUTOR 5M M30710

AIR-DISTRIBUTOR 5M (BLACK) M30712

AIR-DISTRIBUTOR 5M DIN-PROBE M34563

AIR-ZV-DISTRIB.1,5M NIST EN-C. 8602531

AIR-ZV-DISTRIB.3M NIST EN-COL. 8602532

AIR-ZV-DISTRIB.5M NIST EN-COL. 8602533

Central O2 distributor

DIAPHRAGM SEPARATION M34492

O2-DISTR.1,5M DIN-ST.NIST-FN M34941

O2-HOSE NIST 5M DIN PROBE M34403

O2-ZV-DISTRIB.1,5M DIN BLUE 8602534

O2-ZV-DISTRIB.1,5M DIN BLUE 8602534

O2-ZV-DISTRIB.1,5M NIST EN-C. 8602528

O2-ZV-DISTRIB.3M DIN BLUE 8602535

O2-ZV-DISTRIB.3M DIN BLUE 8602535

O2-ZV-DISTRIB.3M NIST EN-COLOR 8602529

O2-ZV-DISTRIB.5M DIN BLUE 8602536

O2-ZV-DISTRIB.5M DIN BLUE 8602536

O2-ZV-DISTRIB.5M NIST EN-COLOR 8602530

Clutch adapter

Adapter AIR DIN/DIN-coupling M28031

Adapter AIR NIST/DIN-coupling M35058

ADAPTOR N20 NIST/DIN-COUPLING M35057

ADAPTOR O2 NIST/DIN-COUPLING M35056

N2O-COUPLING HOSE 0,15M M23875

O2-COUPLING HOSE 0,15M M23874

Hose DIN, device NIST

ADAPTER O2 (DIN/NIST) M32366

ADAPTOR AIR (DIN/NIST) M32368

ADAPTOR AIR/O2 (DIN/NIST) M32370

ADAPTOR N2O (DIN/NIST) M32367

ADAPTOR VAC (DIN/NIST) M32369

5330.500

Revision: 2005-09

9

Page 66

Fabius GS

Assembly Description Part No.

Parts catalog

Hose DISS, device NIST

ADAPTOR-AIR,DISS-NIST M34877

ADAPTOR-N2O,DISS-NIST M34876

ADAPTOR-O2,DISS-NIST M34875

ADAPTOR-VAC,DISS-NIST M34878

Hose NIST, device DIN

ADAPTOR AIR (NIST/DIN) M32495

ADAPTOR AIR/O2 (NIST/DIN) M32497

ADAPTOR N2O (NIST/DIN) M32494

ADAPTOR O2 (NIST/DIN) M32493

ADAPTOR VAC (NIST/DIN) M32496

5330.500

Revision: 2005-09

10

Page 67

Fabius GS

Assembly Description Part No.

Parts catalog

Instructions for Use

AGS A-Gas Awayline hu/cz 9038239

AGS A-Gas Awayline ru/pl 9038207

AGS A-Gas Awayline sv/no 9038206

AGS A-Gas Awayline zh/jp 9038208

GA Fabius GS 2.n en gb 9037933

GA Fabius GS cs 9037794

GA Fabius GS de 9037780

GA Fabius GS en 9037781

GA Fabius GS enUS 9037796

GA Fabius GS es 9037784

GA Fabius GS fr 9037782

GA Fabius GS it 9037785

GA Fabius GS ja 9037783

GA Fabius GS nl 9037791

GA Fabius GS no 9037786

GA Fabius GS pl 9037792

GA Fabius GS pt 9037788

GA Fabius GS ro 9037795

GA Fabius GS ru 9037787

GA Fabius GS sv 9037793

GA Fabius GS zh 9037789

IfU Fabius GS 2.n cs 9037946

IfU Fabius GS 2.n de 9037932

IfU Fabius GS 2.n en us 9037948

IfU Fabius GS 2.n es 9037936

IfU Fabius GS 2.n fr 9037934

IfU Fabius GS 2.n hu 9037942

IfU Fabius GS 2.n it 9037937

IfU Fabius GS 2.n ja 9037935

IfU Fabius GS 2.n nl 9037943

IfU Fabius GS 2.n no 9037938

IfU Fabius GS 2.n pl 9037944

IfU Fabius GS 2.n pt 9037940

IfU Fabius GS 2.n ro 9037947

IfU Fabius GS 2.n ru 9037939

IfU Fabius GS 2.n sv 9037945

IfU Fabius GS 2.n zh 9037941

INSTRUCTIONS FOR USE AGS DA/IT 9029425

Instructions for Use AGS de/en 9029327

INSTRUCTIONS FOR USE AGS FR/ES 9029426

INSTRUCTIONS FOR USE AGS FR/NL 9037424

KIT AGS Adapter

MODIF.AGS-ADAPTER TITUS/SA2 M32976

5330.500

Revision: 2005-09

11

Page 68

Fabius GS

Assembly Description Part No.

