®

knife

set of jaws

set of jaws

up to 250 mm

up to 500 mm

Operating Instructions for the Metal-Shear SD5-1 and S1001N-1

valid 10/2002

To avoid any disturbance, please read the following instructions:

For your safety:

1 2 3 4 5

1 Safe operation of this machine is possible, only

when the operating instructions and the safety

precautions are read completely and the

instructions contained therein are strictly observed.

2 The machine must not be used when damp and must

not be operated in a wet environment.

3 Always inspect cable and plug before using machine.

Have damage repaired by a qualified professional, only.

Put the plug into the main socket only, when the

machine is in off position.

4+5 Always wear protective goggles, protective gloves

and heavy-duty shoes when working.

F For further notes on safety we refer to enclosed red safety instructions sheet

Technical Data:

DRÄCO metal shears SD5-1 S1001N-1 SD5-1 S1001N-1

max. cutting capacity

steel 400 N/mm² mm/ga.

stainless steel 600 N/mm² mm/ga.

stainless steel 800 N/mm² mm/ga.

aluminium 250 N/mm² mm/ga.

tightest radius mm/ga.

working speed ± m/min

strokes

motor capacity Watt

weight kg

all units are ready to use BG=Set other voltages available

Art.no. 61000-1 61010-1

1,0 / 19 1,3 / 18

0,7 / 21 1,0 / 19

0,4 / 24 0,7 / 21

1,5 / 16 2,0 / 14

50 100

5-9 5-9

3000 3000

-1

min

300 300

1,6 1,6

l Do not carry the machine by the cable.

l Always remove the plug from the power supply

socket before carrying out any work on the

machine, when interrupting work and when not

using the machine.

l Always place the cable to the rear, away from

the machine.

l Apply the machine to the sheet metal only, when

switched on.

l Always provide for secure footing when working.

l Firmly clamp the work piece, if it dose not

remain stationary from its own weight.

l The knife should not rub on the jaws: Possible

danger of cutting tool breakage.

l Do not exceed the maximum allowable material

thickness, especially when cutting over double

folded joints, or welded seams.

spare parts spare parts

optional accessories

metal-box

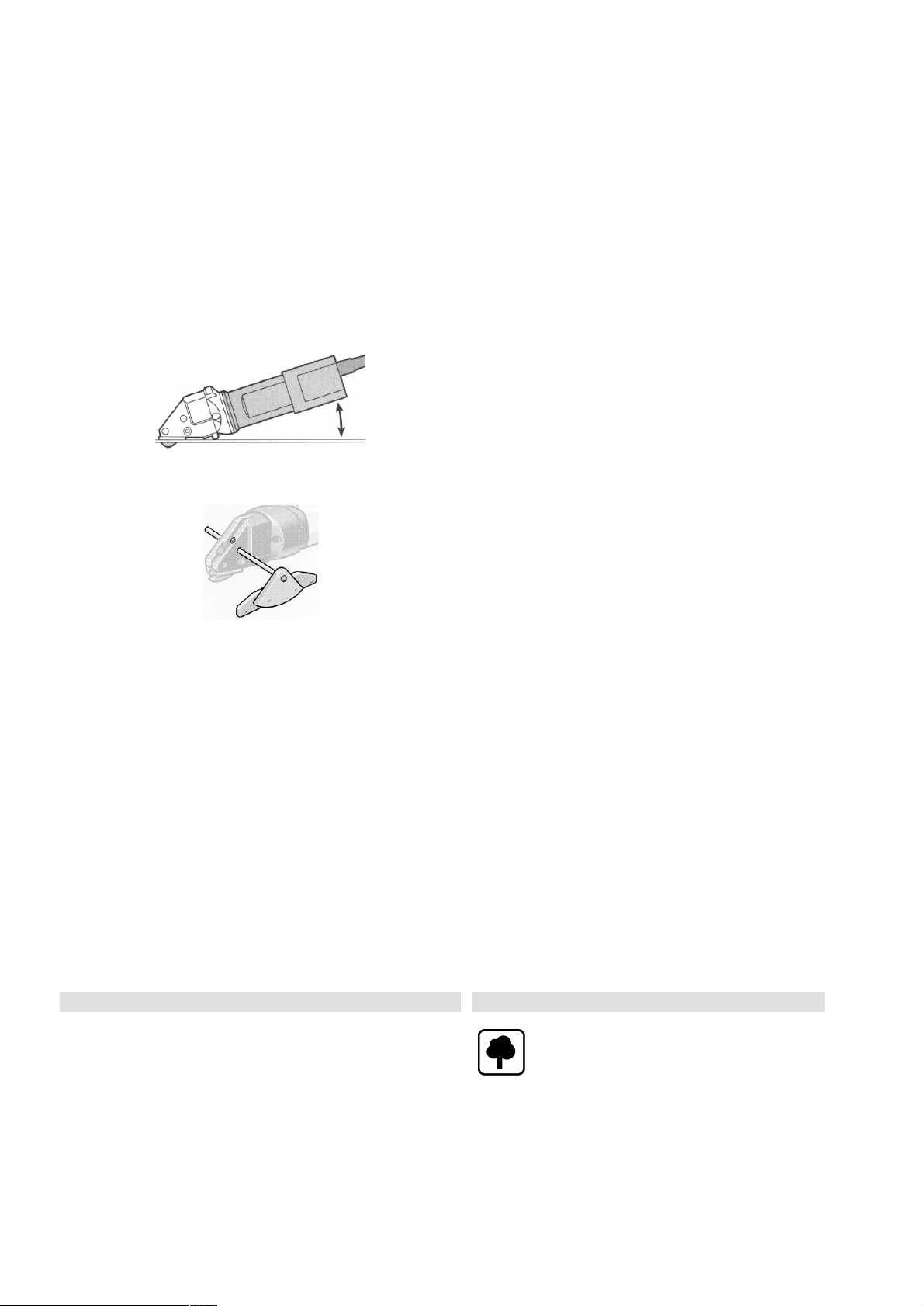

adjustable guide S/01 up to 100 mm 10059

adjustable guide S/01

adjustable guide S/01

support roller BG10076

01011 knife 01001

BG13574/1

knife-pin set BG12555

BG10600

18000

10060

10061

Spare parts for SD5-1 and S1001N-1

SERVICE TIPS

Before working on machine disconnect from power

supply by removing plug from socket.

Wear protective glasses!

*optional

1. One drop of oil between knife (11) and head-casting (1) keeps the

spacing shims (15) in place.

2. Dismantle Spring cover (20) and take spring out (19).

3. Take circlip (16) and washer (17) off.

4. Push knife pin (18) out of casting.

5. Take knife out of housing

6. Attention, do not exchange the spacing shims (15).

7. Place the knife inside the housing feed shims in on one side and

push knife pin (18) into housing up to the middle of the knife.

8. Feed the shims on the other side of the knife.

9. Push knife pin in completely, and secure washer (17) and circlip

(16) again.

10. Assemble spring (19) and spring cover (20).

11. Between the knife (11) and the jaws (10) should be some

distance, approximately 0,1 mm on each side. Knife (11) must be

placed tight in the head casting.

12. Adjustment for the play between the jaws. (a): 0,1 - 0,15 mm.

13. If knife has contact with the jaws on both sides, adjust with screws

in the head casting.

If a burr is on the material, adjust the space between the knife and

the jaws.

Spare parts for SD5-1 and S1001N-1

Pos.

96

96

96

Pos. Order Pcs.

No. No. Description No. No. Description

1 BG10500 Head casting (SD5, S1001N) 1 42 81249 Securing washer 3

1-52 10057 Shear head S1001N cpl. assembled, without motor 1 43 81012 Flat fillister head screw 3

1-52 10557 Shear head SD5 cpl. assembled, without motor 1 51 81243 Securing washer 2

3 81263 Hex socket screw 1 52 81181 Hex socket screw 2

4 81089 Spacing-block set screw 1

5 81272 Flat fillister head screw 1 604-6 BG10002 Spacing Block Pos. 4-6 1 606 10002 Spacing Block 1 608 81286 Flat Head Screw 4 60 16013 PT-Screw 4

9 81248 Pin 4 61 16015 Bearing end plate 1

Knife for S1001N cutting (width: 4 mm) 62 10038 Ball bearing 1

11 01001 Knife 1001 Standard up to 1,3 mm 1 63 16014 Circlip 1

01001HM Knife 1001 carbide tipped 1 64 16009 Armature 1

10111 Knife for radius cutting 1001/01 0,75 mm 1 65 10040 Ballbearing 1

10110 Pattern Knife up to 0,5 mm 1 66 16029 Insulating ring 1

8-10 BG10600 Jaws for S1001N SET Pos.8-10 1 67 16030 Ventilation cover 1

10600HM Jaws for S1001N carbide tipped 1 68 16007 Field 230 V 1

Knife SD5 for SD5 cutting (width: 5 mm ! ) 69 16039 Housing 1

11 01011 Knife SD5 1 70-71 BG16035 Brush Holder and Spring 2

8-10 BG13574/1 Set of jaws SD 5 Pos.8-10 1 72 16002 Carbon Brush 2

13 35566 Knife Lock ring with Adjusting Screw 1 73 16021 Cable collar 1

15 BG12400 Spacing shims 1 74 16019 Hex. Nut 1

16 81275 Circlip 2 75 16020 Screw 2

17 81072 Washer 2 76 16036 Switch Cover 1

18 12500 Knife pin 1 77 16018 Screw 1

15-18 BG12555 Knife pin set Pos. 15-18 1 81 16032 Switch Connection Lever 1

19 12200 Spring 1 82 16033 Switch Knob 1

19-21 BG12300 Spring cover Pos. 19-21 1 90 16017 Connection Wire 2

20 12300 Spring cover 1 91 16031 Switch 1

21 81285 Flat Head Screw 4 92 16005 Condensator 1

24 17900 Knife pin bushing Ø 10 mm 2 95 16022 Rubber-Sleeve 1

24 17911 Knife pin bushing Ø 11 mm 2 96 32046 Cable with Plug Europe (VDE) 1

25 BG10076 Support roller 1 96 20260 Cable with plug CH (SEV) 1

32-39 BG10058 Drive Shaft cpl. Assembled Pos. 32-39 1 96 20250 Cable with plug IT 1