Parts catalog

Maintanance Parts/Service Sets

FILTER M33294

maintenance parts/Service kits

CAPSULE FOR O2-DETECTOR (DW) 6850645

HOSE 4X1,5-SI 50 SH A NF 1190520

Hose Asm-PEEP/Pmax-APL Byp LFT 8604875

Hose Asm-PEEP/Pmax-APL Byp RHS 8604874

Set of 5 Spirolog sensors 8403735

VALVE DISK M23225

Manuals Tiro

IfU Fabius Tiro 2.n de 9038131

lfU Fabius Tiro 2.n en 9038132

lfU Fabius Tiro 2.n enUS 9038147

lfU Fabius Tiro 2.n es 9038135

lfU Fabius Tiro 2.n fr 9038133

lfU Fabius Tiro 2.n it 9038136

lfU Fabius Tiro 2.n nl 9038142

TD Fabius Tiro de 9036220

TD Fabius Tiro en 9036221

TD Fabius Tiro es 9036222

TD Fabius Tiro fr 9036223

N2O

N2O-CONNECT.HOSE 1,5M (BACK) M29277

N2O-CONNECT.HOSE 3M (BLACK) M29237

N2O-CONNECT.HOSE 5M (BLACK) M29257

N2O-CONNECTING HOSE 1,5M M29275

N2O-CONNECTING HOSE 5M M29255

N2O-CONNECTION HOSE 3M M29235

N2O-HOSE NIST 1,5M DIN PROBE M34404

N2O-HOSE NIST 3M DIN PROBE M34405

N2O-HOSE NIST 5M DIN PROBE M34406

N2O-ZV-HOSE 1,5M NIST EN-COLOR 8602516

N2O-ZV-HOSE 3M NIST EN-COLOR 8602517

N2O-ZV-HOSE 5M NIST EN-COLOR 8602518

5330.500

Revision: 2005-09

12

Page 69

Fabius GS

Assembly Description Part No.

Parts catalog

O2

O2-CONNECT.HOSE 1,5M (BLACK) M29273

O2-CONNECT.HOSE 3M (BLACK) M29233

O2-CONNECT.HOSE 5M (BLACK) M29253

O2-CONNECTING HOSE 1,5M M29271

O2-CONNECTING HOSE 5M M29251

O2-CONNECTION HOSE 3M M29231

O2-HOSE NIST 1,5M DIN-PROBE M34401

O2-HOSE NIST 3M DIN PROBE M34402

O2-HOSE NIST 5M DIN PROBE M34403

O2-ZV-HOSE 1,5M NIST EN-COLOR 8602513

O2-ZV-HOSE 5M NIST EN-COLOR 8602515

O2-ZV-HOSE3M NIST EN-COLOR 8602514

Plugs

AGSS ANGLE PROBE / TYPE 1 / EN G60495

AGSS PROBE/STRAIGHT-TYPE1/ EN G60580

ANAESTH.WASTE GAS PROBE 45 G60440

RS AGS- Schienenklaue

Lever-type clamp M25739

MODIFICATION AGS-RAIL CLAMP M32967

Suction hoses

AGS-SCAVANGER HOSE 0,5M M35015

AGS-SCAVANGER HOSE 1,5M M33297

AGS-SCAVANGER HOSE 3M M33298

AGS-SCAVANGER HOSE 5M M33299

VAC

VAC.-CONNECT.HOSE 1,5M(BLACK) M29289

VAC.-CONNECT.HOSE 3M (BLACK) M29249

VAC.-CONNECT.HOSE 5M (BLACK) M29269

VAC-HOSE NIST 1,5M DIN PROBE M34413

VAC-HOSE NIST 3M DIN PROBE M34414

VAC-HOSE NIST 5M DIN PROBE M34415

VACUUM-CONNECTION HOSE 1,5M M29287

VACUUM-CONNECTION HOSE 3M M29247

VACUUM-CONNECTION HOSE 5M M29267

VAC-ZV-HOSE 1,5M NIST EN-COLOR 8602522

VAC-ZV-HOSE 3M NIST EN-COLOR 8602523

VAC-ZV-HOSE 5M NIST EN-COLOR 8602524

Valve

5330.500

CAP 1,BLACK M24597

Revision: 2005-09

13

Page 70

Fabius GS

Assembly Description Part No.