32-34,37+39 BG10004 Eccentric drive shaft Pos. 32-34,37+39 1

32 10004 Eccentric drive shaft 1

33 10250 Ball bearing 1

34 10005 Sleeve 2

35 10300 Needle bearing 2

35-36 BG10450 Cap for needle bearing Pos. 35-36 1

37 10006 Key 1

38 10007 Gear 1 10059 Adjustable guide S/01 100 mm

39 10009 Circlip 1 10060 Adjustable guide S/01 250 mm

40 81239 Tap screw 2 10061 Adjustable guide S/01 500 mm

41-43, 51+ 52 BG10010 Gear case Pos.41-43,51,52 1 18000 Metal Box (Metal)

Specifications are subject to change for improvement without prior notice.

When ordering spares, please mention order number and voltage.

Max Draenert GmbH & Co.KG Electric - Cordless - Pneumatic Tools - Machines Germany

Factory I : Administration D-73777 Deizisau P.O.Box 1120 Tel. 07153-8217-0

Production D-73779 Deizisau Gutenbergstrasse 15-17 Fax 07153-8217-66

Internet http://www.dracotools.com E-mail: draenert@dracotools.com

Dealer address:

Order

16000 Motor cpl. 230 V (VDE) 1

16000 CH Motor cpl. 230 V (CH) 1

16000 I Motor cpl. 230 V ( I ) 1

Pcs.

Accessories

Operating Instructions

1. This Power Tool is intended for industrial applications, for cutting

sheet metal max. capacity is indicated in the technical data. Do

not cut sheet metal through, or along welding points, or multi

layer sheets, which exceed the max. cutting capacity. To cut

spiral wound tubing 4 x 0.9 mm in metal , the model 3514-2 or

3514 -7R must be used.

To Switch ON: Slide the switch (82) forward

To Switch OFF: Slide the switch (82) to the rear.

2. The shear must always be guided flat and the best cutting result

is achieved, when the jaws pos. 10 are positioned flat on top of

the material, also when cutting circular cuts.

Adjustable guide S/01

Care and Maintenance

Before repairing or any maintenance on machine, disconnect from

power supply by removing plug from socket.

Always keep the machine and the ventilation slots clean.

Oil the knife pin 18 and knife 11 at regular intervals.

If the machine should happen to fail, despite the care taken in

manufacture and testing, repair should be carried out by an authorised

customer services agent for Dräco power tools.

Declaration of conformity

We declare under our sole responsibility that this product is in

conformity with the following standards.

EG 98/37 EG, EG 73/ 23 EG, EG 89/336 EG, or standardisation

documents EN 292 part I, EN 292 part II, EN 50 144, EN 55 014,

EN 60 555, HD 400, HD 400.3 part II/H

02 Max Draenert

3. When stopping inside the material, pull metal shear back

straight out of the waste, with motor in operation. If too

long cut waste off, first.

4. Circular cuts, always cut anti clockwise from right to left.

The outside radius is unlimited.

5. For cutting out curved or inside patterns a 12 -14 mm

hole must be drilled or punched or a slot should be

made to insert the cutting knife. Square or rectangle cutouts, drill in each corner a hole between 12 -14 mm.

6. A one side cut with the metal shear is possible, a small

strip can be easily cut off without leaving a burr and any

distortion or scratch marks.

7. Cutting the same parts, a template can be

manufactured. Without risk of damaging the knife, a cut

along the template is possible. Front points of the jaws

left and right are used to cut exact along a marked line.

To cut strips, use adjustable guide S/01. This guide is

infinitely variable, due to the hole in the housing and can

be tightened with the set screw. Adjustable guide S/01

can be delivered in 100, 250 and in 500 mm length.

8. Knife and jaws can be sharpened. After being

sharpened or replaced, the knife at it’s lowest point,

should protrude the jaws by about 2.5 mm. The gap

between the knife and the jaws should be approximately

0.1 mm on both sides. For a burr free cutting adjust the

cutting gap as follow: Loosen screw, adjust the gap with

set screw, to the left narrow, to the right wide, and

tighten screw again. Check gap with a feeler gauge.

9. If you read these suggestions carefully, any kind of

material can be cut about 200 working hours, before

sharpening knife and jaws.

10. The material to be cut, must always be free of oil or

grease.

Guarantee

Dräco tolls carry a guarantee of 24 months from date of

delivery.

Damage attributable to normal wear and tear, overload or

improper handling will be excluded from the guarantee.

In case of complaint please send the machine,

undismantled, to your dealer or the Dräco Service Centre for

electric power tools.

Environmental protection

Recycling raw materials instead of waste

disposal

Machine, accessories and packaging should be sorted for

environment-friendly recycling.

These instructions are printed on recycling paper

manufactured without chlorine.

Loading...

Loading...