Parts catalog

ventilator

DIAPHRAGM,CUP 2600650

O-RING SEAL 2M08777

patient assembly 8604319

Without plug, color EN 739

AIR-DISTRIBUTOR 5M,NO PLUG M34564

CS-HOSE N2O,5M,NO PLUG M34417

CS-HOSE AIR 5M, NO PROBE M34418

CS-HOSE AIR-O2,5M,NO PLUG M34420

CS-HOSE O2 5M, NO PROBE M34416

CS-HOSE VAC,5M,NO PLUG M34419

O2-DISTRIBUTOR 5M,NO PLUG M34565

Without plug, no color

AIR-DISTRIB.NIST 5M,BL,N.PROBE M32677

AIR-HOSE 5M NIST BL., NO PROBE M32039

N2O-HOSE 5M,NIST,BL.,NO PROBE M32038

O2/AIR HOSE 5M NIST,BL.,NO PR. M32047

O2-DISTRIB.NIST 5M,BL,N.PROBE M32679

O2-HOSE 5M NIST BL., NO PROBE M32037

VAC.HOSE 5M,NIST,BL.,NO PROBE M32046

5330.500

Revision: 2005-09

14

Page 71

Technical Information

2005-11-03

Technical Documentation for Fabius GS / Fabius Tiro

according to EMC standard IEC/EN 60601-1-2: 2001

General Information

The EMC conformity includes the use of following external cables, transducers and accessories:

Designation Order no.

Data cable 1 m Sub-D9 f/m 1:1 8601565

Data cable 2 m Sub-D9 f/m 1:1 8601474

Data cable 3 m Sub-D9 f/m 1:1 8601528

The Fabius GS / Fabius Tiro should not be used adjacent to or stacked with other equipment. If adjacent or

stacked use is inevitable, the Fabius GS / Fabius Tiro should be observed to verify normal use in the

configuration in which it will be used.

Other equipment which can be used adjacent to or stacked with the Fabius GS / Fabius Tiro are listed in the

Instructions for Use manual, in the Accessories List / Family Drawing.

Page 1 of 4

Page 72

Electromagnetic Emissions

Electromagnetic Emissions

The Fabius GS / Fabius Tiro is intended for use in the electromagnetic environment specified below. The

user should assure that is used in such an environment.

Emissions Compliance

according to

RF emissions (CISPR 11) Group 1 The Fabius GS / Fabius Tiro uses RF energy only for its

Class B The Fabius GS / Fabius Tiro is suitable for use in all

Harmonic emissions

(IEC 61000-3-2)

Voltage fluctuations / flicker

(IEC 61000-3-3)

Information re electromagnetic emissions (IEC 60101-1-2: 2001, table 201)

Class A N/A

Complies N/A

Electromagnetic environment

internal function. Therefore, its RF emissions are very low

and are not likely to cause any interference in nearby

electronic equipment.

establishments including domestic establishments and

those directly connected to the public low-voltage power

supply network that supplies buildings used for domestic

purposes.

Page 2 of 4

Page 73

Electromagnetic Immunity

c

Electromagnetic Immunity

The Fabius GS / Fabius Tiro is intended for use in the electromagnetic environment specified below. The

user should assure that is used in such an environment.

Immunity against IEC 60601-1-2 test level Compliance

level (of this

equipment)

electrostatic

discharge, ESD

contact discharge: ± 6 kV

air discharge: ± 8 kV

± 6 kV

± 8 kV

(IEC 61000-4-2)

electrical fast

transients / bursts

(IEC 61000-4-4)

surges on AC

mains lines

power supply lines: ± 2 kV

longer input / output lines: ±

1 kV

common mode: ± 2 kV

differential mode: ± 1 kV

± 2 kV

± 1 kV

± 2 kV

± 1 kV

(IEC 61000-4-5)

power frequency

3 A/m 3 A/m In close vicinity to the Fabius GS /

magnetic field

50/60 Hz

(IEC 61000-4-8)

voltage dips and

short interruptions

on AC mains input

lines

dip >95%, 0.5 periods

dip 60%, 5 periods

dip 30%, 25 periods

dip >95%, 5 seconds

>95%, 0.5 per.

60%, 5 per.

30%, 25 per.

>95%, 5 sec.

(IEC 61000-4-11)

radiated RF

(IEC 61000-4-3)

RF coupled into

lines

(IEC 61000-4-6)

80 MHz – 2.5 GHz: 10 (3)

V/m

150 kHz – 80 MHz: 10 (3)

V within

3 V outside ISM bands

ISM bands,

X2

10 V/m Recommended separation distance

10 V

3 V

Electromagnetic environment

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Mains power quality should be that of a

typical commercial or hospital

environment.

Mains power quality should be that of a

typical commercial or hospital

environment.

Fabius Tiro, no equipment with

extraordinary power frequency magneti

fields (power transformers, etc.) should

be operated.

Mains power quality should be that of a

typical commercial or hospital

environment. If user requires continued

operation during power mains

interruptions, it is recommended to

power the Fabius GS / Fabius Tiro from

an uninterruptible supply or a battery.

from portable and mobile RF

transmitters with transmission power

P

to the Fabius GS / Fabius Tiro

EIRP

including its lines: 1.84 m * √P

EIRP

X1

Recommended separation distance

from portable and mobile RF

transmitters with transmission power

P

to the Fabius GS / Fabius Tiro

EIRP

including its lines: 1.84 m * √P

EIRP

X1

Information re electromagnetic immunity (IEC 60601-1-2: 2001, tables 202, 203, 204)

X1

: For P

the highest possible "equivalent isotropic radiated power" of the adjacent RF transmitter has

EIRP

to be inserted (value in Watt). Also in the vicinity of equipment marked with the symbol

interference may occur. Field strengths from fixed, portable or mobile RF transmitters at the

location of the Fabius GS / Fabius Tiro should be less than 3 V/m in the frequency range from 150

kHz to 2.5 GHz and less than 1 V/m above 2.5 GHz.

X2

:ISM bands in this frequency range are: 6.765 MHz - 6.795 MHz, 13.553 MHz - 13.567 MHz, 26.957

MHz - 27.283 MHz, 40.66 MHz - 40.70 MHz.

Page 3 of 4

Page 74

Recommended separation distances

Recommended separation distances between portable and mobile RF telecommunication

devices and the Fabius GS / Fabius Tiro

P

max.

EIRP

(W)

3 V/m

distance*

(m)

1 V/m

distance*

(m)

Note

0.001 0.06 0.17

0.003 0.10 0.30

0.010 0.18 0.55

0.030 0.32 0.95 e.g. WLAN 5250 / 5775 (Europe)

0.100 0.58 1.73 e.g. WLAN 2440 (Europe), Bluetooth

0.200 0.82 2.46 e.g. WLAN 5250 (not in Europe)

0.250 0.91 2.75 e.g. DECT devices

1.000 1.83 5.48

e.g. GSM 1800- / GSM 1900- / UMTS- mobiles,

WLAN 5600 (not in Europe)

2.000 2.60 7.78 e.g. GSM 900 mobiles

3.000 3.16 9.49

Information re separation distances (IEC 60601-1-2: 2001, tables 205 and 206)

* 3 V/m distance to transmitters with frequencies from 150 kHz to 2.5 GHz, otherwise 1 V/m distance.

Page 4 of 4

Page 75

Page 76

Manufacturer:

Dräger Medical AG & Co. KG

Moislinger Allee 53 – 55

D-23542 Lübeck

Germany

Phone: (++49) (0) 1805-3723437

Fax: (++49) 451/882 - 3779

Subject to change without notice

Will not be replaced in the event of modifications.

© Copyright by Dräger Medical AG & Co. KG, Lübeck, Germany.

The warranty and liability conditions of the general terms and conditions for business transactions of

Dräger Medical AG & Co. KG are not extended by this Technical Documentation.

Loading...

Loading...